wheel bolts MERCEDES-BENZ ML320 1997 Complete Owner's Guide

[x] Cancel search | Manufacturer: MERCEDES-BENZ, Model Year: 1997, Model line: ML320, Model: MERCEDES-BENZ ML320 1997Pages: 4133, PDF Size: 88.89 MB

Page 2551 of 4133

Wheel location, hub

Fig. 50: Identifying Press (163 589 03 43 00)

Fig. 51: Identifying Support (163 589 01 43 00)

6Detach upper transverse control

arm (6) from vehicle frame

Installation: Gently tighten the new nuts,

continuing until they seat. Wait until the

vehicle is resting on it s road wheels before

tightening the bolts.

*BA33.20-P-

1006-01D

7Install in the reverse order

8Perform chassis alignment check AR40.20-P-

0200GH

NumberDesignationModel Series

163

BA33.20-P-1001-

01DSelf-locking nut, upper wishbone follower joint to steering

knuckleNM50

BA33.20-P-1006-

01DBolt, upper wishbone to frameNM120

2001 Mercedes-Benz ML320

1998-2005 DRIVELINE/AXLES Front Axle - 163 Chassis

me

Saturday, October 02, 2010 3:38:22 PMPage 32 © 2006 Mitchell Repair Information Company, LLC.

