sensor MERCEDES-BENZ SPRINTER 2005 Service Manual PDF

[x] Cancel search | Manufacturer: MERCEDES-BENZ, Model Year: 2005, Model line: SPRINTER, Model: MERCEDES-BENZ SPRINTER 2005Pages: 1232, PDF Size: 39.23 MB

Page 242 of 1232

splices, splice block connectors, and many different

types of wire harness terminal connectors and insu-

lators. Refer to the appropriate wiring information.

The wiring information includes wiring diagrams,

proper wire and connector repair procedures, further

details on wire harness routing and retention, as well

as pin-out and location views for the various wire

harness connectors, splices and grounds.

OPERATION

ACTIVE RESTRAINTS

The primary passenger restraints in this or any

other vehicle are the standard equipment factory-in-

stalled seat belts. Seat belts are referred to as an

active restraint because the vehicle occupants are

required to physically fasten and properly adjust

these restraints in order to benefit from them. See

the owner's manual in the vehicle glove box for more

information on the features, use and operation of all

of the factory-installed active restraints.

PASSIVE RESTRAINTS

The passive restraints are referred to as a supple-

mental restraint system because they were designed

and are intended to enhance the protection for the

occupants of the vehicleonlywhen used in conjunc-

tion with the seat belts. They are referred to as pas-

sive restraints because the vehicle occupants are not

required to do anything to make them operate; how-

ever, the vehicle occupants must be wearing their

seat belts in order to obtain the maximum safety

benefit from the factory-installed supplemental

restraint system.

The supplemental restraint system electrical cir-

cuits are continuously monitored and controlled by a

microprocessor and software contained within the

Airbag Control Module (ACM). An airbag indicator in

the ElectroMechanical Instrument Cluster (EMIC)

illuminates for about four seconds as a bulb test each

time the ignition switch is turned to the On or Start

positions. Following the bulb test, the airbag indica-

tor is turned on or off by the ACM to indicate the

status of the supplemental restraint system. If the

airbag indicator comes on either solid or flashing at

any time other than during the bulb test, it indicates

that there is a problem in the supplemental restraint

system electrical circuits. Such a problem may cause

airbags not to deploy when required, or to deploy

when not required.

Deployment of the supplemental restraints

depends upon the angle and severity of an impact.Deployment is not based upon vehicle speed; rather,

deployment is based upon the rate of deceleration as

measured by the forces of gravity (G force) upon the

impact sensor. When an impact is severe enough, the

microprocessor in the ACM signals the inflator of the

appropriate airbag units to deploy their airbag cush-

ions. The front seat belt tensioners are provided with

a deployment signal by the ACM in conjunction with

the driver and passenger airbags. During a frontal

vehicle impact, the knee blockers work in concert

with properly fastened and adjusted seat belts to

restrain both the driver and the front seat passenger

in the proper position for an airbag deployment. The

knee blockers also absorb and distribute the crash

energy from the driver and the front seat passenger

to the structure of the instrument panel. The seat

belt tensioners remove the slack from the front seat

belts to provide further assurance that the driver and

front seat passenger are properly positioned and

restrained for an airbag deployment.

Typically, the vehicle occupants recall more about

the events preceding and following a collision than

they do of an airbag deployment itself. This is

because the airbag deployment and deflation occur so

rapidly. In a typical 48 kilometer-per-hour (30 mile-

per-hour) barrier impact, from the moment of impact

until the airbags are fully inflated takes only a few

milliseconds. Within one to two seconds from the

moment of impact, the airbags are almost entirely

deflated. The times cited for these events are approx-

imations, which apply only to a barrier impact at the

given speed. Actual times will vary somewhat,

depending upon the vehicle speed, impact angle,

severity of the impact, and the type of collision.

When the ACM monitors a problem in any of the

front airbag system circuits or components, including

the seat belt tensioners, it stores a fault code or

Diagnostic Trouble Code (DTC) in its memory circuit

and sends a hard wired output to the EMIC to turn

on the airbag indicator. If the EMIC detects a prob-

lem in the airbag indicator or airbag indicator circuit,

the cluster will flash the seatbelt indicator on and

off. Proper testing of the supplemental restraint sys-

tem components as well as the retrieval or erasure of

a DTC from the ACM requires the use of a DRBIIIt

scan tool. Refer to the appropriate diagnostic infor-

mation.

See the owner's manual in the vehicle glove box for

more information on the features, use and operation

of all of the factory-installed passive restraints.

8O - 4 RESTRAINTSVA

RESTRAINTS (Continued)

Page 244 of 1232

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE SUPPLEMENTAL RESTRAINT

SYSTEM BEFORE ATTEMPTING ANY STEERING

WHEEL, STEERING COLUMN, DRIVER AIRBAG,

PASSENGER AIRBAG, SEAT BELT TENSIONER, OR

INSTRUMENT PANEL COMPONENT DIAGNOSIS OR

SERVICE. DISCONNECT AND ISOLATE THE BAT-

TERY NEGATIVE (GROUND) CABLE, THEN WAIT

TWO MINUTES FOR THE SYSTEM CAPACITOR TO

DISCHARGE BEFORE PERFORMING FURTHER

DIAGNOSIS OR SERVICE. THIS IS THE ONLY SURE

WAY TO DISABLE THE SUPPLEMENTAL

RESTRAINT SYSTEM. FAILURE TO TAKE THE

PROPER PRECAUTIONS COULD RESULT IN ACCI-

DENTAL AIRBAG DEPLOYMENT AND POSSIBLE

PERSONAL INJURY.

STANDARD PROCEDURE

STANDARD PROCEDURE - HANDLING

NON-DEPLOYED SUPPLEMENTAL RESTRAINTS

At no time should any source of electricity be per-

mitted near the inflator on the back of a non-de-

ployed airbag or seat belt tensioner. When carrying a

non-deployed airbag, the trim cover or airbag cushion

side of the unit should be pointed away from the

body to minimize injury in the event of an accidental

deployment. If the airbag unit is placed on a bench or

any other surface, the trim cover or airbag cushion

side of the unit should be face up to minimize move-

ment in the event of an accidental deployment. When

handling a non-deployed seat belt tensioner, take

proper care to keep fingers out from under the

retractor cover and away from the seat belt webbing

where it exits from the retractor cover. In addition,

the supplemental restraint system should be dis-

armed whenever any steering wheel, steering col-

umn, seat belt tensioner, driver airbag, passenger

airbag, or instrument panel components require diag-

nosis or service. Failure to observe this warning

could result in accidental deployment and possible

personal injury.

All damaged, faulty or non-deployed airbags and

seat belt tensioners which are replaced on vehicles

are to be handled and disposed of properly. If an air-

bag or seat belt tensioner unit is faulty or damaged

and non-deployed, refer to the Hazardous Substance

Control System for proper disposal. Dispose of all

non-deployed and deployed airbags and seat belt ten-

sioners in a manner consistent with state, provincial,

local and federal regulations.

SUPPLEMENTAL RESTRAINT STORAGE

Airbags and seat belt tensioners must be stored in

their original, special container until they are used

for service. Also, they must be stored in a clean, dry

environment; away from sources of extreme heat,

sparks, and high electrical energy. Always place or

store any airbag on a surface with its trim cover or

airbag cushion side facing up, to minimize movement

in case of an accidental deployment.

STANDARD PROCEDURE - SERVICE AFTER A

SUPPLEMENTAL RESTRAINT DEPLOYMENT

Any vehicle which is to be returned to use follow-

ing a supplemental restraint deployment, must have

the deployed restraints replaced. In addition, if the

driver airbag has been deployed, the clockspring and

the steering wheel must be replaced. The seat belt

tensioners are deployed by the same signal that

deploys the driver and passenger airbags and must

also be replaced if either airbag has been deployed.

These components are not intended for reuse and

will be damaged or weakened as a result of a supple-

mental restraint deployment, which may or may not

be obvious during a visual inspection.

It is also critical that the mounting surfaces and/or

mounting brackets for the Airbag Control Module

(ACM) be closely inspected and restored to their orig-

inal conditions following any vehicle impact damage.

Because the ACM contains the impact sensor that is

used by the supplemental restraint system to moni-

tor or confirm the direction and severity of a vehicle

impact, improper orientation or insecure fastening of

this component may cause airbags not to deploy

when required, or to deploy when not required. All

other vehicle components should be closely inspected

following any supplemental restraint deployment, but

are to be replaced only as required by the extent of

the visible damage incurred.

