air bleeding MERCEDES-BENZ SPRINTER 2005 Service Repair Manual

[x] Cancel search | Manufacturer: MERCEDES-BENZ, Model Year: 2005, Model line: SPRINTER, Model: MERCEDES-BENZ SPRINTER 2005Pages: 1232, PDF Size: 39.23 MB

Page 68 of 1232

A worn, damaged wheel bearing or suspension

component are further causes of pull. A damaged

front tire (bruised, ply separation) can also cause

pull.

A common and frequently misdiagnosed pull condi-

tion is where direction of pull changes after a few

stops. The cause is a combination of brake drag fol-

lowed by fade at one of the brake units.

As the dragging brake overheats, efficiency is so

reduced that fade occurs. Since the opposite brake

unit is still functioning normally, its braking effect is

magnified. This causes pull to switch direction in

favor of the normally functioning brake unit.

An additional point when diagnosing a change in

pull condition concerns brake cool down. Remember

that pull will return to the original direction, if the

dragging brake unit is allowed to cool down (and is

not seriously damaged).

REAR BRAKE GRAB OR PULL

Rear grab or pull is usually caused by improperly

adjusted or seized parking brake cables, contami-

nated lining, bent or binding shoes and support

plates, or improperly assembled components. This is

particularly true when only one rear wheel is

involved. However, when both rear wheels are

affected, the master cylinder or proportioning valve

could be at fault.

BRAKES DO NOT HOLD AFTER DRIVING THROUGH DEEP

WATER PUDDLES

This condition is generally caused by water soaked

lining. If the lining is only wet, it can be dried by

driving with the brakes very lightly applied for a

mile or two. However, if the lining is both soaked and

dirt contaminated, cleaning and/or replacement will

be necessary.

BRAKE LINING CONTAMINATION

Brake lining contamination is mostly a product of

leaking calipers or worn seals, driving through deep

water puddles, or lining that has become covered

with grease and grit during repair. Contaminated lin-

ing should be replaced to avoid further brake prob-

lems.

WHEEL AND TIRE PROBLEMS

Some conditions attributed to brake components

may actually be caused by a wheel or tire problem.

A damaged wheel can cause shudder, vibration and

pull. A worn or damaged tire can also cause pull.

Severely worn tires with very little tread left can

produce a grab-like condition as the tire loses and

recovers traction. Flat-spotted tires can cause vibra-

tion and generate shudder during brake operation. A

tire with internal damage such as a severe bruise,

cut, or ply separation can cause pull and vibration.BRAKE NOISES

Some brake noise is common with rear drum

brakes and on some disc brakes during the first few

stops after a vehicle has been parked overnight or

stored. This is primarily due to the formation of trace

corrosion (light rust) on metal surfaces. This light

corrosion is typically cleared from the metal surfaces

after a few brake applications causing the noise to

subside.

BRAKE SQUEAK/SQUEAL

Brake squeak or squeal may be due to linings that

are wet or contaminated with brake fluid, grease, or

oil. Glazed linings and rotors with hard spots can

also contribute to squeak. Dirt and foreign material

embedded in the brake lining will also cause squeak/

squeal.

A very loud squeak or squeal is frequently a sign of

severely worn brake lining. If the lining has worn

through to the brake pads in spots, metal-to-metal

contact occurs. If the condition is allowed to continue,

rotors can become so scored that replacement is nec-

essary.

BRAKE CHATTER

Brake chatter is usually caused by loose or worn

components, or glazed/burnt lining. Rotors with hard

spots can also contribute to chatter. Additional causes

of chatter are out-of-tolerance rotors, brake lining not

securely attached to the shoes, loose wheel bearings

and contaminated brake lining.

THUMP/CLUNK NOISE

Thumping or clunk noises during braking are fre-

quentlynotcaused by brake components. In many

cases, such noises are caused by loose or damaged

steering, suspension, or engine components. However,

calipers that bind on the slide surfaces can generate

a thump or clunk noise.

STANDARD PROCEDURE

STANDARD PROCEDURE - MANUAL BLEEDING

Use Mopar brake fluid, or an equivalent quality

fluid meeting SAE and DOT 4 standards only. Use

fresh, clean fluid from a sealed container at all times.

(1) Remove reservoir filler caps and fill reservoir.

(2) If calipers, or wheel cylinders were overhauled,

open all caliper and wheel cylinder bleed screws.

Then close each bleed screw as fluid starts to drip

from it. Top off master cylinder reservoir once more

before proceeding.

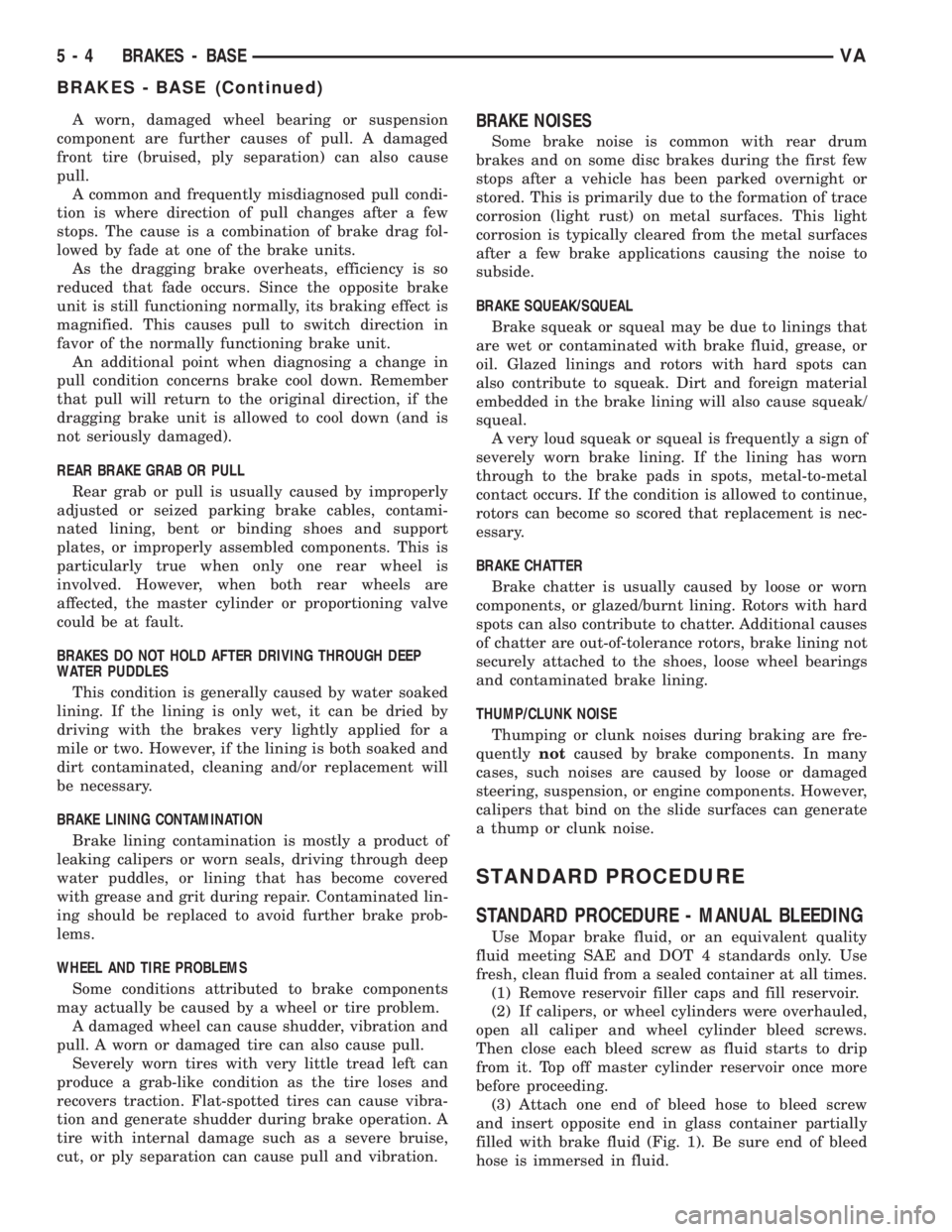

(3) Attach one end of bleed hose to bleed screw

and insert opposite end in glass container partially

filled with brake fluid (Fig. 1). Be sure end of bleed

hose is immersed in fluid.

5 - 4 BRAKES - BASEVA

BRAKES - BASE (Continued)

Page 69 of 1232

(4) Open up bleeder, then have a helper press

down the brake pedal. Once the pedal is down close

the bleeder. Repeat bleeding until fluid stream is

clear and free of bubbles. Then move to the next

wheel.

STANDARD PROCEDURE - PRESSURE

BLEEDING

Use Mopar brake fluid, or an equivalent quality

fluid meeting SAE and DOT 4 standards only. Use

fresh, clean fluid from a sealed container at all times.

Follow the manufacturers instructions carefully

when using pressure equipment. Do not exceed the

tank manufacturers pressure recommendations. Gen-

erally, a tank pressure of 15-20 psi is sufficient for

bleeding.

Fill the bleeder tank with recommended fluid and

purge air from the tank lines before bleeding.

Do not pressure bleed without a proper master cyl-

inder adapter. The wrong adapter can lead to leak-

age, or drawing air back into the system.

HYDRAULIC/MECHANICAL

SPECIFICATIONS

SPECIFICATIONS - TORQUE CHART

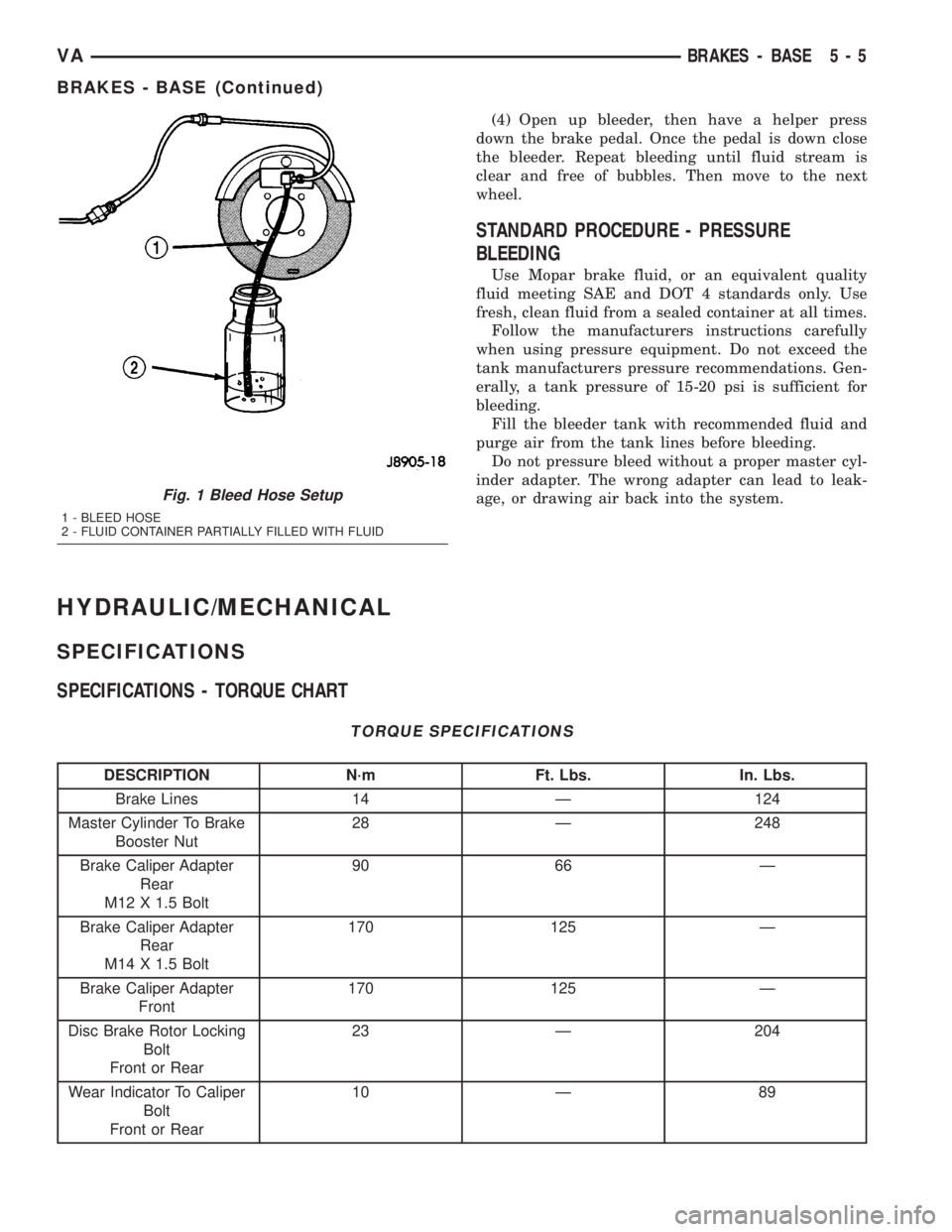

TORQUE SPECIFICATIONS

DESCRIPTION N´m Ft. Lbs. In. Lbs.

