diagram MERCEDES-BENZ ML320 1997 Complete Manual PDF

[x] Cancel search | Manufacturer: MERCEDES-BENZ, Model Year: 1997, Model line: ML320, Model: MERCEDES-BENZ ML320 1997Pages: 4133, PDF Size: 88.89 MB

Page 1833 of 4133

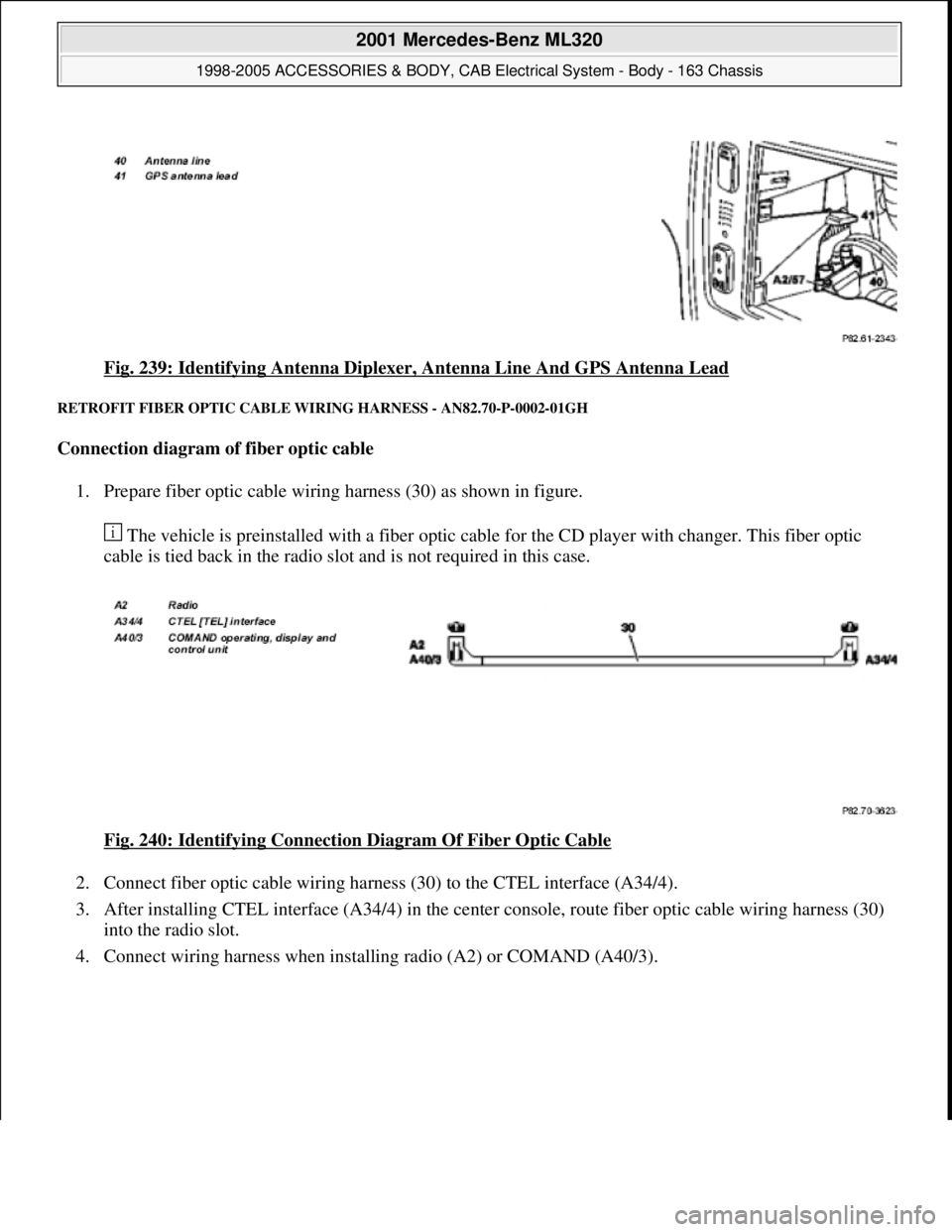

Fig. 239: Identifying Antenna Diplexer, Antenna Line And GPS Antenna Lead

RETROFIT FIBER OPTIC CABLE WIRING HARNESS - AN82.70-P-0002-01GH

Connection diagram of fiber optic cable

1. Prepare fiber optic cable wiring harness (30) as shown in figure.

The vehicle is preinstalled with a fiber optic cable for the CD player with changer. This fiber optic

cable is tied back in the radio slot and is not required in this case.

Fig. 240: Identifying Connection Diagram Of Fiber Optic Cable

2. Connect fiber optic cable wiring harness (30) to the CTEL interface (A34/4).

3. After installing CTEL interface (A34/4) in the center console, route fiber optic cable wiring harness (30)

into the radio slot.

4. Connect wiring harness when installing radio (A2) or COMAND (A40/3).

2001 Mercedes-Benz ML320

1998-2005 ACCESSORIES & BODY, CAB Electrical System - Body - 163 Chassis

me

Saturday, October 02, 2010 3:30:11 PMPage 338 © 2006 Mitchell Repair Information Company, LLC.

