clock MERCEDES-BENZ SLS AMG 2013 User Guide

[x] Cancel search | Manufacturer: MERCEDES-BENZ, Model Year: 2013, Model line: SLS AMG, Model: MERCEDES-BENZ SLS AMG 2013Pages: 286, PDF Size: 3.26 MB

Page 232 of 286

X

Do not remove any foreign objects which

have penetrated the tire, e.g. screws or

nails.

X Take the TIREFIT kit out of the trunk

(Y page 228). X

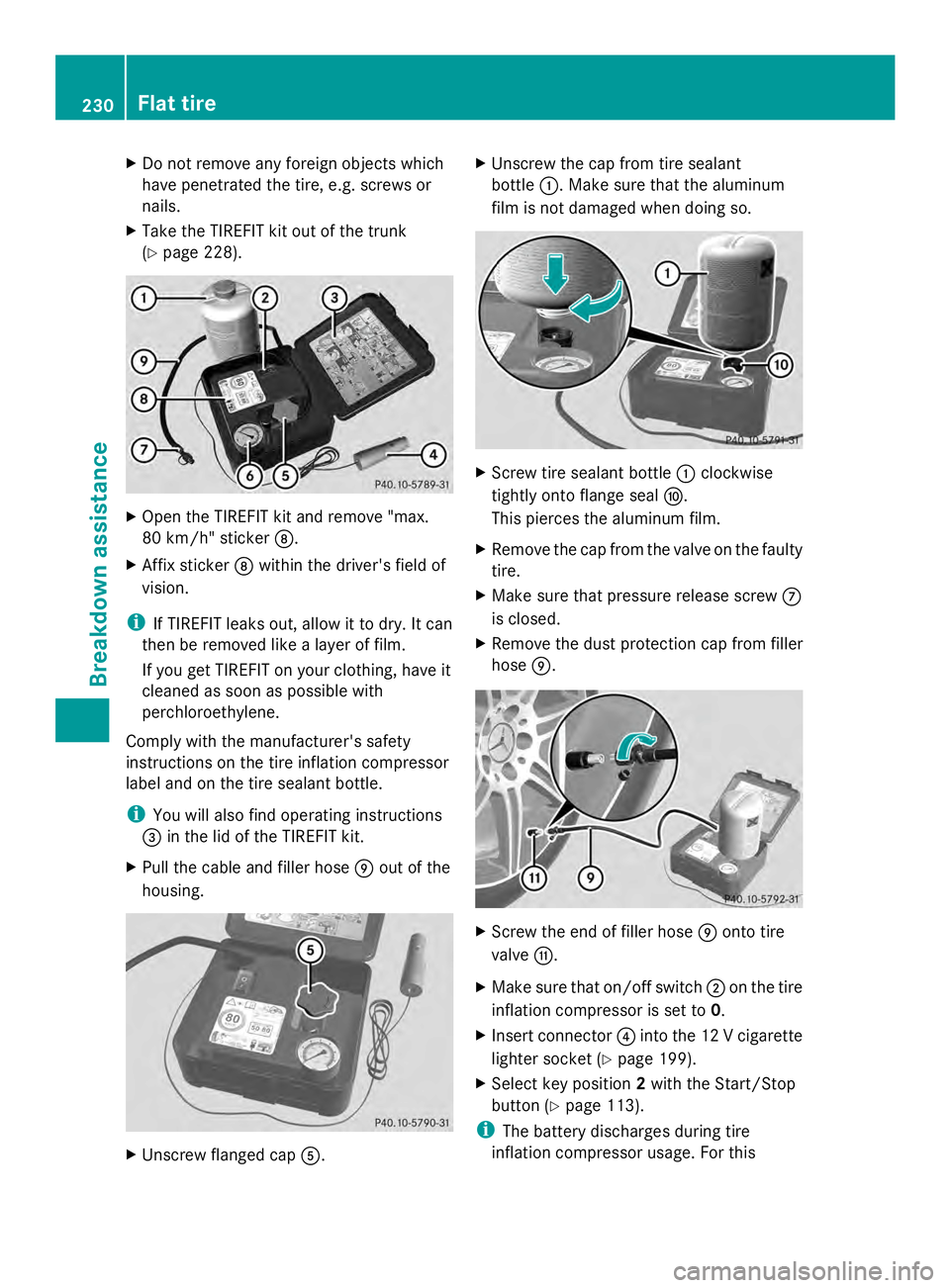

Open the TIREFIT kit and remove "max.

80 km/h" sticker 006C.

X Affix sticker 006Cwithin the driver's field of

vision.

i If TIREFIT leaks out, allow it to dry. It can

then be removed like a layer of film.

If you get TIREFIT on your clothing, have it

cleaned as soon as possible with

perchloroethylene.

Comply with the manufacturer's safety

instructions on the tire inflation compressor

label and on the tire sealant bottle.

i You will also find operating instructions

0087 in the lid of the TIREFIT kit.

X Pull the cable and filler hose 006Dout of the

housing. X

Unscrew flanged cap 0083. X

Unscrew the cap from tire sealant

bottle 0043. Make sure that the aluminum

film is not damaged when doing so. X

Screw tire sealant bottle 0043clockwise

tightly onto flange seal 006E.

This pierces the aluminum film.

X Remove the cap from the valve on the faulty

tire.

X Make sure that pressure release screw 006B

is closed.

X Remove the dust protection cap from filler

hose 006D. X

Screw the end of filler hose 006Donto tire

valve 006F.

X Make sure that on/off switch 0044on the tire

inflation compressor is set to 0.

X Insert connector 0085into the 12 V cigarette

lighter socket ( Ypage 199).

X Select key position 2with the Start/Stop

button ( Ypage 113).

i The battery discharges during tire

inflation compressor usage. For this 230

Flat tireBreakdown assistance

Page 236 of 286

Make sure that the ground on which the

vehicle is standing and where you place the

jack is solid, level and not slippery. If

necessary, use a large underlay. On slippery

surfaces, such as tiled floors, you should use

a non-slip underlay, for example a rubber mat.

Do not use wooden blocks or similar objects

as a jack underlay. Otherwise, the jack may

not be able to achieve its load-bearing

capacity if it is not at its full height.

Never start the engine when the vehicle is

raised.

