MERCEDES-BENZ R-CLASS FAMILY TOURER 2013 Owners Manual

Manufacturer: MERCEDES-BENZ, Model Year: 2013, Model line: R-CLASS FAMILY TOURER, Model: MERCEDES-BENZ R-CLASS FAMILY TOURER 2013Pages: 364, PDF Size: 28.68 MB

Page 341 of 364

Mounting

anew wheel G

WARNING

Oiled or greased wheel bolts or damaged

wheel bolts/hub threads can cause the wheel

bolts to come loose .As a result, you could

lose a wheel while driving. There is a risk of

accident.

Never oil or grease wheel bolts. In the event

of damage to the threads, contact a qualified

specialist workshop immediately.H ave the

damaged wheel bolts or hub threads

replaced/renewed. Do notc ontinue driving.G

WARNING

If you tighten the wheel bolts or wheel nuts

when the vehicle is raised, the jack could tip

over. There is a risk of injury.

Only tighten the wheel bolts or wheel nuts

when the vehicle is on the ground.

! To prevent damage to the paintwork, hold

the wheel securely against the wheel hub

while screwing in the first wheel bolt.

Always pay attention to the instructions and

safety notes in the "Changing a wheel"

section (Y page 334).

Only use wheel bolts that have been designed

for the wheel and the vehicle. For safety

reasons, Mercedes-Benz recommends that

you only use wheel bolts which have been

approved for Mercedes-Benz vehicles and the

respective wheel.

! Always use wheel bolts ;to mount the

collapsible spare wheel. Using other wheel

bolts to mount the collapsible spare wheel

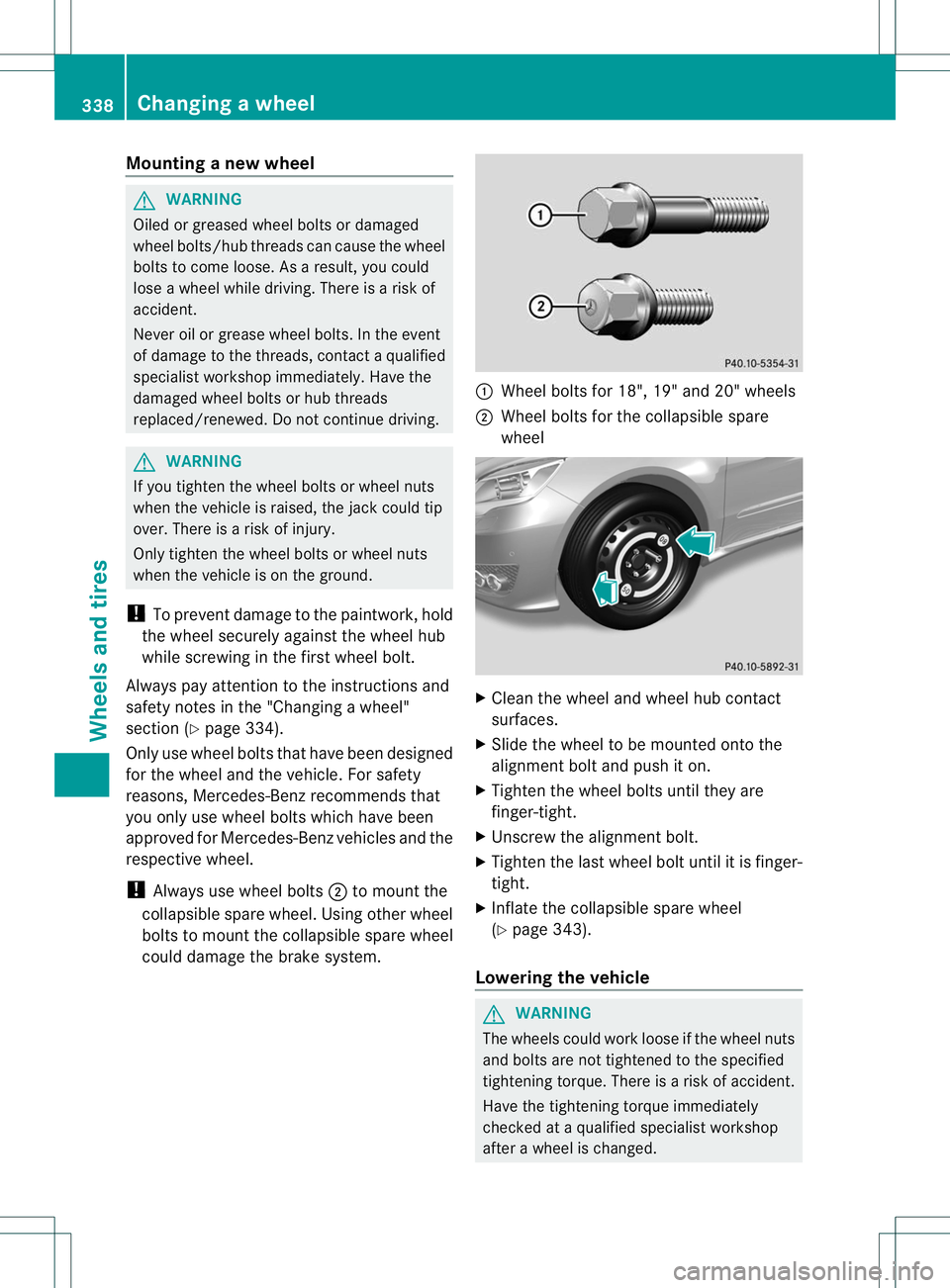

could damage the brake system. :

Wheel bolts for 18", 19" and 20" wheels

2 Wheel bolts for the collapsible spare

wheel X

Clean the wheel and wheel hub contact

surfaces.

X Slide the wheel to be mounted onto the

alignment bolt and push it on.

X Tighten the wheel bolts until they are

finger-tight.

X Unscrew the alignment bolt.

X Tighten the last wheel bolt until it is finger-

tight.

