fuel MERCEDES-BENZ SPRINTER 2006 Service Manual

[x] Cancel search | Manufacturer: MERCEDES-BENZ, Model Year: 2006, Model line: SPRINTER, Model: MERCEDES-BENZ SPRINTER 2006Pages: 2305, PDF Size: 48.12 MB

Page 1616 of 2305

CAUTION: Oil thread and head contact surfaces of

bolts that retain the crankshaft bearing caps;

tighten bolts from inside to outside, beginning at

the fit bearing. Rotate crankshaft to check clear-

ance.

(1) Install crankshaft.

CAUTION: The crankshaft bearing caps are num-

bered consecutively, beginning with the first crank-

shaft bearing cap at the front of the engine.

Attention must be paid to the way the crankshaft

bearing caps fit. If correctly installed, the lug, or

raised boss, on the crankshaft bearing cap is point-

ing to the left when viewed in the direction of travel

(intake side).

(2) Install the crankshaft bearing caps. Tighten

bolts in two stages. 55N´m (40.5 lbs. ft.), then 90É.

(3) Install the pistons (Refer to 9 - ENGINE/EN-

GINE BLOCK/PISTON & CONNECTING ROD -

INSTALLATION).

(4) Install the end cover (Refer to 9 - ENGINE/EN-

GINE BLOCK/CRANKSHAFT OIL SEAL - REAR -

INSTALLATION).

(5) Install the timing case cover (Refer to 9 -

ENGINE/VALVE TIMING/TIMING BELT / CHAIN

COVER(S) - INSTALLATION).

(6) Install the engine (Refer to 9 - ENGINE -

INSTALLATION).

(7) Fill the crankcase with the correct engine oil,

to the proper level. Refer to the owners manual for

specifications.

(8) Fill the cooling system with the proper coolant,

to the proper level (Refer to 7 - COOLING/ENGINE/

COOLANT - STANDARD PROCEDURE).

(9) Connect the negative battery cable.

WARNING: USE EXTREME CAUTION WHEN THE

ENGINE IS OPERATING. DO NOT STAND IN A

DIRECT LINE WITH THE FAN. DO NOT PUT YOUR

HANDS NEAR THE PULLEYS, BELTS, OR FAN. DO

NOT WEAR LOOSE CLOTHES.

(10) Start engine and inspect for leaks. Care must

be taken to observe the fuel system warning (Refer to

14 - FUEL SYSTEM - WARNING).

CRANKSHAFT OIL SEAL -

REAR

REMOVAL

This must be done with the transmission removed

from the vehicle.

(1) Disconnect the negative battery cable.

(2) Raise and support the vehicle.

(3) Drain the engine oil.NOTE: Loosen all of the oil pan bolts to assure that

the oil pan gasket is not damaged when removing

the rear main oil seal and end cover assembly.

NOTE: Inspect the oil pan gasket for damage. If the

oil pan gasket is damaged, remove the oil pan and

replace the oil pan gasket.

(4) Loosen the oil pan bolts.

(5) Remove the flywheel.

CAUTION: Care must be taken when removing the

rear main seal and adaptor assembly. Failure to do

so will result in damage to the oil pan gasket.

(6) Remove the rear main seal/adaptor retaining

bolts and carefully pry the adaptor from the crank-

case at the adaptor shoulders (Fig. 33).

VAENGINE 9 - 41

Page 1627 of 2305

(19) Fill the cooing system with proper coolant, to

the proper level (Refer to 7 - COOLING/ENGINE/

COOLANT - STANDARD PROCEDURE).

(20) Connect negative battery cable.

WARNING: USE EXTREME CAUTION WHEN THE

ENGINE IS OPERATING. DO NOT STAND IN A

DIRECT LINE WITH THE FAN. DO NOT PUT YOUR

HANDS NEAR THE PULLEYS, BELTS, OR FAN. DO

NOT WEAR LOOSE CLOTHES.

WARNING: (Refer to 14 - FUEL SYSTEM - WARN-

ING).

(21) Start the engine and inspect for leaks.

PISTON RINGS

STANDARD PROCEDURE - PISTON RING FIT-

TING

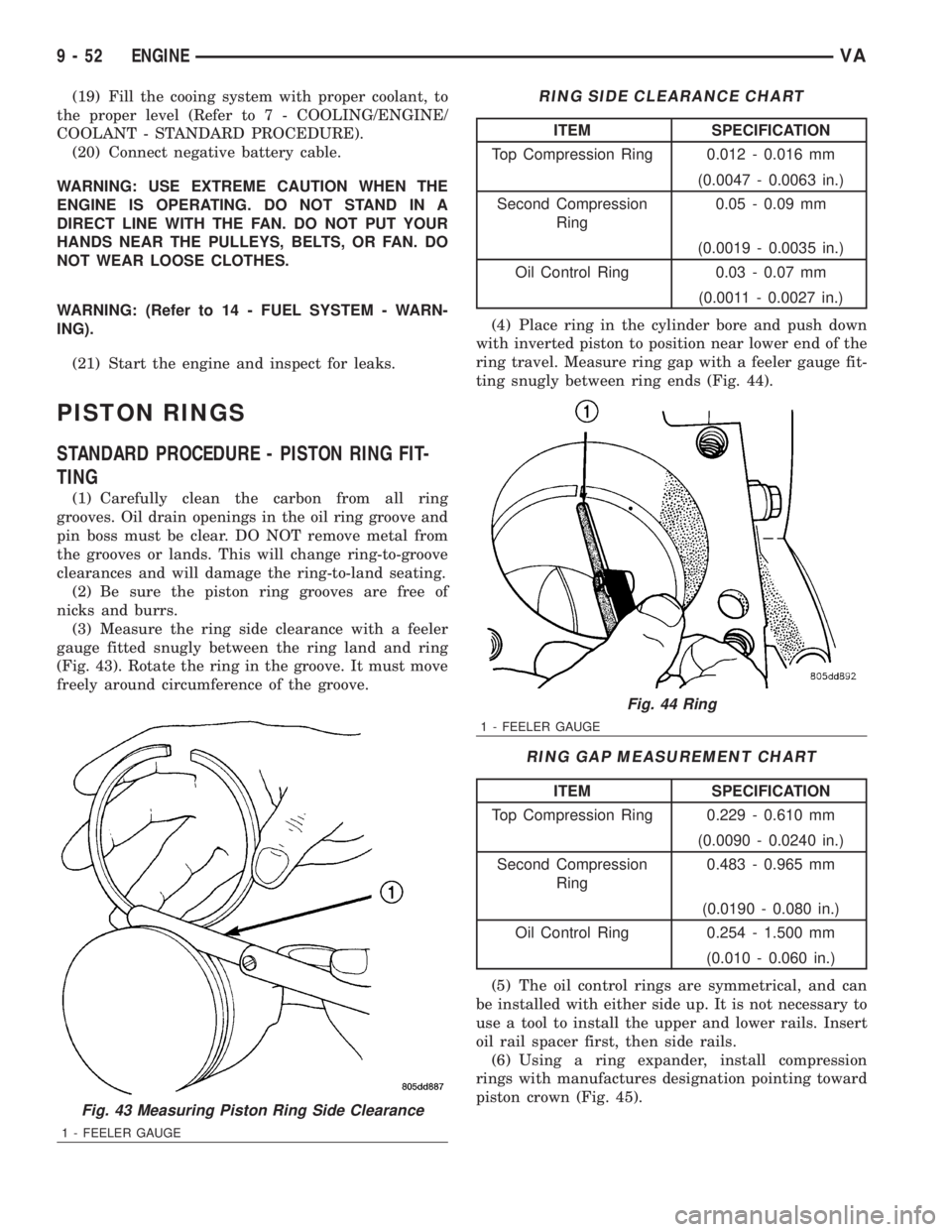

(1) Carefully clean the carbon from all ring

grooves. Oil drain openings in the oil ring groove and

pin boss must be clear. DO NOT remove metal from

the grooves or lands. This will change ring-to-groove

clearances and will damage the ring-to-land seating.

