MERCEDES-BENZ SLK-CLASS ROADSTER 2014 Owners Manual

Manufacturer: MERCEDES-BENZ, Model Year: 2014, Model line: SLK-CLASS ROADSTER, Model: MERCEDES-BENZ SLK-CLASS ROADSTER 2014Pages: 356, PDF Size: 48.94 MB

Page 331 of 356

Direction of rotation

Tires with a specified direction of rotation

have additional benefits, e.g. if there is a risk

of hydroplaning. You will only gain these

benefits if the correct direction of rotation is

maintained.

An arrow on the sidewall of the tire indicates

its correct direction of rotation. Storing wheels

Store wheels that are not being used in a cool,

dry and preferably dark place. Protect the

tires from oil, grease, gasoline and diesel. Cleaning the wheels

G

WARNING

The water jet from a circular jet nozzle (dirt

blasters) can cause invisible exterior damage

to the tires or chassis components.

Components damaged in this way may fail

unexpectedly. There is a risk of an accident.

Do not use power washers with circular jet

nozzles to clean the vehicle. Have damaged

tires or chassis components replaced

immediately. Mounting a wheel

Preparing the vehicle X

Stop the vehicle on solid, non-slippery and

level ground.

X Apply the electric parking brake manually.

X Bring the front wheels into the straight-

ahead position.

X Vehicles with manual transmission:

fully depress the clutch pedal and engage

first or reverse gear.

X Vehicles with automatic transmission:

move the selector lever to P.

X Switch off the engine. X

Vehicles without KEYLESS-GO: remove

the SmartKey from the ignition lock.

X Vehicles with KEYLESS-GO: open the

driver's door.

The on-board electronics now have status

0. This is the same as the SmartKey having

been removed.

X Vehicles with KEYLESS-GO: remove the

Start/Stop button from the ignition lock

(Y page 139).

X If included in the vehicle equipment,

remove the tire-change tool kit from the

vehicle.

X Secure the vehicle to prevent it from rolling

away.

i Due to differences in vehicle equipment,

not all vehicles are equipped with a tire-

change tool kit. For information on which

tools are required to perform a wheel

change on your vehicle, consult an

authorized Mercedes-Benz Center.

Necessary wheel-changing tools can

include, for example:

R Jack

R Wheel chock

R Lug wrench

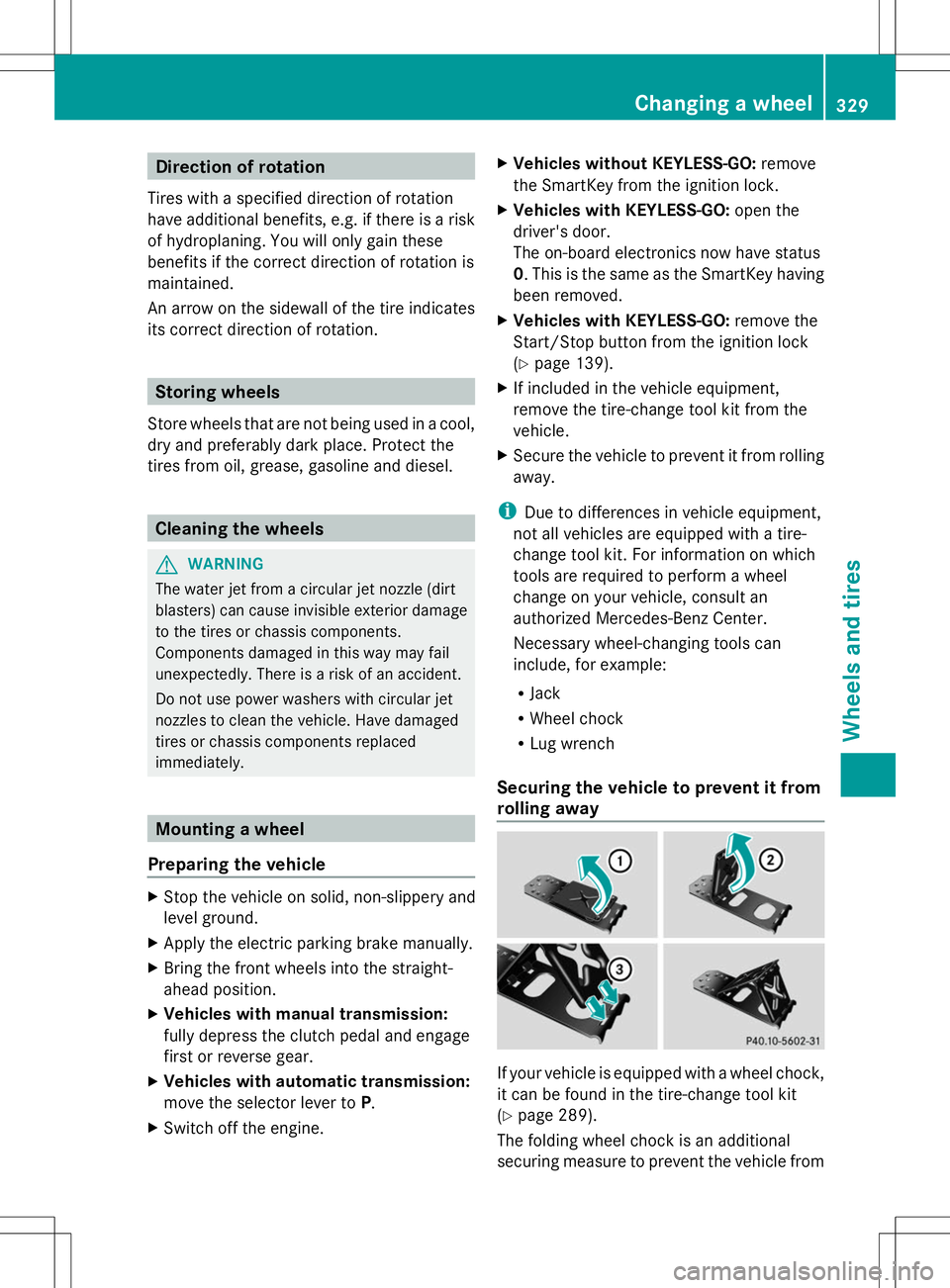

Securing the vehicle to prevent it from

rolling away If your vehicle is equipped with a wheel chock,

it can be found in the tire-change tool kit

(Y

page 289).

The folding wheel chock is an additional

securing measure to prevent the vehicle from Changing a wheel

329Wheels andtires Z

Page 332 of 356

rolling away, for example when changing a

wheel.

X Fold both plates upwards :.

X Fold out lower plate ;.

