MERCEDES-BENZ ML430 1997 Complete Repair Manual

Manufacturer: MERCEDES-BENZ, Model Year: 1997, Model line: ML430, Model: MERCEDES-BENZ ML430 1997Pages: 4133, PDF Size: 88.89 MB

Page 311 of 4133

261 Exterior lamps

Te ch n ica l

data Instruments

and controlsOperation DrivingInstrument

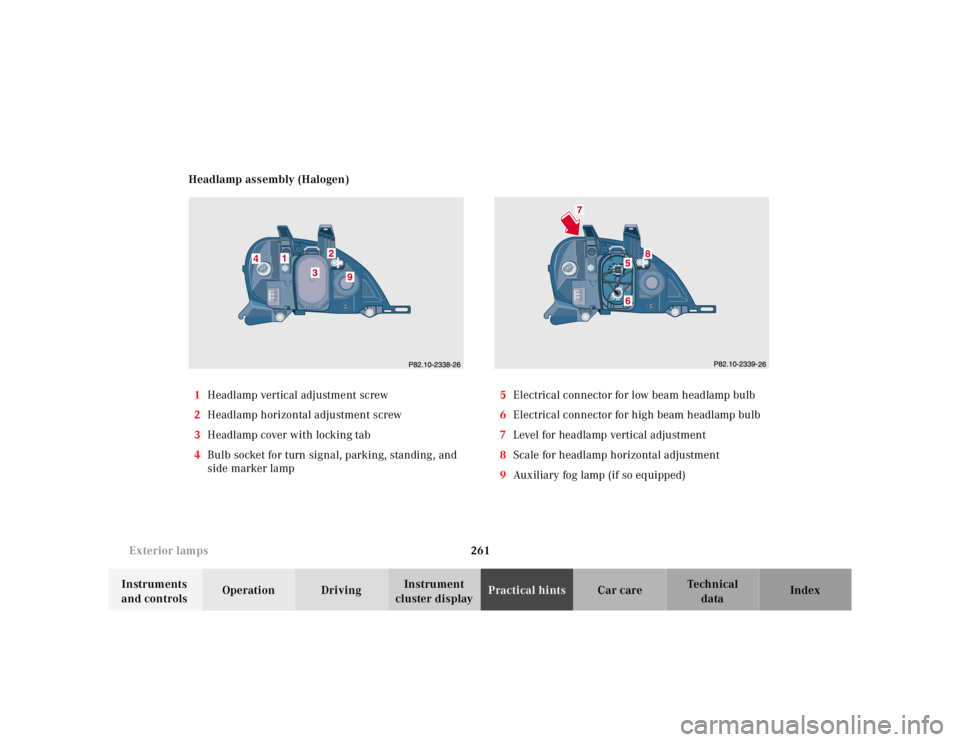

cluster displayPractical hintsCar care Index Headlamp assembly (Halogen)

1Headlamp vertical adjustment screw

2Headlamp horizontal adjustment screw

3Headlamp cover with locking tab

4Bulb socket for turn signal, parking, standing, and

side marker lamp5Electrical connector for low beam headlamp bulb

6Electrical connector for high beam headlamp bulb

7Level for headlamp vertical adjustment

8Scale for headlamp horizontal adjustment

9Auxiliary fog lamp (if so equipped)