Page 1836 of 4133

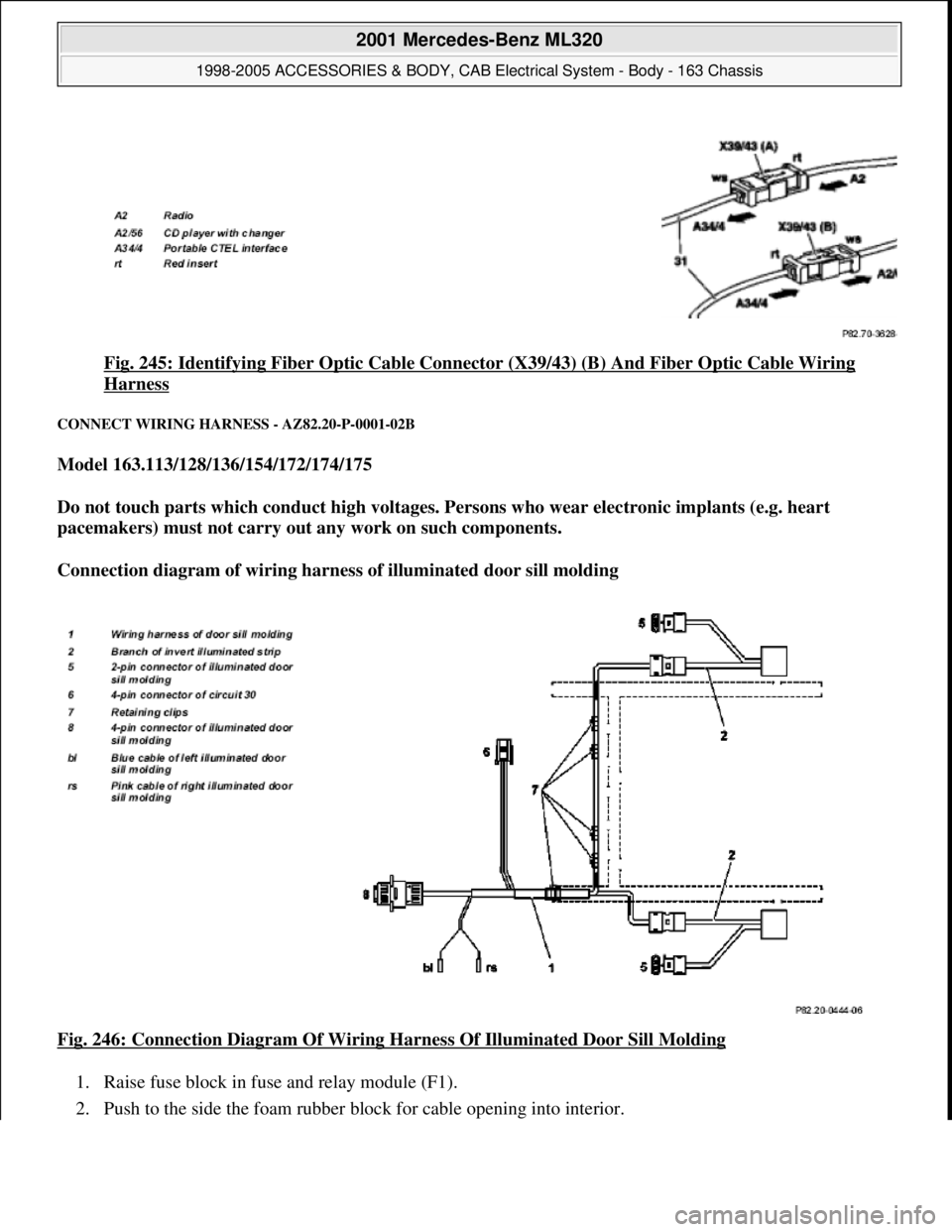

Fig. 245: Identifying Fiber Optic Cable Connector (X39/43) (B) And Fiber Optic Cable Wiring

Harness

CONNECT WIRING HARNESS - AZ82.20-P-0001-02B

Model 163.113/128/136/154/172/174/175

Do not touch parts which conduct high voltages. Persons who wear electronic implants (e.g. heart

pacemakers) must not carry out any work on such components.

Connection diagram of wiring harness of illuminated door sill molding

Fig. 246: Connection Diagram Of Wiring Harness Of Illuminated Door Sill Molding

1. Raise fuse block in fuse and relay module (F1).

2. Push to the side the foam rubber block for cable openin

g into interior.

2001 Mercedes-Benz ML320

1998-2005 ACCESSORIES & BODY, CAB Electrical System - Body - 163 Chassis

me

Saturday, October 02, 2010 3:30:11 PMPage 341 © 2006 Mitchell Repair Information Company, LLC.