X Guide the lugs on the lower plate fully into

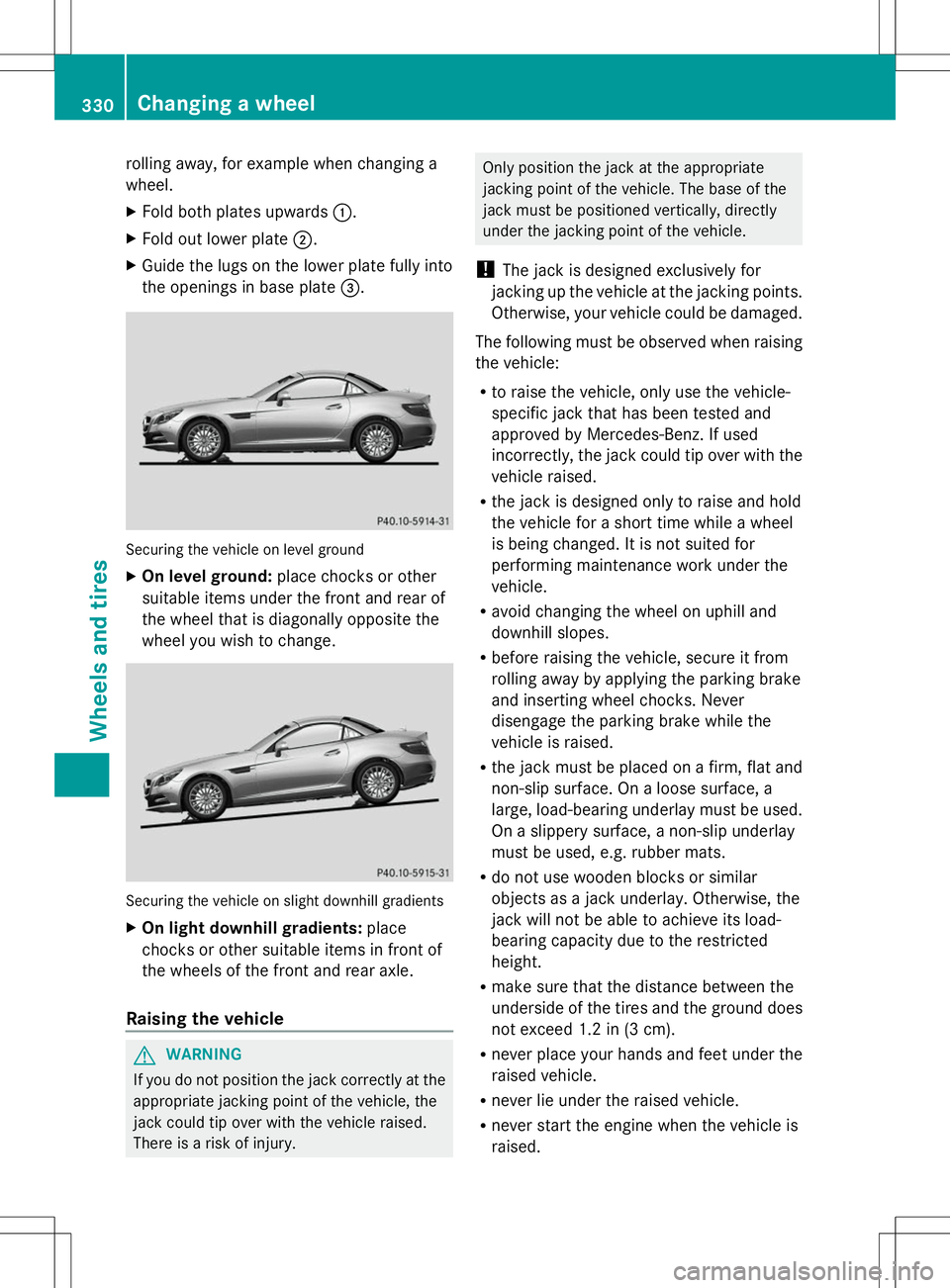

the openings in base plate =.Securing the vehicle on level ground

X

On level ground: place chocks or other

suitable items under the front and rear of

the wheel that is diagonally opposite the

wheel you wish to change. Securing the vehicle on slight downhill gradients

X On light downhill gradients: place

chocks or other suitable items in front of

the wheels of the front and rear axle.

Raising the vehicle G

WARNING

If you do not position the jack correctly at the

appropriate jacking point of the vehicle, the

jack could tip over with the vehicle raised.

There is a risk of injury. Only position the jack at the appropriate

jacking point of the vehicle. The base of the

jack must be positioned vertically, directly

under the jacking point of the vehicle.

! The jack is designed exclusively for

jacking up the vehicle at the jacking points.

Otherwise, your vehicle could be damaged.

The following must be observed when raising

the vehicle:

R to raise the vehicle, only use the vehicle-

specific jack that has been tested and

approved by Mercedes-Benz. If used

incorrectly, the jack could tip over with the

vehicle raised.

R the jack is designed only to raise and hold

the vehicle for a short time while a wheel

is being changed. It is not suited for

performing maintenance work under the

vehicle.

R avoid changing the wheel on uphill and

downhill slopes.

R before raising the vehicle, secure it from

rolling away by applying the parking brake

and inserting wheel chocks. Never

disengage the parking brake while the

vehicle is raised.

R the jack must be placed on a firm, flat and

non-slip surface. On a loose surface, a

large, load-bearing underlay must be used.

On a slippery surface, a non-slip underlay

must be used, e.g. rubber mats.

R do not use wooden blocks or similar

objects as a jack underlay. Otherwise, the

jack will not be able to achieve its load-

bearing capacity due to the restricted

height.

R make sure that the distance between the

underside of the tires and the ground does

not exceed 1.2 in (3 cm).

R never place your hands and feet under the

raised vehicle.

R never lie under the raised vehicle.

R never start the engine when the vehicle is

raised. 330

Changing a wheelWheels and tires

Page 333 of 356

R

never open or close a door or the trunk lid

when the vehicle is raised.

