open hood MERCEDES-BENZ SPRINTER 2006 User Guide

[x] Cancel search | Manufacturer: MERCEDES-BENZ, Model Year: 2006, Model line: SPRINTER, Model: MERCEDES-BENZ SPRINTER 2006Pages: 2305, PDF Size: 48.12 MB

Page 1046 of 2305

both the wiper and washer systems. (Refer to 8 -

ELECTRICAL/LAMPS/LIGHTING - EXTERIOR/

MULTI-FUNCTION SWITCH - DESCRIPTION)

²Rain Sensor- Vehicles equipped with an

optional automatic wiper feature have an electronic

rain sensor concealed within the base of the rear

view mirror unit on the inside of the laminated wind-

shield glass.

²Rain Sensor Control Module- Vehicles

equipped with an optional automatic wiper feature

have an electronic rain sensor control module located

under the lower instrument panel above the acceler-

ator pedal in the passenger compartment of the vehi-

cle.

²Washer Fluid Level Switch- The optional

washer fluid level switch is integral to a unique ver-

sion of the washer pump/motor unit, which is located

in a dedicated hole on the top of the sump area near

the back of the windshield washer reservoir on the

right front fender wheel house in the engine com-

partment.

²Washer Nozzle- A single washer nozzle with

three separate orifices is secured with integral snap

features to each wiper arm. The hoses for the washer

nozzles are concealed beneath a molded plastic guide

on the underside of each wiper arm and routed to the

engine compartment through unique molded plastic

elbow fittings located near each wiper pivot at the

base of the windshield.

²Washer Pump/Motor- Two different washer

pump/motor units are available for this model. One

version has an integral washer fluid level switch that

provides a hard wired input to the instrument cluster

for control of the optional washer fluid indicator. The

washer pump/motor unit is located in a dedicated

hole on the top of the sump area near the back of the

windshield washer reservoir on the right front fender

wheel house in the engine compartment.

²Washer Reservoir- The washer reservoir is

located on the right front fender wheel house in the

engine compartment. The washer reservoir filler is

accessed from the right front corner of the engine

compartment.

²Wiper Arm- The two unequal length wiper

arms are secured to the two wiper pivots, which

extend through the cowl panel near the base of the

windshield. The longer arm is installed on the left

(driver) side of the windshield.

²Wiper Blade- The two unequal length wiper

blades are secured to the two wiper arms, and are

parked on the glass near the bottom of the wind-

shield when the wiper system is not in operation.

The longer blade is installed on the left (driver) side

of the windshield.

²Wiper Linkage- The wiper pivots are the only

visible components of the wiper linkage. The remain-

der of the linkage is concealed within the engine

compartment just behind the hood opening. Thewiper linkage module includes the two wiper drive

links, the wiper motor crank arm, the two wiper piv-

ots, and the linkage and motor mounting bracket.

²Wiper Motor- The wiper motor is secured to

the wiper linkage module bracket on the underside of

the cowl panel within the engine compartment. The

wiper motor output shaft and crank arm extend

through a clearance hole in the mounting bracket,

where they are connected to a crank arm that drives

the wiper linkage.

²Wiper Relay- The wiper relay is located in a

dedicated receptacle on the lower left surface of the

fuse block underneath the steering column behind

the fuse access panel and the steering column open-

ing panel. The wiper relay is a passive component on

vehicles equipped with the optional automatic wiper

system.

²Wiper, Turn Signals, Engine Start Control

Module- The wiper, turn signals and engine start

control module is integral to the fuse block located

underneath the steering column. The fuse block is

concealed behind the fuse access panel and the steer-

ing column opening panel, where it is secured with

screws to the steering column. The wiper system

functions of this module are passive on vehicles

equipped with the optional automatic wiper system.

Hard wired circuitry connects the wiper and

washer system components to the electrical system of

the vehicle. These hard wired circuits are integral to

several wire harnesses, which are routed throughout

the vehicle and retained by many different methods.

These circuits may be connected to each other, to the

vehicle electrical system and to the wiper and washer

system components through the use of a combination

of soldered splices, splice block connectors, and many

different types of wire harness terminal connectors

and insulators. Refer to the appropriate wiring infor-

mation. The wiring information includes wiring dia-

grams, proper wire and connector repair procedures,

further details on wire harness routing and reten-

tion, as well as pin-out and location views for the

various wire harness connectors, splices and grounds.

