MERCEDES-BENZ ML430 1997 Complete Repair Manual

Manufacturer: MERCEDES-BENZ, Model Year: 1997, Model line: ML430, Model: MERCEDES-BENZ ML430 1997Pages: 4133, PDF Size: 88.89 MB

Page 2661 of 4133

NOTES ON REPLACING SAFETY - RELEVANT COMPONENTS - AH00.19-P-1000-02A

General

With the approval of repair solutions for wiring harnesses (in particular airbag, side airbag, window airbag,

emergency tensioning retractor wiring harness), it is necessary to introduce a modified ordering routine for

procuring safety-relevant components. The order formalities are by and large the same as those which are

already familiar from theft-relevant components.

Procedure

It is only possible to order safety-relevant components by stating the vehicle ident number (refer parts order

note on the parts microfiche).

The repair orders and invoices should be filed in the usual way.

All orders received for safety-relevant components are additionally automatically documented in Fdok.

ADVANTAGES OF REPAIRING WIRING HARNESSES - AH00.19-P-1000-03A

Model 124, 126, 129, 140, 163, 164, 168, 169, 170, 171, 199, 202, 203, 208, 209, 210, 211, 215, 216, 219, 220,

221, 230, 240, 245, 251, 414, 461, 463

Advantages of repairing wiring harnesses

Wiring harnesses are essentially repaired to reduce repair costs.

If repairs are carried out properly, there is no difference in function or quality between the repaired wiring

harness and a brand new wiring harness.

Repairing wiring harnesses helps to save resources.

This also complies with the "Technical Alliance Center" requirements for less dismantling and

installation cost.

REPAIR METHODS FOR WIRING HARNESSES - AH00.19-P-1000-04A

Model 124, 126, 129, 140, 163, 164, 168, 169, 170, 171, 199, 202, 203, 208, 209, 210, 211, 215, 216, 219, 220,

221, 230, 240, 245, 251, 414, 461, 463

Repair method summary

The following methods have been approved by DaimlerChrysler for repairing wiring harnesses in Mercedes-

Benz passenger cars:

Repair methods:

1.20711.21811.22901.23981.25051.302811.27171.229011.29251.30281.3130

7801.21481.22591.23691.24781.25851.23691.21.27981.29041.30081.32141.3214

2004 Mercedes-Benz ML350

1998-2005 GENINFO Overall vehicle - 163 Chassis

me

Saturday, October 02, 2010 3:47:44 PMPage 16 © 2006 Mitchell Repair Information Company, LLC.

Page 2662 of 4133

Crimping

Solder connection (Raychem)

Axial solder connection (Raychem)

Combination of Raychem and cable tail

Soldering

Insulation displacement method

Flat conductor pliers

Application

Individual cases must be analyzed in detail to decide which method can and cannot be used to repair wiring

harnesses (wires, contacts and connectors).

Crimping repair method

In crimping, the insulation is first stripped off an appropriate distance (a) from the end of the wire. Then the

contact pin is placed over the stripped end of the wire and pinched ("crimped") in place by means of a special

pliers-like crimping tool. Crimping is performed quickly and with ease. A special crimper is required.

Only lines up to 4 mm

2 shall be crimped.

Fig. 6: Identifying Crimping Repair Method

Raychem repair method

With this method, special solder connectors are used. The solder connections contain the solder and they also

feature insulation and a seal. A special hot air blower provides the heat required for soldering and shrinking the

insulation. A special reflector is fitted to the hot air blower. The minimum temperature for this repair method is

400°C.

Raychem is the manufacturer of the solder connections that are required for this method. The Raychem

repair method is mainly used for integrating repair wiring harnesses (cable tails): ?

Combination of Raychem repair method and cable tail repair

2004 Mercedes-Benz ML350

1998-2005 GENINFO Overall vehicle - 163 Chassis

me

Saturday, October 02, 2010 3:47:44 PMPage 17 © 2006 Mitchell Repair Information Company, LLC.