Brake Lines 14 Ð 124

Master Cylinder To Brake

Booster Nut28 Ð 248

Brake Caliper Adapter

Rear

M12 X 1.5 Bolt90 66 Ð

Brake Caliper Adapter

Rear

M14 X 1.5 Bolt170 125 Ð

Brake Caliper Adapter

Front170 125 Ð

Disc Brake Rotor Locking

Bolt

Front or Rear23 Ð 204

Wear Indicator To Caliper

Bolt

Front or Rear10 Ð 89

Fig. 1 Bleed Hose Setup

1 - BLEED HOSE

2 - FLUID CONTAINER PARTIALLY FILLED WITH FLUID

VABRAKES - BASE 5 - 5

BRAKES - BASE (Continued)

Page 80 of 1232

(8) Raise the vehicle and adjust the ALB controller

(Refer to 5 - BRAKES/HYDRAULIC/MECHANICAL/

ALB CONTROLLER - ADJUSTMENTS).

(9) Lower the vehicle and test drive.

ADJUSTMENTS

ADJUSTMENT

(1) Clean any debris away from the test ports caps

at the ALB controller.

(2) Connect brake adapters special tool 9297 to the

test ports at the ALB controller.

(3) Install a Pressure Gauge, Special Tool

C-4007-A, to the adapters.

(4) Tighten all tube nut fittings to 17 N´m (145 in.

lbs.) torque.

(5) Bleed any air out of the system. This includes

bleeding the air from the hose between the pressure

test fitting and pressure gauge, which is done at the

pressure gauge.

NOTE: Adjustment is determined for the automatic

load-dependent brake power control system accord-

ing to the ALB plate. This is housed in the stowage

compartment under the front passenger's door

panel. The part number of the rear spring is

stamped into the spring eye. This must correspond

to the part number of the rear spring on the ALB

plate.

(6) To accurately adjust the rear axle load you

must first determine the rear axle load by weighing

the vehicle at a local scale.

(7) Install the brake pedal winch Special tool 9296

between the brake pedal and the driver seat and

slowly turn the dial until the specified inlet brake

pressure is indicated at the gauge.

NOTE: The pressure gauge, connected at the ALB

controller must indicate the outlet pressure which

is assigned on the ALB plate to the rear axle load

determined.

NOTE: If the rear axle load determined is between

two figures indicated on the ALB plate, the outlet

pressure should be determined accordingly.

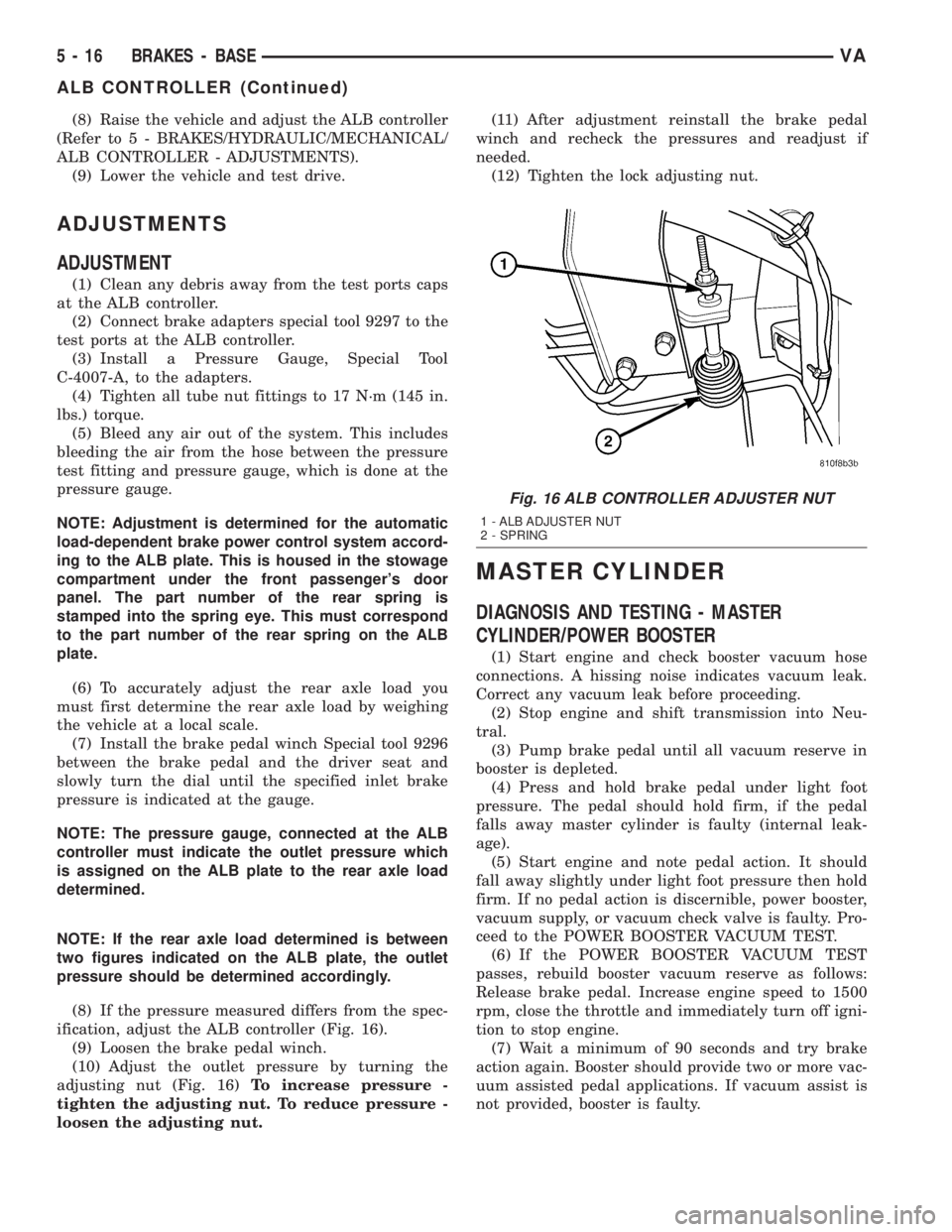

(8) If the pressure measured differs from the spec-

ification, adjust the ALB controller (Fig. 16).

(9) Loosen the brake pedal winch.

(10) Adjust the outlet pressure by turning the

adjusting nut (Fig. 16)To increase pressure -

tighten the adjusting nut. To reduce pressure -

loosen the adjusting nut.(11) After adjustment reinstall the brake pedal

winch and recheck the pressures and readjust if

needed.

(12) Tighten the lock adjusting nut.

MASTER CYLINDER

DIAGNOSIS AND TESTING - MASTER

CYLINDER/POWER BOOSTER

(1) Start engine and check booster vacuum hose

connections. A hissing noise indicates vacuum leak.

Correct any vacuum leak before proceeding.

(2) Stop engine and shift transmission into Neu-

tral.

(3) Pump brake pedal until all vacuum reserve in

booster is depleted.

(4) Press and hold brake pedal under light foot

pressure. The pedal should hold firm, if the pedal

falls away master cylinder is faulty (internal leak-

age).

(5) Start engine and note pedal action. It should

fall away slightly under light foot pressure then hold

firm. If no pedal action is discernible, power booster,

vacuum supply, or vacuum check valve is faulty. Pro-

ceed to the POWER BOOSTER VACUUM TEST.

(6) If the POWER BOOSTER VACUUM TEST

passes, rebuild booster vacuum reserve as follows:

Release brake pedal. Increase engine speed to 1500

rpm, close the throttle and immediately turn off igni-

tion to stop engine.

(7) Wait a minimum of 90 seconds and try brake

action again. Booster should provide two or more vac-

uum assisted pedal applications. If vacuum assist is

not provided, booster is faulty.

Fig. 16 ALB CONTROLLER ADJUSTER NUT

1 - ALB ADJUSTER NUT

2 - SPRING

5 - 16 BRAKES - BASEVA

ALB CONTROLLER (Continued)

Page 81 of 1232

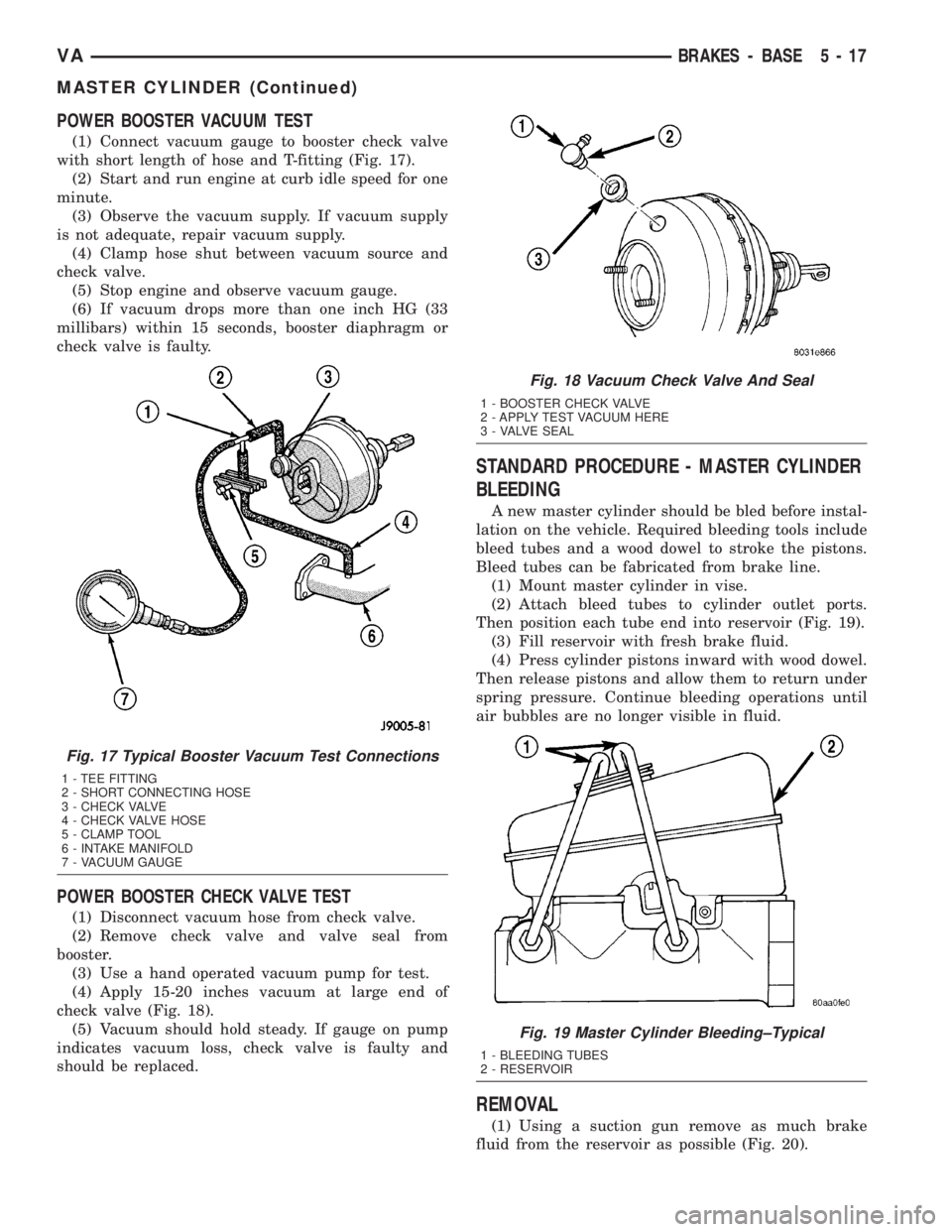

POWER BOOSTER VACUUM TEST

(1) Connect vacuum gauge to booster check valve

with short length of hose and T-fitting (Fig. 17).

