battery MERCEDES-BENZ SPRINTER 2005 Service Repair Manual

[x] Cancel search | Manufacturer: MERCEDES-BENZ, Model Year: 2005, Model line: SPRINTER, Model: MERCEDES-BENZ SPRINTER 2005Pages: 1232, PDF Size: 39.23 MB

Page 4 of 1232

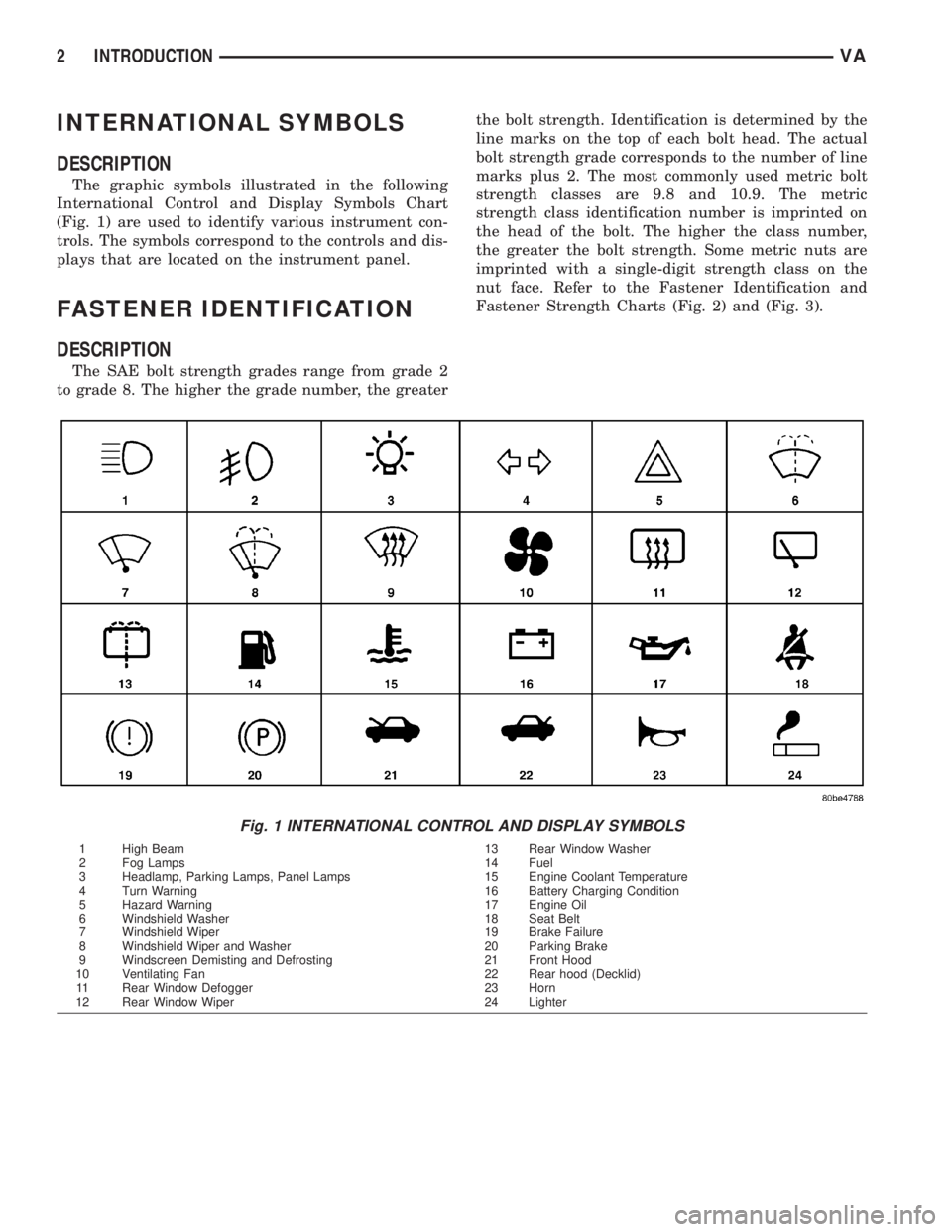

INTERNATIONAL SYMBOLS

DESCRIPTION

The graphic symbols illustrated in the following

International Control and Display Symbols Chart

(Fig. 1) are used to identify various instrument con-

trols. The symbols correspond to the controls and dis-

plays that are located on the instrument panel.

FASTENER IDENTIFICATION

DESCRIPTION

The SAE bolt strength grades range from grade 2

to grade 8. The higher the grade number, the greaterthe bolt strength. Identification is determined by the

line marks on the top of each bolt head. The actual

bolt strength grade corresponds to the number of line

marks plus 2. The most commonly used metric bolt

strength classes are 9.8 and 10.9. The metric

strength class identification number is imprinted on

the head of the bolt. The higher the class number,

the greater the bolt strength. Some metric nuts are

imprinted with a single-digit strength class on the

nut face. Refer to the Fastener Identification and

Fastener Strength Charts (Fig. 2) and (Fig. 3).

Fig. 1 INTERNATIONAL CONTROL AND DISPLAY SYMBOLS

1 High Beam 13 Rear Window Washer

2 Fog Lamps 14 Fuel

3 Headlamp, Parking Lamps, Panel Lamps 15 Engine Coolant Temperature

4 Turn Warning 16 Battery Charging Condition

5 Hazard Warning 17 Engine Oil

6 Windshield Washer 18 Seat Belt

7 Windshield Wiper 19 Brake Failure

8 Windshield Wiper and Washer 20 Parking Brake

9 Windscreen Demisting and Defrosting 21 Front Hood

10 Ventilating Fan 22 Rear hood (Decklid)

11 Rear Window Defogger 23 Horn

12 Rear Window Wiper 24 Lighter

2 INTRODUCTIONVA

Page 16 of 1232

JUMP STARTING

STANDARD PROCEDURE - JUMP STARTING

WARNING: REVIEW ALL SAFETY PRECAUTIONS

AND WARNINGS IN THE BATTERY SYSTEM SEC-

TION OF THE SERVICE MANUAL. (Refer to 8 -

ELECTRICAL/BATTERY SYSTEM/BATTERY - STAN-

DARD PROCEDURE)

²DO NOT JUMP START A FROZEN BATTERY,

PERSONAL INJURY CAN RESULT.

²IF EQUIPPED, DO NOT JUMP START WHEN

MAINTENANCE FREE BATTERY INDICATOR DOT IS

YELLOW OR BRIGHT COLOR.

²DO NOT JUMP START A VEHICLE WHEN THE

BATTERY FLUID IS BELOW THE TOP OF LEAD

PLATES.

²DO NOT ALLOW JUMPER CABLE CLAMPS TO

TOUCH EACH OTHER WHEN CONNECTED TO A

BOOSTER SOURCE.

²DO NOT USE OPEN FLAME NEAR BATTERY.

²REMOVE METALLIC JEWELRY WORN ON

HANDS OR WRISTS TO AVOID INJURY BY ACCI-

DENTAL ARCING OF BATTERY CURRENT.

