Jack MERCEDES-BENZ S-Class 2011 W221 User Guide

[x] Cancel search | Manufacturer: MERCEDES-BENZ, Model Year: 2011, Model line: S-Class, Model: MERCEDES-BENZ S-Class 2011 W221Pages: 524, PDF Size: 22.53 MB

Page 424 of 524

Vehicle equipment

i This manual describes all the standard

and optional equipment of your vehicle

which was available at the time of

purchase. Country-specific differences are

possible. Bear in mind that your vehicle

may not feature all functions described

here. This also refers to safety-related

systems and functions.

Loading guidelines

GWarning!

Always fasten items being carried as securely

as possible. Use cargo tie-down rings and

fastening materials appropriate for the weight

and size of the load.

In an accident, during hard braking or sudden

maneuvers, loose items will be thrown around

inside the vehicle. This can cause injury to

vehicle occupants unless the items are

securely fastened in the vehicle.

To help avoid personal injury during a collision

or sudden maneuver, exercise care when

transporting cargo. Do not pile luggage or

cargo higher than the seat backrests.

The trunk is the preferred place to carry

objects.

Never drive a vehicle with the trunk open.

Deadly carbon monoxide (CO) gases may

enter vehicle interior resulting in

unconsciousness and death.

The handling characteristics of a laden

vehicle are dependent on the distribution of

the load within the vehicle. For this reason,

you should observe the following notes when

transporting a load:

R when transporting a load, never exceed the

maximum permissible gross vehicle weight

or the permissible axle loads for the vehicle

(including occupants). The values are

specified on the vehicle identification plate

on the B-pillar of the driver's door.

R position heavy loads as far forwards as

possible and as low down in the trunk as

possible.

R the load must not protrude above the upper

edge of the seat backrests.

R always place the load against the rear seat

backrests.

R always place the load behind unoccupied

seats if possible.

R secure the load with sufficiently strong and

wear-resistant lashing material. Pad sharp

edges for protection.

Stowage compartments

Important safety notes

GWarning!

To help avoid personal injury during a collision

or sudden maneuver, exercise care when

storing objects in the vehicle. Put luggage or

cargo in the trunk if possible.

Do not pile luggage or cargo higher than the

seat backrests.

Keep compartment lids closed. This will help

to prevent stored objects from being thrown

about and injuring vehicle occupants during

R braking

R vehicle maneuvers

R an accident

Stowage compartments in the front

Glove box

i Depending on the vehicle's equipment,

you will find the following installed in the

glove box: an audio and video AUX jack, a

USB socket or Media Interface, a universal

interface for portable audio equipment, e.g.

for an iPod or USB device, and a bracket for

a remote control (see the COMAND section

of this Operator's Manual.

422Stowage compartmentsLoading, stowing and features

Page 464 of 524

Vehicle equipment

i This manual describes all the standard

and optional equipment of your vehicle

which was available at the time of

purchase. Country-specific differences are

possible. Bear in mind that your vehicle

may not feature all functions described

here. This also refers to safety-related

systems and functions.

Where will I find...?

First-aid kit

XOpen the trunk lid.XRelease retainer strap :.XRemove first-aid kit ; from the parcel net.

i

Check the expiration date on the first-aid

kit at least once a year. Replace the

contents if necessary, and replace missing

contents.