Page 2034 of 4133

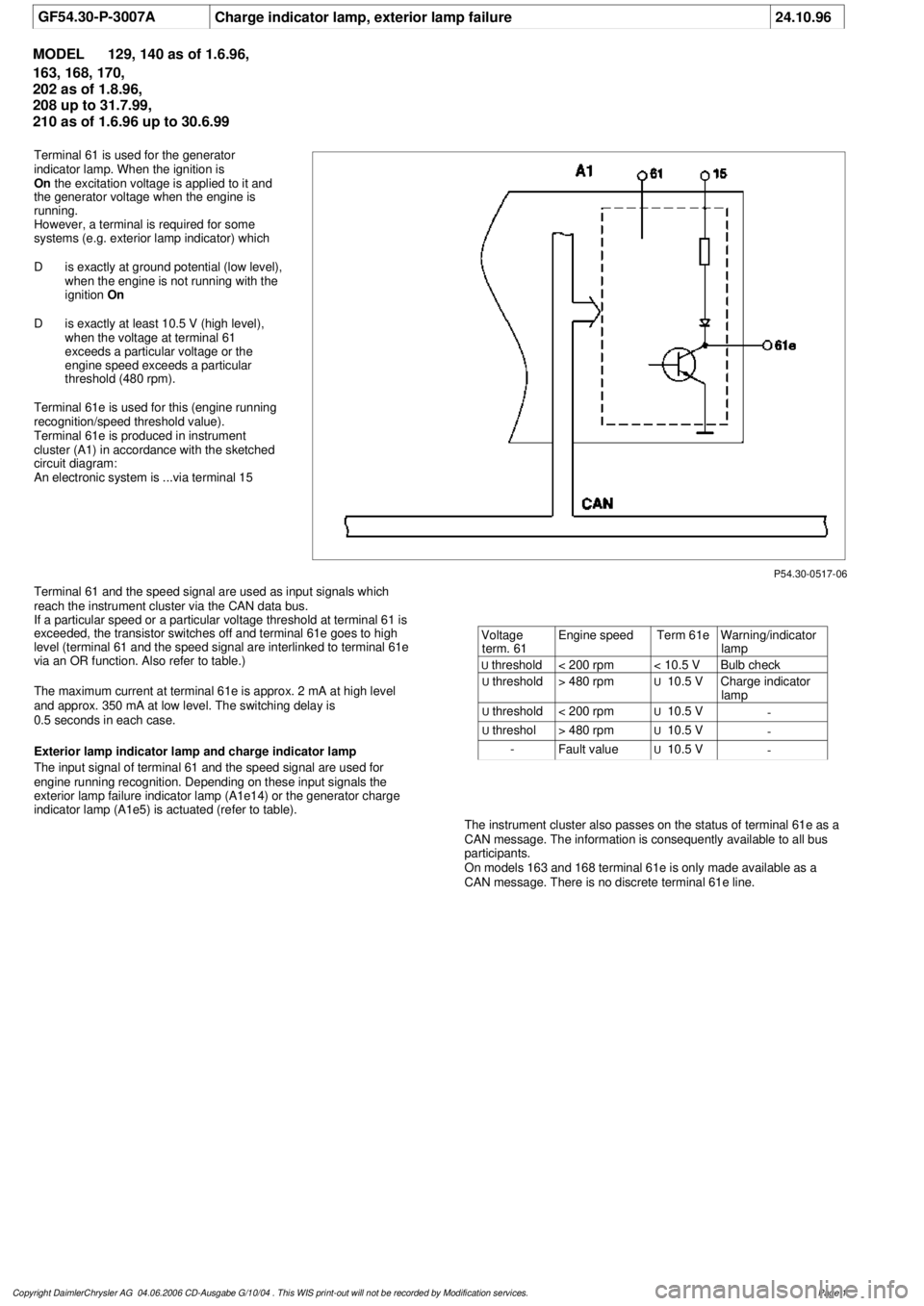

GF54.30-P-3007A

Charge indicator lamp, exterior lamp failure

24.10.96

MODEL

129, 140 as of 1.6.96,

163, 168, 170,

202 as of 1.8.96,

208 up to 31.7.99,

210 as of 1.6.96 up to 30.6.99

P54.30-0517-06

Terminal 61 is used for the generator

indicator lamp. When the ignition is

On

the excitation voltage is applied to it and

the generator voltage when the engine is

running.

However, a terminal is required for some

systems (e.g. exterior lamp indicator) which

D

is exactly at ground potential (low level),

when the engine is not running with the

ignition

On

D

is exactly at least 10.5 V (high level),

when the voltage at terminal 61

exceeds a particular voltage or the

engine speed exceeds a particular

threshold (480 rpm).

Terminal 61e is used for this (engine running

recognition/speed threshold value).

Terminal 61e is produced in instrument

cluster (A1) in accordance with the sketched

circuit diagram:

An electronic system is ...via terminal 15

Terminal 61 and the speed signal are used as input signals which

reach the instrument cluster via the CAN data bus.

If a particular speed or a particular voltage threshold at terminal 61 is

exceeded, the transistor switches off and terminal 61e goes to high

level (terminal 61 and the speed signal are interlinked to terminal 61e

via an OR function. Also refer to table.)

The maximum current at terminal 61e is approx. 2 mA at high level

and approx. 350 mA at low level. The switching delay is

0.5 seconds in each case.

Exterior lamp indicator lamp and charge indicator lamp

The input signal of terminal 61 and the speed signal are used for

engine running recognition. Depending on these input signals the

exterior lamp failure indicator lamp (A1e14) or the generator charge

indicator lamp (A1e5) is actuated (refer to table).

The instrument cluster also passes on the status of terminal 61e as a

CAN message. The information is consequently available to all bus

participants.

On models 163 and 168 terminal 61e is only made available as a

CAN message. There is no discrete terminal 61e line.

Voltage

term. 61

Engine speed

Term 61e

Warning/indicator

lamp

U

threshold

< 200 rpm

< 10.5 V

Bulb check

U

threshold

> 480 rpm

U

10.5 V

Charge indicator

lamp

U

threshold

< 200 rpm

U

10.5 V

-

U

threshol

> 480 rpm

U

10.5 V

-

-

Fault value

U

10.5 V

-

Copyright DaimlerChrysler AG 04.06.2006 CD-Ausgabe G/10/04 . This WIS print-out will not be recorde

d by Modification services.

