oil filter MERCEDES-BENZ ML320 1997 Complete Owner's Manual

[x] Cancel search | Manufacturer: MERCEDES-BENZ, Model Year: 1997, Model line: ML320, Model: MERCEDES-BENZ ML320 1997Pages: 4133, PDF Size: 88.89 MB

Page 2419 of 4133

lRemove/install

External torx setFig. 49

Torx bit setFig. 48

1Remove engine trim panel

2Remove air filter housing

(1).

3Remove resonance body (2)

4Remove the resonance tube

(3) with hot film mass air

flow sensor

At this time pull out the

hot film mass air flow

sensor plug.

Removal:

Pay attention to the

mounting projection of the

resonance tube (3)!

All except model 163 with

engine 113.942/981AR07.07-P-1454A

Model 163 with engine

113.942/981AR07.07-P-1454MV

5Unbolt dipstick guide tube

of automatic transmission

6Unbolt ignition coils (6, 7)

at cylinder head covers

AR15.12-P-2003A

*BA01.20

-P-1002-01E

7Disconnect spark plug

connectors

Pay attention to markings

for spark plug connectors

on cylinder head covers

and ignition coils

Fig. 57

8Detach the vacuum hoses at

connections (8, 9) of the

cylinder head covers

9Detach crankcase

ventilation hose at cylinder

head cover fitting (10) Only on left side.

Risk of explosion caused

by ignition of flammable

products, risk of poisoning

caused by inhaling fuel

vapors or swallowing fuel

as well as risk of injury to

skin and eyes exposed to

fuel.No fire, sparks, open

flames or smoking. Pour

fuels only into suitable

and appropriately marked

containers.

Wear protective clothing

when handling fuel.AS47.00-Z-0001-01A

10Disconnect fuel line at fuel Only in case of

2001 Mercedes-Benz ML320

1998-2005 ENGINE Complete engine - 163 Chassis

me

Saturday, October 02, 2010 3:17:56 PMPage 63 © 2006 Mitchell Repair Information Company, LLC.

