parking brake MERCEDES-BENZ SPRINTER 2005 Service Repair Manual

[x] Cancel search | Manufacturer: MERCEDES-BENZ, Model Year: 2005, Model line: SPRINTER, Model: MERCEDES-BENZ SPRINTER 2005Pages: 1232, PDF Size: 39.23 MB

Page 4 of 1232

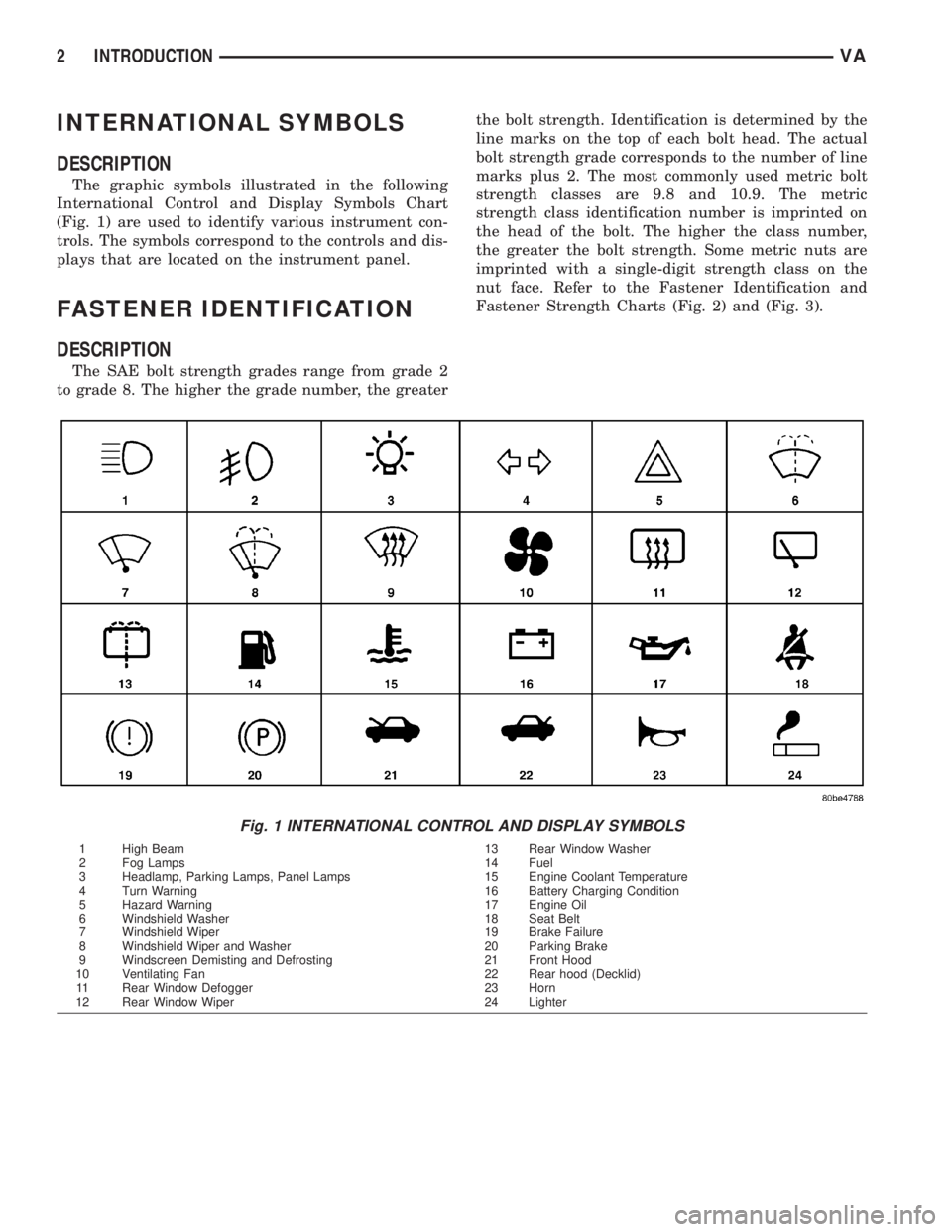

INTERNATIONAL SYMBOLS

DESCRIPTION

The graphic symbols illustrated in the following

International Control and Display Symbols Chart

(Fig. 1) are used to identify various instrument con-

trols. The symbols correspond to the controls and dis-

plays that are located on the instrument panel.

FASTENER IDENTIFICATION

DESCRIPTION

The SAE bolt strength grades range from grade 2

to grade 8. The higher the grade number, the greaterthe bolt strength. Identification is determined by the

line marks on the top of each bolt head. The actual

bolt strength grade corresponds to the number of line

marks plus 2. The most commonly used metric bolt

strength classes are 9.8 and 10.9. The metric

strength class identification number is imprinted on

the head of the bolt. The higher the class number,

the greater the bolt strength. Some metric nuts are

imprinted with a single-digit strength class on the

nut face. Refer to the Fastener Identification and

Fastener Strength Charts (Fig. 2) and (Fig. 3).

Fig. 1 INTERNATIONAL CONTROL AND DISPLAY SYMBOLS

1 High Beam 13 Rear Window Washer

2 Fog Lamps 14 Fuel

3 Headlamp, Parking Lamps, Panel Lamps 15 Engine Coolant Temperature

4 Turn Warning 16 Battery Charging Condition

5 Hazard Warning 17 Engine Oil

6 Windshield Washer 18 Seat Belt

7 Windshield Wiper 19 Brake Failure

8 Windshield Wiper and Washer 20 Parking Brake

9 Windscreen Demisting and Defrosting 21 Front Hood

10 Ventilating Fan 22 Rear hood (Decklid)

11 Rear Window Defogger 23 Horn

12 Rear Window Wiper 24 Lighter

2 INTRODUCTIONVA

Page 16 of 1232

JUMP STARTING

STANDARD PROCEDURE - JUMP STARTING

WARNING: REVIEW ALL SAFETY PRECAUTIONS

AND WARNINGS IN THE BATTERY SYSTEM SEC-

TION OF THE SERVICE MANUAL. (Refer to 8 -

ELECTRICAL/BATTERY SYSTEM/BATTERY - STAN-

DARD PROCEDURE)

²DO NOT JUMP START A FROZEN BATTERY,

PERSONAL INJURY CAN RESULT.

²IF EQUIPPED, DO NOT JUMP START WHEN

MAINTENANCE FREE BATTERY INDICATOR DOT IS

YELLOW OR BRIGHT COLOR.