(2) Start and run engine at curb idle speed for one

minute.

(3) Observe the vacuum supply. If vacuum supply

is not adequate, repair vacuum supply.

(4) Clamp hose shut between vacuum source and

check valve.

(5) Stop engine and observe vacuum gauge.

(6) If vacuum drops more than one inch HG (33

millibars) within 15 seconds, booster diaphragm or

check valve is faulty.

POWER BOOSTER CHECK VALVE TEST

(1) Disconnect vacuum hose from check valve.

(2) Remove check valve and valve seal from

booster.

(3) Use a hand operated vacuum pump for test.

(4) Apply 15-20 inches vacuum at large end of

check valve (Fig. 18).

(5) Vacuum should hold steady. If gauge on pump

indicates vacuum loss, check valve is faulty and

should be replaced.

STANDARD PROCEDURE - MASTER CYLINDER

BLEEDING

A new master cylinder should be bled before instal-

lation on the vehicle. Required bleeding tools include

bleed tubes and a wood dowel to stroke the pistons.

Bleed tubes can be fabricated from brake line.

(1) Mount master cylinder in vise.

(2) Attach bleed tubes to cylinder outlet ports.

Then position each tube end into reservoir (Fig. 19).

(3) Fill reservoir with fresh brake fluid.

(4) Press cylinder pistons inward with wood dowel.

Then release pistons and allow them to return under

spring pressure. Continue bleeding operations until

air bubbles are no longer visible in fluid.

REMOVAL

(1) Using a suction gun remove as much brake

fluid from the reservoir as possible (Fig. 20).

Fig. 17 Typical Booster Vacuum Test Connections

1 - TEE FITTING

2 - SHORT CONNECTING HOSE

3 - CHECK VALVE

4 - CHECK VALVE HOSE

5 - CLAMP TOOL

6 - INTAKE MANIFOLD

7 - VACUUM GAUGE

Fig. 18 Vacuum Check Valve And Seal

1 - BOOSTER CHECK VALVE

2 - APPLY TEST VACUUM HERE

3 - VALVE SEAL

Fig. 19 Master Cylinder Bleeding±Typical

1 - BLEEDING TUBES

2 - RESERVOIR

VABRAKES - BASE 5 - 17

MASTER CYLINDER (Continued)