Page 1

Page 2043 of 4133

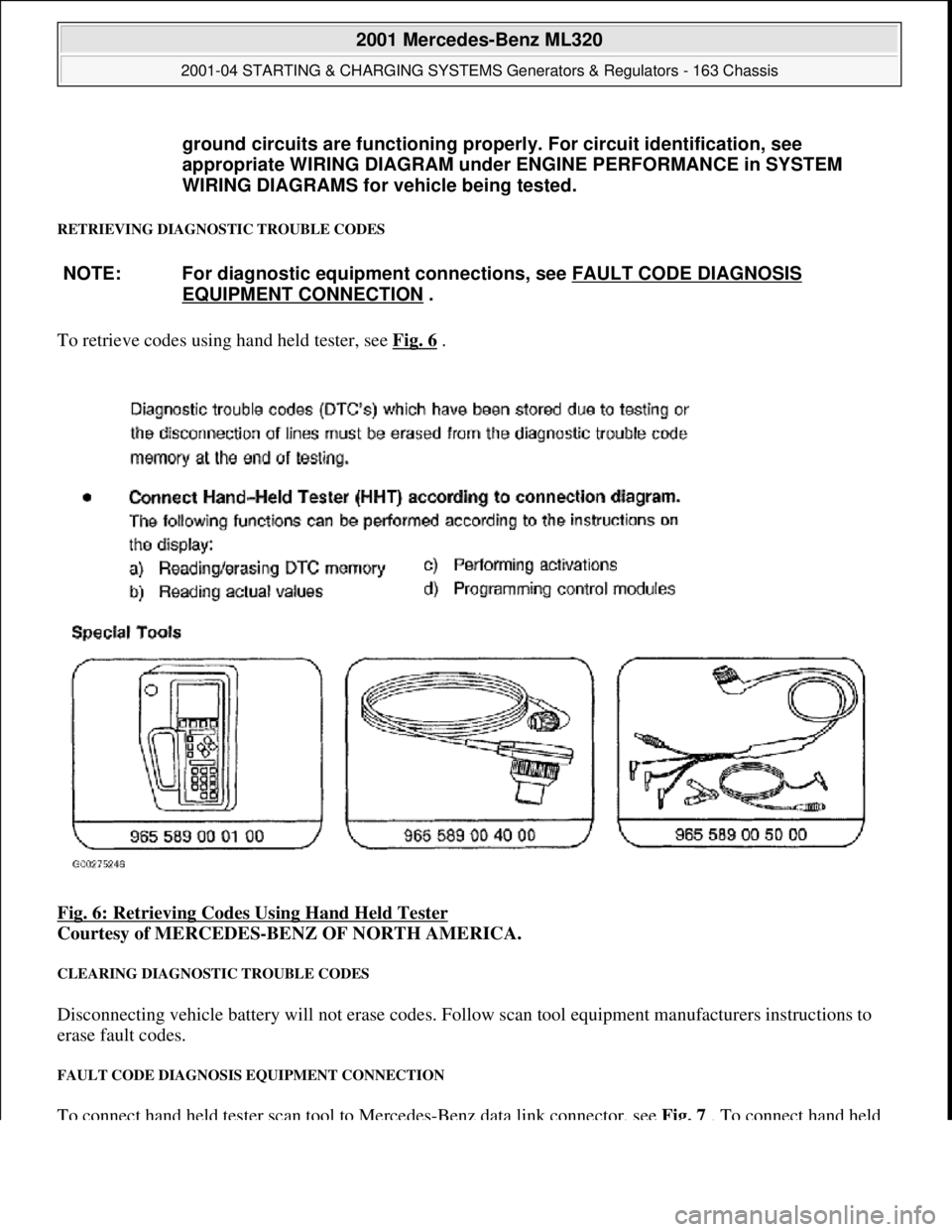

RETRIEVING DIAGNOSTIC TROUBLE CODES

To retrieve codes using hand held tester, see Fig. 6 .

Fig. 6: Retrieving Codes Using Hand Held Tester

Courtesy of MERCEDES-BENZ OF NORTH AMERICA.

CLEARING DIAGNOSTIC TROUBLE CODES

Disconnecting vehicle battery will not erase codes. Follow scan tool equipment manufacturers instructions to

erase fault codes.

FAULT CODE DIAGNOSIS EQUIPMENT CONNECTION

To connect hand held tester scan tool to Mercedes-Benz data link connector, see Fig. 7 . To connect hand held

ground circuits are functioning properl

y. For circuit identification, see

appropriate WIRING DIAGRAM unde r ENGINE PERFORMANCE in SYSTEM

WIRING DIAGRAMS for vehicle being tested.

NOTE: For diagnostic equipment conn ections, see FAULT CODE DIAGNOSIS

EQUIPMENT CONNECTION .

2001 Mercedes-Benz ML320

2001-04 STARTING & CHARGING SYSTEMS Gene rators & Regulators - 163 Chassis

me

Saturday, October 02, 2010 3:20:32 PMPage 9 © 2006 Mitchell Repair Information Company, LLC.

Page 2060 of 4133

TORQUE SPECIFICATIONS

TORQUE SPECIFICATIONS

WIRING DIAGRAMS

See CHARGING SYSTEM in appropriate SYSTEM WIRING DIAGRAMS article in ELECTRICAL.

ApplicationFt. Lbs. (N.m)

Generator Mounting Bolts30 (42)

Generator Pulley Nut52 (70)

2001 Mercedes-Benz ML320

2001-04 STARTING & CHARGING SYSTEMS Generators & Regulators - 163 Chassis

me

Saturday, October 02, 2010 3:20:32 PMPage 26 © 2006 Mitchell Repair Information Company, LLC.