CLEANUP PROCEDURE

Following a supplemental restraint deployment,

the vehicle interior will contain a powdery residue.

This residue consists primarily of harmless particu-

late by-products of the small pyrotechnic charge that

initiates the propellant used to deploy a supplemen-

tal restraint. However, this residue may also contain

traces of sodium hydroxide powder, a chemical

by-product of the propellant material that is used to

generate the inert gas that inflates the airbag. Since

sodium hydroxide powder can irritate the skin, eyes,

nose, or throat, be certain to wear safety glasses,

rubber gloves, and a long-sleeved shirt during

cleanup (Fig. 3).

8O - 6 RESTRAINTSVA

RESTRAINTS (Continued)

Page 247 of 1232

an electronic impact sensor, and an energy storage

capacitor. The ACM housing has three integral

mounting tabs. A stamped metal cover plate is per-

manently secured to the bottom of the ACM housing

to enclose and protect the internal electronic circuitry

and components. An arrow printed on a label on the

top of the ACM housing near the rear provides a

visual verification of the proper orientation of the

unit, and should always be pointed toward the front

of the vehicle. A molded plastic electrical connector

receptacle containing numerous terminal pins is inte-

gral to the left facing side of the ACM housing. These

terminal pins connect the ACM to the vehicle electri-

cal system through a dedicated take out and connec-

tor of the vehicle wire harness.

The impact sensor internal to the ACM is cali-

brated for the specific vehicle, and is only serviced as

a unit with the ACM. The ACM cannot be repaired or

adjusted and, if damaged or faulty, it must be

replaced.

OPERATION

The microprocessor in the Airbag Control Module

(ACM) contains the supplemental restraint system

logic circuits and controls all of the supplemental

restraint system components. The ACM uses

On-Board Diagnostics (OBD) and can communicate

with the DRBIIItscan tool using a diagnostic Serial

Communication Interface (SCI) data bus line for sup-

plemental restraint system programming or diagno-

sis and testing through the 16-way Data Link

Connector (DLC) located on the dash panel below the

driver side end of the instrument panel. A hard wired

output from the ACM is used for control of the airbag

indicator in the ElectroMechanical Instrument Clus-

ter (EMIC). (Refer to 8 - ELECTRICAL/INSTRU-

MENT CLUSTER/AIRBAG INDICATOR -

OPERATION).

The ACM microprocessor continuously monitors all

of the supplemental restraint system electrical cir-

cuits to determine the system readiness. If the ACM

detects a monitored system fault, it sets an appropri-

ate Diagnostic Trouble Code (DTC) and sends an out-

put to the EMIC to turn on the airbag indicator. The

ACM illuminates the indicator for about four seconds

each time the ignition switch is turned to the On

position as a bulb test. If the indicator remains illu-

minated for about ten seconds after the ignition

switch is turned to the On position, the ACM has

detected a non-critical fault that poses no danger to

the vehicle occupants. If the airbag indicator illumi-

nates solid (not flashing) while driving or stays on

longer than ten seconds following the bulb test, the

ACM has detected a critical fault that may cause the

airbags not to deploy when required or to deploy

when not required. An active fault only remains forthe duration of the fault, or in some cases, for the

duration of the current ignition switch cycle, while a

stored fault causes a DTC to be stored in memory by

the ACM.

The ACM receives battery current through a fused

ignition switch output circuit. The ACM receives

ground through a ground circuit and take out of the

vehicle wire harness. This take out has an eyelet ter-

minal connector secured by a nut to a ground stud on

the floor panel directly below the ACM within the

driver side seat riser. A case ground is also provided

for the ACM through a ground circuit and eyelet ter-

minal connector secured under the left rear ACM

mounting screw. These connections allow the ACM to

be operational whenever the ignition switch is in the

On position. The ACM also contains an energy-stor-

age capacitor. When the ignition switch is in the On

position, this capacitor is continually being charged

with enough electrical energy to deploy the supple-

mental restraint components for up to one second fol-

lowing a battery disconnect or failure. The purpose of

the capacitor is to provide backup supplemental

restraint system protection in case there is a loss of

battery current supply to the ACM during an impact.

An electronic impact sensor is contained within the

ACM. The electronic impact sensor is an accelerome-

ter that senses the rate of vehicle deceleration, which

provides verification of the direction and severity of

an impact. A pre-programmed decision algorithm in

the ACM microprocessor determines when the decel-

eration rate as signaled by the impact sensor indi-

cates an impact that is severe enough to require

supplemental restraint system protection. When the

programmed conditions are met, the ACM sends the

proper electrical signals to deploy the seat belt ten-

sioners and front airbags.

The ACM also provides a hard wired electrical

crash signal output following a supplemental

restraint deployment event. This output is used to

signal other electronic modules in the vehicle to pro-

vide their enhanced accident response features,

which include automatically disabling the engine

from running and unlocking all of the doors. How-

ever, these responses are each dependent upon the

circuits, components, and modules controlling these

features remaining intact from collateral damage

incurred during the vehicle impact.

A single ACM is used for all variations of the sup-

plemental restraint system available in this vehicle.

This ACM is programmable and in order to function

properly it must be programmed for the correct vehi-

cle supplemental restraint system equipment using

an initialization procedure. The initialization proce-

dure requires the use of a DRBIIItscan tool. Refer to

the appropriate diagnostic information. The hard

wired inputs and outputs for the ACM may be diag-

VARESTRAINTS 8O - 9

AIRBAG CONTROL MODULE (Continued)

Page 248 of 1232

nosed and tested using conventional diagnostic tools

and procedures. However, conventional diagnostic

methods will not prove conclusive in the diagnosis of

the ACM or the supplemental restraint system. The

most reliable, efficient, and accurate means to diag-

nose the ACM or the supplemental restraint system

requires the use of a DRBIIItscan tool. Refer to the

appropriate diagnostic information.

REMOVAL

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE SUPPLEMENTAL RESTRAINT

SYSTEM BEFORE ATTEMPTING ANY STEERING

WHEEL, STEERING COLUMN, DRIVER AIRBAG,

PASSENGER AIRBAG, SEAT BELT TENSIONER, OR

INSTRUMENT PANEL COMPONENT DIAGNOSIS OR

SERVICE. DISCONNECT AND ISOLATE THE BAT-

TERY NEGATIVE (GROUND) CABLE, THEN WAIT

TWO MINUTES FOR THE SYSTEM CAPACITOR TO

DISCHARGE BEFORE PERFORMING FURTHER

DIAGNOSIS OR SERVICE. THIS IS THE ONLY SURE

WAY TO DISABLE THE SUPPLEMENTAL

RESTRAINT SYSTEM. FAILURE TO TAKE THE

PROPER PRECAUTIONS COULD RESULT IN ACCI-

DENTAL AIRBAG DEPLOYMENT AND POSSIBLE

PERSONAL INJURY.

WARNING: THE AIRBAG CONTROL MODULE CON-

TAINS THE IMPACT SENSOR, WHICH ENABLES

THE SYSTEM TO DEPLOY THE SUPPLEMENTAL

RESTRAINTS. NEVER STRIKE OR DROP THE AIR-

BAG CONTROL MODULE, AS IT CAN DAMAGE THE

IMPACT SENSOR OR AFFECT ITS CALIBRATION. IF

AN AIRBAG CONTROL MODULE IS ACCIDENTALLY

DROPPED DURING SERVICE, THE MODULE MUST

BE SCRAPPED AND REPLACED WITH A NEW UNIT.

FAILURE TO OBSERVE THIS WARNING COULD

RESULT IN ACCIDENTAL, INCOMPLETE, OR

IMPROPER SUPPLEMENTAL RESTRAINT DEPLOY-

MENT AND POSSIBLE OCCUPANT INJURIES.

(1) Disconnect and isolate the battery negative

cable. Wait two minutes for the system capacitor to

discharge before further service.