R make sure that no persons are present in

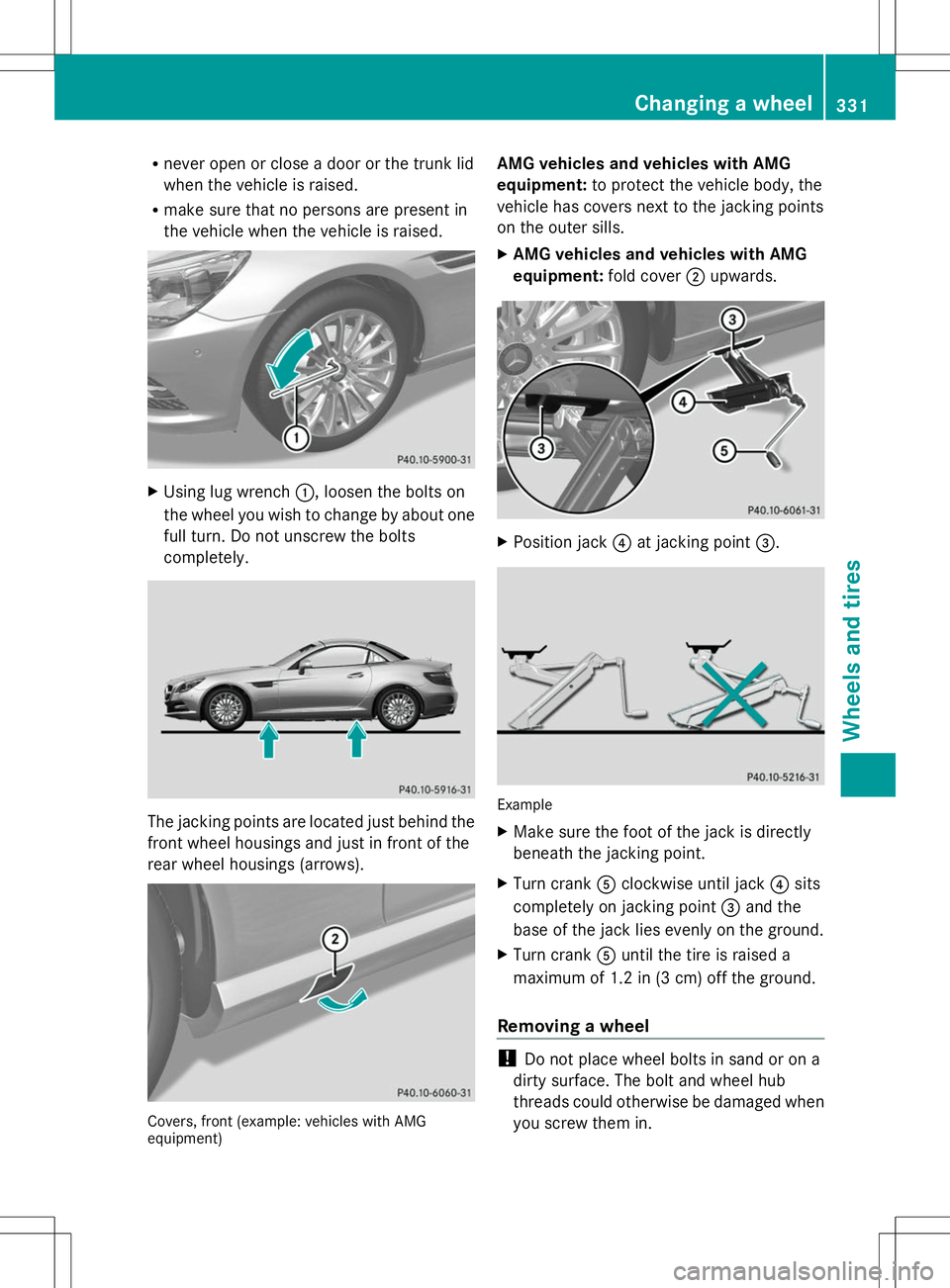

the vehicle when the vehicle is raised. X

Using lug wrench :, loosen the bolts on

the wheel you wish to change by about one

full turn. Do not unscrew the bolts

completely. The jacking points are located just behind the

front wheel housings and just in front of the

rear wheel housings (arrows). Covers, front (example: vehicles with AMG

equipment) AMG vehicles and vehicles with AMG

equipment:

to protect the vehicle body, the

vehicle has covers next to the jacking points

on the outer sills.

X AMG vehicles and vehicles with AMG

equipment: fold cover;upwards. X

Position jack ?at jacking point =. Example

X

Make sure the foot of the jack is directly

beneath the jacking point.

X Turn crank Aclockwise until jack ?sits

completely on jacking point =and the

base of the jack lies evenly on the ground.

X Turn crank Auntil the tire is raised a

maximum of 1.2 in (3 cm) off the ground.

Removing a wheel !