Page 2555 of 4133

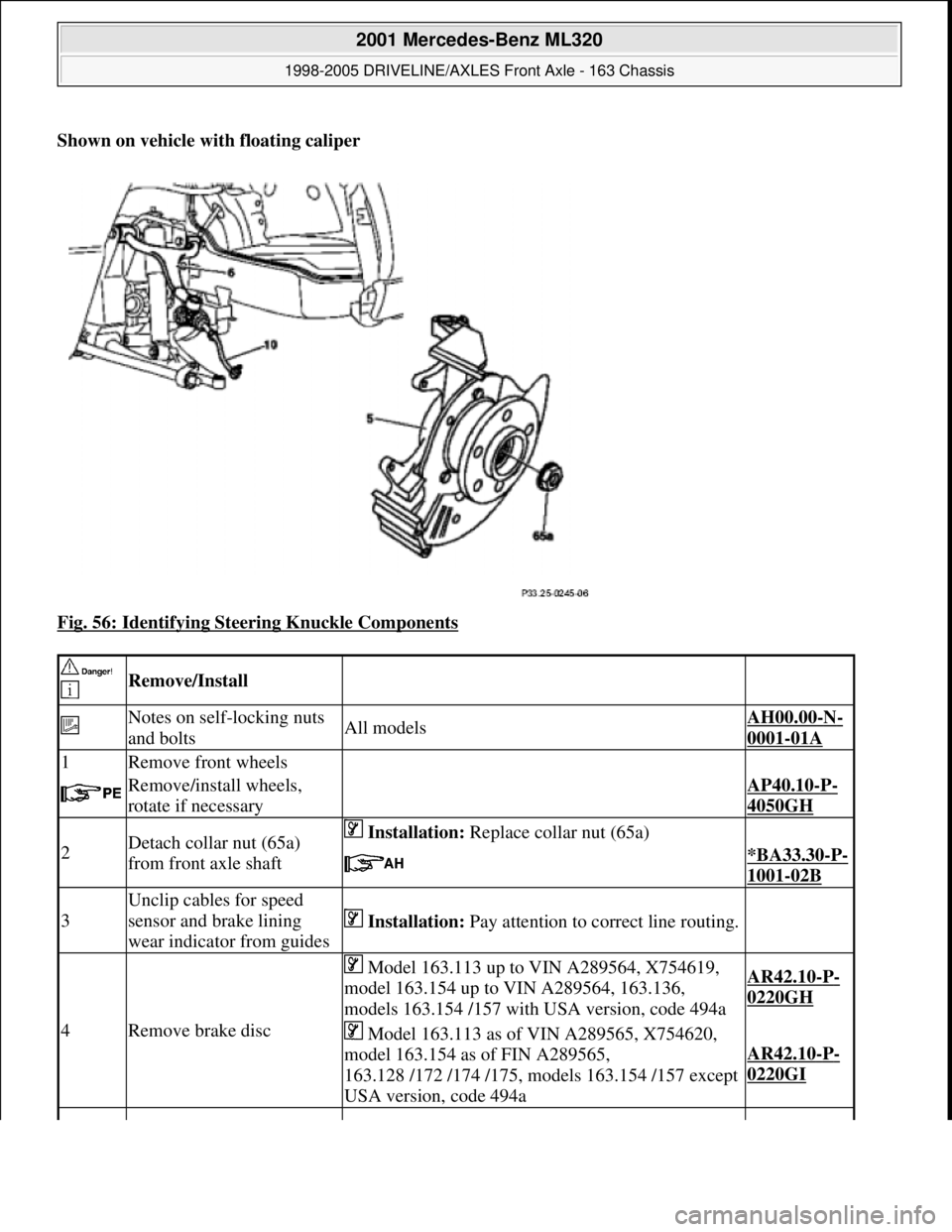

Shown on vehicle with floating caliper

Fig. 56: Identifying Steering Knuckle Components

Remove/Install

Notes on self-locking nuts

and boltsAll modelsAH00.00-N-

0001-01A

1Remove front wheels

Remove/install wheels,

rotate if necessaryAP40.10-P-

4050GH

2Detach collar nut (65a)

from front axle shaft Installation: Replace collar nut (65a)

*BA33.30-P-

1001-02B

3

Unclip cables for speed

sensor and brake lining

wear indicator from guides

Installation: Pay attention to correct line routing.

4Remove brake disc

Model 163.113 up to VIN A289564, X754619,

model 163.154 up to VIN A289564, 163.136,

models 163.154 /157 with USA version, code 494aAR42.10-P-

0220GH

Model 163.113 as of VIN A289565, X754620,

model 163.154 as of FIN A289565,

163.128 /172 /174 /175, models 163.154 /157 except

USA version, code 494a

AR42.10-P-

0220GI

2001 Mercedes-Benz ML320

1998-2005 DRIVELINE/AXLES Front Axle - 163 Chassis

me

Saturday, October 02, 2010 3:38:22 PMPage 36 © 2006 Mitchell Repair Information Company, LLC.

Page 2562 of 4133

Wheel location, hub

Front final-drive unit

Propeller shaft of front axle gear

Front axle gear

Thrust pieceFig. 45

SupportFig. 46

PressFig. 47

5Remove lower engine compartment

panelingModel 163.157 /172 /174 /175AR61.20-P-

1105GH

Model 163.113 /128AR94.30-P-

5400GH

6Press left and right front axle shafts out

of front axle gear Do not damage shield.

Suspend steering knuckle with

wire.

7Disconnect vent hose from front axle

gear

8Remove bolts (14a) *BA33.30-P-

1001-03B

9Remove front axle gear (14).

10Install in the reverse order

NumberDesignationModel 163

BA33.20-P-1001-01DSelf-locking nut, upper wishbone follower joint to steering knuckleNm50

NumberDesignationModel 163

BA33.30-P-1001-03BBolt securing front axle gear to front axle carrierNm135

BA33.30-P-1002-03BOil filler screw, front axle gearNm50

BA33.30-P-1003-03BOil drain screw, front axle gearNm50

NumberDesignationModel 163

BA41.20-P-1001-01ASelf-locking bolt of propeller shaft to front-axle gear flangeNm40

Number Designation Model 163

BF33.30-P-1001-

03BFilling capacityFront axle gearLiters1.2

Specifications for Operating

FluidsSheetBB00.40-P-0235-

07B

2001 Mercedes-Benz ML320

1998-2005 DRIVELINE/AXLES Front Axle - 163 Chassis

me

Saturday, October 02, 2010 3:38:22 PMPage 43 © 2006 Mitchell Repair Information Company, LLC.