(2) Be sure the piston ring grooves are free of

nicks and burrs.

(3) Measure the ring side clearance with a feeler

gauge fitted snugly between the ring land and ring

(Fig. 43). Rotate the ring in the groove. It must move

freely around circumference of the groove.

RING SIDE CLEARANCE CHART

ITEM SPECIFICATION

Top Compression Ring 0.012 - 0.016 mm

(0.0047 - 0.0063 in.)

Second Compression

Ring0.05 - 0.09 mm

(0.0019 - 0.0035 in.)

Oil Control Ring 0.03 - 0.07 mm

(0.0011 - 0.0027 in.)

(4) Place ring in the cylinder bore and push down

with inverted piston to position near lower end of the

ring travel. Measure ring gap with a feeler gauge fit-

ting snugly between ring ends (Fig. 44).

RING GAP MEASUREMENT CHART

ITEM SPECIFICATION

Top Compression Ring 0.229 - 0.610 mm

(0.0090 - 0.0240 in.)

Second Compression

Ring0.483 - 0.965 mm

(0.0190 - 0.080 in.)

Oil Control Ring 0.254 - 1.500 mm

(0.010 - 0.060 in.)

(5) The oil control rings are symmetrical, and can

be installed with either side up. It is not necessary to

use a tool to install the upper and lower rails. Insert

oil rail spacer first, then side rails.

(6) Using a ring expander, install compression

rings with manufactures designation pointing toward

piston crown (Fig. 45).

Fig. 43 Measuring Piston Ring Side Clearance

1 - FEELER GAUGE

Fig. 44 Ring

1 - FEELER GAUGE

9 - 52 ENGINEVA

Page 1640 of 2305

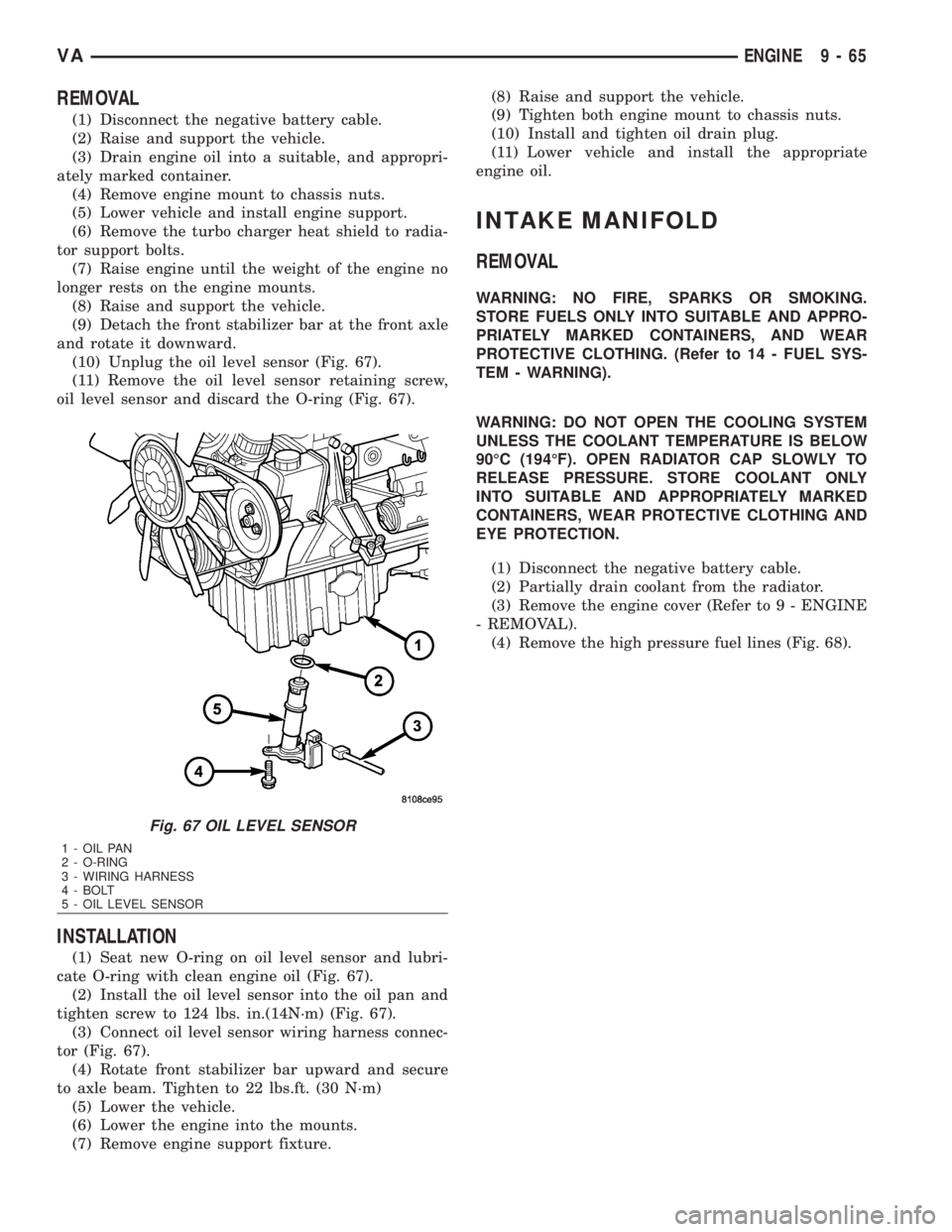

REMOVAL

(1) Disconnect the negative battery cable.

(2) Raise and support the vehicle.

(3) Drain engine oil into a suitable, and appropri-

ately marked container.

(4) Remove engine mount to chassis nuts.

(5) Lower vehicle and install engine support.

(6) Remove the turbo charger heat shield to radia-

tor support bolts.

(7) Raise engine until the weight of the engine no

longer rests on the engine mounts.

(8) Raise and support the vehicle.

(9) Detach the front stabilizer bar at the front axle

and rotate it downward.

(10) Unplug the oil level sensor (Fig. 67).

(11) Remove the oil level sensor retaining screw,

oil level sensor and discard the O-ring (Fig. 67).

INSTALLATION

(1) Seat new O-ring on oil level sensor and lubri-

cate O-ring with clean engine oil (Fig. 67).

(2) Install the oil level sensor into the oil pan and

tighten screw to 124 lbs. in.(14N´m) (Fig. 67).

(3) Connect oil level sensor wiring harness connec-

tor (Fig. 67).

(4) Rotate front stabilizer bar upward and secure

to axle beam. Tighten to 22 lbs.ft. (30 N´m)

(5) Lower the vehicle.