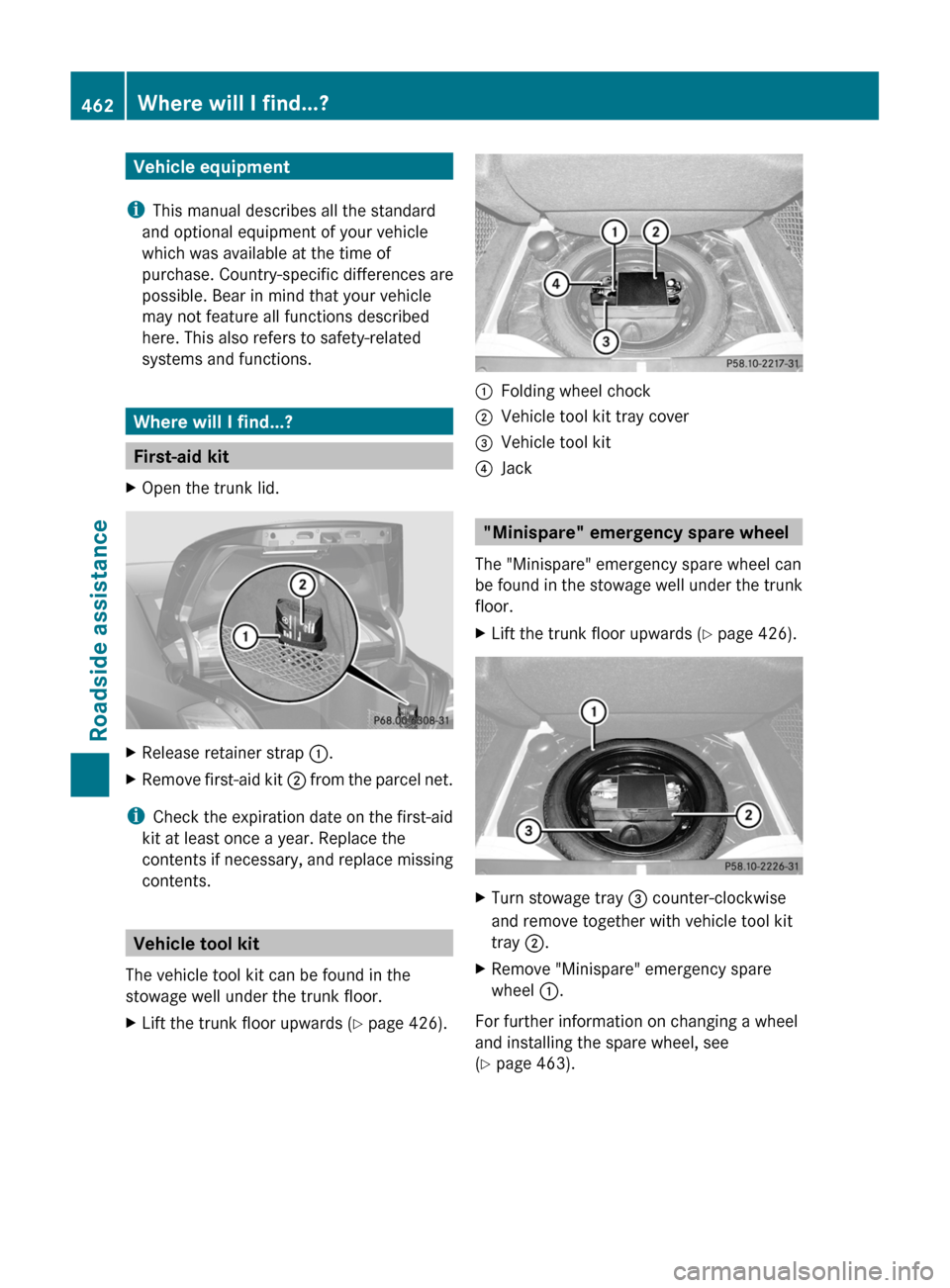

Vehicle tool kit

The vehicle tool kit can be found in the

stowage well under the trunk floor.

XLift the trunk floor upwards ( Y page 426).:Folding wheel chock;Vehicle tool kit tray cover=Vehicle tool kit?Jack

"Minispare" emergency spare wheel

The "Minispare" emergency spare wheel can

be found in the stowage well under the trunk

floor.

XLift the trunk floor upwards ( Y page 426).XTurn stowage tray = counter-clockwise

and remove together with vehicle tool kit

tray ;.XRemove "Minispare" emergency spare

wheel :.

For further information on changing a wheel

and installing the spare wheel, see

( Y page 463).

462Where will I find...?Roadside assistance

Page 466 of 524

XPrepare the vehicle as described

(Y page 463).

XRemove the following items from the

stowage well under the trunk floor:

XSecure the vehicle to prevent it from rolling

away.

Securing the vehicle to prevent it from

rolling away

GWarning

Only jack up the vehicle on level ground or on

slight inclines/declines. The vehicle could

otherwise fall off the jack and injure you or

others.

