reset MERCEDES-BENZ SPRINTER 2005 Service User Guide

[x] Cancel search | Manufacturer: MERCEDES-BENZ, Model Year: 2005, Model line: SPRINTER, Model: MERCEDES-BENZ SPRINTER 2005Pages: 1232, PDF Size: 39.23 MB

Page 792 of 1232

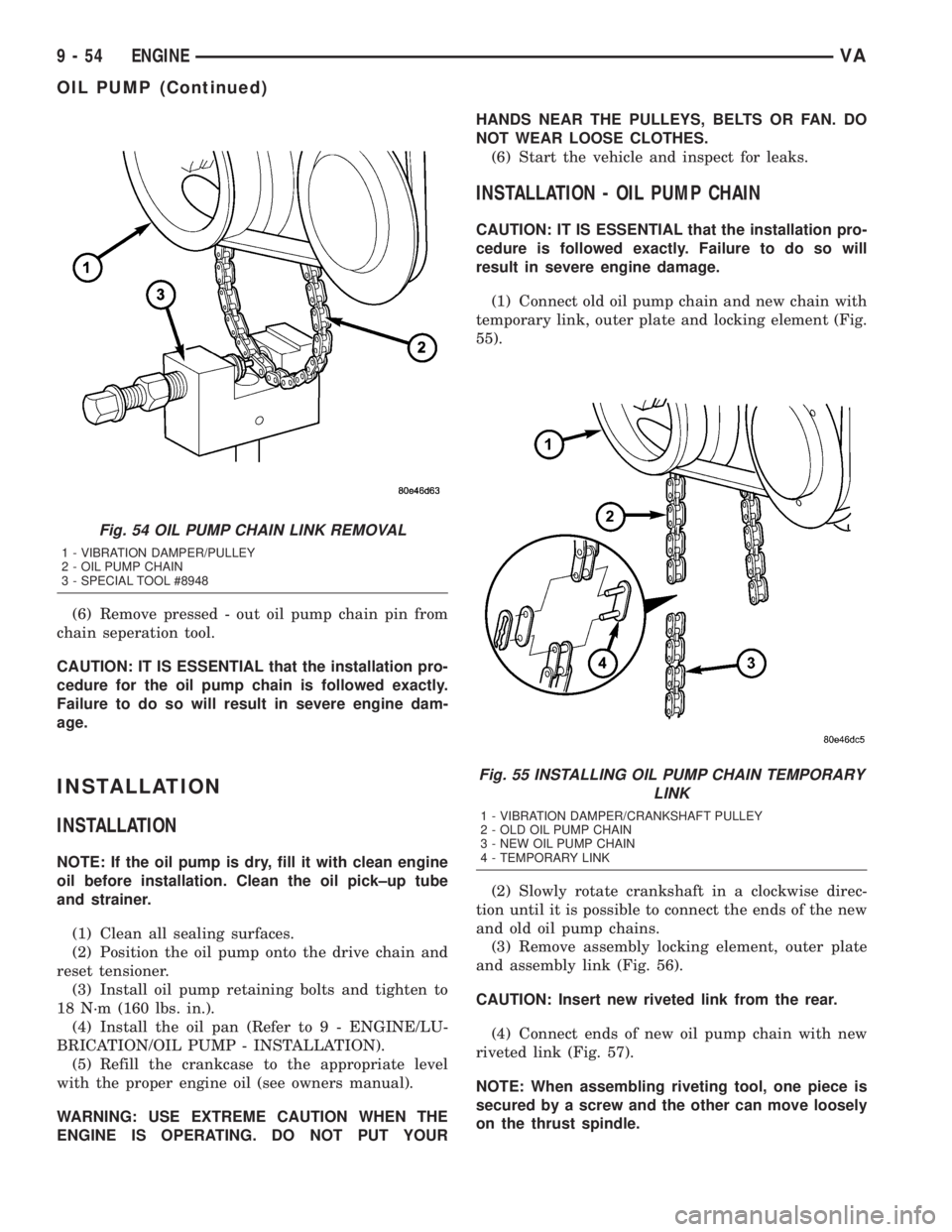

(6) Remove pressed - out oil pump chain pin from

chain seperation tool.

CAUTION: IT IS ESSENTIAL that the installation pro-

cedure for the oil pump chain is followed exactly.

Failure to do so will result in severe engine dam-

age.

INSTALLATION

INSTALLATION

NOTE: If the oil pump is dry, fill it with clean engine

oil before installation. Clean the oil pick±up tube

and strainer.

(1) Clean all sealing surfaces.

(2) Position the oil pump onto the drive chain and

reset tensioner.

(3) Install oil pump retaining bolts and tighten to

18 N´m (160 lbs. in.).

(4) Install the oil pan (Refer to 9 - ENGINE/LU-

BRICATION/OIL PUMP - INSTALLATION).

(5) Refill the crankcase to the appropriate level

with the proper engine oil (see owners manual).