Do not place wheel bolts in sand or on a

dirty surface. The bolt and wheel hub

threads could otherwise be damaged when

you screw them in. Changing a wheel

331Wheels and tires Z

Page 334 of 356

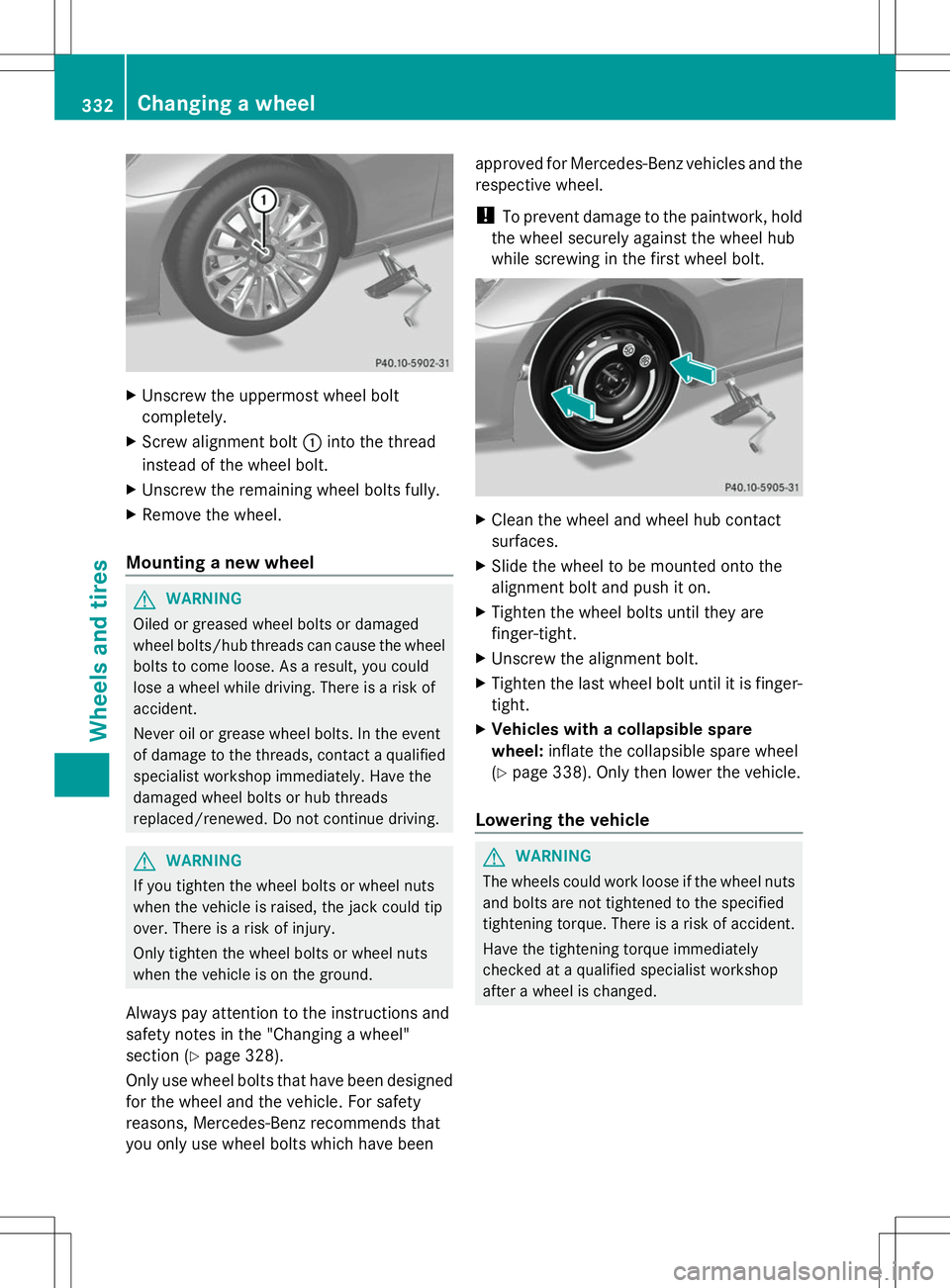

X

Unscrew the uppermost wheel bolt

completely.

X Screw alignment bolt :into the thread

instead of the wheel bolt.

X Unscrew the remaining wheel bolts fully.

X Remove the wheel.

Mounting a new wheel G

WARNING

Oiled or greased wheel bolts or damaged

wheel bolts/hub threads can cause the wheel

bolts to come loose. As a result, you could

lose a wheel while driving. There is a risk of

accident.

Never oil or grease wheel bolts. In the event

of damage to the threads, contact a qualified

specialist workshop immediately. Have the

damaged wheel bolts or hub threads

replaced/renewed. Do not continue driving. G

WARNING

If you tighten the wheel bolts or wheel nuts

when the vehicle is raised, the jack could tip

over. There is a risk of injury.

Only tighten the wheel bolts or wheel nuts

when the vehicle is on the ground.

Always pay attention to the instructions and

safety notes in the "Changing a wheel"

section (Y page 328).

Only use wheel bolts that have been designed

for the wheel and the vehicle. For safety

reasons, Mercedes-Benz recommends that

you only use wheel bolts which have been approved for Mercedes-Benz vehicles and the

respective wheel.

!

To prevent damage to the paintwork, hold

the wheel securely against the wheel hub

while screwing in the first wheel bolt. X

Clean the wheel and wheel hub contact

surfaces.

X Slide the wheel to be mounted onto the

alignment bolt and push it on.

X Tighten the wheel bolts until they are

finger-tight.

X Unscrew the alignment bolt.

X Tighten the last wheel bolt until it is finger-

tight.

X Vehicles with a collapsible spare

wheel: inflate the collapsible spare wheel

(Y page 338). Only then lower the vehicle.

Lowering the vehicle G

WARNING

The wheels could work loose if the wheel nuts

and bolts are not tightened to the specified

tightening torque. There is a risk of accident.

Have the tightening torque immediately

checked at a qualified specialist workshop

after a wheel is changed. 332

Changing a wheelWheels and tires

Page 335 of 356

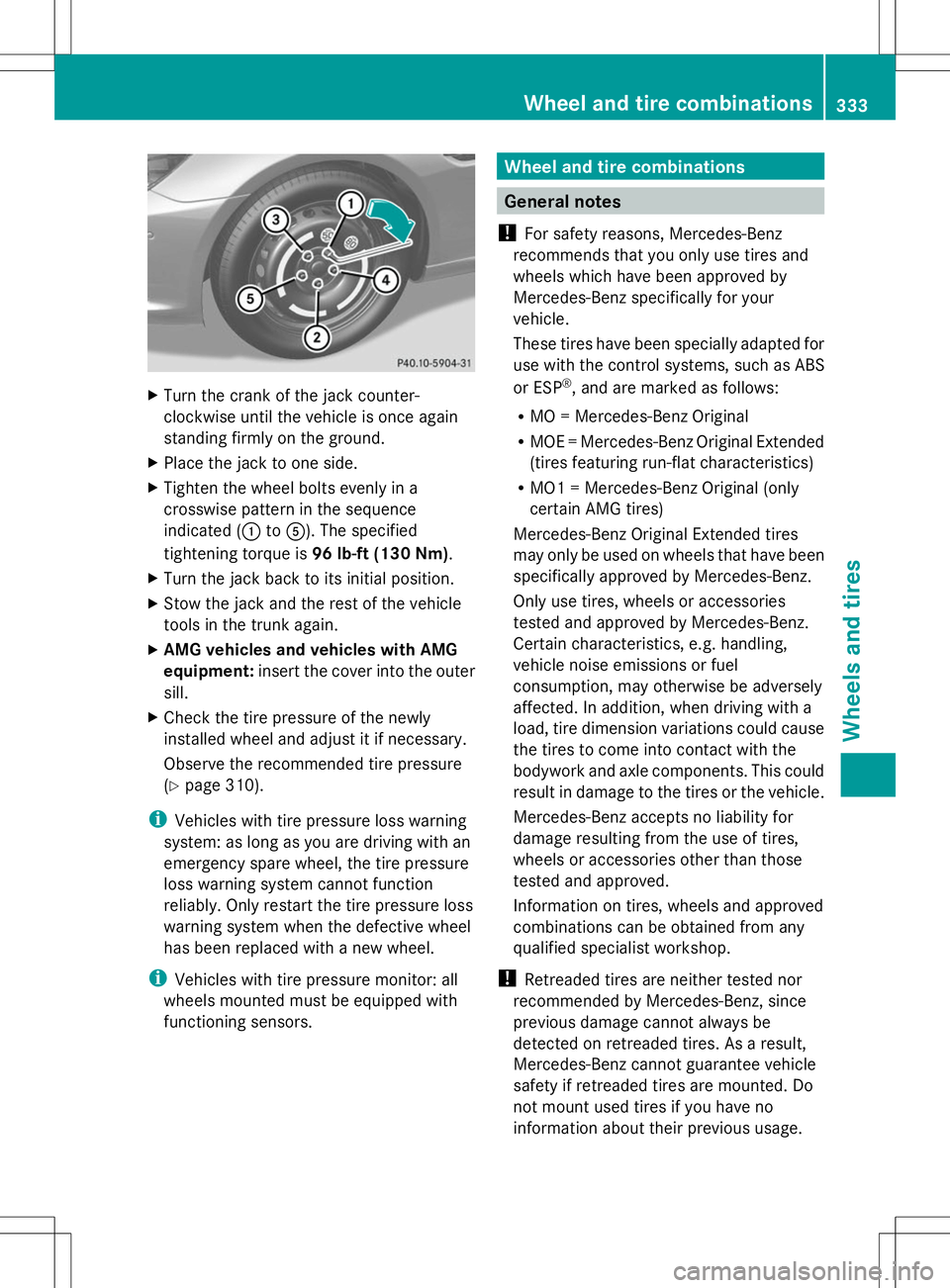

X

Turn the crank of the jack counter-

clockwise until the vehicle is once again

standing firmly on the ground.