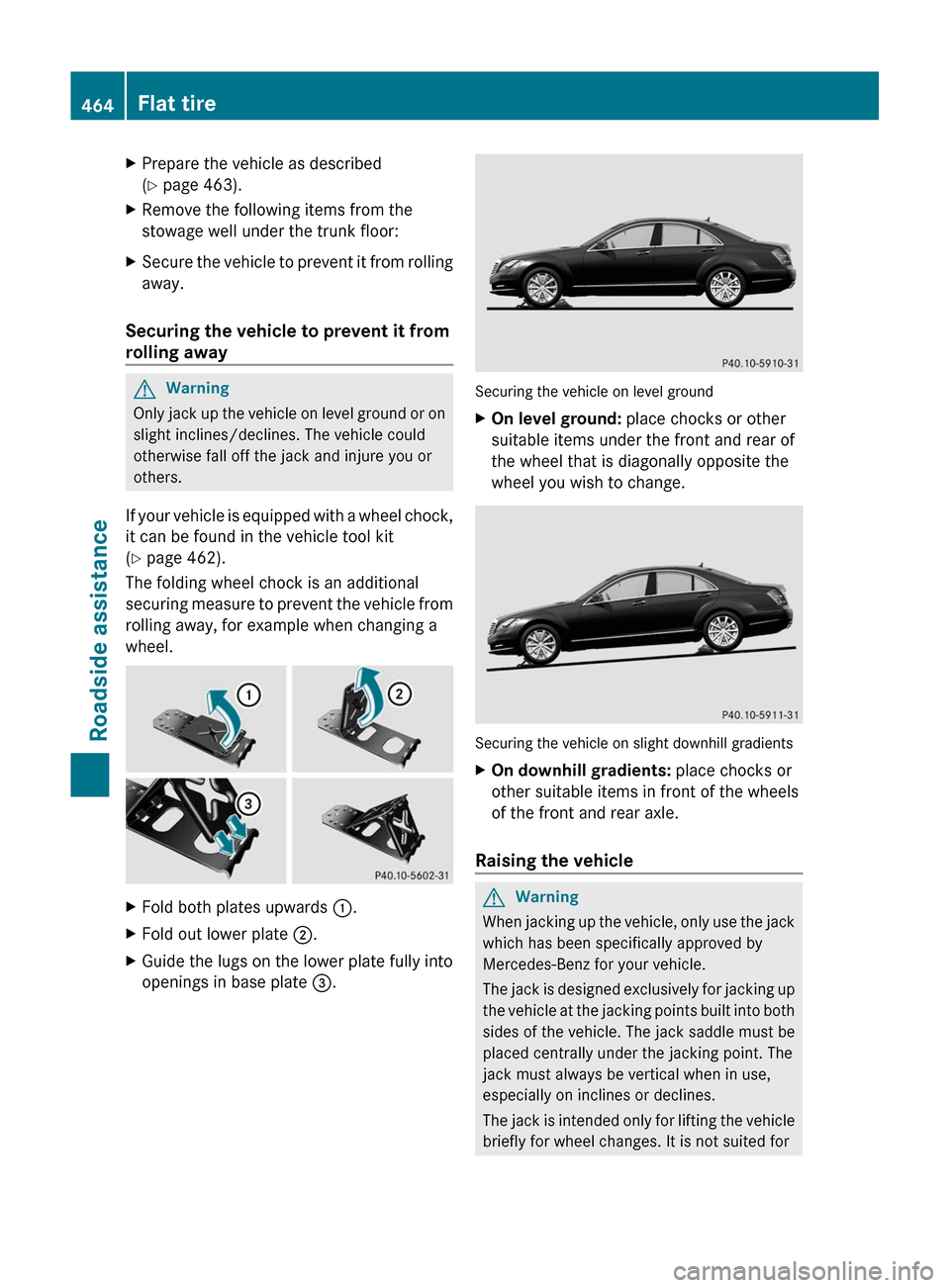

If your vehicle is equipped with a wheel chock,

it can be found in the vehicle tool kit

(Y page 462).

The folding wheel chock is an additional

securing measure to prevent the vehicle from

rolling away, for example when changing a

wheel.

XFold both plates upwards :.XFold out lower plate ;.XGuide the lugs on the lower plate fully into

openings in base plate =.

Securing the vehicle on level ground

XOn level ground: place chocks or other

suitable items under the front and rear of

the wheel that is diagonally opposite the

wheel you wish to change.

Securing the vehicle on slight downhill gradients

XOn downhill gradients: place chocks or

other suitable items in front of the wheels

of the front and rear axle.

Raising the vehicle

GWarning

When jacking up the vehicle, only use the jack

which has been specifically approved by

Mercedes-Benz for your vehicle.