Page 312 of 4133

262 Exterior lamps

Te ch n ica l

data Instruments

and controlsOperation DrivingInstrument

cluster displayPractical hintsCar care Index

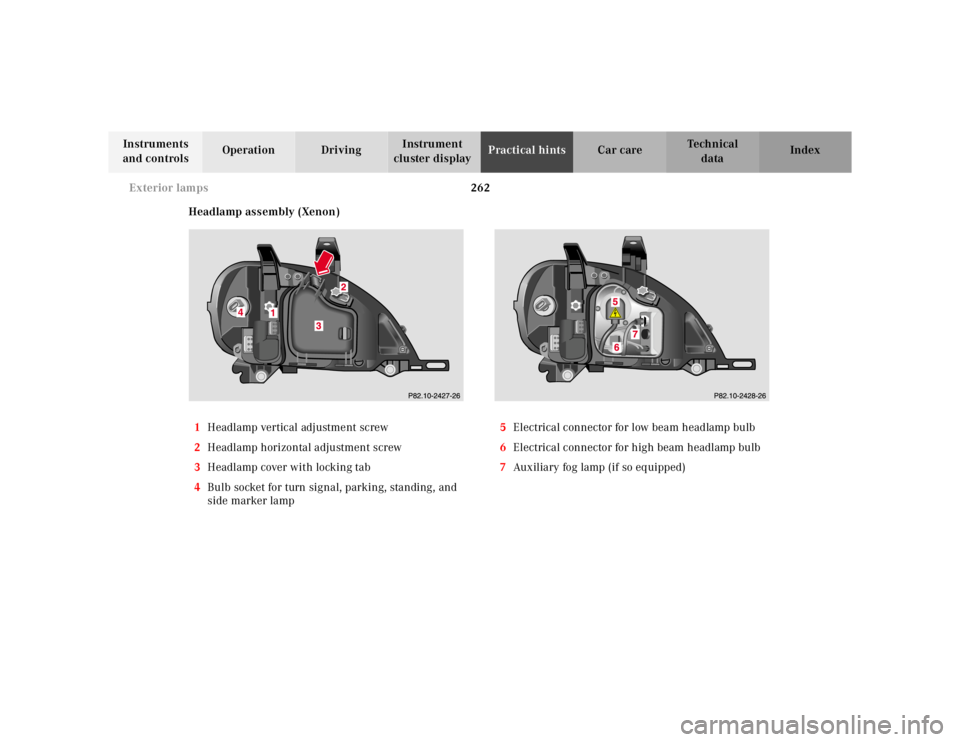

Headlamp assembly (Xenon)

1Headlamp vertical adjustment screw

2Headlamp horizontal adjustment screw

3Headlamp cover with locking tab

4Bulb socket for turn signal, parking, standing, and

side marker lamp5Electrical connector for low beam headlamp bulb

6Electrical connector for high beam headlamp bulb

7Auxiliary fog lamp (if so equipped)

Page 313 of 4133

263 Exterior lamps

Te ch n ica l

data Instruments

and controlsOperation DrivingInstrument

cluster displayPractical hintsCar care Index Bulbs for high beam (only Halogen headlamps)

H1 U (55 W)

Bulbs for low beam

H7 (55 W)

Open hood.

Push down tab at top end of cover (3) and remove. Pull

off electrical connector (5 or 6). Unhook and move aside

clamping ring. Remove bulb.

Insert new bulb (seating properly in cutouts of bulb

socket), mount clamping ring. Reinstall and push

electrical connector on securely. Reinstall cover (3).Xenon (optional)

Bulb for low beam

Xenon (optional)

Bulb for high beam

Note:

Vehicles with Xenon headlamps:

We recommend that you have changed the bulb for the

high beam by a qualified technician.

Wa r n i n g !

Because of high voltage in Xenon lamps, it is

dangerous to replace the bulb or repair the lamp

and its components. We recommend that you have

such work done by a qualified technician.

Page 314 of 4133

264 Exterior lamps

Te ch n ica l

data Instruments

and controlsOperation DrivingInstrument

cluster displayPractical hintsCar care Index

Parking, standing, side marker and turn signal lamp

115 6 N A ( 3 2 / 4 c p b u l b )

Open hood.

Twist bulb socket (4) counterclockwise and pull out.

Push bulb into socket, turn counterclockwise and

remove.

Insert new bulb in socket, push in and twist clockwise.

Reinstall bulb socket.Bulbs for auxiliary fog lamp (optional)

H3 U (55 W)

Open hood.

Remove cover (9). Unhook clamping ring and remove

bulb. Pull off electrical connector.

Insert new bulb in socket (seating properly in cutouts of

bulb socket), and mount clamping ring. Reinstall and

push electrical connector on securely.

Reinstall cover (9).