Page 2567 of 4133

Fig. 80: Identifying Press Ou t Radial Shaft Sealing Ring

Fig. 81: Identifying Radial Sh aft Sealing Ring And Drift

Modification notes

8.1.07Filling capacity, Specificat ions for Operating FluidsModel 163*BF33.30-P-1001-03B

Remove/install

Notes on self-locking nuts and

boltsAll modelsAH00.00-N-

0001-01A

1

Remove front wheels

Remove/install wheels, rotate

if necessaryAP40.10-P-

4050GH

2Drain front axle oil *BF33.30-P-

1001-03B

3

Press follower joint out of

upper transverse control arm

using puller

AR33.20-P-

0500-01GH

*BA33.20-P-

1001-01D

Thrust pieceFig. 45

SupportFig. 46

PressFig. 47

2001 Mercedes-Benz ML320

1998-2005 DRIVELINE/AXLES Front Axle - 163 Chassis

me

Saturday, October 02, 2010 3:38:22 PMPage 48 © 2006 Mitchell Repair Information Company, LLC.

Page 2570 of 4133

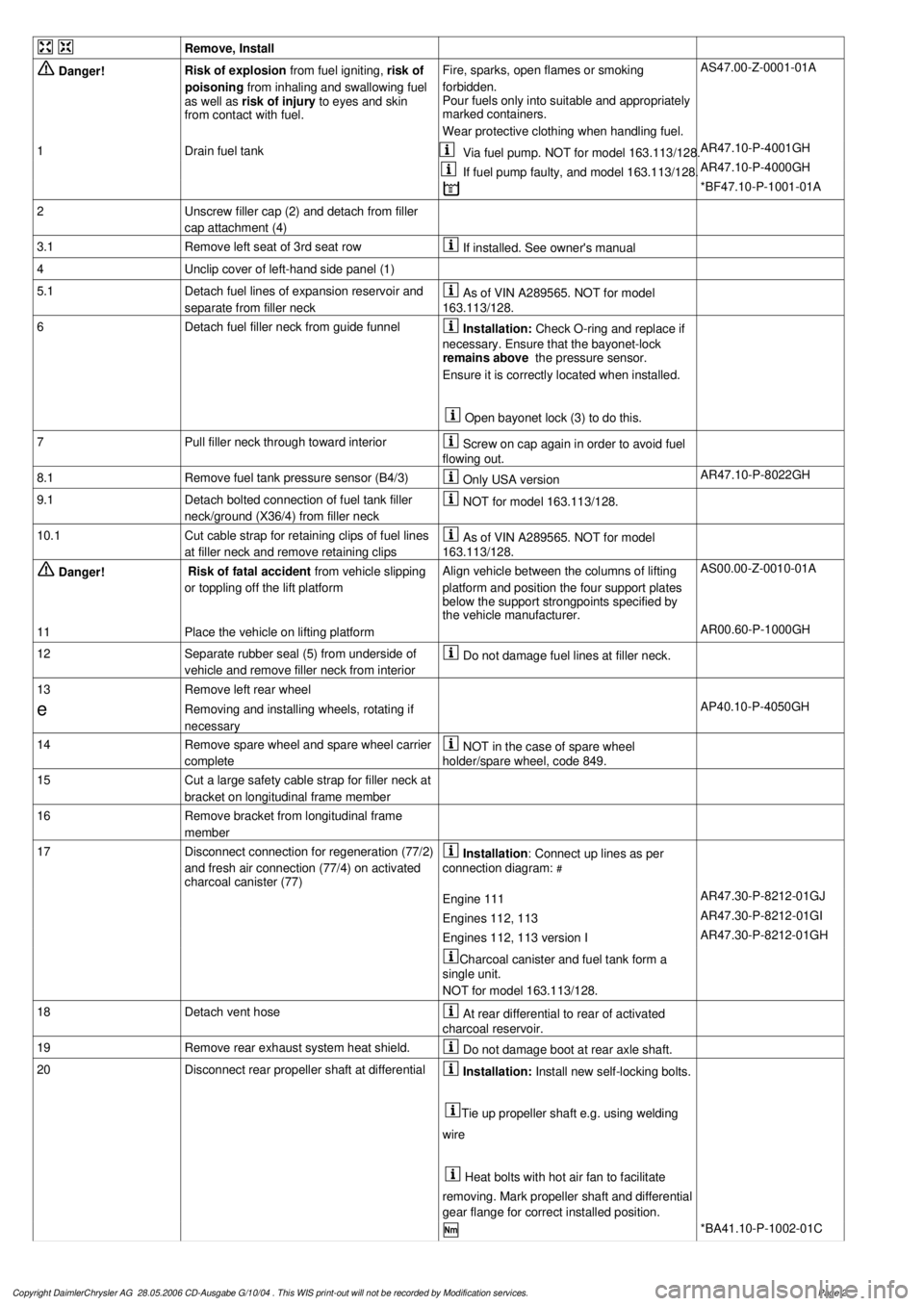

Fig. 87: Identifying Front Axle Shaft Flange

REMOVE/INSTALL FRON T AXLE SHAFTS - AR33.30-P-0620GH

MODEL 163.113 /128 /136 /154 /157 /172 /174 /175

Illustration shows left-hand side

Fig. 88: Identifying Front Axle Shaft Components

Remove/Install

Notes on self-locking nuts

and boltsAll modelsAH00.00-N-

0001-01A

1Remove rear wheels

2001 Mercedes-Benz ML320

1998-2005 DRIVELINE/AXLES Front Axle - 163 Chassis

me

Saturday, October 02, 2010 3:38:22 PMPage 51 © 2006 Mitchell Repair Information Company, LLC.

Page 2609 of 4133

Remove, Install

Danger!

Risk of explosion

from fuel igniting,

risk of

poisoning

from inhaling and swallowing fuel

as well as

risk of injury

to eyes and skin

from contact with fuel.

Fire, sparks, open flames or smoking

forbidden.

Pour fuels only into suitable and appropriately

marked containers.

Wear protective clothing when handling fuel.

AS47.00-Z-0001-01A

1

Drain fuel tank

Via fuel pump. NOT for model 163.113/128.

AR47.10-P-4001GH

If fuel pump faulty, and model 163.113/128.

AR47.10-P-4000GH

*BF47.10-P-1001-01A

2

Unscrew filler cap (2) and detach from filler

cap attachment (4)

3.1

Remove left seat of 3rd seat row

If installed. See owner's manual

4

Unclip cover of left-hand side panel (1)

5.1

Detach fuel lines of expansion reservoir and

separate from filler neck