OPERATION

The wiper and washer system is designed to pro-

vide the vehicle operator with a convenient, safe, and

reliable means of maintaining visibility through the

windshield glass. The various components of this sys-

tem are designed to convert electrical energy pro-

duced by the vehicle electrical system into the

mechanical action of the wiper blades to wipe the

outside surface of the glass, as well as into the

hydraulic action of the washer system to apply

washer fluid stored in an on-board reservoir to the

area of the glass to be wiped. When combined, these

components provide the means to effectively main-

tain clear visibility for the vehicle operator by remov-

ing excess accumulations of rain, snow, bugs, mud, or

VAWIPERS/WASHERS 8R - 3

Page 1054 of 2305

CHECK VALVE

DESCRIPTION

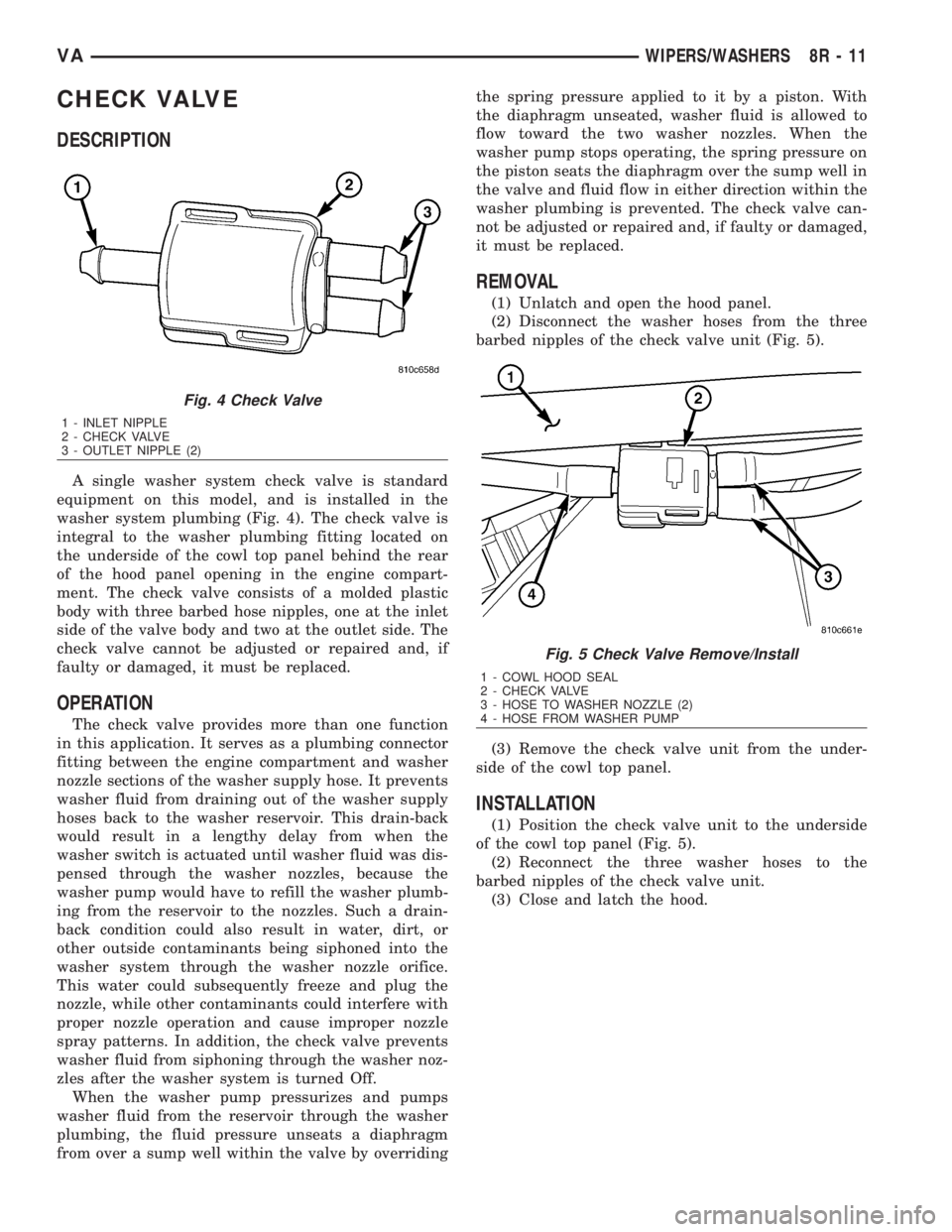

A single washer system check valve is standard

equipment on this model, and is installed in the

washer system plumbing (Fig. 4). The check valve is

integral to the washer plumbing fitting located on

the underside of the cowl top panel behind the rear

of the hood panel opening in the engine compart-

ment. The check valve consists of a molded plastic

body with three barbed hose nipples, one at the inlet

side of the valve body and two at the outlet side. The

check valve cannot be adjusted or repaired and, if

faulty or damaged, it must be replaced.

OPERATION

The check valve provides more than one function

in this application. It serves as a plumbing connector

fitting between the engine compartment and washer

nozzle sections of the washer supply hose. It prevents

washer fluid from draining out of the washer supply

hoses back to the washer reservoir. This drain-back

would result in a lengthy delay from when the

washer switch is actuated until washer fluid was dis-

pensed through the washer nozzles, because the

washer pump would have to refill the washer plumb-

ing from the reservoir to the nozzles. Such a drain-

back condition could also result in water, dirt, or

other outside contaminants being siphoned into the

washer system through the washer nozzle orifice.

This water could subsequently freeze and plug the

nozzle, while other contaminants could interfere with

proper nozzle operation and cause improper nozzle

spray patterns. In addition, the check valve prevents

washer fluid from siphoning through the washer noz-

zles after the washer system is turned Off.

When the washer pump pressurizes and pumps

washer fluid from the reservoir through the washer

plumbing, the fluid pressure unseats a diaphragm

from over a sump well within the valve by overridingthe spring pressure applied to it by a piston. With

the diaphragm unseated, washer fluid is allowed to

flow toward the two washer nozzles. When the

washer pump stops operating, the spring pressure on

the piston seats the diaphragm over the sump well in

the valve and fluid flow in either direction within the

washer plumbing is prevented. The check valve can-

not be adjusted or repaired and, if faulty or damaged,

it must be replaced.

REMOVAL

(1) Unlatch and open the hood panel.

(2) Disconnect the washer hoses from the three

barbed nipples of the check valve unit (Fig. 5).

(3) Remove the check valve unit from the under-

side of the cowl top panel.

INSTALLATION

(1) Position the check valve unit to the underside

of the cowl top panel (Fig. 5).

(2) Reconnect the three washer hoses to the

barbed nipples of the check valve unit.

(3) Close and latch the hood.

Fig. 4 Check Valve

1 - INLET NIPPLE

2 - CHECK VALVE

3 - OUTLET NIPPLE (2)

Fig. 5 Check Valve Remove/Install

1 - COWL HOOD SEAL

2 - CHECK VALVE

3 - HOSE TO WASHER NOZZLE (2)

4 - HOSE FROM WASHER PUMP

VAWIPERS/WASHERS 8R - 11

Page 1061 of 2305

WASHER HOSES / TUBES

DESCRIPTION

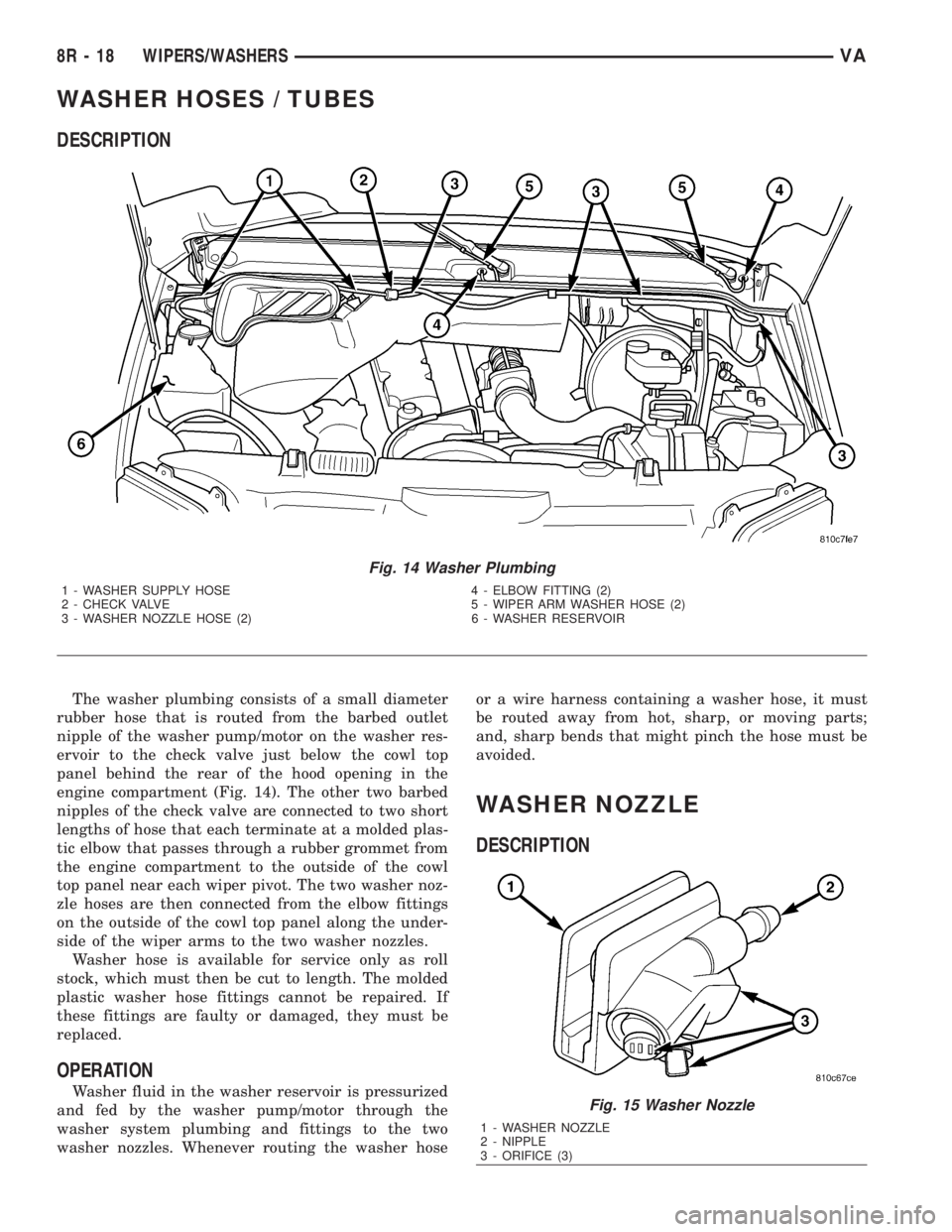

The washer plumbing consists of a small diameter

rubber hose that is routed from the barbed outlet

nipple of the washer pump/motor on the washer res-

ervoir to the check valve just below the cowl top

panel behind the rear of the hood opening in the

engine compartment (Fig. 14). The other two barbed

nipples of the check valve are connected to two short

lengths of hose that each terminate at a molded plas-

tic elbow that passes through a rubber grommet from

the engine compartment to the outside of the cowl

top panel near each wiper pivot. The two washer noz-

zle hoses are then connected from the elbow fittings

on the outside of the cowl top panel along the under-

side of the wiper arms to the two washer nozzles.

