ECU MERCEDES-BENZ SLC 2019 Workshop Manual

[x] Cancel search | Manufacturer: MERCEDES-BENZ, Model Year: 2019, Model line: SLC, Model: MERCEDES-BENZ SLC 2019Pages: 306, PDF Size: 15 MB

Page 265 of 306

Towing and tow-starting

Important safety notes

GWARNING

When towing or tow-starting another vehicle

and its weight is greater than the permissi-

ble gross weight of your vehicle, the:

Rthe towing eye could detach itself

Rthe vehicle/trailer combination could roll-

over.

There is a risk of an accident.

When towing or tow-starting another vehi-

cle, its weight should not be greater than

the permissible gross weight of your vehicle.

Details on the permissible gross vehicle weightof your vehicle can be found on the vehicleidentification plate (Ypage 297).

!When Active Brake Assist, Active DistanceAssist DISTRONIC or the HOLD function isactivated, the vehicle brakes automaticallyin certain situations.

To avoid damage to the vehicle, deactivatethese systems in the following or similar sit-uations:

Rwhen towing the vehicle

Rin the car wash

!Only secure the tow rope or tow bar at thetowing eyes. Otherwise, the vehicle could bedamaged.

!Do not use the towing eye for recovery,this could damage the vehicle. If in doubt,recover the vehicle with a crane.

!When towing, pull away slowly andsmoothly. If the tractive power is too high,the vehicles could be damaged.

!Do not tow with sling-type equipment. Thiscould damage the vehicle.

!When towing away vehicles with KEYLESS-GO, use the key instead of the Start/Stopbutton. The automatic transmission mayotherwise shift to position�]when youopen the driver's or front-passenger door,which could damage the transmission.

!Make sure that the electric parking brakeis released. If the electric parking brake isfaulty, visit a qualified specialist workshop.

!You may tow the vehicle for a maximumdistance of 30 miles (50 kilometers). A tow-ing speed of 30 mph (50 km/h) must not beexceeded.

For towing distances over 30 miles(50 kilometers), the entire vehicle must beraised and transported.

!When you are tow-starting or towinganother vehicle, its weight must not exceedthe maximum permissible gross weight ofyour vehicle.

It is better to have the vehicle transportedthan to have it towed away.

The automatic transmission must be in posi-tion�\\when the vehicle is being towed away.

The battery must be connected and charged.Otherwise, you:

Rcannot turn the SmartKey to position�Hinthe ignition lock

Rcannot shift the automatic transmission toposition�\\

Deactivate the automatic locking featurebefore the vehicle is towed (Ypage 178). Youcould otherwise be locked out when pushingor towing the vehicle.

Installing/removing the towing eye

Installing the towing eye

GWARNING

The exhaust tail pipe may be very hot. There

is a risk of burns when removing the rear

cover.

Do not touch the exhaust pipe. Take particu-

lar care when removing the rear cover.

Towing and tow-starting263

Breakdown assistance

Z

Page 267 of 306

Transporting the vehicle

Vehicles with automatic transmission

!When the vehicle is loaded for transport,the front and rear axles must be stationaryand on the same transportation vehicle.Positioning over the connection point of thetransport vehicle is not permitted. The drivetrain may otherwise be damaged.

All vehicles

!You may only secure the vehicle by thewheels, not by parts of the vehicle such asaxle or steering components. Otherwise, thevehicle could be damaged.

The towing eye can be used to pull the vehicleonto a trailer or transporter for transportingpurposes.

XTurn the SmartKey to position�Hin the igni-tion lock.

XShift the transmission to position�\\.

As soon as the vehicle has been loaded:

XPrevent the vehicle from rolling away byapplying the electric parking brake.

XShift the transmission to position�].

XTurn the SmartKey to position�

Page 275 of 306

Avoid tire pressures that are too high in all

the tires, including the spare wheel.

Overinflated tires may:

Rincrease the braking distance

Radversely affect handling

Rwear excessively and/or unevenly

Rhave an adverse effect on ride comfort

Rbe more susceptible to damage

Maximum tire pressures

�CExample: maximum permissible tire pres-sure

Never exceed the maximum permissible tireinflation pressure. Always observe the recom-mended tire pressure for your vehicle whenadjusting the tire pressure (Ypage 270).

iThe actual values for tires are vehicle-spe-cific and may deviate from the values in theillustration.