As of VIN A289565. NOT for model

163.113/128.

6

Detach fuel filler neck from guide funnel

Installation:

Check O-ring and replace if

necessary. Ensure that the bayonet-lock

remains above

the pressure sensor.

Ensure it is correctly located when installed.

Open bayonet lock (3) to do this.

7

Pull filler neck through toward interior

Screw on cap again in order to avoid fuel

flowing out.

8.1

Remove fuel tank pressure sensor (B4/3)

Only USA version

AR47.10-P-8022GH

9.1

Detach bolted connection of fuel tank filler

neck/ground (X36/4) from filler neck

NOT for model 163.113/128.

10.1

Cut cable strap for retaining clips of fuel lines

at filler neck and remove retaining clips

As of VIN A289565. NOT for model

163.113/128.

Danger!

Risk of fatal accident

from vehicle slipping

or toppling off the lift platform

Align vehicle between the columns of lifting

platform and position the four support plates

below the support strongpoints specified by

the vehicle manufacturer.

AS00.00-Z-0010-01A

11

Place the vehicle on lifting platform

AR00.60-P-1000GH

12

Separate rubber seal (5) from underside of

vehicle and remove filler neck from interior

Do not damage fuel lines at filler neck.

13

Remove left rear wheel

e

Removing and installing wheels, rotating if

necessary

AP40.10-P-4050GH

14

Remove spare wheel and spare wheel carrier

complete

NOT in the case of spare wheel

holder/spare wheel, code 849.

15

Cut a large safety cable strap for filler neck at

bracket on longitudinal frame member

16

Remove bracket from longitudinal frame

member

17

Disconnect connection for regeneration (77/2)

and fresh air connection (77/4) on activated

charcoal canister (77)

Installation

: Connect up lines as per

connection diagram:

#

Engine 111

AR47.30-P-8212-01GJ

Engines 112, 113

AR47.30-P-8212-01GI

Engines 112, 113 version

I

AR47.30-P-8212-01GH

Charcoal canister and fuel tank form a

single unit.

NOT for model 163.113/128.

18

Detach vent hose

At rear differential to rear of activated

charcoal reservoir.

19

Remove rear exhaust system heat shield.

Do not damage boot at rear axle shaft.

20

Disconnect rear propeller shaft at differential

Installation:

Install new self-locking bolts.