Page 1212 of 1232

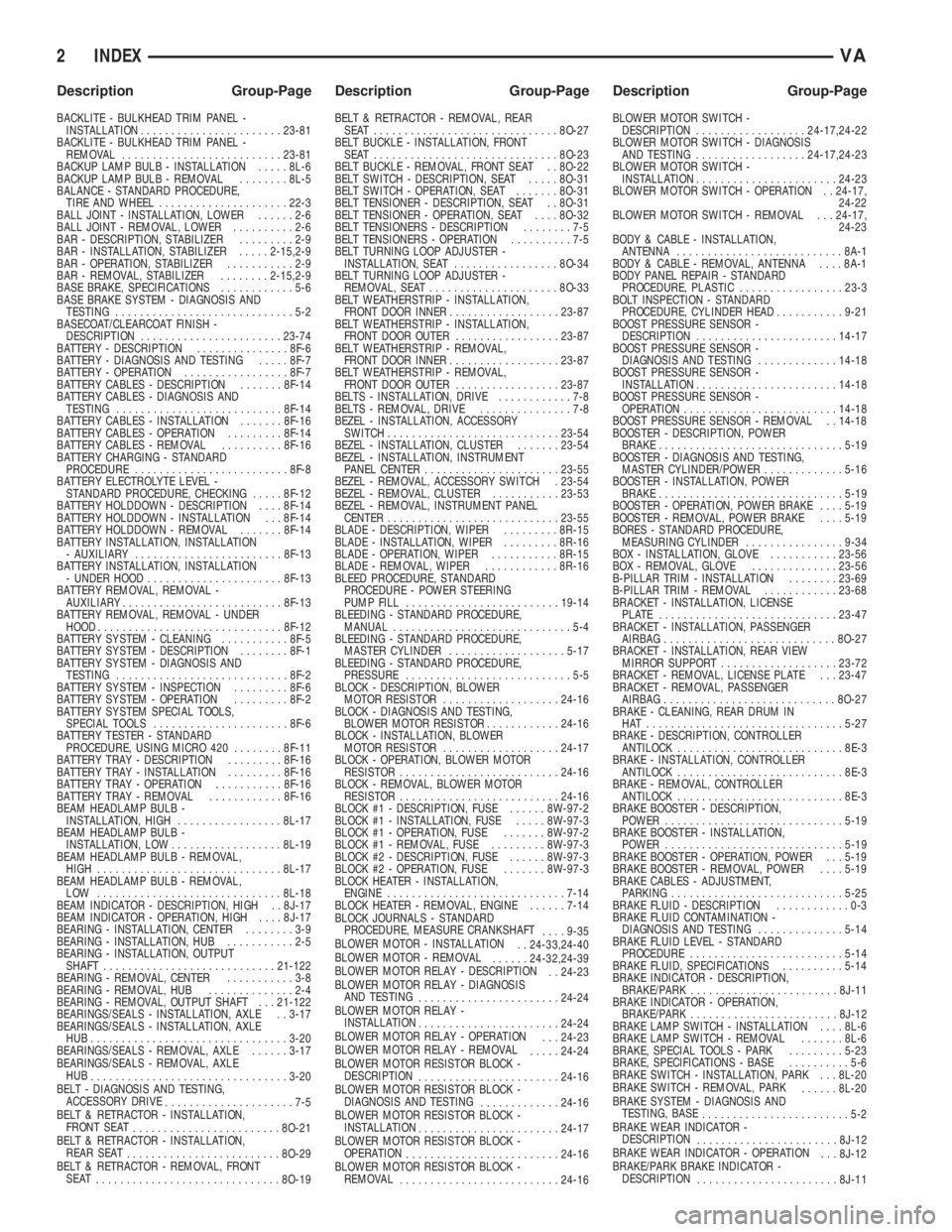

BACKLITE - BULKHEAD TRIM PANEL -

INSTALLATION.......................23-81

BACKLITE - BULKHEAD TRIM PANEL -

REMOVAL..........................23-81

BACKUP LAMP BULB - INSTALLATION.....8L-6

BACKUP LAMP BULB - REMOVAL........8L-5

BALANCE - STANDARD PROCEDURE,

TIRE AND WHEEL.....................22-3

BALL JOINT - INSTALLATION, LOWER......2-6

BALL JOINT - REMOVAL, LOWER..........2-6

BAR - DESCRIPTION, STABILIZER.........2-9

BAR - INSTALLATION, STABILIZER.....2-15,2-9

BAR - OPERATION, STABILIZER...........2-9

BAR - REMOVAL, STABILIZER........2-15,2-9

BASE BRAKE, SPECIFICATIONS............5-6

BASE BRAKE SYSTEM - DIAGNOSIS AND

TESTING.............................5-2

BASECOAT/CLEARCOAT FINISH -

DESCRIPTION.......................23-74

BATTERY - DESCRIPTION...............8F-6

BATTERY - DIAGNOSIS AND TESTING.....8F-7

BATTERY - OPERATION.................8F-7

BATTERY CABLES - DESCRIPTION.......8F-14

BATTERY CABLES - DIAGNOSIS AND

TESTING...........................8F-14

BATTERY CABLES - INSTALLATION.......8F-16

BATTERY CABLES - OPERATION.........8F-14

BATTERY CABLES - REMOVAL..........8F-16

BATTERY CHARGING - STANDARD

PROCEDURE.........................8F-8

BATTERY ELECTROLYTE LEVEL -

STANDARD PROCEDURE, CHECKING.....8F-12

BATTERY HOLDDOWN - DESCRIPTION....8F-14

BATTERY HOLDDOWN - INSTALLATION . . . 8F-14

BATTERY HOLDDOWN - REMOVAL.......8F-14

BATTERY INSTALLATION, INSTALLATION

- AUXILIARY........................8F-13

BATTERY INSTALLATION, INSTALLATION

- UNDER HOOD......................8F-13

BATTERY REMOVAL, REMOVAL -

AUXILIARY..........................8F-13

BATTERY REMOVAL, REMOVAL - UNDER

HOOD..............................8F-12

BATTERY SYSTEM - CLEANING...........8F-5

BATTERY SYSTEM - DESCRIPTION........8F-1

BATTERY SYSTEM - DIAGNOSIS AND

TESTING............................8F-2

BATTERY SYSTEM - INSPECTION.........8F-6

BATTERY SYSTEM - OPERATION.........8F-2

BATTERY SYSTEM SPECIAL TOOLS,

SPECIAL TOOLS......................8F-6

BATTERY TESTER - STANDARD

PROCEDURE, USING MICRO 420........8F-11

BATTERY TRAY - DESCRIPTION.........8F-16

BATTERY TRAY - INSTALLATION.........8F-16

BATTERY TRAY - OPERATION...........8F-16

BATTERY TRAY - REMOVAL............8F-16

BEAM HEADLAMP BULB -

INSTALLATION, HIGH.................8L-17

BEAM HEADLAMP BULB -

INSTALLATION, LOW..................8L-19

BEAM HEADLAMP BULB - REMOVAL,

HIGH..............................8L-17

BEAM HEADLAMP BULB - REMOVAL,

LOW ..............................8L-18

BEAM INDICATOR - DESCRIPTION, HIGH . . 8J-17

BEAM INDICATOR - OPERATION, HIGH....8J-17

BEARING - INSTALLATION, CENTER........3-9

BEARING - INSTALLATION, HUB...........2-5

BEARING - INSTALLATION, OUTPUT

SHAFT............................21-122

BEARING - REMOVAL, CENTER...........3-8

BEARING - REMOVAL, HUB..............2-4

BEARING - REMOVAL, OUTPUT SHAFT . . . 21-122

BEARINGS/SEALS - INSTALLATION, AXLE . . 3-17

BEARINGS/SEALS - INSTALLATION, AXLE

HUB................................3-20

BEARINGS/SEALS - REMOVAL, AXLE......3-17

BEARINGS/SEALS - REMOVAL, AXLE

HUB

................................3-20

BELT - DIAGNOSIS AND TESTING,

ACCESSORY DRIVE

.....................7-5

BELT & RETRACTOR - INSTALLATION,

FRONT SEAT

........................8O-21

BELT & RETRACTOR - INSTALLATION,

REAR SEAT

.........................8O-29

BELT & RETRACTOR - REMOVAL, FRONT

SEAT

..............................8O-19BELT & RETRACTOR - REMOVAL, REAR

SEAT ..............................8O-27

BELT BUCKLE - INSTALLATION, FRONT

SEAT ..............................8O-23

BELT BUCKLE - REMOVAL, FRONT SEAT . . 8O-22

BELT SWITCH - DESCRIPTION, SEAT.....8O-31

BELT SWITCH - OPERATION, SEAT.......8O-31

BELT TENSIONER - DESCRIPTION, SEAT . . 8O-31

BELT TENSIONER - OPERATION, SEAT....8O-32

BELT TENSIONERS - DESCRIPTION........7-5

BELT TENSIONERS - OPERATION..........7-5

BELT TURNING LOOP ADJUSTER -

INSTALLATION, SEAT.................8O-34

BELT TURNING LOOP ADJUSTER -

REMOVAL, SEAT.....................8O-33

BELT WEATHERSTRIP - INSTALLATION,

FRONT DOOR INNER..................23-87

BELT WEATHERSTRIP - INSTALLATION,

FRONT DOOR OUTER.................23-87

BELT WEATHERSTRIP - REMOVAL,

FRONT DOOR INNER..................23-87

BELT WEATHERSTRIP - REMOVAL,

FRONT DOOR OUTER.................23-87

BELTS - INSTALLATION, DRIVE............7-8

BELTS - REMOVAL, DRIVE...............7-8

BEZEL - INSTALLATION, ACCESSORY

SWITCH............................23-54

BEZEL - INSTALLATION, CLUSTER.......23-54

BEZEL - INSTALLATION, INSTRUMENT

PANEL CENTER......................23-55

BEZEL - REMOVAL, ACCESSORY SWITCH . 23-54

BEZEL - REMOVAL, CLUSTER...........23-53

BEZEL - REMOVAL, INSTRUMENT PANEL

CENTER............................23-55

BLADE - DESCRIPTION, WIPER.........8R-15

BLADE - INSTALLATION, WIPER.........8R-16

BLADE - OPERATION, WIPER...........8R-15

BLADE - REMOVAL, WIPER............8R-16

BLEED PROCEDURE, STANDARD

PROCEDURE - POWER STEERING

PUMP FILL.........................19-14

BLEEDING - STANDARD PROCEDURE,

MANUAL.............................5-4

BLEEDING - STANDARD PROCEDURE,

MASTER CYLINDER...................5-17

BLEEDING - STANDARD PROCEDURE,

PRESSURE...........................5-5

BLOCK - DESCRIPTION, BLOWER

MOTOR RESISTOR...................24-16

BLOCK - DIAGNOSIS AND TESTING,

BLOWER MOTOR RESISTOR............24-16

BLOCK - INSTALLATION, BLOWER

MOTOR RESISTOR...................24-17

BLOCK - OPERATION, BLOWER MOTOR

RESISTOR..........................24-16

BLOCK - REMOVAL, BLOWER MOTOR

RESISTOR..........................24-16

BLOCK #1 - DESCRIPTION, FUSE......8W-97-2

BLOCK #1 - INSTALLATION, FUSE.....8W-97-3

BLOCK #1 - OPERATION, FUSE.......8W-97-2

BLOCK #1 - REMOVAL, FUSE.........8W-97-3

BLOCK #2 - DESCRIPTION, FUSE......8W-97-3

BLOCK #2 - OPERATION, FUSE.......8W-97-3

BLOCK HEATER - INSTALLATION,

ENGINE.............................7-14

BLOCK HEATER - REMOVAL, ENGINE......7-14

BLOCK JOURNALS - STANDARD

PROCEDURE, MEASURE CRANKSHAFT

....9-35

BLOWER MOTOR - INSTALLATION

. . 24-33,24-40

BLOWER MOTOR - REMOVAL

......24-32,24-39

BLOWER MOTOR RELAY - DESCRIPTION

. . 24-23

BLOWER MOTOR RELAY - DIAGNOSIS

AND TESTING

.......................24-24

BLOWER MOTOR RELAY -

INSTALLATION

.......................24-24

BLOWER MOTOR RELAY - OPERATION

. . . 24-23

BLOWER MOTOR RELAY - REMOVAL

.....24-24

BLOWER MOTOR RESISTOR BLOCK -

DESCRIPTION

.......................24-16

BLOWER MOTOR RESISTOR BLOCK -

DIAGNOSIS AND TESTING

.............24-16

BLOWER MOTOR RESISTOR BLOCK -

INSTALLATION

.......................24-17

BLOWER MOTOR RESISTOR BLOCK -

OPERATION

.........................24-16

BLOWER MOTOR RESISTOR BLOCK -

REMOVAL

..........................24-16BLOWER MOTOR SWITCH -

DESCRIPTION..................24-17,24-22

BLOWER MOTOR SWITCH - DIAGNOSIS

AND TESTING..................24-17,24-23

BLOWER MOTOR SWITCH -

INSTALLATION.......................24-23

BLOWER MOTOR SWITCH - OPERATION . . 24-17,

24-22

BLOWER MOTOR SWITCH - REMOVAL . . . 24-17,

24-23

BODY & CABLE - INSTALLATION,

ANTENNA...........................8A-1

BODY & CABLE - REMOVAL, ANTENNA....8A-1

BODY PANEL REPAIR - STANDARD

PROCEDURE, PLASTIC.................23-3