Washer hose is available for service only as roll

stock, which must then be cut to length. The molded

plastic washer hose fittings cannot be repaired. If

these fittings are faulty or damaged, they must be

replaced.

OPERATION

Washer fluid in the washer reservoir is pressurized

and fed by the washer pump/motor through the

washer system plumbing and fittings to the two

washer nozzles. Whenever routing the washer hoseor a wire harness containing a washer hose, it must

be routed away from hot, sharp, or moving parts;

and, sharp bends that might pinch the hose must be

avoided.

WASHER NOZZLE

DESCRIPTION

Fig. 14 Washer Plumbing

1 - WASHER SUPPLY HOSE 4 - ELBOW FITTING (2)

2 - CHECK VALVE 5 - WIPER ARM WASHER HOSE (2)

3 - WASHER NOZZLE HOSE (2) 6 - WASHER RESERVOIR

Fig. 15 Washer Nozzle

1 - WASHER NOZZLE

2 - NIPPLE

3 - ORIFICE (3)

8R - 18 WIPERS/WASHERSVA

Page 1954 of 2305

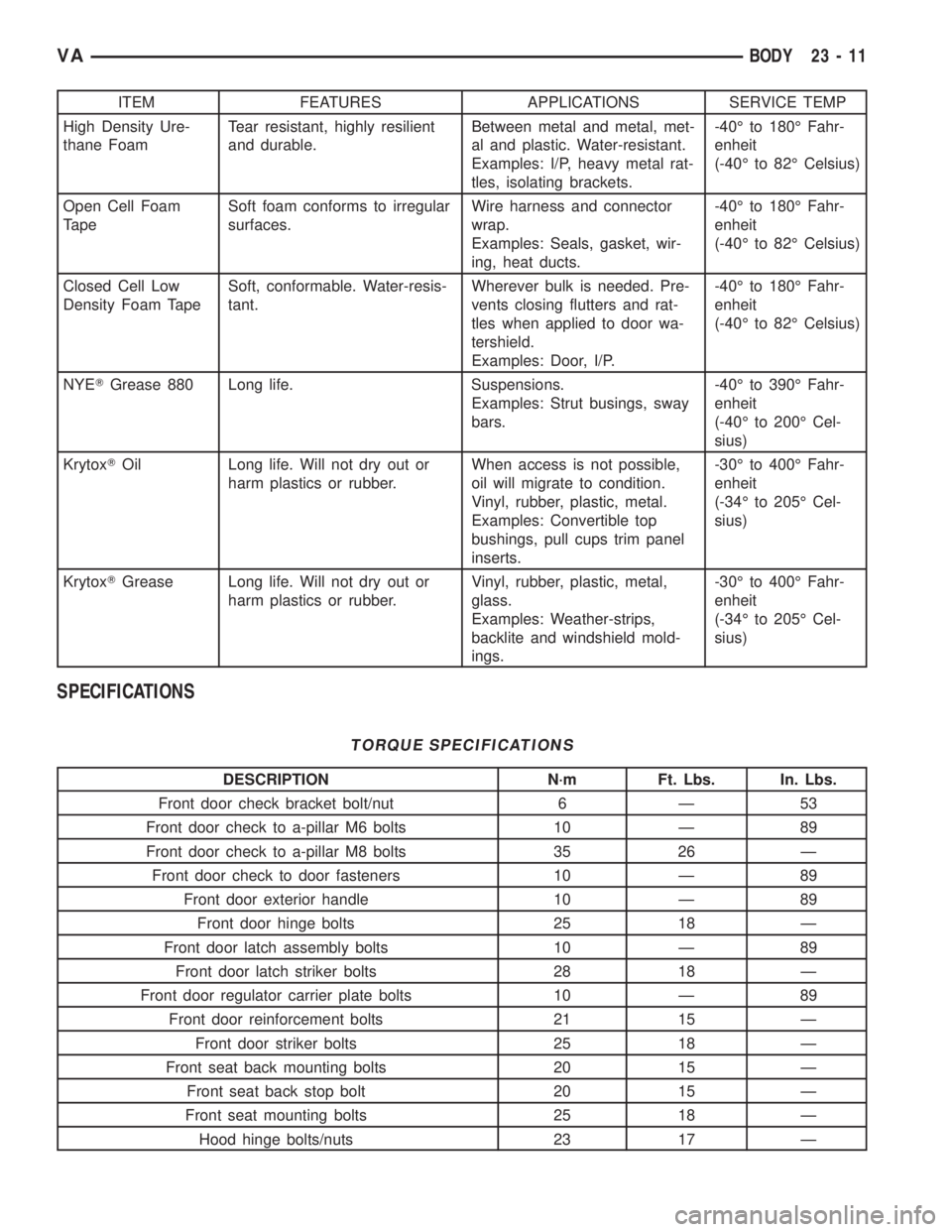

ITEM FEATURES APPLICATIONS SERVICE TEMP

High Density Ure-

thane FoamTear resistant, highly resilient

and durable.Between metal and metal, met-

al and plastic. Water-resistant.

Examples: I/P, heavy metal rat-

tles, isolating brackets.-40É to 180É Fahr-

enheit

(-40É to 82É Celsius)

Open Cell Foam

TapeSoft foam conforms to irregular

surfaces.Wire harness and connector

wrap.

Examples: Seals, gasket, wir-

ing, heat ducts.-40É to 180É Fahr-

enheit

(-40É to 82É Celsius)

Closed Cell Low

Density Foam TapeSoft, conformable. Water-resis-

tant.Wherever bulk is needed. Pre-

vents closing flutters and rat-

tles when applied to door wa-

tershield.

Examples: Door, I/P.-40É to 180É Fahr-

enheit

(-40É to 82É Celsius)

NYETGrease 880 Long life. Suspensions.

Examples: Strut busings, sway

bars.-40É to 390É Fahr-

enheit

(-40É to 200É Cel-

sius)

KrytoxTOil Long life. Will not dry out or

harm plastics or rubber.When access is not possible,

oil will migrate to condition.

Vinyl, rubber, plastic, metal.

Examples: Convertible top

bushings, pull cups trim panel

inserts.-30É to 400É Fahr-

enheit

(-34É to 205É Cel-

sius)

KrytoxTGrease Long life. Will not dry out or

harm plastics or rubber.Vinyl, rubber, plastic, metal,

glass.

Examples: Weather-strips,

backlite and windshield mold-

ings.-30É to 400É Fahr-

enheit

(-34É to 205É Cel-

sius)

SPECIFICATIONS

TORQUE SPECIFICATIONS

DESCRIPTION N´m Ft. Lbs. In. Lbs.

Front door check bracket bolt/nut 6 Ð 53

Front door check to a-pillar M6 bolts 10 Ð 89

Front door check to a-pillar M8 bolts 35 26 Ð

Front door check to door fasteners 10 Ð 89

Front door exterior handle 10 Ð 89

Front door hinge bolts 25 18 Ð

Front door latch assembly bolts 10 Ð 89

Front door latch striker bolts 28 18 Ð

Front door regulator carrier plate bolts 10 Ð 89

Front door reinforcement bolts 21 15 Ð

Front door striker bolts 25 18 Ð

Front seat back mounting bolts 20 15 Ð

Front seat back stop bolt 20 15 Ð

Front seat mounting bolts 25 18 Ð

Hood hinge bolts/nuts 23 17 Ð

VABODY 23 - 11

Page 1994 of 2305

HOOD

TABLE OF CONTENTS

page page

HINGE

REMOVAL.............................51

INSTALLATION.........................51

HOOD

REMOVAL.............................51

INSTALLATION.........................51

ADJUSTMENTS

ADJUSTMENT........................52

LATCH

REMOVAL.............................52

INSTALLATION.........................52

LATCH RELEASE CABLE

REMOVAL.............................52INSTALLATION.........................52

LATCH RELEASE HANDLE

REMOVAL.............................52

INSTALLATION.........................52

PROP ROD

REMOVAL.............................53

INSTALLATION.........................53

SAFETY LATCH

REMOVAL.............................53

INSTALLATION.........................54

HINGE

REMOVAL

NOTE: It is not necessary to remove the hood to

replace one or both hinges. The hinges can be

replaced one at a time.