Page 315 of 4133

![MERCEDES-BENZ ML430 1997 Complete Repair Manual 265 Exterior lamps

Te ch n ica l

data Instruments

and controlsOperation DrivingInstrument

cluster displayPractical hintsCar care Index Taillamp assemblies

1Stop lamp (1073 [32 cp bulb])

2Backup lamp MERCEDES-BENZ ML430 1997 Complete Repair Manual 265 Exterior lamps

Te ch n ica l

data Instruments

and controlsOperation DrivingInstrument

cluster displayPractical hintsCar care Index Taillamp assemblies

1Stop lamp (1073 [32 cp bulb])

2Backup lamp](/img/4/57307/w960_57307-314.png)

265 Exterior lamps

Te ch n ica l

data Instruments

and controlsOperation DrivingInstrument

cluster displayPractical hintsCar care Index Taillamp assemblies

1Stop lamp (1073 [32 cp bulb])

2Backup lamp (1073 [32 cp bulb])

3Turn signal lamp (P Y 21 W bulb)

4Tail, parking, standing and side marker lamp,

driver’s side rear fog lamp (P 21 / 4 W bulb)Open liftgate.

Remove nuts (1).

Remove taillamp.

P82.10-2342-26

P82.10-2343-26

Page 316 of 4133

266 Exterior lamps

Te ch n ica l

data Instruments

and controlsOperation DrivingInstrument

cluster displayPractical hintsCar care Index

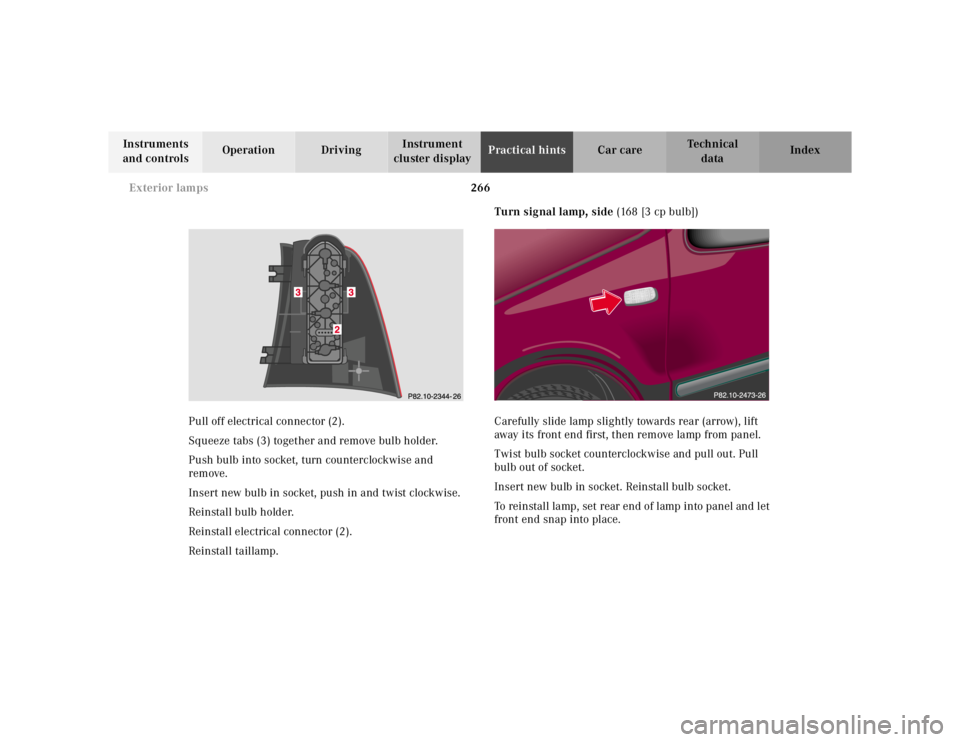

Pull off electrical connector (2).

Squeeze tabs (3) together and remove bulb holder.

Push bulb into socket, turn counterclockwise and

remove.

Insert new bulb in socket, push in and twist clockwise.

Reinstall bulb holder.

Reinstall electrical connector (2).

Reinstall taillamp.Turn signal lamp, side (168 [3 cp bulb])

Carefully slide lamp slightly towards rear (arrow), lift

away its front end first, then remove lamp from panel.

Twist bulb socket counterclockwise and pull out. Pull

bulb out of socket.

Insert new bulb in socket. Reinstall bulb socket.

To reinstall lamp, set rear end of lamp into panel and let

front end snap into place.

