fuel MERCEDES-BENZ SPRINTER 2006 Service Manual

[x] Cancel search | Manufacturer: MERCEDES-BENZ, Model Year: 2006, Model line: SPRINTER, Model: MERCEDES-BENZ SPRINTER 2006Pages: 2305, PDF Size: 48.12 MB

Page 1729 of 2305

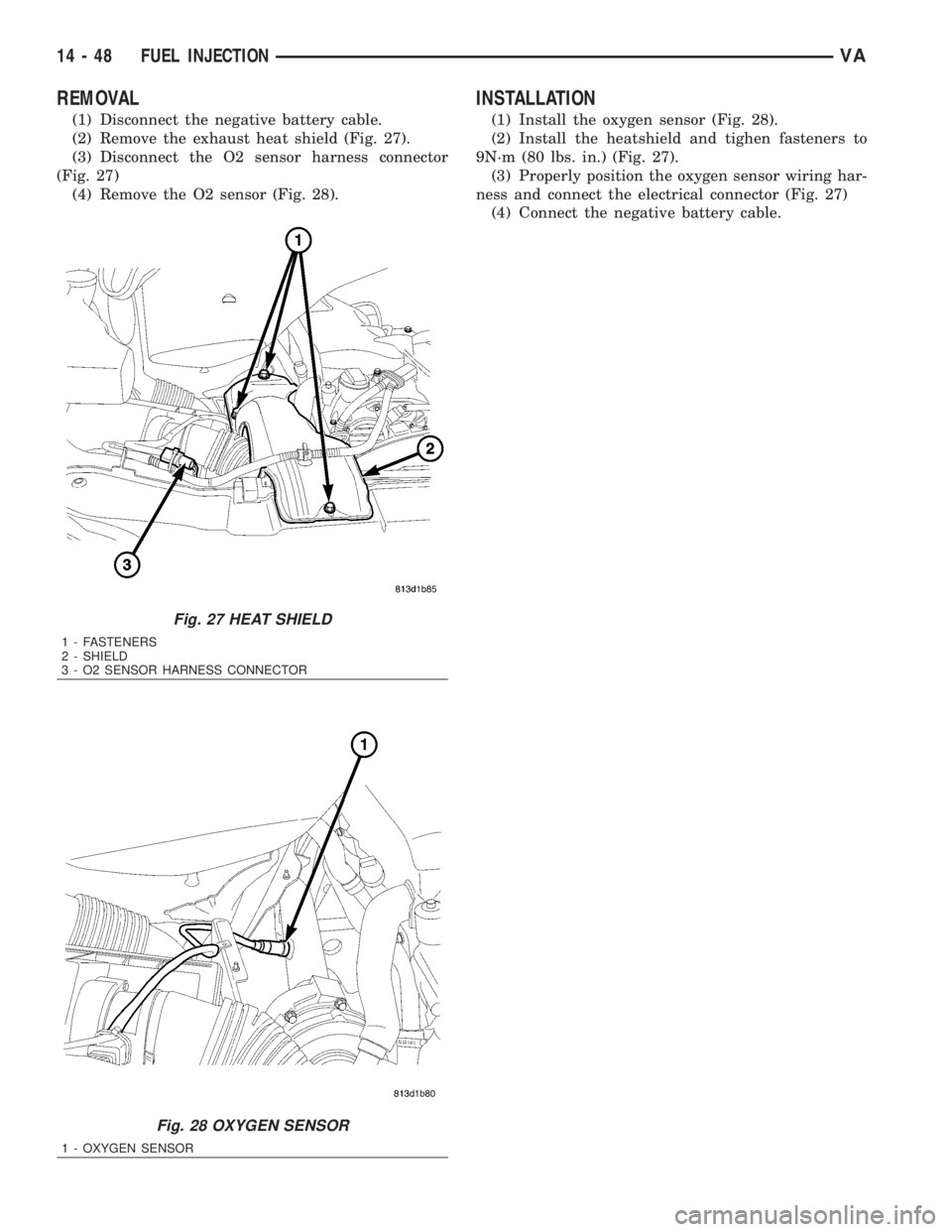

REMOVAL

(1) Disconnect the negative battery cable.