²WHEN USING A HIGH OUTPUT BOOSTING

DEVICE, DO NOT ALLOW BATTERY VOLTAGE TO

EXCEED 16 VOLTS. REFER TO INSTRUCTIONS

PROVIDED WITH DEVICE BEING USED.

FAILURE TO FOLLOW THESE INSTRUCTIONS MAY

RESULT IN PERSONAL INJURY.

CAUTION: When using another vehicle as a

booster, do not allow vehicles to touch. Electrical

systems can be damaged on either vehicle.

TO JUMP START A DISABLED VEHICLE:

(1) Raise hood on disabled vehicle and visually

inspect engine compartment for:

²Battery cable clamp condition, clean if necessary.

²Frozen battery.

²Yellow or bright color test indicator, if equipped.

²Low battery fluid level.

²Generator drive belt condition and tension.

²Fuel fumes or leakage, correct if necessary.

CAUTION: If the cause of starting problem on dis-

abled vehicle is severe, damage to booster vehicle

charging system can result.

(2) When using another vehicle as a booster

source, park the booster vehicle within cable reach.

Turn off all accessories, set the parking brake, place

the automatic transmission in PARK or the manual

transmission in NEUTRAL and turn the ignition

OFF.(3) On disabled vehicle, place gear selector in park

or neutral and set park brake. Turn off all accesso-

ries.

(4) Connect jumper cables to booster battery. RED

clamp to positive terminal (+). BLACK clamp to neg-

ative terminal (-). DO NOT allow clamps at opposite

end of cables to touch, electrical arc will result.

Review all warnings in this procedure.

(5) On disabled vehicle, connect RED jumper cable

clamp to positive (+) terminal. Connect BLACK

jumper cable clamp to engine ground as close to the

ground cable attaching point as possible.

(6) Start the engine in the vehicle which has the

booster battery, let the engine idle a few minutes,

then start the engine in the vehicle with the dis-

charged battery.

CAUTION: Do not crank starter motor on disabled

vehicle for more than 15 seconds, starter will over-

heat and could fail.

(7) Allow battery in disabled vehicle to charge to

at least 12.4 volts (75% charge) before attempting to

start engine. If engine does not start within 15 sec-

onds, stop cranking engine and allow starter to cool

(15 min.), before cranking again.

DISCONNECT CABLE CLAMPS AS FOLLOWS:

²Disconnect BLACK cable clamp from engine

ground on disabled vehicle.

²When using a Booster vehicle, disconnect

BLACK cable clamp from battery negative terminal.

Disconnect RED cable clamp from battery positive

terminal.

²Disconnect RED cable clamp from battery posi-

tive terminal on disabled vehicle.

TOWING

STANDARD PROCEDURE - TOWING

WARNING: Do not tow the vehicle if the key cannot

be turned in the ignition lock. If the key cannot be

turned, the ignition lock remains locked and the

vehicle cannot be steered. With the engine not run-

ning there is no power assistance for the braking

and steering systems. In this case, it is important to

keep in mind that a considerably higher degree of

effort is necessary to brake and steer the vehicle.

The vehicle must not be towed with the front axle

raised and the key in position 2 in the ignition lock

as the drive wheels could then lock due to the

acceleration skid control (ASR)

0 - 6 LUBRICATION & MAINTENANCEVA

Page 18 of 1232

MAINTENANCE - WITH ASSYST MAINTENANCE

COMPUTER

ASSYST provides information on the best possible

timing for maintenance work.

NOTE: The engine manufacturer strongly recom-

mends the use of synthetic engine oils, such as

TMobil 1 SAE 0W-40.

When the next maintenance service is due, this

will be indicated in the multi-function display with

the wrench icon symbol displayed in km/miles or

days.

²One wrench icon showing indicates Oil Service

is necessary.

²Two wrench icons showing indicates Mainte-

nance Service is necessary ± displayed in km/miles or

days.

If the display shows the number of days, a clock

symbol will also appear in the multi-function display.

You should have the maintenance performed

within the stated period/distance.

The service indicator should be reset after an oil

service and/or maintenance service has been per-

formed.

REGULAR CHECK-UPS

To maintain the safe operation of the vehicle, it is

recommended that the following tasks be performed

on a regular basis (i.e. weekly or whenever the vehi-

cle is refueled). Check:

²Engine oil level

²Brake system, clutch mechanism ± fluid level

²Battery ± acid level

²Windshield washer system and headlamp clean-

ing system ± fluid level

²Mechanical assemblies (e. g. engine, transmis-

sion, etc.) ± check for leaks

²Condition of tires and tires pressures

²All exterior lights

SPECIAL MAINTENANCE REQUIREMENTS

If bodies built by manufacturers other than

DaimlerChrysler Corporation are fitted to the vehi-

cle, the maintenance requirements and lubrication

intervals specified by the body manufacturer must be

adhered to, in addition to all standard maintenance

requirements.

Brake Fluid

Only use brake fluids approved by the manufac-

turer (DOT 4 plus).

Coolant

Corrosion inhibitor/antifreeze concentration in the

coolant should be checked before the onset of winter

(once year in countries with high prevailing temper-

atures).Replace the coolant every five years or 100,000

miles.

Dust Filter for Heating/Ventilation Replace-

ment

The dust filter and the tailgate interior filter are to

be renewed during routine maintenance service. If

operating conditions are dusty, these filters should be

renewed more frequently.

ENGINE OIL CHANGE AND FILTER REPLACEMENT

At the minimum, change the engine oil and oil fil-

ter once a year ± even if the vehicle mileage per year

is extremely low. For standard oil service schedules

refer to the chapter oil service and maintenance ser-

vice.

Once a Year

Select the viscosity of the engine oil (SAE classes)

according to the outside air temperature.

Only use engine oil approved by DaimlerChrysler

Corporation if following the ASSYST system guide-

lines.

If the fuel used has a sulphur content exceeding

0.05% by weight, the service intervals should be split

in half.

SCOPE OF WORK FOR MAINTENANCE SERVICE

Oil Service

²Engine:

Oil change and filter replacement

Check fluid levels of the following system,

refill as necessary.

²If fluid is lost, trace and eliminate cause ± as a

separate order.

²Power-assisted steering

Lubrication work:

²Trailer tow hitch (original equipment)

Maintenance

²ASSYST maintenance computer reset

Function check

²Signalling system, warning and indicator lamps

²Headlamps, exterior lighting

²Windshield wipers, windshield washer system

Check for leaks and damage.

²Check for abrasion points and ensure that lines

are correctly routed!

²All lines and hoses, sensor cables

²Rubber boots on front axle drive shafts, rubber

boots on front axle suspension ball joints, shock

absorbers

Check fluid levels for the following systems,

correct as necessary.

NOTE: Should there be a loss of fluid which cannot

be explained by regular use, trace and eliminate the

cause.

0 - 8 LUBRICATION & MAINTENANCEVA

MAINTENANCE SCHEDULES (Continued)

Page 19 of 1232

²Engine cooling system. Check corrosion inhibi-

tor/antifreeze, refill as necessary.

²Hydraulic brake system

²Battery

²Windshield washer system

Engine

²Fuel filter renewal

²Air cleaner with maintenance indicator:

²Check degree of contamination.

