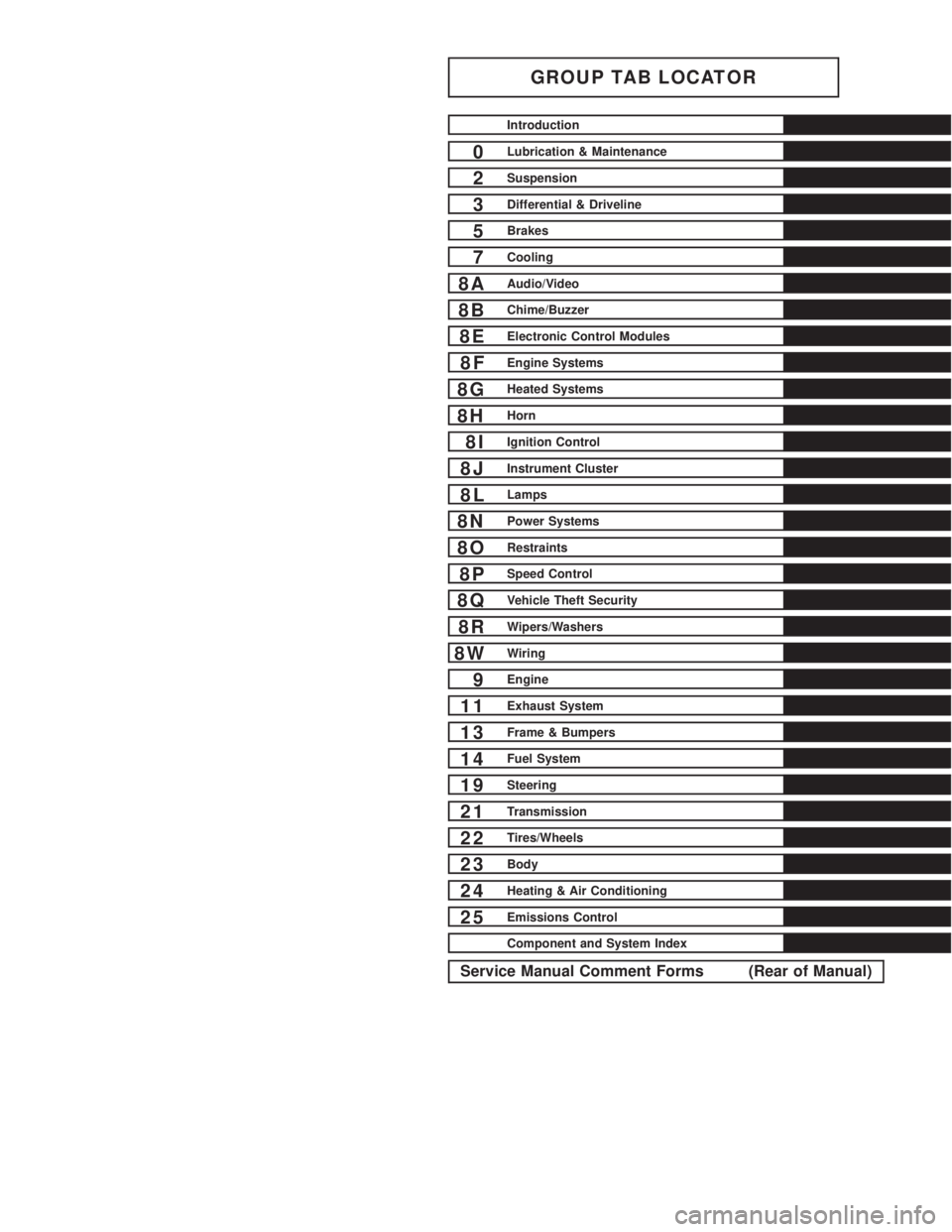

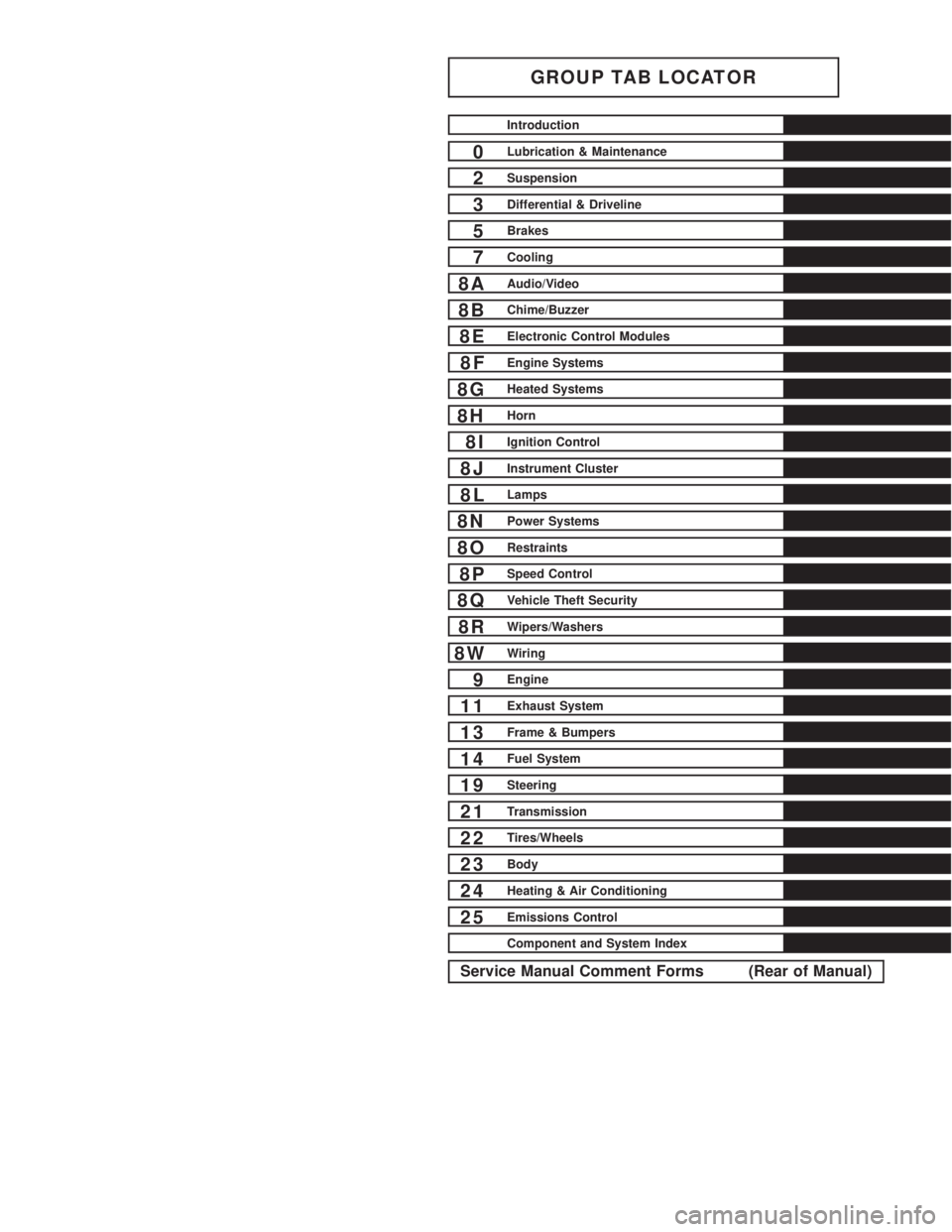

GROUP TAB LOCATOR

Introduction

0Lubrication & Maintenance

2Suspension

3Differential & Driveline

5Brakes

7Cooling

8AAudio/Video

8BChime/Buzzer

8EElectronic Control Modules

8FEngine Systems

8GHeated Systems

8HHorn

8IIgnition Control

8JInstrument Cluster

8LLamps

8NPower Systems

8ORestraints

8PSpeed Control

8QVehicle Theft Security

8RWipers/Washers

8WWiring

9Engine

11Exhaust System

13Frame & Bumpers

14Fuel System

19Steering

21Transmission

22Tires/Wheels

23Body

24Heating & Air Conditioning

25Emissions Control

Component and System Index

Service Manual Comment Forms (Rear of Manual)