(2) Remove the exhaust heat shield (Fig. 27).

(3) Disconnect the O2 sensor harness connector

(Fig. 27)

(4) Remove the O2 sensor (Fig. 28).

INSTALLATION

(1) Install the oxygen sensor (Fig. 28).

(2) Install the heatshield and tighen fasteners to

9N´m (80 lbs. in.) (Fig. 27).

(3) Properly position the oxygen sensor wiring har-

ness and connect the electrical connector (Fig. 27)

(4) Connect the negative battery cable.

Fig. 27 HEAT SHIELD

1 - FASTENERS

2 - SHIELD

3 - O2 SENSOR HARNESS CONNECTOR

Fig. 28 OXYGEN SENSOR

1 - OXYGEN SENSOR

14 - 48 FUEL INJECTIONVA

Page 1746 of 2305

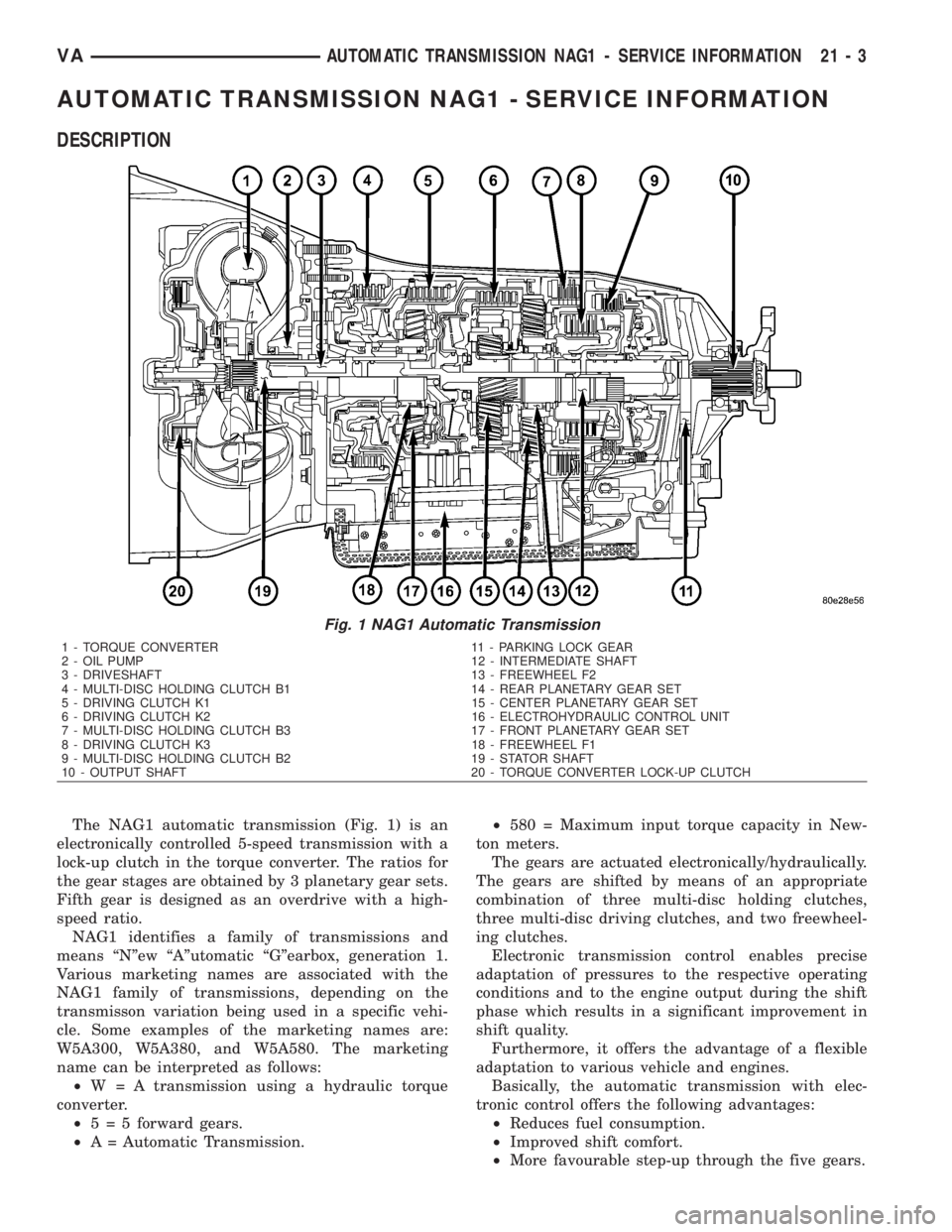

AUTOMATIC TRANSMISSION NAG1 - SERVICE INFORMATION

DESCRIPTION

The NAG1 automatic transmission (Fig. 1) is an

electronically controlled 5-speed transmission with a

lock-up clutch in the torque converter. The ratios for

the gear stages are obtained by 3 planetary gear sets.

Fifth gear is designed as an overdrive with a high-

speed ratio.

NAG1 identifies a family of transmissions and

means ªNºew ªAºutomatic ªGºearbox, generation 1.

Various marketing names are associated with the

NAG1 family of transmissions, depending on the

transmisson variation being used in a specific vehi-

cle. Some examples of the marketing names are:

W5A300, W5A380, and W5A580. The marketing

name can be interpreted as follows:

²W = A transmission using a hydraulic torque

converter.

²5 = 5 forward gears.

²A = Automatic Transmission.²580 = Maximum input torque capacity in New-

ton meters.

The gears are actuated electronically/hydraulically.

The gears are shifted by means of an appropriate

combination of three multi-disc holding clutches,

three multi-disc driving clutches, and two freewheel-

ing clutches.

Electronic transmission control enables precise

adaptation of pressures to the respective operating

conditions and to the engine output during the shift

phase which results in a significant improvement in

shift quality.

Furthermore, it offers the advantage of a flexible

adaptation to various vehicle and engines.

Basically, the automatic transmission with elec-

tronic control offers the following advantages:

²Reduces fuel consumption.

²Improved shift comfort.

²More favourable step-up through the five gears.