Page 317 of 4133

![MERCEDES-BENZ ML430 1997 Complete Repair Manual 267 Exterior lamps

Te ch n ica l

data Instruments

and controlsOperation DrivingInstrument

cluster displayPractical hintsCar care Index License plate lamps (C 5 W [tubular] bulb)

Remove both securing MERCEDES-BENZ ML430 1997 Complete Repair Manual 267 Exterior lamps

Te ch n ica l

data Instruments

and controlsOperation DrivingInstrument

cluster displayPractical hintsCar care Index License plate lamps (C 5 W [tubular] bulb)

Remove both securing](/img/4/57307/w960_57307-316.png)

267 Exterior lamps

Te ch n ica l

data Instruments

and controlsOperation DrivingInstrument

cluster displayPractical hintsCar care Index License plate lamps (C 5 W [tubular] bulb)

Remove both securing screws, remove lamp and take

out bulb.High mounted stop lamp (1073 [32 cp bulb])

To replace bulb, squeeze both sides (1, arrows) of cover,

fold forward and remove.

Press tab (2, arrow) on reflector and remove reflector.

Press bulb down, turn counterclockwise and remove.

Insert new bulb in socket, push in and twist clockwise.

Reinstall reflector.

Position tabs of cover in slots (3, arrows) and reinstall

cover until properly seated.

P82.10-2347-26

P82.10-2346-26

Page 318 of 4133

268 Exterior lamps

Te ch n ica l

data Instruments

and controlsOperation DrivingInstrument

cluster displayPractical hintsCar care Index

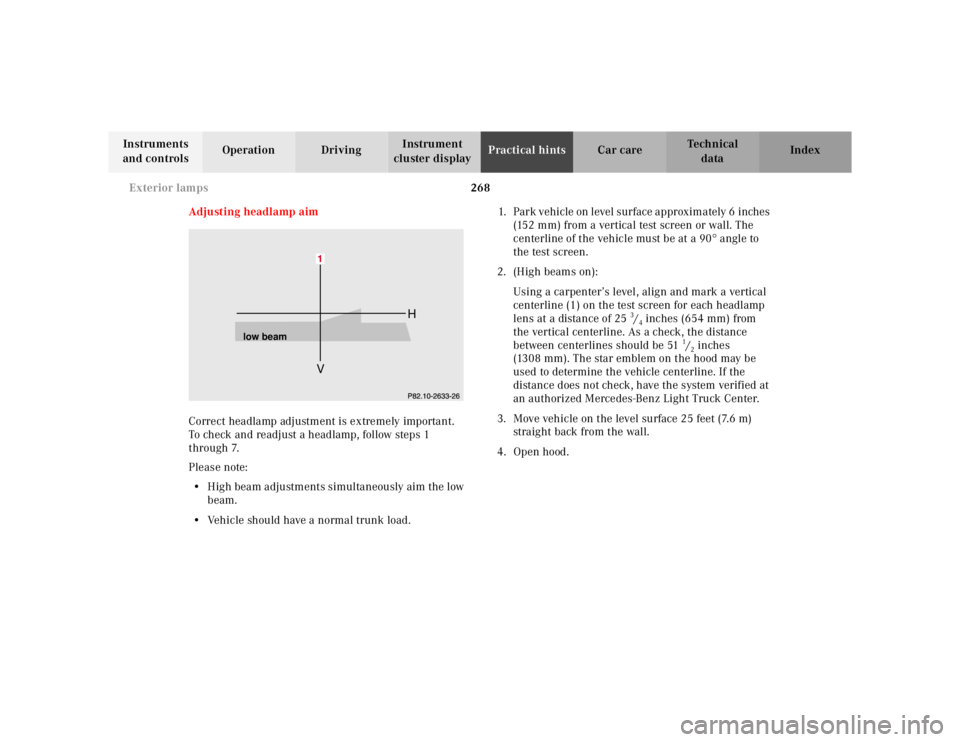

Adjusting headlamp aim

Correct headlamp adjustment is extremely important.

To check and readjust a headlamp, follow steps 1

through 7.

Please note:

•High beam adjustments simultaneously aim the low

beam.

•Vehicle should have a normal trunk load.1. Park vehicle on level surface approximately 6 inches

(152 mm) from a vertical test screen or wall. The

centerline of the vehicle must be at a 90° angle to

the test screen.

2. (High beams on):

Using a carpenter’s level, align and mark a vertical

centerline (1) on the test screen for each headlamp

lens at a distance of 25

3/4inches (654 mm) from

the vertical centerline. As a check, the distance

between centerlines should be 51

1/2inches

(1308 mm). The star emblem on the hood may be

used to determine the vehicle centerline. If the

distance does not check, have the system verified at

an authorized Mercedes-Benz Light Truck Center.