Page 2663 of 4133

Cable tails are prefabricated partial wiring harness kits available as Mercedes-Benz replacement parts. They

have the appropriate cable cr oss-sections and crimped contacts. The Rayc hem repair method is used to integrate

the cable tails into the wiring harnesses.

Only use cable tails for lines between 4 and 10 mm

2 . Starting at 10 mm2 the wiring harnesses must be

replaced.

Fig. 7: Identifying Raychem Repair Method

Soldering repair method

The strands of the cable (2) are soldered in the solder c ontact (axial or radial version) (1) using a soldering iron.

Commercially available solder is used for the soldered connection. This method is only used for repairing plug

connections.

Fig. 8: Identifying Soldering Repair Method

Repair method using rapid connection technology

This method uses special rapid-connect ion wire connector blocks. Mercedes-Benz permits the 2-, 4-, and 6-pin

versions. They contain tin-plated rapi d connection contacts, which are pressed together to touch the wires of the

cables using pliers. The lines do not ha ve to be separated or stripped.

This method can be used for connection to ca bles with a cross section of 0.35 to 0.75 mm

2 and for wire end

connections.

2004 Mercedes-Benz ML350

1998-2005 GENINFO Overall vehicle - 163 Chassis

me

Saturday, October 02, 2010 3:47:44 PMPage 18 © 2006 Mitchell Repair Information Company, LLC.

Page 2664 of 4133

The rapid connection method must only be used inside the vehicle or in the trunk because the connection is

not watertight. They are not permissible for CAN lines.

Fig. 9: Identifying Repair Method Using Rapid Connection Technology

Flat conductor cable repair method

Select crimp contacts in the wiring harness repair kit an d insert into the tool head of the open manual crimp

pliers (2). The flat conductor cable (7) must make contact with the tool head, and the correct edge of the flat

conductor cable (7) must make contac t with the adjusting stop (3). The optical adjusting device (4) in the

manual crimp pliers (2) must be fully visible between 2 conductor tracks. Press the manual crimp pliers (2)

together all the way. After it has been pressed down al l the way, it can be opened again. Remove the finished

crimp connection.