Fig. 1 NAG1 Automatic Transmission

1 - TORQUE CONVERTER 11 - PARKING LOCK GEAR

2 - OIL PUMP 12 - INTERMEDIATE SHAFT

3 - DRIVESHAFT 13 - FREEWHEEL F2

4 - MULTI-DISC HOLDING CLUTCH B1 14 - REAR PLANETARY GEAR SET

5 - DRIVING CLUTCH K1 15 - CENTER PLANETARY GEAR SET

6 - DRIVING CLUTCH K2 16 - ELECTROHYDRAULIC CONTROL UNIT

7 - MULTI-DISC HOLDING CLUTCH B3 17 - FRONT PLANETARY GEAR SET

8 - DRIVING CLUTCH K3 18 - FREEWHEEL F1

9 - MULTI-DISC HOLDING CLUTCH B2 19 - STATOR SHAFT

10 - OUTPUT SHAFT 20 - TORQUE CONVERTER LOCK-UP CLUTCH

VAAUTOMATIC TRANSMISSION NAG1 - SERVICE INFORMATION 21 - 3

Page 1921 of 2305

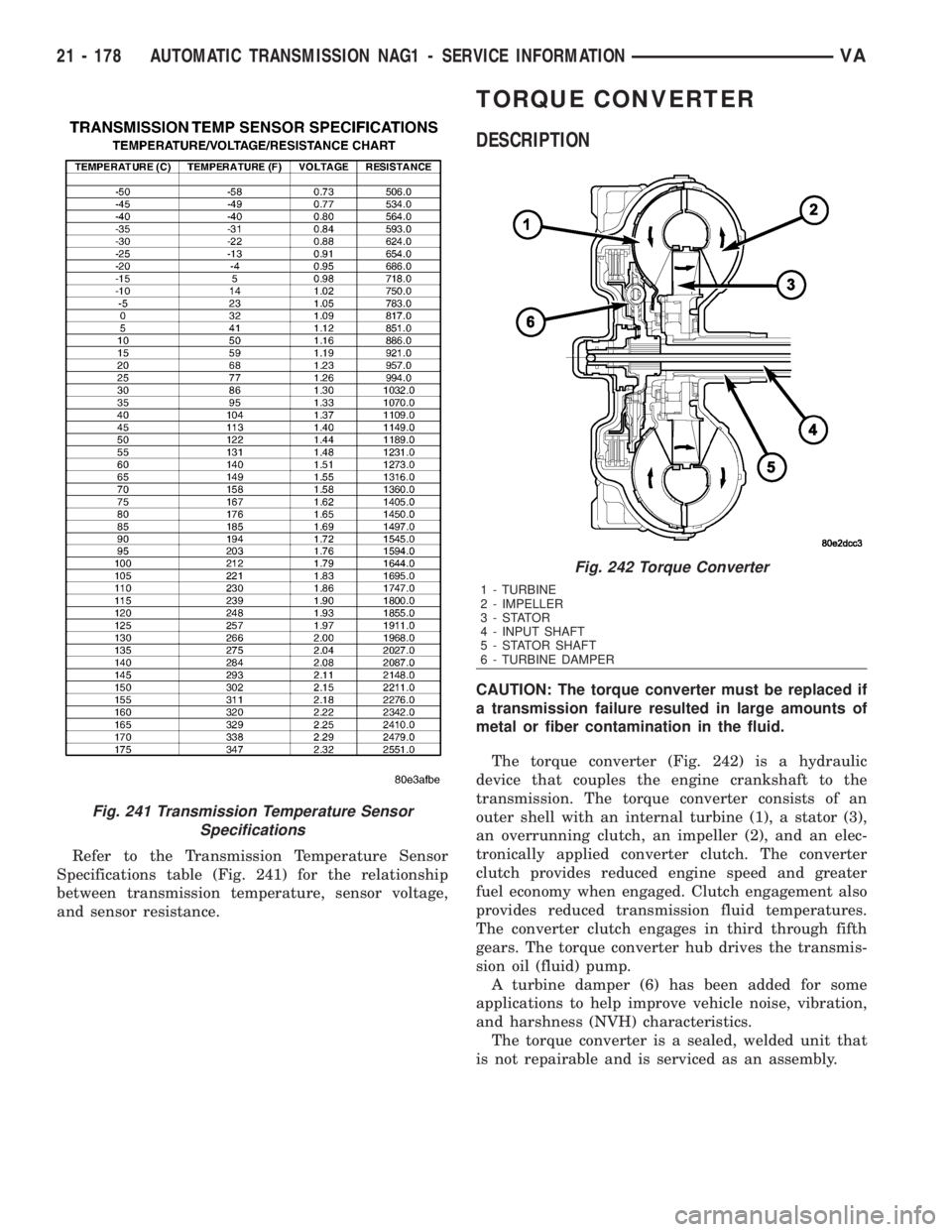

Refer to the Transmission Temperature Sensor

Specifications table (Fig. 241) for the relationship

between transmission temperature, sensor voltage,

and sensor resistance.

TORQUE CONVERTER

DESCRIPTION

CAUTION: The torque converter must be replaced if

a transmission failure resulted in large amounts of

metal or fiber contamination in the fluid.

The torque converter (Fig. 242) is a hydraulic

device that couples the engine crankshaft to the

transmission. The torque converter consists of an

outer shell with an internal turbine (1), a stator (3),

an overrunning clutch, an impeller (2), and an elec-

tronically applied converter clutch. The converter

clutch provides reduced engine speed and greater

fuel economy when engaged. Clutch engagement also

provides reduced transmission fluid temperatures.