Tie up propeller shaft e.g. using welding

wire

Heat bolts with hot air fan to facilitate

removing. Mark propeller shaft and differential

gear flange for correct installed position.

*BA41.10-P-1002-01C

Copyright DaimlerChrysler AG 28.05.2006 CD-Ausgabe G/10/04 . This WIS print-out will not be recorde

d by Modification services.

Page 2

Page 3232 of 4133

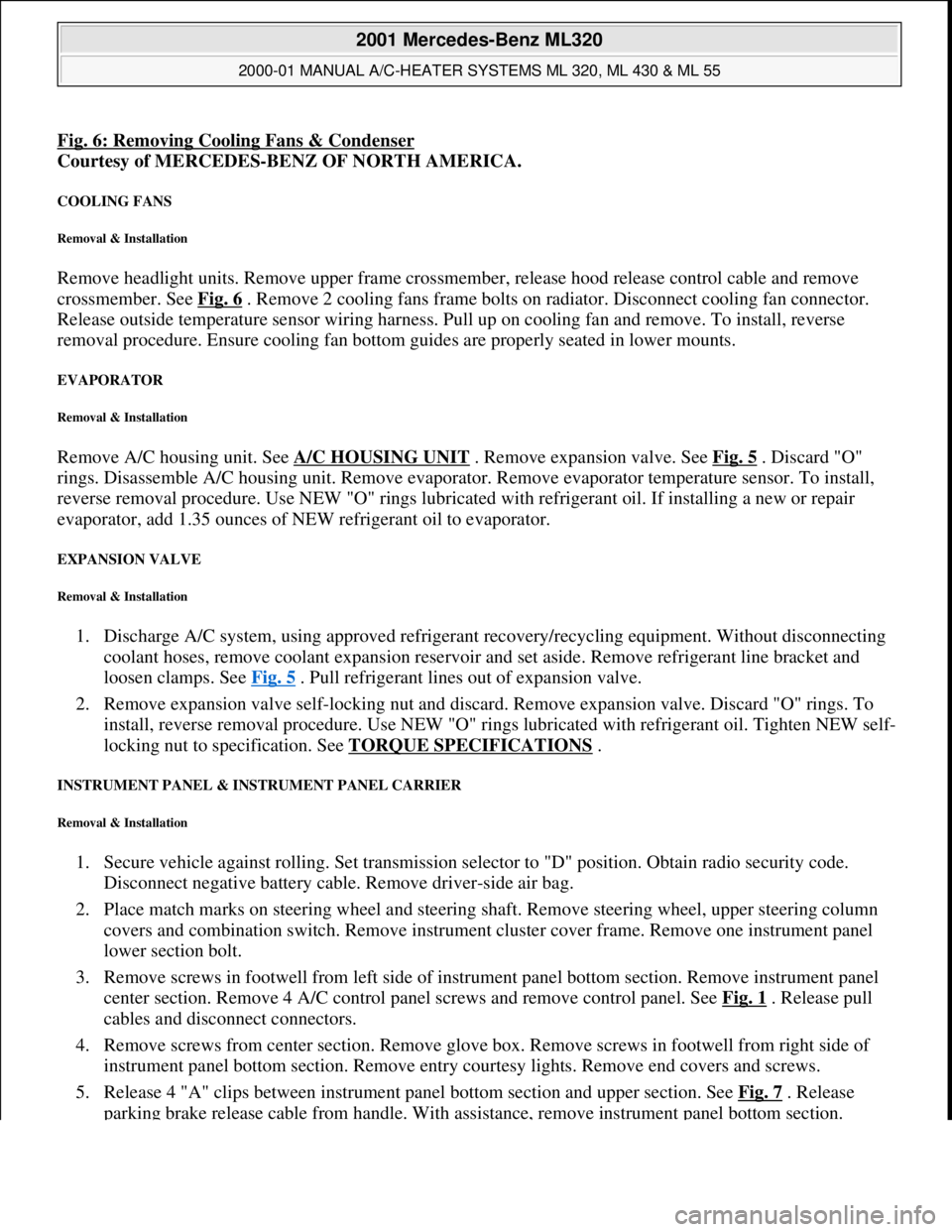

Fig. 6: Removing Cooling Fans & Condenser

Courtesy of MERCEDES-BENZ OF NORTH AMERICA.