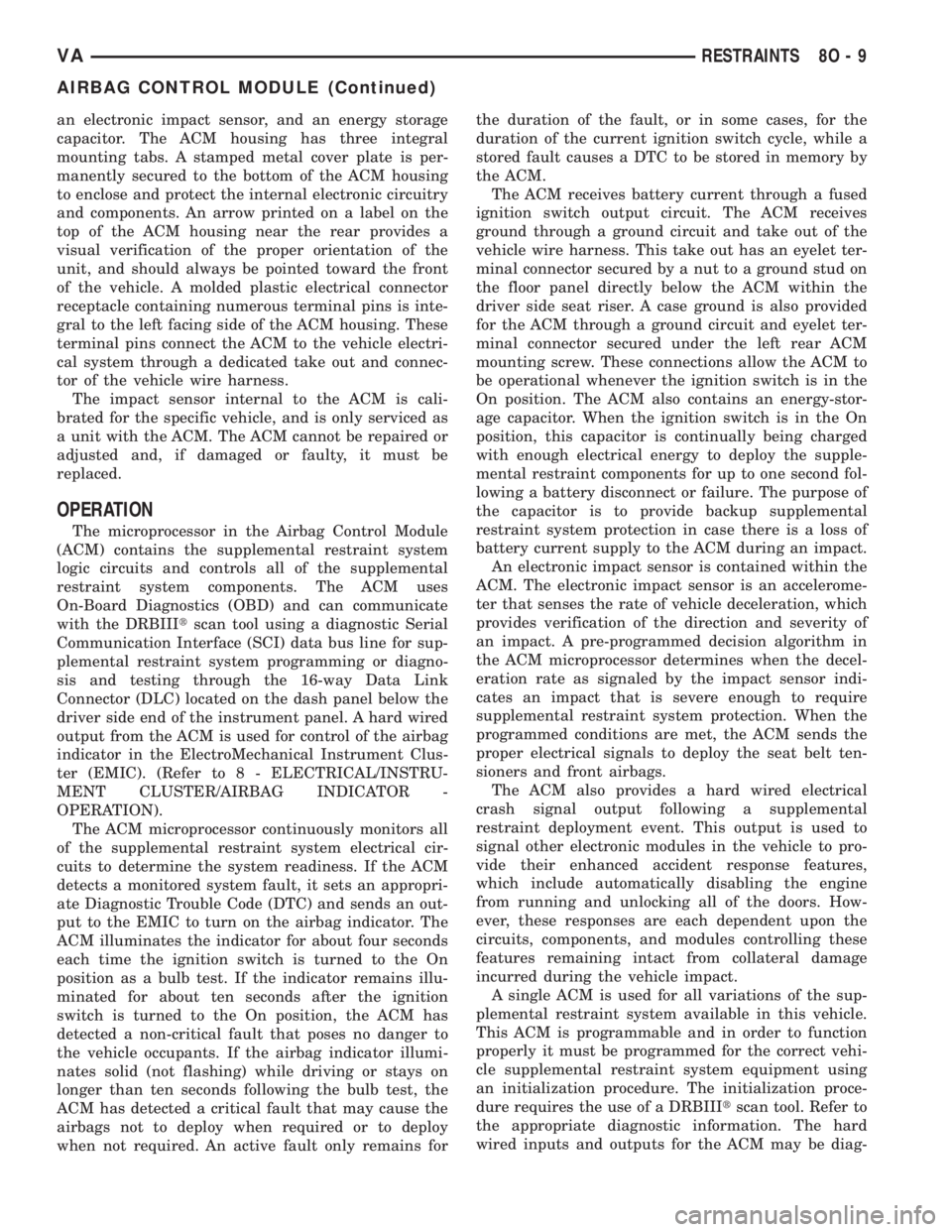

(2) Move the driver side front seat to its most for-

ward position for easiest access to the seat riser

cover panel (Fig. 8).

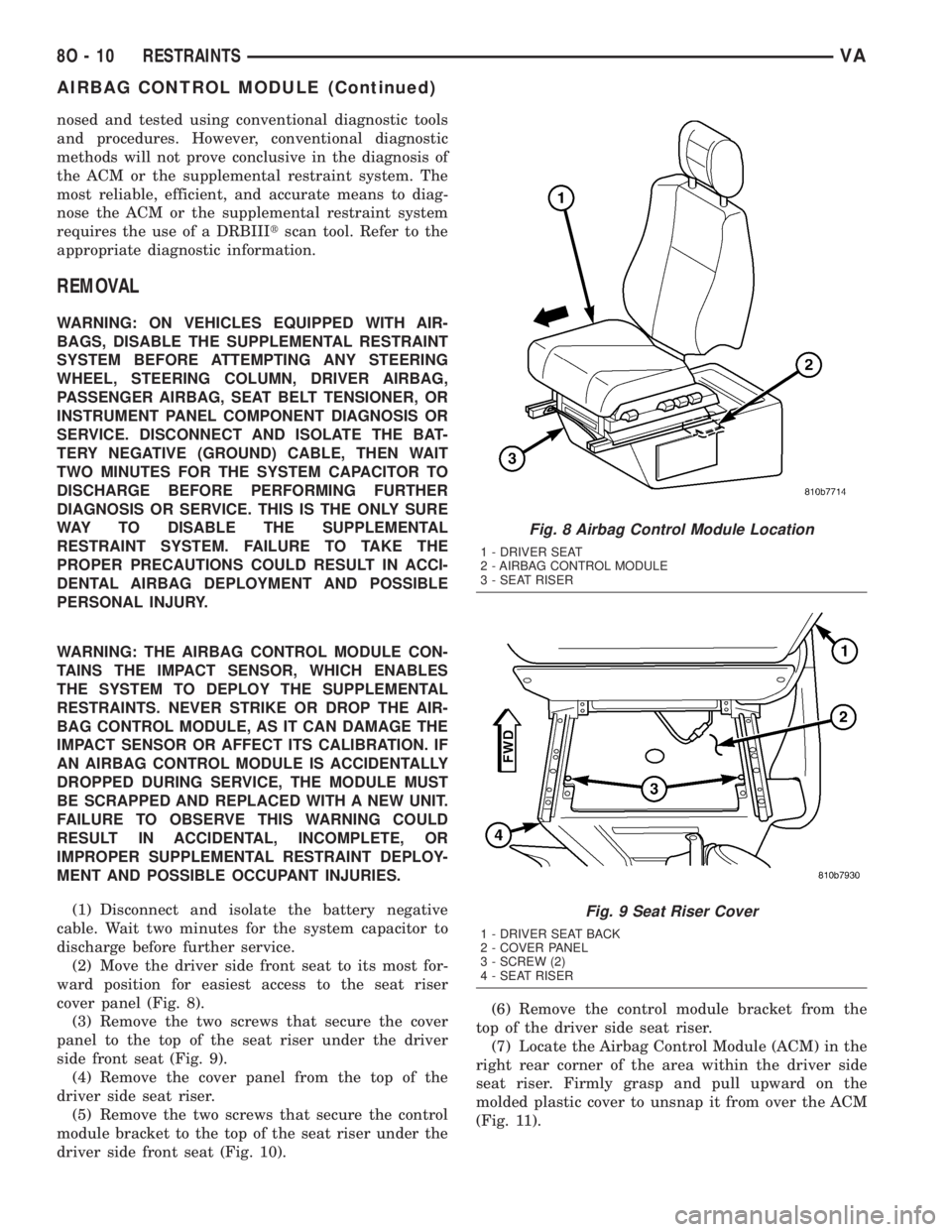

(3) Remove the two screws that secure the cover

panel to the top of the seat riser under the driver

side front seat (Fig. 9).

(4) Remove the cover panel from the top of the

driver side seat riser.