BOLT INSPECTION - STANDARD

PROCEDURE, CYLINDER HEAD...........9-21

BOOST PRESSURE SENSOR -

DESCRIPTION.......................14-17

BOOST PRESSURE SENSOR -

DIAGNOSIS AND TESTING.............14-18

BOOST PRESSURE SENSOR -

INSTALLATION.......................14-18

BOOST PRESSURE SENSOR -

OPERATION.........................14-18

BOOST PRESSURE SENSOR - REMOVAL . . 14-18

BOOSTER - DESCRIPTION, POWER

BRAKE..............................5-19

BOOSTER - DIAGNOSIS AND TESTING,

MASTER CYLINDER/POWER.............5-16

BOOSTER - INSTALLATION, POWER

BRAKE..............................5-19

BOOSTER - OPERATION, POWER BRAKE....5-19

BOOSTER - REMOVAL, POWER BRAKE....5-19

BORES - STANDARD PROCEDURE,

MEASURING CYLINDER................9-34

BOX - INSTALLATION, GLOVE...........23-56

BOX - REMOVAL, GLOVE..............23-56

B-PILLAR TRIM - INSTALLATION........23-69

B-PILLAR TRIM - REMOVAL............23-68

BRACKET - INSTALLATION, LICENSE

PLATE .............................23-47

BRACKET - INSTALLATION, PASSENGER

AIRBAG............................8O-27

BRACKET - INSTALLATION, REAR VIEW

MIRROR SUPPORT...................23-72

BRACKET - REMOVAL, LICENSE PLATE . . . 23-47

BRACKET - REMOVAL, PASSENGER

AIRBAG............................8O-27

BRAKE - CLEANING, REAR DRUM IN

HAT ................................5-27

BRAKE - DESCRIPTION, CONTROLLER

ANTILOCK...........................8E-3

BRAKE - INSTALLATION, CONTROLLER

ANTILOCK...........................8E-3

BRAKE - REMOVAL, CONTROLLER

ANTILOCK...........................8E-3

BRAKE BOOSTER - DESCRIPTION,

POWER.............................5-19

BRAKE BOOSTER - INSTALLATION,

POWER.............................5-19

BRAKE BOOSTER - OPERATION, POWER . . . 5-19

BRAKE BOOSTER - REMOVAL, POWER....5-19

BRAKE CABLES - ADJUSTMENT,

PARKING............................5-25

BRAKE FLUID - DESCRIPTION............0-3

BRAKE FLUID CONTAMINATION -

DIAGNOSIS AND TESTING..............5-14

BRAKE FLUID LEVEL - STANDARD

PROCEDURE.........................5-14

BRAKE FLUID, SPECIFICATIONS..........5-14

BRAKE INDICATOR - DESCRIPTION,

BRAKE/PARK........................8J-11

BRAKE INDICATOR - OPERATION,

BRAKE/PARK........................8J-12

BRAKE LAMP SWITCH - INSTALLATION....8L-6

BRAKE LAMP SWITCH - REMOVAL.......8L-6

BRAKE, SPECIAL TOOLS - PARK.........5-23

BRAKE, SPECIFICATIONS - BASE..........5-6

BRAKE SWITCH - INSTALLATION, PARK . . . 8L-20

BRAKE SWITCH - REMOVAL, PARK

......8L-20

BRAKE SYSTEM - DIAGNOSIS AND

TESTING, BASE

........................5-2

BRAKE WEAR INDICATOR -

DESCRIPTION

.......................8J-12

BRAKE WEAR INDICATOR - OPERATION

. . . 8J-12

BRAKE/PARK BRAKE INDICATOR -

DESCRIPTION

.......................8J-11

2 INDEXVA

Description Group-Page Description Group-Page Description Group-Page

Page 1215 of 1232

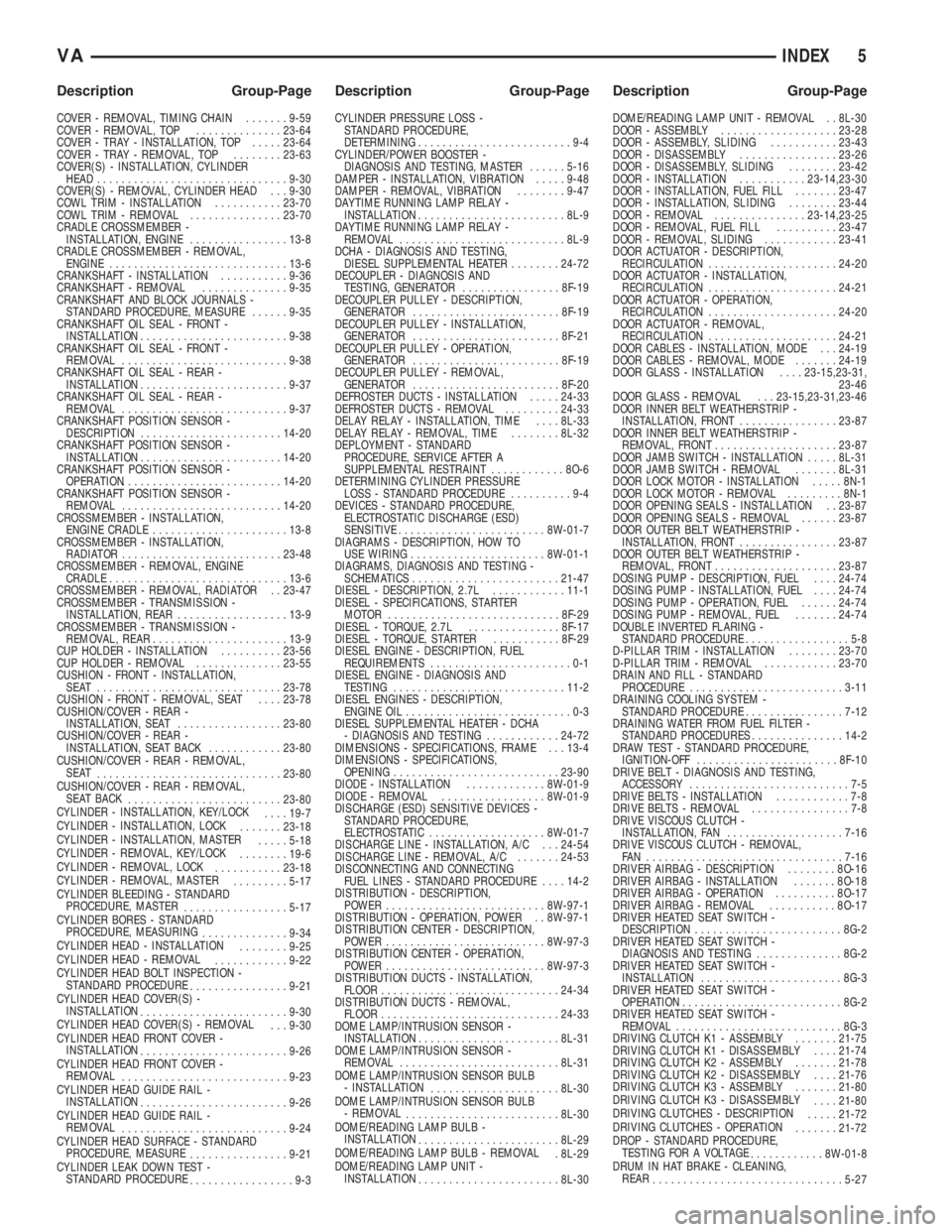

COVER - REMOVAL, TIMING CHAIN.......9-59

COVER - REMOVAL, TOP..............23-64

COVER - TRAY - INSTALLATION, TOP.....23-64

COVER - TRAY - REMOVAL, TOP........23-63

COVER(S) - INSTALLATION, CYLINDER

HEAD...............................9-30

COVER(S) - REMOVAL, CYLINDER HEAD . . . 9-30

COWL TRIM - INSTALLATION...........23-70

COWL TRIM - REMOVAL...............23-70

CRADLE CROSSMEMBER -

INSTALLATION, ENGINE................13-8

CRADLE CROSSMEMBER - REMOVAL,

ENGINE.............................13-6

CRANKSHAFT - INSTALLATION...........9-36

CRANKSHAFT - REMOVAL..............9-35

CRANKSHAFT AND BLOCK JOURNALS -

STANDARD PROCEDURE, MEASURE......9-35

CRANKSHAFT OIL SEAL - FRONT -

INSTALLATION........................9-38

CRANKSHAFT OIL SEAL - FRONT -

REMOVAL...........................9-38

CRANKSHAFT OIL SEAL - REAR -

INSTALLATION........................9-37

CRANKSHAFT OIL SEAL - REAR -

REMOVAL...........................9-37

CRANKSHAFT POSITION SENSOR -

DESCRIPTION.......................14-20

CRANKSHAFT POSITION SENSOR -

INSTALLATION.......................14-20

CRANKSHAFT POSITION SENSOR -

OPERATION..........................14-20

CRANKSHAFT POSITION SENSOR -

REMOVAL..........................14-20

CROSSMEMBER - INSTALLATION,

ENGINE CRADLE......................13-8

CROSSMEMBER - INSTALLATION,

RADIATOR..........................23-48

CROSSMEMBER - REMOVAL, ENGINE

CRADLE.............................13-6

CROSSMEMBER - REMOVAL, RADIATOR . . 23-47

CROSSMEMBER - TRANSMISSION -

INSTALLATION, REAR..................13-9

CROSSMEMBER - TRANSMISSION -

REMOVAL, REAR......................13-9

CUP HOLDER - INSTALLATION..........23-56

CUP HOLDER - REMOVAL..............23-55

CUSHION - FRONT - INSTALLATION,

SEAT ..............................23-78

CUSHION - FRONT - REMOVAL, SEAT....23-78

CUSHION/COVER - REAR -

INSTALLATION, SEAT.................23-80

CUSHION/COVER - REAR -

INSTALLATION, SEAT BACK............23-80

CUSHION/COVER - REAR - REMOVAL,

SEAT

..............................23-80

CUSHION/COVER - REAR - REMOVAL,

SEAT BACK

.........................23-80

CYLINDER - INSTALLATION, KEY/LOCK

....19-7

CYLINDER - INSTALLATION, LOCK

.......23-18

CYLINDER - INSTALLATION, MASTER

.....5-18

CYLINDER - REMOVAL, KEY/LOCK

........19-6

CYLINDER - REMOVAL, LOCK

...........23-18

CYLINDER - REMOVAL, MASTER

.........5-17

CYLINDER BLEEDING - STANDARD

PROCEDURE, MASTER

.................5-17

CYLINDER BORES - STANDARD

PROCEDURE, MEASURING

..............9-34

CYLINDER HEAD - INSTALLATION

........9-25

CYLINDER HEAD - REMOVAL

............9-22

CYLINDER HEAD BOLT INSPECTION -

STANDARD PROCEDURE

................9-21

CYLINDER HEAD COVER(S) -

INSTALLATION

........................9-30

CYLINDER HEAD COVER(S) - REMOVAL

. . . 9-30

CYLINDER HEAD FRONT COVER -

INSTALLATION

........................9-26

CYLINDER HEAD FRONT COVER -

REMOVAL

...........................9-23

CYLINDER HEAD GUIDE RAIL -

INSTALLATION

........................9-26

CYLINDER HEAD GUIDE RAIL -

REMOVAL

...........................9-24

CYLINDER HEAD SURFACE - STANDARD

PROCEDURE, MEASURE

................9-21

CYLINDER LEAK DOWN TEST -

STANDARD PROCEDURE

.................9-3CYLINDER PRESSURE LOSS -

STANDARD PROCEDURE,

DETERMINING.........................9-4

CYLINDER/POWER BOOSTER -

DIAGNOSIS AND TESTING, MASTER......5-16

DAMPER - INSTALLATION, VIBRATION.....9-48

DAMPER - REMOVAL, VIBRATION........9-47

DAYTIME RUNNING LAMP RELAY -

INSTALLATION........................8L-9

DAYTIME RUNNING LAMP RELAY -

REMOVAL...........................8L-9

DCHA - DIAGNOSIS AND TESTING,

DIESEL SUPPLEMENTAL HEATER........24-72

DECOUPLER - DIAGNOSIS AND

TESTING, GENERATOR................8F-19

DECOUPLER PULLEY - DESCRIPTION,

GENERATOR........................8F-19

DECOUPLER PULLEY - INSTALLATION,

GENERATOR........................8F-21

DECOUPLER PULLEY - OPERATION,

GENERATOR........................8F-19

DECOUPLER PULLEY - REMOVAL,

GENERATOR........................8F-20

DEFROSTER DUCTS - INSTALLATION.....24-33

DEFROSTER DUCTS - REMOVAL.........24-33

DELAY RELAY - INSTALLATION, TIME....8L-33

DELAY RELAY - REMOVAL, TIME........8L-32

DEPLOYMENT - STANDARD

PROCEDURE, SERVICE AFTER A

SUPPLEMENTAL RESTRAINT............8O-6

DETERMINING CYLINDER PRESSURE

LOSS - STANDARD PROCEDURE..........9-4

DEVICES - STANDARD PROCEDURE,

ELECTROSTATIC DISCHARGE (ESD)