Page 2423 of 4133

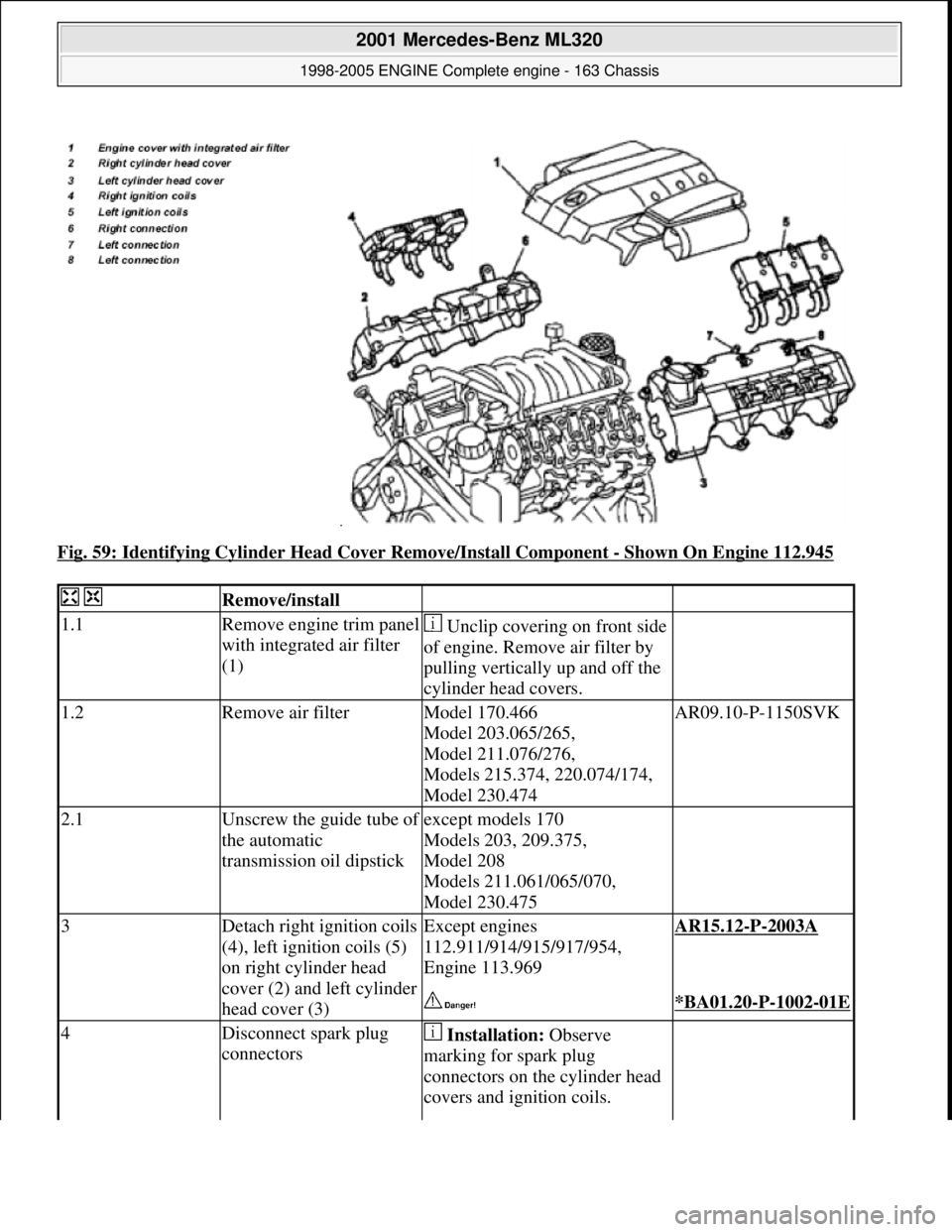

Fig. 59: Identifying Cylinder Head Cover Remove/Install Component - Shown On Engine 112.945

Remove/install

1.1Remove engine trim panel

with integrated air filter

(1) Unclip covering on front side

of engine. Remove air filter by

pulling vertically up and off the

cylinder head covers.

1.2Remove air filterModel 170.466

Model 203.065/265,

Model 211.076/276,

Models 215.374, 220.074/174,

Model 230.474AR09.10-P-1150SVK

2.1Unscrew the guide tube of

the automatic

transmission oil dipstickexcept models 170

Models 203, 209.375,

Model 208

Models 211.061/065/070,

Model 230.475

3Detach right ignition coils

(4), left ignition coils (5)

on right cylinder head

cover (2) and left cylinder

head cover (3)Except engines

112.911/914/915/917/954,

Engine 113.969AR15.12-P-2003A

*BA01.20-P-1002-01E

4Disconnect spark plug

connectors Installation: Observe

marking for spark plug

connectors on the cylinder head

covers and ignition coils.

2001 Mercedes-Benz ML320

1998-2005 ENGINE Complete engine - 163 Chassis

me

Saturday, October 02, 2010 3:17:56 PMPage 67 © 2006 Mitchell Repair Information Company, LLC.

Page 2444 of 4133

TDC on first cylinder Rotate engine at cra nkshaft in direction of

rotation until 40° marking on belt pulley/

vibration damper is al igned with marking on

timing case cover.

The grooves on the camshafts must be pointing

toward the inner V.

23Lock camshafts with

locating plate Locating plateFig. 85

Locating plateFig. 86

24Remove chain

tensioner (17)Model 163.154 /157 with Engine 112.942 /970,

model 163.172 with Engine 113.942.AR05.10-P-

7800C

Model 163.174/175 with Engine 113.981 /965.AR05.10-P-

7800CA

25.1Remove oil filter

housing (18) with

oil/water heat

exchangerEngine 113.942.AR18.20-P-

3471B

Engines 113.965/981.AR18.20-P-

3471BA

26Remove camshaft

sprockets (19) If the camshaft sprockets are removed, the

engine must no longer be cranked otherwise the

timing chain might jam.

Engines 113.942 /965/981: ?

Tie timing chain tight on both camshaft

sprockets with cable straps.

Engine 112.942 /970: ?

Right-hand camshaft sprocket:

Tie timing chain tight on camshaft sprocket

with cable strap.

Left-hand camshaft sprocket:

Mark camshaft sprocket to timing chain and

remove camshaft sprocket.

It is not possible for the timing chain to

jump across at the crankshaft and balancing

shaft.

After installation: ?

Inspect basic positi on of camshafts.