INTRODUCTION

TABLE OF CONTENTS

page page

VEHICLE IDENTIFICATION NUMBER

DESCRIPTION..........................1

INTERNATIONAL SYMBOLS

DESCRIPTION..........................2

FASTENER IDENTIFICATION

DESCRIPTION..........................2

FASTENER USAGE

DESCRIPTION - FASTENER USAGE.........5THREADED HOLE REPAIR

DESCRIPTION - THREADED HOLE REPAIR....5

METRIC SYSTEM

DESCRIPTION..........................5

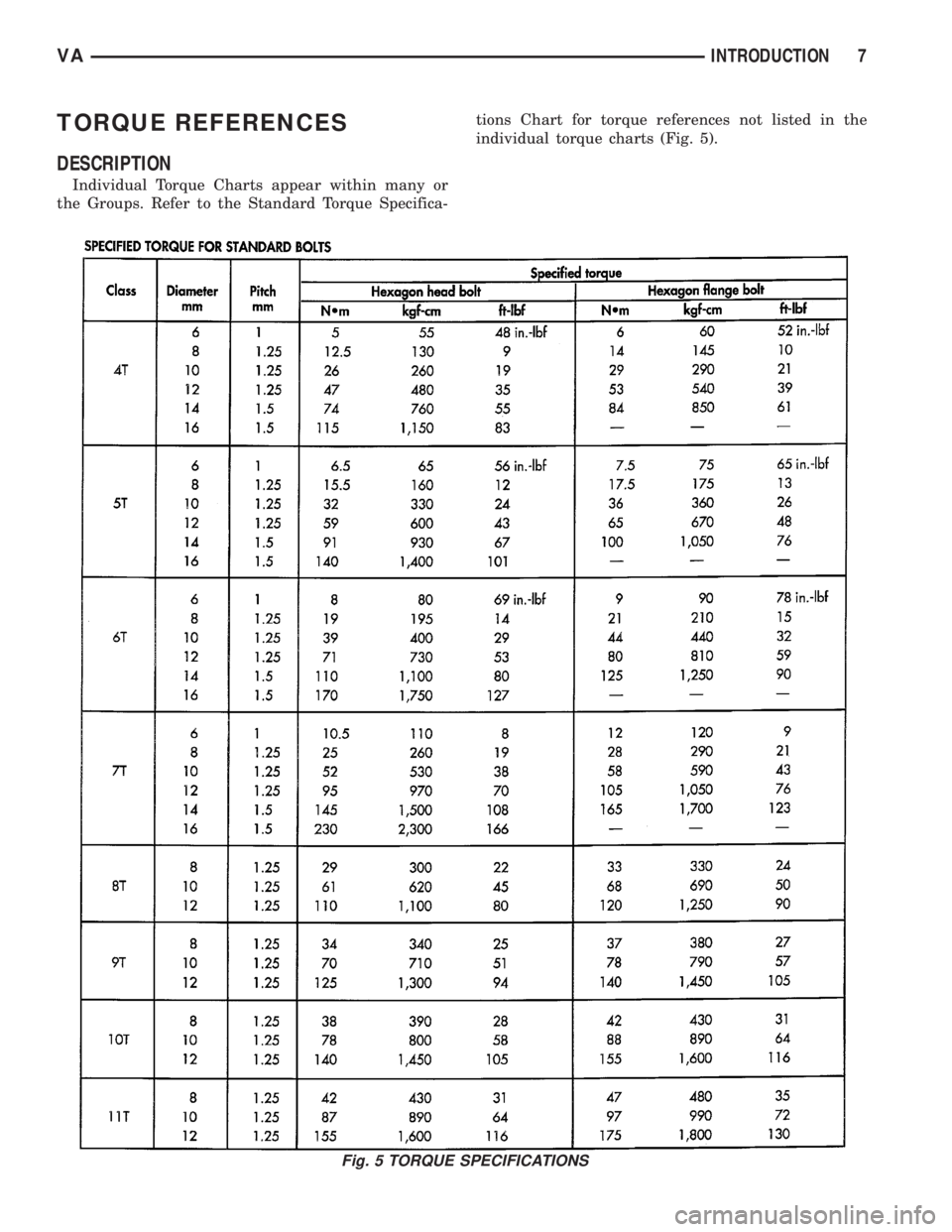

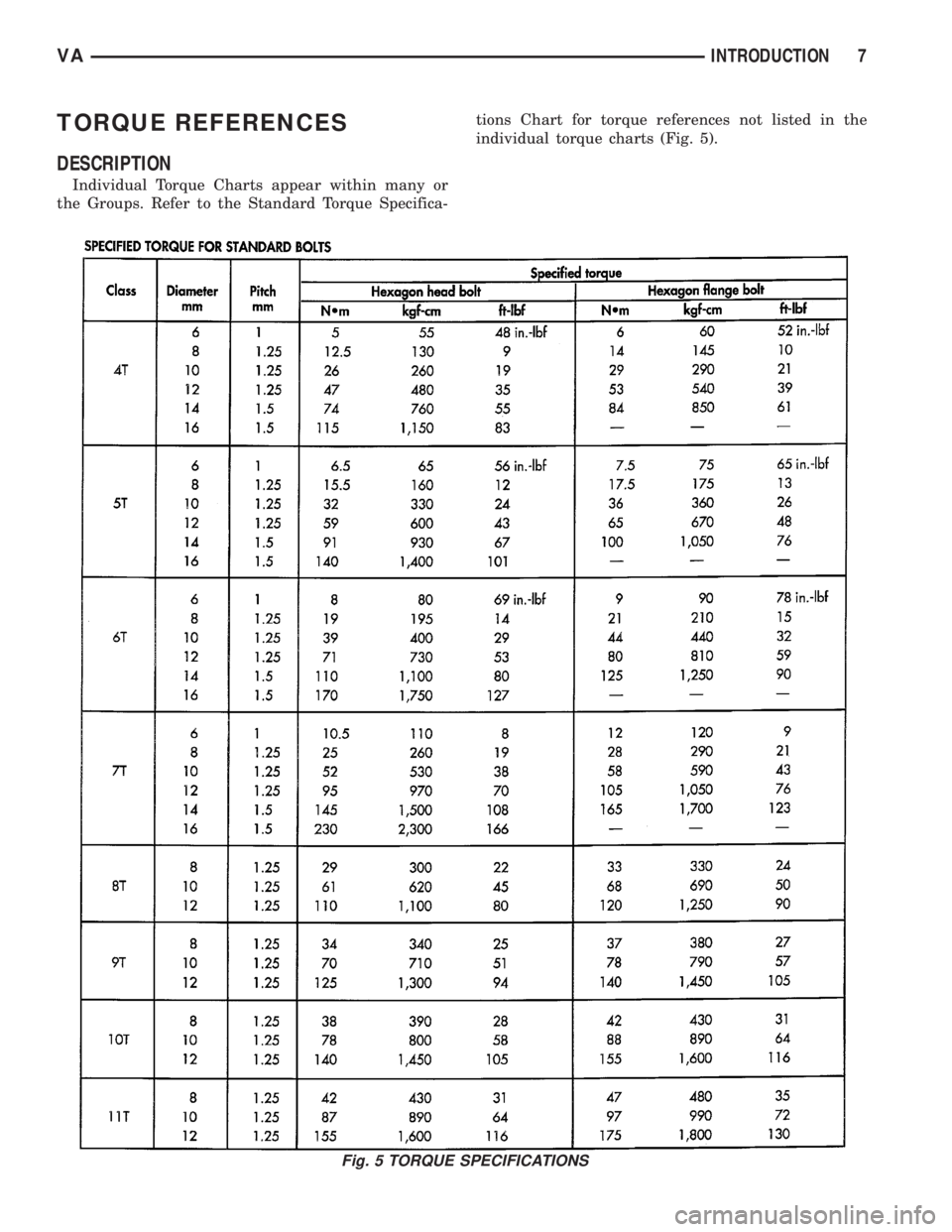

TORQUE REFERENCES

DESCRIPTION..........................7

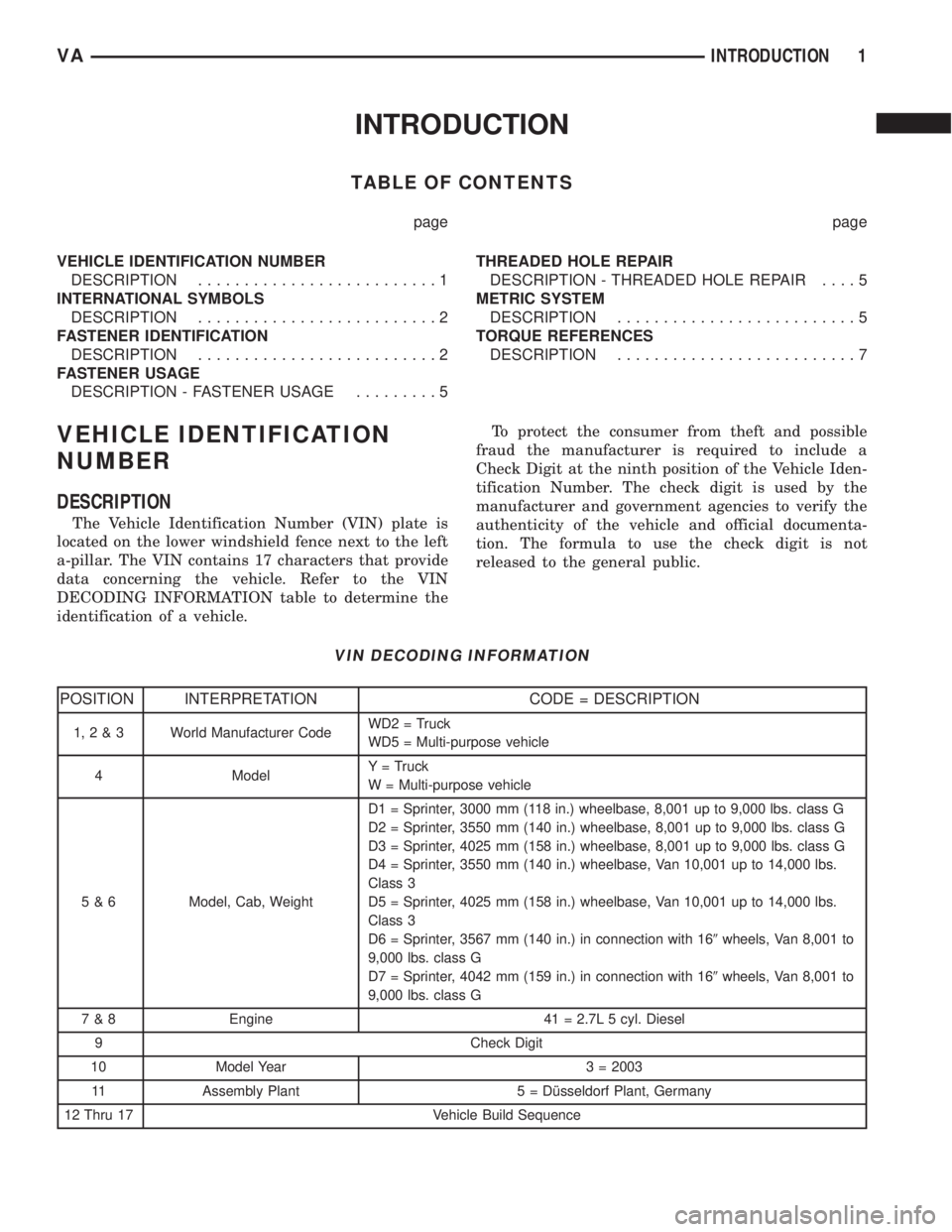

VEHICLE IDENTIFICATION

NUMBER

DESCRIPTION

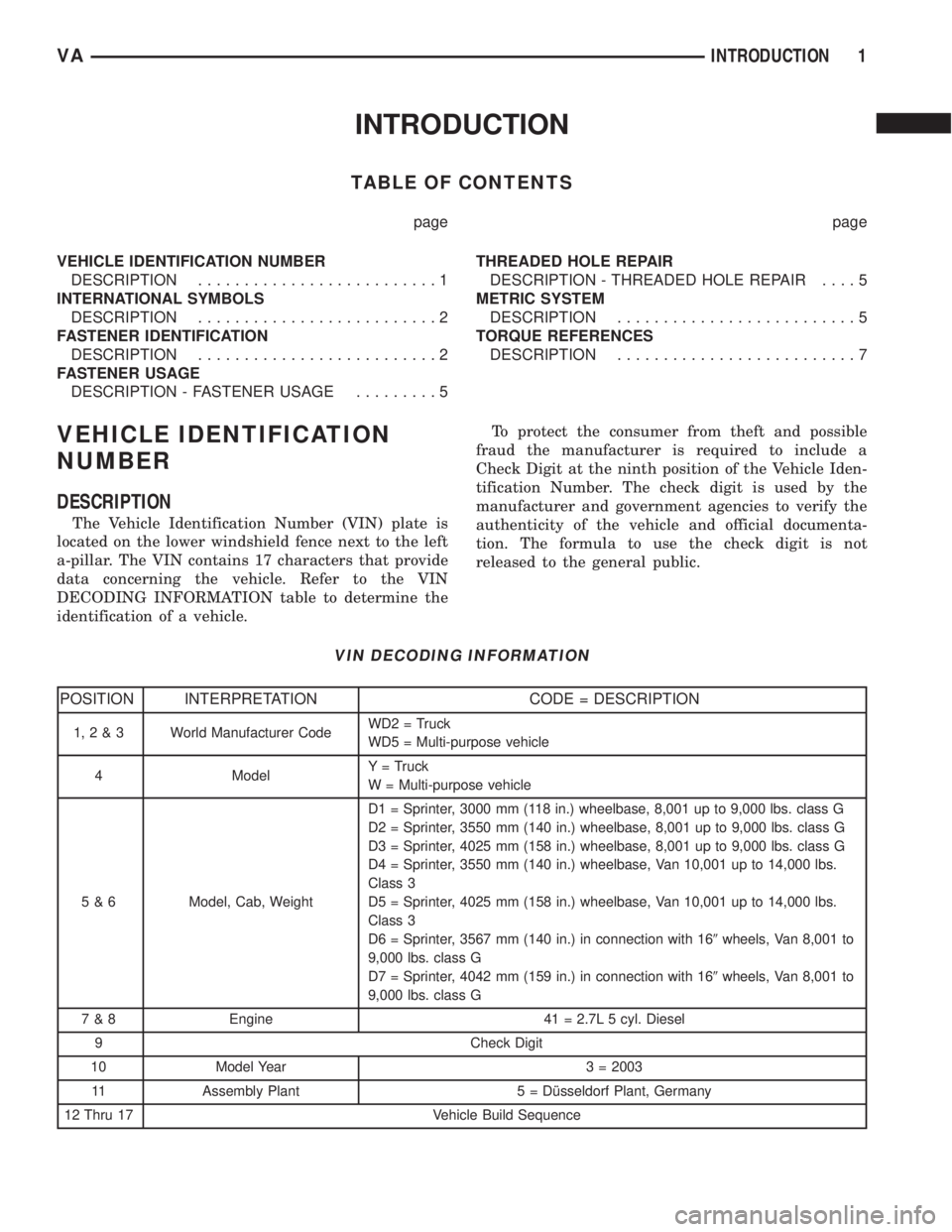

The Vehicle Identification Number (VIN) plate is

located on the lower windshield fence next to the left

a-pillar. The VIN contains 17 characters that provide

data concerning the vehicle. Refer to the VIN

DECODING INFORMATION table to determine the

identification of a vehicle.To protect the consumer from theft and possible

fraud the manufacturer is required to include a

Check Digit at the ninth position of the Vehicle Iden-

tification Number. The check digit is used by the

manufacturer and government agencies to verify the

authenticity of the vehicle and official documenta-

tion. The formula to use the check digit is not

released to the general public.

VIN DECODING INFORMATION

POSITION INTERPRETATION CODE = DESCRIPTION

1,2&3 World Manufacturer CodeWD2 = Truck

WD5 = Multi-purpose vehicle

4 ModelY = Truck

W = Multi-purpose vehicle

5 & 6 Model, Cab, WeightD1 = Sprinter, 3000 mm (118 in.) wheelbase, 8,001 up to 9,000 lbs. class G

D2 = Sprinter, 3550 mm (140 in.) wheelbase, 8,001 up to 9,000 lbs. class G

D3 = Sprinter, 4025 mm (158 in.) wheelbase, 8,001 up to 9,000 lbs. class G

D4 = Sprinter, 3550 mm (140 in.) wheelbase, Van 10,001 up to 14,000 lbs.

Class 3

D5 = Sprinter, 4025 mm (158 in.) wheelbase, Van 10,001 up to 14,000 lbs.