WARNING: USE EXTREME CAUTION WHEN THE

ENGINE IS OPERATING. DO NOT PUT YOURHANDS NEAR THE PULLEYS, BELTS OR FAN. DO

NOT WEAR LOOSE CLOTHES.

(6) Start the vehicle and inspect for leaks.

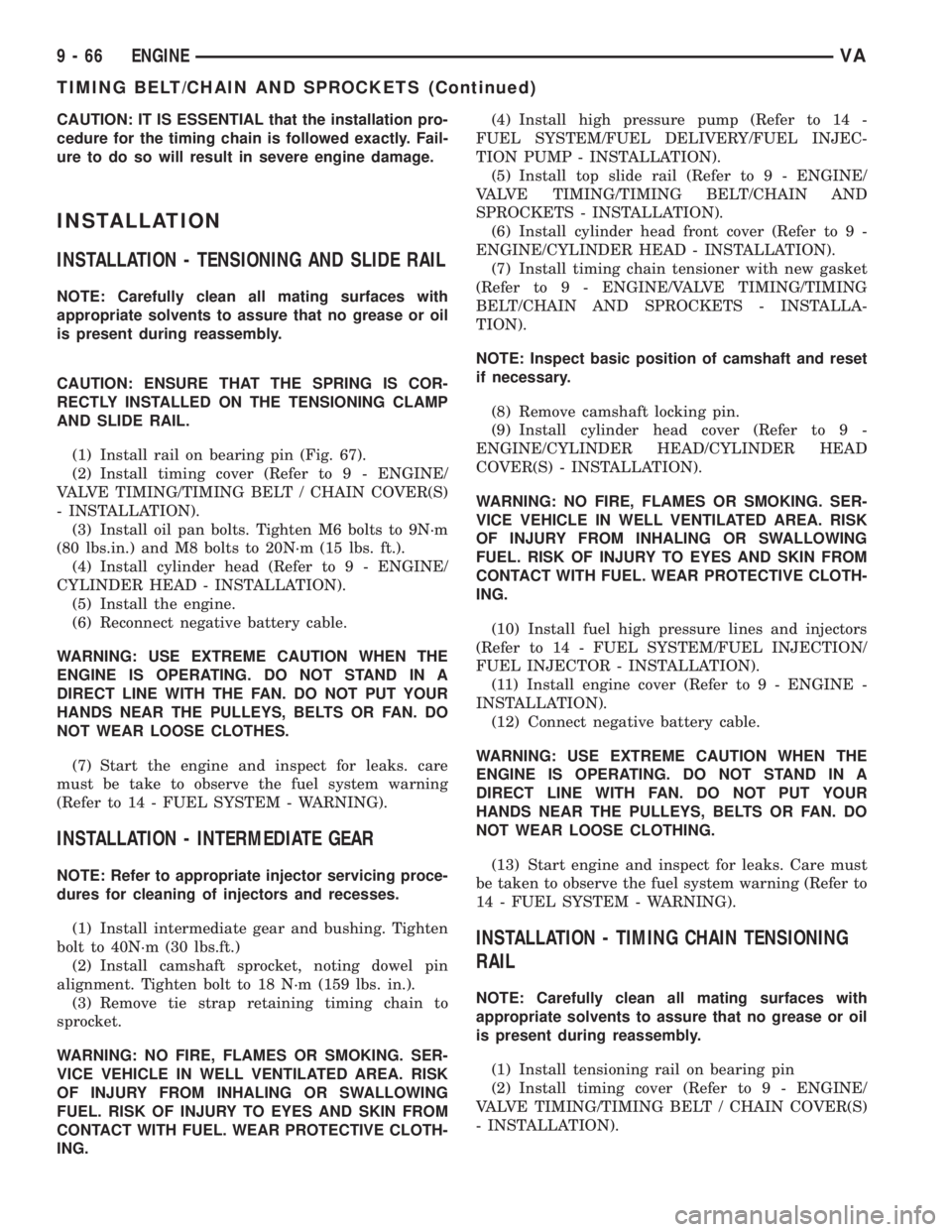

INSTALLATION - OIL PUMP CHAIN

CAUTION: IT IS ESSENTIAL that the installation pro-

cedure is followed exactly. Failure to do so will

result in severe engine damage.

(1) Connect old oil pump chain and new chain with

temporary link, outer plate and locking element (Fig.

55).

(2) Slowly rotate crankshaft in a clockwise direc-

tion until it is possible to connect the ends of the new

and old oil pump chains.

(3) Remove assembly locking element, outer plate

and assembly link (Fig. 56).

CAUTION: Insert new riveted link from the rear.

(4) Connect ends of new oil pump chain with new

riveted link (Fig. 57).

NOTE: When assembling riveting tool, one piece is

secured by a screw and the other can move loosely

on the thrust spindle.