If necessary after checking: ?AR05.10-P-

6858V

Set the basic position of camshafts.AR05.20-P-

6020AU

Open-end wrenchFig. 87

Insertion toolFig. 88

Torque wrenchFig. 92

*BA05.20-P-

1001-01B

27Remove camshaft

bearing bridges (28) Observe slackening and tightening pattern!AR05.20-P-

7103AU

2001 Mercedes-Benz ML320

1998-2005 ENGINE Complete engine - 163 Chassis

me

Saturday, October 02, 2010 3:17:57 PMPage 88 © 2006 Mitchell Repair Information Company, LLC.

Page 2456 of 4133

Engine 113 in model 129, 202, 208, 210

Engine 113 (except 113.965 /981) in model 163

Engine 112 in model 202, 208, 210AR13.22-P-

1202BA

Engine 112 in model 220

Engine 113 in model 215.373 /375

Engine 113 in models

220.070 /073 /075 /083 /084 /170 /173 /175 /183 /184 /875

Engine 113.965 in model 163.175

Engine 113.981 in model 163.174

Engine 113.984 in model 208.374 /474

Engine 113.963 in models 230.475AR13.22-P-

1202R

Engine 113.992 in model 230.474

Engine 112.947 in model 170.465AR13.22-P-

1202SV

10Remove cylinder

head covers (6)Engine 112, 113 air filter located on vehicle sideAR01.20-P-

5014B

Engine 112, 113 air filter located on engine sideAR01.20-P-

5014BV

11Detach coolant

line (17, 18) from

coolant pump

(12).

12Detach coolant

line (16) at

thermostat

housing (13).

13Dismount

refrigerant

compressor (A9) Place to the side with lines connected.

*BA83.55-P-

1001-01A

14.1Remove

alternator (G2)Engine 113.963 in models 230.475

Engine 113.992 in model 230.474AR15.40-P-

5032R

15.1Remove ATF line

bracket (23).Model 230

15.2Detach ATF line

from front axle

carrierModel 163

16Remove oil pan

bottom section (9)Engine 112.942 in model 163.154AR01.45-P-

7555V

Engine 112.970 in model 163.157

Engine 113.942 in model 163.172

Engine 113.965 in model 163.175AR01.45-P-

7555VE

2001 Mercedes-Benz ML320

1998-2005 ENGINE Complete engine - 163 Chassis

me

Saturday, October 02, 2010 3:17:57 PMPage 100 © 2006 Mitchell Repair Information Company, LLC.

Page 2458 of 4133

20Remove poly-V-

belt tensioning

device (5)Engine 112 in models 129, 163AR13.25-P-

3200B

Engine 113 in model 129, 202, 208, 210

Engine 113 (except 113.965 /981) in model 163

Models 129, 202, 210 with manual transmission.

Unscrew damper of belt te nsioning device at coolant

pump.

Engine 113.963 in models 230.475AR13.25-P-

3200R

Engine 113.992 in model 230.474

21Remove vibration

damper (4)Engine 112 in models 129, 163AR03.30-P-

1600C

Engine 113 in models 129, 202.033 /093

Engine 113 (except 113.981) in model 163

Engine 113 (except 113.980) in model 210

Engine 113 (except 113.984) in model 208

Engine 112.947 in model 170AR03.30-P-

1600CA

Engine 112 in model 202, 208, 210, 220

Engine 113.981 in model 163.174

Engine 113 (except 113.991) in models 215, 220.

Engine 113.963 in models 230.475

Engine 113.992 in model 230.474AR03.30-P-

1600RVK

22Remove chain

tensioner (14)ENGINE 112 in models 129, 163

Engine 113 (except 113.965 /981) in model 163

Engine 113 in model 129, 202, 208, 210AR05.10-P-

7800C

Engine 112 in model 170, 202, 208, 210

Engine 113 in model 163.174 /175AR05.10-P-

7800CA

Engine 112 in model 220

Engine 113 in model 215.373 /375

Engine 113 in models

220.070 /073 /075 /083 /084 /170 /173 /175 /183 /184 /875

Engine 113 in model 230.474 /475AR05.10-P-

7800AM

23.1Remove oil filter

housingEngine 113.992 in model 230.474AR18.20-P-

3471RKV

23.2Remove oil filter

housing with

oil/water heat

exchanger (7)Engine 112 in models 170, 202, 208, 210, 220AR18.20-P-

3471BA

Engine 113 in model 220

Engine 113.963 in models 230.475

Engine 113.965 in model 163.175

Engine 113.981 in model 163.174

Engine 112 in models 129, 163AR18.20-P-

3471B

2001 Mercedes-Benz ML320

1998-2005 ENGINE Complete engine - 163 Chassis

me

Saturday, October 02, 2010 3:17:57 PMPage 102 © 2006 Mitchell Repair Information Company, LLC.