Page 2061 of 4133

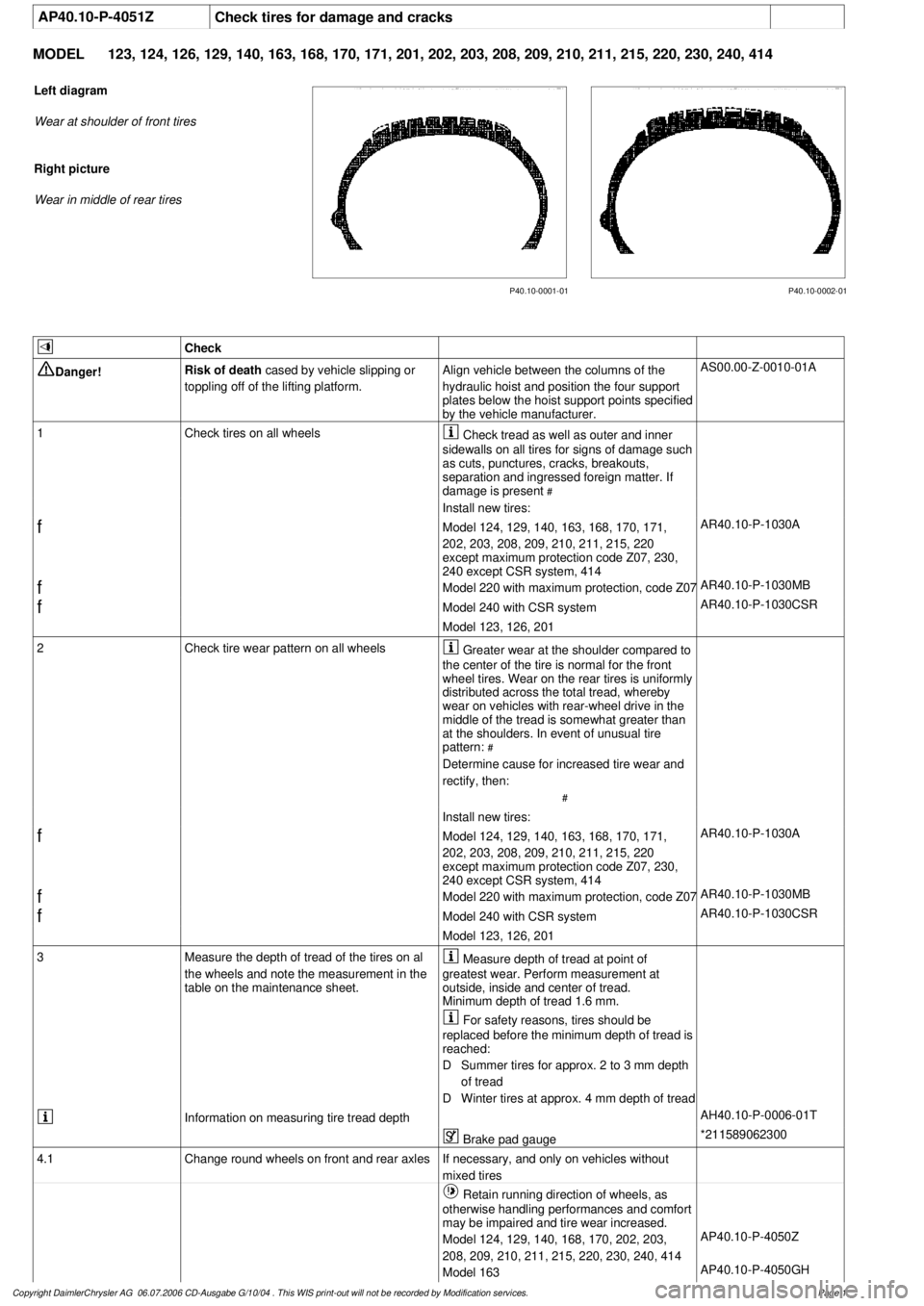

AP40.10-P-4051Z

Check tires for damage and cracks

MODEL

123, 124, 126, 129, 140, 163, 168, 170, 171, 201, 202, 203, 208, 209, 210, 211, 215, 220, 230, 240, 414

P40.10-0002-01

P40.10-0001-01

Left diagram

Wear at shoulder of front tires

Right picture

Wear in middle of rear tires

Check

Danger!

Risk of death

cased by vehicle slipping or

toppling off of the lifting platform.

Align vehicle between the columns of the

hydraulic hoist and position the four support

plates below the hoist support points specified

by the vehicle manufacturer.

AS00.00-Z-0010-01A

1

Check tires on all wheels

Check tread as well as outer and inner

sidewalls on all tires for signs of damage such

as cuts, punctures, cracks, breakouts,

separation and ingressed foreign matter. If

damage is present

#

Install new tires:

f

Model 124, 129, 140, 163, 168, 170, 171,

202, 203, 208, 209, 210, 211, 215, 220

except maximum protection code Z07, 230,

240 except CSR system, 414

AR40.10-P-1030A

f

Model 220 with maximum protection, code Z07

AR40.10-P-1030MB

f

Model 240 with CSR system

AR40.10-P-1030CSR

Model 123, 126, 201

2

Check tire wear pattern on all wheels

Greater wear at the shoulder compared to

the center of the tire is normal for the front

wheel tires. Wear on the rear tires is uniformly

distributed across the total tread, whereby

wear on vehicles with rear-wheel drive in the

middle of the tread is somewhat greater than

at the shoulders. In event of unusual tire

pattern:

#

Determine cause for increased tire wear and

rectify, then:

#

Install new tires:

f

Model 124, 129, 140, 163, 168, 170, 171,

202, 203, 208, 209, 210, 211, 215, 220

except maximum protection code Z07, 230,

240 except CSR system, 414

AR40.10-P-1030A

f

Model 220 with maximum protection, code Z07

AR40.10-P-1030MB

f

Model 240 with CSR system

AR40.10-P-1030CSR

Model 123, 126, 201

3

Measure the depth of tread of the tires on al

the wheels and note the measurement in the

table on the maintenance sheet.

Measure depth of tread at point of

greatest wear. Perform measurement at

outside, inside and center of tread.

Minimum depth of tread 1.6 mm.

For safety reasons, tires should be

replaced before the minimum depth of tread is

reached:

D

Summer tires for approx. 2 to 3 mm depth

of tread

D

Winter tires at approx. 4 mm depth of tread

Information on measuring tire tread depth

AH40.10-P-0006-01T

Brake pad gauge

*211589062300

4.1

Change round wheels on front and rear axles

If necessary, and only on vehicles without

mixed tires

Retain running direction of wheels, as

otherwise handling performances and comfort

may be impaired and tire wear increased.

Model 124, 129, 140, 168, 170, 202, 203,

208, 209, 210, 211, 215, 220, 230, 240, 414

AP40.10-P-4050Z

Model 163

AP40.10-P-4050GH

Copyright DaimlerChrysler AG 06.07.2006 CD-Ausgabe G/10/04 . This WIS print-out will not be recorde

d by Modification services.