(6) Lower the engine into the mounts.

(7) Remove engine support fixture.(8) Raise and support the vehicle.

(9) Tighten both engine mount to chassis nuts.

(10) Install and tighten oil drain plug.

(11) Lower vehicle and install the appropriate

engine oil.

INTAKE MANIFOLD

REMOVAL

WARNING: NO FIRE, SPARKS OR SMOKING.

STORE FUELS ONLY INTO SUITABLE AND APPRO-

PRIATELY MARKED CONTAINERS, AND WEAR

PROTECTIVE CLOTHING. (Refer to 14 - FUEL SYS-

TEM - WARNING).

WARNING: DO NOT OPEN THE COOLING SYSTEM

UNLESS THE COOLANT TEMPERATURE IS BELOW

90ÉC (194ÉF). OPEN RADIATOR CAP SLOWLY TO

RELEASE PRESSURE. STORE COOLANT ONLY

INTO SUITABLE AND APPROPRIATELY MARKED

CONTAINERS, WEAR PROTECTIVE CLOTHING AND

EYE PROTECTION.

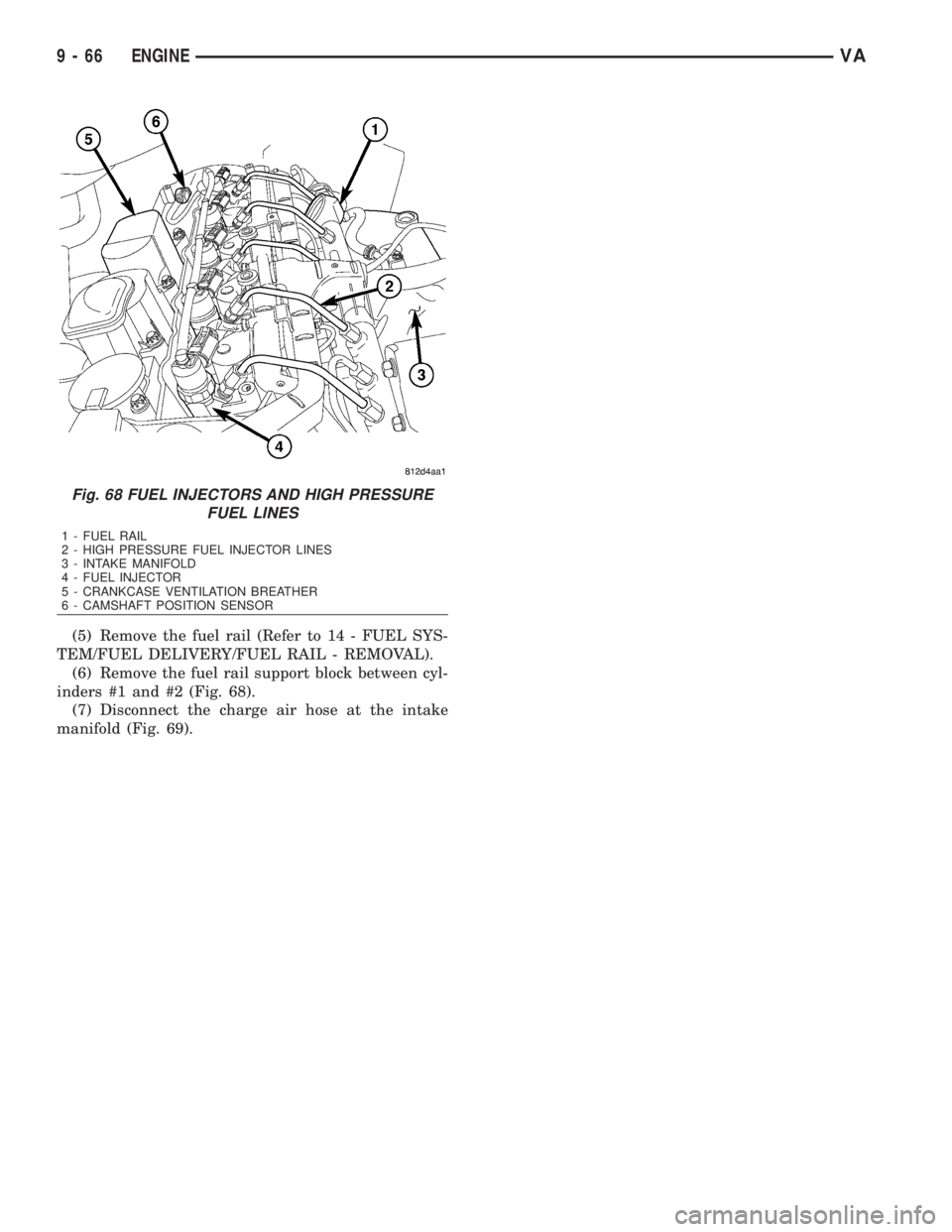

(1) Disconnect the negative battery cable.

(2) Partially drain coolant from the radiator.

(3) Remove the engine cover (Refer to 9 - ENGINE

- REMOVAL).

(4) Remove the high pressure fuel lines (Fig. 68).

Fig. 67 OIL LEVEL SENSOR

1 - OIL PAN

2 - O-RING

3 - WIRING HARNESS

4 - BOLT

5 - OIL LEVEL SENSOR

VAENGINE 9 - 65

Page 1641 of 2305

(5) Remove the fuel rail (Refer to 14 - FUEL SYS-

TEM/FUEL DELIVERY/FUEL RAIL - REMOVAL).

(6) Remove the fuel rail support block between cyl-

inders #1 and #2 (Fig. 68).