The converter clutch engages in third through fifth

gears. The torque converter hub drives the transmis-

sion oil (fluid) pump.

A turbine damper (6) has been added for some

applications to help improve vehicle noise, vibration,

and harshness (NVH) characteristics.

The torque converter is a sealed, welded unit that

is not repairable and is serviced as an assembly.

Fig. 241 Transmission Temperature Sensor

Specifications

Fig. 242 Torque Converter

1 - TURBINE

2 - IMPELLER

3-STATOR

4 - INPUT SHAFT

5 - STATOR SHAFT

6 - TURBINE DAMPER

21 - 178 AUTOMATIC TRANSMISSION NAG1 - SERVICE INFORMATIONVA

Page 1935 of 2305

Radial-ply tires must always be used in sets of

four. Under no circumstances should they be used on

the front only. They may be mixed with temporary

spare tires when necessary. A maximum speed of 50

MPH is recommended while a temporary spare is in

use.

Radial-ply tires have the same load-carrying capac-

ity as other types of tires of the same size. They also

use the same recommended inflation pressures.

The use of oversized tires, either in the front or

rear of the vehicle, can cause vehicle drive train fail-

ure. This could also cause inaccurate wheel speed

signals when the vehicle is equipped with Anti-Lock

Brakes.

The use of tires from different manufactures on the

same vehicle is NOT recommended. The proper tire

pressure should be maintained on all four tires.

DESCRIPTION - TIRE PRESSURE FOR HIGH

SPEEDS

Where speed limits allow the vehicle to be driven

at high speeds, correct tire inflation pressure is very

important. For speeds up to and including 120 km/h

(75 mph), tires must be inflated to the pressures

shown on the tire placard. For continuous speeds in

excess of 120 km/h (75 mph), tires must be inflated

to the maximum pressure specified on the tire side-

wall.

Vehicles loaded to the maximum capacity should

not be driven at continuous speeds above 75 mph

(120 km/h).

For emergency vehicles that are driven at speeds

over 90 mph (144 km/h), special high speed tires

must be used. Consult tire manufacturer for correct

inflation pressure recommendations.

DESCRIPTION - REPLACEMENT TIRES

The original equipment tires provide a proper bal-

ance of many characteristics such as:

²Ride

²Noise

²Handling

²Durability

²Tread life

²Traction

²Rolling resistance

²Speed capability

It is recommended that tires equivalent to the orig-

inal equipment tires be used when replacement is

needed.

Failure to use equivalent replacement tires may

adversely affect the safety and handling of the vehi-

cle.The use of oversize tires may cause interference

with vehicle components. Under extremes of suspen-

sion and steering travel, interference with vehicle

components may cause tire damage.

WARNING: FAILURE TO EQUIP THE VEHICLE WITH

TIRES HAVING ADEQUATE SPEED CAPABILITY

CAN RESULT IN SUDDEN TIRE FAILURE.