X Inflate the collapsible spare wheel

(Y page 343).

Lowering the vehicle G

WARNING

The wheels could work loose if the wheel nuts

and bolts are not tightened to the specified

tightening torque. There is a risk of accident.

Have the tightening torque immediately

checked at a qualified specialist workshop

after a wheel is changed. 338

Changing

awheelWheels and tires

Page 342 of 364

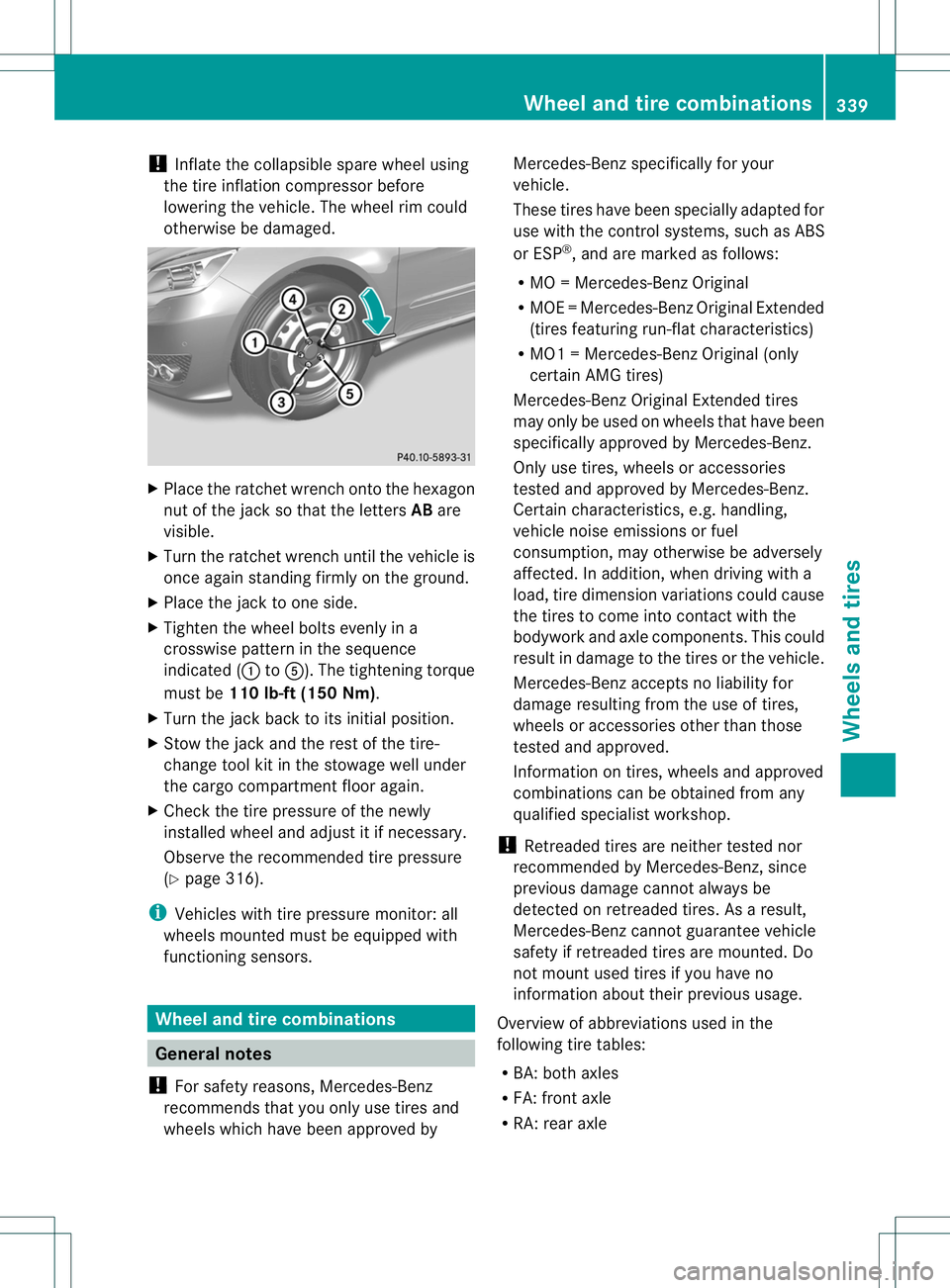

!

Inflate the collapsible spare wheel using

the tire inflation compressor before

lowering the vehicle. The wheel rim could

otherwise be damaged. X

Place the ratchet wrench onto the hexagon

nut of the jack so that the letters ABare

visible.

X Turn the ratchet wrench until the vehicle is

once agains tanding firml yonthe ground.

X Place the jack to one side.

X Tighten the wheel bolts evenly in a

crosswise pattern in the sequence

indicated ( :toA). The tightening torque

must be 110 lb-ft (150 Nm) .

X Turn the jack back to its initial position.

X Stow the jack and the rest of the tire-

change tool kit in the stowage well under

the cargo compartment floor again.

X Check the tire pressure of the newly

installed wheel and adjust it if necessary.

Observe the recommended tire pressure

(Y page 316).

i Vehicles with tire pressure monitor: all

wheels mounted must be equipped with

functioning sensors. Wheel and tire combinations

General notes

! For safety reasons, Mercedes-Benz

recommends that you only use tires and

wheels which have been approved by Mercedes-Benzs

pecifically for your

vehicle.

These tires have been specially adapted for

use with the control systems, such as ABS

or ESP ®

, and are marked as follows:

R MO =Mercedes-BenzO riginal

R MOE =Mercedes-BenzO riginal Extended

(tires featuring run-flat characteristics)

R MO1 =Mercedes-BenzO riginal (only

certain AMG tires)

Mercedes-Benz Original Extended tires

may only be used on wheels that have been

specifically approved by Mercedes-Benz.

Only use tires, wheels or accessories

tested and approved by Mercedes-Benz.