²DO NOT JUMP START A VEHICLE WHEN THE

BATTERY FLUID IS BELOW THE TOP OF LEAD

PLATES.

²DO NOT ALLOW JUMPER CABLE CLAMPS TO

TOUCH EACH OTHER WHEN CONNECTED TO A

BOOSTER SOURCE.

²DO NOT USE OPEN FLAME NEAR BATTERY.

²REMOVE METALLIC JEWELRY WORN ON

HANDS OR WRISTS TO AVOID INJURY BY ACCI-

DENTAL ARCING OF BATTERY CURRENT.

²WHEN USING A HIGH OUTPUT BOOSTING

DEVICE, DO NOT ALLOW BATTERY VOLTAGE TO

EXCEED 16 VOLTS. REFER TO INSTRUCTIONS

PROVIDED WITH DEVICE BEING USED.

FAILURE TO FOLLOW THESE INSTRUCTIONS MAY

RESULT IN PERSONAL INJURY.

CAUTION: When using another vehicle as a

booster, do not allow vehicles to touch. Electrical

systems can be damaged on either vehicle.

TO JUMP START A DISABLED VEHICLE:

(1) Raise hood on disabled vehicle and visually

inspect engine compartment for:

²Battery cable clamp condition, clean if necessary.

²Frozen battery.

²Yellow or bright color test indicator, if equipped.

²Low battery fluid level.

²Generator drive belt condition and tension.

²Fuel fumes or leakage, correct if necessary.

CAUTION: If the cause of starting problem on dis-

abled vehicle is severe, damage to booster vehicle

charging system can result.

(2) When using another vehicle as a booster

source, park the booster vehicle within cable reach.

Turn off all accessories, set the parking brake, place

the automatic transmission in PARK or the manual

transmission in NEUTRAL and turn the ignition

OFF.(3) On disabled vehicle, place gear selector in park

or neutral and set park brake. Turn off all accesso-

ries.

(4) Connect jumper cables to booster battery. RED

clamp to positive terminal (+). BLACK clamp to neg-

ative terminal (-). DO NOT allow clamps at opposite

end of cables to touch, electrical arc will result.

Review all warnings in this procedure.

(5) On disabled vehicle, connect RED jumper cable

clamp to positive (+) terminal. Connect BLACK

jumper cable clamp to engine ground as close to the

ground cable attaching point as possible.

(6) Start the engine in the vehicle which has the

booster battery, let the engine idle a few minutes,

then start the engine in the vehicle with the dis-

charged battery.

CAUTION: Do not crank starter motor on disabled

vehicle for more than 15 seconds, starter will over-

heat and could fail.

(7) Allow battery in disabled vehicle to charge to

at least 12.4 volts (75% charge) before attempting to

start engine. If engine does not start within 15 sec-

onds, stop cranking engine and allow starter to cool

(15 min.), before cranking again.

DISCONNECT CABLE CLAMPS AS FOLLOWS:

²Disconnect BLACK cable clamp from engine

ground on disabled vehicle.

²When using a Booster vehicle, disconnect

BLACK cable clamp from battery negative terminal.

Disconnect RED cable clamp from battery positive

terminal.

²Disconnect RED cable clamp from battery posi-

tive terminal on disabled vehicle.

TOWING

STANDARD PROCEDURE - TOWING

WARNING: Do not tow the vehicle if the key cannot

be turned in the ignition lock. If the key cannot be

turned, the ignition lock remains locked and the

vehicle cannot be steered. With the engine not run-

ning there is no power assistance for the braking

and steering systems. In this case, it is important to

keep in mind that a considerably higher degree of

effort is necessary to brake and steer the vehicle.

The vehicle must not be towed with the front axle

raised and the key in position 2 in the ignition lock

as the drive wheels could then lock due to the

acceleration skid control (ASR)

0 - 6 LUBRICATION & MAINTENANCEVA

Page 51 of 1232

heard during a coast, the front pinion bearing is the

source.

Differential bearings usually produce a low pitch

noise. Differential bearing noise is similar to pinion

bearing noise. The pitch of differential bearing noise

is also constant and varies only with vehicle speed.

Axle shaft bearingsproduce noise and vibration

when worn or damaged. The noise generally changes

when the bearings are loaded. Road test the vehicle.

Turn the vehicle sharply to the left and to the right.

This will load the bearings and change the noise

level. Where axle bearing damage is slight, the noise

is usually not noticeable at speeds above 30 mph.

LOW SPEED KNOCK

Low speed knock is generally caused by a worn

U-joint or by worn side-gear thrust washers. A worn

pinion shaft bore will also cause low speed knock.

VIBRATION

Vibration at the rear of the vehicle is usually

caused by a:

²Damaged drive shaft.

²Missing drive shaft balance weight(s).

²Worn or out-of-balance wheels.

²Loose wheel lug nuts.

²Worn U-joint(s).

²Loose/broken springs.

²Damaged axle shaft bearing(s).

²Loose pinion gear nut.

²Excessive pinion yoke run out.

²Bent axle shaft(s).

Check for loose or damaged front-end components

or engine/transmission mounts. These components

can contribute to what appears to be a rearend vibra-

tion. Do not overlook engine accessories, brackets

and drive belts.

NOTE: All driveline components should be exam-

ined before starting any repair.

DRIVELINE SNAP

A snap or clunk noise when the vehicle is shifted

into gear (or the clutch engaged), can be caused by:

²High engine idle speed.

²Transmission shift operation.

²Loose engine/transmission/transfer case mounts.

²Worn U-joints.

²Loose spring mounts.

²Loose pinion gear nut and yoke.

²Excessive ring gear backlash.

²Excessive side gear to case clearance.

The source of a snap or a clunk noise can be deter-

mined with the assistance of a helper. Raise the vehi-

cle on a hoist with the wheels free to rotate. Instruct

the helper to shift the transmission into gear. Listenfor the noise, a mechanics stethoscope is helpful in

isolating the source of a noise.