The jack is designed exclusively for jacking up

the vehicle at the jacking points built into both

sides of the vehicle. The jack saddle must be

placed centrally under the jacking point. The

jack must always be vertical when in use,

especially on inclines or declines.

The jack is intended only for lifting the vehicle

briefly for wheel changes. It is not suited for

464Flat tireRoadside assistance

Page 467 of 524

performing maintenance work under the

vehicle. To help avoid personal injury, use the

jack only to lift the vehicle during a wheel

change.

Never get beneath the vehicle while it is

supported by the jack. Keep hands and feet

away from the area under the lifted vehicle.

Always lower the vehicle onto sufficient

capacity jackstands before working under the

vehicle.

Always firmly engage the parking brake and

block the wheels with wheel chocks or other

sizable objects before raising the vehicle with

the jack. Do not disengage the parking brake

while the vehicle is raised.

Make sure that the ground on which the

vehicle is standing and where you place the

jack is solid, level and not slippery. If

necessary, use a large underlay. On slippery

surfaces, such as tiled floors, you should use

a non-slip underlay, for example a rubber mat.

Do not use wooden blocks or similar objects

as a jack underlay. Otherwise, the jack may

not be able to achieve its load-bearing

capacity if it is not at its full height.

Never start the engine when the vehicle is

raised.

Also observe the notes on the jack.