Certain characteristics, e.g. handling,

vehicle noise emissions or fuel

consumption, may otherwise be adversely

affected. In addition, when driving with a

load, tire dimension variations could cause

the tires to come into contact with the

bodywork and axle components. This could

result in damage to the tires or the vehicle.

Mercedes-Benz accepts no liability for

damage resulting from the use of tires,

wheels or accessories other than those

tested and approved.

Information on tires, wheels and approved

combinations can be obtained from any

qualified specialist workshop.

! Retreaded tires are neither tested nor

recommended by Mercedes-Benz, since

previous damage cannot always be

detected on retreaded tires. As a result,

Mercedes-Benz cannot guarantee vehicle

safety if retreaded tires are mounted. Do

not mount used tires if you have no

information about their previous usage.

Overview of abbreviations usedint he

following tire tables:

R BA: both axles

R FA: front axle

R RA: rear axle Wheel and tire combinations

339Wheels and tires Z

Page 343 of 364

The recommended pressures for various

operating conditions can be found:

R

on the Tire and Loading Information placard

with the recommended tire pressures on

the B-pillar on the driver's side

R in the tire pressure table on the inside of

the fuel filler flap

Observe the notes on recommended tire

pressures under various operating conditions

(Y page 316).

Check tire pressures regularly, and only when

the tires are cold. Comply with the

maintenance recommendations of the tire

manufacturer in the vehicle document wallet.

Notes on the vehicle equipment –always

equip the vehicle with:

R tires of the same size on a given axle (left/

right)

R the same type of tires at a given time

(summer tires, winter tires, MOExtended

tires)

Vehicles with MOExtended tires are not

equipped with a TIREFIT kit at the factory. It

is therefore recommended that you

additionally equip your vehicle with a TIREFIT

kit if you mountt ires that do not feature run-

flat properties, e.g. winter tires. ATIREFIT kit

may be obtained from a qualified specialist

workshop.

In the following table, the wheel/tire

combinations are assigned to the vehicle

models through variants, e.g. V1, V2 etc.: V1

R 350

18 V2 R 350 BlueTEC

i

Not all wheel and tire combinations are

available at the factory for all countries.

i On the following pages, you can find

information on approved wheelr ims and

tire sizes for equipping your vehicle with

winter tires. Winter tires are not available at the factory as standard equipmen

tor

optional extras.

If you would like to equip your vehicle with

approved winter tires, you may also, in

certain circumstances, require rims of the

appropriate size. The sizes of the approved

winter tires may deviate from that of the

standard tires. This is dependent on the

model and the equipment installed at the

factory.

The tires and wheel rims, as well as further

information, can be obtained at a qualified

specialist workshop.