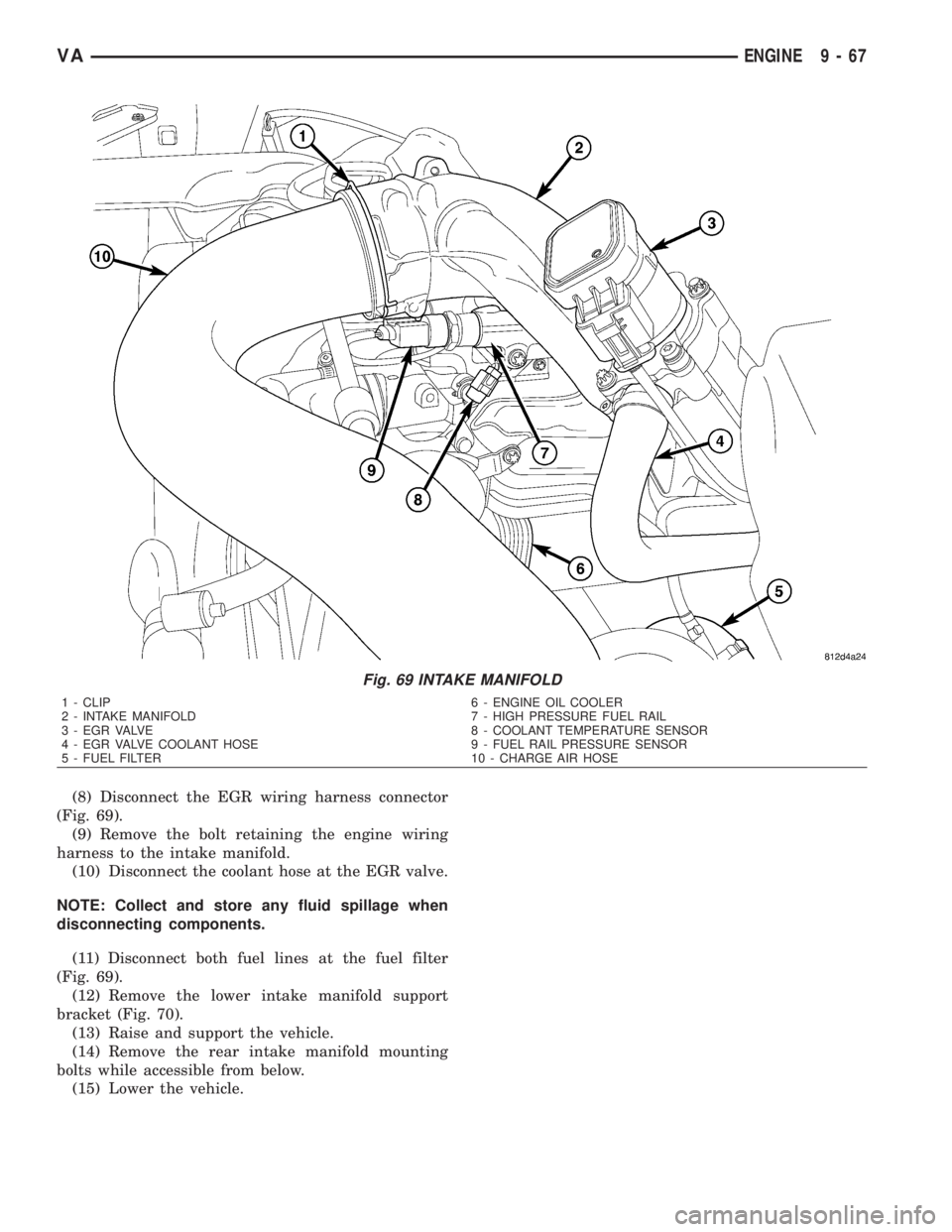

(7) Disconnect the charge air hose at the intake

manifold (Fig. 69).

Fig. 68 FUEL INJECTORS AND HIGH PRESSURE

FUEL LINES

1 - FUEL RAIL

2 - HIGH PRESSURE FUEL INJECTOR LINES

3 - INTAKE MANIFOLD

4 - FUEL INJECTOR

5 - CRANKCASE VENTILATION BREATHER

6 - CAMSHAFT POSITION SENSOR

9 - 66 ENGINEVA

Page 1642 of 2305

(8) Disconnect the EGR wiring harness connector

(Fig. 69).

(9) Remove the bolt retaining the engine wiring

harness to the intake manifold.

(10) Disconnect the coolant hose at the EGR valve.

NOTE: Collect and store any fluid spillage when

disconnecting components.

(11) Disconnect both fuel lines at the fuel filter

(Fig. 69).

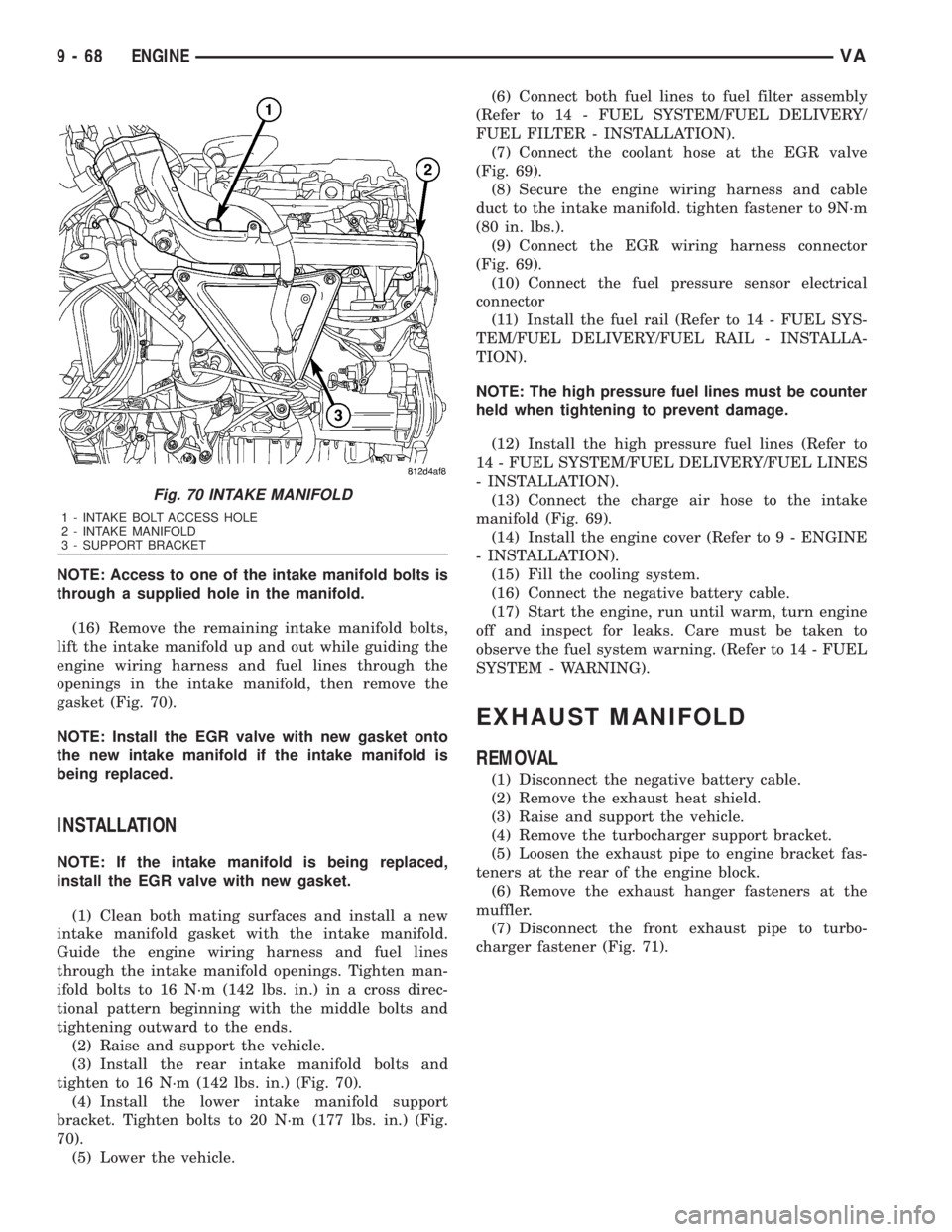

(12) Remove the lower intake manifold support

bracket (Fig. 70).

(13) Raise and support the vehicle.

(14) Remove the rear intake manifold mounting

bolts while accessible from below.

(15) Lower the vehicle.

Fig. 69 INTAKE MANIFOLD

1 - CLIP 6 - ENGINE OIL COOLER

2 - INTAKE MANIFOLD 7 - HIGH PRESSURE FUEL RAIL

3 - EGR VALVE 8 - COOLANT TEMPERATURE SENSOR

4 - EGR VALVE COOLANT HOSE 9 - FUEL RAIL PRESSURE SENSOR

5 - FUEL FILTER 10 - CHARGE AIR HOSE

VAENGINE 9 - 67

Page 1643 of 2305

NOTE: Access to one of the intake manifold bolts is

through a supplied hole in the manifold.