COOLING FANS

Removal & Installation

Remove headlight units. Remove upper frame crossmember, release hood release control cable and remove

crossmember. See Fig. 6

. Remove 2 cooling fans frame bolts on radiator. Disconnect cooling fan connector.

Release outside temperature sensor wiring harness. Pull up on cooling fan and remove. To install, reverse

removal procedure. Ensure cooling fan bottom guides are properly seated in lower mounts.

EVAPORATOR

Removal & Installation

Remove A/C housing unit. See A/C HOUSING UNIT . Remove expansion valve. See Fig. 5 . Discard "O"

rings. Disassemble A/C housing unit. Remove evaporator. Remove evaporator temperature sensor. To install,

reverse removal procedure. Use NEW "O" rings lubricated with refrigerant oil. If installing a new or repair

evaporator, add 1.35 ounces of NEW refrigerant oil to evaporator.

EXPANSION VALVE

Removal & Installation

1. Discharge A/C system, using approved refrigerant recovery/recycling equipment. Without disconnecting

coolant hoses, remove coolant expansion reservoir and set aside. Remove refrigerant line bracket and

loosen clamps. See Fig. 5

. Pull refrigerant lines out of expansion valve.

2. Remove expansion valve self-locking nut and discard. Remove expansion valve. Discard "O" rings. To

install, reverse removal procedure. Use NEW "O" rings lubricated with refrigerant oil. Tighten NEW self-

locking nut to specification. See TORQUE SPECIFICATIONS

.

INSTRUMENT PANEL & INSTRUMENT PANEL CARRIER

Removal & Installation

1. Secure vehicle against rolling. Set transmission selector to "D" position. Obtain radio security code.

Disconnect negative battery cable. Remove driver-side air bag.

2. Place match marks on steering wheel and steering shaft. Remove steering wheel, upper steering column

covers and combination switch. Remove instrument cluster cover frame. Remove one instrument panel

lower section bolt.

3. Remove screws in footwell from left side of instrument panel bottom section. Remove instrument panel

center section. Remove 4 A/C control panel screws and remove control panel. See Fig. 1

. Release pull

cables and disconnect connectors.

4. Remove screws from center section. Remove glove box. Remove screws in footwell from right side of

instrument panel bottom section. Remove entry courtesy lights. Remove end covers and screws.

5. Release 4 "A" clips between instrument panel bottom section and upper section. See Fig. 7

. Release

parkin

g brake release cable from handle. With assistance, remove instrument panel bottom section.

2001 Mercedes-Benz ML320

2000-01 MANUAL A/C-HEATER SYSTEMS ML 320, ML 430 & ML 55

me

Saturday, October 02, 2010 3:25:10 PMPage 21 © 2006 Mitchell Repair Information Company, LLC.

Page 3485 of 4133

Rims

D

When changing wheels, for instance, when replacing steel

wheels with light-alloy rims, ensure that the wheel bolts

required for the spare wheel are stored in a clearly visible

location.

D

Since December 1994 models 202 and 124 with special

equipment light alloy disk wheels, are supplied with a sheet

steel spare wheel instead of a light alloy spare wheel. The

necessary wheel bolts are included with the steel spare wheel.

D

Only use approved Mercedes-Benz rims of the same version.

D

Reinforced steel rims are identified by a sticker on the wheel

disc.

D

The wheel bolts on steel and light-alloy rims should always be

tightened to the specified tightening torque using a torque

wrench.

It is not necessary to retorque the lug bolts after approximately

100 to 500 km.

D

The seat for the tire bead must display no corrosion marks.

D

Before inserting a new rubber valve, clean the contact surfaces

on the disk wheel.

On sheet steel-disk wheel wheel trims must be fitted to support

the rubber valve.

Damaged or deformed rims must not be repaired.

Tire pressure monitor

D

Before replacing a tire, check the date of manufacturer of the

wheel sensor: wheel sensors which are more than 5 years old

must be replaced.

D

Use STAR DIAGNOSIS to read out the actual values of the tire

pressure monitor. Check the remaining life of the wheel sensor

battery, replace the wheel sensor if necessary.

Copyright DaimlerChrysler AG 06.07.2006 CD-Ausgabe G/10/04 . This WIS print-out will not be recorde

d by Modification services.