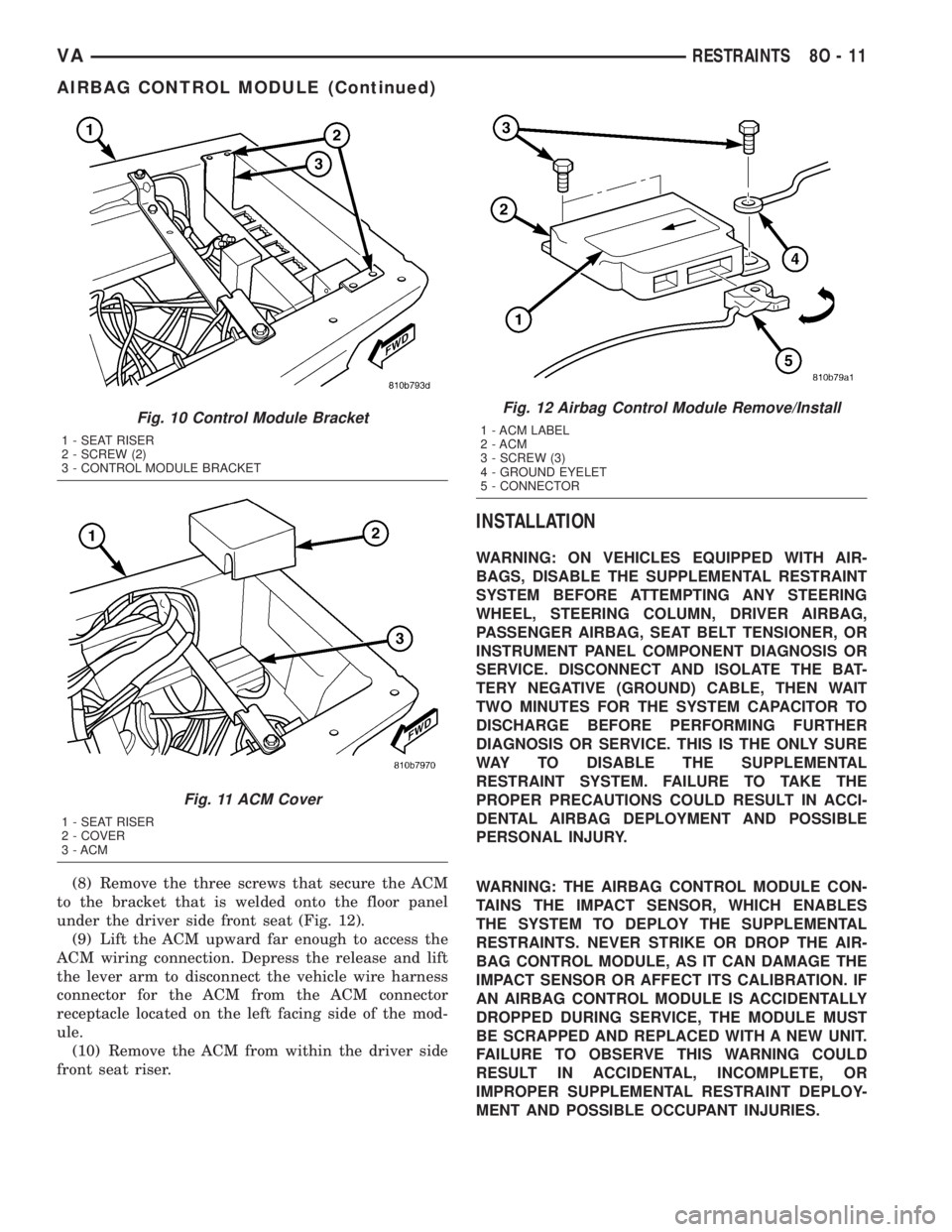

(5) Remove the two screws that secure the control

module bracket to the top of the seat riser under the

driver side front seat (Fig. 10).(6) Remove the control module bracket from the

top of the driver side seat riser.

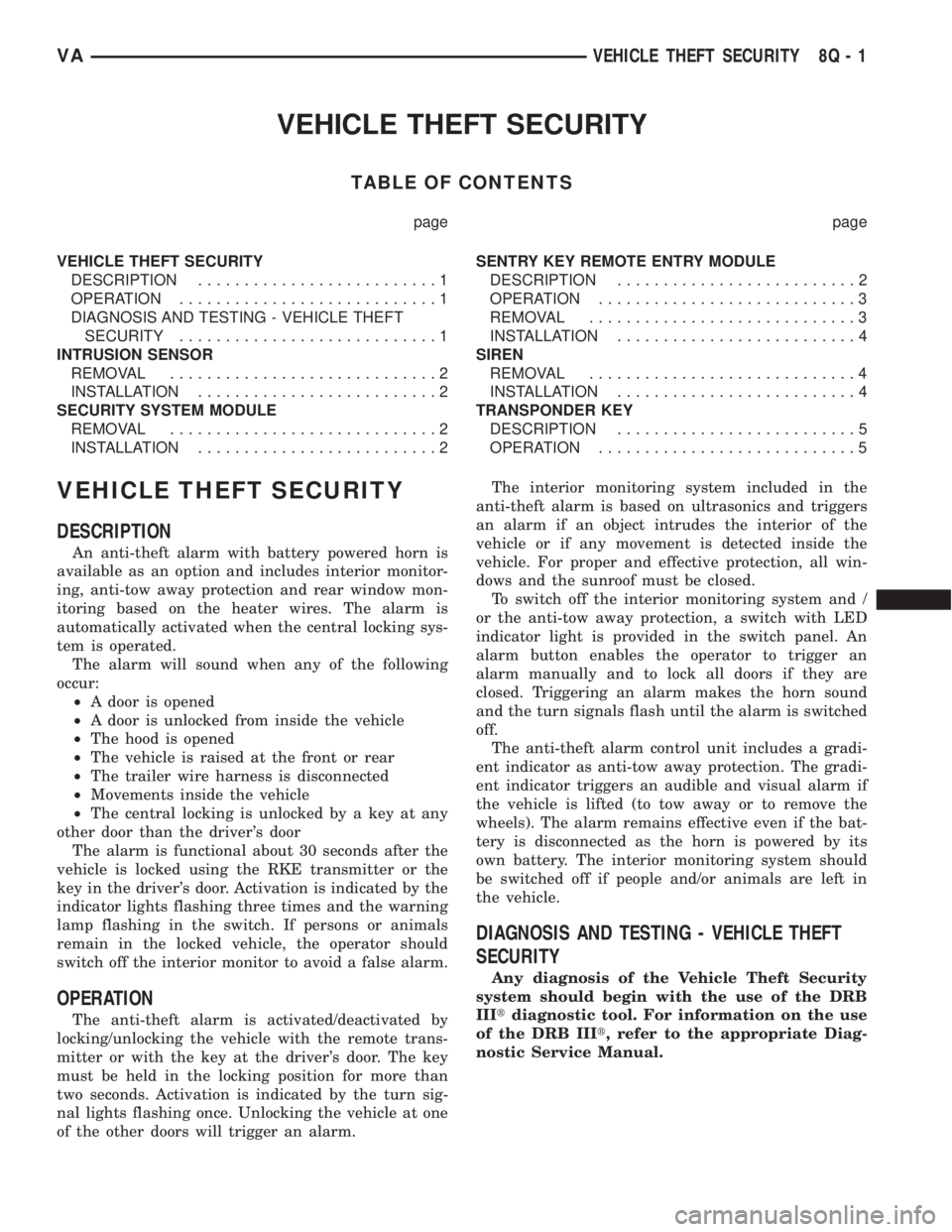

(7) Locate the Airbag Control Module (ACM) in the

right rear corner of the area within the driver side

seat riser. Firmly grasp and pull upward on the

molded plastic cover to unsnap it from over the ACM

(Fig. 11).

Fig. 8 Airbag Control Module Location

1 - DRIVER SEAT

2 - AIRBAG CONTROL MODULE

3 - SEAT RISER

Fig. 9 Seat Riser Cover

1 - DRIVER SEAT BACK

2 - COVER PANEL

3 - SCREW (2)

4 - SEAT RISER

8O - 10 RESTRAINTSVA

AIRBAG CONTROL MODULE (Continued)