SENSITIVE........................8W-01-7

DIAGRAMS - DESCRIPTION, HOW TO

USE WIRING......................8W-01-1

DIAGRAMS, DIAGNOSIS AND TESTING -

SCHEMATICS........................21-47

DIESEL - DESCRIPTION, 2.7L............11-1

DIESEL - SPECIFICATIONS, STARTER

MOTOR............................8F-29

DIESEL - TORQUE, 2.7L...............8F-17

DIESEL - TORQUE, STARTER...........8F-29

DIESEL ENGINE - DESCRIPTION, FUEL

REQUIREMENTS.......................0-1

DIESEL ENGINE - DIAGNOSIS AND

TESTING............................11-2

DIESEL ENGINES - DESCRIPTION,

ENGINE OIL...........................0-3

DIESEL SUPPLEMENTAL HEATER - DCHA

- DIAGNOSIS AND TESTING............24-72

DIMENSIONS - SPECIFICATIONS, FRAME . . . 13-4

DIMENSIONS - SPECIFICATIONS,

OPENING...........................23-90

DIODE - INSTALLATION.............8W-01-9

DIODE - REMOVAL.................8W-01-9

DISCHARGE (ESD) SENSITIVE DEVICES -

STANDARD PROCEDURE,

ELECTROSTATIC...................8W-01-7

DISCHARGE LINE - INSTALLATION, A/C . . . 24-54

DISCHARGE LINE - REMOVAL, A/C.......24-53

DISCONNECTING AND CONNECTING

FUEL LINES - STANDARD PROCEDURE....14-2

DISTRIBUTION - DESCRIPTION,

POWER..........................8W-97-1

DISTRIBUTION - OPERATION, POWER . . 8W-97-1

DISTRIBUTION CENTER - DESCRIPTION,

POWER..........................8W-97-3

DISTRIBUTION CENTER - OPERATION,

POWER..........................8W-97-3

DISTRIBUTION DUCTS - INSTALLATION,

FLOOR.............................24-34

DISTRIBUTION DUCTS - REMOVAL,

FLOOR.............................24-33

DOME LAMP/INTRUSION SENSOR -

INSTALLATION.......................8L-31

DOME LAMP/INTRUSION SENSOR -

REMOVAL..........................8L-31

DOME LAMP/INTRUSION SENSOR BULB

- INSTALLATION

.....................8L-30

DOME LAMP/INTRUSION SENSOR BULB

- REMOVAL

.........................8L-30

DOME/READING LAMP BULB -

INSTALLATION

.......................8L-29

DOME/READING LAMP BULB - REMOVAL

. 8L-29

DOME/READING LAMP UNIT -

INSTALLATION

.......................8L-30DOME/READING LAMP UNIT - REMOVAL . . 8L-30

DOOR - ASSEMBLY...................23-28

DOOR - ASSEMBLY, SLIDING...........23-43

DOOR - DISASSEMBLY................23-26

DOOR - DISASSEMBLY, SLIDING........23-42

DOOR - INSTALLATION...........23-14,23-30

DOOR - INSTALLATION, FUEL FILL.......23-47

DOOR - INSTALLATION, SLIDING........23-44

DOOR - REMOVAL...............23-14,23-25

DOOR - REMOVAL, FUEL FILL..........23-47

DOOR - REMOVAL, SLIDING............23-41

DOOR ACTUATOR - DESCRIPTION,

RECIRCULATION.....................24-20

DOOR ACTUATOR - INSTALLATION,

RECIRCULATION.....................24-21

DOOR ACTUATOR - OPERATION,

RECIRCULATION.....................24-20

DOOR ACTUATOR - REMOVAL,

RECIRCULATION.....................24-21

DOOR CABLES - INSTALLATION, MODE . . . 24-19

DOOR CABLES - REMOVAL, MODE.......24-19

DOOR GLASS - INSTALLATION....23-15,23-31,

23-46

DOOR GLASS - REMOVAL . . . 23-15,23-31,23-46

DOOR INNER BELT WEATHERSTRIP -

INSTALLATION, FRONT................23-87

DOOR INNER BELT WEATHERSTRIP -

REMOVAL, FRONT....................23-87

DOOR JAMB SWITCH - INSTALLATION.....8L-31

DOOR JAMB SWITCH - REMOVAL.......8L-31

DOOR LOCK MOTOR - INSTALLATION.....8N-1

DOOR LOCK MOTOR - REMOVAL.........8N-1

DOOR OPENING SEALS - INSTALLATION . . 23-87

DOOR OPENING SEALS - REMOVAL......23-87

DOOR OUTER BELT WEATHERSTRIP -

INSTALLATION, FRONT................23-87

DOOR OUTER BELT WEATHERSTRIP -

REMOVAL, FRONT....................23-87

DOSING PUMP - DESCRIPTION, FUEL....24-74

DOSING PUMP - INSTALLATION, FUEL....24-74

DOSING PUMP - OPERATION, FUEL......24-74

DOSING PUMP - REMOVAL, FUEL.......24-74

DOUBLE INVERTED FLARING -

STANDARD PROCEDURE.................5-8

D-PILLAR TRIM - INSTALLATION........23-70

D-PILLAR TRIM - REMOVAL............23-70

DRAIN AND FILL - STANDARD

PROCEDURE.........................3-11

DRAINING COOLING SYSTEM -

STANDARD PROCEDURE................7-12

DRAINING WATER FROM FUEL FILTER -

STANDARD PROCEDURES...............14-2

DRAW TEST - STANDARD PROCEDURE,

IGNITION-OFF.......................8F-10

DRIVE BELT - DIAGNOSIS AND TESTING,

ACCESSORY..........................7-5

DRIVE BELTS - INSTALLATION............7-8

DRIVE BELTS - REMOVAL................7-8

DRIVE VISCOUS CLUTCH -

INSTALLATION, FAN...................7-16

DRIVE VISCOUS CLUTCH - REMOVAL,

FAN ................................7-16

DRIVER AIRBAG - DESCRIPTION........8O-16

DRIVER AIRBAG - INSTALLATION.......8O-18

DRIVER AIRBAG - OPERATION..........8O-17

DRIVER AIRBAG - REMOVAL...........8O-17

DRIVER HEATED SEAT SWITCH -

DESCRIPTION........................8G-2

DRIVER HEATED SEAT SWITCH -

DIAGNOSIS AND TESTING..............8G-2

DRIVER HEATED SEAT SWITCH -

INSTALLATION.......................8G-3

DRIVER HEATED SEAT SWITCH -

OPERATION..........................8G-2

DRIVER HEATED SEAT SWITCH -

REMOVAL...........................8G-3

DRIVING CLUTCH K1 - ASSEMBLY.......21-75

DRIVING CLUTCH K1 - DISASSEMBLY....21-74

DRIVING CLUTCH K2 - ASSEMBLY.......21-78

DRIVING CLUTCH K2 - DISASSEMBLY....21-76

DRIVING CLUTCH K3 - ASSEMBLY.......21-80

DRIVING CLUTCH K3 - DISASSEMBLY

....21-80

DRIVING CLUTCHES - DESCRIPTION

.....21-72

DRIVING CLUTCHES - OPERATION

.......21-72

DROP - STANDARD PROCEDURE,

TESTING FOR A VOLTAGE

............8W-01-8

DRUM IN HAT BRAKE - CLEANING,

REAR

...............................5-27

VAINDEX 5

Description Group-Page Description Group-Page Description Group-Page

Page 1220 of 1232

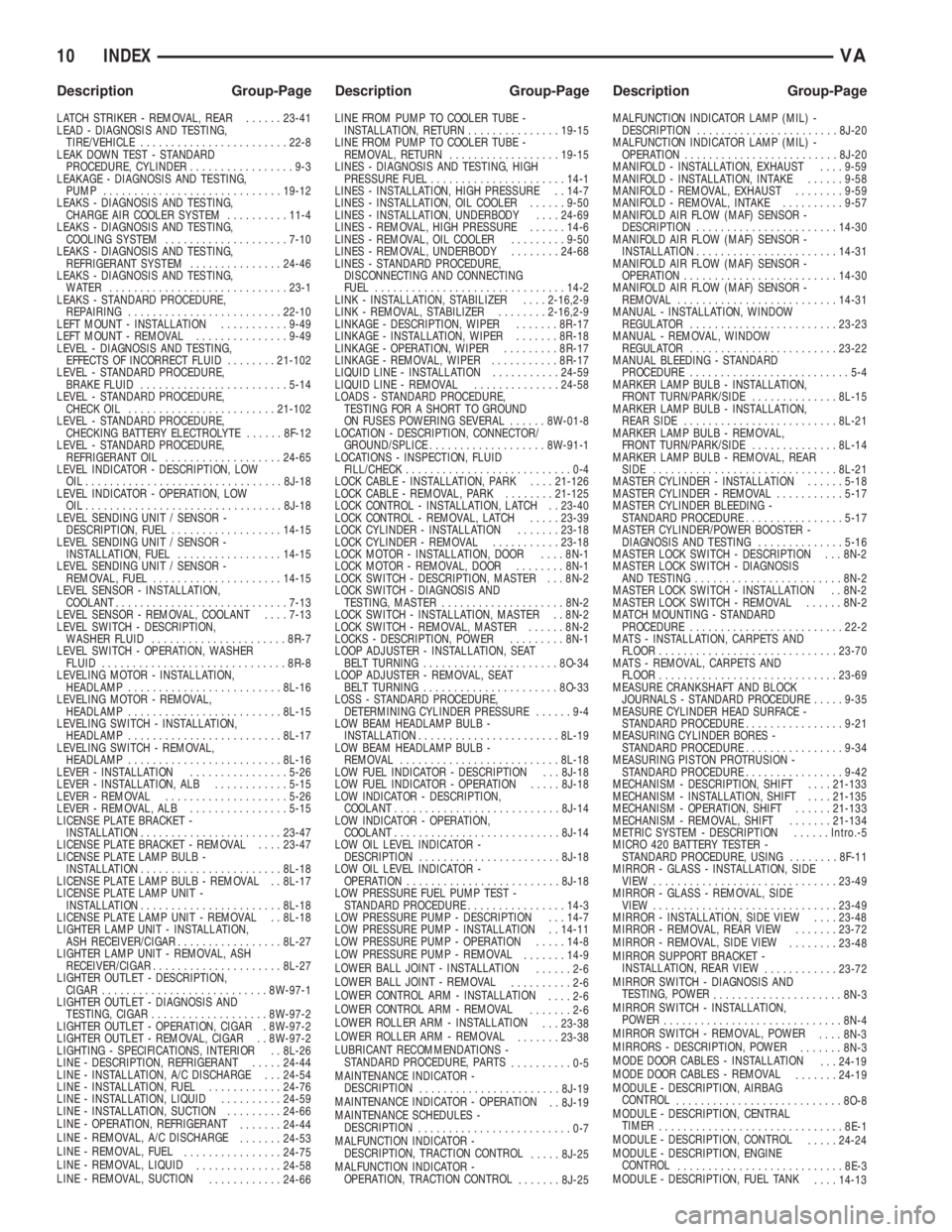

LATCH STRIKER - REMOVAL, REAR......23-41

LEAD - DIAGNOSIS AND TESTING,

TIRE/VEHICLE........................22-8

LEAK DOWN TEST - STANDARD

PROCEDURE, CYLINDER.................9-3

LEAKAGE - DIAGNOSIS AND TESTING,

PUMP.............................19-12

LEAKS - DIAGNOSIS AND TESTING,

CHARGE AIR COOLER SYSTEM..........11-4

LEAKS - DIAGNOSIS AND TESTING,

COOLING SYSTEM....................7-10

LEAKS - DIAGNOSIS AND TESTING,

REFRIGERANT SYSTEM...............24-46

LEAKS - DIAGNOSIS AND TESTING,

WATER .............................23-1

LEAKS - STANDARD PROCEDURE,

REPAIRING.........................22-10

LEFT MOUNT - INSTALLATION...........9-49

LEFT MOUNT - REMOVAL...............9-49

LEVEL - DIAGNOSIS AND TESTING,

EFFECTS OF INCORRECT FLUID........21-102

LEVEL - STANDARD PROCEDURE,

BRAKE FLUID........................5-14

LEVEL - STANDARD PROCEDURE,

CHECK OIL........................21-102

LEVEL - STANDARD PROCEDURE,

CHECKING BATTERY ELECTROLYTE......8F-12

LEVEL - STANDARD PROCEDURE,

REFRIGERANT OIL...................24-65

LEVEL INDICATOR - DESCRIPTION, LOW

OIL................................8J-18

LEVEL INDICATOR - OPERATION, LOW

OIL.................................8J-18

LEVEL SENDING UNIT / SENSOR -

DESCRIPTION, FUEL..................14-15

LEVEL SENDING UNIT / SENSOR -

INSTALLATION, FUEL.................14-15

LEVEL SENDING UNIT / SENSOR -

REMOVAL, FUEL.....................14-15

LEVEL SENSOR - INSTALLATION,

COOLANT............................7-13

LEVEL SENSOR - REMOVAL, COOLANT....7-13

LEVEL SWITCH - DESCRIPTION,

WASHER FLUID......................8R-7

LEVEL SWITCH - OPERATION, WASHER

FLUID..............................8R-8

LEVELING MOTOR - INSTALLATION,

HEADLAMP.........................8L-16

LEVELING MOTOR - REMOVAL,

HEADLAMP.........................8L-15

LEVELING SWITCH - INSTALLATION,

HEADLAMP.........................8L-17

LEVELING SWITCH - REMOVAL,

HEADLAMP.........................8L-16

LEVER - INSTALLATION................5-26

LEVER - INSTALLATION, ALB............5-15

LEVER - REMOVAL....................5-26

LEVER - REMOVAL, ALB................5-15

LICENSE PLATE BRACKET -

INSTALLATION.......................23-47

LICENSE PLATE BRACKET - REMOVAL....23-47

LICENSE PLATE LAMP BULB -

INSTALLATION.......................8L-18

LICENSE PLATE LAMP BULB - REMOVAL . . 8L-17

LICENSE PLATE LAMP UNIT -

INSTALLATION.......................8L-18

LICENSE PLATE LAMP UNIT - REMOVAL . . 8L-18

LIGHTER LAMP UNIT - INSTALLATION,

ASH RECEIVER/CIGAR.................8L-27

LIGHTER LAMP UNIT - REMOVAL, ASH

RECEIVER/CIGAR.....................8L-27

LIGHTER OUTLET - DESCRIPTION,

CIGAR...........................8W-97-1

LIGHTER OUTLET - DIAGNOSIS AND

TESTING, CIGAR...................8W-97-2

LIGHTER OUTLET - OPERATION, CIGAR . 8W-97-2

LIGHTER OUTLET - REMOVAL, CIGAR . . 8W-97-2

LIGHTING - SPECIFICATIONS, INTERIOR . . 8L-26

LINE - DESCRIPTION, REFRIGERANT.....24-44