Page 2475 of 4133

oil feed up to final repair

size.

12Measure cylinder boreAllow crankcase to cool

down to approx. 20°C

before measuring

Cylinder diameter*BE01.40-P-1001-01F

Internal measuring

instrument ø 50 to 150

mm, with 0.01 mm

indication and measuring

point pressure relief*WE58.40-Z-1003-21A

13Clean cylinder bore and

dry

14Set honing machine for

lapping Set to same diameter as

after polishing (final

diameter).

Cylinder diameter

according to machining

stage.*BE01.40-P-1003-01F

Stroke setting with 70 mm

felt length on 70th stroke

scale of machine*BE01.40-P-1012-01F

Felt insert overrun at top

and bottom*BE01.40-P-1013-01F

Engine speed*BE01.40-P-1008-01F

Feed*BE01.40-P-1009-01F

Stroke*BE01.40-P-1010-01F

Display*BE01.40-P-1011-01F

Felt insert C 30-F 85*WH58.30-Z-1036-04A

Set of felt insert holders

CK3130*WH58.30-Z-1035-04A

Stone holder for felt

insert CK-30 35*WH58.30-Z-1034-04A

15Rub-in cylinder bore and

filter insert using honing

paste Without honing oil

feed, the cylinder wall

must be dry. Only the

specified honing paste may

be used. Only this one

guarantees the specified

final result.

Polmot honing paste order

no. 600.11

*BR00.45-Z-1050-06A

16Lap cylinder bore and

expose silicone crystals. Without honing oil

feed.

2001 Mercedes-Benz ML320

1998-2005 ENGINE Complete engine - 163 Chassis

me

Saturday, October 02, 2010 3:17:57 PMPage 119 © 2006 Mitchell Repair Information Company, LLC.

Page 2476 of 4133

Check values for crankcase

Operating time of honing

machine

*BE01.40-P-1014-01F

17Coat filter insert again

with honing paste Do not coat cylinder

bore with honing paste.

Polmot honing paste order

no. 600.11

*BR00.45-Z-1050-06A

18Lap cylinder bore and

expose silicone crystals. Without honing oil

feed, removed material

cannot be measured.

Operating time of honing

machine

*BE01.40-P-1014-01F

19Clean cylinder bore and

dry Clean crankcase very

carefully with honing

paste. If possible, clean

crankcase in a major

assembly washing

machine, so that no

cylinder wall damage will

be caused by residues

when running the engine

later.

20Inspect cylinder boreAllow crankcase to cool

down to approx. 20°C

before inspecting.

Cylinder diameter of repair

size

*BE01.40-P-1001-01F

NumberDesignation

Engine 112

except 112.951,

113.940/941/

942/943/944/

945/946/948/

960/961/963/

965/966/967/

968/980/981/

984/986/992/

995

Engine

113.962/982/

987/988/989/

990/991/993

BE01.40-P-

1001-02E Cylinder borePeak-to-valley

height (R

Z ) of

top separating

surface

mm0.001 to 0.00450.001 to 0.0045

Wear limit at

BDC and TDC

of 1st piston ringmm< or = 30.03< or = 0.03

2001 Mercedes-Benz ML320

1998-2005 ENGINE Complete engine - 163 Chassis

me

Saturday, October 02, 2010 3:17:57 PMPage 120 © 2006 Mitchell Repair Information Company, LLC.