3. Move vehicle on the level surface 25 feet (7.6 m)

straight back from the wall.

4. Open hood.

VH

low beam

Page 319 of 4133

269 Exterior lamps

Te ch n ica l

data Instruments

and controlsOperation DrivingInstrument

cluster displayPractical hintsCar care Index 5. (High beams on):

Simultaneously turn adjusting screws (1 and 2 on

page 261 or 262) counterclockwise to adjust

headlamp downward, clockwise upward) equally

until bubble in the level (7 on page 261) is centered

on the “0” mark.

Graduations:

screw 1: 0.50° pitch,

screw 2: 0.67° pitch.

6. Horizontal headlamp aim (High beams on):

Turn adjusting screw (2) (left headlamp:

counterclockwise to adjust to the left, clockwise to

the right [right headlamp in opposite direction])

until the headlamp (high beam pattern) is centered

about the vertical centerline (1) as shown.

The left and right headlamps must be adjusted

individually.7. For proper aim, the indicator (8 on page 261) should

align with the “0” mark after horizontal adjustment.

Graduations: 0.33° pitch.

Note:

If it is not possible to obtain a proper headlamp

adjustment, have the system checked at your authorized

Mercedes-Benz Light Truck Center.

Page 320 of 4133

270 Remote control

Te ch n ica l

data Instruments

and controlsOperation DrivingInstrument

cluster displayPractical hintsCar care Index

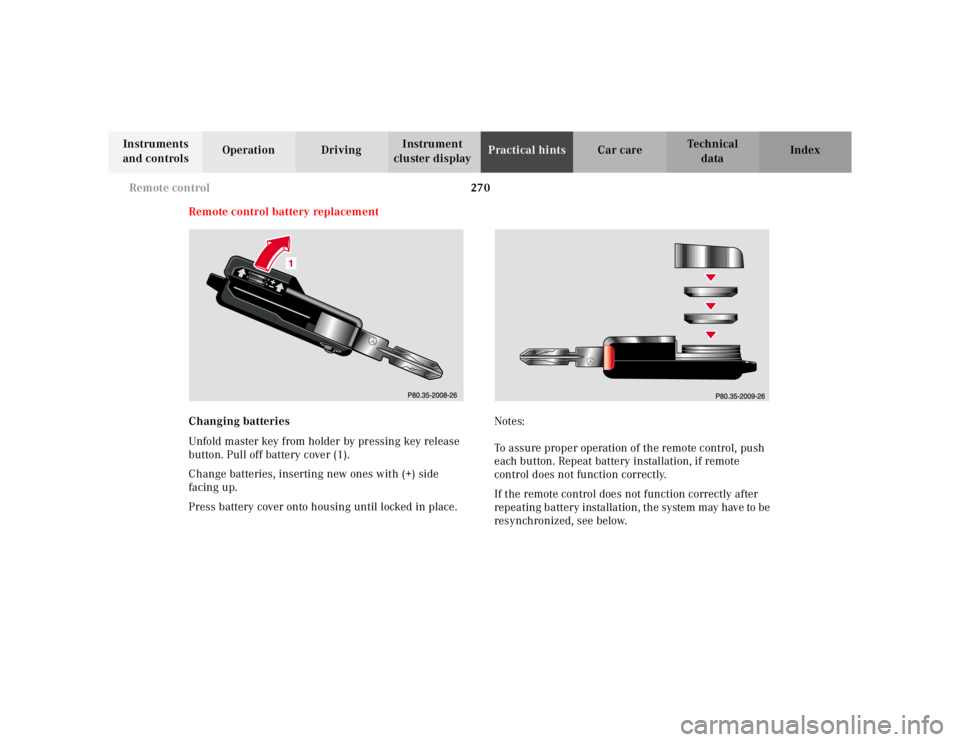

Remote control battery replacement

Changing batteries

Unfold master key from holder by pressing key release

button. Pull off battery cover (1).

Change batteries, inserting new ones with (+) side

facing up.

Press battery cover onto housing until locked in place.Notes:

To assure proper operation of the remote control, push

each button. Repeat battery installation, if remote

control does not function correctly.

If the remote control does not function correctly after

repeating battery installation, the system may have to be

resynchronized, see below.