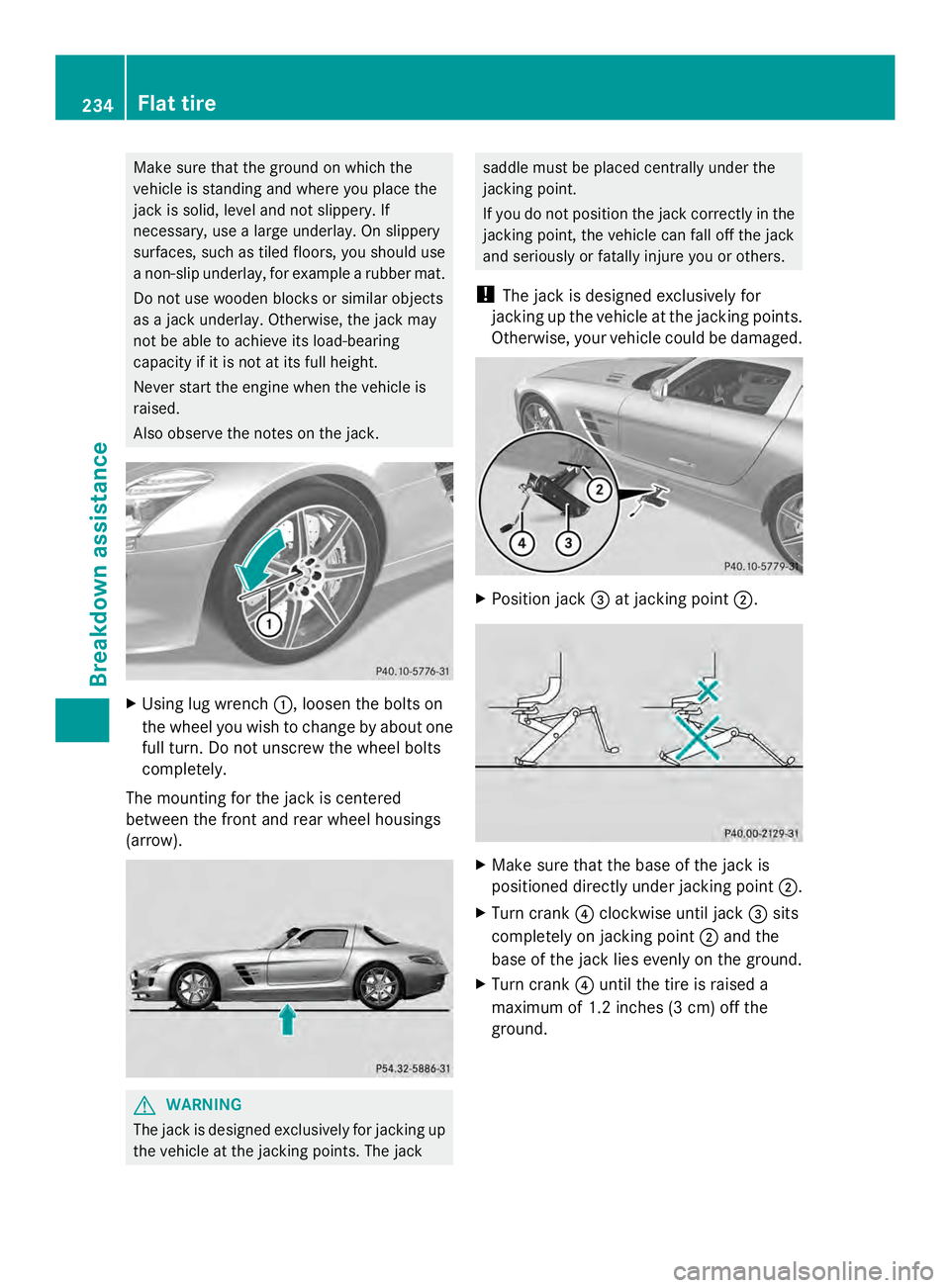

Also observe the notes on the jack. X

Using lug wrench 0043, loosen the bolts on

the wheel you wish to change by about one

full turn. Do not unscrew the wheel bolts

completely.

The mounting for the jack is centered

between the front and rear wheel housings

(arrow). G

WARNING

The jack is designed exclusively for jacking up

the vehicle at the jacking points. The jack saddle must be placed centrally under the

jacking point.

If you do not position the jack correctly in the

jacking point, the vehicle can fall off the jack

and seriously or fatally injure you or others.

! The jack is designed exclusively for

jacking up the vehicle at the jacking points.

Otherwise, your vehicle could be damaged. X

Position jack 0087at jacking point 0044. X

Make sure that the base of the jack is

positioned directly under jacking point 0044.

X Turn crank 0085clockwise until jack 0087sits

completely on jacking point 0044and the

base of the jack lies evenly on the ground.