²Air cleaner filter element renewed as necessary.

Chassis and body

²Trailer coupling:

Check operation, play and retaining fixtures

²Secondary rubber springs:

Visual check

²Tire pressures:

Correct as necessary, including spare tire

²Check thickness of brake pads

²Brake test

²Check condition of steering mechanism

²Heating/ventilation dust filter renewal

ADDITIONAL MAINTENANCE WORK

Automatic transmission once only at 80,000

miles/128000 km

Oil and filter change

During every second maintenance service

Air cleaner without maintenance indicator:

Air cleaner filter element renewal

Check poly-V-belt for wear and signs of damage

During every 6th maintenance service

Rear axle

ADDITIONAL MAINTENANCE WORK AFTER YEARS

Every 3 years

Air cleaner filter element renewal (note installa-

tion date)

Every 5 years or 100,000 miles

Coolant renewal

Note coolant composition

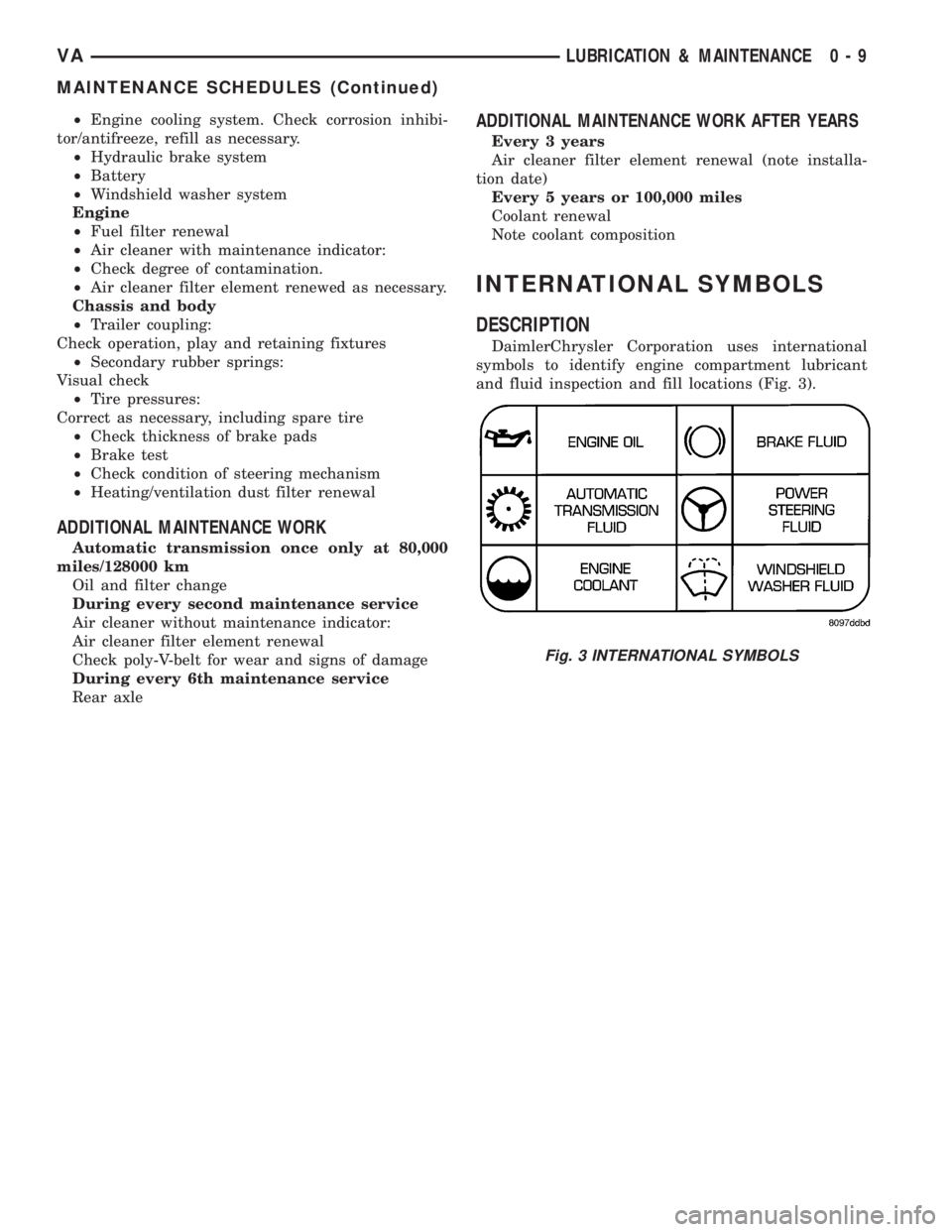

INTERNATIONAL SYMBOLS

DESCRIPTION

DaimlerChrysler Corporation uses international

symbols to identify engine compartment lubricant

and fluid inspection and fill locations (Fig. 3).

Fig. 3 INTERNATIONAL SYMBOLS

VALUBRICATION & MAINTENANCE 0 - 9

MAINTENANCE SCHEDULES (Continued)

Page 95 of 1232

INSTALLATION

(1) Connect separate wheel speed sensor cables

with shrink-fit sleeves and shrink-fit tubing (Fig.

3).Only due this step if replacing the sensor.

(2) Install the wheel speed sensor all the way into

the axle tube, the wheel speed sensor will self adjust

when the vehicle is moved (Fig. 3).

(3) Install the rear wheels.

(4) Lower the vehicle.