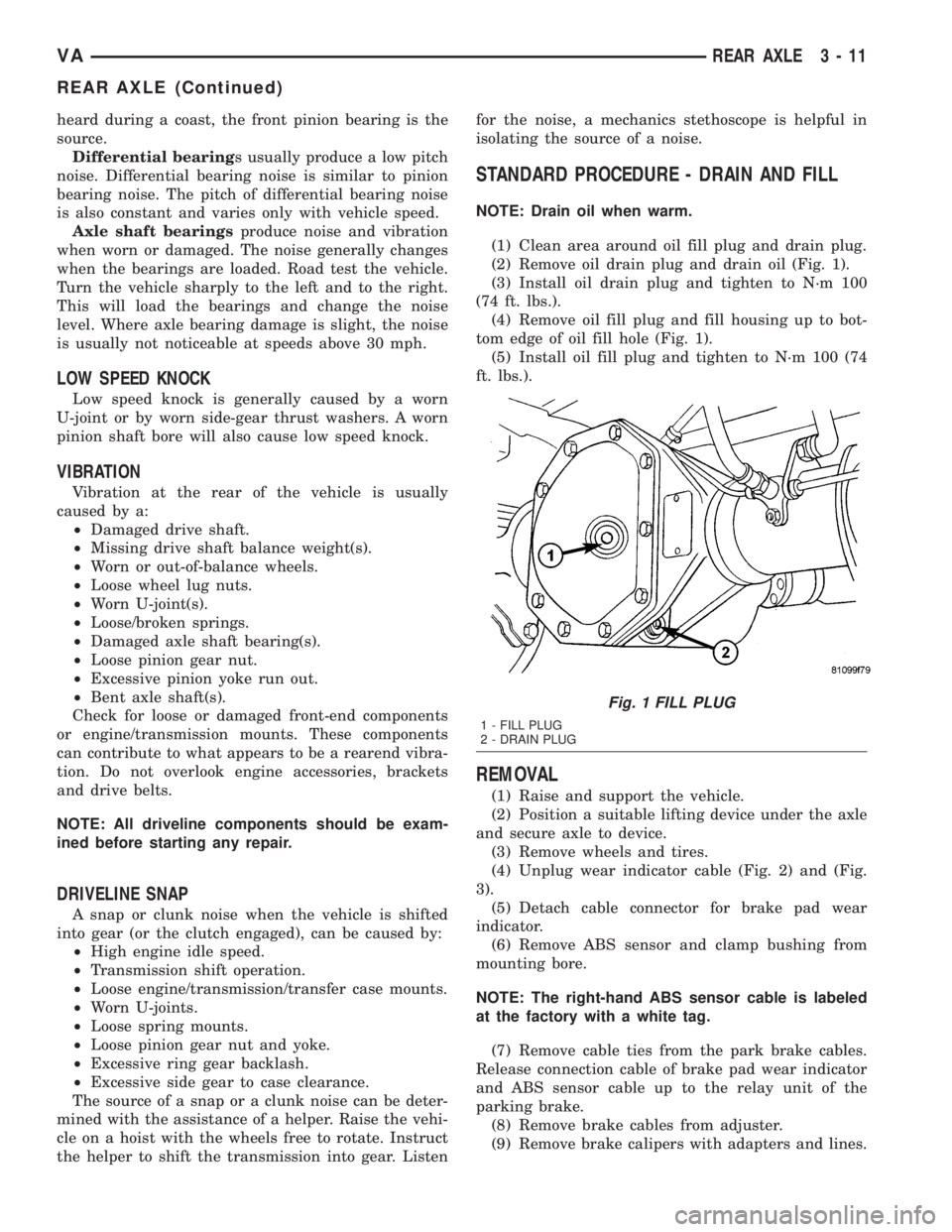

STANDARD PROCEDURE - DRAIN AND FILL

NOTE: Drain oil when warm.

(1) Clean area around oil fill plug and drain plug.

(2) Remove oil drain plug and drain oil (Fig. 1).

(3) Install oil drain plug and tighten to N´m 100

(74 ft. lbs.).

(4) Remove oil fill plug and fill housing up to bot-

tom edge of oil fill hole (Fig. 1).

(5) Install oil fill plug and tighten to N´m 100 (74

ft. lbs.).