18 BlueEFFICIENCY 340

Wheel and tire combinationsWheels and tires

Page 344 of 364

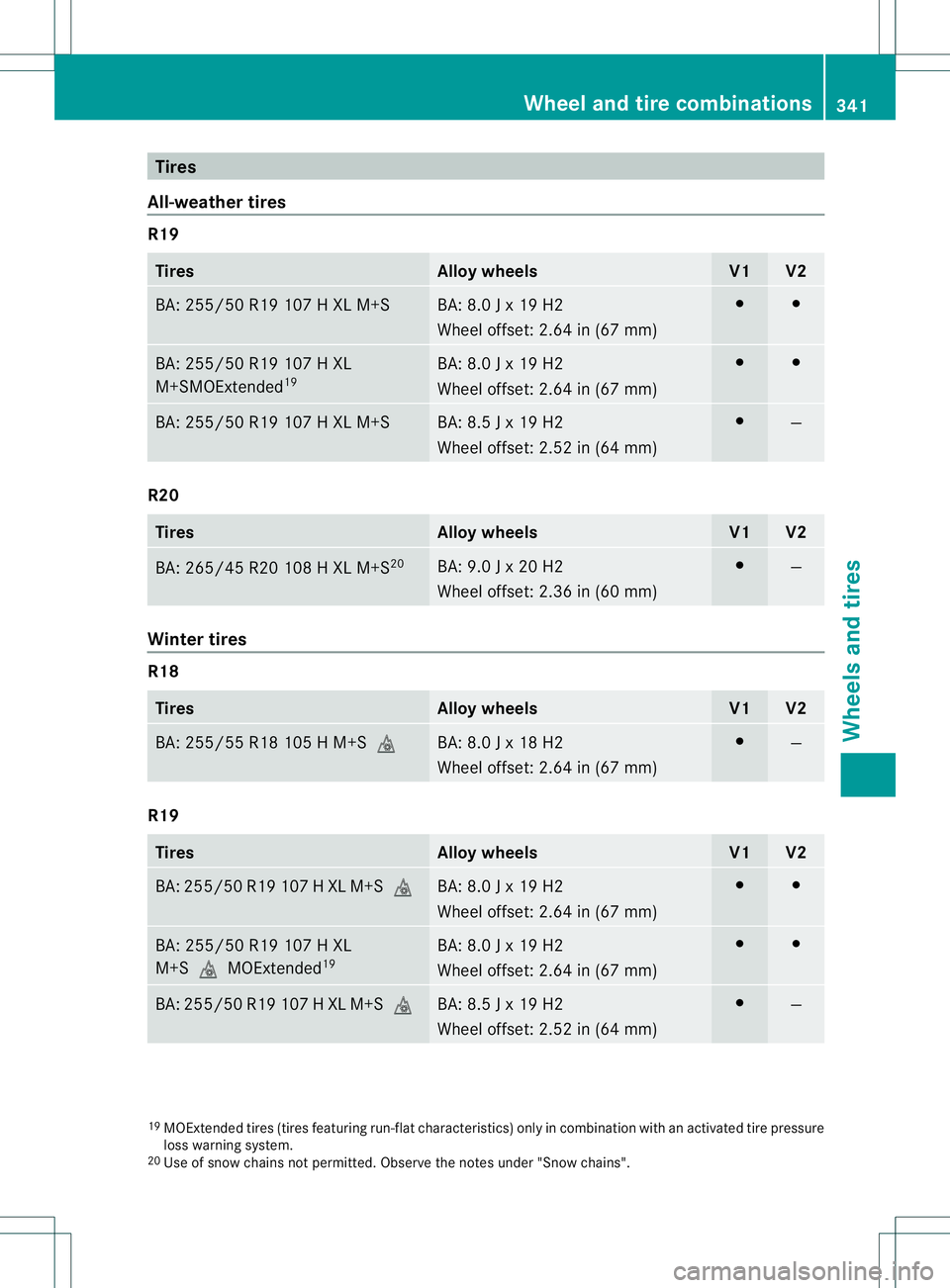

Tires

All-weather tires R19

Tires Allo

ywheels V1 V2

BA: 255/50 R19 107 H XL M+S BA: 8.0 J x 19 H2

Wheel offset: 2.64 in (67 mm) # #

BA: 255/50 R19 107 H XL

M+SMOExtended

19 BA: 8.0 J x 19 H2

Wheel offset: 2.64 in (67 mm) # #

BA: 255/50 R19 107 H XL M+S BA: 8.5 J x 19 H2

Wheel offset: 2.52 in (64 mm) #

—

R20

Tires Alloy wheels V1 V2

BA: 265/45 R20 108 H XL M+S

20 BA: 9.0 J x 20 H2

Wheel offset: 2.36 in (60 mm) #

—

Winter tires

R18

Tires Alloy wheels V1 V2

BA: 255/55 R18 105 H M+S

i BA: 8.0 J x 18 H2

Wheel offset: 2.64 in (67 mm) #

—

R19

Tires Alloy wheels V1 V2

BA: 255/50 R19 107 H XL M+Si BA: 8.0 J x 19 H2

Wheel offset: 2.64 in (67 mm) # #

BA: 255/50 R19 107 H XL

M+SiMOExtended

19 BA: 8.0 J x 19 H2

Wheel offset: 2.64 in (67 mm) # #

BA: 255/50 R19 107 H XL M+Si BA: 8.5 J x 19 H2

Wheel offset: 2.52 in (64 mm) #

—

19

MOExtended tires (tires featuring run-fla tcharacteristics) only in combination with an activated tire pressure

loss warning system.

20 Use of snow chains not permitted. Observe the notes under "Snow chains". Wheel and tire combinations

341Wheels and tires Z

Page 345 of 364

R20

Tires Alloyw

heels V1 V2

BA: 265/45 R20 108 H XL

M+Si

20 BA: 9.0 J x 20 H2

Wheel offset: 2.36 in (60 mm) #

—

Emergency spare wheel

Important safety notes

G

WARNING

The wheel or tire size as well as the tire type

of the spare wheel or emergency spare wheel

and the wheel to be replaced may differ.

Mounting an emergency spare wheel may

severely impair the driving characteristics.

There is a risk of an accident.

To avoid hazardous situations:

R adapt yourd riving style accordingly and

drive carefully.

R never install more than one spare wheel or

emergency spare wheel that differs in size.

R only use a spare wheel or emergency spare

wheel of a different size briefly.

R do not switch ESP ®

off.

R have a spare wheel or emergency spare

wheel of a different size replaced at the

nearest qualified specialist workshop.

Observe that the wheel and tire dimensions

as well as the tire type must be correct.

When using an emergency spare wheel or

spare wheel of a different size, you must not

exceed the maximum speed of 50 mph

(80 km/h).

Snow chains must not be mounted on

emergency spare wheels. General notes

Mounting the emergency spare wheel is

described under "Mounting a wheel"

(Y page 335). An emergency spare wheel may also be

mounted against the direction of rotation.

Observe the time restriction on use as well as

the speed limitation specified on the

emergency spare wheel.

Replace the tires after six years at the latest,

regardless of wear. This also applies to the

emergency spare wheel.