TONE WHEEL

REMOVAL

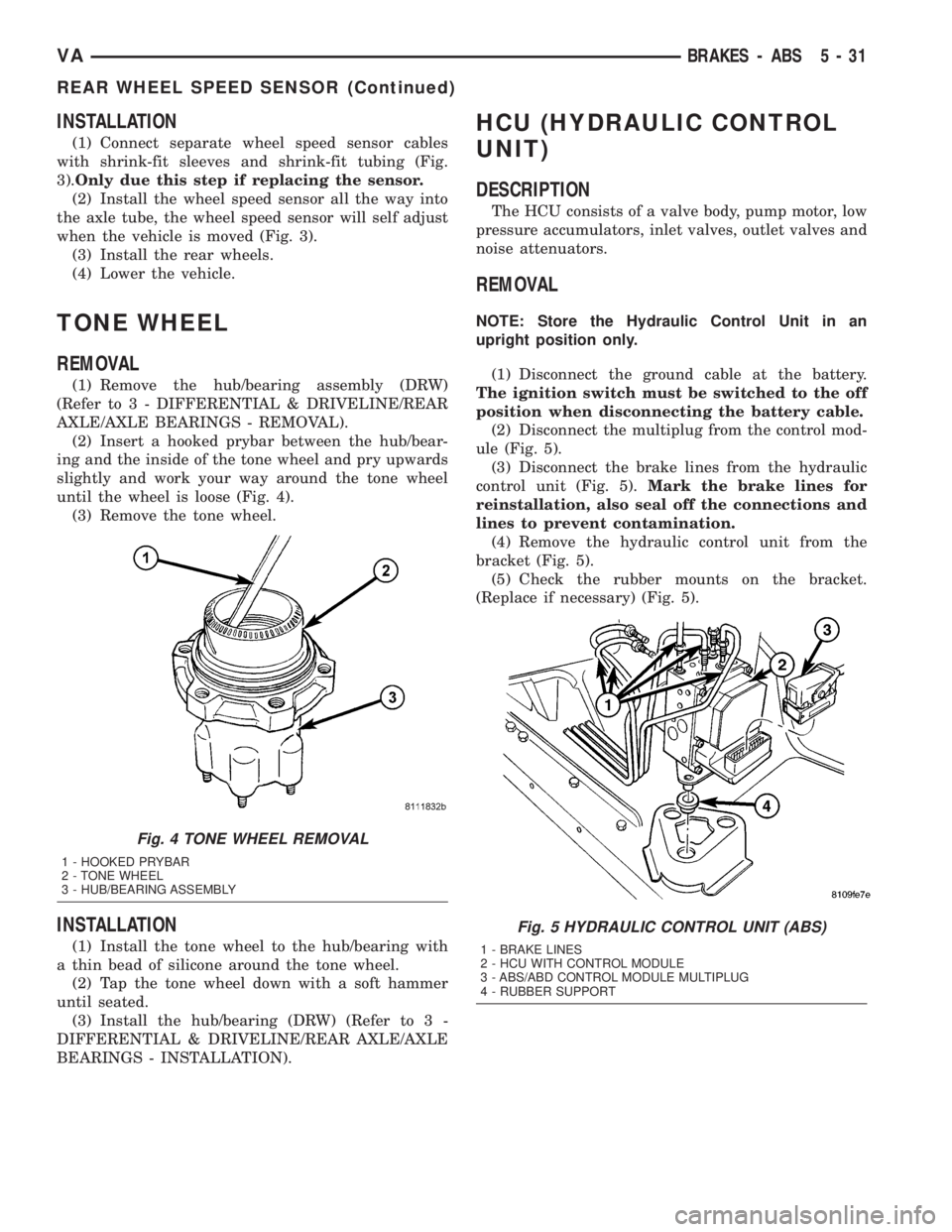

(1) Remove the hub/bearing assembly (DRW)

(Refer to 3 - DIFFERENTIAL & DRIVELINE/REAR

AXLE/AXLE BEARINGS - REMOVAL).

(2) Insert a hooked prybar between the hub/bear-

ing and the inside of the tone wheel and pry upwards

slightly and work your way around the tone wheel

until the wheel is loose (Fig. 4).

(3) Remove the tone wheel.

INSTALLATION

(1) Install the tone wheel to the hub/bearing with

a thin bead of silicone around the tone wheel.

(2) Tap the tone wheel down with a soft hammer

until seated.

(3) Install the hub/bearing (DRW) (Refer to 3 -

DIFFERENTIAL & DRIVELINE/REAR AXLE/AXLE

BEARINGS - INSTALLATION).

HCU (HYDRAULIC CONTROL

UNIT)

DESCRIPTION

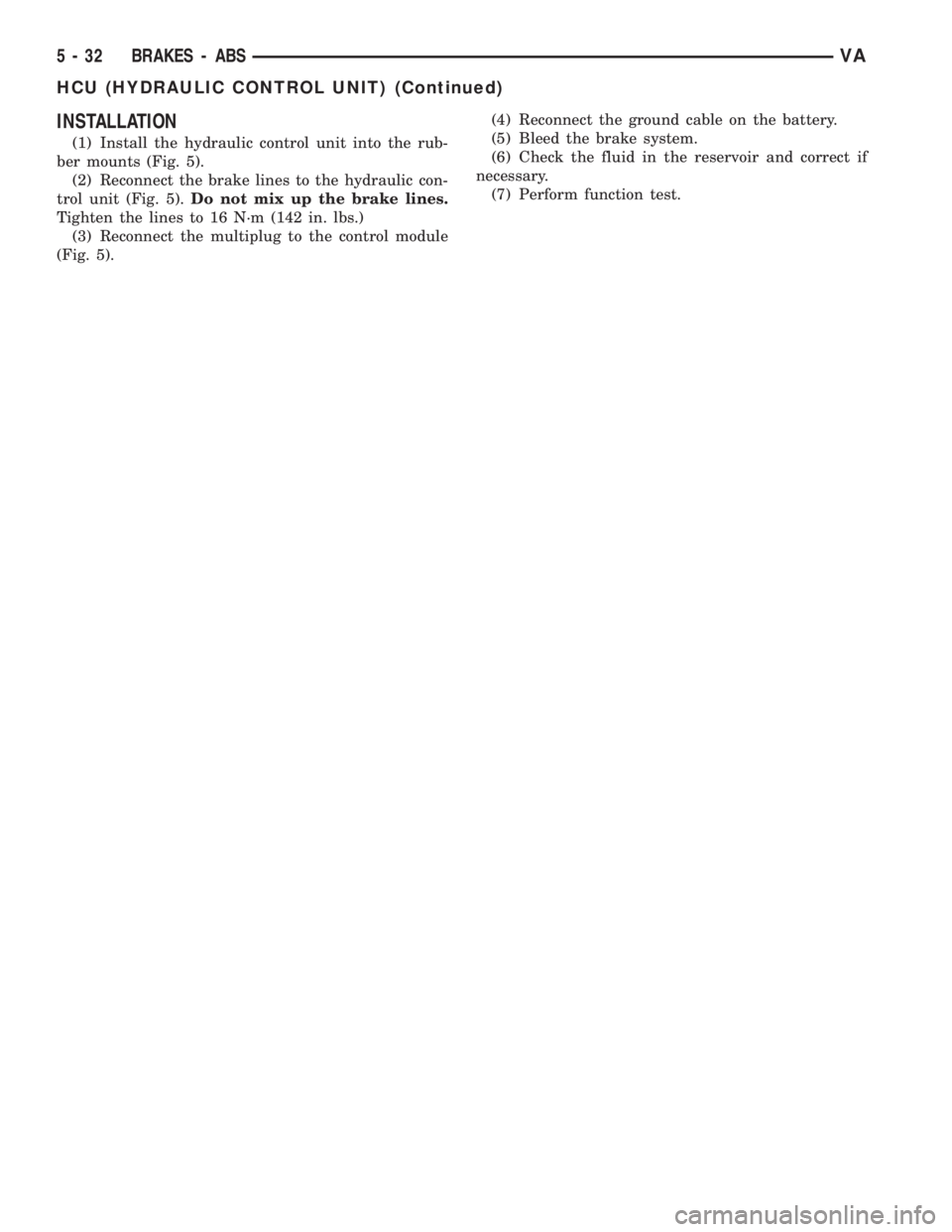

The HCU consists of a valve body, pump motor, low

pressure accumulators, inlet valves, outlet valves and

noise attenuators.

REMOVAL

NOTE: Store the Hydraulic Control Unit in an

upright position only.

(1) Disconnect the ground cable at the battery.

The ignition switch must be switched to the off

position when disconnecting the battery cable.

(2) Disconnect the multiplug from the control mod-

ule (Fig. 5).

(3) Disconnect the brake lines from the hydraulic

control unit (Fig. 5).Mark the brake lines for

reinstallation, also seal off the connections and

lines to prevent contamination.