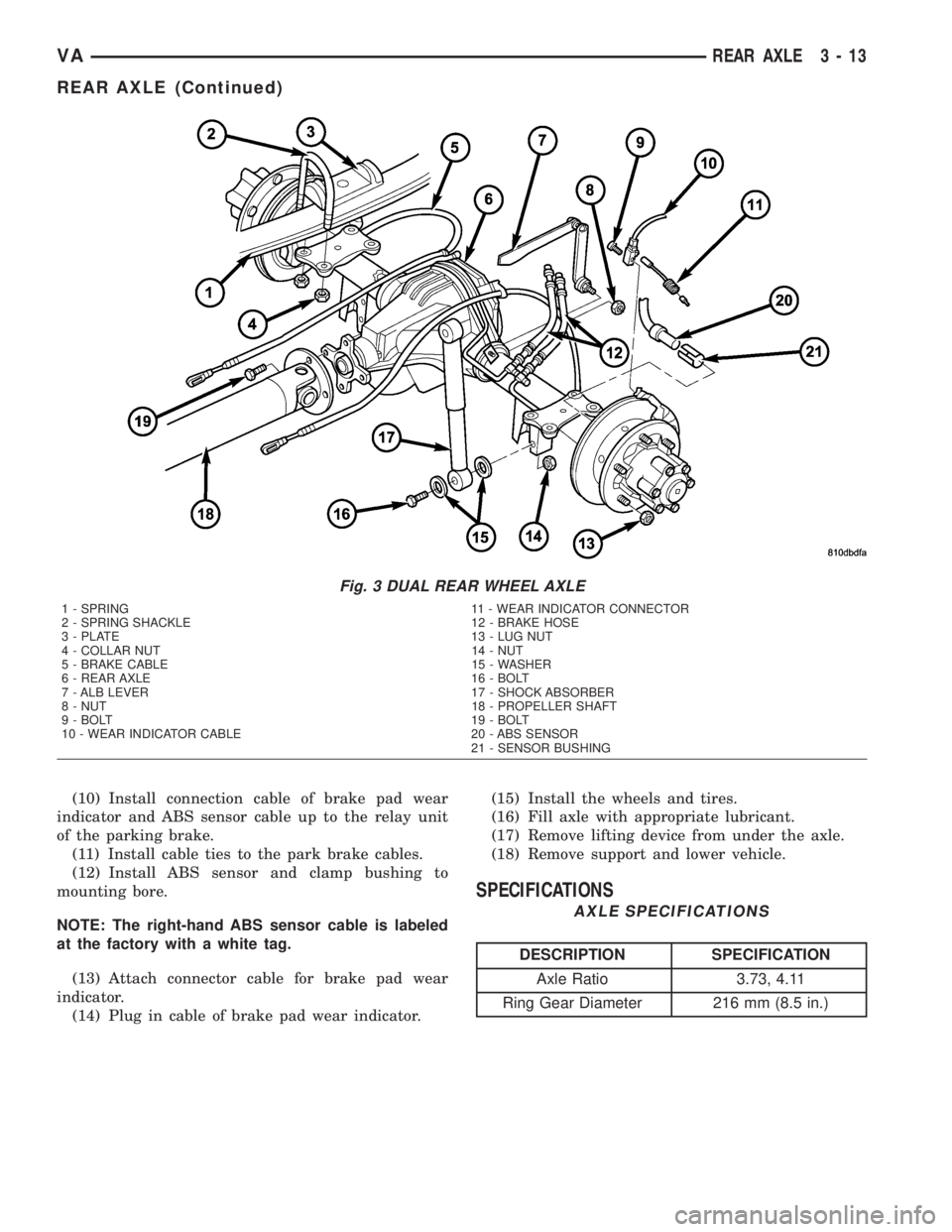

REMOVAL

(1) Raise and support the vehicle.

(2) Position a suitable lifting device under the axle

and secure axle to device.

(3) Remove wheels and tires.

(4) Unplug wear indicator cable (Fig. 2) and (Fig.

3).

(5) Detach cable connector for brake pad wear

indicator.

(6) Remove ABS sensor and clamp bushing from

mounting bore.

NOTE: The right-hand ABS sensor cable is labeled

at the factory with a white tag.

(7) Remove cable ties from the park brake cables.

Release connection cable of brake pad wear indicator

and ABS sensor cable up to the relay unit of the

parking brake.

(8) Remove brake cables from adjuster.

(9) Remove brake calipers with adapters and lines.

Fig. 1 FILL PLUG

1 - FILL PLUG

2 - DRAIN PLUG

VAREAR AXLE 3 - 11

REAR AXLE (Continued)

Page 53 of 1232

(10) Install connection cable of brake pad wear

indicator and ABS sensor cable up to the relay unit

of the parking brake.

(11) Install cable ties to the park brake cables.

(12) Install ABS sensor and clamp bushing to

mounting bore.

NOTE: The right-hand ABS sensor cable is labeled

at the factory with a white tag.

(13) Attach connector cable for brake pad wear

indicator.

(14) Plug in cable of brake pad wear indicator.(15) Install the wheels and tires.

(16) Fill axle with appropriate lubricant.

(17) Remove lifting device from under the axle.

(18) Remove support and lower vehicle.

SPECIFICATIONS

AXLE SPECIFICATIONS

DESCRIPTION SPECIFICATION

Axle Ratio 3.73, 4.11

Ring Gear Diameter 216 mm (8.5 in.)

Fig. 3 DUAL REAR WHEEL AXLE

1 - SPRING 11 - WEAR INDICATOR CONNECTOR

2 - SPRING SHACKLE 12 - BRAKE HOSE

3 - PLATE 13 - LUG NUT

4 - COLLAR NUT 14 - NUT

5 - BRAKE CABLE 15 - WASHER

6 - REAR AXLE 16 - BOLT

7 - ALB LEVER 17 - SHOCK ABSORBER

8 - NUT 18 - PROPELLER SHAFT

9 - BOLT 19 - BOLT

10 - WEAR INDICATOR CABLE 20 - ABS SENSOR

21 - SENSOR BUSHING

VAREAR AXLE 3 - 13

REAR AXLE (Continued)

Page 55 of 1232

AXLE SHAFTS

REMOVAL

(1) Remove wheels.

(2) Detach front brake cable.

(3) Pull ABS sensor together with clamp bushing

out of bearing cap (Fig. 4).

(4) Remove brake disk at rear axle. Attach brake

caliper with lines connected in wheel house.

(5) Remove brake shoes of parking brake.

(6) Remove brake control cable lock.

(7) Remove bearing cap bolts and pull axle shaft

out of axle tube (Fig. 4).

(8) Remove seal/gasket.

INSTALLATION

(1) Install sealing ring.

(2) Install rear axle shaft in the axle tube (Fig. 5).

(3) Installnewbearing cap bolts and tighten to 72

N´m (53 ft. lbs.) (Fig. 6).

NOTE: Tighten bolts diagonally across.

(4) Install brake control cable lock.

(5) Install parking brake shoes.

(6) Install brake disk and calipers.

(7) Coat clamping bush with acid-free grease.

Insert ABS sensor with clamping bush fully into the

mounting hole.

(8) Install front brake cable.

(9) Operate brake pedal several times until brake

pads contact brake discs (brake pressure built up).

(10) Install wheels.