Checking the tire pressures

Important safety notes

The tire pressure monitor does not warn youof:

Rincorrectly set tire pressure

Rsudden loss of tire pressure, e.g. from a for-eign object that has penetrated the tire

Observe the notes on tire pressure(Ypage 270).

Information on air pressure for the tires onyour vehicle can be found:

Ron the vehicle's Tire and Loading Informa-tion placard on the B-pillar

Ron the tire pressure table in the fuel fillerflap

Rin the "Tire pressure" section

Checking tire pressures manually

To determine and set the correct tire pressure,proceed as follows:

XRemove the valve cap of the tire that is tobe checked.

XPress the tire pressure gauge securely ontothe valve.

XRead the tire pressure and compare it to therecommended value on the Tire and LoadingInformation placard or the tire pressuretable (Ypage 270).

XIf the tire pressure is too low, increase thetire pressure to the recommended value.

XIf the tire pressure is too high, release air.To do so, press down the metal pin in thevalve, using the tip of a pen for example.Then check the tire pressure again using thetire pressure checker.

XScrew the valve cap onto the valve.

XRepeat these steps for the other tires.

Tire pressure loss warning system

(Canada only)

General notes

While the vehicle is in motion, the tire pres-sure loss warning system monitors the set tirepressure using the rotational speed of thewheels. This enables the system to detect sig-nificant pressure loss in a tire. If the speed ofrotation of a wheel changes as a result of aloss of pressure, a corresponding warningmessage will appear in the multifunction dis-play.

You can recognize the tire pressure loss warn-ing by theRun Flat Indicator ActiveRun Flat Indicator ActivePress 'OK' to RestartPress 'OK' to Restartmessage whichappears in theServ.Serv.menu of the multifunc-tion display. Information on the message dis-play can be found in the "Restarting the tire

Tire pressure273

Wheels and tires

Z

Page 279 of 306

If the wheel positions on the vehicle are rota-ted, the tire pressures may be displayed forthe wrong positions for a short time. This isrectified after a few minutes of driving, and thetire pressures are displayed for the correctpositions.

Restarting the tire pressure monitor

When you restart the tire pressure monitor, allexisting warning messages are deleted and thewarning lamps go out. The monitor uses thecurrently set tire pressures as the referencevalues for monitoring. In most cases, the tirepressure monitor will automatically detect thenew reference values after you have changedthe tire pressure. However, you can also setreference values manually as described here.The tire pressure monitor then monitors thenew tire pressure values.

XSet the tire pressure to the value recom-mended for the corresponding driving situa-tion on the Tire and Loading Informationplacard on the driver's side B-pillar(Ypage 270).

Additional tire pressure values for differentloads can also be found on the tire pressuretable on the inside of the fuel filler flap(Ypage 270).

XMake sure that the tire pressure is correcton all four wheels.

XEnsure that the SmartKey is in position�Hin the ignition lock.

XPress the�Yor�ebutton on the steer-ing wheel to select theServ.Serv.menu.

XPress the�cor�dbutton to selectTire PressureTire Pressure.

XPress�v.The multifunction display shows the currenttire pressure for the individual tires or theTire pressure will be displayedTire pressure will be displayedafter driving a few minutesafter driving a few minutesmessage.

XPress the�dbutton.TheUse Current Pressures as NewUse Current Pressures as NewReference ValuesReference Valuesmessage appears in themultifunction display.

If you wish to confirm the restart:

XPress�v.TheTire Press. Monitor RestartedTire Press. Monitor Restartedmessage appears in the multifunction dis-play.

After driving for a few minutes, the systemchecks whether the current tire pressuresare within the specified range. The new tirepressures are then accepted as referencevalues and monitored.

If you wish to cancel the restart:

XPress�8.The tire pressure values stored at the lastrestart will continue to be monitored.

Tire pressure277

Wheels and tires

Z

Page 290 of 306

Tread

The part of the tire that comes into contactwith the road.

Bead

The tire bead ensures that the tire sitssecurely on the wheel. There are several steelwires in the bead to prevent the tire from com-ing loose from the wheel rim.

Sidewall

The part of the tire between the tread and thebead.

Weight of optional extras

The combined weight of those optional extrasthat weigh more than the replaced standardparts and more than 2.3 kg (5 lbs). Theseoptional extras, such as high-performancebrakes, level control, a roof rack or a high-per-formance battery, are not included in the curbweight and the weight of the accessories.

TIN (Tire Identification Number)

This is a unique identifier which can be usedby a tire manufacturer to identify tires, forexample for a product recall, and thus identifythe purchasers. The TIN is made up of themanufacturer's identity code, tire size, tiretype code and the manufacturing date.