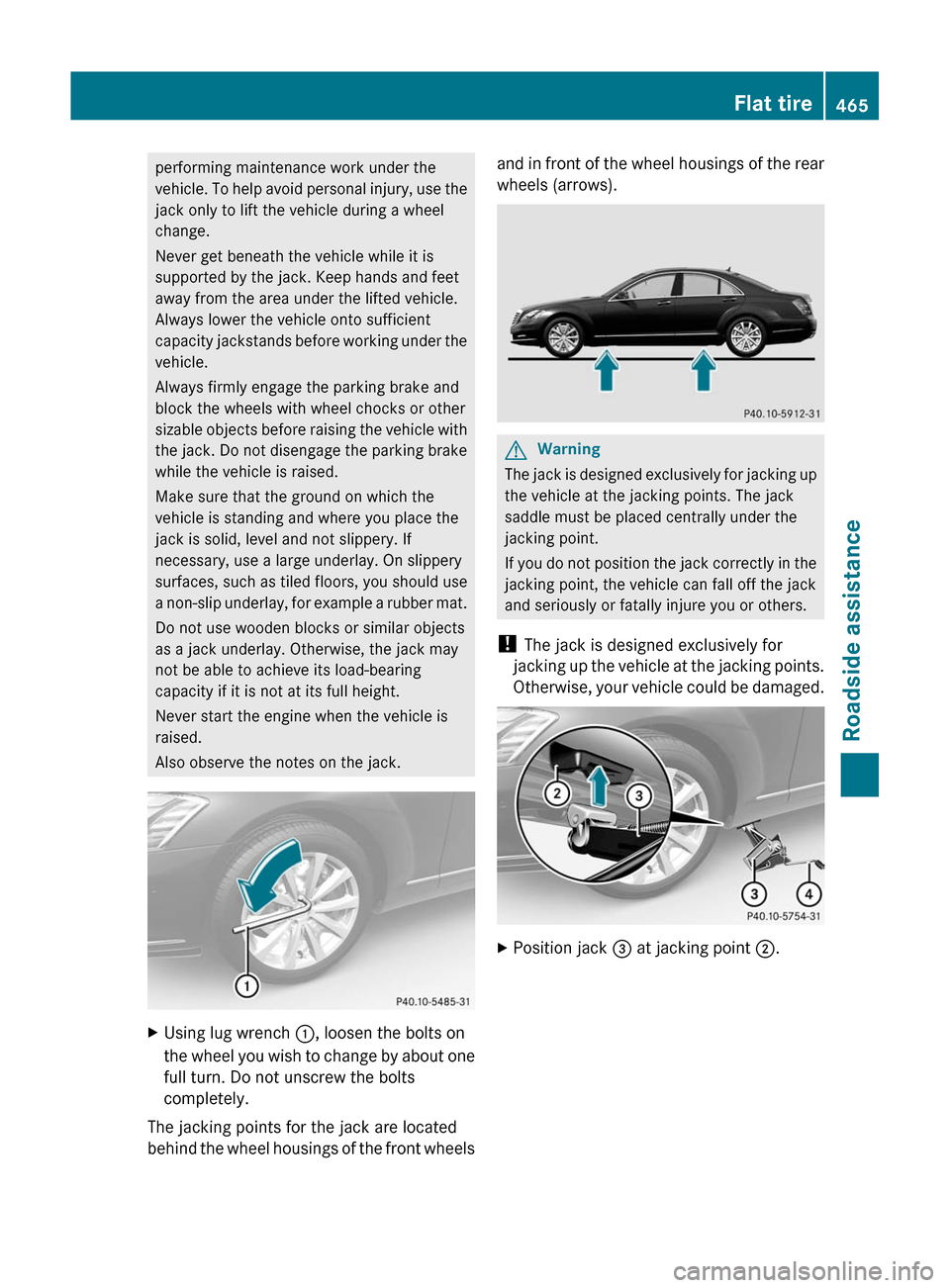

XUsing lug wrench :, loosen the bolts on

the wheel you wish to change by about one

full turn. Do not unscrew the bolts

completely.

The jacking points for the jack are located

behind the wheel housings of the front wheels

and in front of the wheel housings of the rear

wheels (arrows).

GWarning

The jack is designed exclusively for jacking up

the vehicle at the jacking points. The jack

saddle must be placed centrally under the

jacking point.

If you do not position the jack correctly in the

jacking point, the vehicle can fall off the jack

and seriously or fatally injure you or others.

! The jack is designed exclusively for

jacking up the vehicle at the jacking points.

Otherwise, your vehicle could be damaged.

XPosition jack = at jacking point ;.Flat tire465Roadside assistanceZ

Page 468 of 524

XMake sure that the base of the jack is

positioned directly under the jacking point.

XTurn crank ? clockwise until jack = sits

completely on jacking point ; and the

base of the jack lies evenly on the ground.

XTurn crank ? until the tire is raised a

maximum of 1.2 inches (3 centimeters)

from the ground.

Removing a wheel

XUnscrew the uppermost wheel bolt

completely.

XScrew alignment bolt : into the thread

instead of the wheel bolt.

XUnscrew the remaining wheel bolts fully.

! Do not place wheel bolts in sand or on a

dirty surface. The bolt and wheel hub

threads could otherwise be damaged when

you screw them in.

XRemove the wheel.Mounting a new wheelGWarning!

Always replace wheel bolts that are damaged

or rusted.

Never apply oil or grease to wheel bolts.

Damaged wheel hub threads should be

repaired immediately. Do not continue to

drive under these circumstances! Contact an

authorized Mercedes-Benz Center or call

Roadside Assistance.

Incorrect wheel bolts or improperly tightened

wheel bolts can cause the wheel to come off.

This could cause an accident. Make sure to

use the correct wheel bolts.

GWarning

Only use genuine Mercedes-Benz wheel bolts.

Other wheel bolts may come loose.

Do not tighten the wheel bolts when the

vehicle is raised. Otherwise, the vehicle could

fall off the jack.

GWarning

Make sure to use the original length wheel

bolts when remounting the original wheel

after it has been repaired.