LINE - INSTALLATION, A/C DISCHARGE . . . 24-54

LINE - INSTALLATION, FUEL............24-76

LINE - INSTALLATION, LIQUID..........24-59

LINE - INSTALLATION, SUCTION.........24-66

LINE - OPERATION, REFRIGERANT

.......24-44

LINE - REMOVAL, A/C DISCHARGE

.......24-53

LINE - REMOVAL, FUEL

................24-75

LINE - REMOVAL, LIQUID

..............24-58

LINE - REMOVAL, SUCTION

............24-66LINE FROM PUMP TO COOLER TUBE -

INSTALLATION, RETURN...............19-15

LINE FROM PUMP TO COOLER TUBE -

REMOVAL, RETURN..................19-15

LINES - DIAGNOSIS AND TESTING, HIGH

PRESSURE FUEL......................14-1

LINES - INSTALLATION, HIGH PRESSURE . . 14-7

LINES - INSTALLATION, OIL COOLER......9-50

LINES - INSTALLATION, UNDERBODY....24-69

LINES - REMOVAL, HIGH PRESSURE......14-6

LINES - REMOVAL, OIL COOLER.........9-50

LINES - REMOVAL, UNDERBODY........24-68

LINES - STANDARD PROCEDURE,

DISCONNECTING AND CONNECTING

FUEL...............................14-2

LINK - INSTALLATION, STABILIZER....2-16,2-9

LINK - REMOVAL, STABILIZER........2-16,2-9

LINKAGE - DESCRIPTION, WIPER.......8R-17

LINKAGE - INSTALLATION, WIPER.......8R-18

LINKAGE - OPERATION, WIPER.........8R-17

LINKAGE - REMOVAL, WIPER...........8R-17

LIQUID LINE - INSTALLATION...........24-59

LIQUID LINE - REMOVAL..............24-58

LOADS - STANDARD PROCEDURE,

TESTING FOR A SHORT TO GROUND

ON FUSES POWERING SEVERAL......8W-01-8

LOCATION - DESCRIPTION, CONNECTOR/

GROUND/SPLICE...................8W-91-1

LOCATIONS - INSPECTION, FLUID

FILL/CHECK............................0-4

LOCK CABLE - INSTALLATION, PARK....21-126

LOCK CABLE - REMOVAL, PARK........21-125

LOCK CONTROL - INSTALLATION, LATCH . . 23-40

LOCK CONTROL - REMOVAL, LATCH.....23-39

LOCK CYLINDER - INSTALLATION.......23-18

LOCK CYLINDER - REMOVAL...........23-18

LOCK MOTOR - INSTALLATION, DOOR....8N-1

LOCK MOTOR - REMOVAL, DOOR........8N-1

LOCK SWITCH - DESCRIPTION, MASTER . . . 8N-2

LOCK SWITCH - DIAGNOSIS AND

TESTING, MASTER....................8N-2

LOCK SWITCH - INSTALLATION, MASTER . . 8N-2

LOCK SWITCH - REMOVAL, MASTER......8N-2

LOCKS - DESCRIPTION, POWER.........8N-1

LOOP ADJUSTER - INSTALLATION, SEAT

BELT TURNING......................8O-34

LOOP ADJUSTER - REMOVAL, SEAT

BELT TURNING......................8O-33

LOSS - STANDARD PROCEDURE,

DETERMINING CYLINDER PRESSURE......9-4

LOW BEAM HEADLAMP BULB -

INSTALLATION.......................8L-19

LOW BEAM HEADLAMP BULB -

REMOVAL..........................8L-18

LOW FUEL INDICATOR - DESCRIPTION . . . 8J-18

LOW FUEL INDICATOR - OPERATION.....8J-18

LOW INDICATOR - DESCRIPTION,

COOLANT...........................8J-14

LOW INDICATOR - OPERATION,

COOLANT...........................8J-14

LOW OIL LEVEL INDICATOR -

DESCRIPTION.......................8J-18

LOW OIL LEVEL INDICATOR -

OPERATION.........................8J-18

LOW PRESSURE FUEL PUMP TEST -

STANDARD PROCEDURE................14-3

LOW PRESSURE PUMP - DESCRIPTION . . . 14-7

LOW PRESSURE PUMP - INSTALLATION . . 14-11

LOW PRESSURE PUMP - OPERATION.....14-8

LOW PRESSURE PUMP - REMOVAL

.......14-9

LOWER BALL JOINT - INSTALLATION

......2-6

LOWER BALL JOINT - REMOVAL

..........2-6

LOWER CONTROL ARM - INSTALLATION

....2-6

LOWER CONTROL ARM - REMOVAL

.......2-6

LOWER ROLLER ARM - INSTALLATION

. . . 23-38

LOWER ROLLER ARM - REMOVAL

.......23-38

LUBRICANT RECOMMENDATIONS -

STANDARD PROCEDURE, PARTS

..........0-5

MAINTENANCE INDICATOR -

DESCRIPTION

.......................8J-19

MAINTENANCE INDICATOR - OPERATION

. . 8J-19

MAINTENANCE SCHEDULES -

DESCRIPTION

.........................0-7

MALFUNCTION INDICATOR -

DESCRIPTION, TRACTION CONTROL

.....8J-25

MALFUNCTION INDICATOR -

OPERATION, TRACTION CONTROL

.......8J-25MALFUNCTION INDICATOR LAMP (MIL) -

DESCRIPTION.......................8J-20

MALFUNCTION INDICATOR LAMP (MIL) -

OPERATION.........................8J-20

MANIFOLD - INSTALLATION, EXHAUST....9-59

MANIFOLD - INSTALLATION, INTAKE......9-58

MANIFOLD - REMOVAL, EXHAUST........9-59

MANIFOLD - REMOVAL, INTAKE..........9-57

MANIFOLD AIR FLOW (MAF) SENSOR -

DESCRIPTION.......................14-30

MANIFOLD AIR FLOW (MAF) SENSOR -

INSTALLATION.......................14-31

MANIFOLD AIR FLOW (MAF) SENSOR -

OPERATION.........................14-30

MANIFOLD AIR FLOW (MAF) SENSOR -

REMOVAL..........................14-31

MANUAL - INSTALLATION, WINDOW

REGULATOR........................23-23

MANUAL - REMOVAL, WINDOW

REGULATOR........................23-22

MANUAL BLEEDING - STANDARD

PROCEDURE..........................5-4

MARKER LAMP BULB - INSTALLATION,

FRONT TURN/PARK/SIDE..............8L-15

MARKER LAMP BULB - INSTALLATION,

REAR SIDE.........................8L-21

MARKER LAMP BULB - REMOVAL,

FRONT TURN/PARK/SIDE..............8L-14

MARKER LAMP BULB - REMOVAL, REAR

SIDE..............................8L-21

MASTER CYLINDER - INSTALLATION......5-18

MASTER CYLINDER - REMOVAL...........5-17

MASTER CYLINDER BLEEDING -

STANDARD PROCEDURE................5-17

MASTER CYLINDER/POWER BOOSTER -

DIAGNOSIS AND TESTING..............5-16

MASTER LOCK SWITCH - DESCRIPTION . . . 8N-2

MASTER LOCK SWITCH - DIAGNOSIS

AND TESTING........................8N-2

MASTER LOCK SWITCH - INSTALLATION . . 8N-2

MASTER LOCK SWITCH - REMOVAL......8N-2

MATCH MOUNTING - STANDARD

PROCEDURE.........................22-2

MATS - INSTALLATION, CARPETS AND

FLOOR.............................23-70

MATS - REMOVAL, CARPETS AND

FLOOR.............................23-69

MEASURE CRANKSHAFT AND BLOCK

JOURNALS - STANDARD PROCEDURE.....9-35

MEASURE CYLINDER HEAD SURFACE -

STANDARD PROCEDURE................9-21

MEASURING CYLINDER BORES -

STANDARD PROCEDURE................9-34

MEASURING PISTON PROTRUSION -

STANDARD PROCEDURE................9-42

MECHANISM - DESCRIPTION, SHIFT....21-133

MECHANISM - INSTALLATION, SHIFT....21-135

MECHANISM - OPERATION, SHIFT......21-133

MECHANISM - REMOVAL, SHIFT.......21-134

METRIC SYSTEM - DESCRIPTION......Intro.-5

MICRO 420 BATTERY TESTER -

STANDARD PROCEDURE, USING........8F-11

MIRROR - GLASS - INSTALLATION, SIDE

VIEW..............................23-49

MIRROR - GLASS - REMOVAL, SIDE

VIEW..............................23-49

MIRROR - INSTALLATION, SIDE VIEW....23-48

MIRROR - REMOVAL, REAR VIEW.......23-72

MIRROR - REMOVAL, SIDE VIEW

........23-48

MIRROR SUPPORT BRACKET -

INSTALLATION, REAR VIEW

............23-72

MIRROR SWITCH - DIAGNOSIS AND

TESTING, POWER

.....................8N-3

MIRROR SWITCH - INSTALLATION,

POWER

.............................8N-4

MIRROR SWITCH - REMOVAL, POWER

....8N-3

MIRRORS - DESCRIPTION, POWER

.......8N-3

MODE DOOR CABLES - INSTALLATION

. . . 24-19

MODE DOOR CABLES - REMOVAL

.......24-19

MODULE - DESCRIPTION, AIRBAG

CONTROL

...........................8O-8

MODULE - DESCRIPTION, CENTRAL

TIMER

..............................8E-1

MODULE - DESCRIPTION, CONTROL

.....24-24

MODULE - DESCRIPTION, ENGINE

CONTROL

...........................8E-3

MODULE - DESCRIPTION, FUEL TANK

....14-13

10 INDEXVA

Description Group-Page Description Group-Page Description Group-Page

Page 1222 of 1232

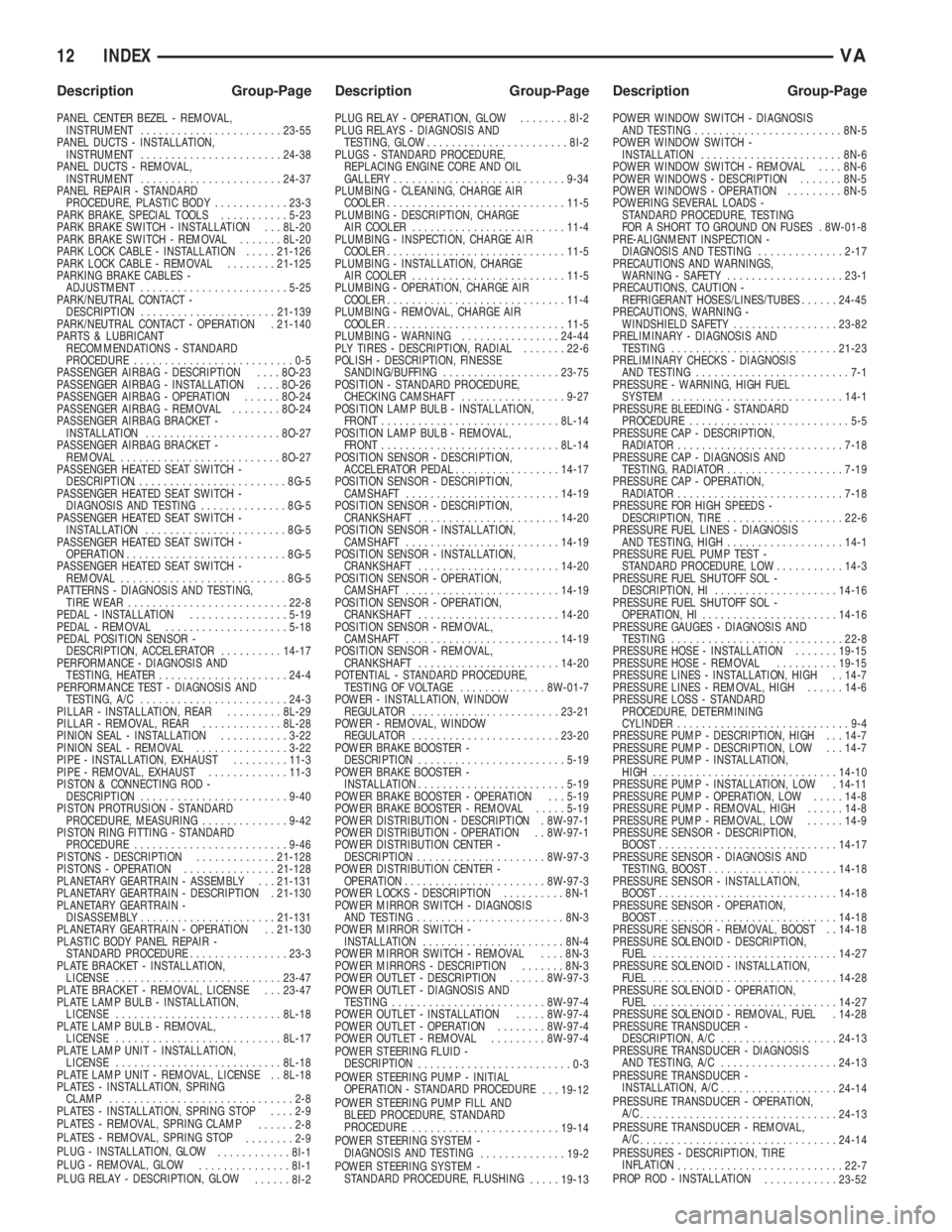

PANEL CENTER BEZEL - REMOVAL,

INSTRUMENT.......................23-55

PANEL DUCTS - INSTALLATION,

INSTRUMENT.......................24-38

PANEL DUCTS - REMOVAL,

INSTRUMENT.......................24-37

PANEL REPAIR - STANDARD

PROCEDURE, PLASTIC BODY............23-3

PARK BRAKE, SPECIAL TOOLS...........5-23

PARK BRAKE SWITCH - INSTALLATION . . . 8L-20

PARK BRAKE SWITCH - REMOVAL.......8L-20

PARK LOCK CABLE - INSTALLATION.....21-126

PARK LOCK CABLE - REMOVAL........21-125

PARKING BRAKE CABLES -

ADJUSTMENT........................5-25

PARK/NEUTRAL CONTACT -

DESCRIPTION......................21-139

PARK/NEUTRAL CONTACT - OPERATION . 21-140

PARTS & LUBRICANT

RECOMMENDATIONS - STANDARD

PROCEDURE..........................0-5

PASSENGER AIRBAG - DESCRIPTION....8O-23

PASSENGER AIRBAG - INSTALLATION....8O-26

PASSENGER AIRBAG - OPERATION......8O-24

PASSENGER AIRBAG - REMOVAL........8O-24

PASSENGER AIRBAG BRACKET -

INSTALLATION......................8O-27

PASSENGER AIRBAG BRACKET -

REMOVAL..........................8O-27

PASSENGER HEATED SEAT SWITCH -

DESCRIPTION.........................8G-5

PASSENGER HEATED SEAT SWITCH -

DIAGNOSIS AND TESTING..............8G-5

PASSENGER HEATED SEAT SWITCH -

INSTALLATION.......................8G-5

PASSENGER HEATED SEAT SWITCH -