Load bearing index

The load bearing index (also load index) is acode that contains the maximum load bearingcapacity of a tire.

Traction

Traction is the result of friction between thetires and the road surface.

Treadwear indicators

Narrow bars (tread wear bars) that are distrib-uted over the tire tread. If the tire tread is levelwith the bars, the wear limit of�

Page 291 of 306

Clean the contact surfaces of the wheel andthe brake disc thoroughly every time a wheelis rotated. Check the tire pressure and, if nec-essary, restart the tire pressure loss warningsystem or the tire pressure monitor.

Direction of rotation

Tires with a specified direction of rotation haveadditional benefits, e.g. if there is a risk ofhydroplaning. These advantages can only begained if the tires are installed correspondingto the direction of rotation.

An arrow on the sidewall of the tire indicatesits correct direction of rotation.

Storing wheels

Store wheels that are not being used in a cool,dry and preferably dark place. Protect the tiresfrom oil, grease, gasoline and diesel.

Mounting a wheel

Preparing the vehicle

XStop the vehicle on solid, non-slippery andlevel ground.

XApply the electric parking brake manually.

XBring the front wheels into the straight-ahead position.

XShift the transmission to position�].

XSwitch off the engine.

XVehicles without KEYLESS-GO:removethe SmartKey from the ignition lock.

XVehicles with KEYLESS-GO:open the driv-er's door.The vehicle electronics now have status0.This is the same as the SmartKey havingbeen removed.

XVehicles with KEYLESS-GO:remove theStart/Stop button from the ignition lock(Ypage 118).

XIf included in the vehicle equipment, removethe tire-change tool kit from the vehicle.

XSafeguard the vehicle against rolling away.

iDue to differences in vehicle equipment,not all vehicles are equipped with a tire-change tool kit. For information on which

tools are required to perform a wheelchange on your vehicle, consult an author-ized Mercedes-Benz Center.

Necessary tire-changing tools can include,for example:

RJack

RWheel chock

RLug wrench

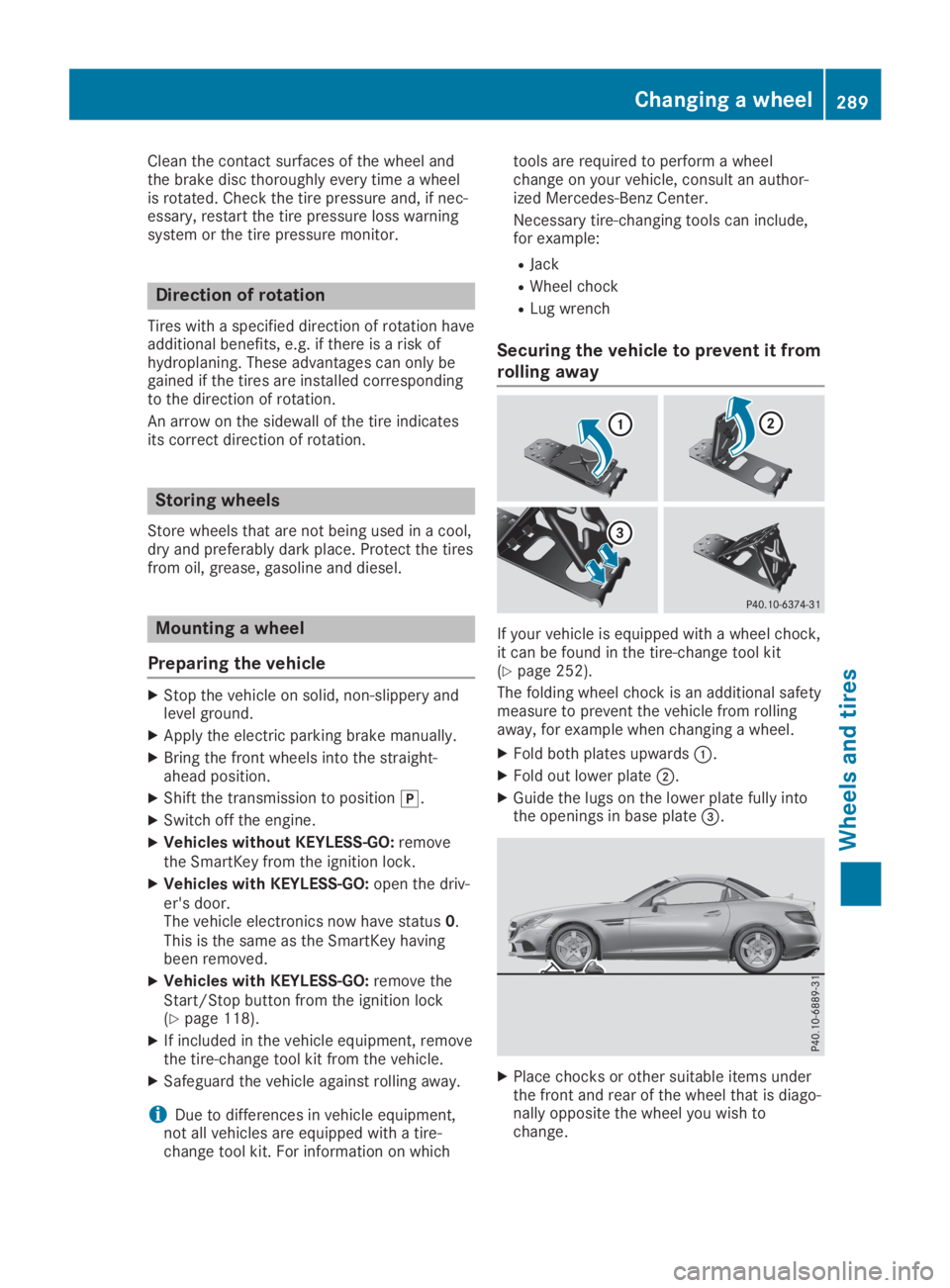

Securing the vehicle to prevent it from

rolling away

If your vehicle is equipped with a wheel chock,it can be found in the tire-change tool kit(Ypage 252).

The folding wheel chock is an additional safetymeasure to prevent the vehicle from rollingaway, for example when changing a wheel.

XFold both plates upwards�C.

XFold out lower plate�D.

XGuide the lugs on the lower plate fully intothe openings in base plate�

Page 292 of 306

Raising the vehicle

GWARNING

If you do not position the jack correctly at

the appropriate jacking point of the vehicle,

the jack could tip over with the vehicle

raised. There is a risk of injury.

Only position the jack at the appropriate

jacking point of the vehicle. The base of the

jack must be positioned vertically, directly

under the jacking point of the vehicle.

!Only position the jack at the appropriatejacking point of the vehicle. Otherwise, youcould damage the vehicle.

Observe the following when raising the vehi-cle:

RTo raise the vehicle, only use the vehicle-specific jack that has been tested andapproved by Mercedes-Benz. If used incor-rectly, the jack could tip over with the vehi-cle raised.

RThe jack is designed only to raise and holdthe vehicle for a short time while a wheelis being changed. It must not be used forperforming maintenance work under thevehicle.

RAvoid changing the wheel on uphill anddownhill slopes.

RBefore raising the vehicle, secure it fromrolling away by applying the parking brakeand inserting wheel chocks. Do not disen-gage the parking brake while the vehicle israised.

RThe jack must be placed on a firm, flat andnon-slip surface. On a loose surface, a large,flat, load-bearing underlay must be used. Ona slippery surface, a non-slip underlay mustbe used, e.g. rubber mats.

RDo not use wooden blocks or similar objectsas a jack underlay. Otherwise, the jack willnot be able to achieve its load-bearing capa-city due to the restricted height.

RMake sure that the distance between theunderside of the tires and the ground doesnot exceed 1.2 in (3 cm).

RNever place your hands and feet under theraised vehicle.

RDo not lie under the vehicle.

RDo not start the engine when the vehicle israised.

RDo not open or close a door or the trunk lidwhen the vehicle is raised.

RMake sure that no persons are present inthe vehicle when the vehicle is raised.