Fig. 10: Identifying Flat Conductor Cable Repair Method

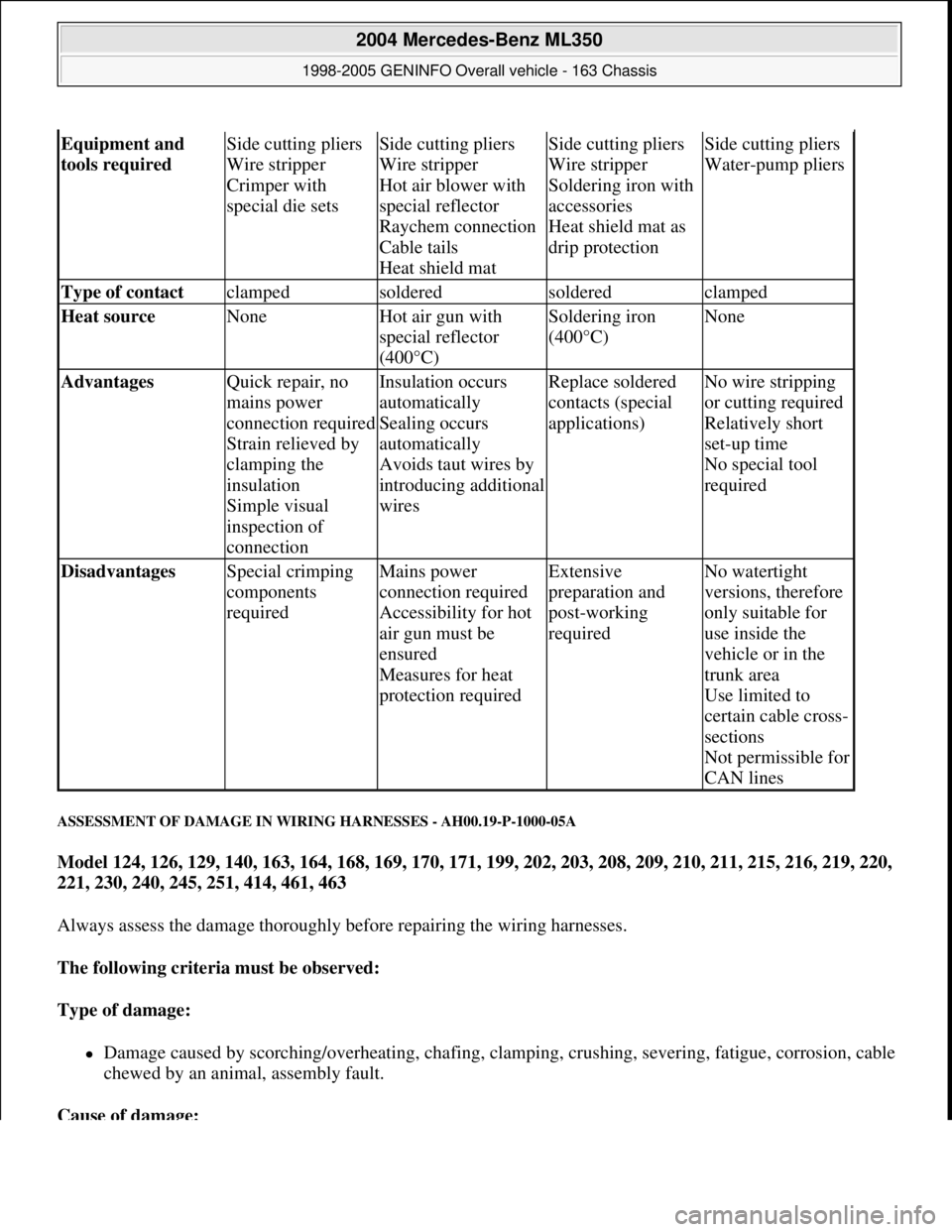

Comparison of circular conductor repair methods

CrimpingRaychem/cable tail

repair methodSolderingRapid connection

technology

Applications Repair cables

Replace damaged

contacts

Repair connectors

Additional line

connectionRepair cables

Cable extension

Integrate repaired

cables (cable tails,

replacement wires) in

the wiring harnessReplace soldered

contacts (special

applications)Repair cables

Additional line

connection

Wire end

connection

2004 Mercedes-Benz ML350

1998-2005 GENINFO Overall vehicle - 163 Chassis

me

Saturday, October 02, 2010 3:47:44 PMPage 19 © 2006 Mitchell Repair Information Company, LLC.