Class 3

D6 = Sprinter, 3567 mm (140 in.) in connection with 169wheels, Van 8,001 to

9,000 lbs. class G

D7 = Sprinter, 4042 mm (159 in.) in connection with 169wheels, Van 8,001 to

9,000 lbs. class G

7 & 8 Engine 41 = 2.7L 5 cyl. Diesel

9 Check Digit

10 Model Year 3 = 2003

11 Assembly Plant 5 = Dîsseldorf Plant, Germany

12 Thru 17 Vehicle Build Sequence

VAINTRODUCTION 1

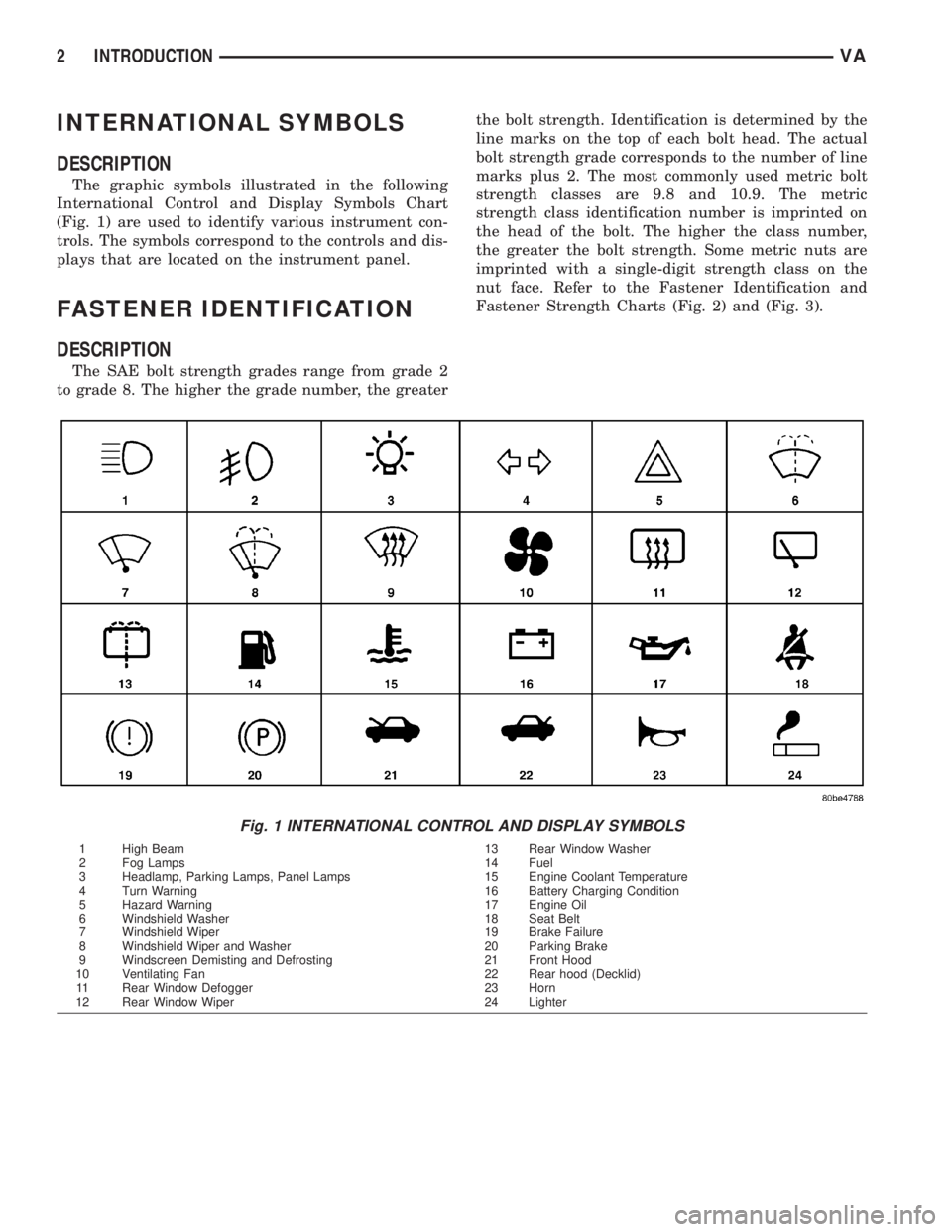

INTERNATIONAL SYMBOLS

DESCRIPTION

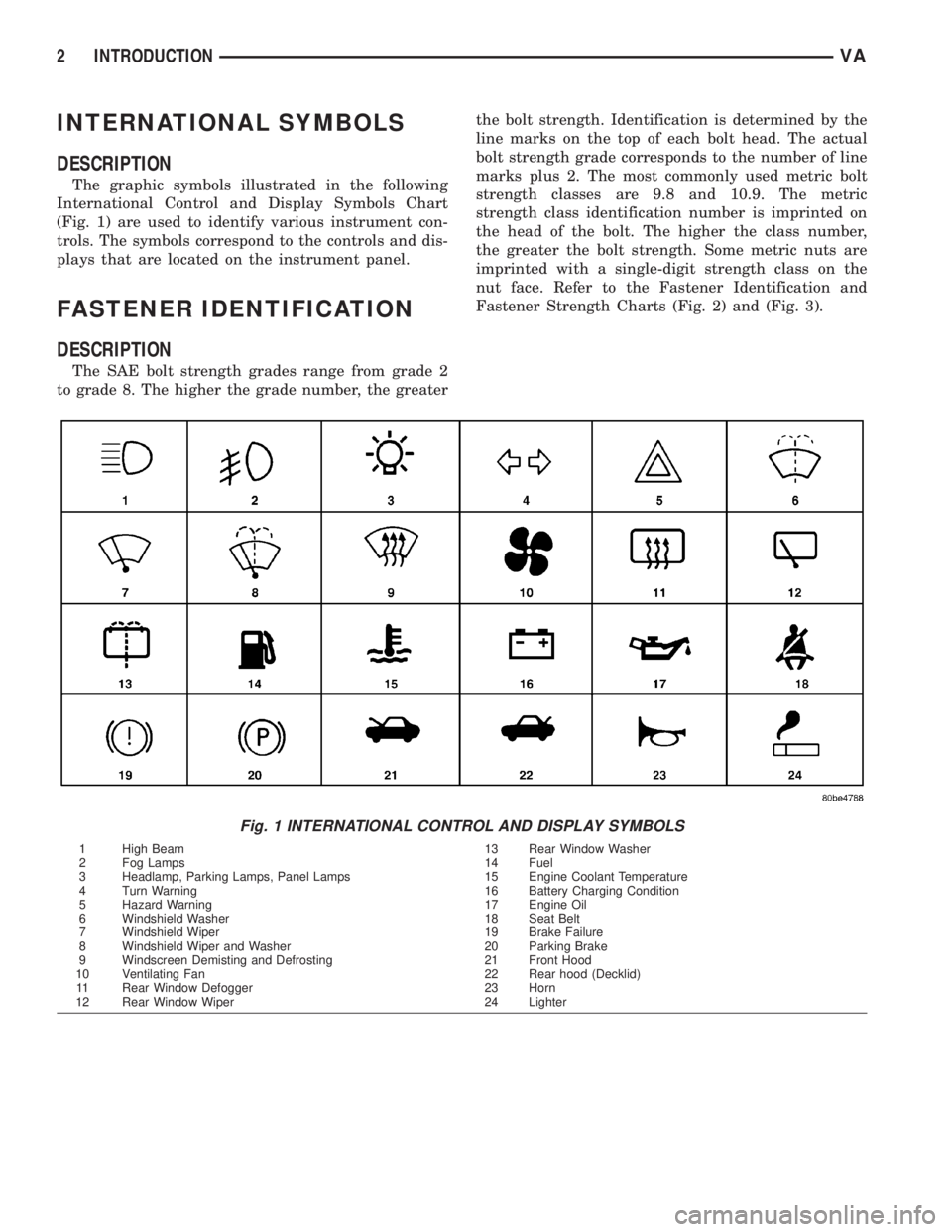

The graphic symbols illustrated in the following

International Control and Display Symbols Chart

(Fig. 1) are used to identify various instrument con-

trols. The symbols correspond to the controls and dis-

plays that are located on the instrument panel.