Page 2

Page 3752 of 4133

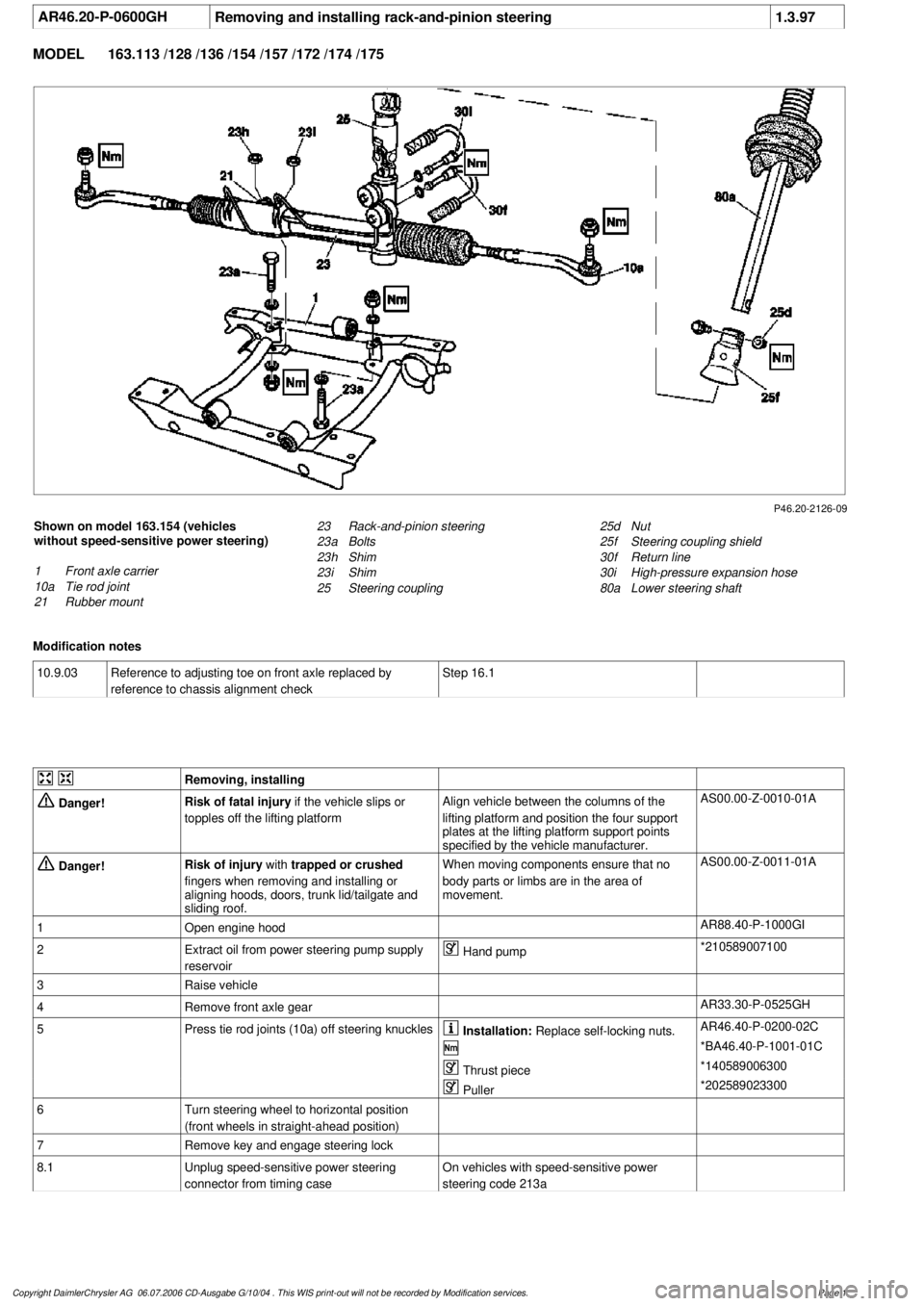

AR46.20-P-0600GH

Removing and installing rack-and-pinion steering

1.3.97

MODEL

163.113 /128 /136 /154 /157 /172 /174 /175

P46.20-2126-09

Shown on model 163.154 (vehicles

without speed-sensitive power steering)

1

Front axle carrier

10a

Tie rod joint

21

Rubber mount

25d

Nut

25f

Steering coupling shield

30f

Return line

30i

High-pressure expansion hose

80a

Lower steering shaft

23

Rack-and-pinion steering

23a

Bolts

23h

Shim

23i

Shim

25

Steering coupling

Modification notes

10.9.03

Reference to adjusting toe on front axle replaced by

reference to chassis alignment check

Step 16.1

Removing, installing

Danger!