(16) Remove the remaining intake manifold bolts,

lift the intake manifold up and out while guiding the

engine wiring harness and fuel lines through the

openings in the intake manifold, then remove the

gasket (Fig. 70).

NOTE: Install the EGR valve with new gasket onto

the new intake manifold if the intake manifold is

being replaced.

INSTALLATION

NOTE: If the intake manifold is being replaced,

install the EGR valve with new gasket.

(1) Clean both mating surfaces and install a new

intake manifold gasket with the intake manifold.

Guide the engine wiring harness and fuel lines

through the intake manifold openings. Tighten man-

ifold bolts to 16 N´m (142 lbs. in.) in a cross direc-

tional pattern beginning with the middle bolts and

tightening outward to the ends.

(2) Raise and support the vehicle.

(3) Install the rear intake manifold bolts and

tighten to 16 N´m (142 lbs. in.) (Fig. 70).

(4) Install the lower intake manifold support

bracket. Tighten bolts to 20 N´m (177 lbs. in.) (Fig.

70).

(5) Lower the vehicle.(6) Connect both fuel lines to fuel filter assembly

(Refer to 14 - FUEL SYSTEM/FUEL DELIVERY/

FUEL FILTER - INSTALLATION).

(7) Connect the coolant hose at the EGR valve

(Fig. 69).

(8) Secure the engine wiring harness and cable

duct to the intake manifold. tighten fastener to 9N´m

(80 in. lbs.).

(9) Connect the EGR wiring harness connector

(Fig. 69).

(10) Connect the fuel pressure sensor electrical

connector

(11) Install the fuel rail (Refer to 14 - FUEL SYS-

TEM/FUEL DELIVERY/FUEL RAIL - INSTALLA-

TION).

NOTE: The high pressure fuel lines must be counter

held when tightening to prevent damage.

(12) Install the high pressure fuel lines (Refer to

14 - FUEL SYSTEM/FUEL DELIVERY/FUEL LINES

- INSTALLATION).

(13) Connect the charge air hose to the intake

manifold (Fig. 69).

(14) Install the engine cover (Refer to 9 - ENGINE

- INSTALLATION).

(15) Fill the cooling system.

(16) Connect the negative battery cable.

(17) Start the engine, run until warm, turn engine

off and inspect for leaks. Care must be taken to

observe the fuel system warning. (Refer to 14 - FUEL

SYSTEM - WARNING).

EXHAUST MANIFOLD

REMOVAL

(1) Disconnect the negative battery cable.

(2) Remove the exhaust heat shield.

(3) Raise and support the vehicle.

(4) Remove the turbocharger support bracket.

(5) Loosen the exhaust pipe to engine bracket fas-

teners at the rear of the engine block.

(6) Remove the exhaust hanger fasteners at the

muffler.

(7) Disconnect the front exhaust pipe to turbo-

charger fastener (Fig. 71).

Fig. 70 INTAKE MANIFOLD

1 - INTAKE BOLT ACCESS HOLE

2 - INTAKE MANIFOLD

3 - SUPPORT BRACKET

9 - 68 ENGINEVA

Page 1645 of 2305

(8) Install the exhaust hanger fasteners at the

muffler.

(9) Tighten the exhaust hanger bracket to engine

block.

(10) Install the turbocharger support bracket.

(11) Lower the vehicle.

(12) Install the air cleaner duct to the turbo-

charger (Fig. 71).

(13) Install the exhaust heat shield.

(14) Connect the negative battery cable.

TIMING CHAIN COVER

REMOVAL

WARNING: DO NOT OPEN COOLING SYSTEM

UNLESS TEMPERATURE IS BELOW 90ÉC (194ÉF).

OPEN CAP SLOWLY TO RELEASE PRESSURE.

STORE COOLANT IN APPROVED CONTAINER

ONLY. RISK OF INJURY TO SKIN AND EYES FROM

SCALDING COOLANT. WEAR PROTECTIVE

GLOVES, CLOTHING AND EYE WEAR.

(1) Disconnect negative battery cable.

NOTE: Rotate engine on crankshaft. DO NOT crank

the engine at the bolt of the camshaft sprocket.

NOTE: DO NOT crank engine back.

(2) Position piston of cylinder 1 to ignition TDC.

Markings on the camshaft bearing cap must be

aligned.

(3) Drain coolant (Refer to 7 - COOLING/ENGINE/

COOLANT - STANDARD PROCEDURE).

(4) Install retaining lock for crankshaft/starter

ring gear (Refer to 9 - ENGINE/ENGINE BLOCK/

FLEX PLATE - INSTALLATION).

(5) Drain engine oil.

(6) Remove the oil filter to allow the oil to flow off

into the oil pan.

(7) Remove the radiator assembly (Refer to 7 -

COOLING/ENGINE/RADIATOR - REMOVAL).

(8) Remove engine cover (Refer to 9 - ENGINE -

REMOVAL).

(9) Remove front cover at cylinder head (Refer to 9

- ENGINE/CYLINDER HEAD - REMOVAL).

(10) Remove accessory drive belt.

(11) Remove the high pressure fuel pump (Refer to

14 - FUEL SYSTEM/FUEL DELIVERY/FUEL PUMP

- REMOVAL).

(12) Remove water pump (Refer to 7 - COOLING/

ENGINE/WATER PUMP - REMOVAL).

(13) Remove accessory drive belt pulley and vibra-

tion damper (Refer to 9 - ENGINE/ENGINE BLOCK/

VIBRATION DAMPER - REMOVAL).

(14) Remove the power steering pump.NOTE: NO NOT open the air conditioning system.

(15) Unplug AC compressor electrical connector

and unbolt AC compressor. Relocate in lower engine

compartmentwith outopening the system.

(16) Remove the generator with wiring attached

and relocate somewhere in the engine compartment.

(17) Install engine support fixture.

(18) Remove the oil pan.