Page 2665 of 4133

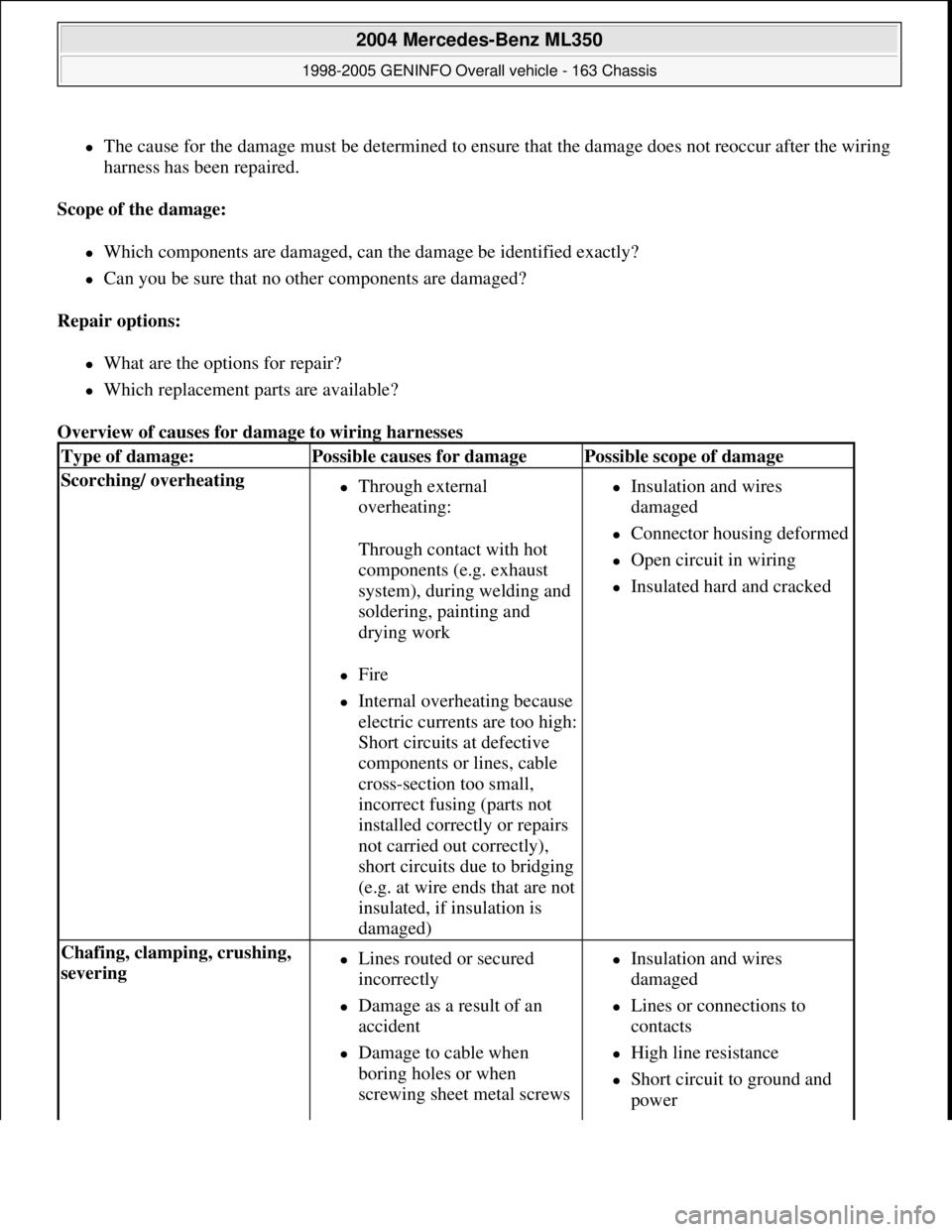

ASSESSMENT OF DAMAGE IN WIRING HARNESSES - AH00.19-P-1000-05A

Model 124, 126, 129, 140, 163, 164, 168, 169, 170, 171, 199, 202, 203, 208, 209, 210, 211, 215, 216, 219, 220,

221, 230, 240, 245, 251, 414, 461, 463

Always assess the damage thoroughly before repairing the wiring harnesses.

The following criteria must be observed:

Type of damage:

Damage caused by scorching/overheating, chafing, clamping, crushing, severing, fatigue, corrosion, cable

chewed by an animal, assembly fault.

Cause of damage:

Equipment and

tools required Side cutting pliers

Wire stripper

Crimper with

special die setsSide cutting pliers

Wire stripper

Hot air blower with

special reflector

Raychem connection

Cable tails

Heat shield matSide cutting pliers

Wire stripper

Soldering iron with

accessories

Heat shield mat as

drip protectionSide cutting pliers

Water-pump pliers

Type of contact clampedsolderedsolderedclamped

Heat source NoneHot air gun with

special reflector

(400°C)Soldering iron

(400°C)None

Advantages Quick repair, no

mains power

connection required

Strain relieved by

clamping the

insulation

Simple visual

inspection of

connectionInsulation occurs

automatically

Sealing occurs

automatically

Avoids taut wires by

introducing additional

wiresReplace soldered

contacts (special

applications)No wire stripping

or cutting required

Relatively short

set-up time

No special tool

required

Disadvantages Special crimping

components

requiredMains power

connection required

Accessibility for hot

air gun must be

ensured

Measures for heat

protection requiredExtensive

preparation and

post-working

requiredNo watertight

versions, therefore

only suitable for

use inside the

vehicle or in the

trunk area

Use limited to

certain cable cross-

sections

Not permissible for

CAN lines

2004 Mercedes-Benz ML350

1998-2005 GENINFO Overall vehicle - 163 Chassis

me

Saturday, October 02, 2010 3:47:44 PMPage 20 © 2006 Mitchell Repair Information Company, LLC.