Risk of fatal injury

if the vehicle slips or

topples off the lifting platform

Align vehicle between the columns of the

lifting platform and position the four support

plates

at the lifting platform support points

specified by the vehicle manufacturer.

AS00.00-Z-0010-01A

Danger!

Risk of injury

with

trapped or crushed

fingers when removing and installing or

aligning hoods, doors, trunk lid/tailgate and

sliding roof.

When moving components ensure that no

body parts or limbs are in the area of

movement.

AS00.00-Z-0011-01A

1

Open engine hood

AR88.40-P-1000GI

2

Extract oil from power steering pump supply

reservoir

Hand pump

*210589007100

3

Raise vehicle

4

Remove front axle gear

AR33.30-P-0525GH

5

Press tie rod joints (10a) off steering knuckles

Installation:

Replace self-locking nuts.

AR46.40-P-0200-02C

*BA46.40-P-1001-01C

Thrust piece

*140589006300

Puller

*202589023300

6

Turn steering wheel to horizontal position

(front wheels in straight-ahead position)

7

Remove key and engage steering lock

8.1

Unplug speed-sensitive power steering

connector from timing case

On vehicles with speed-sensitive power

steering code 213a

Copyright DaimlerChrysler AG 06.07.2006 CD-Ausgabe G/10/04 . This WIS print-out will not be recorde

d by Modification services.

Page 1

Page 3891 of 4133

Fig. 4: Connecting Hand Held Tester Scan Tool To OBD-II Data Link Connector

Courtesy of MERCEDES-BENZ OF NORTH AMERICA.

TESTING

Starter malfunctions may cause a Di agnostic Trouble Codes (DTCs) to be stored in Motor Electronics

Sequential Fuel Injection (ME-SFI) sy stem. After repairs are completed check for and erase any DTCs stored in

(ME-SFI) system. See appropriate SE LF-DIAGNOSTICS article in ENGINE PERFORMANCE. If cause of

starter malfunction is not engine pe rformance related, replace starter.

REMOVAL & INSTALLATION

STARTER

Removal & Installation

1. Disconnect and shield negative battery cable. See BATTERY DISCONNECT/CONNECT under

SERVICE PRECAUTIONS.

2. Remove nut (2) for inner fender. See Fig. 5

. Pull front and rear section of inner fender (1) downward.

Move inner fender away inward and downward. Pull toward outside over wheel. DO NOT damage fender

cutout or paint.

3. On vehicles with 112 engine, remove nut (6) at shield (5) of left engine mount and take out shield. See

Fig. 6

.

4. On all vehicles, disconnect circuit 30 (1) and circuit 50 (2) cables from starter. See Fig. 6

. Remove bolts

(3) for starter-to-crankcase. Take starter (M1) out to the side.

5. If replacing starter on vehicles with manual transmission, check ring gear at flywheel for wear and

damage. If replacing starter on vehicles with auto matic transmission, check ring gear on drive plate for

wear and damage. Repair or repl ace damaged parts as necessary.

6. To install, reverse removal proce dure. Replace bolts with locking splines, micro-encapsulated bolts and

self-locking nuts. Mating thread of mi cro-encapsulated bolts must be cleaned to remove all residue of old

bolt locking compound. Tighten fasteners to specification. See TORQUE SPECIFICATIONS

. Connect

battery. See BATTERY DISCONNECT/CONNECTunder SERVICE PRECAUTIONS.

NOTE: Numbers and letters in text refe

r to numbers and letters in figures.

2001 Mercedes-Benz ML320

2001-04 STARTING & CHARGING SYSTEMS Starters - 163 Chassis

me

Saturday, October 02, 2010 3:19:47 PMPage 9 © 2006 Mitchell Repair Information Company, LLC.