Fig. 54 OIL PUMP CHAIN LINK REMOVAL

1 - VIBRATION DAMPER/PULLEY

2 - OIL PUMP CHAIN

3 - SPECIAL TOOL #8948

Fig. 55 INSTALLING OIL PUMP CHAIN TEMPORARY

LINK

1 - VIBRATION DAMPER/CRANKSHAFT PULLEY

2 - OLD OIL PUMP CHAIN

3 - NEW OIL PUMP CHAIN

4 - TEMPORARY LINK

9 - 54 ENGINEVA

OIL PUMP (Continued)

Page 804 of 1232

CAUTION: IT IS ESSENTIAL that the installation pro-

cedure for the timing chain is followed exactly. Fail-

ure to do so will result in severe engine damage.

INSTALLATION

INSTALLATION - TENSIONING AND SLIDE RAIL

NOTE: Carefully clean all mating surfaces with

appropriate solvents to assure that no grease or oil

is present during reassembly.

CAUTION: ENSURE THAT THE SPRING IS COR-

RECTLY INSTALLED ON THE TENSIONING CLAMP

AND SLIDE RAIL.

(1) Install rail on bearing pin (Fig. 67).

(2) Install timing cover (Refer to 9 - ENGINE/

VALVE TIMING/TIMING BELT / CHAIN COVER(S)

- INSTALLATION).

(3) Install oil pan bolts. Tighten M6 bolts to 9N´m

(80 lbs.in.) and M8 bolts to 20N´m (15 lbs. ft.).

(4) Install cylinder head (Refer to 9 - ENGINE/

CYLINDER HEAD - INSTALLATION).

(5) Install the engine.

(6) Reconnect negative battery cable.

WARNING: USE EXTREME CAUTION WHEN THE

ENGINE IS OPERATING. DO NOT STAND IN A

DIRECT LINE WITH THE FAN. DO NOT PUT YOUR

HANDS NEAR THE PULLEYS, BELTS OR FAN. DO

NOT WEAR LOOSE CLOTHES.

(7) Start the engine and inspect for leaks. care

must be take to observe the fuel system warning

(Refer to 14 - FUEL SYSTEM - WARNING).

INSTALLATION - INTERMEDIATE GEAR

NOTE: Refer to appropriate injector servicing proce-

dures for cleaning of injectors and recesses.

(1) Install intermediate gear and bushing. Tighten

bolt to 40N´m (30 lbs.ft.)

(2) Install camshaft sprocket, noting dowel pin

alignment. Tighten bolt to 18 N´m (159 lbs. in.).

(3) Remove tie strap retaining timing chain to

sprocket.

WARNING: NO FIRE, FLAMES OR SMOKING. SER-

VICE VEHICLE IN WELL VENTILATED AREA. RISK

OF INJURY FROM INHALING OR SWALLOWING

FUEL. RISK OF INJURY TO EYES AND SKIN FROM

CONTACT WITH FUEL. WEAR PROTECTIVE CLOTH-

ING.(4) Install high pressure pump (Refer to 14 -

FUEL SYSTEM/FUEL DELIVERY/FUEL INJEC-

TION PUMP - INSTALLATION).

(5) Install top slide rail (Refer to 9 - ENGINE/

VALVE TIMING/TIMING BELT/CHAIN AND

SPROCKETS - INSTALLATION).

(6) Install cylinder head front cover (Refer to 9 -

ENGINE/CYLINDER HEAD - INSTALLATION).

(7) Install timing chain tensioner with new gasket

(Refer to 9 - ENGINE/VALVE TIMING/TIMING

BELT/CHAIN AND SPROCKETS - INSTALLA-

TION).

NOTE: Inspect basic position of camshaft and reset

if necessary.

(8) Remove camshaft locking pin.

(9) Install cylinder head cover (Refer to 9 -

ENGINE/CYLINDER HEAD/CYLINDER HEAD

COVER(S) - INSTALLATION).

WARNING: NO FIRE, FLAMES OR SMOKING. SER-

VICE VEHICLE IN WELL VENTILATED AREA. RISK

OF INJURY FROM INHALING OR SWALLOWING

FUEL. RISK OF INJURY TO EYES AND SKIN FROM

CONTACT WITH FUEL. WEAR PROTECTIVE CLOTH-

ING.

(10) Install fuel high pressure lines and injectors

(Refer to 14 - FUEL SYSTEM/FUEL INJECTION/

FUEL INJECTOR - INSTALLATION).

(11) Install engine cover (Refer to 9 - ENGINE -

INSTALLATION).

(12) Connect negative battery cable.

WARNING: USE EXTREME CAUTION WHEN THE

ENGINE IS OPERATING. DO NOT STAND IN A

DIRECT LINE WITH FAN. DO NOT PUT YOUR

HANDS NEAR THE PULLEYS, BELTS OR FAN. DO

NOT WEAR LOOSE CLOTHING.

(13) Start engine and inspect for leaks. Care must

be taken to observe the fuel system warning (Refer to

14 - FUEL SYSTEM - WARNING).