Page 2666 of 4133

The cause for the damage must be determined to ensure that the damage does not reoccur after the wiring

harness has been repaired.

Scope of the damage:

Which components are damaged, can the damage be identified exactly?

Can you be sure that no other components are damaged?

Repair options:

What are the options for repair?

Which replacement parts are available?

Overview of causes for damage to wiring harnesses

Type of damage:Possible causes for damagePossible scope of damage

Scorching/ overheating Through external

overheating:

Through contact with hot

components (e.g. exhaust

system), during welding and

soldering, painting and

drying work

Fire

Internal overheating because

electric currents are too high:

Short circuits at defective

components or lines, cable

cross-section too small,

incorrect fusing (parts not

installed correctly or repairs

not carried out correctly),

short circuits due to bridging

(e.g. at wire ends that are not

insulated, if insulation is

damaged)

Insulation and wires

damaged

Connector housing deformed

Open circuit in wiring

Insulated hard and cracked

Chafing, clamping, crushing,

severing Lines routed or secured

incorrectly

Damage as a result of an

accident

Damage to cable when

boring holes or when

screwing sheet metal screws

Insulation and wires

damaged

Lines or connections to

contacts

High line resistance

Short circuit to ground and

power

2004 Mercedes-Benz ML350

1998-2005 GENINFO Overall vehicle - 163 Chassis

me

Saturday, October 02, 2010 3:47:44 PMPage 21 © 2006 Mitchell Repair Information Company, LLC.