(4) Remove the hydraulic control unit from the

bracket (Fig. 5).

(5) Check the rubber mounts on the bracket.

(Replace if necessary) (Fig. 5).

Fig. 4 TONE WHEEL REMOVAL

1 - HOOKED PRYBAR

2 - TONE WHEEL

3 - HUB/BEARING ASSEMBLY

Fig. 5 HYDRAULIC CONTROL UNIT (ABS)

1 - BRAKE LINES

2 - HCU WITH CONTROL MODULE

3 - ABS/ABD CONTROL MODULE MULTIPLUG

4 - RUBBER SUPPORT

VABRAKES - ABS 5 - 31

REAR WHEEL SPEED SENSOR (Continued)

Page 96 of 1232

INSTALLATION

(1) Install the hydraulic control unit into the rub-

ber mounts (Fig. 5).

(2) Reconnect the brake lines to the hydraulic con-

trol unit (Fig. 5).Do not mix up the brake lines.

Tighten the lines to 16 N´m (142 in. lbs.)

(3) Reconnect the multiplug to the control module

(Fig. 5).(4) Reconnect the ground cable on the battery.

(5) Bleed the brake system.

(6) Check the fluid in the reservoir and correct if

necessary.

(7) Perform function test.

5 - 32 BRAKES - ABSVA

HCU (HYDRAULIC CONTROL UNIT) (Continued)

Page 109 of 1232

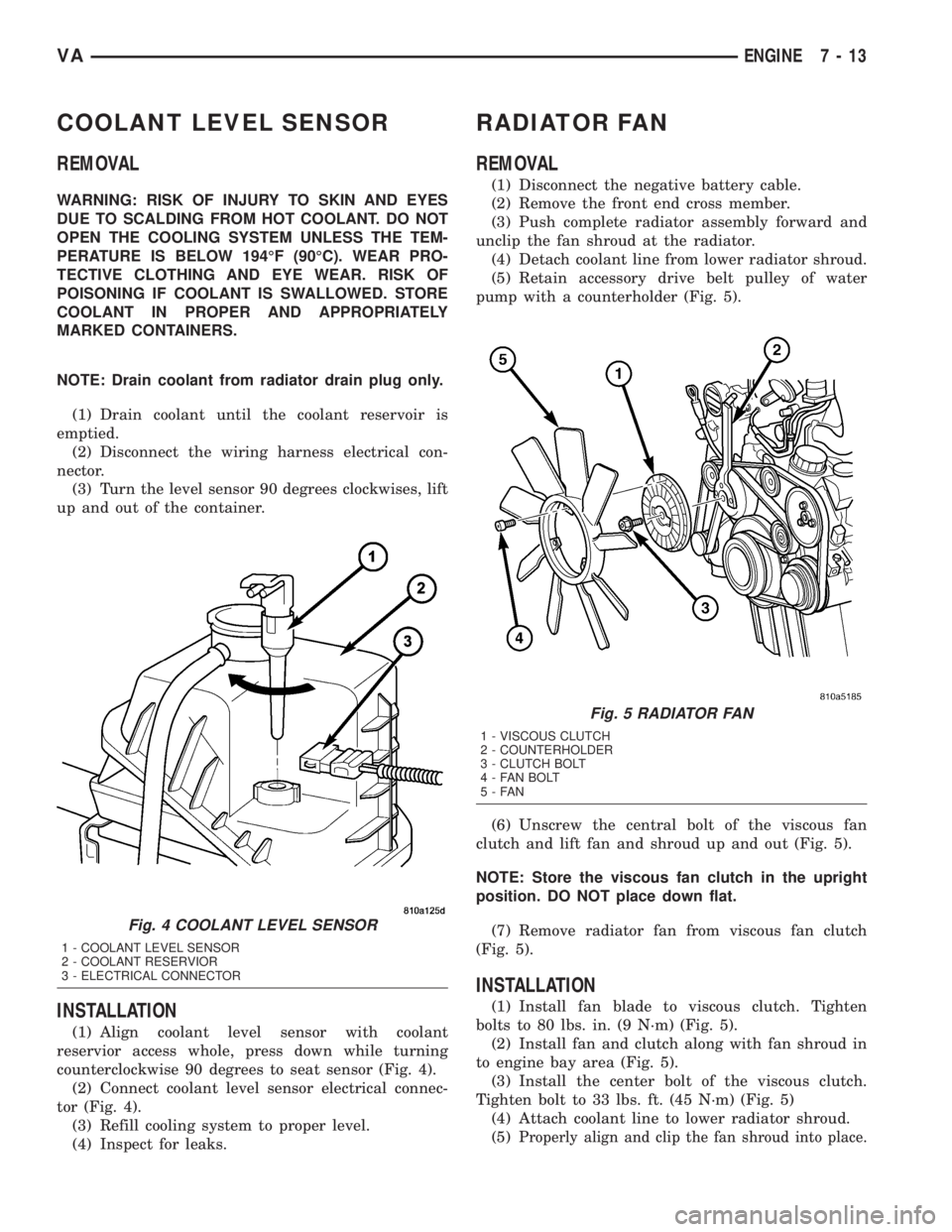

COOLANT LEVEL SENSOR

REMOVAL

WARNING: RISK OF INJURY TO SKIN AND EYES

DUE TO SCALDING FROM HOT COOLANT. DO NOT

OPEN THE COOLING SYSTEM UNLESS THE TEM-

PERATURE IS BELOW 194ÉF (90ÉC). WEAR PRO-

TECTIVE CLOTHING AND EYE WEAR. RISK OF

POISONING IF COOLANT IS SWALLOWED. STORE

COOLANT IN PROPER AND APPROPRIATELY

MARKED CONTAINERS.

NOTE: Drain coolant from radiator drain plug only.

(1) Drain coolant until the coolant reservoir is

emptied.

(2) Disconnect the wiring harness electrical con-

nector.

(3) Turn the level sensor 90 degrees clockwises, lift

up and out of the container.

INSTALLATION

(1) Align coolant level sensor with coolant

reservior access whole, press down while turning

counterclockwise 90 degrees to seat sensor (Fig. 4).

(2) Connect coolant level sensor electrical connec-

tor (Fig. 4).

(3) Refill cooling system to proper level.

(4) Inspect for leaks.