Page 249 of 1232

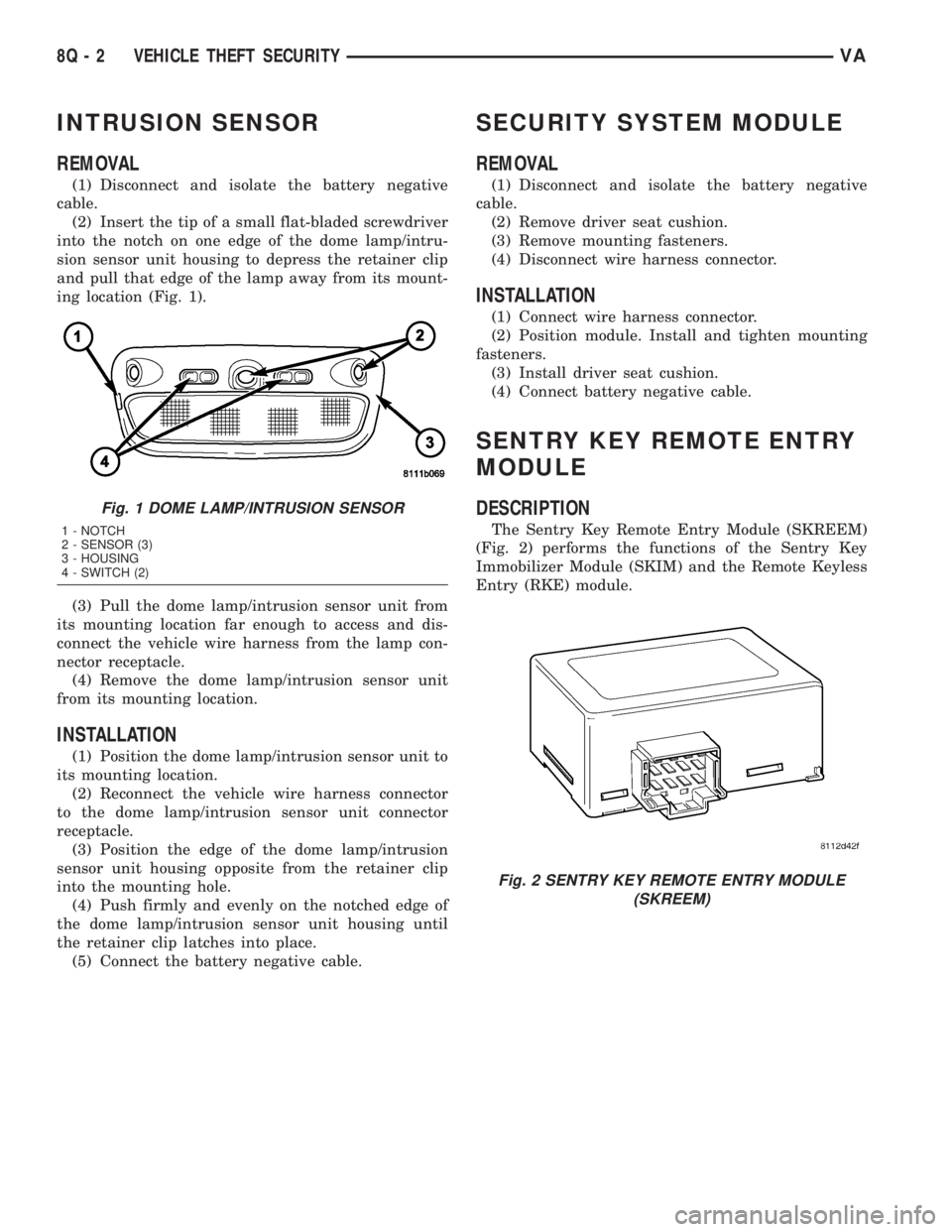

(8) Remove the three screws that secure the ACM

to the bracket that is welded onto the floor panel

under the driver side front seat (Fig. 12).

(9) Lift the ACM upward far enough to access the

ACM wiring connection. Depress the release and lift

the lever arm to disconnect the vehicle wire harness

connector for the ACM from the ACM connector

receptacle located on the left facing side of the mod-

ule.

(10) Remove the ACM from within the driver side

front seat riser.

INSTALLATION

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE SUPPLEMENTAL RESTRAINT

SYSTEM BEFORE ATTEMPTING ANY STEERING

WHEEL, STEERING COLUMN, DRIVER AIRBAG,

PASSENGER AIRBAG, SEAT BELT TENSIONER, OR

INSTRUMENT PANEL COMPONENT DIAGNOSIS OR

SERVICE. DISCONNECT AND ISOLATE THE BAT-

TERY NEGATIVE (GROUND) CABLE, THEN WAIT

TWO MINUTES FOR THE SYSTEM CAPACITOR TO

DISCHARGE BEFORE PERFORMING FURTHER

DIAGNOSIS OR SERVICE. THIS IS THE ONLY SURE

WAY TO DISABLE THE SUPPLEMENTAL

RESTRAINT SYSTEM. FAILURE TO TAKE THE

PROPER PRECAUTIONS COULD RESULT IN ACCI-

DENTAL AIRBAG DEPLOYMENT AND POSSIBLE

PERSONAL INJURY.

WARNING: THE AIRBAG CONTROL MODULE CON-

TAINS THE IMPACT SENSOR, WHICH ENABLES

THE SYSTEM TO DEPLOY THE SUPPLEMENTAL

RESTRAINTS. NEVER STRIKE OR DROP THE AIR-

BAG CONTROL MODULE, AS IT CAN DAMAGE THE

IMPACT SENSOR OR AFFECT ITS CALIBRATION. IF

AN AIRBAG CONTROL MODULE IS ACCIDENTALLY

DROPPED DURING SERVICE, THE MODULE MUST

BE SCRAPPED AND REPLACED WITH A NEW UNIT.

FAILURE TO OBSERVE THIS WARNING COULD

RESULT IN ACCIDENTAL, INCOMPLETE, OR

IMPROPER SUPPLEMENTAL RESTRAINT DEPLOY-

MENT AND POSSIBLE OCCUPANT INJURIES.

Fig. 10 Control Module Bracket

1 - SEAT RISER

2 - SCREW (2)

3 - CONTROL MODULE BRACKET

Fig. 11 ACM Cover

1 - SEAT RISER

2 - COVER

3 - ACM

Fig. 12 Airbag Control Module Remove/Install

1 - ACM LABEL

2 - ACM

3 - SCREW (3)

4 - GROUND EYELET

5 - CONNECTOR

VARESTRAINTS 8O - 11

AIRBAG CONTROL MODULE (Continued)

Page 277 of 1232

VEHICLE THEFT SECURITY

TABLE OF CONTENTS

page page

VEHICLE THEFT SECURITY

DESCRIPTION..........................1

OPERATION............................1

DIAGNOSIS AND TESTING - VEHICLE THEFT

SECURITY............................1

INTRUSION SENSOR

REMOVAL.............................2

INSTALLATION..........................2

SECURITY SYSTEM MODULE

REMOVAL.............................2

INSTALLATION..........................2SENTRY KEY REMOTE ENTRY MODULE

DESCRIPTION..........................2

OPERATION............................3

REMOVAL.............................3

INSTALLATION..........................4

SIREN

REMOVAL.............................4

INSTALLATION..........................4

TRANSPONDER KEY

DESCRIPTION..........................5

OPERATION............................5

VEHICLE THEFT SECURITY

DESCRIPTION

An anti-theft alarm with battery powered horn is

available as an option and includes interior monitor-

ing, anti-tow away protection and rear window mon-

itoring based on the heater wires. The alarm is

automatically activated when the central locking sys-

tem is operated.

The alarm will sound when any of the following

occur:

²A door is opened

²A door is unlocked from inside the vehicle

²The hood is opened

²The vehicle is raised at the front or rear

²The trailer wire harness is disconnected

²Movements inside the vehicle

²The central locking is unlocked by a key at any

other door than the driver's door

The alarm is functional about 30 seconds after the

vehicle is locked using the RKE transmitter or the

key in the driver's door. Activation is indicated by the

indicator lights flashing three times and the warning

lamp flashing in the switch. If persons or animals

remain in the locked vehicle, the operator should

switch off the interior monitor to avoid a false alarm.

OPERATION

The anti-theft alarm is activated/deactivated by

locking/unlocking the vehicle with the remote trans-

mitter or with the key at the driver's door. The key

must be held in the locking position for more than

two seconds. Activation is indicated by the turn sig-

nal lights flashing once. Unlocking the vehicle at one

of the other doors will trigger an alarm.The interior monitoring system included in the

anti-theft alarm is based on ultrasonics and triggers

an alarm if an object intrudes the interior of the

vehicle or if any movement is detected inside the

vehicle. For proper and effective protection, all win-

dows and the sunroof must be closed.

To switch off the interior monitoring system and /

or the anti-tow away protection, a switch with LED

indicator light is provided in the switch panel. An

alarm button enables the operator to trigger an

alarm manually and to lock all doors if they are

closed. Triggering an alarm makes the horn sound

and the turn signals flash until the alarm is switched

off.