OPERATION..........................8G-5

PASSENGER HEATED SEAT SWITCH -

REMOVAL...........................8G-5

PATTERNS - DIAGNOSIS AND TESTING,

TIRE WEAR..........................22-8

PEDAL - INSTALLATION................5-19

PEDAL - REMOVAL....................5-18

PEDAL POSITION SENSOR -

DESCRIPTION, ACCELERATOR..........14-17

PERFORMANCE - DIAGNOSIS AND

TESTING, HEATER.....................24-4

PERFORMANCE TEST - DIAGNOSIS AND

TESTING, A/C........................24-3

PILLAR - INSTALLATION, REAR.........8L-29

PILLAR - REMOVAL, REAR.............8L-28

PINION SEAL - INSTALLATION...........3-22

PINION SEAL - REMOVAL...............3-22

PIPE - INSTALLATION, EXHAUST.........11-3

PIPE - REMOVAL, EXHAUST.............11-3

PISTON & CONNECTING ROD -

DESCRIPTION........................9-40

PISTON PROTRUSION - STANDARD

PROCEDURE, MEASURING..............9-42

PISTON RING FITTING - STANDARD

PROCEDURE.........................9-46

PISTONS - DESCRIPTION.............21-128

PISTONS - OPERATION...............21-128

PLANETARY GEARTRAIN - ASSEMBLY . . . 21-131

PLANETARY GEARTRAIN - DESCRIPTION . 21-130

PLANETARY GEARTRAIN -

DISASSEMBLY......................21-131

PLANETARY GEARTRAIN - OPERATION . . 21-130

PLASTIC BODY PANEL REPAIR -

STANDARD PROCEDURE................23-3

PLATE BRACKET - INSTALLATION,

LICENSE...........................23-47

PLATE BRACKET - REMOVAL, LICENSE . . . 23-47

PLATE LAMP BULB - INSTALLATION,

LICENSE...........................8L-18

PLATE LAMP BULB - REMOVAL,

LICENSE...........................8L-17

PLATE LAMP UNIT - INSTALLATION,

LICENSE...........................8L-18

PLATE LAMP UNIT - REMOVAL, LICENSE . . 8L-18

PLATES - INSTALLATION, SPRING

CLAMP..............................2-8

PLATES - INSTALLATION, SPRING STOP....2-9

PLATES - REMOVAL, SPRING CLAMP

......2-8

PLATES - REMOVAL, SPRING STOP

........2-9

PLUG - INSTALLATION, GLOW

............8I-1

PLUG - REMOVAL, GLOW

...............8I-1

PLUG RELAY - DESCRIPTION, GLOW

......8I-2PLUG RELAY - OPERATION, GLOW........8I-2

PLUG RELAYS - DIAGNOSIS AND

TESTING, GLOW.......................8I-2

PLUGS - STANDARD PROCEDURE,

REPLACING ENGINE CORE AND OIL

GALLERY............................9-34

PLUMBING - CLEANING, CHARGE AIR

COOLER.............................11-5

PLUMBING - DESCRIPTION, CHARGE

AIR COOLER.........................11-4

PLUMBING - INSPECTION, CHARGE AIR

COOLER.............................11-5

PLUMBING - INSTALLATION, CHARGE

AIR COOLER.........................11-5

PLUMBING - OPERATION, CHARGE AIR

COOLER.............................11-4

PLUMBING - REMOVAL, CHARGE AIR

COOLER.............................11-5

PLUMBING - WARNING................24-44

PLY TIRES - DESCRIPTION, RADIAL.......22-6

POLISH - DESCRIPTION, FINESSE

SANDING/BUFFING...................23-75

POSITION - STANDARD PROCEDURE,

CHECKING CAMSHAFT.................9-27

POSITION LAMP BULB - INSTALLATION,

FRONT.............................8L-14

POSITION LAMP BULB - REMOVAL,

FRONT.............................8L-14

POSITION SENSOR - DESCRIPTION,

ACCELERATOR PEDAL.................14-17

POSITION SENSOR - DESCRIPTION,

CAMSHAFT.........................14-19

POSITION SENSOR - DESCRIPTION,

CRANKSHAFT.......................14-20

POSITION SENSOR - INSTALLATION,

CAMSHAFT.........................14-19

POSITION SENSOR - INSTALLATION,

CRANKSHAFT.......................14-20

POSITION SENSOR - OPERATION,

CAMSHAFT.........................14-19

POSITION SENSOR - OPERATION,

CRANKSHAFT.......................14-20

POSITION SENSOR - REMOVAL,

CAMSHAFT.........................14-19

POSITION SENSOR - REMOVAL,

CRANKSHAFT.......................14-20

POTENTIAL - STANDARD PROCEDURE,

TESTING OF VOLTAGE..............8W-01-7

POWER - INSTALLATION, WINDOW

REGULATOR........................23-21

POWER - REMOVAL, WINDOW

REGULATOR........................23-20

POWER BRAKE BOOSTER -

DESCRIPTION........................5-19

POWER BRAKE BOOSTER -

INSTALLATION........................5-19

POWER BRAKE BOOSTER - OPERATION . . . 5-19

POWER BRAKE BOOSTER - REMOVAL.....5-19

POWER DISTRIBUTION - DESCRIPTION . 8W-97-1

POWER DISTRIBUTION - OPERATION . . 8W-97-1

POWER DISTRIBUTION CENTER -

DESCRIPTION.....................8W-97-3

POWER DISTRIBUTION CENTER -

OPERATION.......................8W-97-3

POWER LOCKS - DESCRIPTION..........8N-1

POWER MIRROR SWITCH - DIAGNOSIS

AND TESTING........................8N-3

POWER MIRROR SWITCH -

INSTALLATION.......................8N-4

POWER MIRROR SWITCH - REMOVAL....8N-3

POWER MIRRORS - DESCRIPTION.......8N-3

POWER OUTLET - DESCRIPTION......8W-97-3

POWER OUTLET - DIAGNOSIS AND

TESTING.........................8W-97-4

POWER OUTLET - INSTALLATION.....8W-97-4

POWER OUTLET - OPERATION........8W-97-4

POWER OUTLET - REMOVAL.........8W-97-4

POWER STEERING FLUID -

DESCRIPTION

.........................0-3

POWER STEERING PUMP - INITIAL

OPERATION - STANDARD PROCEDURE

. . . 19-12

POWER STEERING PUMP FILL AND

BLEED PROCEDURE, STANDARD

PROCEDURE

........................19-14

POWER STEERING SYSTEM -

DIAGNOSIS AND TESTING

..............19-2

POWER STEERING SYSTEM -

STANDARD PROCEDURE, FLUSHING

.....19-13POWER WINDOW SWITCH - DIAGNOSIS

AND TESTING........................8N-5

POWER WINDOW SWITCH -

INSTALLATION.......................8N-6

POWER WINDOW SWITCH - REMOVAL....8N-6

POWER WINDOWS - DESCRIPTION.......8N-5

POWER WINDOWS - OPERATION.........8N-5

POWERING SEVERAL LOADS -

STANDARD PROCEDURE, TESTING

FOR A SHORT TO GROUND ON FUSES . 8W-01-8

PRE-ALIGNMENT INSPECTION -

DIAGNOSIS AND TESTING..............2-17

PRECAUTIONS AND WARNINGS,

WARNING - SAFETY...................23-1

PRECAUTIONS, CAUTION -

REFRIGERANT HOSES/LINES/TUBES......24-45

PRECAUTIONS, WARNING -

WINDSHIELD SAFETY.................23-82

PRELIMINARY - DIAGNOSIS AND

TESTING...........................21-23

PRELIMINARY CHECKS - DIAGNOSIS

AND TESTING.........................7-1

PRESSURE - WARNING, HIGH FUEL

SYSTEM............................14-1

PRESSURE BLEEDING - STANDARD

PROCEDURE..........................5-5

PRESSURE CAP - DESCRIPTION,

RADIATOR...........................7-18

PRESSURE CAP - DIAGNOSIS AND

TESTING, RADIATOR...................7-19

PRESSURE CAP - OPERATION,

RADIATOR...........................7-18

PRESSURE FOR HIGH SPEEDS -

DESCRIPTION, TIRE...................22-6

PRESSURE FUEL LINES - DIAGNOSIS

AND TESTING, HIGH...................14-1

PRESSURE FUEL PUMP TEST -

STANDARD PROCEDURE, LOW...........14-3

PRESSURE FUEL SHUTOFF SOL -

DESCRIPTION, HI....................14-16

PRESSURE FUEL SHUTOFF SOL -

OPERATION, HI......................14-16

PRESSURE GAUGES - DIAGNOSIS AND

TESTING............................22-8

PRESSURE HOSE - INSTALLATION.......19-15

PRESSURE HOSE - REMOVAL..........19-15

PRESSURE LINES - INSTALLATION, HIGH . . 14-7

PRESSURE LINES - REMOVAL, HIGH......14-6

PRESSURE LOSS - STANDARD

PROCEDURE, DETERMINING

CYLINDER............................9-4

PRESSURE PUMP - DESCRIPTION, HIGH . . . 14-7

PRESSURE PUMP - DESCRIPTION, LOW . . . 14-7

PRESSURE PUMP - INSTALLATION,

HIGH..............................14-10

PRESSURE PUMP - INSTALLATION, LOW . 14-11

PRESSURE PUMP - OPERATION, LOW.....14-8

PRESSURE PUMP - REMOVAL, HIGH......14-8

PRESSURE PUMP - REMOVAL, LOW......14-9

PRESSURE SENSOR - DESCRIPTION,

BOOST.............................14-17

PRESSURE SENSOR - DIAGNOSIS AND

TESTING, BOOST.....................14-18

PRESSURE SENSOR - INSTALLATION,

BOOST.............................14-18

PRESSURE SENSOR - OPERATION,

BOOST.............................14-18

PRESSURE SENSOR - REMOVAL, BOOST . . 14-18

PRESSURE SOLENOID - DESCRIPTION,

FUEL..............................14-27

PRESSURE SOLENOID - INSTALLATION,

FUEL..............................14-28

PRESSURE SOLENOID - OPERATION,

FUEL..............................14-27

PRESSURE SOLENOID - REMOVAL, FUEL . 14-28

PRESSURE TRANSDUCER -

DESCRIPTION, A/C...................24-13

PRESSURE TRANSDUCER - DIAGNOSIS

AND TESTING, A/C...................24-13

PRESSURE TRANSDUCER -

INSTALLATION, A/C

...................24-14

PRESSURE TRANSDUCER - OPERATION,

A/C

................................24-13

PRESSURE TRANSDUCER - REMOVAL,

A/C

................................24-14

PRESSURES - DESCRIPTION, TIRE

INFLATION

...........................22-7

PROP ROD - INSTALLATION

............23-52

12 INDEXVA

Description Group-Page Description Group-Page Description Group-Page