(1) Open hood and support as needed.

(2) Using a grease pencil or equivalent, mark the

position of the hinge on the hood and cowl.

(3) Remove the two hood nuts.

(4) Remove the two cowl bolts and remove hinge.

INSTALLATION

(1) Position hinge on vehicle and align reference

marks.

(2) Install cowl bolts and tighten to 23 N´m (17 ft.

lbs.).

(3) Install hood nuts and tighten to 23 N´m (17 ft.

lbs.).

(4) Check and adjust hood if necessary. (Refer to

23 - BODY/HOOD/HOOD - ADJUSTMENTS)

HOOD

REMOVAL

(1) Raise and support hood.

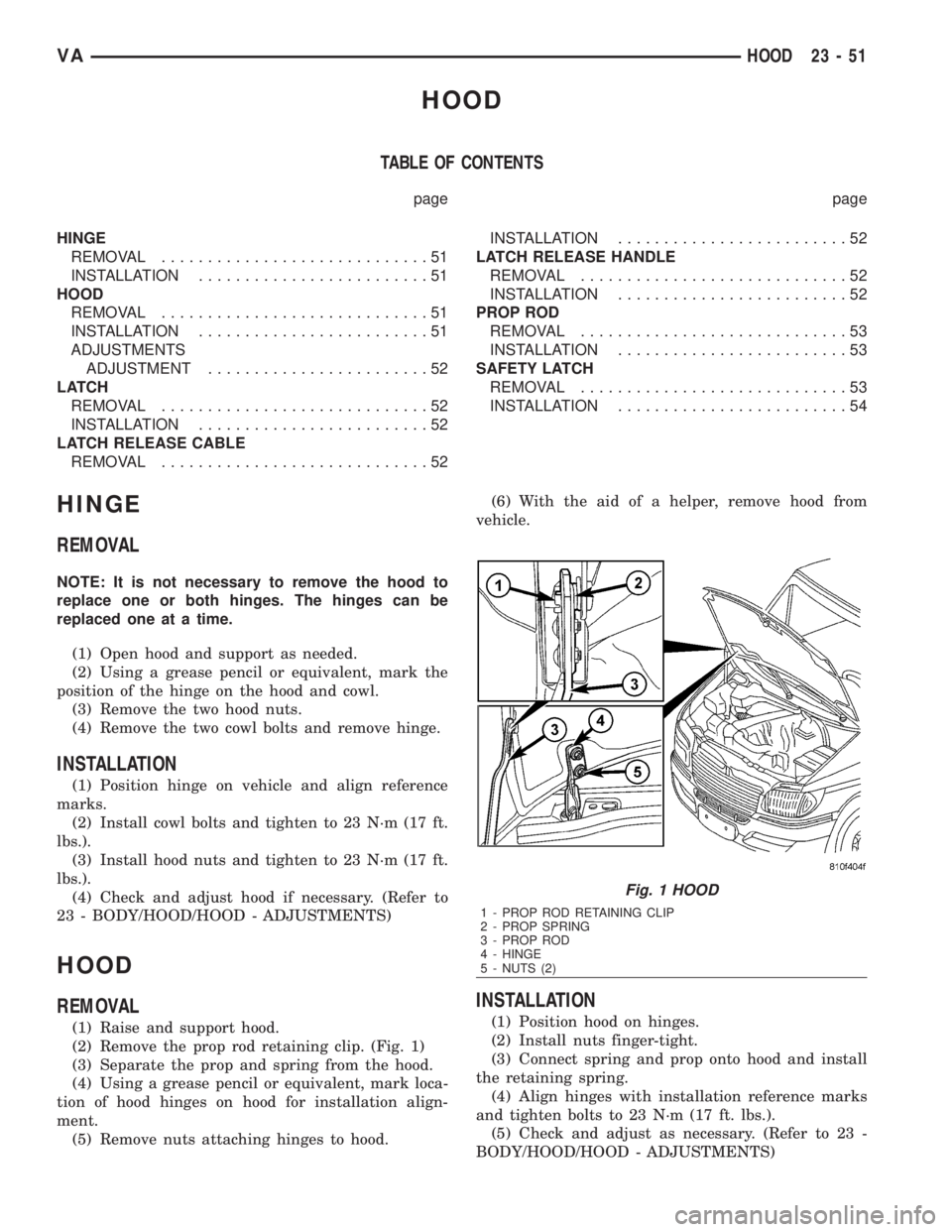

(2) Remove the prop rod retaining clip. (Fig. 1)

(3) Separate the prop and spring from the hood.

(4) Using a grease pencil or equivalent, mark loca-

tion of hood hinges on hood for installation align-

ment.

(5) Remove nuts attaching hinges to hood.(6) With the aid of a helper, remove hood from

vehicle.

INSTALLATION

(1) Position hood on hinges.

(2) Install nuts finger-tight.

(3) Connect spring and prop onto hood and install

the retaining spring.

(4) Align hinges with installation reference marks

and tighten bolts to 23 N´m (17 ft. lbs.).

(5) Check and adjust as necessary. (Refer to 23 -

BODY/HOOD/HOOD - ADJUSTMENTS)

Fig. 1 HOOD

1 - PROP ROD RETAINING CLIP

2 - PROP SPRING

3 - PROP ROD

4 - HINGE

5 - NUTS (2)