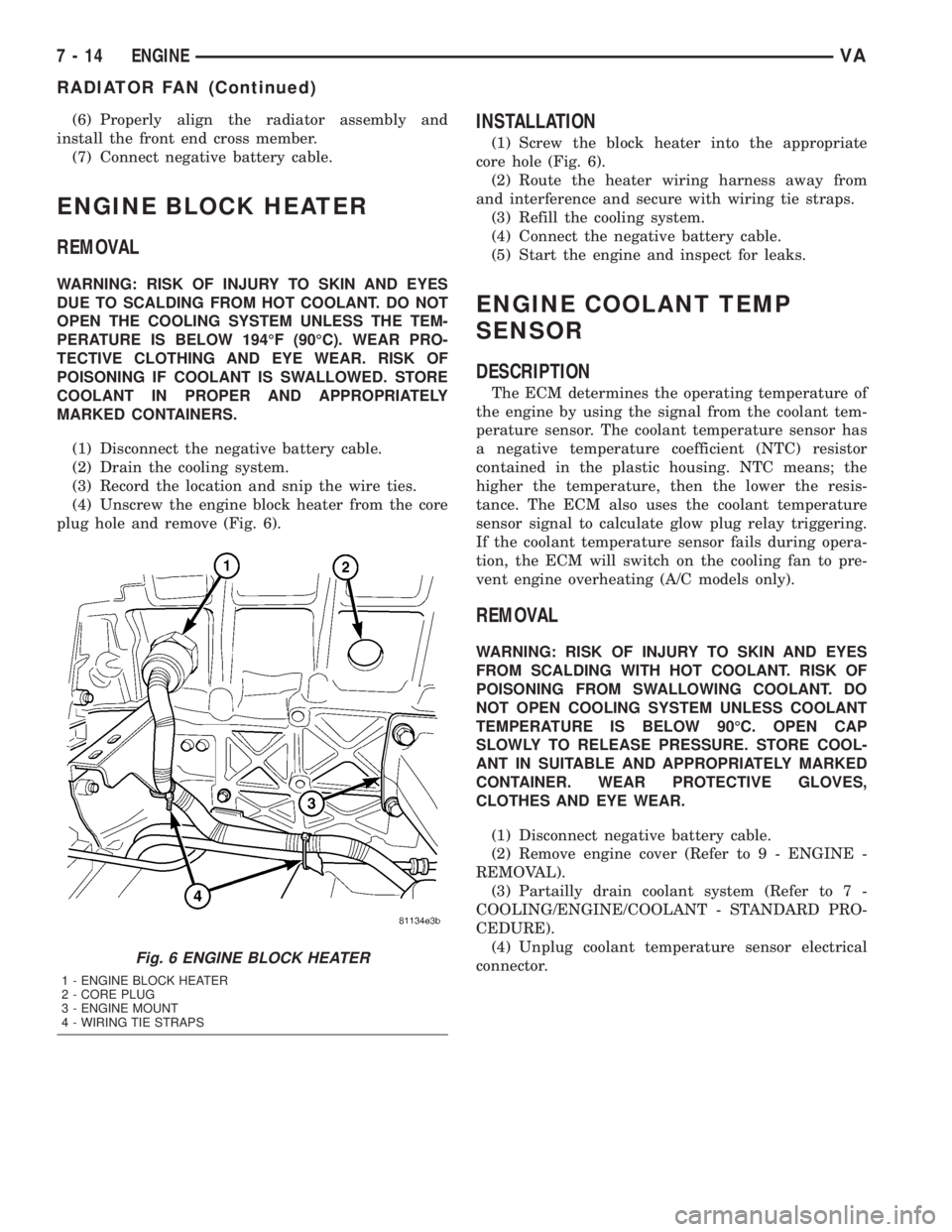

RADIATOR FAN

REMOVAL

(1) Disconnect the negative battery cable.

(2) Remove the front end cross member.

(3) Push complete radiator assembly forward and

unclip the fan shroud at the radiator.

(4) Detach coolant line from lower radiator shroud.

(5) Retain accessory drive belt pulley of water

pump with a counterholder (Fig. 5).

(6) Unscrew the central bolt of the viscous fan

clutch and lift fan and shroud up and out (Fig. 5).

NOTE: Store the viscous fan clutch in the upright

position. DO NOT place down flat.

(7) Remove radiator fan from viscous fan clutch

(Fig. 5).

INSTALLATION

(1) Install fan blade to viscous clutch. Tighten

bolts to 80 lbs. in. (9 N´m) (Fig. 5).

(2) Install fan and clutch along with fan shroud in

to engine bay area (Fig. 5).

(3) Install the center bolt of the viscous clutch.

Tighten bolt to 33 lbs. ft. (45 N´m) (Fig. 5)

(4) Attach coolant line to lower radiator shroud.

(5)

Properly align and clip the fan shroud into place.

Fig. 4 COOLANT LEVEL SENSOR

1 - COOLANT LEVEL SENSOR

2 - COOLANT RESERVIOR

3 - ELECTRICAL CONNECTOR

Fig. 5 RADIATOR FAN

1 - VISCOUS CLUTCH

2 - COUNTERHOLDER

3 - CLUTCH BOLT

4 - FAN BOLT

5-FAN

VAENGINE 7 - 13

Page 110 of 1232

(6) Properly align the radiator assembly and

install the front end cross member.

(7) Connect negative battery cable.

ENGINE BLOCK HEATER

REMOVAL

WARNING: RISK OF INJURY TO SKIN AND EYES

DUE TO SCALDING FROM HOT COOLANT. DO NOT

OPEN THE COOLING SYSTEM UNLESS THE TEM-

PERATURE IS BELOW 194ÉF (90ÉC). WEAR PRO-

TECTIVE CLOTHING AND EYE WEAR. RISK OF

POISONING IF COOLANT IS SWALLOWED. STORE

COOLANT IN PROPER AND APPROPRIATELY

MARKED CONTAINERS.

(1) Disconnect the negative battery cable.

(2) Drain the cooling system.

(3) Record the location and snip the wire ties.

(4) Unscrew the engine block heater from the core

plug hole and remove (Fig. 6).

INSTALLATION

(1) Screw the block heater into the appropriate

core hole (Fig. 6).

(2) Route the heater wiring harness away from

and interference and secure with wiring tie straps.

(3) Refill the cooling system.

(4) Connect the negative battery cable.

(5) Start the engine and inspect for leaks.

ENGINE COOLANT TEMP

SENSOR

DESCRIPTION

The ECM determines the operating temperature of

the engine by using the signal from the coolant tem-

perature sensor. The coolant temperature sensor has

a negative temperature coefficient (NTC) resistor

contained in the plastic housing. NTC means; the

higher the temperature, then the lower the resis-

tance. The ECM also uses the coolant temperature

sensor signal to calculate glow plug relay triggering.

If the coolant temperature sensor fails during opera-

tion, the ECM will switch on the cooling fan to pre-

vent engine overheating (A/C models only).

REMOVAL

WARNING: RISK OF INJURY TO SKIN AND EYES

FROM SCALDING WITH HOT COOLANT. RISK OF

POISONING FROM SWALLOWING COOLANT. DO

NOT OPEN COOLING SYSTEM UNLESS COOLANT

TEMPERATURE IS BELOW 90ÉC. OPEN CAP

SLOWLY TO RELEASE PRESSURE. STORE COOL-

ANT IN SUITABLE AND APPROPRIATELY MARKED

CONTAINER. WEAR PROTECTIVE GLOVES,

CLOTHES AND EYE WEAR.

(1) Disconnect negative battery cable.

(2) Remove engine cover (Refer to 9 - ENGINE -

REMOVAL).

(3) Partailly drain coolant system (Refer to 7 -

COOLING/ENGINE/COOLANT - STANDARD PRO-

CEDURE).

(4) Unplug coolant temperature sensor electrical

connector.