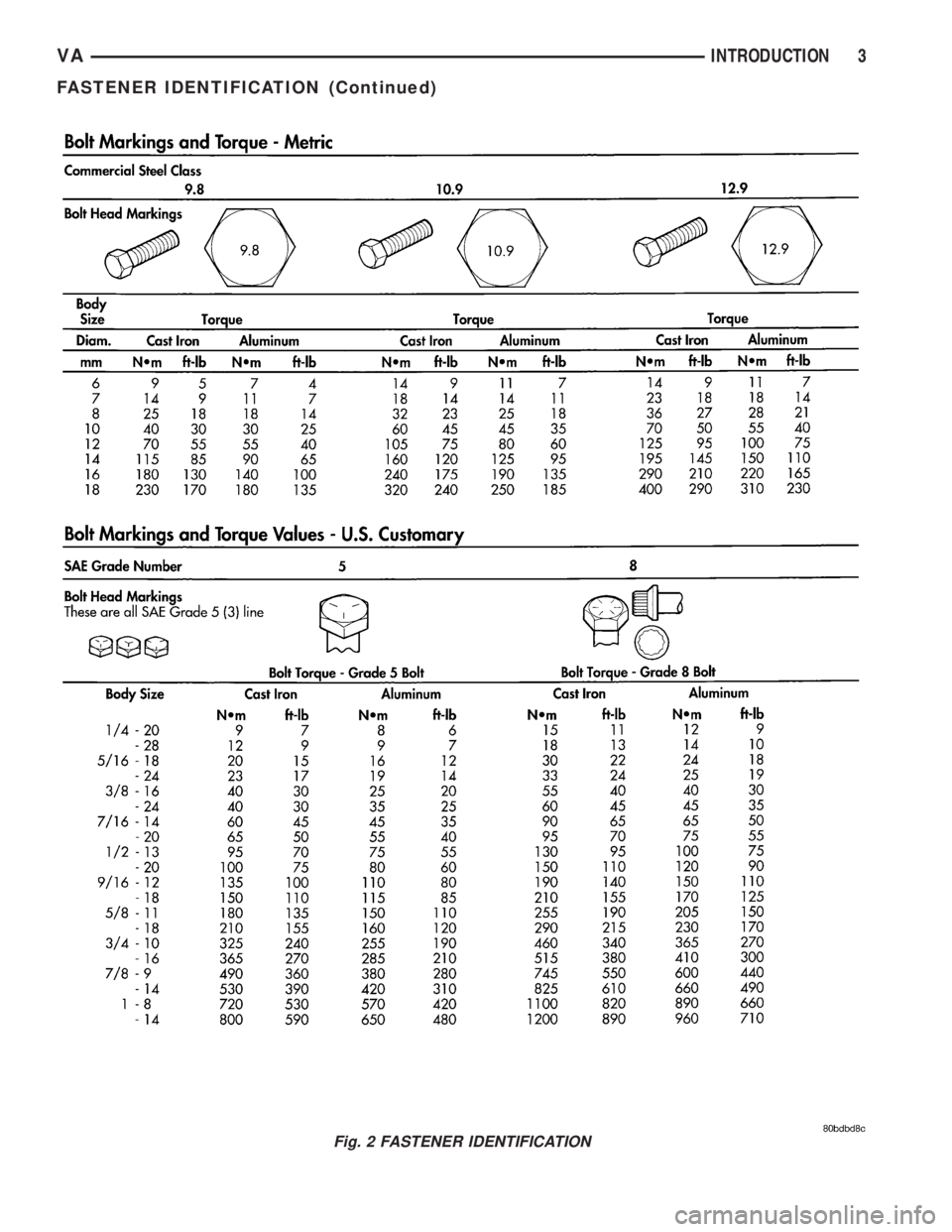

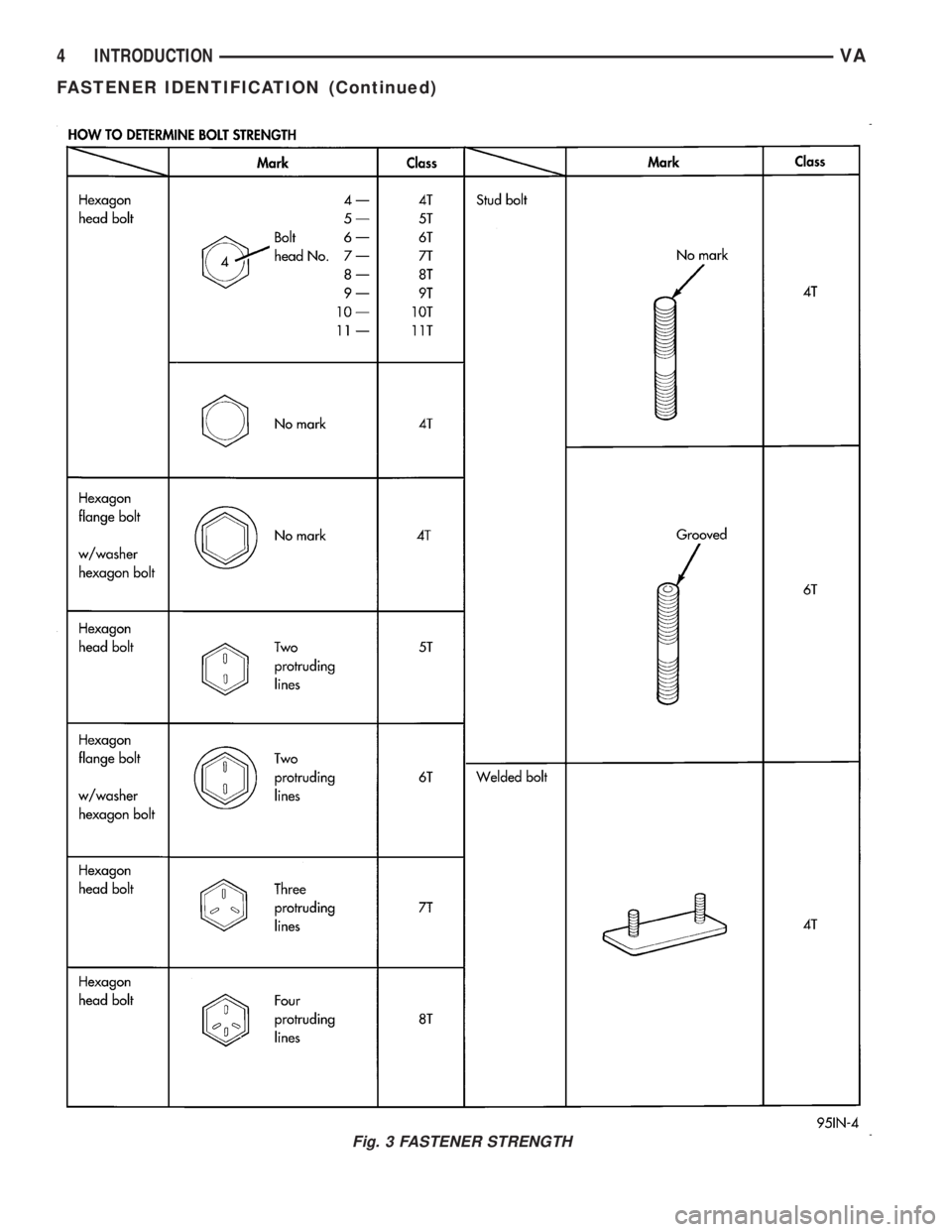

FASTENER IDENTIFICATION

DESCRIPTION

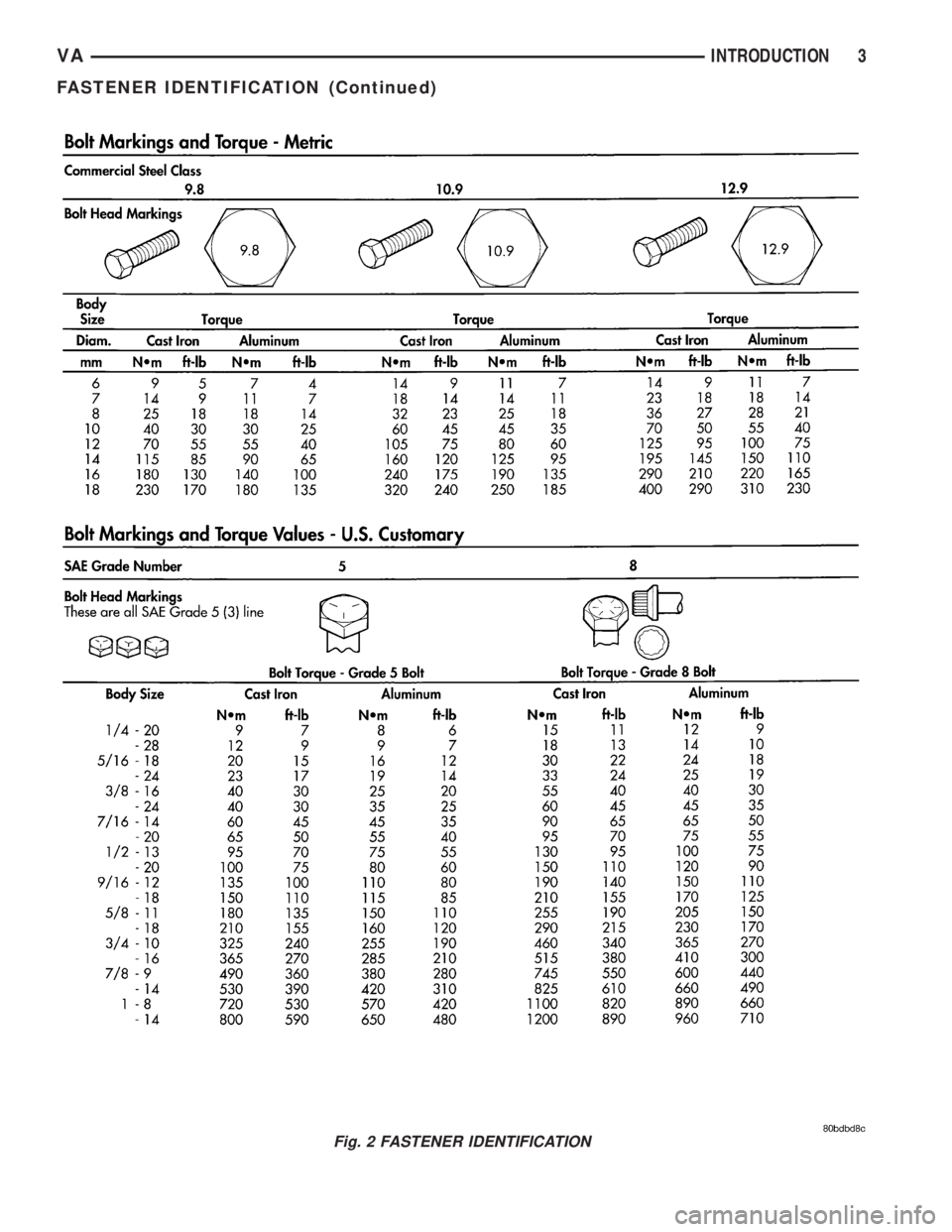

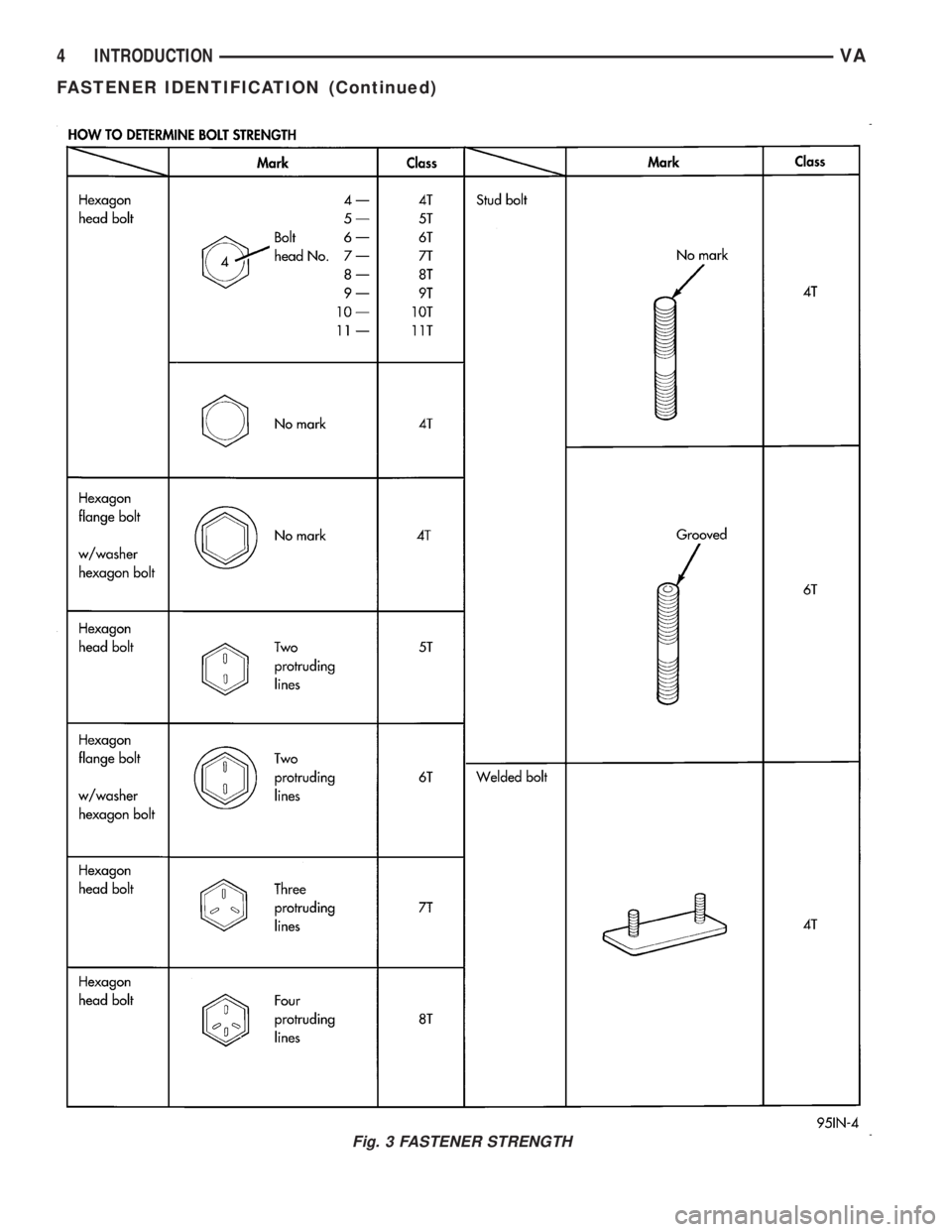

The SAE bolt strength grades range from grade 2

to grade 8. The higher the grade number, the greaterthe bolt strength. Identification is determined by the

line marks on the top of each bolt head. The actual

bolt strength grade corresponds to the number of line

marks plus 2. The most commonly used metric bolt

strength classes are 9.8 and 10.9. The metric

strength class identification number is imprinted on

the head of the bolt. The higher the class number,

the greater the bolt strength. Some metric nuts are

imprinted with a single-digit strength class on the

nut face. Refer to the Fastener Identification and

Fastener Strength Charts (Fig. 2) and (Fig. 3).

Fig. 1 INTERNATIONAL CONTROL AND DISPLAY SYMBOLS

1 High Beam 13 Rear Window Washer

2 Fog Lamps 14 Fuel

3 Headlamp, Parking Lamps, Panel Lamps 15 Engine Coolant Temperature

4 Turn Warning 16 Battery Charging Condition

5 Hazard Warning 17 Engine Oil

6 Windshield Washer 18 Seat Belt

7 Windshield Wiper 19 Brake Failure

8 Windshield Wiper and Washer 20 Parking Brake

9 Windscreen Demisting and Defrosting 21 Front Hood

10 Ventilating Fan 22 Rear hood (Decklid)

11 Rear Window Defogger 23 Horn

12 Rear Window Wiper 24 Lighter

2 INTRODUCTIONVA

FASTENER USAGE

DESCRIPTION - FASTENER USAGE

WARNING: USE OF AN INCORRECT FASTENER

MAY RESULT IN COMPONENT DAMAGE OR PER-

SONAL INJURY.

Fasteners and torque specifications references in

this Service Manual are identified in metric and SAE

format.

During any maintenance or repair procedures, it is

important to salvage all fasteners (nuts, bolts, etc.)

for reassembly. If the fastener is not salvageable, a

fastener of equivalent specification must be used.

THREADED HOLE REPAIR

DESCRIPTION - THREADED HOLE REPAIR

Most stripped threaded holes can be repaired using

a Helicoilt. Follow the vehicle or Helicoiltrecommen-

dations for application and repair procedures.