Page 1

Page 2165 of 4133

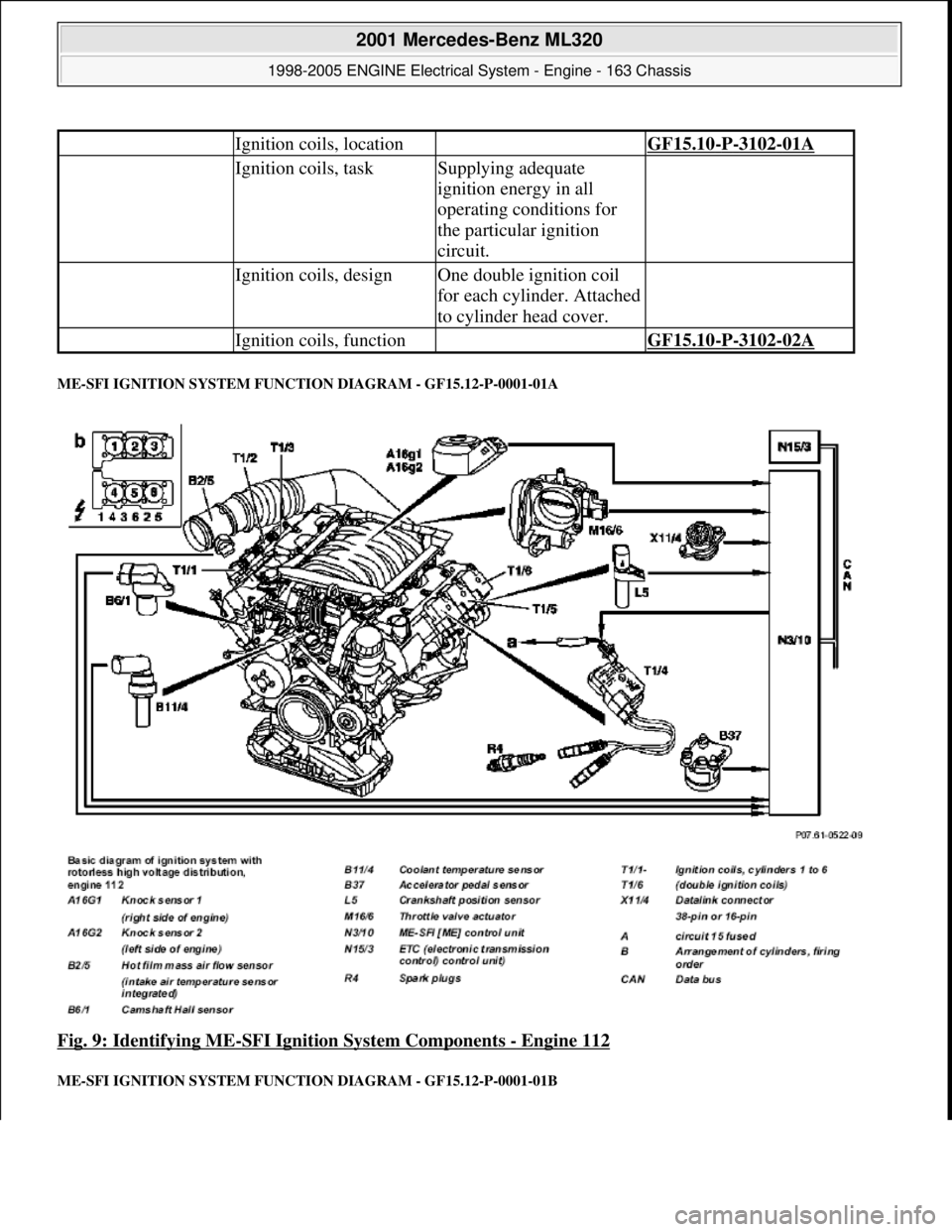

ME-SFI IGNITION SYSTEM FUNCTION DIAGRAM - GF15.12-P-0001-01A

Fig. 9: Identifying ME-SFI Ignition System Components - Engine 112

ME-SFI IGNITION SYSTEM FUNCTION DIAGRAM - GF15.12-P-0001-01B

Ignition coils, location GF15.10-P-3102-01A

Ignition coils, taskSupplying adequate

ignition energy in all

operating conditions for

the particular ignition

circuit.

Ignition coils, designOne double ignition coil

for each cylinder. Attached

to cylinder head cover.

Ignition coils, function GF15.10-P-3102-02A

2001 Mercedes-Benz ML320

1998-2005 ENGINE Electrical System - Engine - 163 Chassis

me

Saturday, October 02, 2010 3:18:54 PMPage 11 © 2006 Mitchell Repair Information Company, LLC.