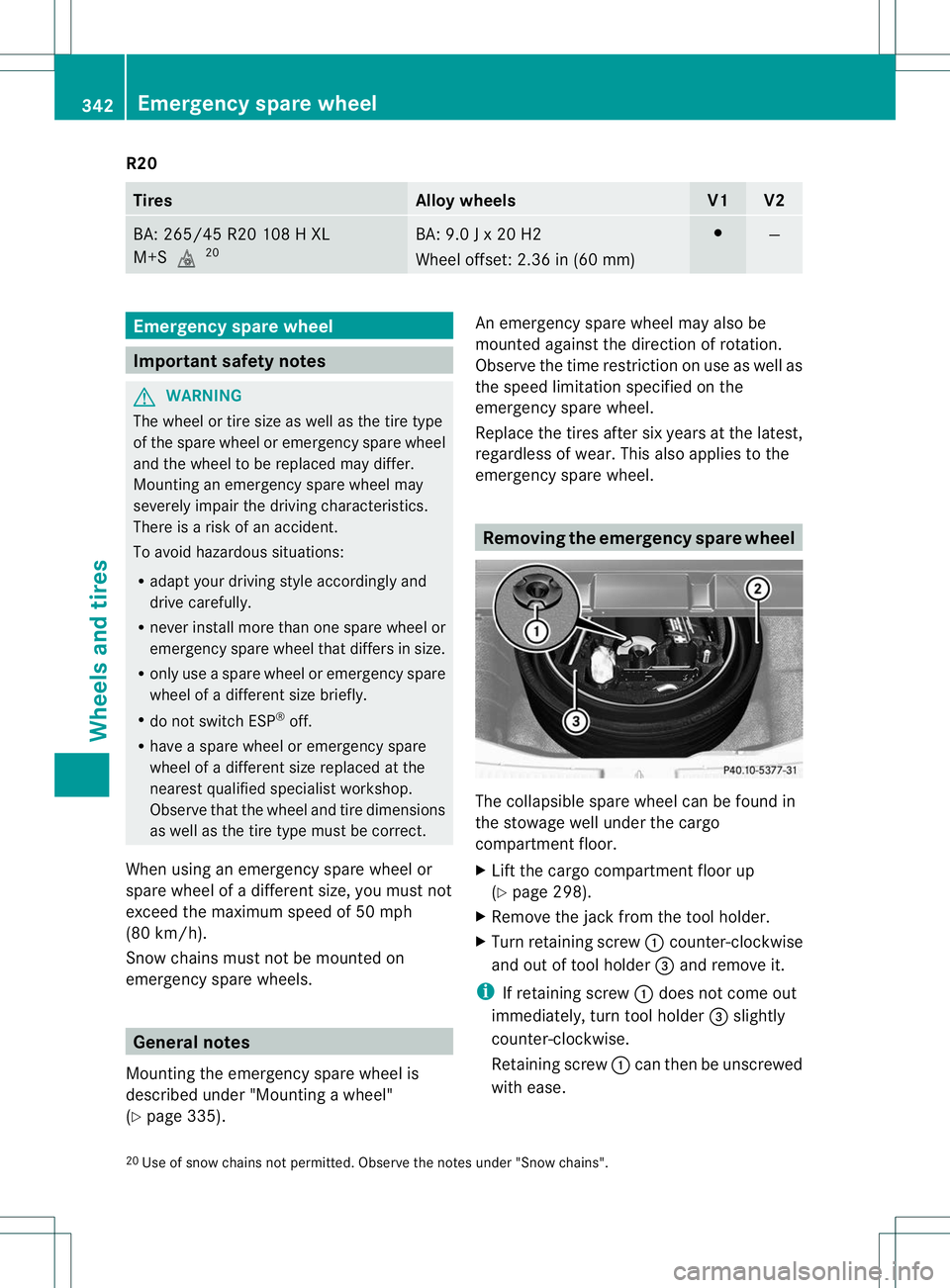

Removing the emergency spare wheel

The collapsible spare wheel can be found in

the stowage well under the cargo

compartment floor.

X

Lift the cargo compartment floor up

(Y page 298).

X Remove the jack from the tool holder.

X Turn retaining screw :counter-clockwise

and out of tool holder =and remove it.

i If retaining screw :does not come out

immediately, turn tool holder =slightly

counter-clockwise.

Retaining screw :can then be unscrewed

with ease.

20 Use of snow chains not permitted. Observe the notes under "Snow chains". 342

Emergency spare wheelWheels and tires

Page 346 of 364

X

Turn tool holder =approximately 180°, so

that the tire inflation compressor points

backwards.

X Remove tool holder =from collapsible

spare wheel ;.

X Remove collapsible spare wheel ;from

the emergency spare wheel well.

For further information on changing a wheel

and mounting the spare wheel, see

(Y page 299). Inflating the collapsible spare wheel

! Inflate the collapsible spare wheel using

the tire inflation compressor before

lowering the vehicle. The wheel rim could

otherwise be damaged.

! Do not operate the tire inflation

compressor for longer than eight minutes

at a time without a break. It may otherwise

overheat.