The anti-theft alarm control unit includes a gradi-

ent indicator as anti-tow away protection. The gradi-

ent indicator triggers an audible and visual alarm if

the vehicle is lifted (to tow away or to remove the

wheels). The alarm remains effective even if the bat-

tery is disconnected as the horn is powered by its

own battery. The interior monitoring system should

be switched off if people and/or animals are left in

the vehicle.

DIAGNOSIS AND TESTING - VEHICLE THEFT

SECURITY

Any diagnosis of the Vehicle Theft Security

system should begin with the use of the DRB

IIItdiagnostic tool. For information on the use

of the DRB IIIt, refer to the appropriate Diag-

nostic Service Manual.

VAVEHICLE THEFT SECURITY 8Q - 1

Page 278 of 1232

INTRUSION SENSOR

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Insert the tip of a small flat-bladed screwdriver

into the notch on one edge of the dome lamp/intru-

sion sensor unit housing to depress the retainer clip

and pull that edge of the lamp away from its mount-

ing location (Fig. 1).

(3) Pull the dome lamp/intrusion sensor unit from

its mounting location far enough to access and dis-

connect the vehicle wire harness from the lamp con-

nector receptacle.

(4) Remove the dome lamp/intrusion sensor unit

from its mounting location.

INSTALLATION

(1) Position the dome lamp/intrusion sensor unit to

its mounting location.

(2) Reconnect the vehicle wire harness connector

to the dome lamp/intrusion sensor unit connector

receptacle.

(3) Position the edge of the dome lamp/intrusion

sensor unit housing opposite from the retainer clip

into the mounting hole.

(4) Push firmly and evenly on the notched edge of

the dome lamp/intrusion sensor unit housing until

the retainer clip latches into place.

(5) Connect the battery negative cable.

SECURITY SYSTEM MODULE

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Remove driver seat cushion.

(3) Remove mounting fasteners.

(4) Disconnect wire harness connector.

INSTALLATION

(1) Connect wire harness connector.

(2) Position module. Install and tighten mounting

fasteners.

(3) Install driver seat cushion.

(4) Connect battery negative cable.

SENTRY KEY REMOTE ENTRY

MODULE

DESCRIPTION

The Sentry Key Remote Entry Module (SKREEM)

(Fig. 2) performs the functions of the Sentry Key

Immobilizer Module (SKIM) and the Remote Keyless

Entry (RKE) module.

Fig. 1 DOME LAMP/INTRUSION SENSOR

1 - NOTCH

2 - SENSOR (3)

3 - HOUSING

4 - SWITCH (2)

Fig. 2 SENTRY KEY REMOTE ENTRY MODULE

(SKREEM)