Fig. 6 ENGINE BLOCK HEATER

1 - ENGINE BLOCK HEATER

2 - CORE PLUG

3 - ENGINE MOUNT

4 - WIRING TIE STRAPS

7 - 14 ENGINEVA

RADIATOR FAN (Continued)

Page 111 of 1232

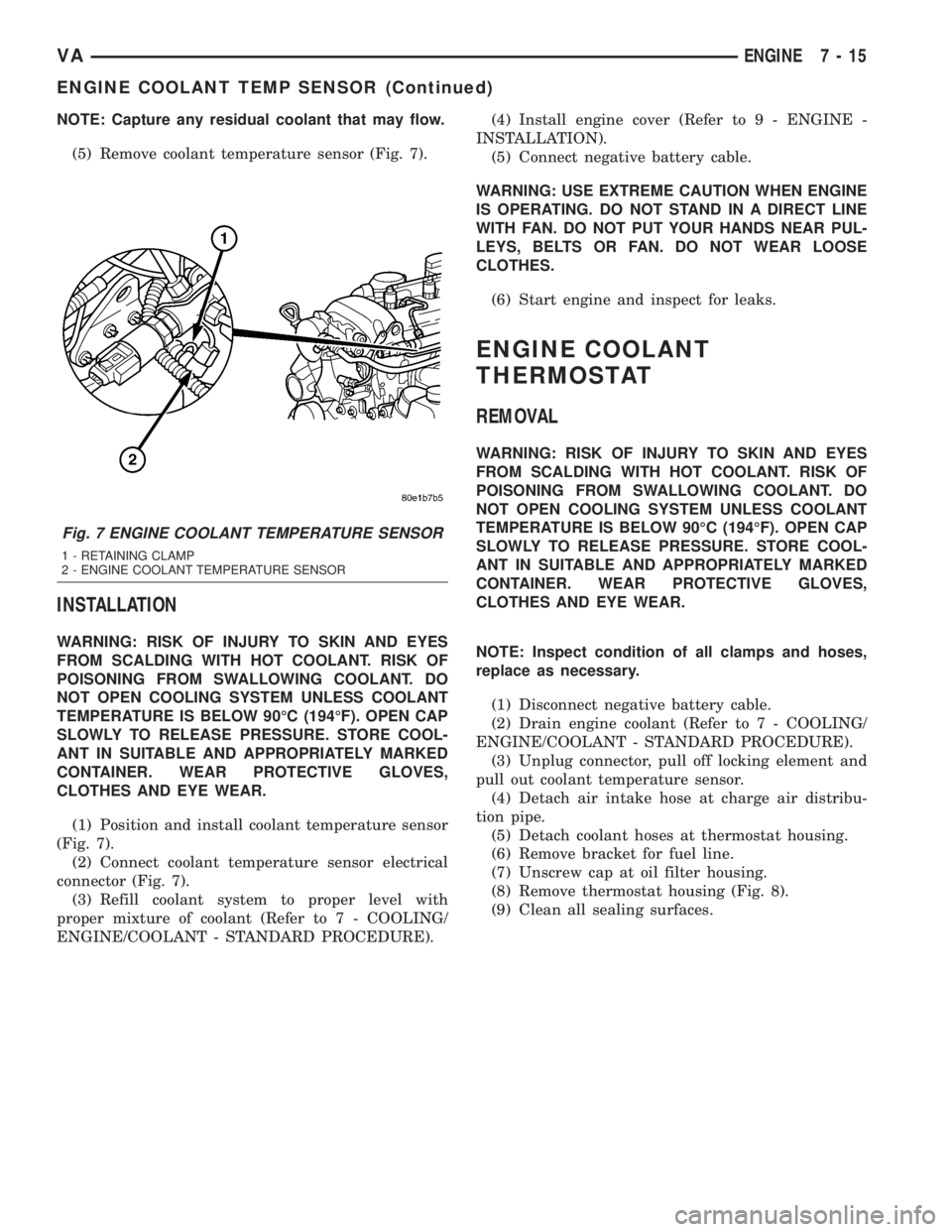

NOTE: Capture any residual coolant that may flow.

(5) Remove coolant temperature sensor (Fig. 7).

INSTALLATION

WARNING: RISK OF INJURY TO SKIN AND EYES

FROM SCALDING WITH HOT COOLANT. RISK OF

POISONING FROM SWALLOWING COOLANT. DO

NOT OPEN COOLING SYSTEM UNLESS COOLANT

TEMPERATURE IS BELOW 90ÉC (194ÉF). OPEN CAP

SLOWLY TO RELEASE PRESSURE. STORE COOL-

ANT IN SUITABLE AND APPROPRIATELY MARKED

CONTAINER. WEAR PROTECTIVE GLOVES,

CLOTHES AND EYE WEAR.

(1) Position and install coolant temperature sensor

(Fig. 7).

(2) Connect coolant temperature sensor electrical

connector (Fig. 7).

(3) Refill coolant system to proper level with

proper mixture of coolant (Refer to 7 - COOLING/

ENGINE/COOLANT - STANDARD PROCEDURE).(4) Install engine cover (Refer to 9 - ENGINE -

INSTALLATION).

(5) Connect negative battery cable.

WARNING: USE EXTREME CAUTION WHEN ENGINE

IS OPERATING. DO NOT STAND IN A DIRECT LINE

WITH FAN. DO NOT PUT YOUR HANDS NEAR PUL-

LEYS, BELTS OR FAN. DO NOT WEAR LOOSE

CLOTHES.

(6) Start engine and inspect for leaks.

ENGINE COOLANT

THERMOSTAT

REMOVAL

WARNING: RISK OF INJURY TO SKIN AND EYES

FROM SCALDING WITH HOT COOLANT. RISK OF

POISONING FROM SWALLOWING COOLANT. DO

NOT OPEN COOLING SYSTEM UNLESS COOLANT

TEMPERATURE IS BELOW 90ÉC (194ÉF). OPEN CAP

SLOWLY TO RELEASE PRESSURE. STORE COOL-

ANT IN SUITABLE AND APPROPRIATELY MARKED

CONTAINER. WEAR PROTECTIVE GLOVES,

CLOTHES AND EYE WEAR.

NOTE: Inspect condition of all clamps and hoses,

replace as necessary.