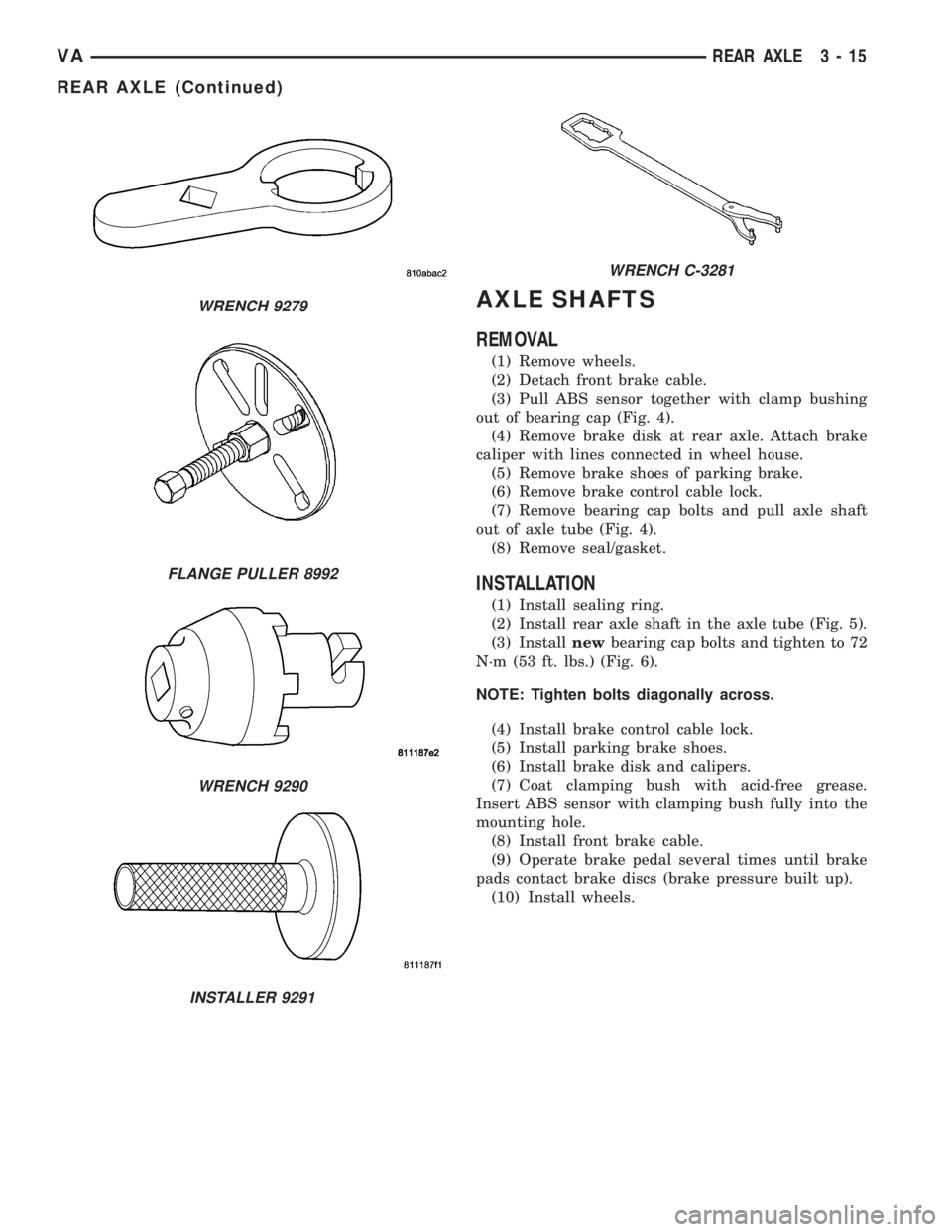

WRENCH 9279

FLANGE PULLER 8992

WRENCH 9290

INSTALLER 9291

WRENCH C-3281

VAREAR AXLE 3 - 15

REAR AXLE (Continued)

Page 60 of 1232

(2) Slide axle shaft into axle tube.

(3) Install axle shaft hub nuts and tighten to N´m

65 (48 ft. lbs.).

(4) Install wheels.

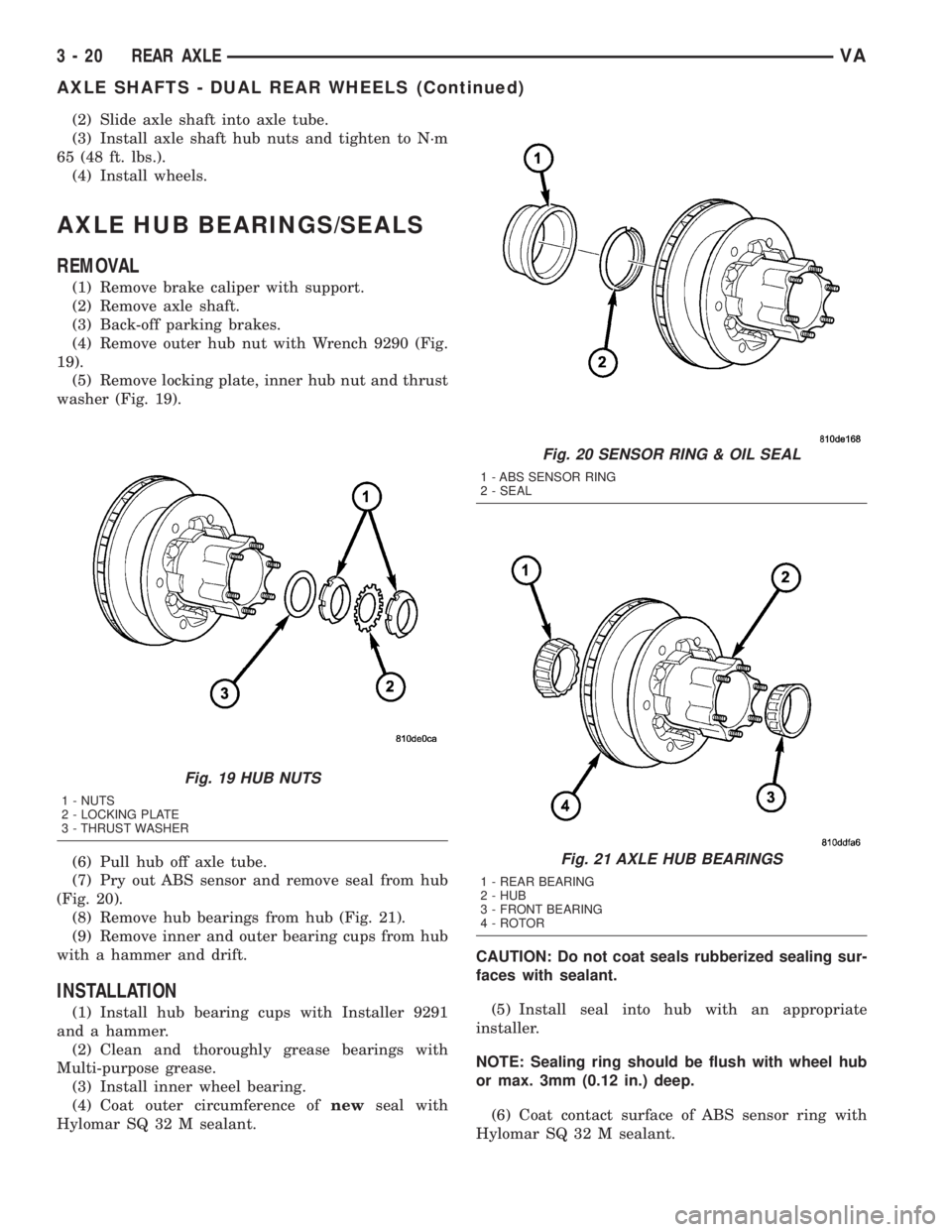

AXLE HUB BEARINGS/SEALS

REMOVAL

(1) Remove brake caliper with support.

(2) Remove axle shaft.

(3) Back-off parking brakes.

(4) Remove outer hub nut with Wrench 9290 (Fig.

19).

(5) Remove locking plate, inner hub nut and thrust

washer (Fig. 19).