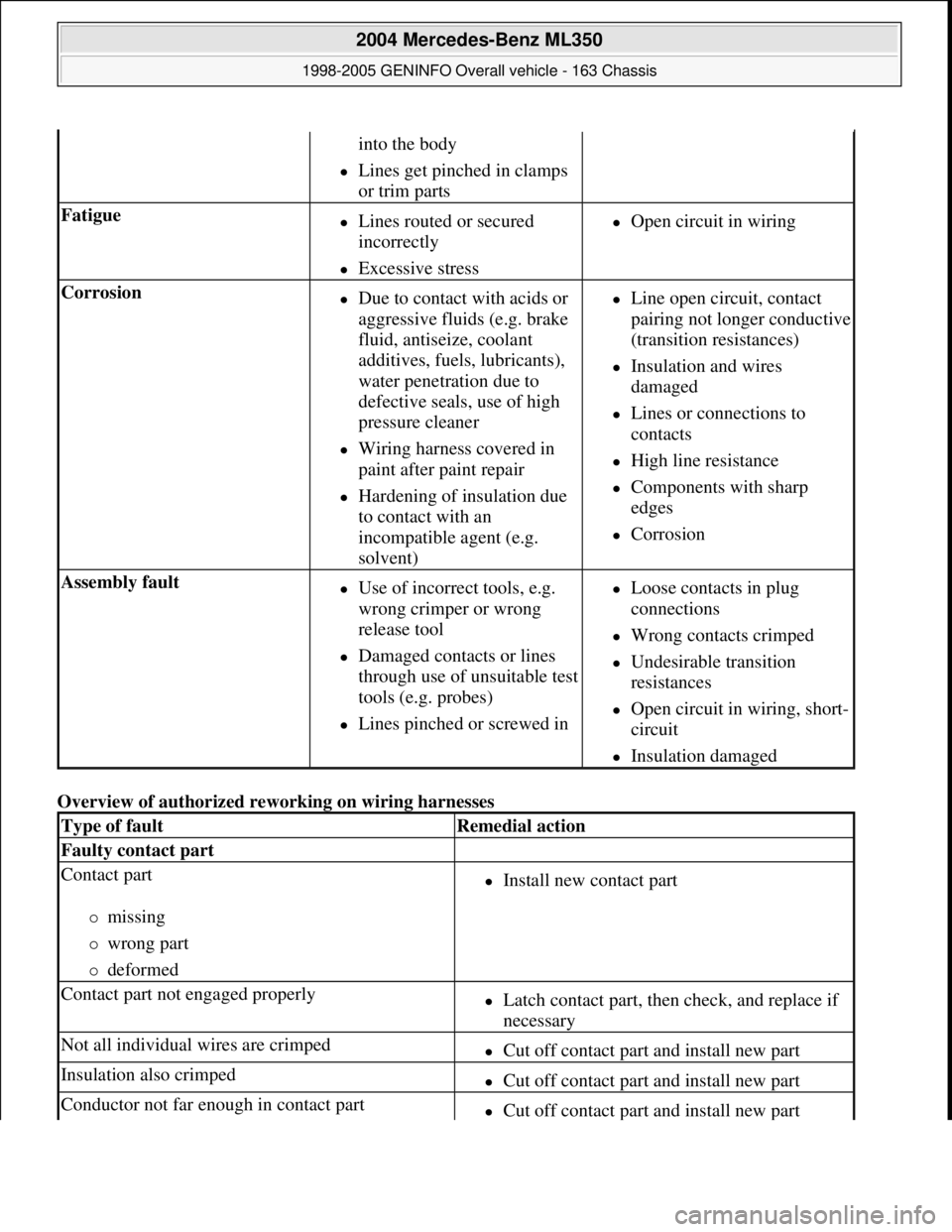

Page 2667 of 4133

Overview of authorized reworking on wiring harnesses

into the body

Lines get pinched in clamps

or trim parts

Fatigue Lines routed or secured

incorrectly

Excessive stress

Open circuit in wiring

Corrosion Due to contact with acids or

aggressive fluids (e.g. brake

fluid, antiseize, coolant

additives, fuels, lubricants),

water penetration due to

defective seals, use of high

pressure cleaner

Wiring harness covered in

paint after paint repair

Hardening of insulation due

to contact with an

incompatible agent (e.g.

solvent)

Line open circuit, contact

pairing not longer conductive

(transition resistances)

Insulation and wires

damaged

Lines or connections to

contacts

High line resistance

Components with sharp

edges

Corrosion

Assembly fault Use of incorrect tools, e.g.

wrong crimper or wrong

release tool

Damaged contacts or lines

through use of unsuitable test

tools (e.g. probes)

Lines pinched or screwed in

Loose contacts in plug

connections

Wrong contacts crimped

Undesirable transition

resistances

Open circuit in wiring, short-

circuit

Insulation damaged

Type of faultRemedial action

Faulty contact part

Contact part

missing

wrong part

deformed

Install new contact part

Contact part not engaged properlyLatch contact part, then check, and replace if

necessary

Not all individual wires are crimpedCut off contact part and install new part

Insulation also crimpedCut off contact part and install new part

Conductor not far enough in contact partCut off contact part and install new part

2004 Mercedes-Benz ML350

1998-2005 GENINFO Overall vehicle - 163 Chassis

me

Saturday, October 02, 2010 3:47:44 PMPage 22 © 2006 Mitchell Repair Information Company, LLC.