X Turn crank 0085until the tire is raised a

maximum of 1.2 inches (3 cm) off the

ground. 234

Flat tireBreakdown assistance

Page 238 of 286

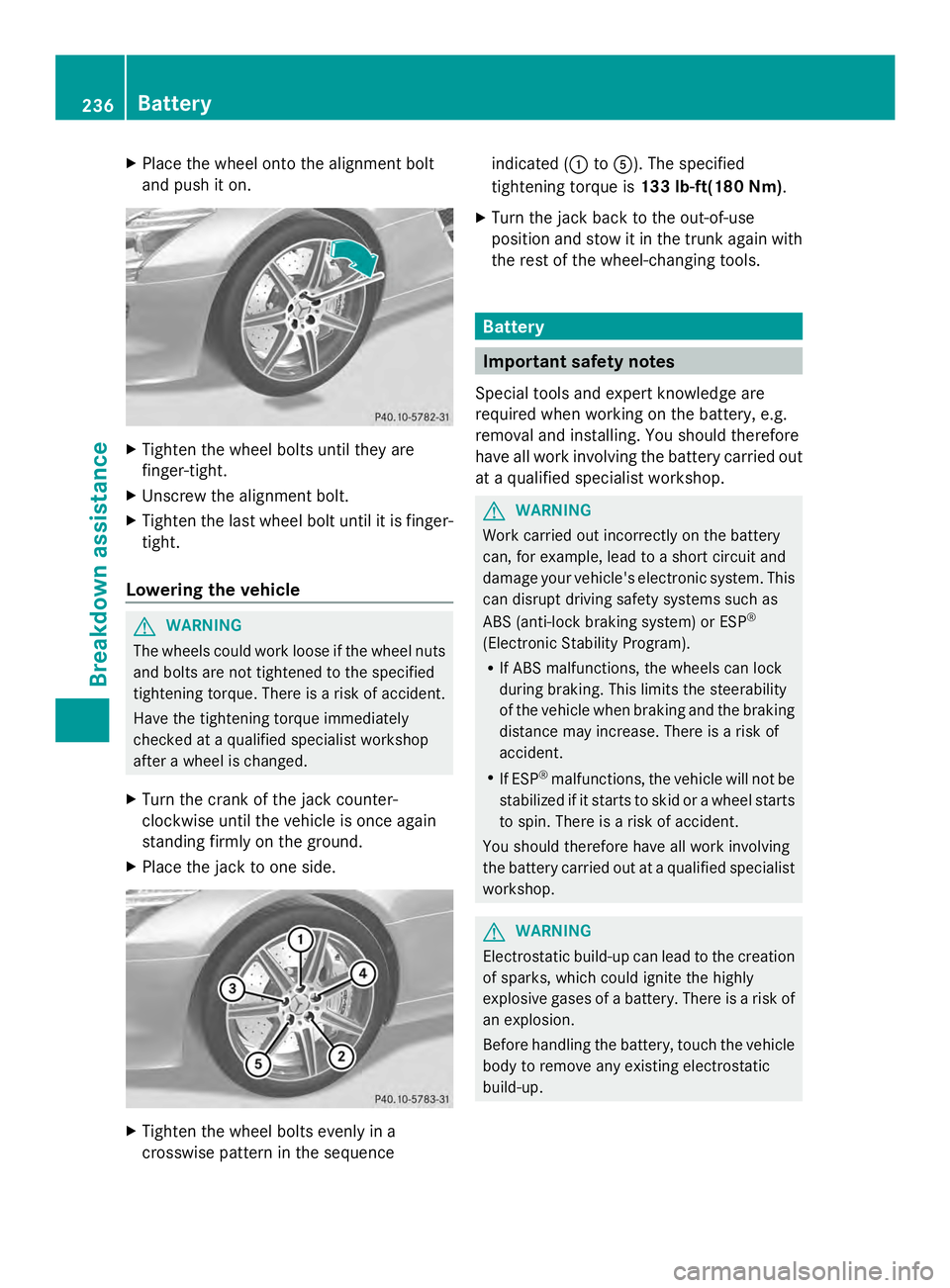

X

Place the wheel onto the alignment bolt

and push it on. X

Tighten the wheel bolts until they are

finger-tight.

X Unscrew the alignment bolt.

X Tighten the last wheel bolt until it is finger-

tight.