(6) Pull hub off axle tube.

(7) Pry out ABS sensor and remove seal from hub

(Fig. 20).

(8) Remove hub bearings from hub (Fig. 21).

(9) Remove inner and outer bearing cups from hub

with a hammer and drift.

INSTALLATION

(1) Install hub bearing cups with Installer 9291

and a hammer.

(2) Clean and thoroughly grease bearings with

Multi-purpose grease.

(3) Install inner wheel bearing.

(4) Coat outer circumference ofnewseal with

Hylomar SQ 32 M sealant.CAUTION: Do not coat seals rubberized sealing sur-

faces with sealant.

(5) Install seal into hub with an appropriate

installer.

NOTE: Sealing ring should be flush with wheel hub

or max. 3mm (0.12 in.) deep.

(6) Coat contact surface of ABS sensor ring with

Hylomar SQ 32 M sealant.

Fig. 19 HUB NUTS

1 - NUTS

2 - LOCKING PLATE

3 - THRUST WASHER

Fig. 20 SENSOR RING & OIL SEAL

1 - ABS SENSOR RING

2 - SEAL

Fig. 21 AXLE HUB BEARINGS

1 - REAR BEARING

2 - HUB

3 - FRONT BEARING

4 - ROTOR

3 - 20 REAR AXLEVA

AXLE SHAFTS - DUAL REAR WHEELS (Continued)

Page 61 of 1232

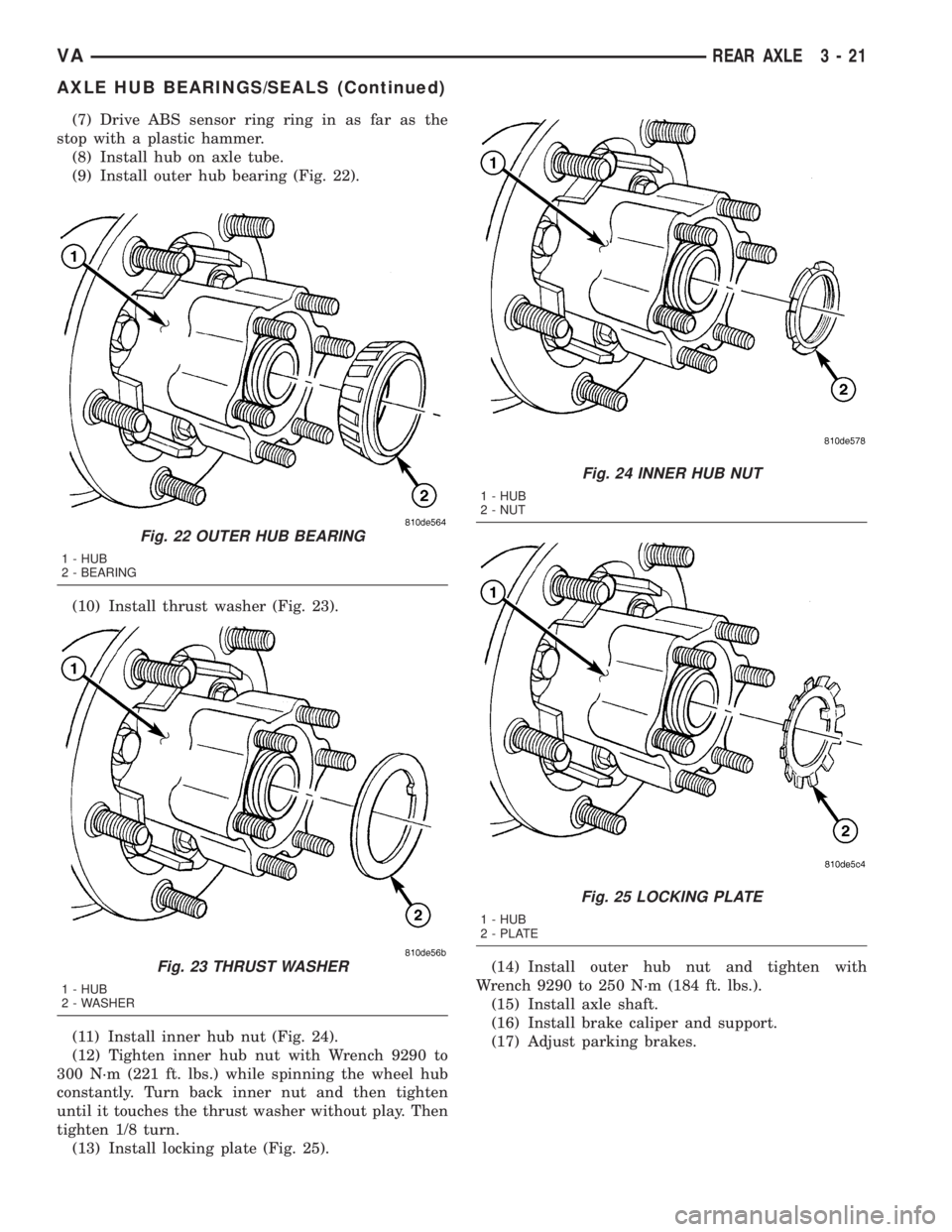

(7) Drive ABS sensor ring ring in as far as the

stop with a plastic hammer.

(8) Install hub on axle tube.

(9) Install outer hub bearing (Fig. 22).

(10) Install thrust washer (Fig. 23).

(11) Install inner hub nut (Fig. 24).

(12) Tighten inner hub nut with Wrench 9290 to

300 N´m (221 ft. lbs.) while spinning the wheel hub

constantly. Turn back inner nut and then tighten

until it touches the thrust washer without play. Then

tighten 1/8 turn.

(13) Install locking plate (Fig. 25).(14) Install outer hub nut and tighten with

Wrench 9290 to 250 N´m (184 ft. lbs.).

(15) Install axle shaft.

(16) Install brake caliper and support.

(17) Adjust parking brakes.