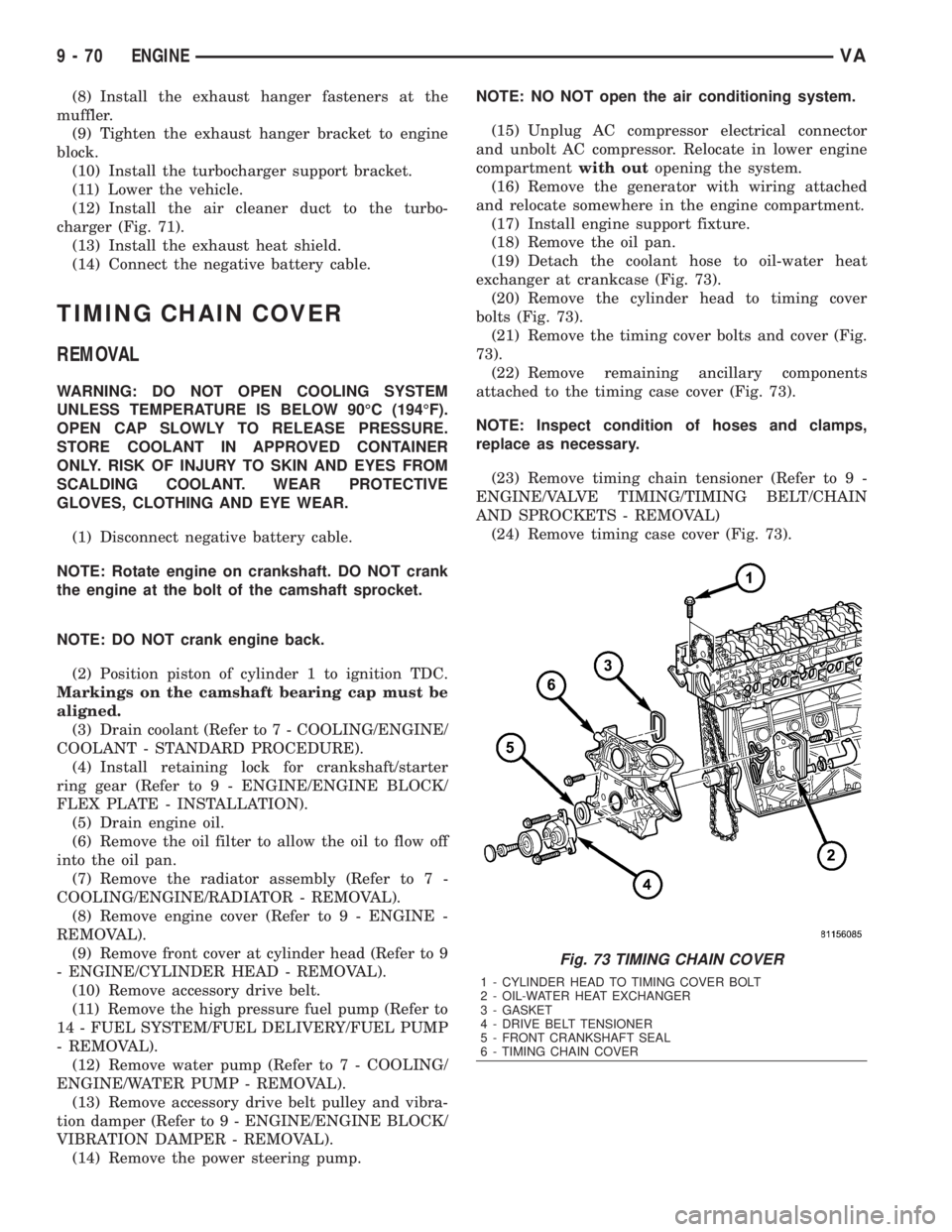

(19) Detach the coolant hose to oil-water heat

exchanger at crankcase (Fig. 73).

(20) Remove the cylinder head to timing cover

bolts (Fig. 73).

(21) Remove the timing cover bolts and cover (Fig.

73).

(22) Remove remaining ancillary components

attached to the timing case cover (Fig. 73).

NOTE: Inspect condition of hoses and clamps,

replace as necessary.

(23) Remove timing chain tensioner (Refer to 9 -

ENGINE/VALVE TIMING/TIMING BELT/CHAIN

AND SPROCKETS - REMOVAL)

(24) Remove timing case cover (Fig. 73).

Fig. 73 TIMING CHAIN COVER

1 - CYLINDER HEAD TO TIMING COVER BOLT

2 - OIL-WATER HEAT EXCHANGER

3 - GASKET

4 - DRIVE BELT TENSIONER

5 - FRONT CRANKSHAFT SEAL

6 - TIMING CHAIN COVER

9 - 70 ENGINEVA

Page 1646 of 2305

INSTALLATION

CAUTION: Care must be taken to closley inspect

the gasket area around the time case cover to cyl-

inder head gasket coolant port. If damage is found,

replace the cylinder head gasket. Failure to do so

may result in engine damage.

NOTE: Thoroughly clean all mating surfaces with

the appropriate solvents to assure that no grease or

oil is present during assembly.

(1) Inspect cylinder head gasket and oil pan gas-

ket. If damaged, replace.

(2) Replace the front crankshaft seal (Refer to 9 -

ENGINE/ENGINE BLOCK/CRANKSHAFT OIL

SEAL - FRONT - INSTALLATION).

(3) Install ancillary components to timing case

cover.

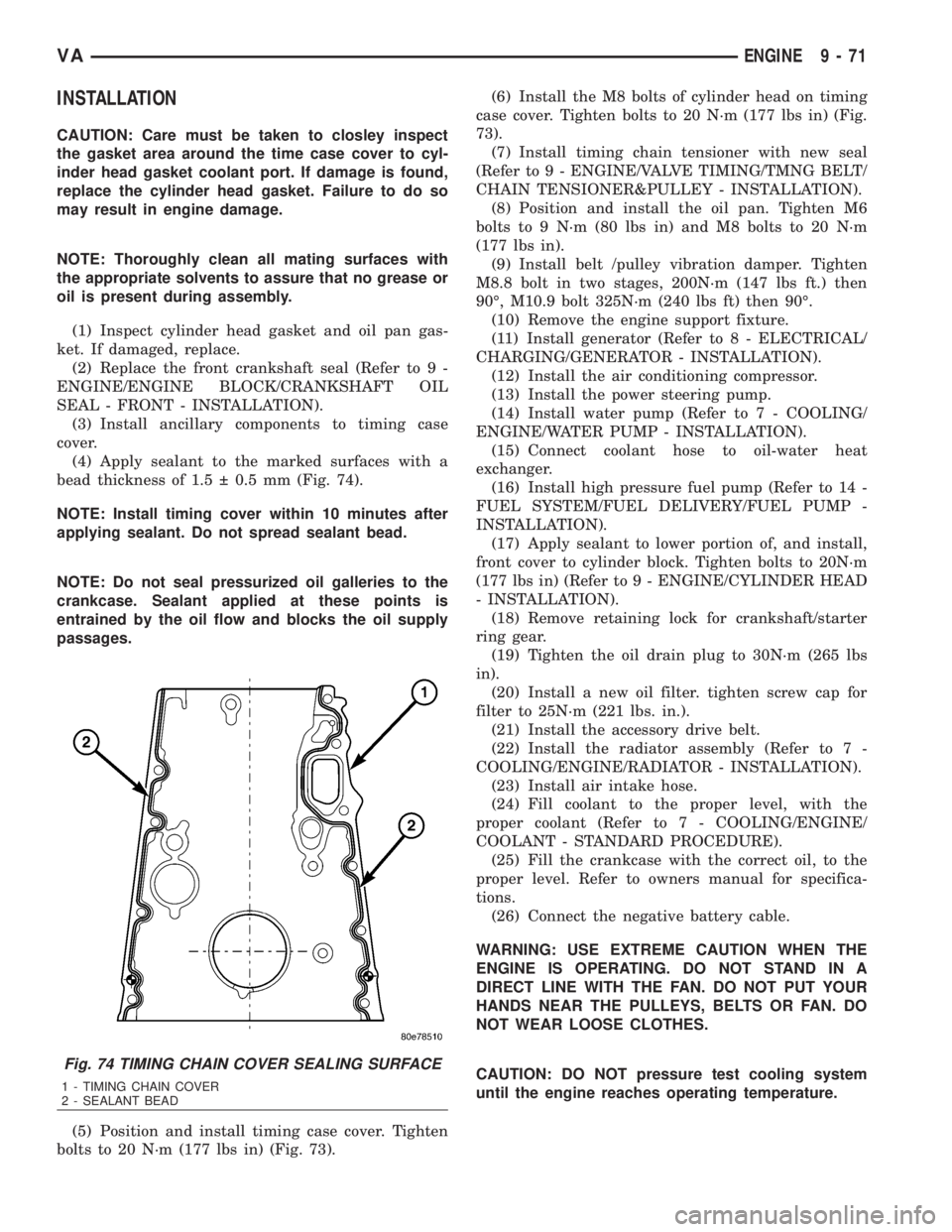

(4) Apply sealant to the marked surfaces with a

bead thickness of 1.5 0.5 mm (Fig. 74).