X Place the jack to one side.

X Tighten the wheel bolts evenly in a

crosswise pattern in the sequence

indicated (: toA). The specified

tightening torque is 96 lb-ft (130 Nm).

X Turn the jack back to its initial position.

X Stow the jack and the rest of the vehicle

tools in the trunk again.

X AMG vehicles and vehicles with AMG

equipment: insert the cover into the outer

sill.

X Check the tire pressure of the newly

installed wheel and adjust it if necessary.

Observe the recommended tire pressure

(Y page 310).

i Vehicles with tire pressure loss warning

system: as long as you are driving with an

emergency spare wheel, the tire pressure

loss warning system cannot function

reliably. Only restart the tire pressure loss

warning system when the defective wheel

has been replaced with a new wheel.

i Vehicles with tire pressure monitor: all

wheels mounted must be equipped with

functioning sensors. Wheel and tire combinations

General notes

! For safety reasons, Mercedes-Benz

recommends that you only use tires and

wheels which have been approved by

Mercedes-Benz specifically for your

vehicle.

These tires have been specially adapted for

use with the control systems, such as ABS

or ESP ®

, and are marked as follows:

R MO = Mercedes-Benz Original

R MOE = Mercedes-Benz Original Extended

(tires featuring run-flat characteristics)

R MO1 = Mercedes-Benz Original (only

certain AMG tires)

Mercedes-Benz Original Extended tires

may only be used on wheels that have been

specifically approved by Mercedes-Benz.

Only use tires, wheels or accessories

tested and approved by Mercedes-Benz.

Certain characteristics, e.g. handling,

vehicle noise emissions or fuel

consumption, may otherwise be adversely

affected. In addition, when driving with a

load, tire dimension variations could cause

the tires to come into contact with the

bodywork and axle components. This could

result in damage to the tires or the vehicle.

Mercedes-Benz accepts no liability for

damage resulting from the use of tires,

wheels or accessories other than those

tested and approved.

Information on tires, wheels and approved

combinations can be obtained from any

qualified specialist workshop.

! Retreaded tires are neither tested nor

recommended by Mercedes-Benz, since

previous damage cannot always be

detected on retreaded tires. As a result,

Mercedes-Benz cannot guarantee vehicle

safety if retreaded tires are mounted. Do

not mount used tires if you have no

information about their previous usage. Wheel and tire combinations

333Wheels and tires Z

Page 336 of 356

Overview of abbreviations used in the

following tire tables:

R BA: both axles

R FA: front axle

R RA: rear axle

The recommended pressures for various

operating conditions can be found:

R on the Tire and Loading Information placard

with the recommended tire pressures on

the B-pillar on the driver's side

R in the tire pressure table on the inside of

the fuel filler flap

Observe the notes on recommended tire

pressures under various operating conditions

(Y page 310).

Check tire pressures regularly, and only when

the tires are cold. Comply with the

maintenance recommendations of the tire

manufacturer in the vehicle document wallet.

Notes on the vehicle equipment – always

equip the vehicle with:

R tires of the same size on a given axle (left/

right)

R the same type of tires at a given time

(summer tires, winter tires, MOExtended

tires)

Exception: it is permissible to install a

different type or make in the event of a flat

tire. Observe the "MOExtended tires (tires

with run-flat characteristics" section

(Y page 290).

Vehicles equipped with MOExtended tires are

not equipped with a TIREFIT kit at the factory.

It is therefore recommended that you

additionally equip your vehicle with a TIREFIT

kit if you mount tires that do not feature run-

flat properties, e.g. winter tires. A TIREFIT kit

may be obtained from a qualified specialist

workshop.

i Not all wheel and tire combinations are

available at the factory for all countries.

i The following pages contain information

on approved wheel rims and tire sizes for

equipping your vehicle with winter tires. Winter tires are not available at the factory

as standard equipment or optional extras.

If you want to equip your vehicle with

approved winter tires, it may be necessary

to obtain wheel rims in the corresponding

size. The size of the approved winter tires

may differ from the standard tires. This is

dependent on the model and the

equipment installed at the factory.