Fig. 22 OUTER HUB BEARING

1 - HUB

2 - BEARING

Fig. 23 THRUST WASHER

1 - HUB

2 - WASHER

Fig. 24 INNER HUB NUT

1 - HUB

2 - NUT

Fig. 25 LOCKING PLATE

1 - HUB

2 - PLATE

VAREAR AXLE 3 - 21

AXLE HUB BEARINGS/SEALS (Continued)

Page 63 of 1232

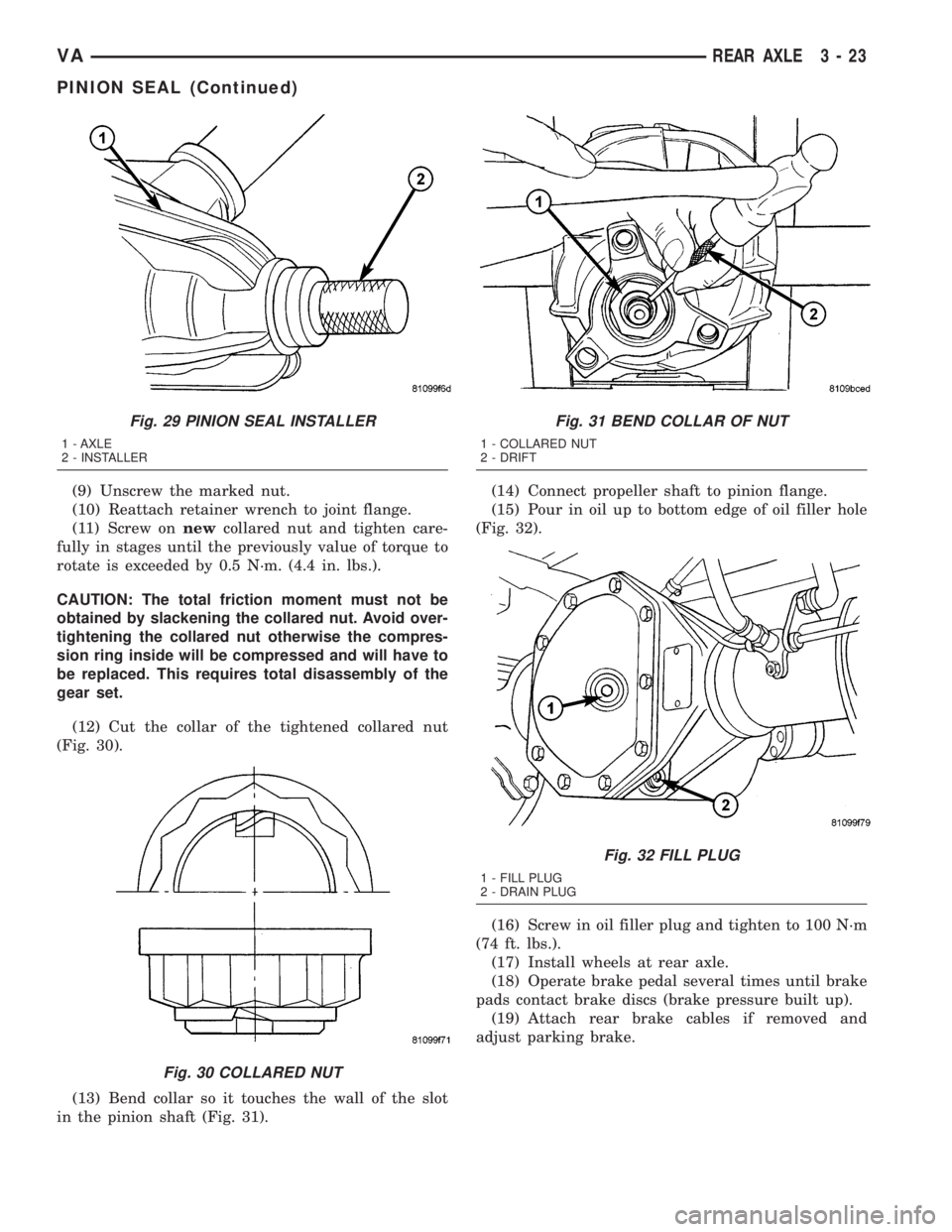

(9) Unscrew the marked nut.

(10) Reattach retainer wrench to joint flange.

(11) Screw onnewcollared nut and tighten care-

fully in stages until the previously value of torque to

rotate is exceeded by 0.5 N´m. (4.4 in. lbs.).

CAUTION: The total friction moment must not be

obtained by slackening the collared nut. Avoid over-

tightening the collared nut otherwise the compres-

sion ring inside will be compressed and will have to

be replaced. This requires total disassembly of the

gear set.

(12) Cut the collar of the tightened collared nut

(Fig. 30).

(13) Bend collar so it touches the wall of the slot

in the pinion shaft (Fig. 31).(14) Connect propeller shaft to pinion flange.

(15) Pour in oil up to bottom edge of oil filler hole

(Fig. 32).

(16) Screw in oil filler plug and tighten to 100 N´m

(74 ft. lbs.).

(17) Install wheels at rear axle.

(18) Operate brake pedal several times until brake

pads contact brake discs (brake pressure built up).

(19) Attach rear brake cables if removed and

adjust parking brake.

Fig. 29 PINION SEAL INSTALLER

1 - AXLE

2 - INSTALLER

Fig. 30 COLLARED NUT

Fig. 31 BEND COLLAR OF NUT

1 - COLLARED NUT

2 - DRIFT

Fig. 32 FILL PLUG

1 - FILL PLUG

2 - DRAIN PLUG

VAREAR AXLE 3 - 23

PINION SEAL (Continued)

Page 66 of 1232

STANDARD PROCEDURE - MASTER

CYLINDER BLEEDING..................17

REMOVAL.............................17

INSTALLATION.........................18

PEDAL

REMOVAL.............................18

INSTALLATION.........................19

POWER BRAKE BOOSTER

DESCRIPTION.........................19

OPERATION...........................19

REMOVAL.............................19

INSTALLATION.........................19

ROTORS

REMOVAL

REMOVAL - FRONT (SRW)..............19

REMOVAL - REAR (SRW)...............20

REMOVAL - FRONT (DRW)..............20

REMOVAL - REAR (DRW)...............20

INSTALLATION

INSTALLATION - FRONT (SRW)..........21

INSTALLATION - REAR (SRW)...........21

INSTALLATION - FRONT (DRW)..........21

INSTALLATION - REAR (DRW)...........21

SUPPORT PLATE

REMOVAL - REAR......................22

INSTALLATION - REAR...................22

PARKING BRAKE

SPECIFICATIONS

TORQUE CHART......................22SPECIAL TOOLS

PARK BRAKE........................23

CABLE TENSIONER

REMOVAL.............................23

INSTALLATION.........................23

CABLES

REMOVAL

REMOVAL - FRONT....................24

REMOVAL - REAR.....................24

INSTALLATION

INSTALLATION - FRONT................24

INSTALLATION - REAR.................25

ADJUSTMENTS

ADJUSTMENT - PARKING BRAKE CABLES . 25

LEVER

REMOVAL.............................26

INSTALLATION.........................26

SHOES

REMOVAL

REMOVAL - (SRW)....................26

REMOVAL - (DRW)....................26

CLEANING - REAR DRUM IN HAT BRAKE....27

INSTALLATION

INSTALLATION - (SRW).................27

INSTALLATION - (DRW).................27

ADJUSTMENTS

ADJUSTMENT........................27

BRAKES - BASE

DIAGNOSIS AND TESTING - BASE BRAKE

SYSTEM

Base brake components consist of the brake pads,

calipers, brake drum in hat rotor in the rear, rotors,

brake lines, master cylinder, booster, and parking

brake components.