Page 2173 of 4133

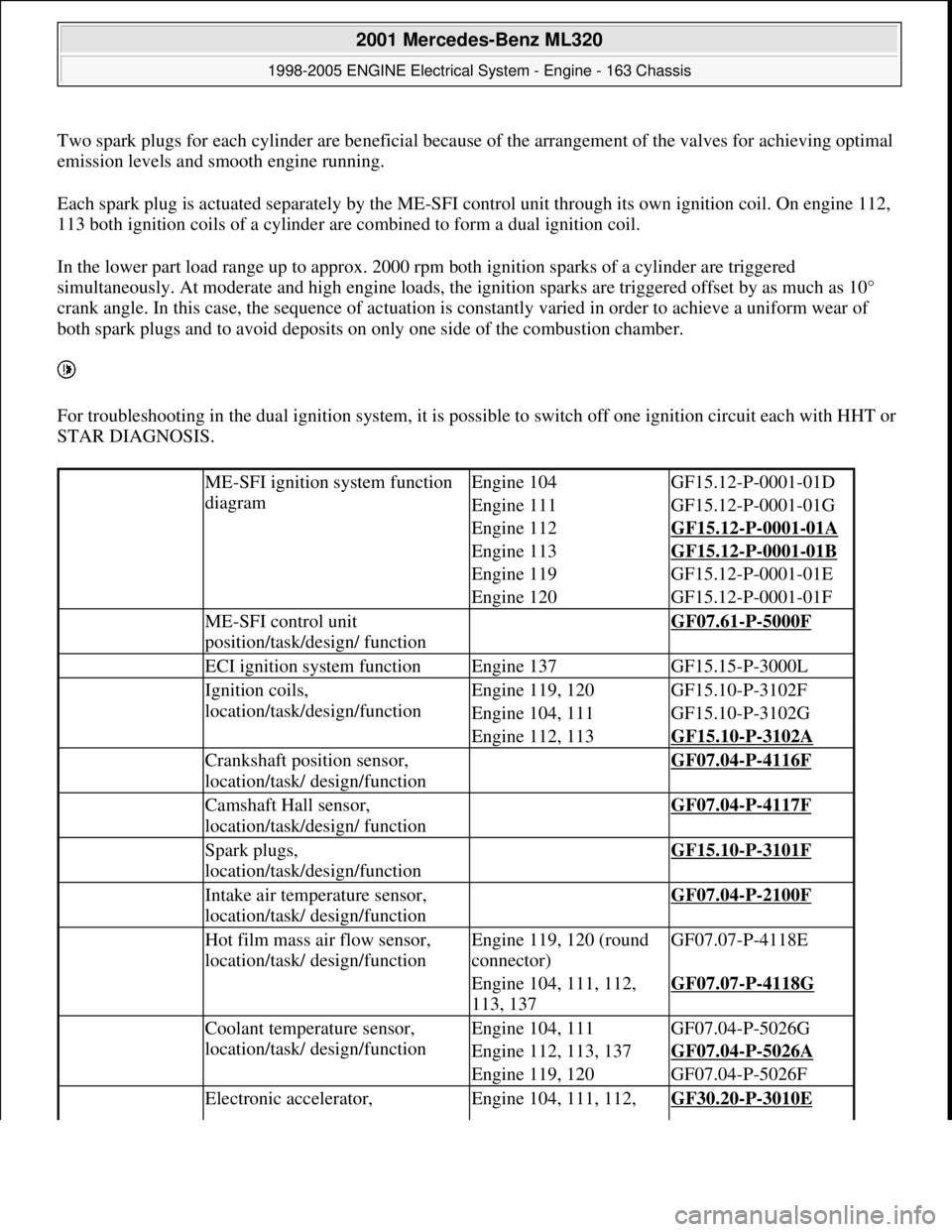

Two spark plugs for each cylinder are beneficial because of the arrangement of the valves for achieving optimal

emission levels and smooth engine running.

Each spark plug is actuated separately by the ME-SFI control unit through its own ignition coil. On engine 112,

113 both ignition coils of a cylinder are combined to form a dual ignition coil.

In the lower part load range up to approx. 2000 rpm both ignition sparks of a cylinder are triggered

simultaneously. At moderate and high engine loads, the ignition sparks are triggered offset by as much as 10°

crank angle. In this case, the sequence of actuation is constantly varied in order to achieve a uniform wear of

both spark plugs and to avoid deposits on only one side of the combustion chamber.

For troubleshooting in the dual ignition system, it is possible to switch off one ignition circuit each with HHT or

STAR DIAGNOSIS.

ME-SFI ignition system function

diagramEngine 104GF15.12-P-0001-01D

Engine 111GF15.12-P-0001-01G

Engine 112GF15.12-P-0001-01A

Engine 113GF15.12-P-0001-01B

Engine 119GF15.12-P-0001-01E

Engine 120GF15.12-P-0001-01F

ME-SFI control unit

position/task/design/ function GF07.61-P-5000F

ECI ignition system functionEngine 137GF15.15-P-3000L

Ignition coils,

location/task/design/functionEngine 119, 120GF15.10-P-3102F

Engine 104, 111GF15.10-P-3102G

Engine 112, 113GF15.10-P-3102A

Crankshaft position sensor,

location/task/ design/function GF07.04-P-4116F

Camshaft Hall sensor,

location/task/design/ function GF07.04-P-4117F

Spark plugs,

location/task/design/function GF15.10-P-3101F

Intake air temperature sensor,

location/task/ design/function GF07.04-P-2100F

Hot film mass air flow sensor,

location/task/ design/functionEngine 119, 120 (round

connector)GF07.07-P-4118E

Engine 104, 111, 112,

113, 137GF07.07-P-4118G

Coolant temperature sensor,

location/task/ design/functionEngine 104, 111GF07.04-P-5026G

Engine 112, 113, 137GF07.04-P-5026A

Engine 119, 120GF07.04-P-5026F

Electronic accelerator, Engine 104, 111, 112, GF30.20-P-3010E

2001 Mercedes-Benz ML320

1998-2005 ENGINE Electrical System - Engine - 163 Chassis

me

Saturday, October 02, 2010 3:18:54 PMPage 19 © 2006 Mitchell Repair Information Company, LLC.