8Q - 2 VEHICLE THEFT SECURITYVA

Page 317 of 1232

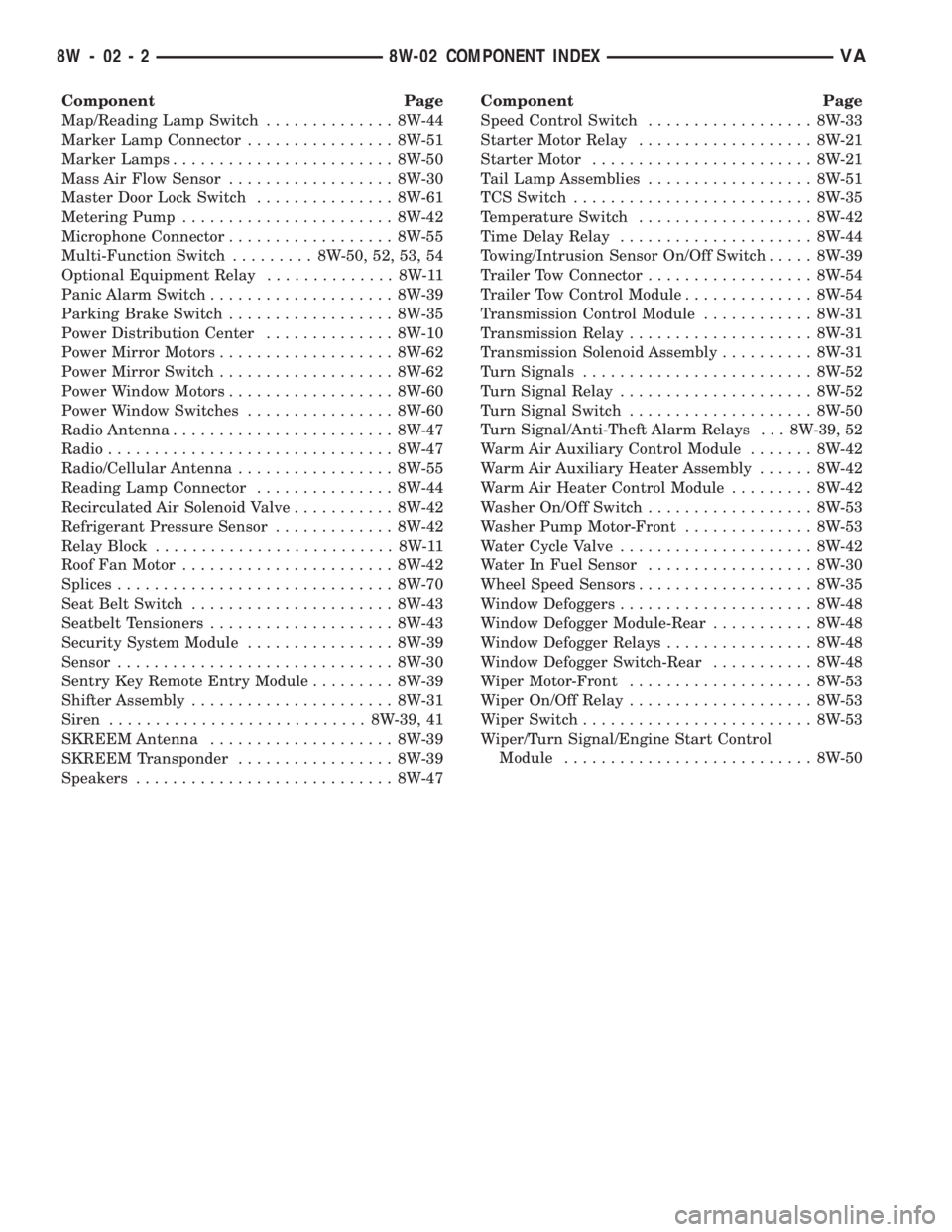

8W-02 COMPONENT INDEX

Component Page

A/C Auxiliary Fan Relay................ 8W-42

A/C Auxiliary Fan..................... 8W-42

A/C Compressor Clutch................. 8W-42

A/C Control Module-Roof................ 8W-42

A/C Fan Switch....................... 8W-42

A/C Switch-Roof...................... 8W-42

Accelerator Pedal Position Sensor......... 8W-30

Air Outlet Temperature Sensor........... 8W-42

Airbag Control Module................. 8W-43

Airbag Squibs........................ 8W-43

Ambient Temperature Sensor............ 8W-42

Ash Receiver Lamp.................... 8W-44

Automatic Temperature Control Module.... 8W-42

Auxiliary Heater Relay................. 8W-42

Auxiliary Heater Switch................ 8W-42

Battery Relay-Auxiliary................ 8W-20

Batteries............................ 8W-20

Beam Select Switch.................... 8W-50

Blower Motors........................ 8W-42

Body Plug Connector................... 8W-11

Boost Pressure Sensor.................. 8W-30

Boost Pressure Solenoid................ 8W-30

Brake Fluid Level Switch............... 8W-35

Brake Lamp Switch.................... 8W-35

Brake Wear Sensors................... 8W-35

Cabin Heater Assembly................. 8W-42

Cabin Heater Control Module............ 8W-42

Camshaft Position Sensor............... 8W-30

Center High Mounted Stop Lamp......... 8W-51

Central Timer Module.................. 8W-45

Cigar Lighter Lamp................... 8W-44

Cigar Lighter......................... 8W-41

Circulation Pump Diode................ 8W-42

Circulation Pump Relay................ 8W-42

Circulation Pump..................... 8W-42

Clockspring....................... 8W-41, 43

Contact Switch Door-Tailgate............ 8W-44

Controller Antilock Brake............... 8W-35

Courtesy Lamps...................... 8W-44

Crankcase Heater..................... 8W-30

Crankshaft Position Sensor.............. 8W-30

Ctel Antenna Connector................ 8W-55

Ctel Connector..................... 8W-47, 55

Cylinder Lock Switch-Driver............. 8W-61

D+ Relay No. 1....................... 8W-10

D+ Relay No. 2....................... 8W-11

Data Link Connector................... 8W-18

Daytime Running Lamp Relays........... 8W-50

Differential Lock Solenoid Valve.......... 8W-31

Dome Lamp.......................... 8W-44

Door Jamb Switches................... 8W-44

Door Lock Motor/Ajar Switch Assemblies . . . 8W-61Component Page

Dosing Pump......................... 8W-42

EGR Valve........................... 8W-30

Engine Control Module................. 8W-30

Engine Control Relay.................. 8W-31

Engine Coolant Level Switch............. 8W-30

Engine Coolant Temperature Sensor....... 8W-30

Engine Oil Sensor..................... 8W-30

Evaporator Temperature Sensor.......... 8W-42

Fan Stage 1 Relay..................... 8W-42

Fog Lamp Relay...................... 8W-50

Fog Lamp Switch..................... 8W-50

Fuel Injectors........................ 8W-30

Fuel Level Sensor..................... 8W-30

Fuel Pressure Sensor.................. 8W-30

Fuel Pressure Solenoid................. 8W-30

Fuel Shutdown Solenoid................ 8W-30

Fuel Temperature Sensor............... 8W-30

Fuses............................ 8W-10, 11

Fuse Blocks.......................... 8W-10

Fuse/Relay Block...................... 8W-11

Fused Ignition Switch Run-Start Relay..... 8W-11

Grounds............................ 8W-70

Generator........................... 8W-20

Glow Plug Control Module.............. 8W-30

Glow Plugs.......................... 8W-30

Hazard Warning Switch................ 8W-52

Headlamp Adjust Switch................ 8W-50

Headlamp Assemblies............... 8W-50, 52

Headlamp Switch..................... 8W-50

Heat Exchanger Connector.............. 8W-42

Heat Exchanger Switch................. 8W-42

Heated Seat Modules.................. 8W-63

Heated Seat Switches.................. 8W-63

Heater Timer-Auxiliary................. 8W-42

Hood Ajar Switch..................... 8W-39

Horn Relay.......................... 8W-41

Horn Switch......................... 8W-41

Horn............................... 8W-41

Ignition Lock Switch................... 8W-40

Ignition Switch....................... 8W-10

Instrument Cluster.................... 8W-40

Instrument Panel Socket................ 8W-40

Intake Air Temperature Sensor........... 8W-30

Interior Lamps....................... 8W-44

Interior Light Switches................. 8W-44

Interior Lighting Connector.............. 8W-44

Intrusion Sensors..................... 8W-39

Kickdown Switch...................... 8W-30

Lamp Relays......................... 8W-50

License Plate Lamps................... 8W-51

Locker Switches...................... 8W-31

Low Fuel Pressure Sensor............... 8W-30

VA8W-02 COMPONENT INDEX 8W - 02 - 1

Page 318 of 1232

Component Page

Map/Reading Lamp Switch.............. 8W-44

Marker Lamp Connector................ 8W-51

Marker Lamps........................ 8W-50

Mass Air Flow Sensor.................. 8W-30

Master Door Lock Switch............... 8W-61

Metering Pump....................... 8W-42

Microphone Connector.................. 8W-55

Multi-Function Switch......... 8W-50, 52, 53, 54

Optional Equipment Relay.............. 8W-11

Panic Alarm Switch.................... 8W-39

Parking Brake Switch.................. 8W-35

Power Distribution Center.............. 8W-10

Power Mirror Motors................... 8W-62

Power Mirror Switch................... 8W-62

Power Window Motors.................. 8W-60

Power Window Switches................ 8W-60

Radio Antenna........................ 8W-47

Radio............................... 8W-47

Radio/Cellular Antenna................. 8W-55

Reading Lamp Connector............... 8W-44

Recirculated Air Solenoid Valve........... 8W-42

Refrigerant Pressure Sensor............. 8W-42

Relay Block.......................... 8W-11

Roof Fan Motor....................... 8W-42

Splices.............................. 8W-70

Seat Belt Switch...................... 8W-43

Seatbelt Tensioners.................... 8W-43

Security System Module................ 8W-39

Sensor.............................. 8W-30

Sentry Key Remote Entry Module......... 8W-39

Shifter Assembly...................... 8W-31

Siren............................ 8W-39, 41

SKREEM Antenna.................... 8W-39

SKREEM Transponder................. 8W-39

Speakers............................ 8W-47Component Page

Speed Control Switch.................. 8W-33

Starter Motor Relay................... 8W-21

Starter Motor........................ 8W-21

Tail Lamp Assemblies.................. 8W-51

TCS Switch.......................... 8W-35

Temperature Switch................... 8W-42