VAHOOD 23 - 51

Page 1996 of 2305

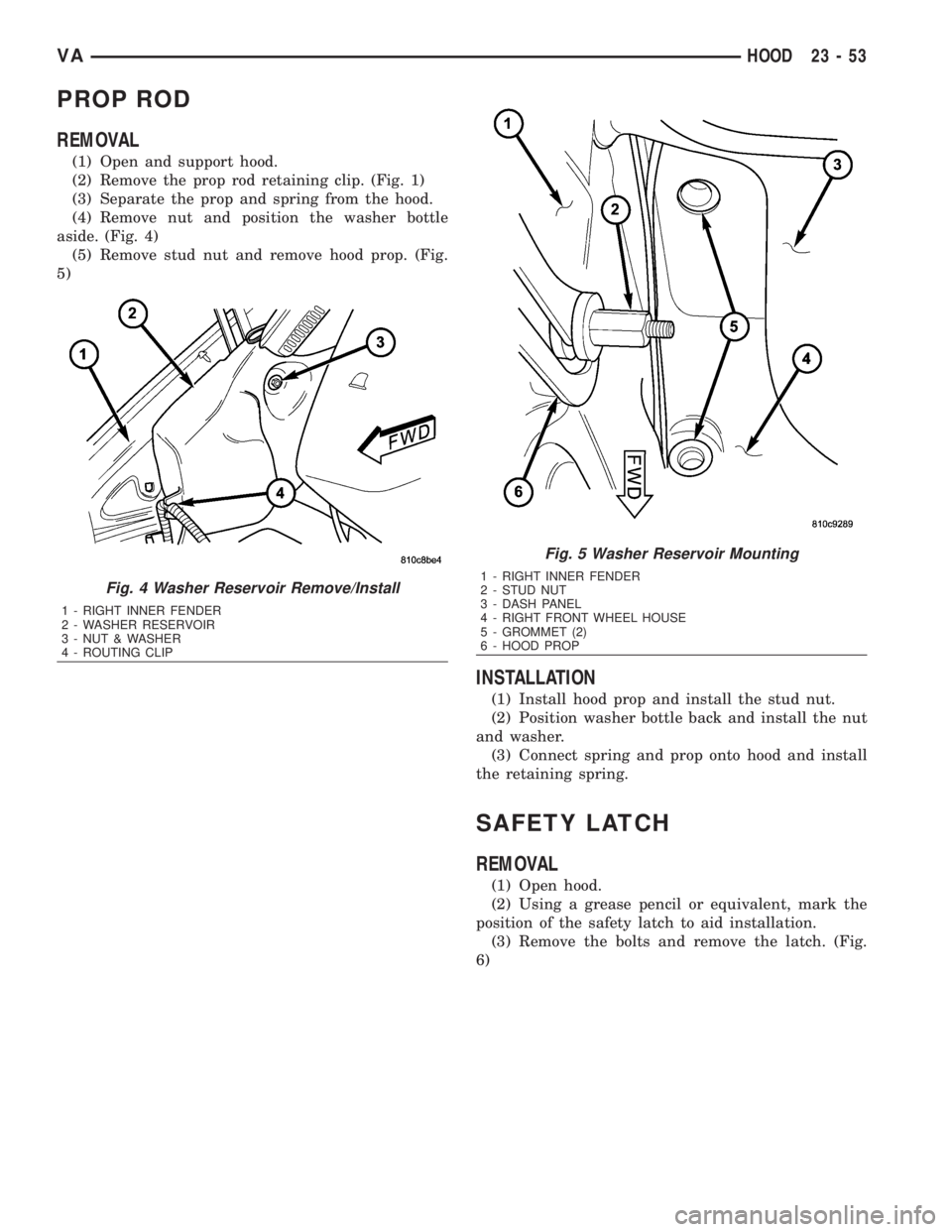

PROP ROD

REMOVAL

(1) Open and support hood.

(2) Remove the prop rod retaining clip. (Fig. 1)

(3) Separate the prop and spring from the hood.

(4) Remove nut and position the washer bottle

aside. (Fig. 4)

(5) Remove stud nut and remove hood prop. (Fig.

5)

INSTALLATION

(1) Install hood prop and install the stud nut.

(2) Position washer bottle back and install the nut

and washer.

(3) Connect spring and prop onto hood and install

the retaining spring.

SAFETY LATCH

REMOVAL

(1) Open hood.

(2) Using a grease pencil or equivalent, mark the

position of the safety latch to aid installation.

(3) Remove the bolts and remove the latch. (Fig.

6)

Fig. 4 Washer Reservoir Remove/Install

1 - RIGHT INNER FENDER

2 - WASHER RESERVOIR

3 - NUT & WASHER

4 - ROUTING CLIP

Fig. 5 Washer Reservoir Mounting

1 - RIGHT INNER FENDER

2 - STUD NUT

3 - DASH PANEL

4 - RIGHT FRONT WHEEL HOUSE

5 - GROMMET (2)

6 - HOOD PROP

VAHOOD 23 - 53

Page 2039 of 2305

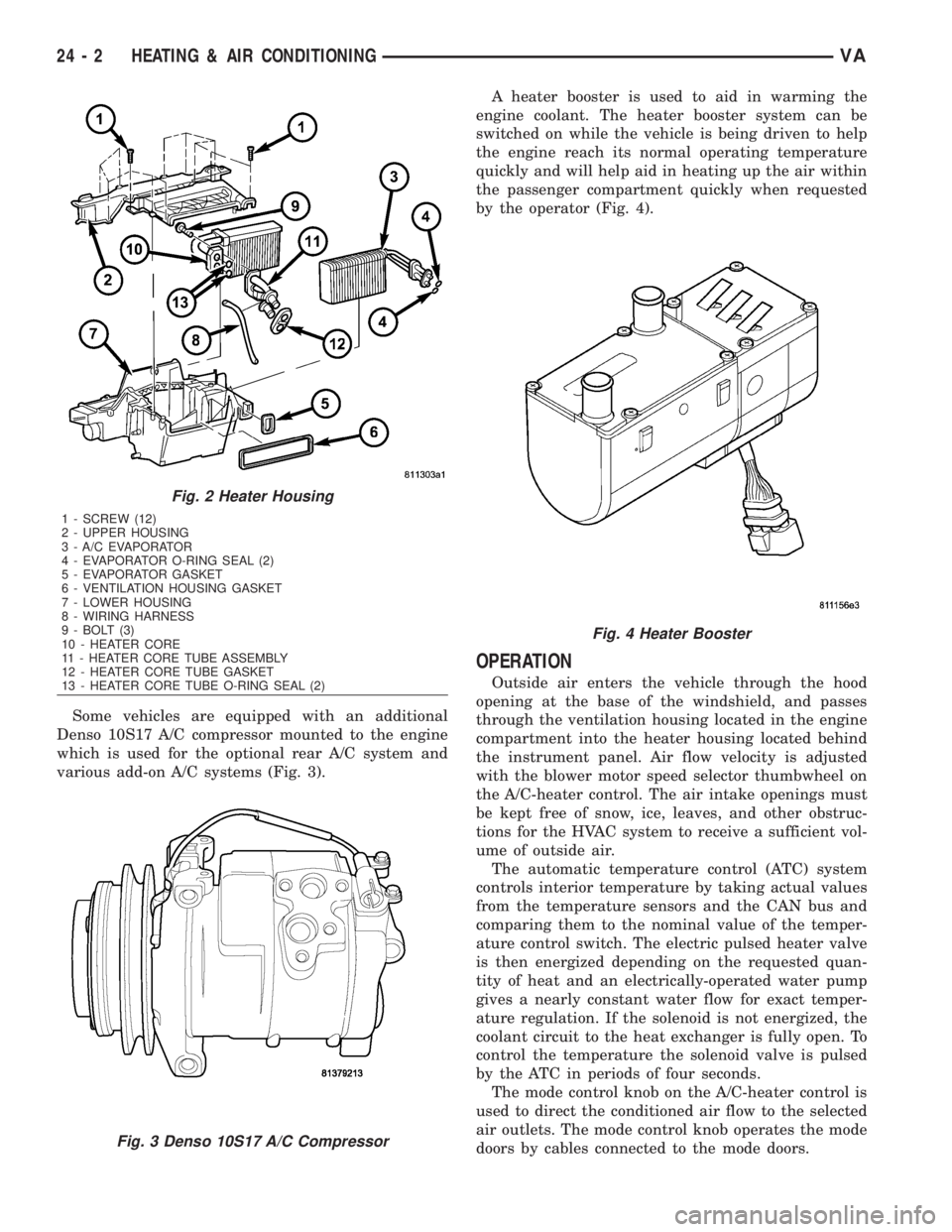

Some vehicles are equipped with an additional

Denso 10S17 A/C compressor mounted to the engine

which is used for the optional rear A/C system and

various add-on A/C systems (Fig. 3).A heater booster is used to aid in warming the

engine coolant. The heater booster system can be

switched on while the vehicle is being driven to help

the engine reach its normal operating temperature

quickly and will help aid in heating up the air within

the passenger compartment quickly when requested

by the operator (Fig. 4).

OPERATION

Outside air enters the vehicle through the hood

opening at the base of the windshield, and passes

through the ventilation housing located in the engine

compartment into the heater housing located behind

the instrument panel. Air flow velocity is adjusted

with the blower motor speed selector thumbwheel on

the A/C-heater control. The air intake openings must

be kept free of snow, ice, leaves, and other obstruc-

tions for the HVAC system to receive a sufficient vol-

ume of outside air.