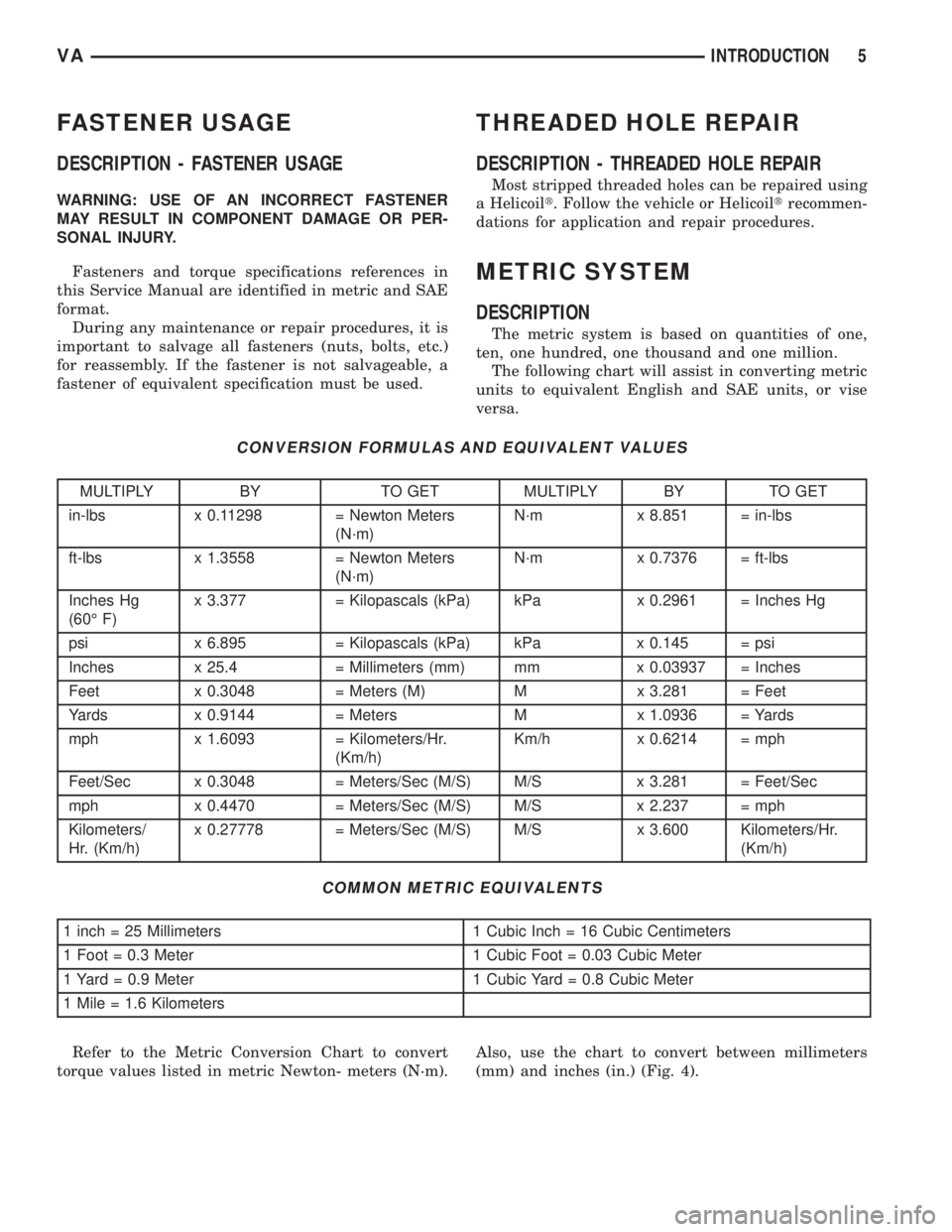

METRIC SYSTEM

DESCRIPTION

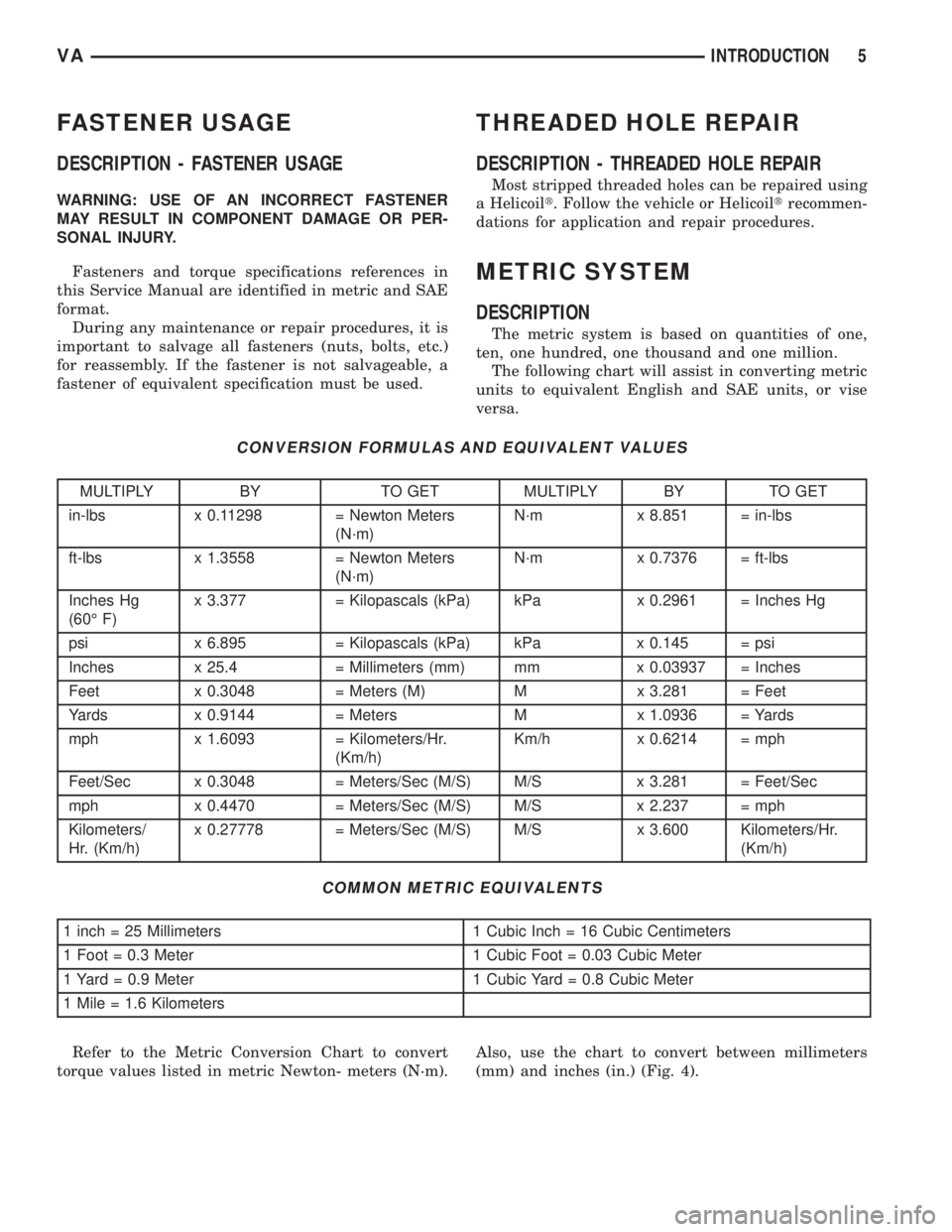

The metric system is based on quantities of one,

ten, one hundred, one thousand and one million.

The following chart will assist in converting metric

units to equivalent English and SAE units, or vise

versa.

CONVERSION FORMULAS AND EQUIVALENT VALUES

MULTIPLY BY TO GET MULTIPLY BY TO GET

in-lbs x 0.11298 = Newton Meters

(N´m)N´m x 8.851 = in-lbs

ft-lbs x 1.3558 = Newton Meters

(N´m)N´m x 0.7376 = ft-lbs

Inches Hg

(60É F)x 3.377 = Kilopascals (kPa) kPa x 0.2961 = Inches Hg

psi x 6.895 = Kilopascals (kPa) kPa x 0.145 = psi

Inches x 25.4 = Millimeters (mm) mm x 0.03937 = Inches

Feet x 0.3048 = Meters (M) M x 3.281 = Feet

Yards x 0.9144 = Meters M x 1.0936 = Yards

mph x 1.6093 = Kilometers/Hr.