The tire inflation compressor can be

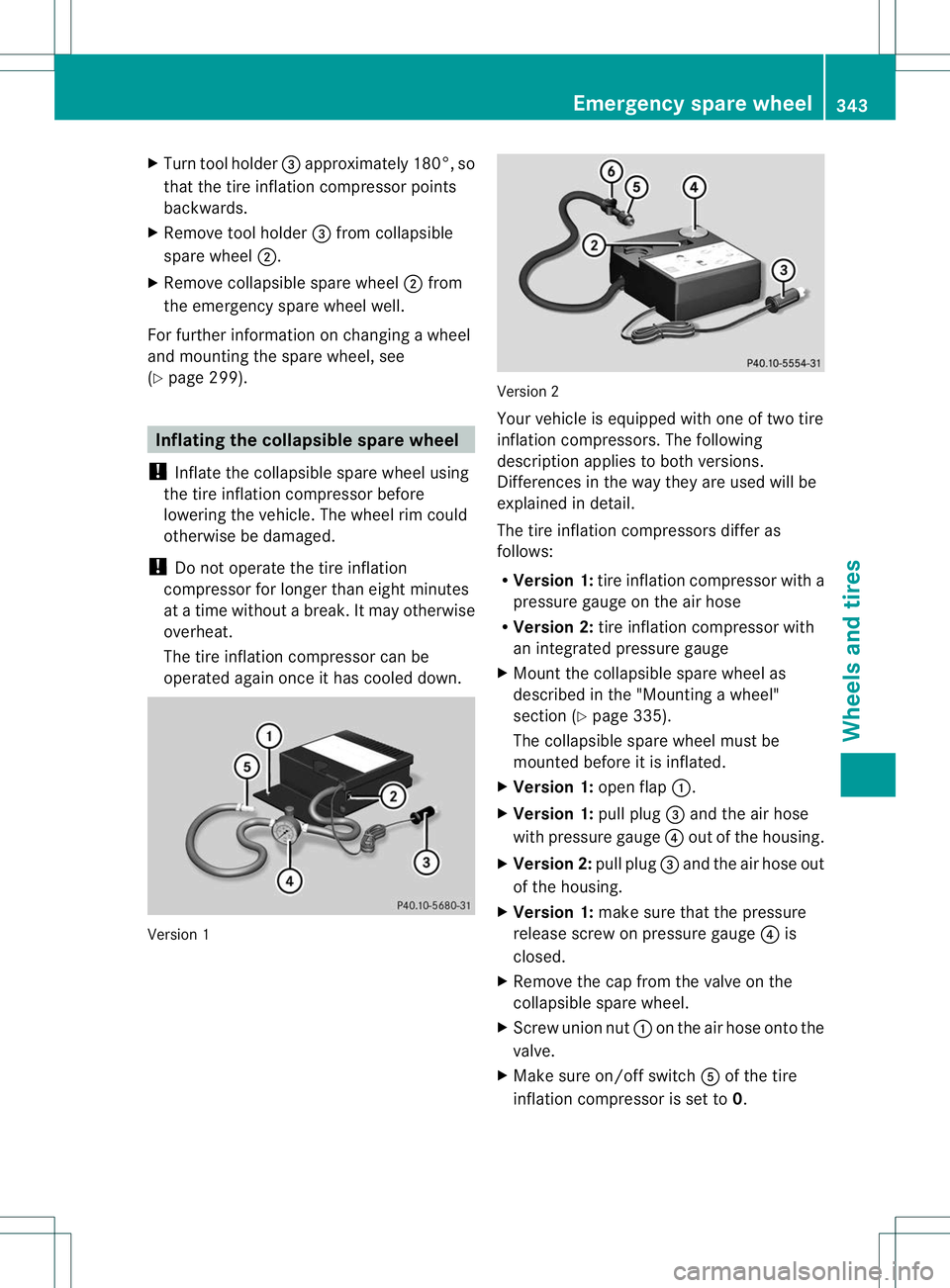

operated again once it has cooled down. Version 1 Version 2

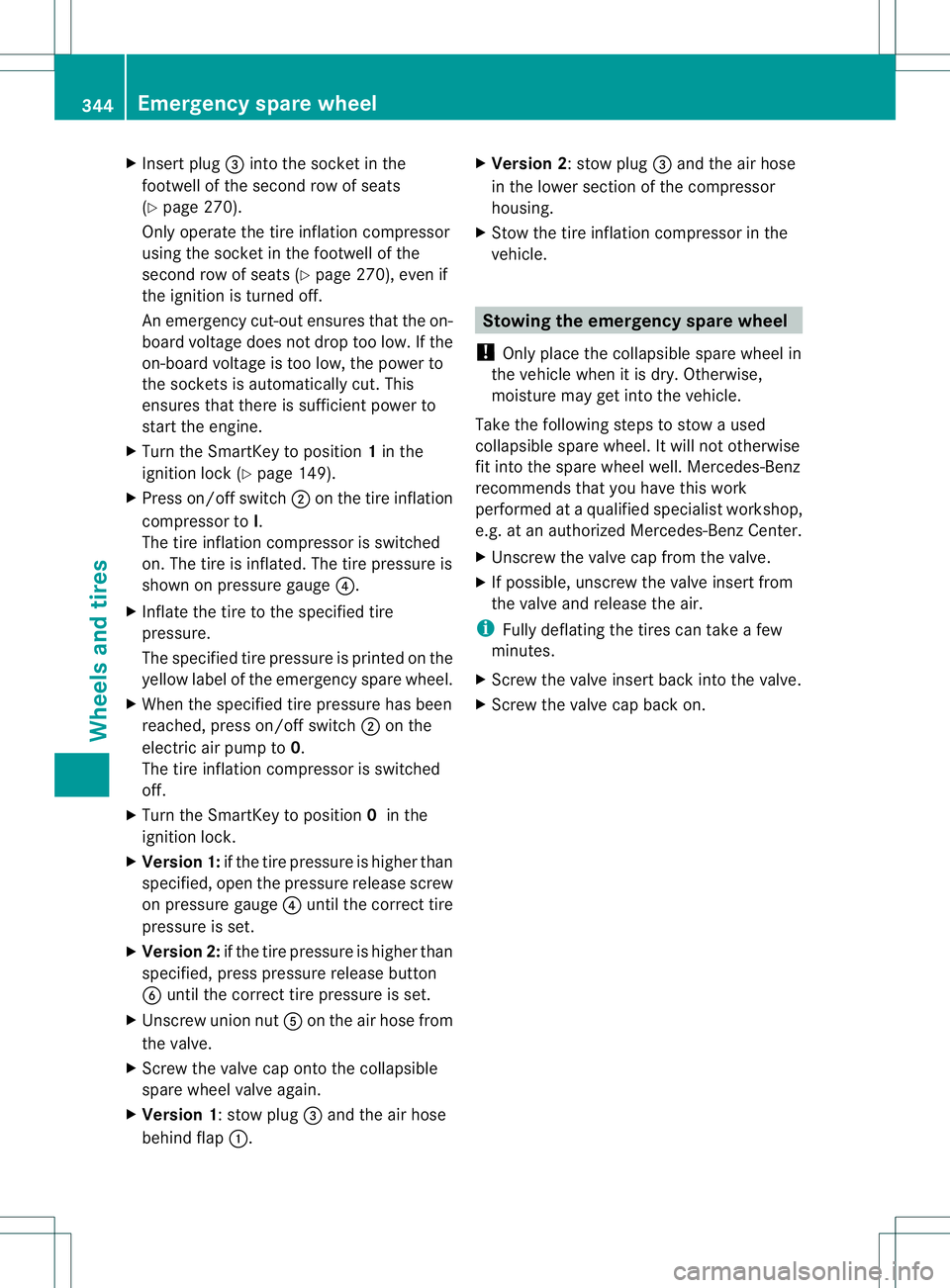

Your vehicle is equipped with one of two tire

inflation compressors. The following

description applies to both versions.

Differences in the way they are used will be

explained in detail.

The tire inflation compressors differ as

follows:

R

Version 1: tire inflation compressor with a

pressure gauge on the air hose

R Version 2: tire inflation compressor with

an integrated pressure gauge

X Mount the collapsible spare wheel as

described in the "Mounting a wheel"

section (Y page 335).

The collapsible spare wheel must be

mounted before it is inflated.

X Version 1: open flap:.

X Version 1: pull plug=and the air hose

with pressure gauge ?out of the housing.

X Version 2: pull plug=and the air hose out

of the housing.

X Version 1: make sure that the pressure

release screw on pressure gauge ?is

closed.

X Remove the cap from the valve on the

collapsible spare wheel.