NOTE: Install timing cover within 10 minutes after

applying sealant. Do not spread sealant bead.

NOTE: Do not seal pressurized oil galleries to the

crankcase. Sealant applied at these points is

entrained by the oil flow and blocks the oil supply

passages.

(5) Position and install timing case cover. Tighten

bolts to 20 N´m (177 lbs in) (Fig. 73).(6) Install the M8 bolts of cylinder head on timing

case cover. Tighten bolts to 20 N´m (177 lbs in) (Fig.

73).

(7) Install timing chain tensioner with new seal

(Refer to 9 - ENGINE/VALVE TIMING/TMNG BELT/

CHAIN TENSIONER&PULLEY - INSTALLATION).

(8) Position and install the oil pan. Tighten M6

bolts to 9 N´m (80 lbs in) and M8 bolts to 20 N´m

(177 lbs in).

(9) Install belt /pulley vibration damper. Tighten

M8.8 bolt in two stages, 200N´m (147 lbs ft.) then

90É, M10.9 bolt 325N´m (240 lbs ft) then 90É.

(10) Remove the engine support fixture.

(11) Install generator (Refer to 8 - ELECTRICAL/

CHARGING/GENERATOR - INSTALLATION).

(12) Install the air conditioning compressor.

(13) Install the power steering pump.

(14) Install water pump (Refer to 7 - COOLING/

ENGINE/WATER PUMP - INSTALLATION).

(15) Connect coolant hose to oil-water heat

exchanger.

(16) Install high pressure fuel pump (Refer to 14 -

FUEL SYSTEM/FUEL DELIVERY/FUEL PUMP -

INSTALLATION).

(17) Apply sealant to lower portion of, and install,

front cover to cylinder block. Tighten bolts to 20N´m

(177 lbs in) (Refer to 9 - ENGINE/CYLINDER HEAD

- INSTALLATION).

(18) Remove retaining lock for crankshaft/starter

ring gear.

(19) Tighten the oil drain plug to 30N´m (265 lbs

in).

(20) Install a new oil filter. tighten screw cap for

filter to 25N´m (221 lbs. in.).

(21) Install the accessory drive belt.

(22) Install the radiator assembly (Refer to 7 -

COOLING/ENGINE/RADIATOR - INSTALLATION).

(23) Install air intake hose.

(24) Fill coolant to the proper level, with the

proper coolant (Refer to 7 - COOLING/ENGINE/

COOLANT - STANDARD PROCEDURE).

(25) Fill the crankcase with the correct oil, to the

proper level. Refer to owners manual for specifica-

tions.

(26) Connect the negative battery cable.

WARNING: USE EXTREME CAUTION WHEN THE

ENGINE IS OPERATING. DO NOT STAND IN A

DIRECT LINE WITH THE FAN. DO NOT PUT YOUR

HANDS NEAR THE PULLEYS, BELTS OR FAN. DO

NOT WEAR LOOSE CLOTHES.

CAUTION: DO NOT pressure test cooling system

until the engine reaches operating temperature.

Fig. 74 TIMING CHAIN COVER SEALING SURFACE

1 - TIMING CHAIN COVER

2 - SEALANT BEAD

VAENGINE 9 - 71

Page 1647 of 2305

(27) Start engine and inspect for leaks. care must

be taken to observe the fuel system warning (Refer to

14 - FUEL SYSTEM - WARNING).

TIMING CHAIN AND SPROCK-

ETS

REMOVAL

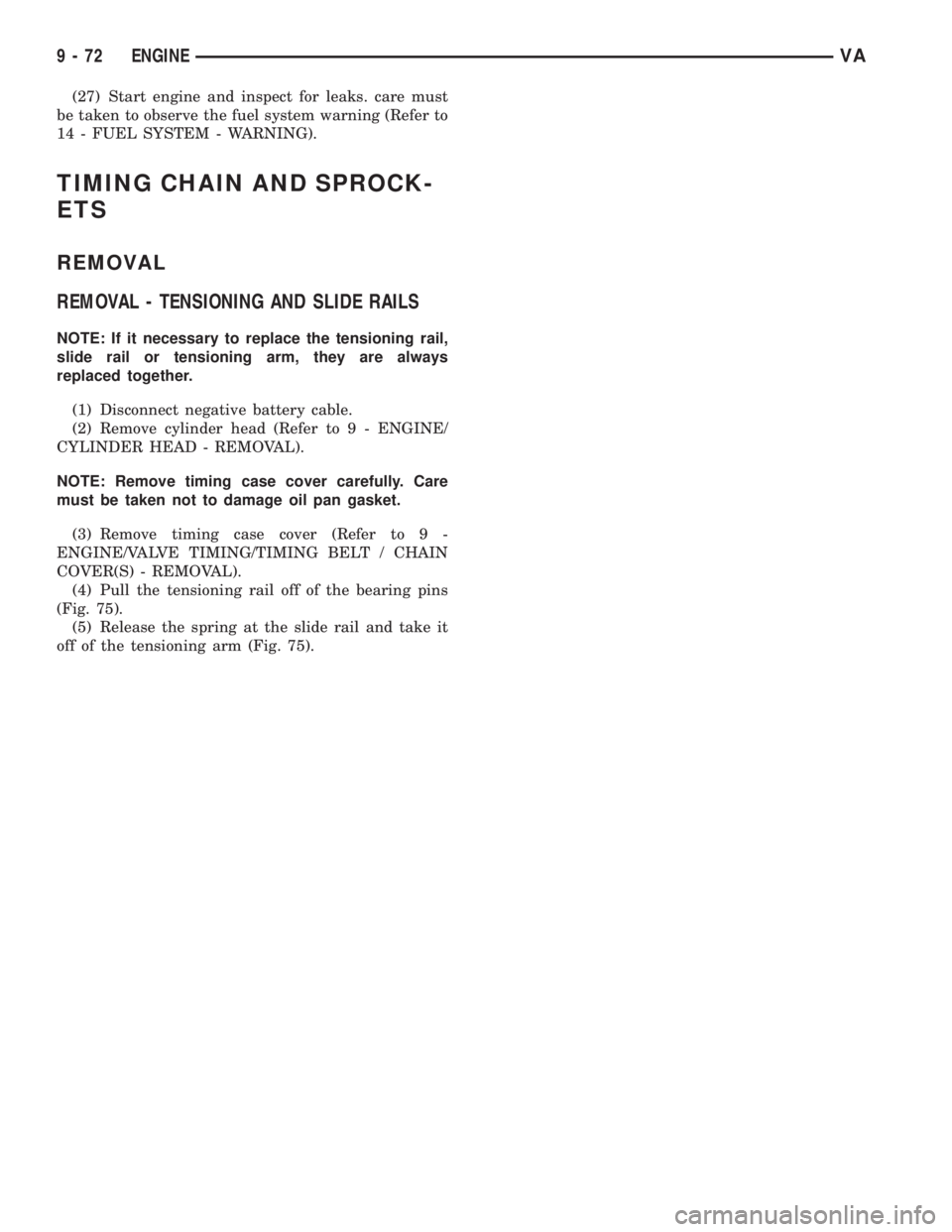

REMOVAL - TENSIONING AND SLIDE RAILS

NOTE: If it necessary to replace the tensioning rail,

slide rail or tensioning arm, they are always

replaced together.