Brake diagnosis involves determining if the prob-

lem is related to a mechanical, hydraulic, or vacuum

operated component.

The first diagnosis step is the preliminary check.

PRELIMINARY BRAKE CHECK

(1) Check condition of tires and wheels. Damaged

wheels and worn, damaged, or underinflated tires

can cause pull, shudder, vibration, and a condition

similar to grab.

(2) If complaint was based on noise when braking,

check suspension components. Jounce front and rear

of vehicle and listen for noise that might be caused

by loose, worn or damaged suspension or steering

components.(3) Inspect brake fluid level and condition. Note

that the brake reservoir fluid level will decrease in

proportion to normal lining wear.Also note that

brake fluid tends to darken over time. This is

normal and should not be mistaken for contam-

ination.

(a) If fluid level is abnormally low, look for evi-

dence of leaks at calipers, wheel cylinders, brake

lines, and master cylinder.

(b) If fluid appears contaminated, drain out a

sample to examine. System will have to be flushed

if fluid is separated into layers, or contains a sub-

stance other than brake fluid. The system seals

and cups will also have to be replaced after flush-

ing. Use clean brake fluid to flush the system.

(4) Check parking brake operation. Verify free

movement and full release of cables and pedal. Also

note if vehicle was being operated with parking

brake partially applied.

(5) Check brake pedal operation. Verify that pedal

does not bind and has adequate free play. If pedal

lacks free play, check pedal and power booster for

being loose or for bind condition. Do not road test

until condition is corrected.

(6) Check booster vacuum check valve and hose.

(7) If components checked appear OK, road test

the vehicle.

5 - 2 BRAKES - BASEVA

Page 67 of 1232

ROAD TESTING

(1) If complaint involved low brake pedal, pump

pedal and note if it comes back up to normal height.

(2) Check brake pedal response with transmission

in Neutral and engine running. Pedal should remain

firm under constant foot pressure.

(3) During road test, make normal and firm brake

stops in 25-40 mph range. Note faulty brake opera-

tion such as low pedal, hard pedal, fade, pedal pulsa-

tion, pull, grab, drag, noise, etc.

(4) Attempt to stop the vehicle with the parking

brake only and note grab, drag, noise, etc.

PEDAL FALLS AWAY

A brake pedal that falls away under steady foot

pressure is generally the result of a system leak. The

leak point could be at a brake line, fitting, hose, or

caliper/wheel cylinder. If leakage is severe, fluid will

be evident at or around the leaking component.

Internal leakage (seal by-pass) in the master cylin-

der caused by worn or damaged piston cups, may

also be the problem cause.

An internal leak in the ABS or RWAL system may

also be the problem with no physical evidence.

LOW PEDAL

If a low pedal is experienced, pump the pedal sev-

eral times. If the pedal comes back up worn linings,

rotors, drums, or rear brakes out of adjustment are

the most likely causes. The proper course of action is

to inspect and replace all worn component and make

the proper adjustments.

SPONGY PEDAL

A spongy pedal is most often caused by air in the

system. However, thin brake drums or substandard

brake lines and hoses can also cause a spongy pedal.

The proper course of action is to bleed the system,

and replace thin drums and substandard quality

brake hoses if suspected.

HARD PEDAL OR HIGH PEDAL EFFORT

A hard pedal or high pedal effort may be due to

lining that is water soaked, contaminated, glazed, or

badly worn. The power booster or check valve could

also be faulty.

PEDAL PULSATION

Pedal pulsation is caused by components that are

loose, or beyond tolerance limits.

The primary cause of pulsation are disc brake

rotors with excessive lateral runout or thickness vari-

ation, or out of round brake drums. Other causes are

loose wheel bearings or calipers and worn, damaged

tires.NOTE: Some pedal pulsation may be felt during

ABS activation.

BRAKE DRAG

Brake drag occurs when the lining is in constant

contact with the rotor or drum. Drag can occur at one

wheel, all wheels, fronts only, or rears only.

Drag is a product of incomplete brake shoe release.

Drag can be minor or severe enough to overheat the

linings, rotors and drums.

Minor drag will usually cause slight surface char-

ring of the lining. It can also generate hard spots in

rotors and drums from the overheat-cool down pro-

cess. In most cases, the rotors, drums, wheels and

tires are quite warm to the touch after the vehicle is

stopped.

Severe drag can char the brake lining all the way

through. It can also distort and score rotors and

drums to the point of replacement. The wheels, tires

and brake components will be extremely hot. In

severe cases, the lining may generate smoke as it

chars from overheating.

Common causes of brake drag are:

²Seized or improperly adjusted parking brake

cables.

²Loose/worn wheel bearing.

²Seized caliper or wheel cylinder piston.

²Caliper binding on corroded bushings or rusted

slide surfaces.

²Loose caliper mounting.

²Drum brake shoes binding on worn/damaged

support plates.

²Mis-assembled components.

²Long booster output rod.

If brake drag occurs at all wheels, the problem

may be related to a blocked master cylinder return

port, or faulty power booster (binds-does not release).

BRAKE FADE

Brake fade is usually a product of overheating

caused by brake drag. However, brake overheating

and resulting fade can also be caused by riding the

brake pedal, making repeated high deceleration stops

in a short time span, or constant braking on steep

mountain roads. Refer to the Brake Drag information

in this section for causes.

BRAKE PULL

Front brake pull condition could result from:

²Contaminated lining in one caliper

²Seized caliper piston

²Binding caliper

²Loose caliper

²Rusty caliper slide surfaces

²Improper brake pads

²Damaged rotor

VABRAKES - BASE 5 - 3

BRAKES - BASE (Continued)