The automatic temperature control (ATC) system

controls interior temperature by taking actual values

from the temperature sensors and the CAN bus and

comparing them to the nominal value of the temper-

ature control switch. The electric pulsed heater valve

is then energized depending on the requested quan-

tity of heat and an electrically-operated water pump

gives a nearly constant water flow for exact temper-

ature regulation. If the solenoid is not energized, the

coolant circuit to the heat exchanger is fully open. To

control the temperature the solenoid valve is pulsed

by the ATC in periods of four seconds.

The mode control knob on the A/C-heater control is

used to direct the conditioned air flow to the selected

air outlets. The mode control knob operates the mode

doors by cables connected to the mode doors.

Fig. 2 Heater Housing

1 - SCREW (12)

2 - UPPER HOUSING

3 - A/C EVAPORATOR

4 - EVAPORATOR O-RING SEAL (2)

5 - EVAPORATOR GASKET

6 - VENTILATION HOUSING GASKET

7 - LOWER HOUSING

8 - WIRING HARNESS

9 - BOLT (3)

10 - HEATER CORE

11 - HEATER CORE TUBE ASSEMBLY

12 - HEATER CORE TUBE GASKET

13 - HEATER CORE TUBE O-RING SEAL (2)

Fig. 3 Denso 10S17 A/C Compressor

Fig. 4 Heater Booster

24 - 2 HEATING & AIR CONDITIONINGVA

Page 2044 of 2305

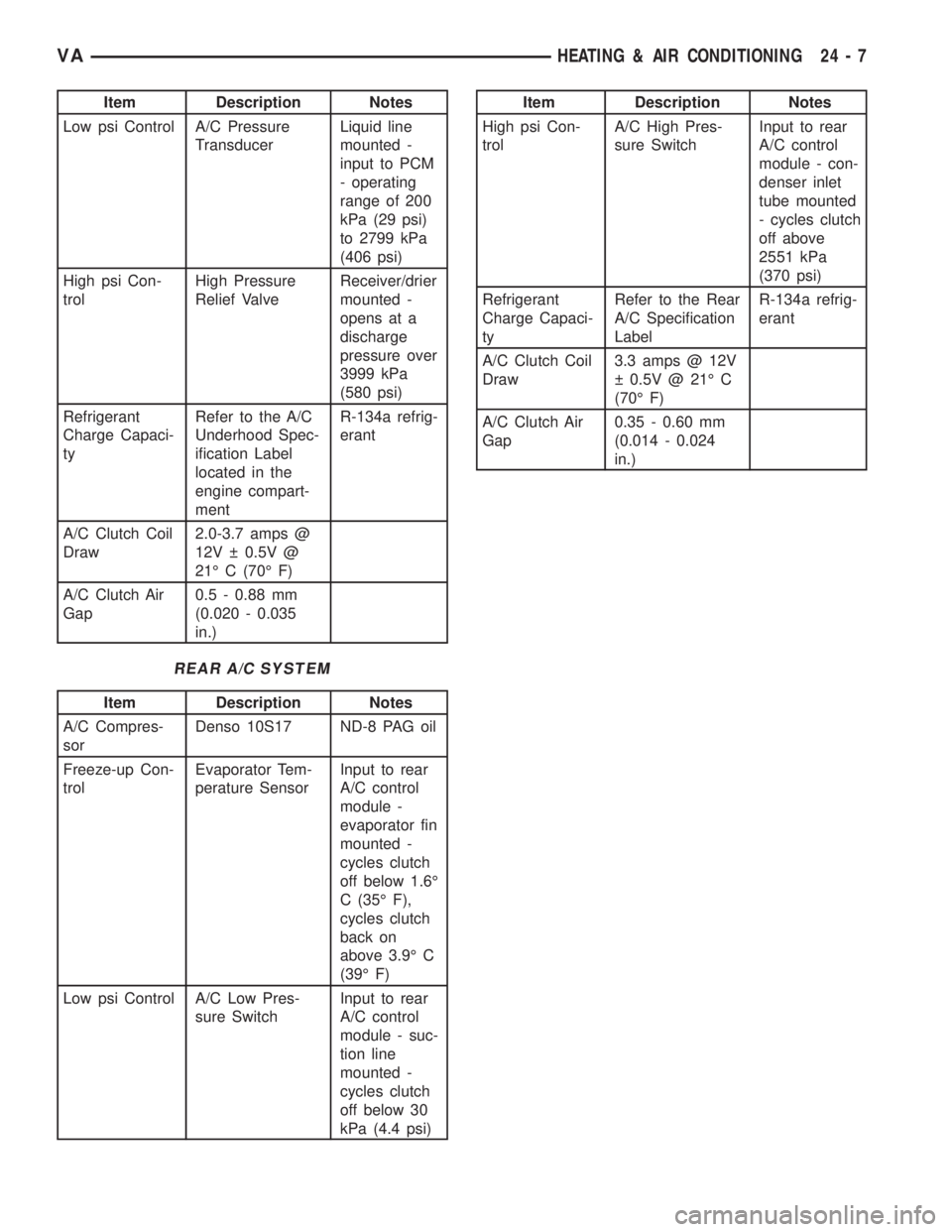

Item Description Notes

Low psi Control A/C Pressure

TransducerLiquid line

mounted -

input to PCM

- operating

range of 200

kPa (29 psi)

to 2799 kPa

(406 psi)

High psi Con-

trolHigh Pressure

Relief ValveReceiver/drier

mounted -

opens at a

discharge

pressure over

3999 kPa

(580 psi)

Refrigerant

Charge Capaci-

tyRefer to the A/C

Underhood Spec-

ification Label

located in the

engine compart-

mentR-134a refrig-

erant

A/C Clutch Coil

Draw2.0-3.7 amps @

12V 0.5V @

21É C (70É F)

A/C Clutch Air

Gap0.5 - 0.88 mm

(0.020 - 0.035

in.)

REAR A/C SYSTEM

Item Description Notes

A/C Compres-

sorDenso 10S17 ND-8 PAG oil

Freeze-up Con-

trolEvaporator Tem-

perature SensorInput to rear

A/C control

module -

evaporator fin

mounted -

cycles clutch

off below 1.6É

C (35É F),

cycles clutch

back on

above 3.9É C

(39É F)

Low psi Control A/C Low Pres-

sure SwitchInput to rear

A/C control

module - suc-

tion line

mounted -

cycles clutch

off below 30

kPa (4.4 psi)

Item Description Notes

High psi Con-

trolA/C High Pres-

sure SwitchInput to rear

A/C control

module - con-

denser inlet

tube mounted

- cycles clutch

off above

2551 kPa

(370 psi)

Refrigerant

Charge Capaci-

tyRefer to the Rear

A/C Specification

LabelR-134a refrig-

erant

A/C Clutch Coil

Draw3.3 amps @ 12V

0.5V @ 21É C

(70É F)

A/C Clutch Air

Gap0.35 - 0.60 mm

(0.014 - 0.024

in.)