X Screw union nut :on the air hose onto the

valve.

X Make sure on/of fswitch Aof the tire

inflatio ncompressor is set to 0. Emergency spare wheel

343Wheels and tires Z

Page 347 of 364

X

Insert plug 3into the socket in the

footwell of the second row of seats

(Y page 270).

Only operate the tire inflatio ncompressor

using the socket in the footwell of the

second row of seats (Y page 270), even if

the ignition is turned off.

An emergency cut-out ensures that the on-

board voltage does not drop too low. If the

on-board voltage is too low, the power to

the sockets is automatically cut. This

ensures that there is sufficient power to

start the engine.

X Turn the SmartKey to position 1in the

ignition lock (Y page 149).

X Press on/offs witch;on the tire inflation

compressor to I.

The tire inflatio ncompressor is switched

on. The tire is inflated. The tire pressure is

shown on pressure gauge ?.

X Inflate the tire to the specified tire

pressure.

The specified tire pressure is printed on the

yellow label of the emergency spare wheel.

X When the specified tire pressure has been

reached, press on/offs witch2on the

electric air pump to 0.

The tire inflatio ncompressor is switched

off.

X Turn the SmartKey to position 0in the

ignition lock.

X Version 1: if the tire pressure is higher than

specified, open the pressure release screw

on pressure gauge 4until the correct tire

pressure is set.

X Version 2: if the tire pressure is higher than

specified, press pressure release button

6 until the correct tire pressure is set.

X Unscrew union nut Aon the air hose from

the valve.

X Screw the valve cap ontot he collapsible

spare wheel valve again.

X Version 1:s tow plug=and the ai rhose

behind flap :. X

Version 2:s tow plug=and the ai rhose

in the lower section of the compressor

housing.

X Stow the tire inflation compressor in the

vehicle. Stowing the emergency sparew

heel

! Only place the collapsible spare wheel in

the vehicle whe nitis dry. Otherwise,

moisture may get into the vehicle.

Take the following steps to stow a used

collapsible spare wheel. It will not otherwise

fit into the spare wheel well.M ercedes-Benz

recommends that you have this work

performed at a qualified specialist workshop,

e.g. at an authorized Mercedes-BenzC enter.

X Unscrew the valve cap from the valve.

X If possible, unscrew the valve insert from

the valve and release the air.

i Fully deflating the tires can take a few

minutes.

X Screw the valve insert back into the valve.

X Screw the valve cap back on. 344

Emergency spare wheelWheels and tires

Page 348 of 364

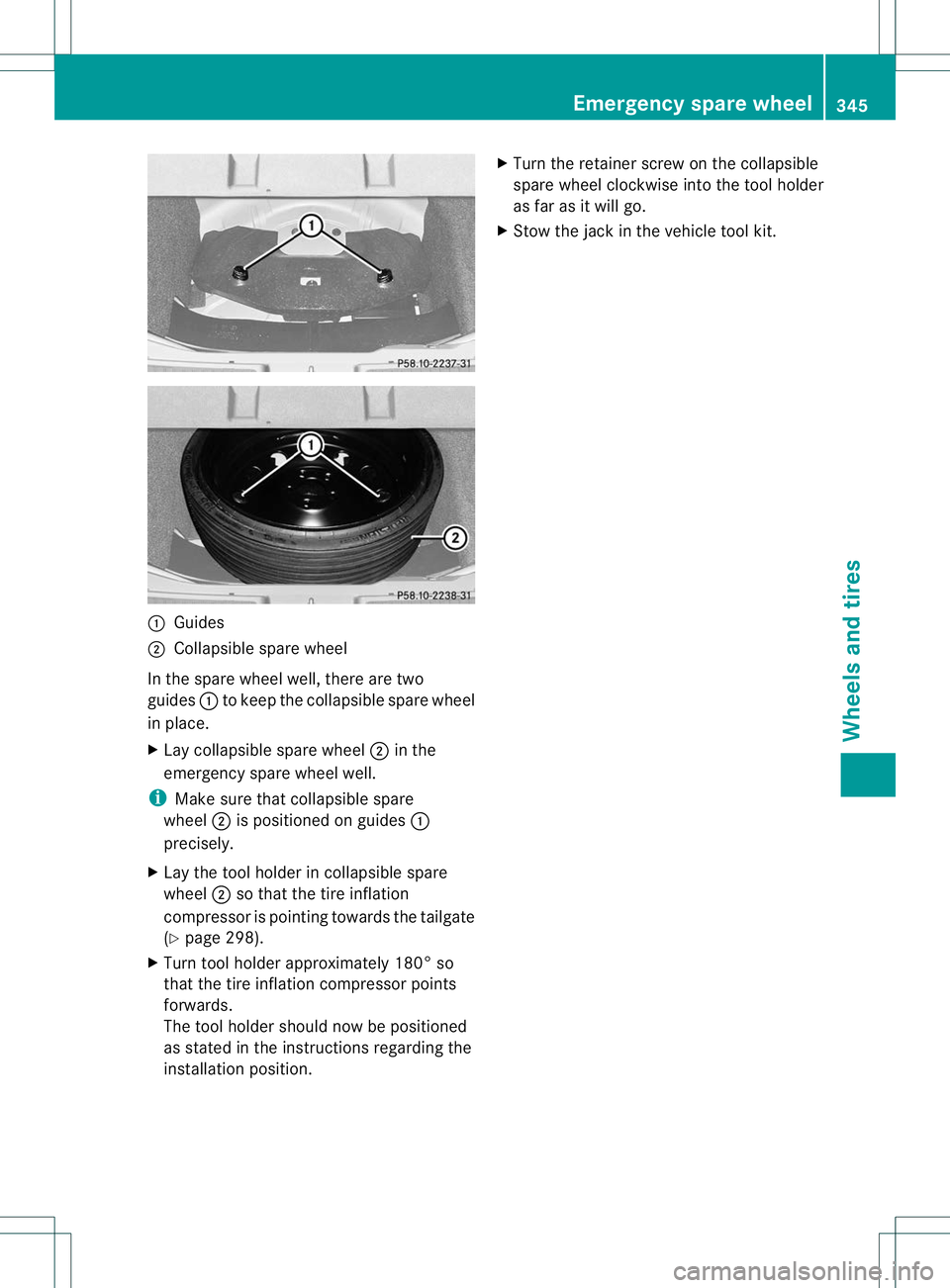

:

Guides

; Collapsible spare wheel

In the spare wheel well, there are two

guides :to keep the collapsible spare wheel

in place.