Page 2208 of 4133

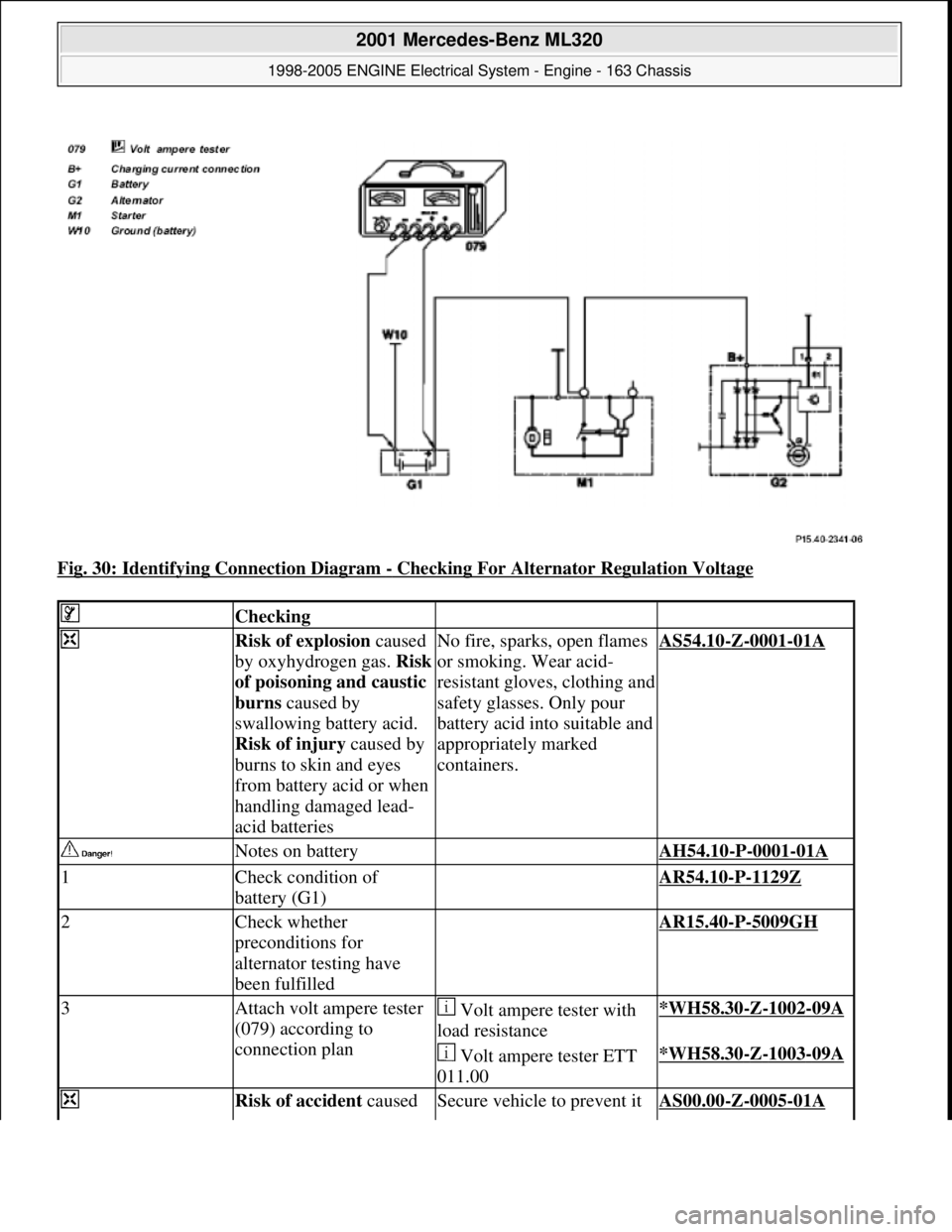

Fig. 30: Identifying Connection Diagram - Checking For Alternator Regulation Voltage

Checking

Risk of explosion caused

by oxyhydrogen gas. Risk

of poisoning and caustic

burns caused by

swallowing battery acid.

Risk of injury caused by

burns to skin and eyes

from battery acid or when

handling damaged lead-

acid batteriesNo fire, sparks, open flames

or smoking. Wear acid-

resistant gloves, clothing and

safety glasses. Only pour

battery acid into suitable and

appropriately marked

containers.

AS54.10-Z-0001-01A

Notes on battery AH54.10-P-0001-01A

1Check condition of

battery (G1) AR54.10-P-1129Z

2Check whether

preconditions for

alternator testing have

been fulfilled AR15.40-P-5009GH

3Attach volt ampere tester

(079) according to

connection plan Volt ampere tester with

load resistance*WH58.30-Z-1002-09A

Volt ampere tester ETT

011.00*WH58.30-Z-1003-09A

Risk of accident caused Secure vehicle to prevent it AS00.00-Z-0005-01A

2001 Mercedes-Benz ML320

1998-2005 ENGINE Electrical System - Engine - 163 Chassis

me

Saturday, October 02, 2010 3:18:54 PMPage 54 © 2006 Mitchell Repair Information Company, LLC.

Page 2212 of 4133

connection diagram011.00

Risk of accident caused

by vehicle starting off by

itself when engine is

running. Risk of injury

caused by contusions and

burns during starting

procedure or when

working near the running

engineSecure vehicle to prevent it

from moving by itself.

Wear closed and snug-

fitting work clothes.

Do not grasp hot or rotating

parts.AS00.00-Z-0005-01A

3Start engine

4Load battery (G1) with

volt ampere tester (079)

and check charging

current of alternator (G2)

with increased engine

speed Vary load resistance

long enough until the

maximum load current is

achieved; when this is

done, the regulating voltage

must not drop below 12.7

V.

Engines 111, 612*BE15.40-P-1001-01A

Engines 112, 113*BE15.40-P-1001-01K

Engine 628*BE15.40-P-1001-01J

Volt ampere tester with

load resistance*WH58.30-Z-1002-09A

Volt ampere tester ETT

011.00*WH58.30-Z-1003-09A

Charging current below

desired value: ?

Check diodes for

alternator (G2).

AR15.40-P-9301-02EA

Engine tester with

oscilloscope

If diodes are faulty: ?

Replace alternator

(G2)

*WH58.30-Z-1046-13A

Engines 111, 112, 113AR15.40-P-5032GH

Engine 612AR15.40-P-5032GI

Engine 628 with water-

cooled alternator (G2)AR15.40-P-5032IA

Engine 628 with air-cooled

alternator (G2)AR15.40-P-5032GD

5Turn off engine

6Disconnect volt ampere

tester (079) with current Volt ampere tester with

load resistance*WH58.30-Z-1002-09A

2001 Mercedes-Benz ML320

1998-2005 ENGINE Electrical System - Engine - 163 Chassis

me

Saturday, October 02, 2010 3:18:54 PMPage 58 © 2006 Mitchell Repair Information Company, LLC.