(Km/h)Km/h x 0.6214 = mph

Feet/Sec x 0.3048 = Meters/Sec (M/S) M/S x 3.281 = Feet/Sec

mph x 0.4470 = Meters/Sec (M/S) M/S x 2.237 = mph

Kilometers/

Hr. (Km/h)x 0.27778 = Meters/Sec (M/S) M/S x 3.600 Kilometers/Hr.

(Km/h)

COMMON METRIC EQUIVALENTS

1 inch = 25 Millimeters 1 Cubic Inch = 16 Cubic Centimeters

1 Foot = 0.3 Meter 1 Cubic Foot = 0.03 Cubic Meter

1 Yard = 0.9 Meter 1 Cubic Yard = 0.8 Cubic Meter

1 Mile = 1.6 Kilometers

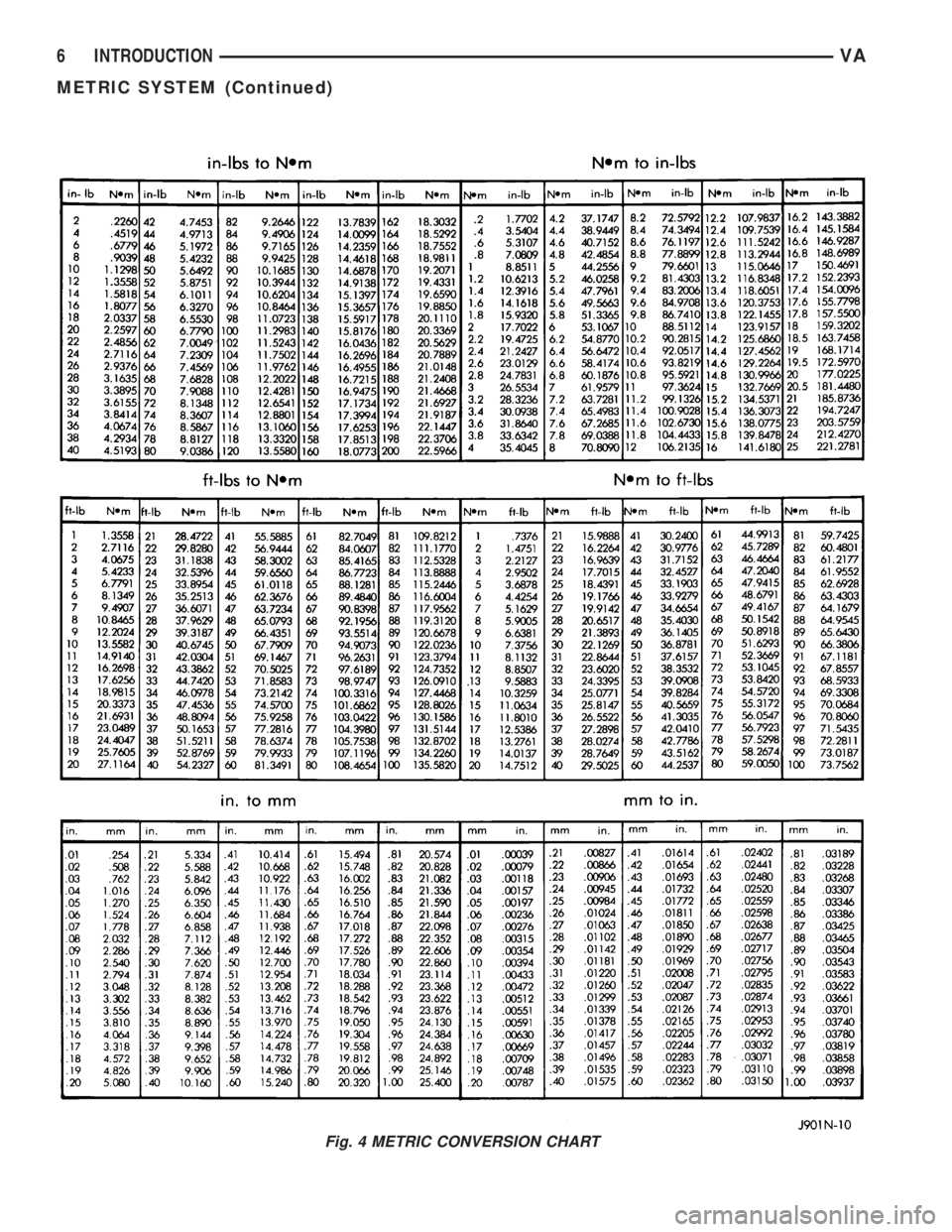

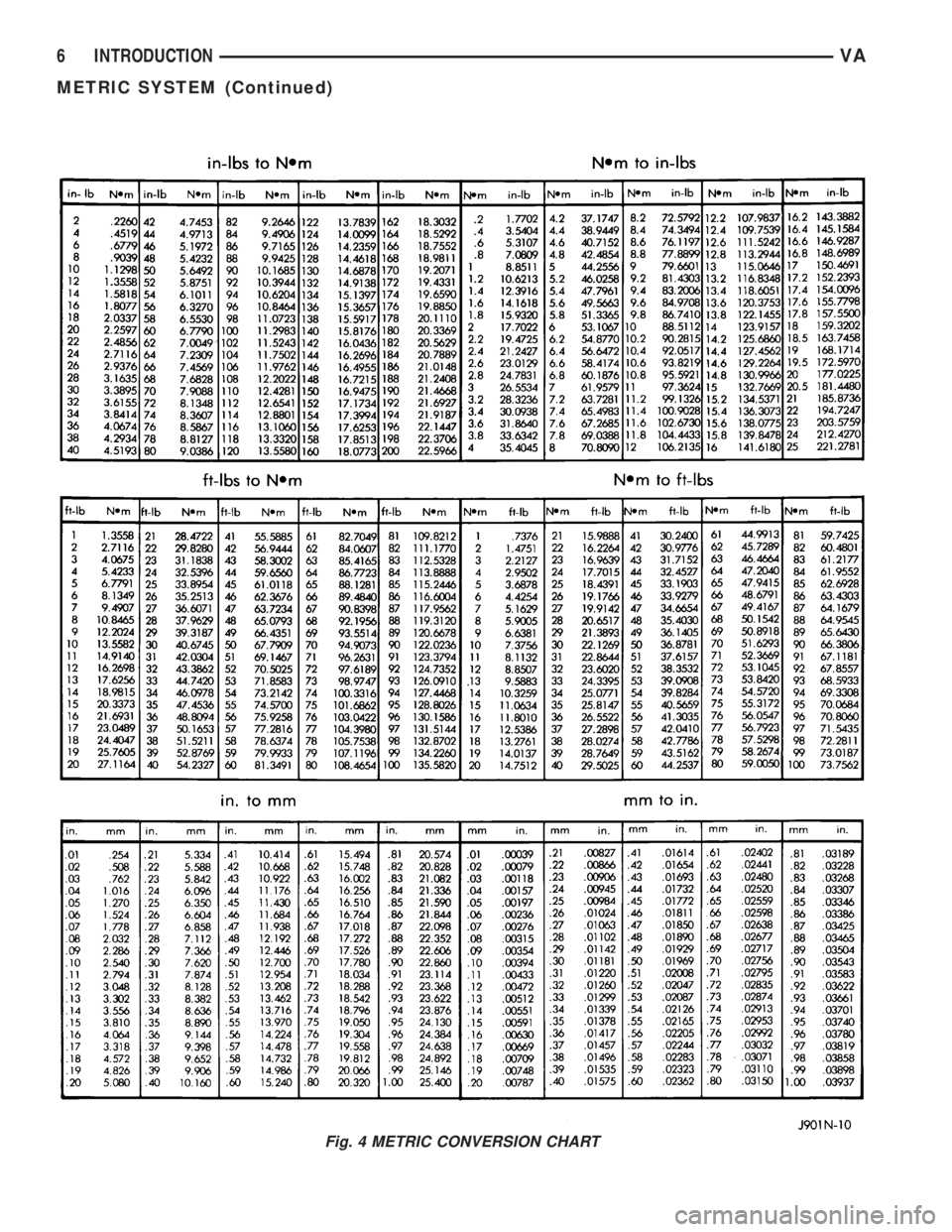

Refer to the Metric Conversion Chart to convert

torque values listed in metric Newton- meters (N´m).Also, use the chart to convert between millimeters

(mm) and inches (in.) (Fig. 4).

VAINTRODUCTION 5