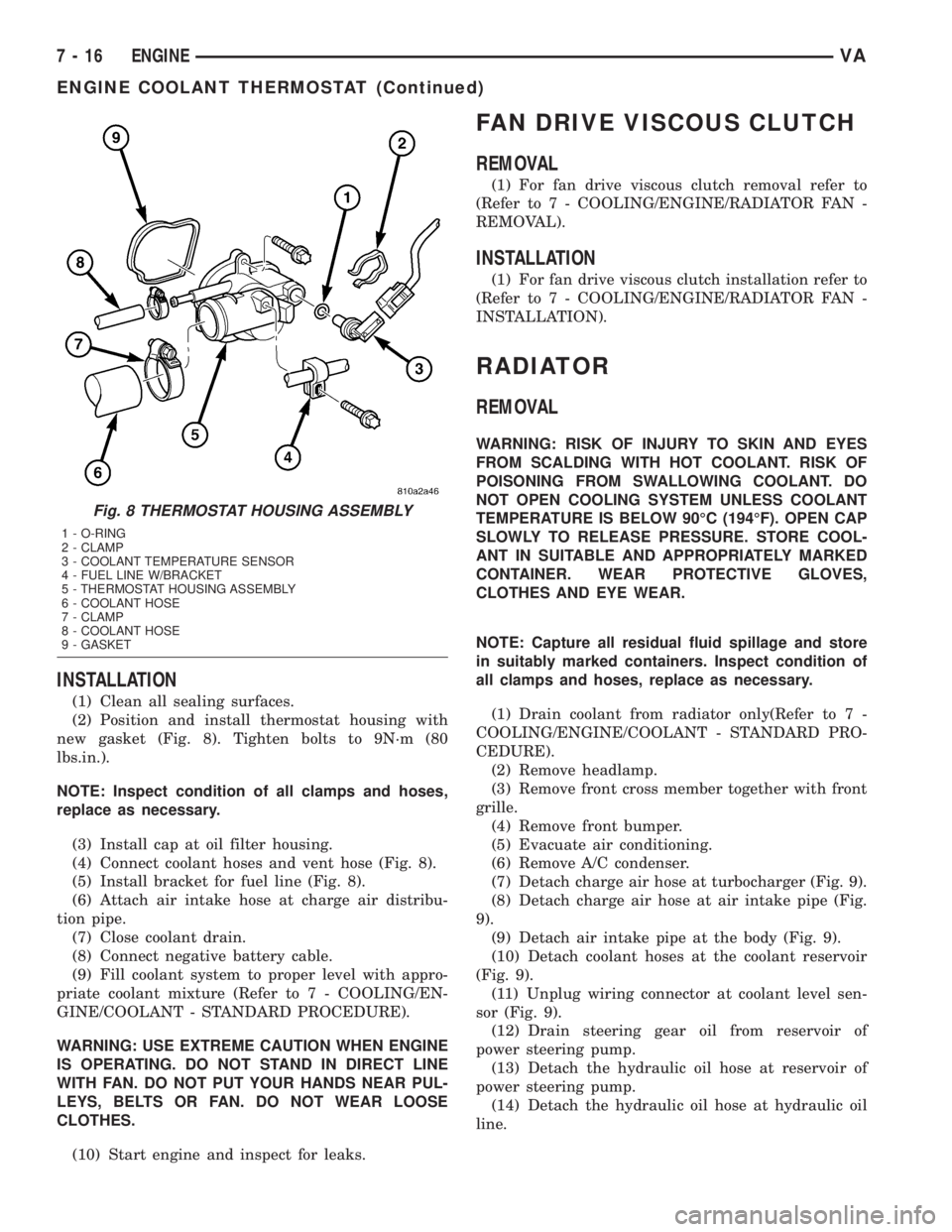

(1) Disconnect negative battery cable.

(2) Drain engine coolant (Refer to 7 - COOLING/

ENGINE/COOLANT - STANDARD PROCEDURE).

(3) Unplug connector, pull off locking element and

pull out coolant temperature sensor.

(4) Detach air intake hose at charge air distribu-

tion pipe.

(5) Detach coolant hoses at thermostat housing.

(6) Remove bracket for fuel line.

(7) Unscrew cap at oil filter housing.

(8) Remove thermostat housing (Fig. 8).

(9) Clean all sealing surfaces.

Fig. 7 ENGINE COOLANT TEMPERATURE SENSOR

1 - RETAINING CLAMP

2 - ENGINE COOLANT TEMPERATURE SENSOR

VAENGINE 7 - 15

ENGINE COOLANT TEMP SENSOR (Continued)

Page 112 of 1232

INSTALLATION

(1) Clean all sealing surfaces.

(2) Position and install thermostat housing with

new gasket (Fig. 8). Tighten bolts to 9N´m (80

lbs.in.).

NOTE: Inspect condition of all clamps and hoses,

replace as necessary.

(3) Install cap at oil filter housing.

(4) Connect coolant hoses and vent hose (Fig. 8).

(5) Install bracket for fuel line (Fig. 8).

(6) Attach air intake hose at charge air distribu-

tion pipe.

(7) Close coolant drain.

(8) Connect negative battery cable.

(9) Fill coolant system to proper level with appro-

priate coolant mixture (Refer to 7 - COOLING/EN-

GINE/COOLANT - STANDARD PROCEDURE).

WARNING: USE EXTREME CAUTION WHEN ENGINE

IS OPERATING. DO NOT STAND IN DIRECT LINE

WITH FAN. DO NOT PUT YOUR HANDS NEAR PUL-

LEYS, BELTS OR FAN. DO NOT WEAR LOOSE

CLOTHES.

(10) Start engine and inspect for leaks.

FAN DRIVE VISCOUS CLUTCH

REMOVAL

(1) For fan drive viscous clutch removal refer to

(Refer to 7 - COOLING/ENGINE/RADIATOR FAN -

REMOVAL).

INSTALLATION

(1) For fan drive viscous clutch installation refer to

(Refer to 7 - COOLING/ENGINE/RADIATOR FAN -

INSTALLATION).

RADIATOR

REMOVAL

WARNING: RISK OF INJURY TO SKIN AND EYES

FROM SCALDING WITH HOT COOLANT. RISK OF

POISONING FROM SWALLOWING COOLANT. DO

NOT OPEN COOLING SYSTEM UNLESS COOLANT

TEMPERATURE IS BELOW 90ÉC (194ÉF). OPEN CAP

SLOWLY TO RELEASE PRESSURE. STORE COOL-

ANT IN SUITABLE AND APPROPRIATELY MARKED

CONTAINER. WEAR PROTECTIVE GLOVES,

CLOTHES AND EYE WEAR.

NOTE: Capture all residual fluid spillage and store

in suitably marked containers. Inspect condition of

all clamps and hoses, replace as necessary.

(1) Drain coolant from radiator only(Refer to 7 -

COOLING/ENGINE/COOLANT - STANDARD PRO-

CEDURE).

(2) Remove headlamp.

(3) Remove front cross member together with front

grille.

(4) Remove front bumper.

(5) Evacuate air conditioning.

(6) Remove A/C condenser.

(7) Detach charge air hose at turbocharger (Fig. 9).

(8) Detach charge air hose at air intake pipe (Fig.

9).

(9) Detach air intake pipe at the body (Fig. 9).

(10) Detach coolant hoses at the coolant reservoir

(Fig. 9).

(11) Unplug wiring connector at coolant level sen-

sor (Fig. 9).

(12) Drain steering gear oil from reservoir of

power steering pump.

(13) Detach the hydraulic oil hose at reservoir of

power steering pump.

(14) Detach the hydraulic oil hose at hydraulic oil

line.

Fig. 8 THERMOSTAT HOUSING ASSEMBLY

1 - O-RING

2 - CLAMP

3 - COOLANT TEMPERATURE SENSOR

4 - FUEL LINE W/BRACKET

5 - THERMOSTAT HOUSING ASSEMBLY

6 - COOLANT HOSE

7 - CLAMP

8 - COOLANT HOSE

9 - GASKET

7 - 16 ENGINEVA

ENGINE COOLANT THERMOSTAT (Continued)