INSTALLATION - TIMING CHAIN TENSIONING

RAIL

NOTE: Carefully clean all mating surfaces with

appropriate solvents to assure that no grease or oil

is present during reassembly.

(1) Install tensioning rail on bearing pin

(2) Install timing cover (Refer to 9 - ENGINE/

VALVE TIMING/TIMING BELT / CHAIN COVER(S)

- INSTALLATION).

9 - 66 ENGINEVA

TIMING BELT/CHAIN AND SPROCKETS (Continued)

Page 867 of 1232

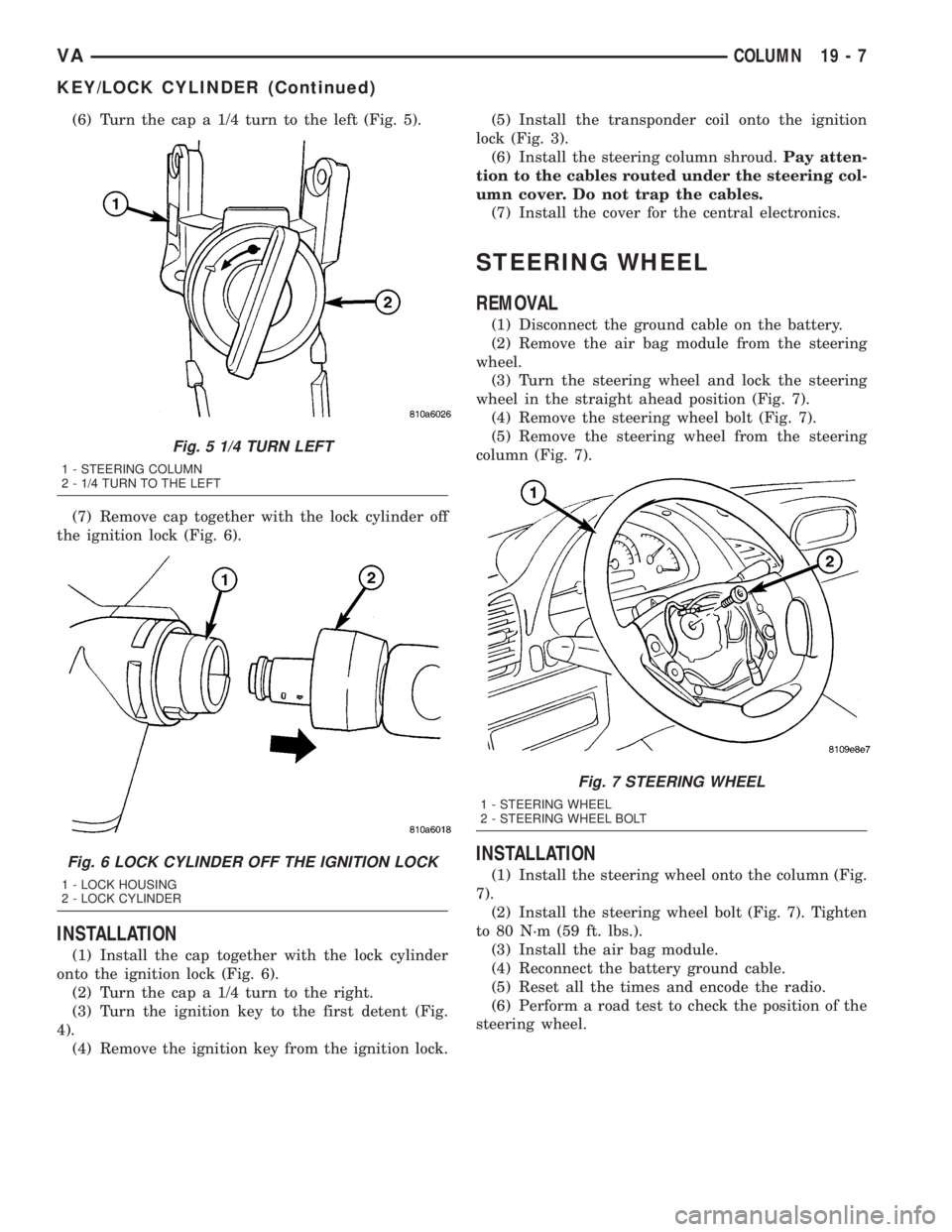

(6) Turn the cap a 1/4 turn to the left (Fig. 5).

(7) Remove cap together with the lock cylinder off

the ignition lock (Fig. 6).

INSTALLATION

(1) Install the cap together with the lock cylinder

onto the ignition lock (Fig. 6).

(2) Turn the cap a 1/4 turn to the right.

(3) Turn the ignition key to the first detent (Fig.

4).

(4) Remove the ignition key from the ignition lock.(5) Install the transponder coil onto the ignition

lock (Fig. 3).

(6) Install the steering column shroud.Pay atten-

tion to the cables routed under the steering col-

umn cover. Do not trap the cables.