X Lay collapsible spare wheel ;in the

emergency spare wheel well.

i Make sure that collapsible spare

wheel ;is positioned on guides :

precisely.

X Lay the tool holde rincollapsible spare

wheel ;so that the tire inflation

compressor is pointing towards the tailgate

(Y page 298).

X Turn tool holder approximately 180° so

that the tire inflation compressor points

forwards.

The tool holder should now be positioned

as stated in the instructions regarding the

installation position. X

Turn the retainer screw on the collapsible

spare wheel clockwise into the tool holder

as far as it will go.

X Stow the jack in the vehicle tool kit. Emergency spare wheel

345Wheels and tires Z

Page 349 of 364

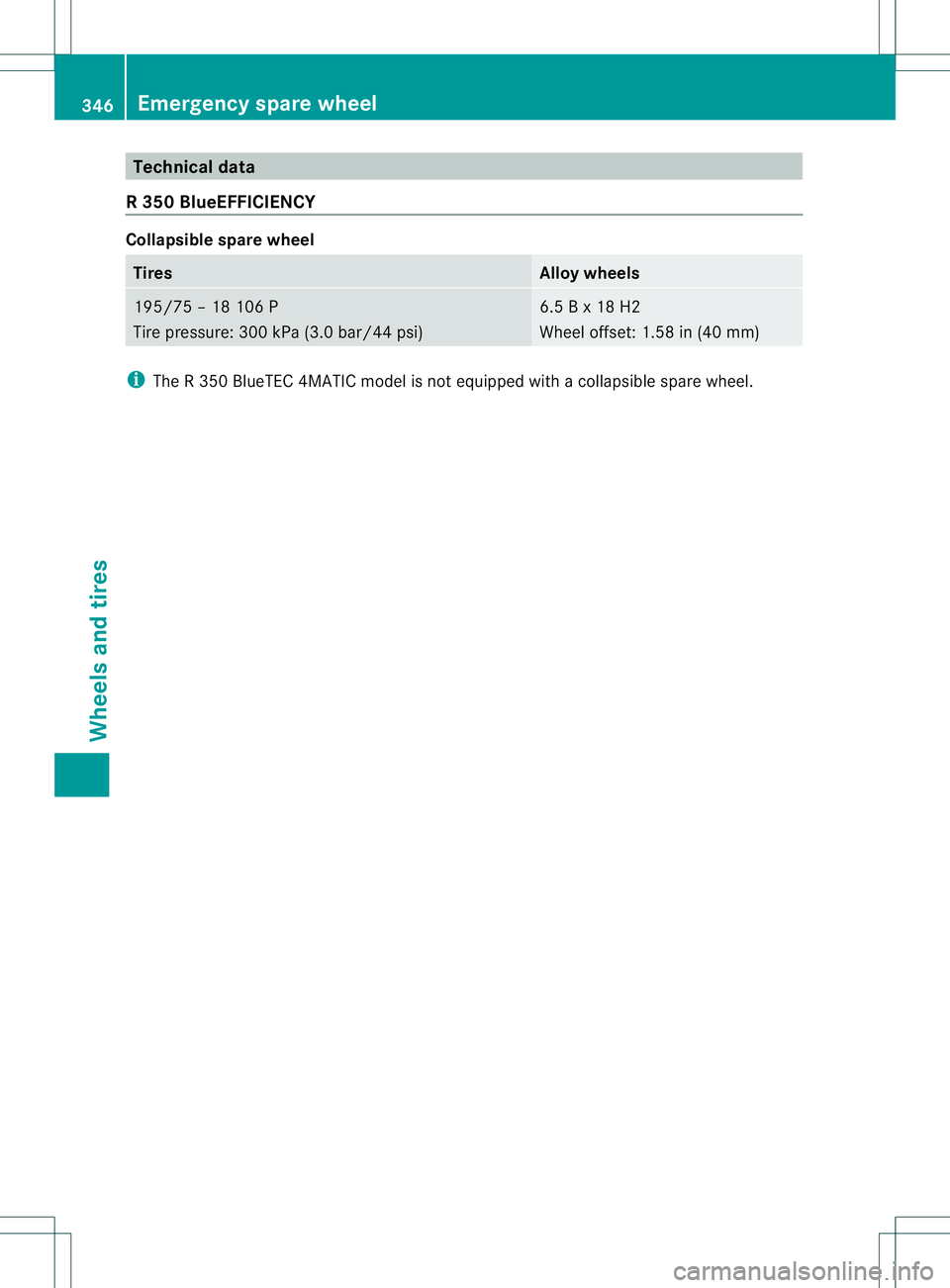

Technical data

R3 50 BlueEFFICIENCY Collapsible spare wheel

Tires Alloy wheels

195/75 – 18 106 P

Tire pressure: 300 kPa (3.0 bar/44 psi) 6.5 B x 18 H2

Wheel offset: 1.58 in (40 mm)

i

The R 350 BlueTEC 4MATIC model is not equipped with a collapsible spare wheel. 346

Emergency spare wheelWheels and tires

Page 350 of 364

Useful information

............................348

Information regarding technical

data .................................................... 348

Genuine Mercedes-Benz parts .........348

Warranty ............................................ 348

Identification plates .........................349

Service products and filling capaci-

ties ..................................................... 350

Vehicle data ...................................... 357 347Technical data