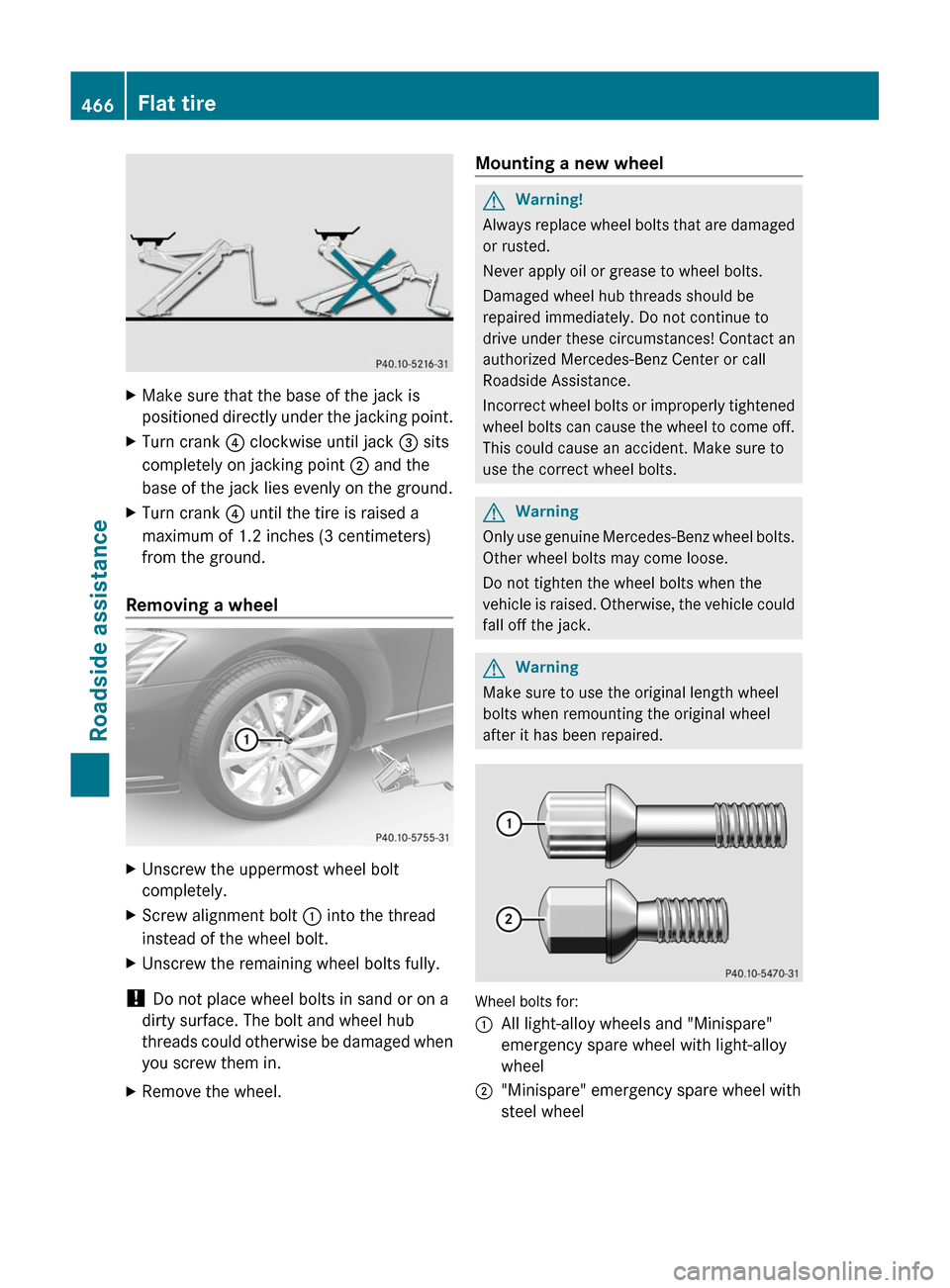

Wheel bolts for:

:All light-alloy wheels and "Minispare"

emergency spare wheel with light-alloy

wheel

;"Minispare" emergency spare wheel with

steel wheel

466Flat tireRoadside assistance

Page 469 of 524

! Always use wheel bolts : to fit the

"Minispare" emergency spare wheel with

light-alloy wheel. Using other wheel bolts

when fitting the "Minispare" emergency

spare wheel with light-alloy wheel could

damage the brake system.

Always use wheel bolts ; to fit the

"Minispare" emergency spare wheel with

steel wheel. Using other wheels when

fitting the "Minispare" emergency spare

wheel with steel wheel could damage the

brake system.

XClean the wheel and wheel hub contact

surfaces.

! To prevent damage to the paintwork, hold

the wheel securely against the wheel hub

while screwing in the first wheel bolt.

XSlide the emergency spare wheel onto the

alignment bolt and push it on.

XTighten the wheel bolts until they are

finger-tight.

XUnscrew the alignment bolt.XTighten the last wheel bolt until it is finger-

tight.

Lowering the vehicle

XTurn the crank of the jack counter-

clockwise until the vehicle is once again

standing firmly on the ground.