(7) Install the cover for the central electronics.

STEERING WHEEL

REMOVAL

(1) Disconnect the ground cable on the battery.

(2) Remove the air bag module from the steering

wheel.

(3) Turn the steering wheel and lock the steering

wheel in the straight ahead position (Fig. 7).

(4) Remove the steering wheel bolt (Fig. 7).

(5) Remove the steering wheel from the steering

column (Fig. 7).

INSTALLATION

(1) Install the steering wheel onto the column (Fig.

7).

(2) Install the steering wheel bolt (Fig. 7). Tighten

to 80 N´m (59 ft. lbs.).

(3) Install the air bag module.

(4) Reconnect the battery ground cable.

(5) Reset all the times and encode the radio.

(6) Perform a road test to check the position of the

steering wheel.

Fig. 5 1/4 TURN LEFT

1 - STEERING COLUMN

2 - 1/4 TURN TO THE LEFT

Fig. 6 LOCK CYLINDER OFF THE IGNITION LOCK

1 - LOCK HOUSING

2 - LOCK CYLINDER

Fig. 7 STEERING WHEEL

1 - STEERING WHEEL

2 - STEERING WHEEL BOLT

VACOLUMN 19 - 7

KEY/LOCK CYLINDER (Continued)

Page 869 of 1232

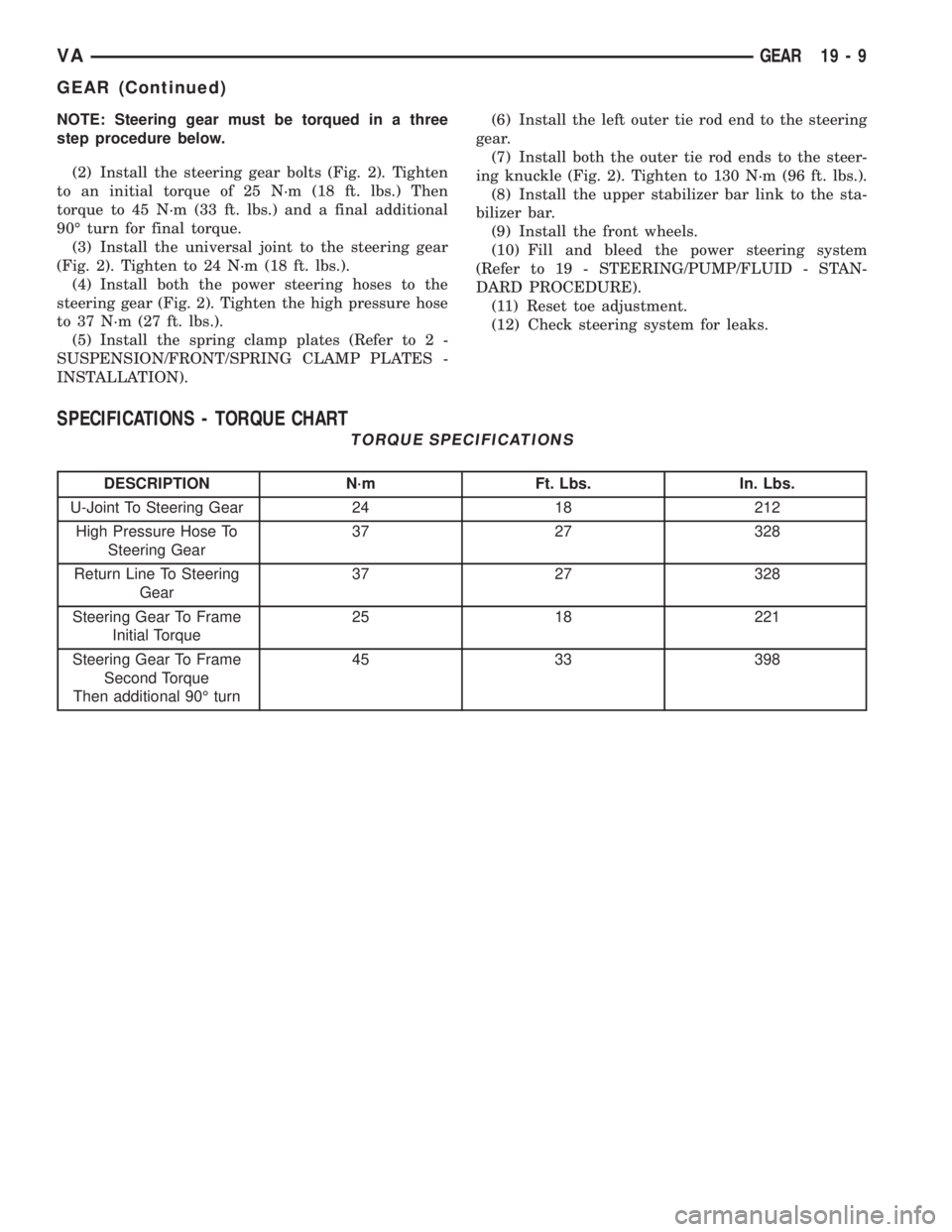

NOTE: Steering gear must be torqued in a three

step procedure below.