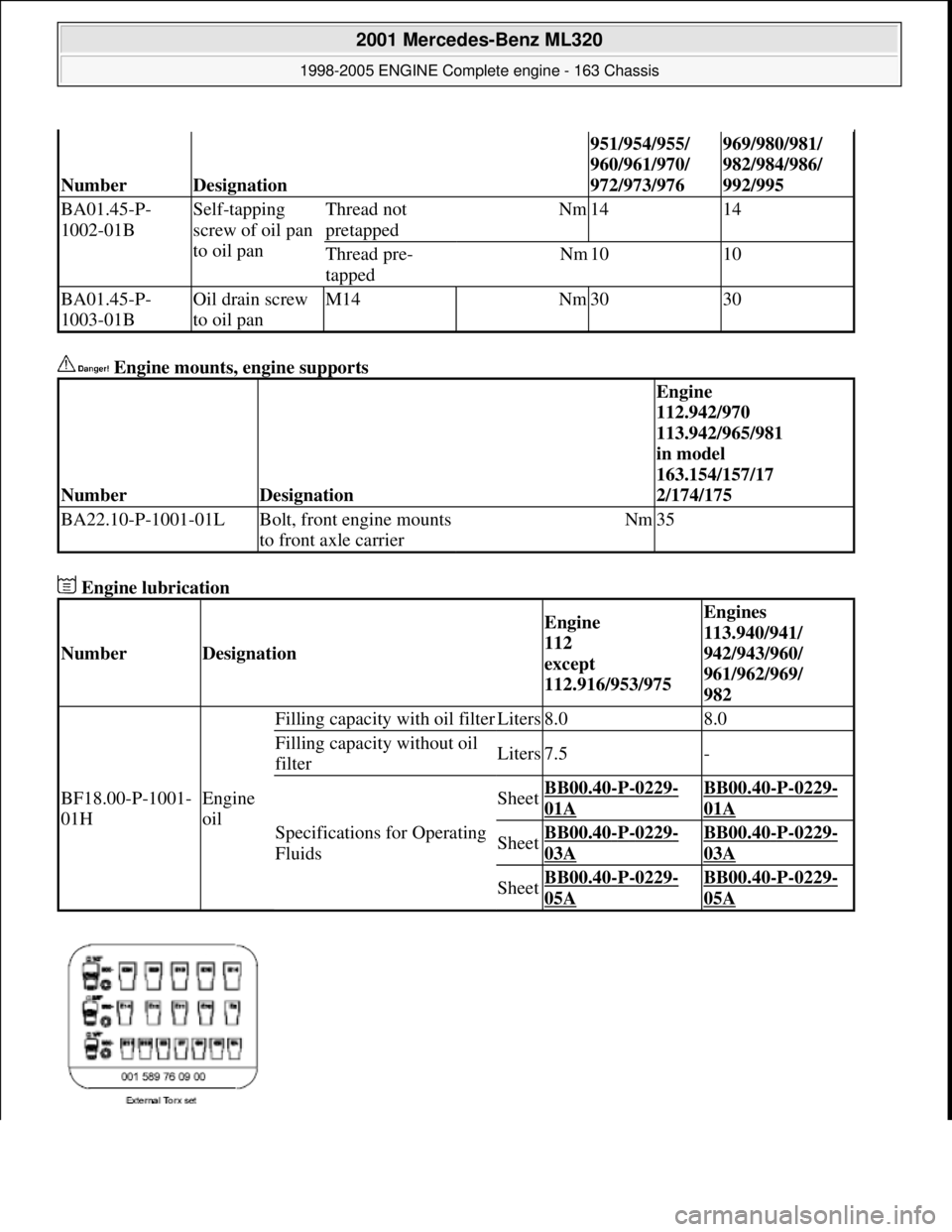

Page 2492 of 4133

Engine mounts, engine supports

Engine lubrication

NumberDesignation

951/954/955/

960/961/970/

972/973/976969/980/981/

982/984/986/

992/995

BA01.45-P-

1002-01BSelf-tapping

screw of oil pan

to oil panThread not

pretappedNm1414

Thread pre-

tappedNm1010

BA01.45-P-

1003-01BOil drain screw

to oil panM14Nm3030

NumberDesignation

Engine

112.942/970

113.942/965/981

in model

163.154/157/17

2/174/175

BA22.10-P-1001-01LBolt, front engine mounts

to front axle carrierNm35

NumberDesignation

Engine

112

except

112.916/953/975Engines

113.940/941/

942/943/960/

961/962/969/

982

BF18.00-P-1001-

01HEngine

oil

Filling capacity with oil filterLiters8.08.0

Filling capacity without oil

filterLiters7.5-

Specifications for Operating

Fluids

SheetBB00.40-P-0229-

01A

BB00.40-P-0229-

01A

SheetBB00.40-P-0229-

03A

BB00.40-P-0229-

03A

SheetBB00.40-P-0229-

05A

BB00.40-P-0229-

05A

2001 Mercedes-Benz ML320

1998-2005 ENGINE Complete engine - 163 Chassis

me

Saturday, October 02, 2010 3:17:58 PMPage 136 © 2006 Mitchell Repair Information Company, LLC.