The tires and wheel rims, as well as further

information, can be obtained at a qualified

specialist workshop.334

Wheel and tire combinationsWheels and tires

Page 337 of 356

Tires

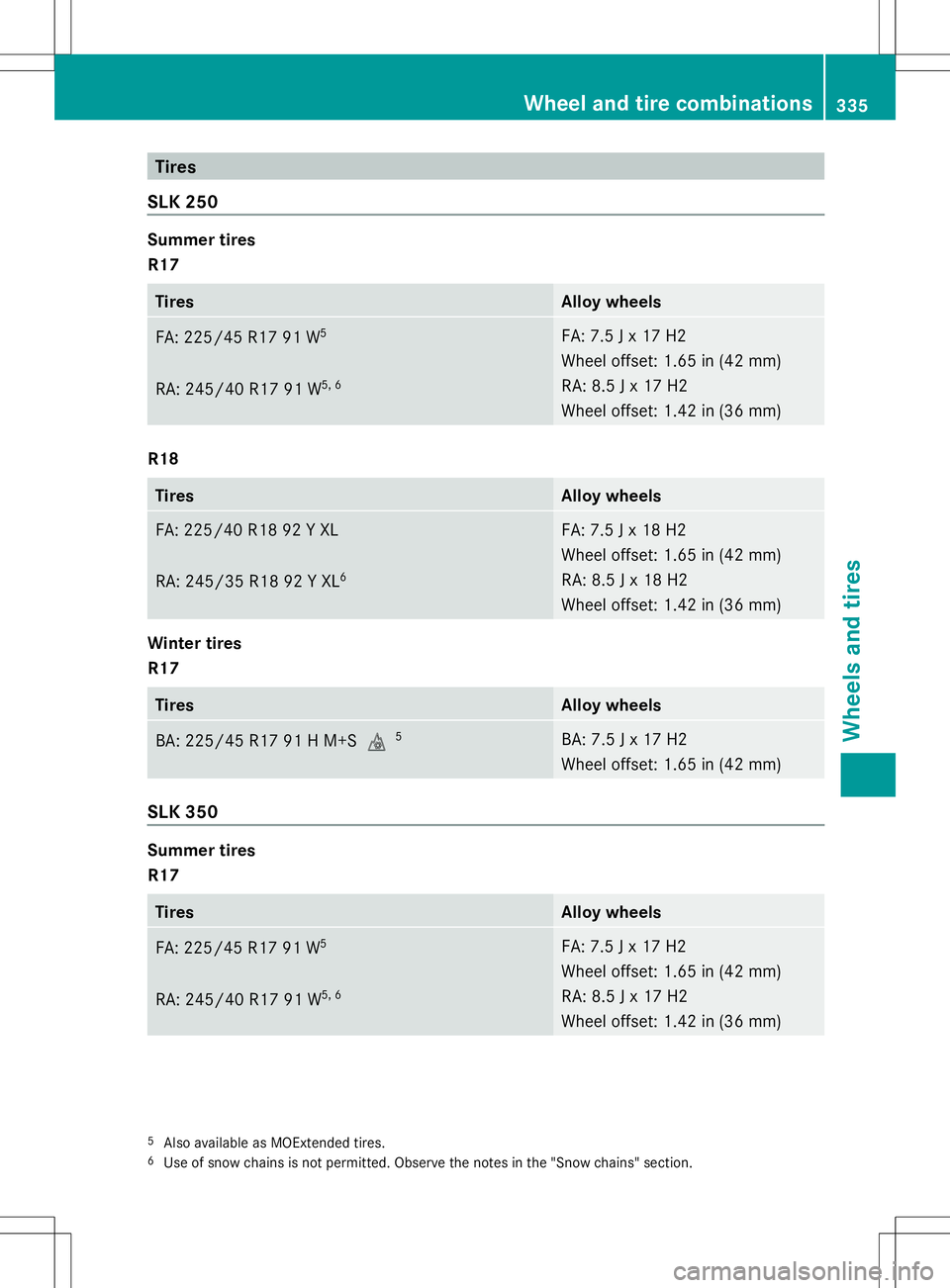

SLK 250 Summer tires

R17

Tires Alloy wheels

FA: 225/4

5 R17 91 W 5

RA : 245/40 R17 91 W 5, 6 FA: 7.5 J x 17 H2

Wheel offset: 1.65 in (42 mm)

RA: 8.5 J x 17 H2

Wheel offset: 1.42 in (36 mm)

R18

Tires Alloy wheels

FA: 225/40 R18 92 Y XL

RA: 245/35 R18 92 Y XL

6 FA: 7.5 J x 18 H2

Wheel offset: 1.65 in (42 mm)

RA: 8.5 J x 18 H2

Wheel offset: 1.42 in (36 mm)

Winter tires

R17

Tires Alloy wheels

BA: 225/45 R17 91 H M+S

i5 BA: 7.5 J x 17 H2

Wheel offset: 1.65 in (42 mm)

SLK 350

Summer tires

R17

Tires Alloy wheels

FA: 225/45 R17 91 W

5

RA: 245/40 R17 91 W 5, 6 FA: 7.5 J x 17 H2

Wheel offset: 1.65 in (42 mm)

RA: 8.5 J x 17 H2

Wheel offset: 1.42 in (36 mm)

5

Also available as MOExtended tires.

6 Use of snow chains is not permitted. Observe the notes in the "Snow chains" section. Wheel and tire combinations

335Wheels and tires Z

Page 338 of 356

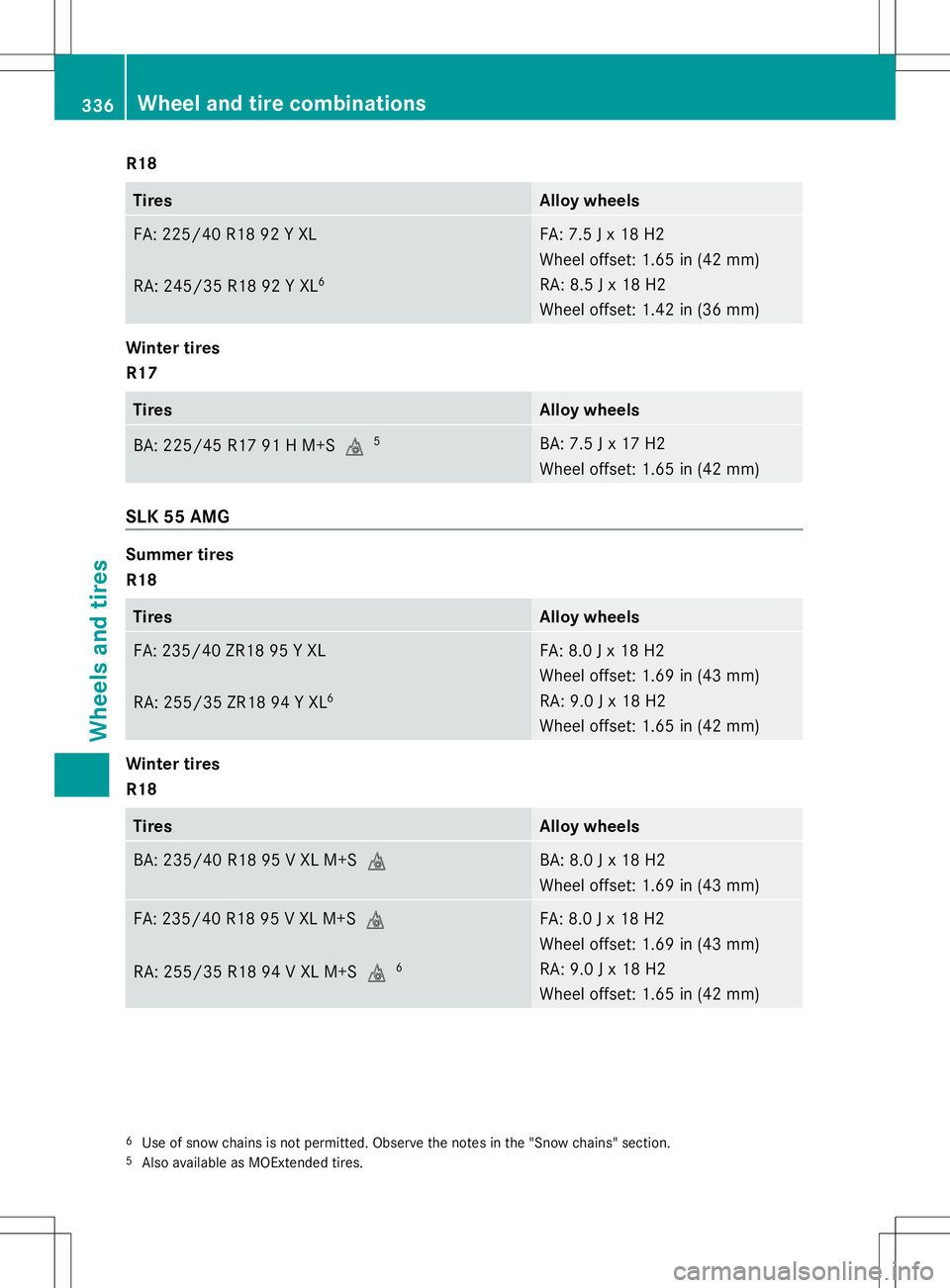

R18

Tires Alloy wheels

FA: 225/40 R18 92 Y XL

RA: 245/35 R18 92 Y XL

6 FA: 7.5 J x 18 H2

Wheel offset: 1.65 in (42 mm)