Lowering the vehicle G

WARNING

The wheels could work loose if the wheel nuts

and bolts are not tightened to the specified

tightening torque. There is a risk of accident.

Have the tightening torque immediately

checked at a qualified specialist workshop

after a wheel is changed.

X Turn the crank of the jack counter-

clockwise until the vehicle is once again

standing firmly on the ground.

X Place the jack to one side. X

Tighten the wheel bolts evenly in a

crosswise pattern in the sequence indicated (0043

to0083). The specified

tightening torque is 133 lb-ft(180 Nm).

X Turn the jack back to the out-of-use

position and stow it in the trunk again with

the rest of the wheel-changing tools. Battery

Important safety notes

Special tools and expert knowledge are

required when working on the battery, e.g.

removal and installing. You should therefore

have all work involving the battery carried out

at a qualified specialist workshop. G

WARNING

Work carried out incorrectly on the battery

can, for example, lead to a short circuit and

damage your vehicle's electronic system. This

can disrupt driving safety systems such as

ABS (anti-lock braking system) or ESP ®

(Electronic Stability Program).

R If ABS malfunctions, the wheels can lock

during braking. This limits the steerability

of the vehicle when braking and the braking

distance may increase. There is a risk of

accident.

R If ESP ®

malfunctions, the vehicle will not be

stabilized if it starts to skid or a wheel starts

to spin. There is a risk of accident.

You should therefore have all work involving

the battery carried out at a qualified specialist

workshop. G

WARNING

Electrostatic build-up can lead to the creation

of sparks, which could ignite the highly

explosive gases of a battery. There is a risk of

an explosion.

Before handling the battery, touch the vehicle

body to remove any existing electrostatic

build-up. 236

BatteryBreakdown assistance

Page 245 of 286

!

Do not use the towing eye for recovery,

as this could damage the vehicle. If in

doubt, recover the vehicle with a crane.

! You may only tow the vehicle a maximum

distance of 30 miles (50 km). A towing

speed of 30 mph (50 km/h) must not be

exceeded.

For towing distances over 30 miles

(50 km), the vehicle must loaded onto a

transporter.

! Do not tow with sling-type equipment.

This could damage the vehicle.

! Tow-starting the vehicle is not permitted.

The transmission may otherwise be

damaged.

Also observe the following notes:

R If the engine does not start, try jump-

starting it (Y page 240). Tow-starting the

vehicle is not permitted.

R If it is not possible to jump-start the vehicle,

have it transported to the nearest qualified

specialist workshop, e.g. an authorized

Mercedes-Benz Center.