VAHEATING & AIR CONDITIONING 24 - 7

Page 2158 of 2305

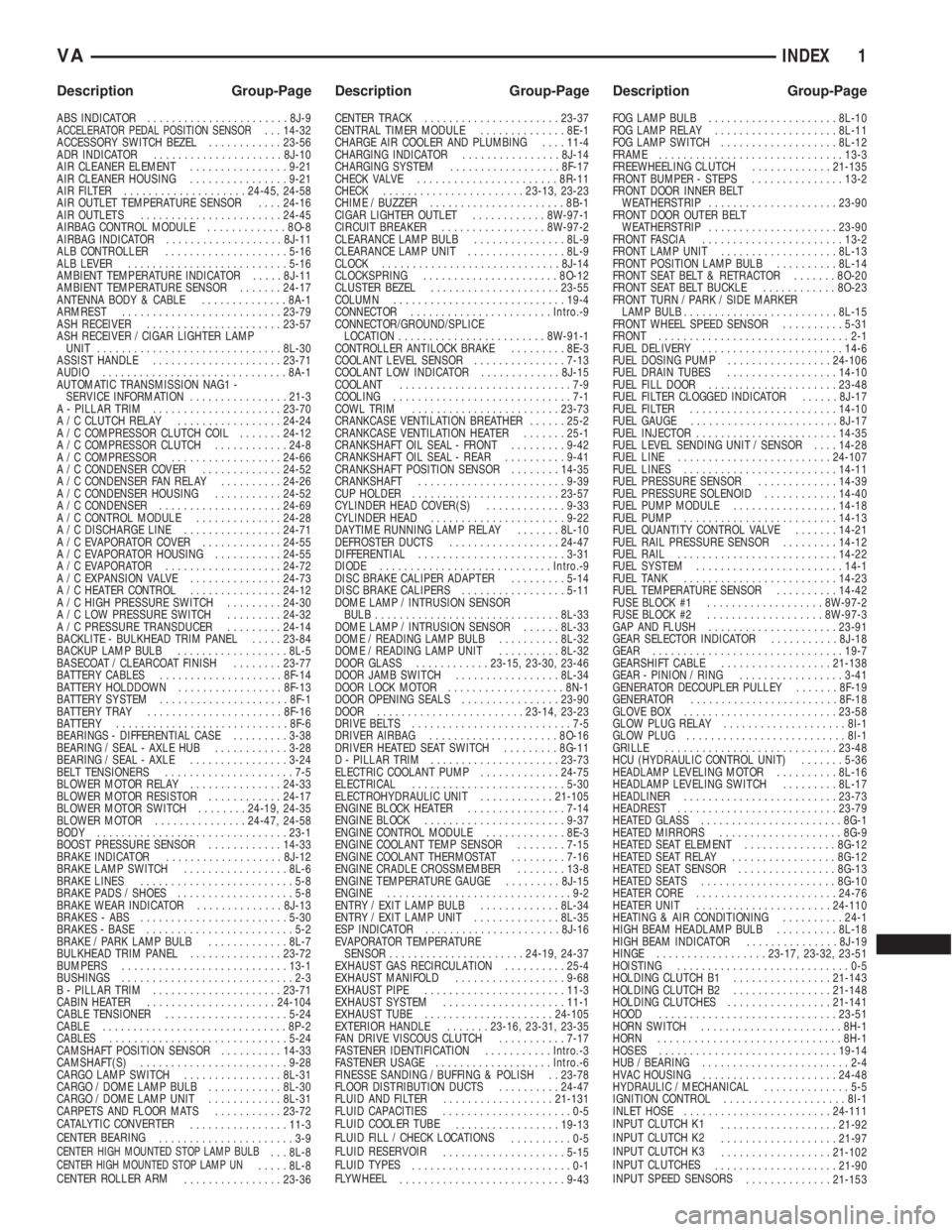

INDEX

ABS INDICATOR.......................8J-9ACCELERATOR PEDAL POSITION SENSOR. . . 14-32

ACCESSORY SWITCH BEZEL............23-56

ADR INDICATOR.....................8J-10

AIR CLEANER ELEMENT................9-21

AIR CLEANER HOUSING................9-21

AIR FILTER ....................24-45, 24-58

AIR OUTLET TEMPERATURE SENSOR....24-16

AIR OUTLETS.......................24-45

AIRBAG CONTROL MODULE.............8O-8

AIRBAG INDICATOR...................8J-11

ALB CONTROLLER....................5-16

ALB LEVER..........................5-16

AMBIENT TEMPERATURE INDICATOR.....8J-11

AMBIENT TEMPERATURE SENSOR.......24-17

ANTENNA BODY & CABLE..............8A-1

ARMREST..........................23-79

ASH RECEIVER......................23-57

ASH RECEIVER / CIGAR LIGHTER LAMP

UNIT..............................8L-30

ASSIST HANDLE.....................23-71

AUDIO..............................8A-1

AUTOMATIC TRANSMISSION NAG1 -

SERVICE INFORMATION................21-3

A - PILLAR TRIM.....................23-70

A / C CLUTCH RELAY.................24-24

A / C COMPRESSOR CLUTCH COIL.......24-12

A / C COMPRESSOR CLUTCH............24-8

A / C COMPRESSOR..................24-66

A / C CONDENSER COVER.............24-52

A / C CONDENSER FAN RELAY..........24-26

A / C CONDENSER HOUSING...........24-52

A / C CONDENSER....................24-69

A / C CONTROL MODULE..............24-28

A / C DISCHARGE LINE................24-71

A / C EVAPORATOR COVER.............24-55

A / C EVAPORATOR HOUSING...........24-55

A / C EVAPORATOR...................24-72

A / C EXPANSION VALVE...............24-73

A / C HEATER CONTROL...............24-12

A / C HIGH PRESSURE SWITCH.........24-30

A / C LOW PRESSURE SWITCH.........24-32

A / C PRESSURE TRANSDUCER.........24-14

BACKLITE - BULKHEAD TRIM PANEL.....23-84

BACKUP LAMP BULB..................8L-5

BASECOAT / CLEARCOAT FINISH........23-77

BATTERY CABLES....................8F-14

BATTERY HOLDDOWN.................8F-13

BATTERY SYSTEM.....................8F-1

BATTERY TRAY......................8F-16

BATTERY............................8F-6

BEARINGS - DIFFERENTIAL CASE.........3-38

BEARING / SEAL - AXLE HUB............3-28

BEARING / SEAL - AXLE................3-24

BELT TENSIONERS.....................7-5

BLOWER MOTOR RELAY...............24-33

BLOWER MOTOR RESISTOR............24-17

BLOWER MOTOR SWITCH........24-19, 24-35

BLOWER MOTOR...............24-47, 24-58

BODY...............................23-1

BOOST PRESSURE SENSOR............14-33

BRAKE INDICATOR...................8J-12

BRAKE LAMP SWITCH.................8L-6

BRAKE LINES.........................5-8

BRAKE PADS / SHOES...................5-8

BRAKE WEAR INDICATOR..............8J-13

BRAKES - ABS........................5-30

BRAKES - BASE........................5-2

BRAKE / PARK LAMP BULB.............8L-7

BULKHEAD TRIM PANEL...............23-72

BUMPERS...........................13-1

BUSHINGS............................2-3

B - PILLAR TRIM.....................23-71

CABIN HEATER.....................24-104

CABLE TENSIONER....................5-24

CABLE..............................8P-2

CABLES.............................5-24

CAMSHAFT POSITION SENSOR..........14-33

CAMSHAFT(S)........................9-28

CARGO LAMP SWITCH................8L-31

CARGO / DOME LAMP BULB............8L-30

CARGO / DOME LAMP UNIT............8L-31

CARPETS AND FLOOR MATS...........23-72

CATALYTIC CONVERTER

................11-3

CENTER BEARING

......................3-9

CENTER HIGH MOUNTED STOP LAMP BULB. . . 8L-8CENTER HIGH MOUNTED STOP LAMP UN.....8L-8

CENTER ROLLER ARM

................23-36CENTER TRACK......................23-37

CENTRAL TIMER MODULE..............8E-1

CHARGE AIR COOLER AND PLUMBING....11-4

CHARGING INDICATOR................8J-14

CHARGING SYSTEM..................8F-17

CHECK VALVE.......................8R-11

CHECK.......................23-13, 23-23

CHIME / BUZZER......................8B-1

CIGAR LIGHTER OUTLET............8W-97-1

CIRCUIT BREAKER.................8W-97-2

CLEARANCE LAMP BULB...............8L-9

CLEARANCE LAMP UNIT................8L-9

CLOCK.............................8J-14

CLOCKSPRING......................8O-12

CLUSTER BEZEL.....................23-55

COLUMN............................19-4

CONNECTOR.......................Intro.-9

CONNECTOR/GROUND/SPLICE

LOCATION........................8W-91-1

CONTROLLER ANTILOCK BRAKE.........8E-3

COOLANT LEVEL SENSOR...............7-13

COOLANT LOW INDICATOR.............8J-15

COOLANT............................7-9

COOLING.............................7-1

COWL TRIM........................23-73

CRANKCASE VENTILATION BREATHER......25-2

CRANKCASE VENTILATION HEATER.......25-1

CRANKSHAFT OIL SEAL - FRONT.........9-42

CRANKSHAFT OIL SEAL - REAR..........9-41

CRANKSHAFT POSITION SENSOR........14-35

CRANKSHAFT........................9-39

CUP HOLDER........................23-57

CYLINDER HEAD COVER(S).............9-33

CYLINDER HEAD......................9-22

DAYTIME RUNNING LAMP RELAY.......8L-10

DEFROSTER DUCTS..................24-47

DIFFERENTIAL........................3-31

DIODE............................Intro.-9

DISC BRAKE CALIPER ADAPTER.........5-14

DISC BRAKE CALIPERS.................5-11

DOME LAMP / INTRUSION SENSOR

BULB..............................8L-33

DOME LAMP / INTRUSION SENSOR......8L-33

DOME / READING LAMP BULB..........8L-32