(1) Disconnect negative battery cable.

(2) Remove cylinder head (Refer to 9 - ENGINE/

CYLINDER HEAD - REMOVAL).

NOTE: Remove timing case cover carefully. Care

must be taken not to damage oil pan gasket.

(3) Remove timing case cover (Refer to 9 -

ENGINE/VALVE TIMING/TIMING BELT / CHAIN

COVER(S) - REMOVAL).

(4) Pull the tensioning rail off of the bearing pins

(Fig. 75).

(5) Release the spring at the slide rail and take it

off of the tensioning arm (Fig. 75).

9 - 72 ENGINEVA

Page 1648 of 2305

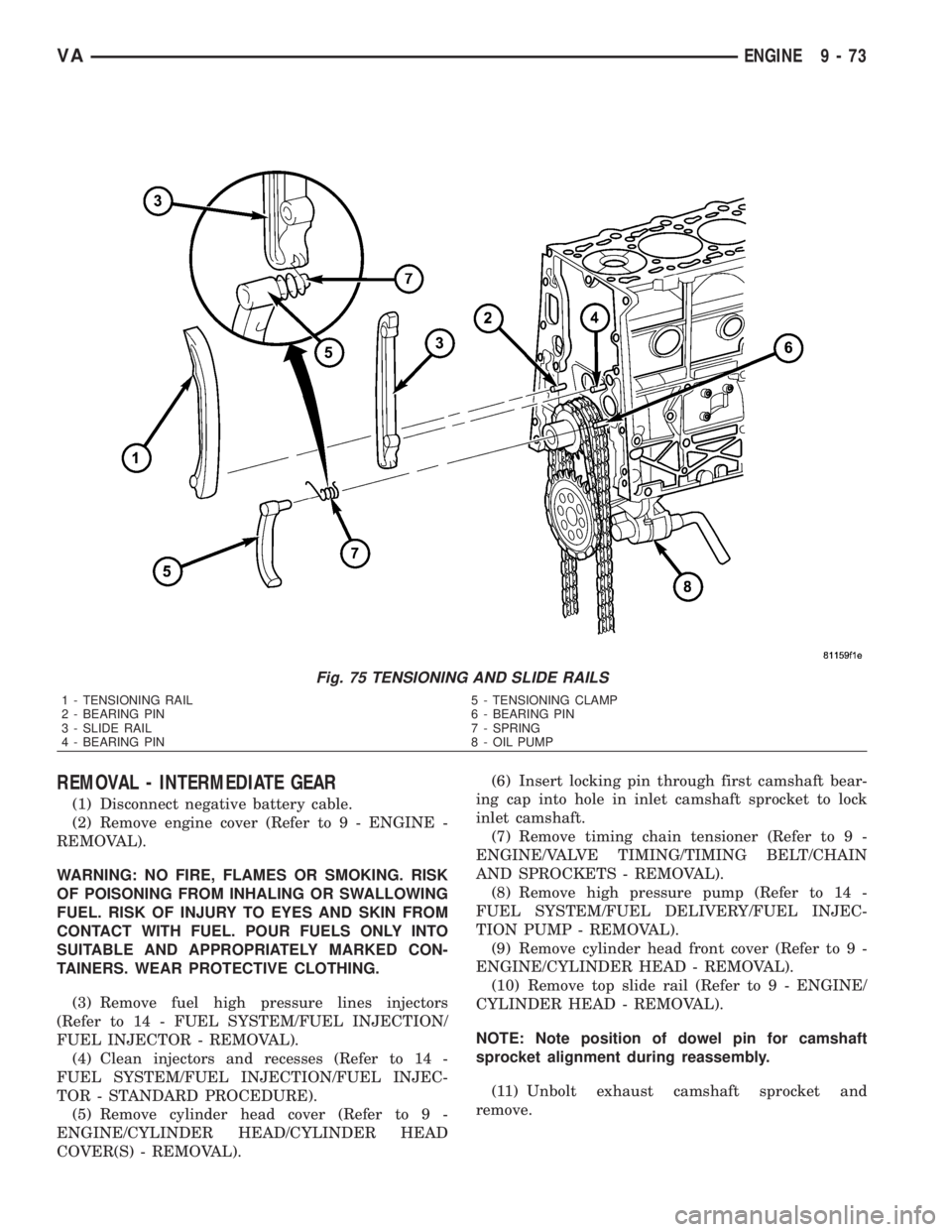

REMOVAL - INTERMEDIATE GEAR

(1) Disconnect negative battery cable.

(2) Remove engine cover (Refer to 9 - ENGINE -

REMOVAL).

WARNING: NO FIRE, FLAMES OR SMOKING. RISK

OF POISONING FROM INHALING OR SWALLOWING

FUEL. RISK OF INJURY TO EYES AND SKIN FROM

CONTACT WITH FUEL. POUR FUELS ONLY INTO

SUITABLE AND APPROPRIATELY MARKED CON-

TAINERS. WEAR PROTECTIVE CLOTHING.

(3) Remove fuel high pressure lines injectors

(Refer to 14 - FUEL SYSTEM/FUEL INJECTION/

FUEL INJECTOR - REMOVAL).

(4) Clean injectors and recesses (Refer to 14 -

FUEL SYSTEM/FUEL INJECTION/FUEL INJEC-

TOR - STANDARD PROCEDURE).

(5) Remove cylinder head cover (Refer to 9 -

ENGINE/CYLINDER HEAD/CYLINDER HEAD

COVER(S) - REMOVAL).(6) Insert locking pin through first camshaft bear-

ing cap into hole in inlet camshaft sprocket to lock

inlet camshaft.

(7) Remove timing chain tensioner (Refer to 9 -

ENGINE/VALVE TIMING/TIMING BELT/CHAIN

AND SPROCKETS - REMOVAL).

(8) Remove high pressure pump (Refer to 14 -

FUEL SYSTEM/FUEL DELIVERY/FUEL INJEC-

TION PUMP - REMOVAL).

(9) Remove cylinder head front cover (Refer to 9 -

ENGINE/CYLINDER HEAD - REMOVAL).

(10) Remove top slide rail (Refer to 9 - ENGINE/

CYLINDER HEAD - REMOVAL).

NOTE: Note position of dowel pin for camshaft

sprocket alignment during reassembly.

(11) Unbolt exhaust camshaft sprocket and

remove.

Fig. 75 TENSIONING AND SLIDE RAILS

1 - TENSIONING RAIL 5 - TENSIONING CLAMP

2 - BEARING PIN 6 - BEARING PIN

3 - SLIDE RAIL 7 - SPRING

4 - BEARING PIN 8 - OIL PUMP

VAENGINE 9 - 73