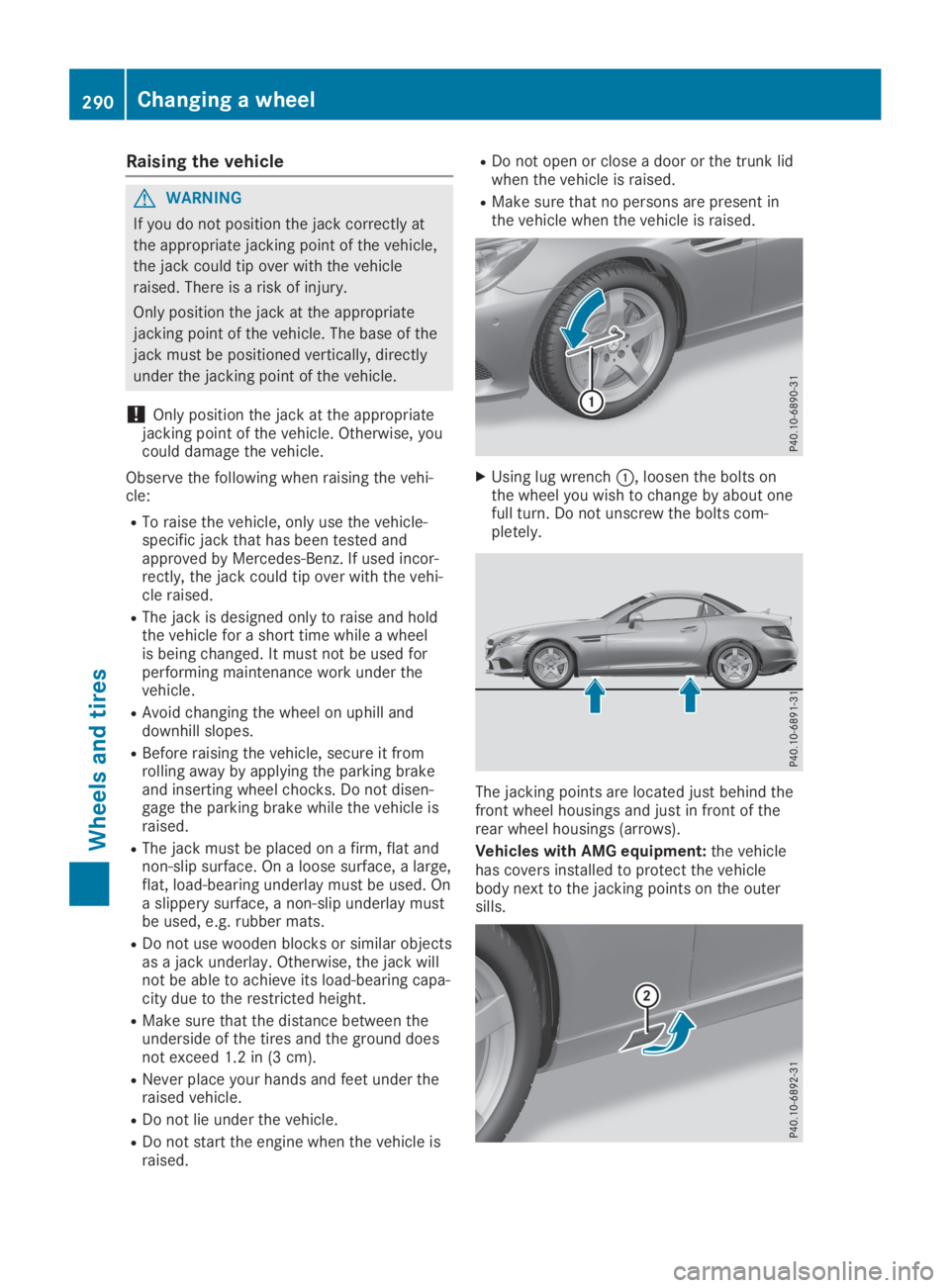

XUsing lug wrench�C, loosen the bolts onthe wheel you wish to change by about onefull turn. Do not unscrew the bolts com-pletely.

The jacking points are located just behind thefront wheel housings and just in front of therear wheel housings (arrows).

Vehicles with AMG equipment:the vehiclehas covers installed to protect the vehiclebody next to the jacking points on the outersills.