DOME / READING LAMP UNIT..........8L-32

DOOR GLASS............23-15, 23-30, 23-46

DOOR JAMB SWITCH.................8L-34

DOOR LOCK MOTOR...................8N-1

DOOR OPENING SEALS................23-90

DOOR........................23-14, 23-23

DRIVE BELTS..........................7-5

DRIVER AIRBAG.....................8O-16

DRIVER HEATED SEAT SWITCH.........8G-11

D - PILLAR TRIM.....................23-73

ELECTRIC COOLANT PUMP.............24-75

ELECTRICAL.........................5-30

ELECTROHYDRAULIC UNIT............21-105

ENGINE BLOCK HEATER................7-14

ENGINE BLOCK.......................9-37

ENGINE CONTROL MODULE.............8E-3

ENGINE COOLANT TEMP SENSOR........7-15

ENGINE COOLANT THERMOSTAT.........7-16

ENGINE CRADLE CROSSMEMBER........13-8

ENGINE TEMPERATURE GAUGE.........8J-15

ENGINE..............................9-2

ENTRY / EXIT LAMP BULB.............8L-34

ENTRY / EXIT LAMP UNIT..............8L-35

ESP INDICATOR......................8J-16

EVAPORATOR TEMPERATURE

SENSOR......................24-19, 24-37

EXHAUST GAS RECIRCULATION..........25-4

EXHAUST MANIFOLD..................9-68

EXHAUST PIPE.......................11-3

EXHAUST SYSTEM....................11-1

EXHAUST TUBE.....................24-105

EXTERIOR HANDLE.......23-16, 23-31, 23-35

FAN DRIVE VISCOUS CLUTCH...........7-17

FASTENER IDENTIFICATION...........Intro.-3

FASTENER USAGE...................Intro.-6

FINESSE SANDING / BUFFING & POLISH . . 23-78

FLOOR DISTRIBUTION DUCTS..........24-47

FLUID AND FILTER..................21-131

FLUID CAPACITIES.....................0-5

FLUID COOLER TUBE

.................19-13

FLUID FILL / CHECK LOCATIONS

..........0-5

FLUID RESERVOIR

....................5-15

FLUID TYPES

..........................0-1

FLYWHEEL

...........................9-43FOG LAMP BULB.....................8L-10

FOG LAMP RELAY....................8L-11

FOG LAMP SWITCH...................8L-12

FRAME..............................13-3

FREEWHEELING CLUTCH.............21-135

FRONT BUMPER - STEPS...............13-2

FRONT DOOR INNER BELT

WEATHERSTRIP.....................23-90

FRONT DOOR OUTER BELT

WEATHERSTRIP.....................23-90

FRONT FASCIA.......................13-2

FRONT LAMP UNIT...................8L-13

FRONT POSITION LAMP BULB..........8L-14

FRONT SEAT BELT & RETRACTOR.......8O-20

FRONT SEAT BELT BUCKLE............8O-23

FRONT TURN / PARK / SIDE MARKER

LAMP BULB.........................8L-15

FRONT WHEEL SPEED SENSOR..........5-31

FRONT...............................2-1

FUEL DELIVERY.......................14-6

FUEL DOSING PUMP.................24-106

FUEL DRAIN TUBES..................14-10

FUEL FILL DOOR.....................23-48

FUEL FILTER CLOGGED INDICATOR......8J-17

FUEL FILTER........................14-10

FUEL GAUGE........................8J-17

FUEL INJECTOR.......................14-35

FUEL LEVEL SENDING UNIT / SENSOR....14-28

FUEL LINE.........................24-107

FUEL LINES.........................14-11

FUEL PRESSURE SENSOR.............14-39

FUEL PRESSURE SOLENOID............14-40

FUEL PUMP MODULE.................14-18

FUEL PUMP.........................14-13

FUEL QUANTITY CONTROL VALVE.......14-21

FUEL RAIL PRESSURE SENSOR.........14-12

FUEL RAIL..........................14-22

FUEL SYSTEM........................14-1

FUEL TANK.........................14-23

FUEL TEMPERATURE SENSOR..........14-42

FUSE BLOCK #1...................8W-97-2

FUSE BLOCK #2...................8W-97-3

GAP AND FLUSH.....................23-91

GEAR SELECTOR INDICATOR...........8J-18

GEAR...............................19-7

GEARSHIFT CABLE..................21-138

GEAR - PINION / RING.................3-41

GENERATOR DECOUPLER PULLEY.......8F-19

GENERATOR........................8F-18

GLOVE BOX.........................23-58

GLOW PLUG RELAY....................8I-1

GLOW PLUG..........................8I-1

GRILLE............................23-48

HCU (HYDRAULIC CONTROL UNIT).......5-36

HEADLAMP LEVELING MOTOR..........8L-16

HEADLAMP LEVELING SWITCH.........8L-17

HEADLINER.........................23-73

HEADREST..........................23-79

HEATED GLASS.......................8G-1

HEATED MIRRORS....................8G-9

HEATED SEAT ELEMENT...............8G-12

HEATED SEAT RELAY.................8G-12

HEATED SEAT SENSOR................8G-13

HEATED SEATS ......................8G-10

HEATER CORE.......................24-76

HEATER UNIT......................24-110

HEATING & AIR CONDITIONING..........24-1

HIGH BEAM HEADLAMP BULB..........8L-18

HIGH BEAM INDICATOR...............8J-19

HINGE..................23-17, 23-32, 23-51

HOISTING............................0-5

HOLDING CLUTCH B1................21-143

HOLDING CLUTCH B2................21-148

HOLDING CLUTCHES.................21-141

HOOD.............................23-51

HORN SWITCH.......................8H-1

HORN..............................8H-1

HOSES.............................19-14

HUB / BEARING........................2-4

HVAC HOUSING......................24-48

HYDRAULIC / MECHANICAL..............5-5

IGNITION CONTROL....................8I-1

INLET HOSE........................24-111

INPUT CLUTCH K1

...................21-92

INPUT CLUTCH K2

...................21-97

INPUT CLUTCH K3

..................21-102

INPUT CLUTCHES

....................21-90

INPUT SPEED SENSORS

..............21-153

VAINDEX 1

Description Group-Page Description Group-Page Description Group-Page