Time Delay Relay..................... 8W-44

Towing/Intrusion Sensor On/Off Switch..... 8W-39

Trailer Tow Connector.................. 8W-54

Trailer Tow Control Module.............. 8W-54

Transmission Control Module............ 8W-31

Transmission Relay.................... 8W-31

Transmission Solenoid Assembly.......... 8W-31

Turn Signals......................... 8W-52

Turn Signal Relay..................... 8W-52

Turn Signal Switch.................... 8W-50

Turn Signal/Anti-Theft Alarm Relays . . . 8W-39, 52

Warm Air Auxiliary Control Module....... 8W-42

Warm Air Auxiliary Heater Assembly...... 8W-42

Warm Air Heater Control Module......... 8W-42

Washer On/Off Switch.................. 8W-53

Washer Pump Motor-Front.............. 8W-53

Water Cycle Valve..................... 8W-42

Water In Fuel Sensor.................. 8W-30

Wheel Speed Sensors................... 8W-35

Window Defoggers..................... 8W-48

Window Defogger Module-Rear........... 8W-48

Window Defogger Relays................ 8W-48

Window Defogger Switch-Rear........... 8W-48

Wiper Motor-Front.................... 8W-53

Wiper On/Off Relay.................... 8W-53

Wiper Switch......................... 8W-53

Wiper/Turn Signal/Engine Start Control

Module........................... 8W-50

8W - 02 - 2 8W-02 COMPONENT INDEXVA

Page 353 of 1232

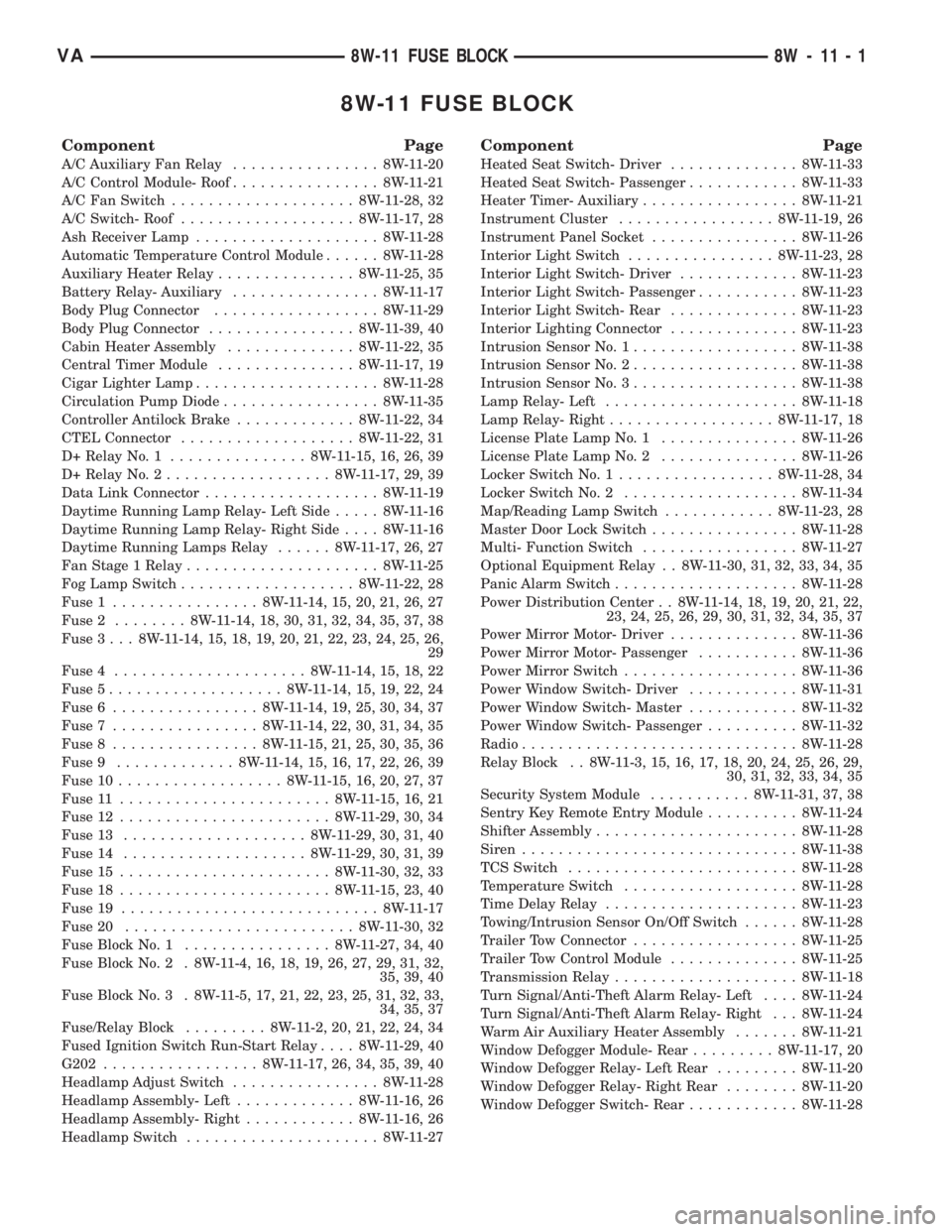

8W-11 FUSE BLOCK

Component Page

A/C Auxiliary Fan Relay................ 8W-11-20

A/C Control Module- Roof................ 8W-11-21

A/C Fan Switch.................... 8W-11-28, 32

A/C Switch- Roof................... 8W-11-17, 28

Ash Receiver Lamp.................... 8W-11-28

Automatic Temperature Control Module...... 8W-11-28

Auxiliary Heater Relay............... 8W-11-25, 35

Battery Relay- Auxiliary................ 8W-11-17

Body Plug Connector.................. 8W-11-29

Body Plug Connector................ 8W-11-39, 40

Cabin Heater Assembly.............. 8W-11-22, 35

Central Timer Module............... 8W-11-17, 19

Cigar Lighter Lamp.................... 8W-11-28

Circulation Pump Diode................. 8W-11-35

Controller Antilock Brake............. 8W-11-22, 34

CTEL Connector................... 8W-11-22, 31

D+ Relay No. 1............... 8W-11-15, 16, 26, 39

D+ Relay No. 2.................. 8W-11-17, 29, 39

Data Link Connector................... 8W-11-19

Daytime Running Lamp Relay- Left Side..... 8W-11-16

Daytime Running Lamp Relay- Right Side.... 8W-11-16

Daytime Running Lamps Relay...... 8W-11-17, 26, 27

Fan Stage 1 Relay..................... 8W-11-25

Fog Lamp Switch................... 8W-11-22, 28

Fuse 1................ 8W-11-14, 15, 20, 21, 26, 27

Fuse 2........ 8W-11-14, 18, 30, 31, 32, 34, 35, 37, 38

Fuse 3 . . . 8W-11-14, 15, 18, 19, 20, 21, 22, 23, 24, 25, 26,

29

Fuse 4..................... 8W-11-14, 15, 18, 22

Fuse 5................... 8W-11-14, 15, 19, 22, 24

Fuse 6................ 8W-11-14, 19, 25, 30, 34, 37

Fuse 7................ 8W-11-14, 22, 30, 31, 34, 35

Fuse 8................ 8W-11-15, 21, 25, 30, 35, 36

Fuse 9............. 8W-11-14, 15, 16, 17, 22, 26, 39

Fuse 10.................. 8W-11-15, 16, 20, 27, 37

Fuse 11....................... 8W-11-15, 16, 21

Fuse 12....................... 8W-11-29, 30, 34

Fuse 13.................... 8W-11-29, 30, 31, 40

Fuse 14.................... 8W-11-29, 30, 31, 39

Fuse 15....................... 8W-11-30, 32, 33

Fuse 18....................... 8W-11-15, 23, 40

Fuse 19............................ 8W-11-17

Fuse 20......................... 8W-11-30, 32

Fuse Block No. 1................ 8W-11-27, 34, 40

Fuse Block No. 2 . 8W-11-4, 16, 18, 19, 26, 27, 29, 31, 32,

35, 39, 40

Fuse Block No. 3 . 8W-11-5, 17, 21, 22, 23, 25, 31, 32, 33,

34, 35, 37

Fuse/Relay Block......... 8W-11-2, 20, 21, 22, 24, 34

Fused Ignition Switch Run-Start Relay.... 8W-11-29, 40

G202................. 8W-11-17, 26, 34, 35, 39, 40

Headlamp Adjust Switch................ 8W-11-28

Headlamp Assembly- Left............. 8W-11-16, 26

Headlamp Assembly- Right............ 8W-11-16, 26

Headlamp Switch..................... 8W-11-27

Component Page

Heated Seat Switch- Driver.............. 8W-11-33

Heated Seat Switch- Passenger............ 8W-11-33

Heater Timer- Auxiliary................. 8W-11-21

Instrument Cluster................. 8W-11-19, 26

Instrument Panel Socket................ 8W-11-26

Interior Light Switch................ 8W-11-23, 28

Interior Light Switch- Driver............. 8W-11-23

Interior Light Switch- Passenger........... 8W-11-23

Interior Light Switch- Rear.............. 8W-11-23

Interior Lighting Connector.............. 8W-11-23

Intrusion Sensor No. 1.................. 8W-11-38

Intrusion Sensor No. 2.................. 8W-11-38

Intrusion Sensor No. 3.................. 8W-11-38

Lamp Relay- Left..................... 8W-11-18

Lamp Relay- Right.................. 8W-11-17, 18

License Plate Lamp No. 1............... 8W-11-26

License Plate Lamp No. 2............... 8W-11-26

Locker Switch No. 1................. 8W-11-28, 34

Locker Switch No. 2................... 8W-11-34

Map/Reading Lamp Switch............ 8W-11-23, 28

Master Door Lock Switch................ 8W-11-28

Multi- Function Switch................. 8W-11-27

Optional Equipment Relay . . 8W-11-30, 31, 32, 33, 34, 35

Panic Alarm Switch.................... 8W-11-28

Power Distribution Center . . 8W-11-14, 18, 19, 20, 21, 22,

23, 24, 25, 26, 29, 30, 31, 32, 34, 35, 37

Power Mirror Motor- Driver.............. 8W-11-36

Power Mirror Motor- Passenger........... 8W-11-36

Power Mirror Switch................... 8W-11-36

Power Window Switch- Driver............ 8W-11-31

Power Window Switch- Master............ 8W-11-32

Power Window Switch- Passenger.......... 8W-11-32

Radio.............................. 8W-11-28

Relay Block . . 8W-11-3, 15, 16, 17, 18, 20, 24, 25, 26, 29,

30, 31, 32, 33, 34, 35

Security System Module........... 8W-11-31, 37, 38

Sentry Key Remote Entry Module.......... 8W-11-24

Shifter Assembly...................... 8W-11-28

Siren.............................. 8W-11-38

TCS Switch......................... 8W-11-28

Temperature Switch................... 8W-11-28

Time Delay Relay..................... 8W-11-23

Towing/Intrusion Sensor On/Off Switch...... 8W-11-28

Trailer Tow Connector.................. 8W-11-25

Trailer Tow Control Module.............. 8W-11-25

Transmission Relay.................... 8W-11-18

Turn Signal/Anti-Theft Alarm Relay- Left.... 8W-11-24

Turn Signal/Anti-Theft Alarm Relay- Right . . . 8W-11-24

Warm Air Auxiliary Heater Assembly....... 8W-11-21

Window Defogger Module- Rear......... 8W-11-17, 20

Window Defogger Relay- Left Rear......... 8W-11-20

Window Defogger Relay- Right Rear........ 8W-11-20

Window Defogger Switch- Rear............ 8W-11-28

VA8W-11 FUSE BLOCK 8W - 11 - 1