(2) Install the steering gear bolts (Fig. 2). Tighten

to an initial torque of 25 N´m (18 ft. lbs.) Then

torque to 45 N´m (33 ft. lbs.) and a final additional

90É turn for final torque.

(3) Install the universal joint to the steering gear

(Fig. 2). Tighten to 24 N´m (18 ft. lbs.).

(4) Install both the power steering hoses to the

steering gear (Fig. 2). Tighten the high pressure hose

to 37 N´m (27 ft. lbs.).

(5) Install the spring clamp plates (Refer to 2 -

SUSPENSION/FRONT/SPRING CLAMP PLATES -

INSTALLATION).(6) Install the left outer tie rod end to the steering

gear.

(7) Install both the outer tie rod ends to the steer-

ing knuckle (Fig. 2). Tighten to 130 N´m (96 ft. lbs.).

(8) Install the upper stabilizer bar link to the sta-

bilizer bar.

(9) Install the front wheels.

(10) Fill and bleed the power steering system

(Refer to 19 - STEERING/PUMP/FLUID - STAN-

DARD PROCEDURE).

(11) Reset toe adjustment.

(12) Check steering system for leaks.

SPECIFICATIONS - TORQUE CHART

TORQUE SPECIFICATIONS

DESCRIPTION N´m Ft. Lbs. In. Lbs.

U-Joint To Steering Gear 24 18 212

High Pressure Hose To

Steering Gear37 27 328

Return Line To Steering

Gear37 27 328

Steering Gear To Frame

Initial Torque25 18 221

Steering Gear To Frame

Second Torque

Then additional 90É turn45 33 398

VAGEAR 19 - 9

GEAR (Continued)