Page 2495 of 4133

Engine mounts, engine supports

Engine lubrication

Fig. 111: Identifying External Torx Set (001 589 76 09 00)

NumberDesignation

965/967/968/

969/980/981/

982/984/986/

992/995

BA01.45-P-1002-

01BSelf-tapping screw

of oil pan to oil panThread not pre-

tappedNm14

Thread pre-tappedNm10

BA01.45-P-1003-

01BOil drain screw to

oil panM14Nm30

NumberDesignation

Engine

112.942/970

113.942/965/981

in model

163.154/157/17

2/174/17 5

BA22.10-P-1001-01LBolt, front engine mounts

to front axle carrierNm35

NumberDesignation

Engine

113.944/980/981

/984/986/991Engine

113.963/

963/965

BF18.00-P-

1001-01HEngine oilFilling capacity

with oil filterLiters7.57.5

Filling capacity

without oil filterLiters-7.0

Specifications

for Operating

FluidsSheetBB00.40-P-

0229-01A

BB00.40-P-

0229-01A

SheetBB00.40-P-

0229-03A

BB00.40-P-

0229-03A

SheetBB00.40-P-

0229-05A

BB00.40-P-

0229-05A

2001 Mercedes-Benz ML320

1998-2005 ENGINE Complete engine - 163 Chassis

me

Saturday, October 02, 2010 3:17:58 PMPage 139 © 2006 Mitchell Repair Information Company, LLC.