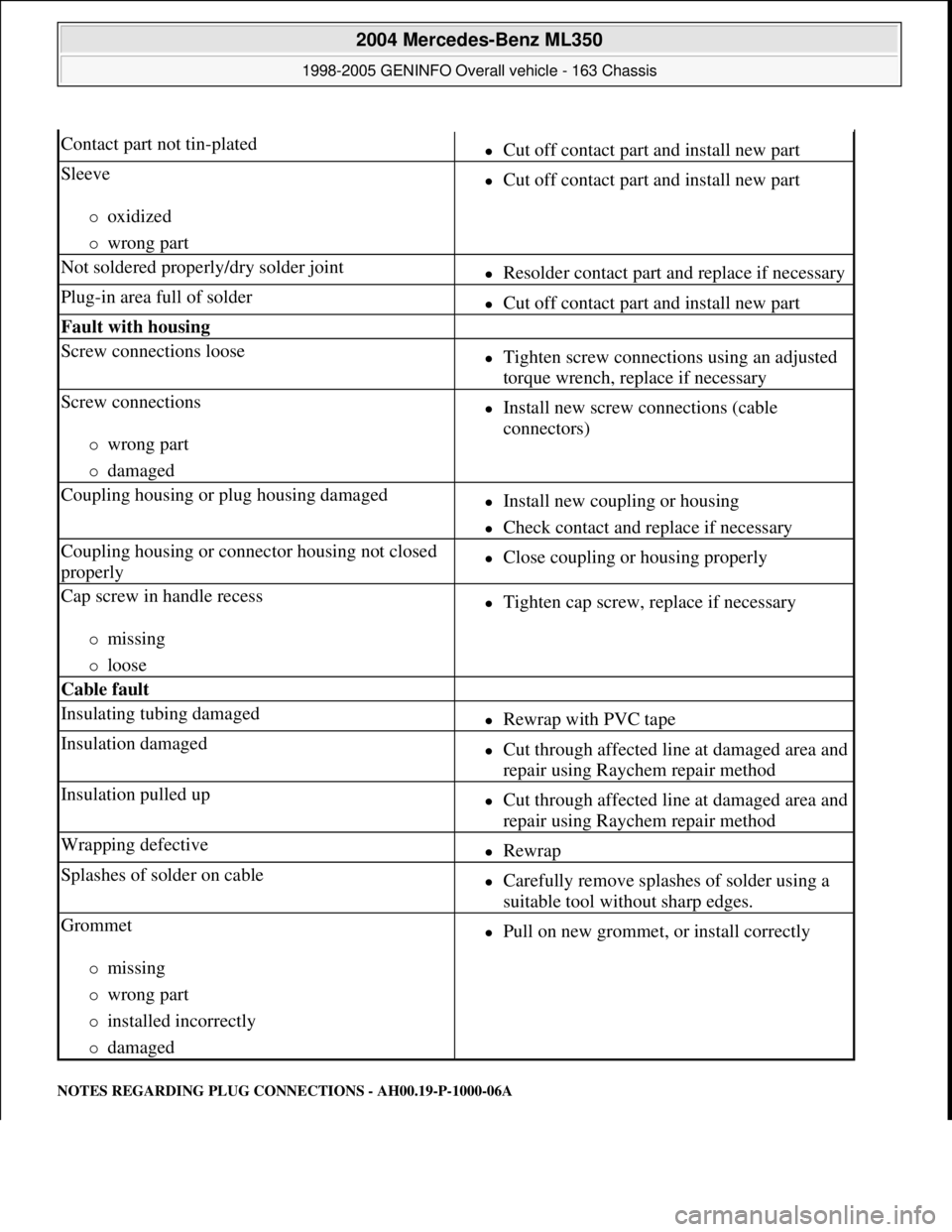

Page 2668 of 4133

NOTES REGARDING PLUG CONNECTIONS - AH00.19-P-1000-06A

Contact part not tin-platedCut off contact part and install new part

Sleeve

oxidized

wrong part

Cut off contact part and install new part

Not soldered properly/dry solder jointResolder contact part and replace if necessary

Plug-in area full of solderCut off contact part and install new part

Fault with housing

Screw connections looseTighten screw connections using an adjusted

torque wrench, replace if necessary

Screw connections

wrong part

damaged

Install new screw connections (cable

connectors)

Coupling housing or plug housing damagedInstall new coupling or housing

Check contact and replace if necessary

Coupling housing or connector housing not closed

properlyClose coupling or housing properly

Cap screw in handle recess

missing

loose

Tighten cap screw, replace if necessary

Cable fault

Insulating tubing damagedRewrap with PVC tape

Insulation damagedCut through affected line at damaged area and

repair using Raychem repair method

Insulation pulled upCut through affected line at damaged area and

repair using Raychem repair method

Wrapping defectiveRewrap

Splashes of solder on cableCarefully remove splashes of solder using a

suitable tool without sharp edges.