Page 880 of 1232

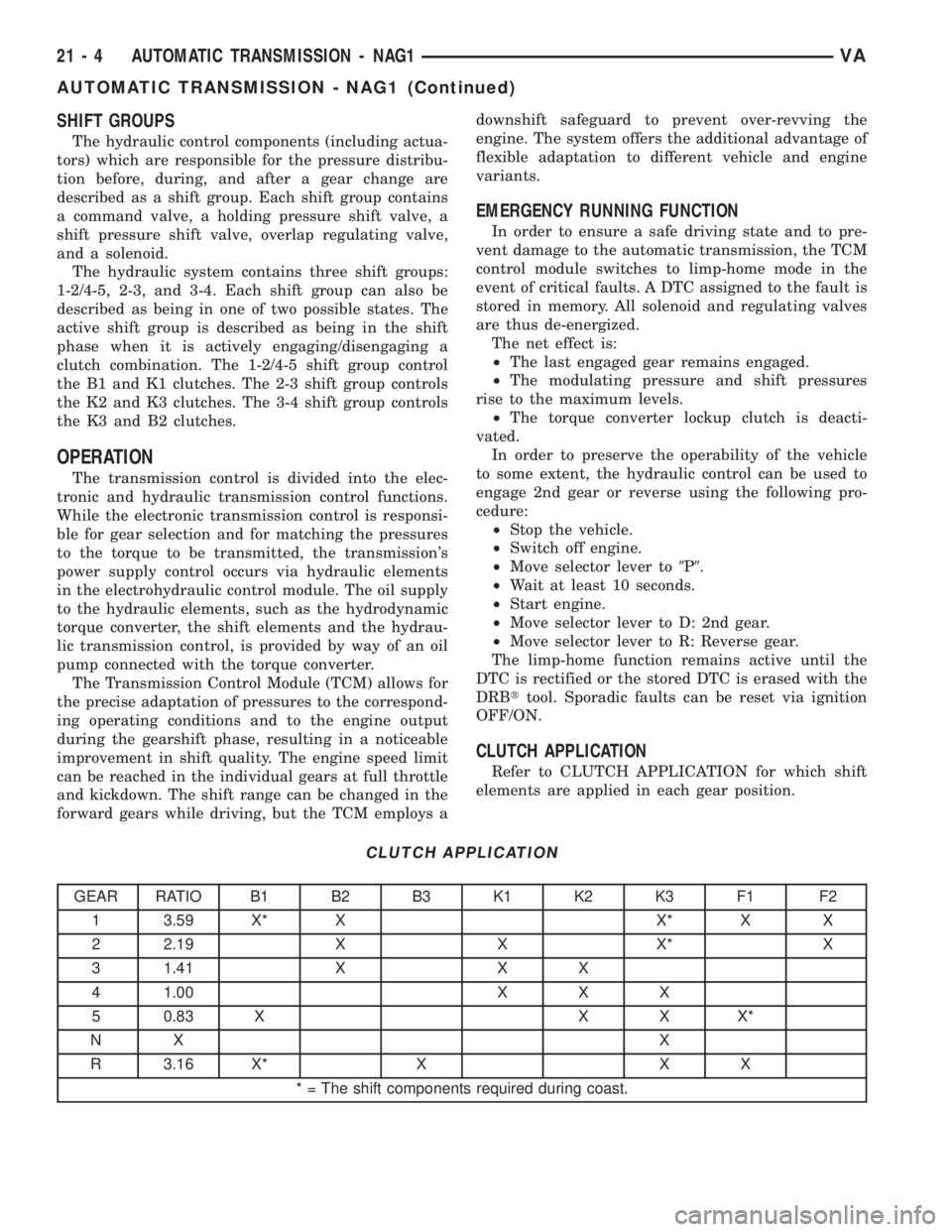

SHIFT GROUPS

The hydraulic control components (including actua-

tors) which are responsible for the pressure distribu-

tion before, during, and after a gear change are

described as a shift group. Each shift group contains

a command valve, a holding pressure shift valve, a

shift pressure shift valve, overlap regulating valve,

and a solenoid.

The hydraulic system contains three shift groups:

1-2/4-5, 2-3, and 3-4. Each shift group can also be

described as being in one of two possible states. The

active shift group is described as being in the shift

phase when it is actively engaging/disengaging a

clutch combination. The 1-2/4-5 shift group control

the B1 and K1 clutches. The 2-3 shift group controls

the K2 and K3 clutches. The 3-4 shift group controls

the K3 and B2 clutches.

OPERATION

The transmission control is divided into the elec-

tronic and hydraulic transmission control functions.

While the electronic transmission control is responsi-

ble for gear selection and for matching the pressures

to the torque to be transmitted, the transmission's

power supply control occurs via hydraulic elements

in the electrohydraulic control module. The oil supply

to the hydraulic elements, such as the hydrodynamic

torque converter, the shift elements and the hydrau-

lic transmission control, is provided by way of an oil

pump connected with the torque converter.

The Transmission Control Module (TCM) allows for

the precise adaptation of pressures to the correspond-

ing operating conditions and to the engine output

during the gearshift phase, resulting in a noticeable

improvement in shift quality. The engine speed limit

can be reached in the individual gears at full throttle

and kickdown. The shift range can be changed in the

forward gears while driving, but the TCM employs adownshift safeguard to prevent over-revving the

engine. The system offers the additional advantage of

flexible adaptation to different vehicle and engine

variants.

EMERGENCY RUNNING FUNCTION

In order to ensure a safe driving state and to pre-

vent damage to the automatic transmission, the TCM

control module switches to limp-home mode in the

event of critical faults. A DTC assigned to the fault is

stored in memory. All solenoid and regulating valves

are thus de-energized.

The net effect is:

²The last engaged gear remains engaged.

²The modulating pressure and shift pressures

rise to the maximum levels.

²The torque converter lockup clutch is deacti-

vated.

In order to preserve the operability of the vehicle

to some extent, the hydraulic control can be used to

engage 2nd gear or reverse using the following pro-

cedure:

²Stop the vehicle.

²Switch off engine.

²Move selector lever to9P9.

²Wait at least 10 seconds.

²Start engine.

²Move selector lever to D: 2nd gear.

²Move selector lever to R: Reverse gear.

The limp-home function remains active until the

DTC is rectified or the stored DTC is erased with the

DRBttool. Sporadic faults can be reset via ignition

OFF/ON.

CLUTCH APPLICATION

Refer to CLUTCH APPLICATION for which shift

elements are applied in each gear position.

CLUTCH APPLICATION

GEAR RATIO B1 B2 B3 K1 K2 K3 F1 F2

1 3.59 X* X X* X X

2 2.19 X X X* X

3 1.41 X X X

4 1.00 X X X

5 0.83 X X X X*

NX X

R 3.16 X* X X X

* = The shift components required during coast.

21 - 4 AUTOMATIC TRANSMISSION - NAG1VA

AUTOMATIC TRANSMISSION - NAG1 (Continued)