RA: 8.5 J x 18 H2

Wheel offset: 1.42 in (36 mm)

Winter tires

R17

Tires Alloy wheels

BA: 225/45 R17 91 H M+S

i5 BA: 7.5 J x 17 H2

Wheel offset: 1.65 in (42 mm)

SLK 55 AMG

Summer tires

R18

Tires Alloy wheels

FA: 235/40 ZR18 95 Y XL

RA: 255/35 ZR18 94 Y XL

6 FA: 8.0 J x 18 H2

Wheel offset: 1.69 in (43 mm)

RA: 9.0 J x 18 H2

Wheel offset: 1.65 in (42 mm)

Winter tires

R18

Tires Alloy wheels

BA: 235/40 R18 95 V XL M+S

i BA: 8.0 J x 18 H2

Wheel offset: 1.69 in (43 mm)

FA: 235/40 R18 95 V XL M+S

i

RA: 255/35 R18 94 V XL M+S i6 FA: 8.0 J x 18 H2

Wheel offset: 1.69 in (43 mm)

RA: 9.0 J x 18 H2

Wheel offset: 1.65 in (42 mm)

6

Use of snow chains is not permitted. Observe the notes in the "Snow chains" section.

5 Also available as MOExtended tires. 336

Wheel and tire combinationsWheels and tires

Page 339 of 356

Emergency spare wheel

Important safety notes

G

WARNING

The wheel or tire size as well as the tire type

of the spare wheel or emergency spare wheel

and the wheel to be replaced may differ.

Mounting an emergency spare wheel may

severely impair the driving characteristics.

There is a risk of an accident.

To avoid hazardous situations:

R adapt your driving style accordingly and

drive carefully.

R never mount more than one spare wheel or

emergency spare wheel that differs in size.

R only use a spare wheel or emergency spare

wheel of a different size briefly.

R do not switch ESP ®

off.

R have a spare wheel or emergency spare

wheel of a different size replaced at the

nearest qualified specialist workshop.

Observe that the wheel and tire dimensions

as well as the tire type must be correct.

When using an emergency spare wheel or

spare wheel of a different size, you must not

exceed the maximum speed of 50 mph

(80 km/h).

Snow chains must not be mounted on

emergency spare wheels. General notes

You should regularly check the pressure of

the emergency spare wheel, particularly prior

to long trips, and correct the pressure as

necessary (Y page 310). The applicable value

is found on the wheel or under "Technical

data" ( Ypage 340).

An emergency spare wheel may also be

mounted against the direction of rotation.

Observe the time restriction on use as well as

the speed limitation specified on the

emergency spare wheel. Replace the tires after six years at the latest,

regardless of wear. This also applies to the

emergency spare wheel.

i

When you are driving with the collapsible

spare wheel mounted, the tire pressure

loss warning system or the tire pressure

monitor cannot function reliably. Only

restart the tire pressure loss warning

system/the tire pressure monitor when the

damaged wheel has been replaced with a

new wheel.

Vehicles with tire pressure monitor:

after mounting an emergency spare wheel,

the system may still display the tire

pressure of the removed wheel for a few

minutes. The value displayed for the

mounted emergency spare wheel is not the

same as the current tire pressure of the

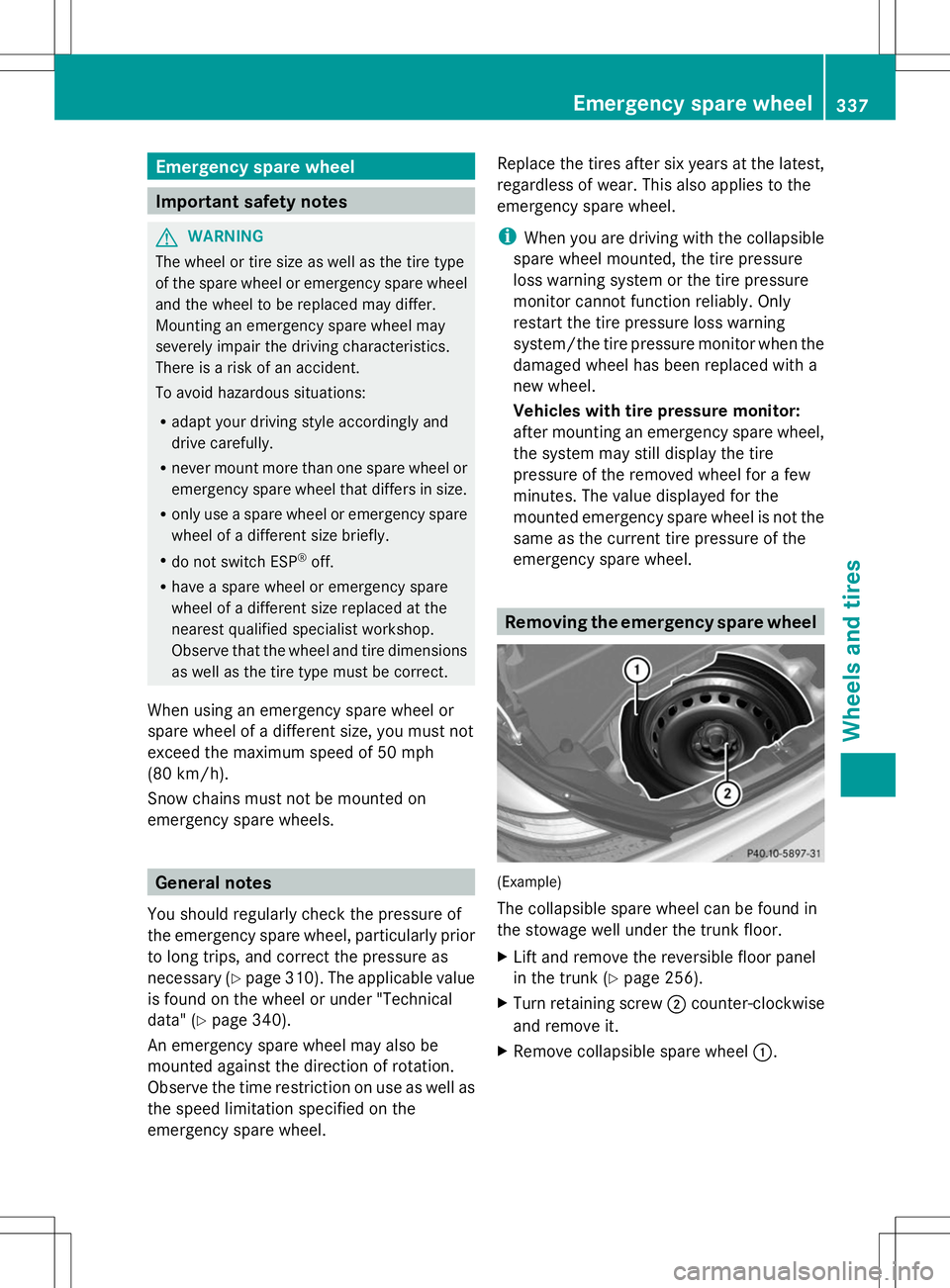

emergency spare wheel. Removing the emergency spare wheel

(Example)

The collapsible spare wheel can be found in

the stowage well under the trunk floor.