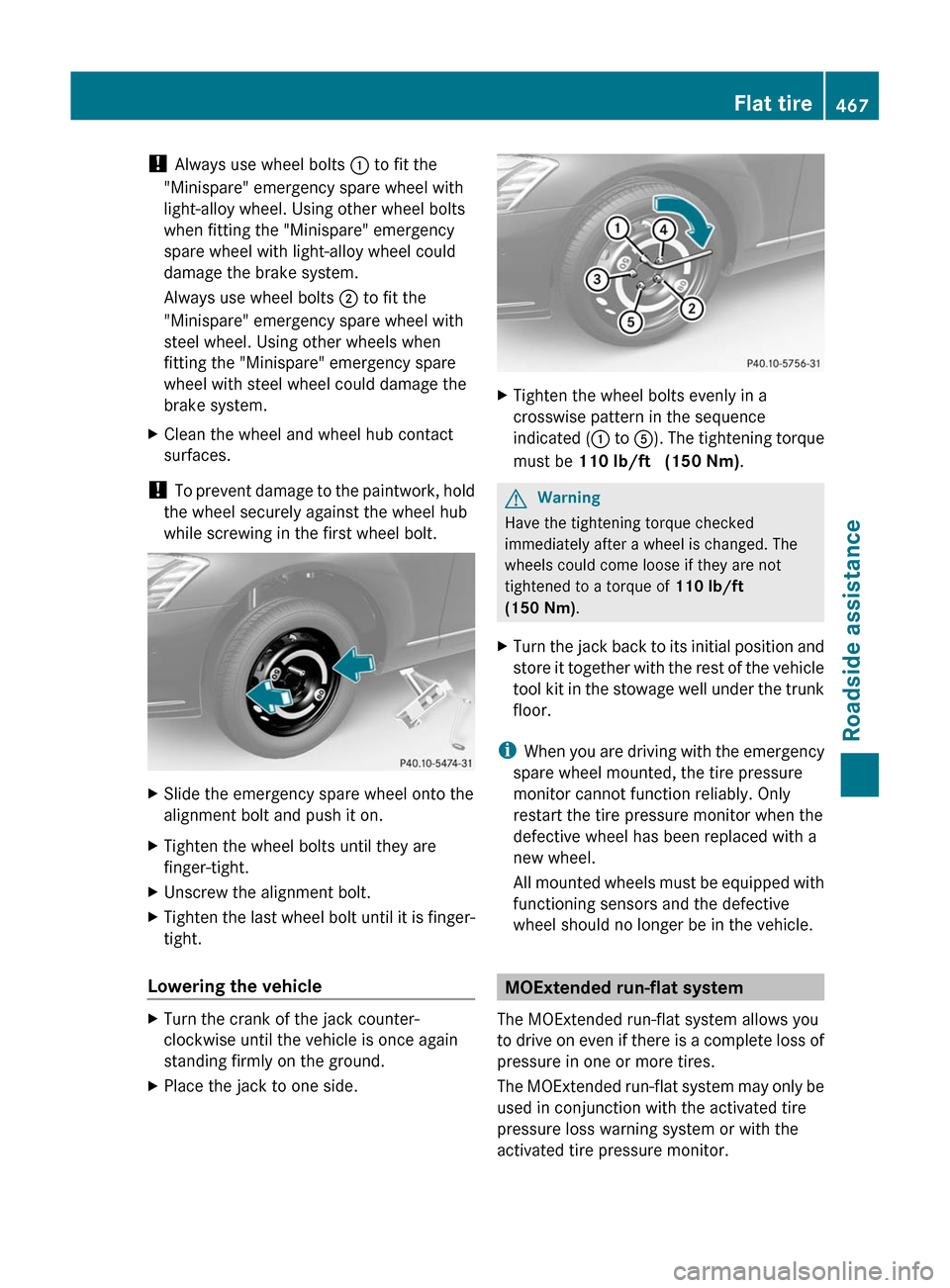

XPlace the jack to one side.XTighten the wheel bolts evenly in a

crosswise pattern in the sequence

indicated (: to A). The tightening torque

must be 110 lb/ft (150 Nm).

GWarning

Have the tightening torque checked

immediately after a wheel is changed. The

wheels could come loose if they are not

tightened to a torque of 110 lb/ft

(150 Nm).

XTurn the jack back to its initial position and

store it together with the rest of the vehicle

tool kit in the stowage well under the trunk

floor.

iWhen you are driving with the emergency

spare wheel mounted, the tire pressure

monitor cannot function reliably. Only

restart the tire pressure monitor when the

defective wheel has been replaced with a

new wheel.

All mounted wheels must be equipped with

functioning sensors and the defective

wheel should no longer be in the vehicle.

MOExtended run-flat system

The MOExtended run-flat system allows you

to drive on even if there is a complete loss of

pressure in one or more tires.

The MOExtended run-flat system may only be

used in conjunction with the activated tire

pressure loss warning system or with the

activated tire pressure monitor.

Flat tire467Roadside assistanceZ