Page 1133 of 1232

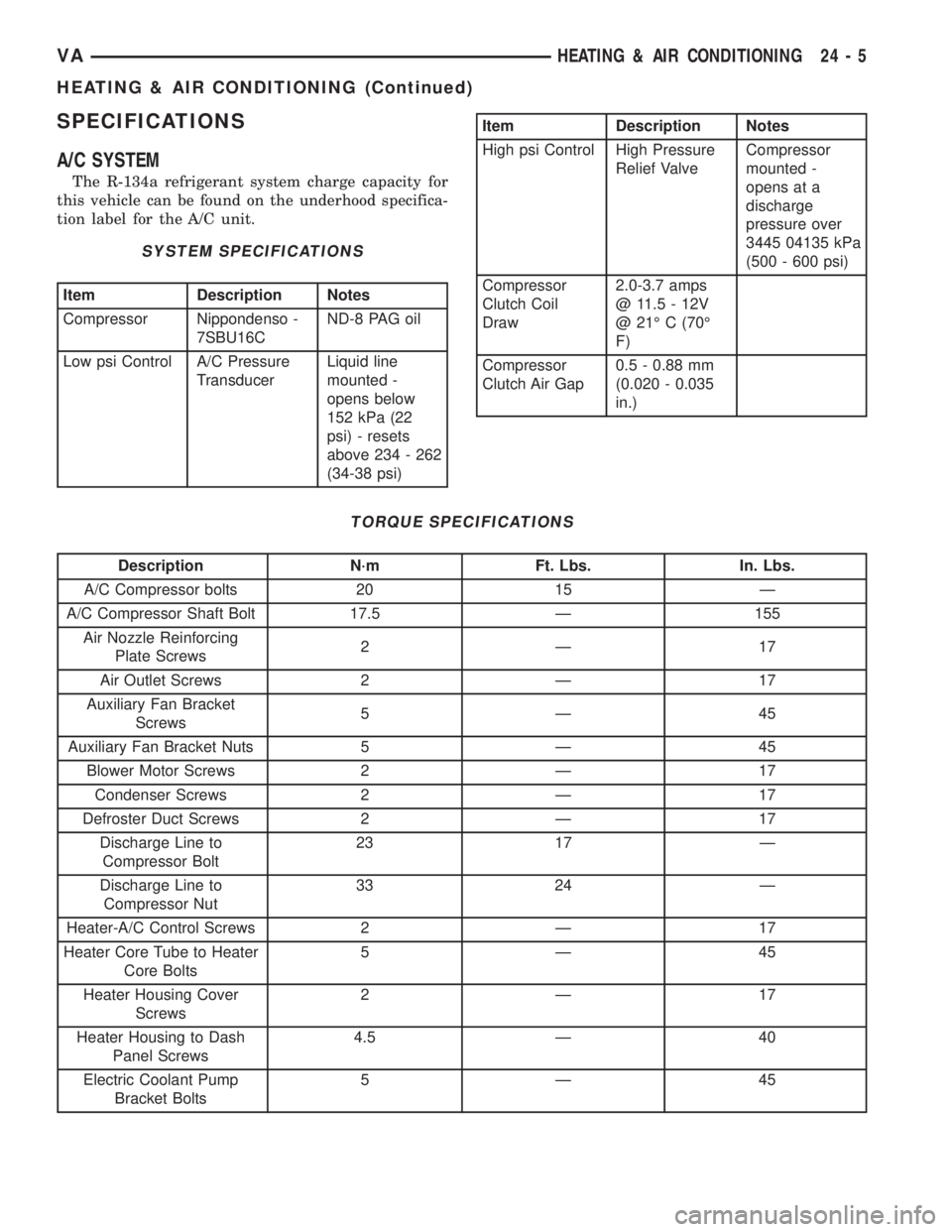

SPECIFICATIONS

A/C SYSTEM

The R-134a refrigerant system charge capacity for

this vehicle can be found on the underhood specifica-

tion label for the A/C unit.

SYSTEM SPECIFICATIONS

Item Description Notes

Compressor Nippondenso -

7SBU16CND-8 PAG oil

Low psi Control A/C Pressure

TransducerLiquid line

mounted -

opens below

152 kPa (22

psi) - resets

above 234 - 262

(34-38 psi)

Item Description Notes

High psi Control High Pressure

Relief ValveCompressor

mounted -

opens at a

discharge

pressure over

3445 04135 kPa

(500 - 600 psi)

Compressor

Clutch Coil

Draw2.0-3.7 amps

@ 11.5 - 12V

@ 21É C (70É

F)

Compressor

Clutch Air Gap0.5 - 0.88 mm

(0.020 - 0.035

in.)

TORQUE SPECIFICATIONS

Description N´m Ft. Lbs. In. Lbs.

A/C Compressor bolts 20 15 Ð

A/C Compressor Shaft Bolt 17.5 Ð 155

Air Nozzle Reinforcing

Plate Screws2Ð 17

Air Outlet Screws 2 Ð 17

Auxiliary Fan Bracket

Screws5Ð 45

Auxiliary Fan Bracket Nuts 5 Ð 45

Blower Motor Screws 2 Ð 17

Condenser Screws 2 Ð 17

Defroster Duct Screws 2 Ð 17

Discharge Line to

Compressor Bolt23 17 Ð

Discharge Line to

Compressor Nut33 24 Ð

Heater-A/C Control Screws 2 Ð 17

Heater Core Tube to Heater

Core Bolts5Ð 45

Heater Housing Cover

Screws2Ð 17

Heater Housing to Dash

Panel Screws4.5 Ð 40

Electric Coolant Pump

Bracket Bolts5Ð 45

VAHEATING & AIR CONDITIONING 24 - 5

HEATING & AIR CONDITIONING (Continued)