Grommet

missing

wrong part

installed incorrectly

damaged

Pull on new grommet, or install correctly

2004 Mercedes-Benz ML350

1998-2005 GENINFO Overall vehicle - 163 Chassis

me

Saturday, October 02, 2010 3:47:44 PMPage 23 © 2006 Mitchell Repair Information Company, LLC.

Page 2669 of 4133

Model 124, 126, 129, 140, 163, 164, 168, 169, 170, 171, 199, 202, 203, 208, 209, 210, 211, 215, 216, 219, 220,

221, 230, 240, 245, 251, 414, 461, 463

Terminology of plug connections:

The coupling and the plug form a plug connection. The female contact and the contact pin form the contact pair.

Illustrated: SLK family, coding A (with circular conductor)

Fig. 11: Identifying Plug Connections

- SLK Family, Coding A (With Circular Conductor)

Plugs and couplings

The plugs and couplings are grouped into families in the same way as the contact groups (e.g. SLK, JPT). The

type and shape of the receptacle chambers in the housing is the major differentiating characteristic. Different

contact families may be installed in the same housing. In addition, different codings (e.g. A, B, C) may exist

within the same plug/coupling family.

Codings are special profiles or teeth on the housings of the coupling and the plug, which may be marked in

different colors (e.g. black, white, violet).

These ensure that connector pairings can only be made with the same codings.

Safety and restraint systems (airbag, emergency tensioning retractor, roll bar) have yellow, orange, or red

plug connections for easy identification.

Part number assignments

The housings are assigned according to the part numbers on the housings. On housings made up of several

components, the number on the external housing is critical. (When ordering, all the individual part numbers

must be ascertained.)

This method of identification by means of part numbers can be used when referring to the literature.

Contacts

2004 Mercedes-Benz ML350

1998-2005 GENINFO Overall vehicle - 163 Chassis

me

Saturday, October 02, 2010 3:47:44 PMPage 24 © 2006 Mitchell Repair Information Company, LLC.

Page 2670 of 4133

A distinction is made between the contact pin and the female contact. Each contact pin and each female contact

can be clearly assigned to one group or "family" (e.g. SLK, JPT). Within these families distinctions are made

according to the cable cross section and whether there is single-strand insulation for watertight connections. The

contacts are also distinguished by their coating (tin, gold or silver).

The contacts are fastened to the cables by means of crimping. ?

Crimp connections

These are used to attach the female contacts or contact pins to the cable. Each contact type must be crimped

with the aid of specifically assigned die sets using a pair of pliers. Determining factors: contact family, size of

cable cross section, with or without single-strand insulation.

Only lines up to 4 mm shall be crimped.

Unpinning

This requires a release tool appropriate to the contact family in order to remove female contacts and contact pins

from plugs and couplings.

On some plugs and couplings the housings must first be disassembled and unlocked (secondary release)

according to the instructions before the actual unpinning.

Contact materials

The contacts used in the interior of the vehicle are primarily tin/tin combinations. Those used on the exterior

and in the splash zone are generally silver/silver. Safety systems (particularly the airbag) are equipped with

gold/gold contacts.

Only "identical" contact pairings are permitted for repair work.

NOTES ON SOFT SOLDERING - AH00.19-P-1000-07A

Model 124, 126, 129, 140, 163, 164, 168, 169, 170, 171, 199, 202, 203, 208, 209, 210, 211, 215, 216, 219, 220,

221, 230, 240, 245, 251, 414, 461, 463

General information

Soft-soldering is a process for creating an inseparable join between two or more metal parts using additional

metals (e.g. soldering tin). The solder melting temperature lies below the melting temperature of the metals to

be joined and is lower than 450°C.

The connection is created by wetting the joint locations with hot liquid solder, without melting the parts to be

joined.

The joining procedure is assisted by using a flux, which releases surface oxides on the parts to be joined,

eliminatin

g and preventing surface films (e.g. greases).

2004 Mercedes-Benz ML350

1998-2005 GENINFO Overall vehicle - 163 Chassis

me

Saturday, October 02, 2010 3:47:44 PMPage 25 © 2006 Mitchell Repair Information Company, LLC.