X

Lift and remove the reversible floor panel

in the trunk (Y page 256).

X Turn retaining screw ;counter-clockwise

and remove it.

X Remove collapsible spare wheel :. Emergency spare wheel

337Wheels and tires Z

Page 340 of 356

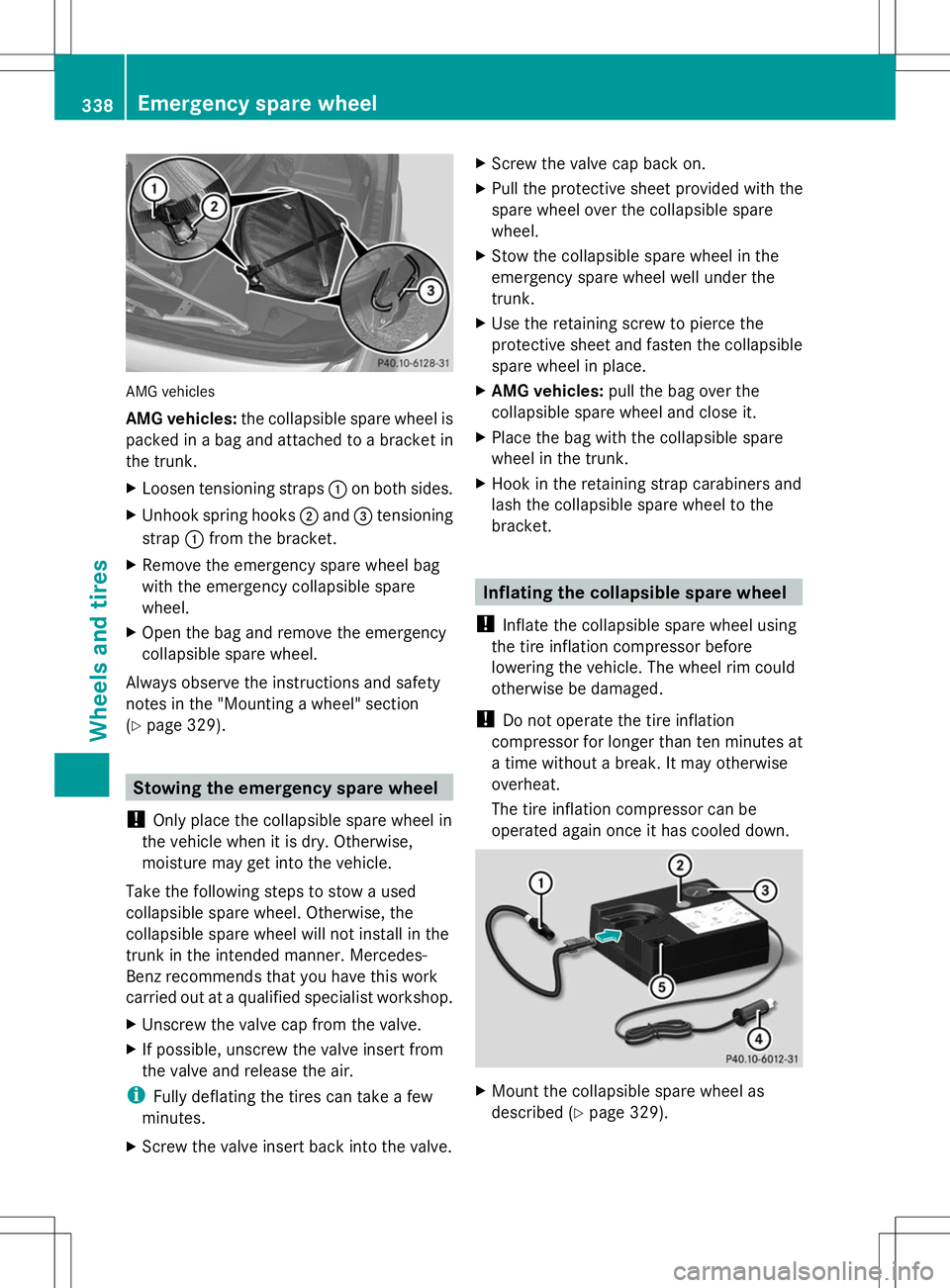

AMG vehicles

AMG vehicles:

the collapsible spare wheel is

packed in a bag and attached to a bracket in

the trunk.

X Loosen tensioning straps :on both sides.

X Unhook spring hooks ;and =tensioning

strap :from the bracket.

X Remove the emergency spare wheel bag

with the emergency collapsible spare

wheel.

X Open the bag and remove the emergency

collapsible spare wheel.

Always observe the instructions and safety

notes in the "Mounting a wheel" section

(Y page 329). Stowing the emergency spare wheel

! Only place the collapsible spare wheel in

the vehicle when it is dry. Otherwise,

moisture may get into the vehicle.

Take the following steps to stow a used

collapsible spare wheel. Otherwise, the

collapsible spare wheel will not install in the

trunk in the intended manner. Mercedes-

Benz recommends that you have this work

carried out at a qualified specialist workshop.

X Unscrew the valve cap from the valve.

X If possible, unscrew the valve insert from

the valve and release the air.

i Fully deflating the tires can take a few

minutes.

X Screw the valve insert back into the valve. X

Screw the valve cap back on.

X Pull the protective sheet provided with the

spare wheel over the collapsible spare

wheel.

X Stow the collapsible spare wheel in the

emergency spare wheel well under the

trunk.

X Use the retaining screw to pierce the

protective sheet and fasten the collapsible

spare wheel in place.

X AMG vehicles: pull the bag over the

collapsible spare wheel and close it.

X Place the bag with the collapsible spare

wheel in the trunk.

X Hook in the retaining strap carabiners and

lash the collapsible spare wheel to the

bracket. Inflating the collapsible spare wheel

! Inflate the collapsible spare wheel using

the tire inflation compressor before

lowering the vehicle. The wheel rim could

otherwise be damaged.

! Do not operate the tire inflation

compressor for longer than ten minutes at

a time without a break. It may otherwise

overheat.

The tire inflation compressor can be

operated again once it has cooled down. X

Mount the collapsible spare wheel as

described (Y page 329).338

Emergency spare wheelWheels and tires