Page 2589 of 4133

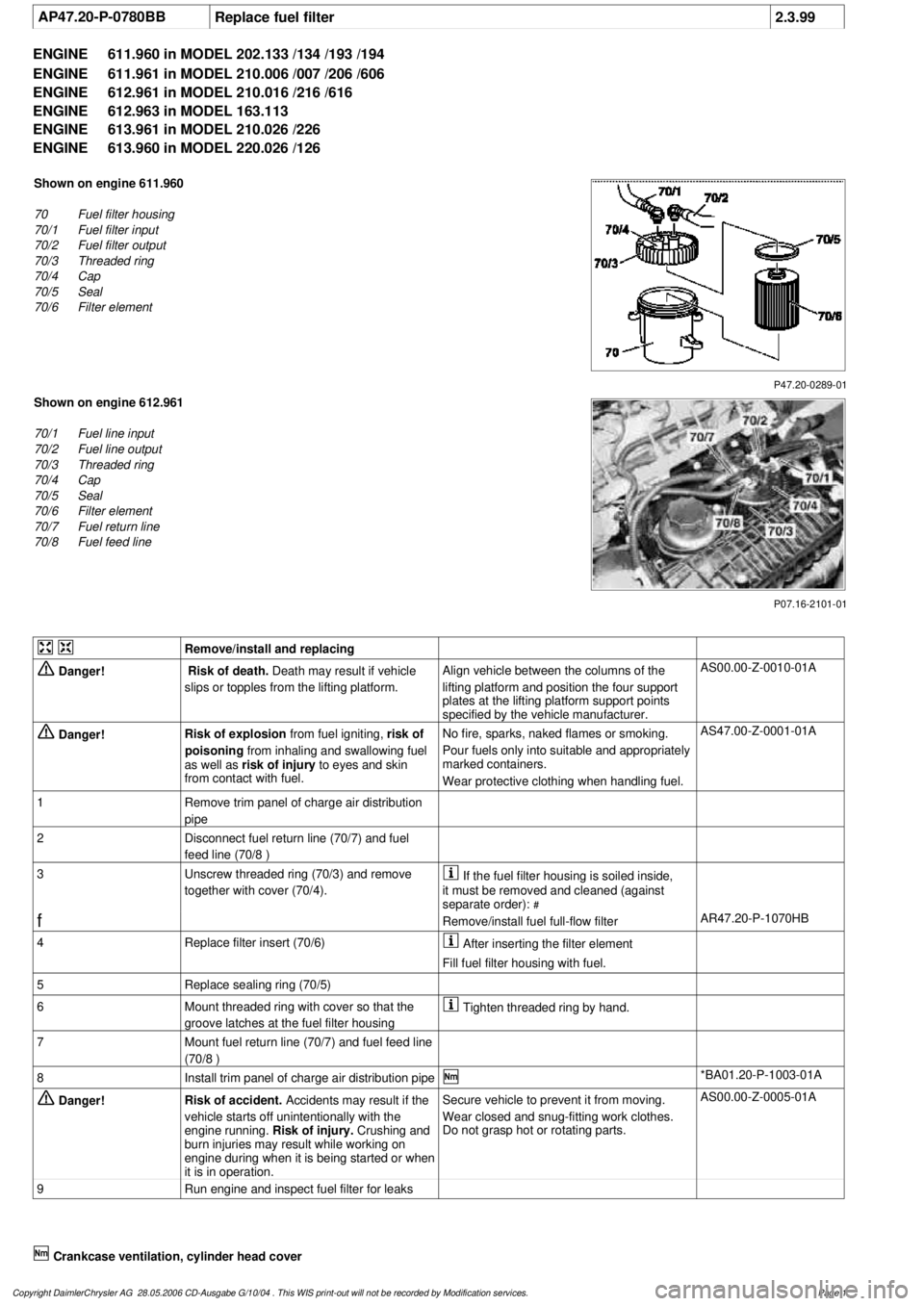

AP47.20-P-0780BB

Replace fuel filter

2.3.99

ENGINE

611.960 in MODEL 202.133 /134 /193 /194

ENGINE

611.961 in MODEL 210.006 /007 /206 /606

ENGINE

612.961 in MODEL 210.016 /216 /616

ENGINE

612.963 in MODEL 163.113

ENGINE

613.961 in MODEL 210.026 /226

ENGINE

613.960 in MODEL 220.026 /126

P47.20-0289-01

Shown on engine 611.960

70

Fuel filter housing

70/1

Fuel filter input

70/2

Fuel filter output

70/3

Threaded ring

70/4

Cap

70/5

Seal

70/6

Filter element

P07.16-2101-01

Shown on engine 612.961

70/1

Fuel line input

70/2

Fuel line output

70/3

Threaded ring

70/4

Cap

70/5

Seal

70/6

Filter element

70/7

Fuel return line

70/8

Fuel feed line

Remove/install and replacing

Danger!

Risk of death.

Death may result if vehicle

slips or topples from the lifting platform.

Align vehicle between the columns of the

lifting platform and position the four support

plates

at the lifting platform support points

specified by the vehicle manufacturer.

AS00.00-Z-0010-01A

Danger!

Risk of explosion

from fuel igniting,

risk of

poisoning

from inhaling and swallowing fuel

as well as

risk of injury

to eyes and skin

from contact with fuel.

No fire, sparks, naked flames or smoking.

Pour fuels only into suitable and appropriately

marked containers.

Wear protective clothing when handling fuel.

AS47.00-Z-0001-01A

1

Remove trim panel of charge air distribution

pipe

2

Disconnect fuel return line (70/7) and fuel

feed line (70/8 )

3

Unscrew threaded ring (70/3) and remove

together with cover (70/4).

If the fuel filter housing is soiled inside,

it must be removed and cleaned (against

separate order):

#

f

Remove/install fuel full-flow filter

AR47.20-P-1070HB

4

Replace filter insert (70/6)

After inserting the filter element

Fill fuel filter housing with fuel.

5

Replace sealing ring (70/5)

6

Mount threaded ring with cover so that the

groove latches at the fuel filter housing

Tighten threaded ring by hand.

7

Mount fuel return line (70/7) and fuel feed line

(70/8 )

8

Install trim panel of charge air distribution pipe

*BA01.20-P-1003-01A

Danger!

Risk of accident.

Accidents may result if the

vehicle starts off unintentionally with the

engine running.

Risk of injury.

Crushing and

burn injuries may result while working on

engine during when it is being started or when

it is in operation.

Secure vehicle to prevent it from moving.

Wear closed and snug-fitting work clothes.

Do not grasp hot or rotating parts.

AS00.00-Z-0005-01A

9

Run engine and inspect fuel filter for leaks

Crankcase ventilation, cylinder head cover

Copyright DaimlerChrysler AG 28.05.2006 CD-Ausgabe G/10/04 . This WIS print-out will not be recorde

d by Modification services.

Page 1