R If the vehicle has transmission damage,

have it transported to a qualified specialist

workshop. Observe the display messages

in the instrument cluster. Installing/removing the towing eye

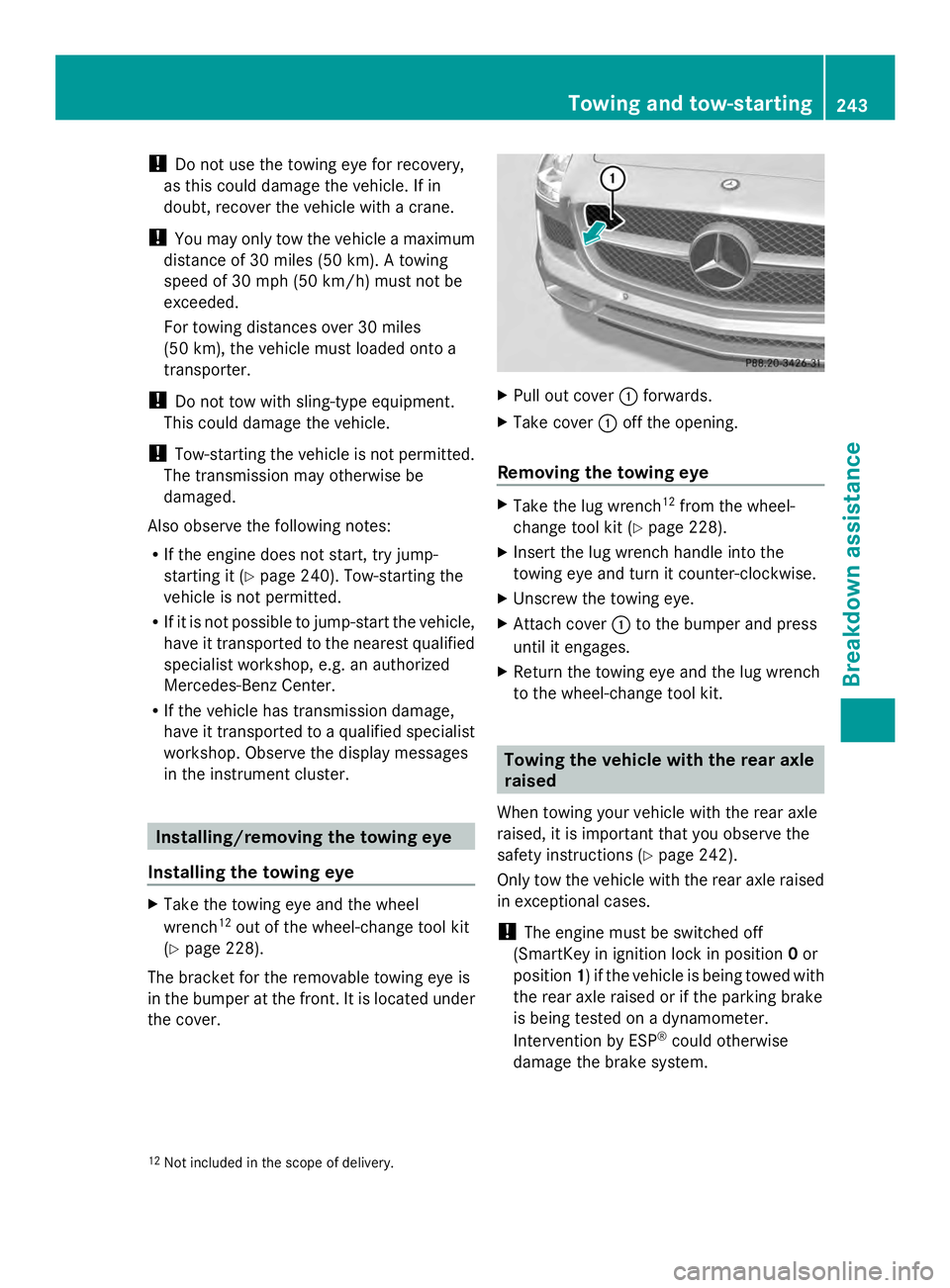

Installing the towing eye X

Take the towing eye and the wheel

wrench 12

out of the wheel-change tool kit

(Y page 228).

The bracket for the removable towing eye is

in the bumper at the front. It is located under

the cover. X

Pull out cover 0043forwards.

X Take cover 0043off the opening.

Removing the towing eye X

Take the lug wrench 12

from the wheel-

change tool kit (Y page 228).

X Insert the lug wrench handle into the

towing eye and turn it counter-clockwise.

X Unscrew the towing eye.

X Attach cover 0043to the bumper and press

until it engages.

X Return the towing eye and the lug wrench

to the wheel-change tool kit. Towing the vehicle with the rear axle

raised

When towing your vehicle with the rear axle

raised, it is important that you observe the

safety instructions (Y page 242).

Only tow the vehicle with the rear axle raised

in exceptional cases.

! The engine must be switched off

(SmartKey in ignition lock in position 0or

position 1) if the vehicle is being towed with

the rear axle raised or if the parking brake

is being tested on a dynamometer.

Intervention by ESP ®

could otherwise

damage the brake system.

12 Not included in the scope of delivery. Towing and tow-starting

243Breakdown assistance Z