290Changing a wheel

Wheels and tires

Page 294 of 306

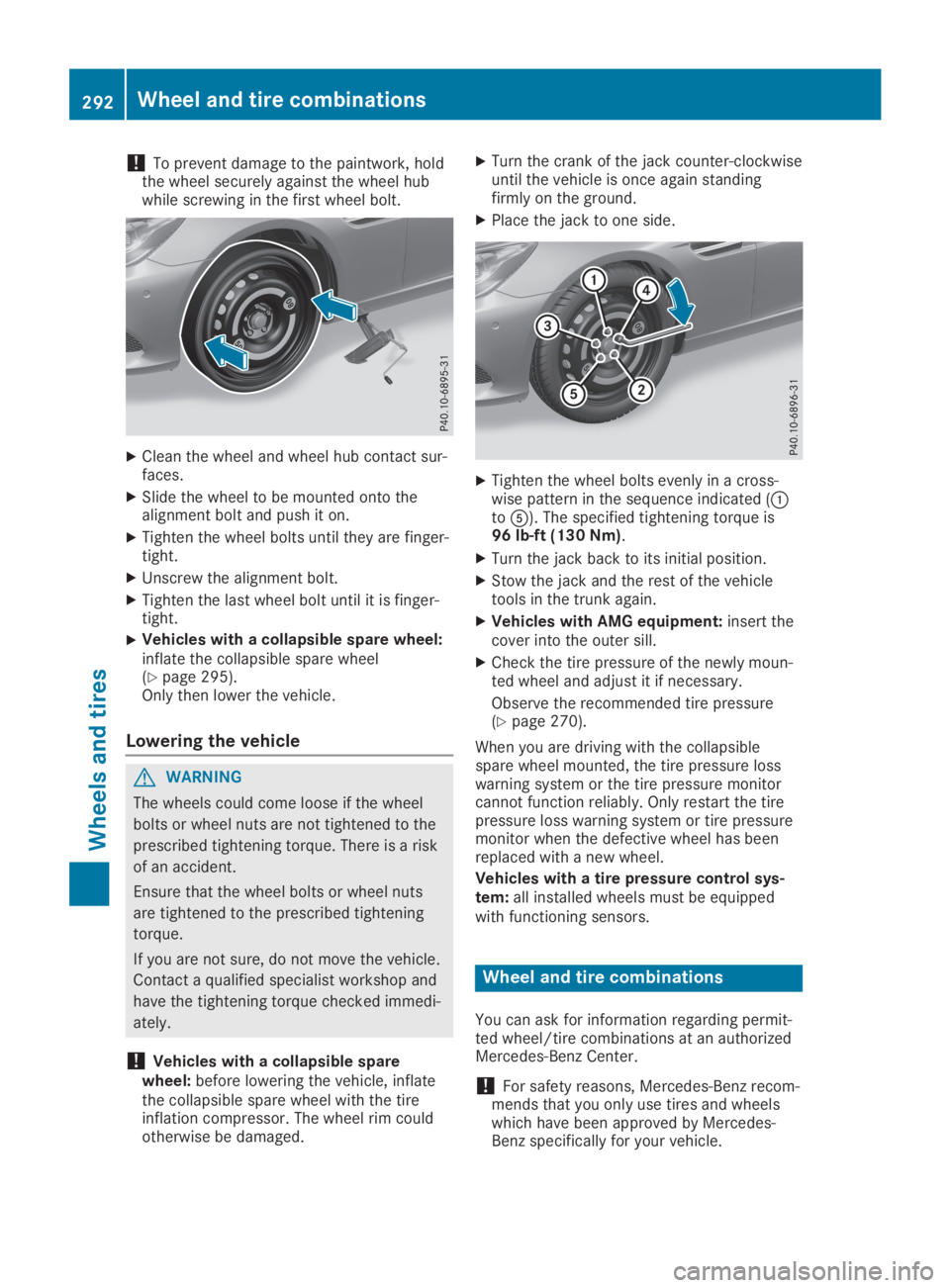

!To prevent damage to the paintwork, holdthe wheel securely against the wheel hubwhile screwing in the first wheel bolt.

XClean the wheel and wheel hub contact sur-faces.

XSlide the wheel to be mounted onto thealignment bolt and push it on.

XTighten the wheel bolts until they are finger-tight.

XUnscrew the alignment bolt.

XTighten the last wheel bolt until it is finger-tight.

XVehicles with a collapsible spare wheel:inflate the collapsible spare wheel(Ypage 295).Only then lower the vehicle.

Lowering the vehicle

GWARNING

The wheels could come loose if the wheel

bolts or wheel nuts are not tightened to the

prescribed tightening torque. There is a risk

of an accident.

Ensure that the wheel bolts or wheel nuts

are tightened to the prescribed tightening

torque.

If you are not sure, do not move the vehicle.

Contact a qualified specialist workshop and

have the tightening torque checked immedi-

ately.

!Vehicles with a collapsible sparewheel:before lowering the vehicle, inflatethe collapsible spare wheel with the tireinflation compressor. The wheel rim couldotherwise be damaged.

XTurn the crank of the jack counter-clockwiseuntil the vehicle is once again standingfirmly on the ground.

XPlace the jack to one side.

XTighten the wheel bolts evenly in a cross-wise pattern in the sequence indicated (�Cto