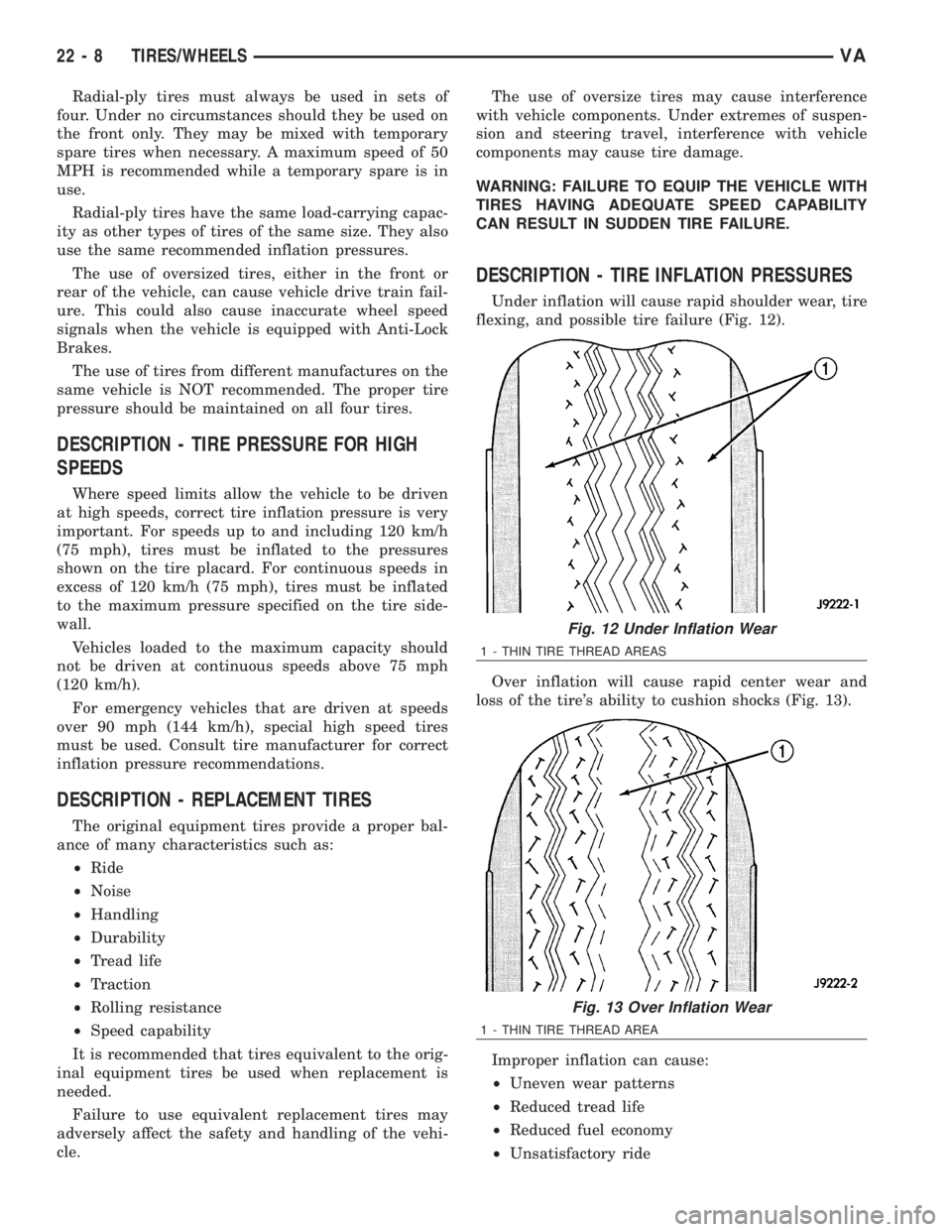

DESCRIPTION - TIRE INFLATION PRESSURES

Under inflation will cause rapid shoulder wear, tire

flexing, and possible tire failure (Fig. 12).

Over inflation will cause rapid center wear and

loss of the tire's ability to cushion shocks (Fig. 13).

Improper inflation can cause:

²Uneven wear patterns

²Reduced tread life

²Reduced fuel economy

²Unsatisfactory ride

Fig. 12 Under Inflation Wear

1 - THIN TIRE THREAD AREAS

Fig. 13 Over Inflation Wear

1 - THIN TIRE THREAD AREA

22 - 8 TIRES/WHEELSVA

Page 1991 of 2305

EXTERIOR

TABLE OF CONTENTS

page page

FUEL FILL DOOR

REMOVAL.............................48

INSTALLATION.........................48

GRILLE

REMOVAL.............................48

INSTALLATION.........................48

LICENSE PLATE BRACKET

REMOVAL.............................48

INSTALLATION.........................48RADIATOR CROSSMEMBER

REMOVAL.............................49

INSTALLATION.........................49

SIDE VIEW MIRROR

REMOVAL.............................49

INSTALLATION.........................50

SIDE VIEW MIRROR - GLASS

REMOVAL.............................50

INSTALLATION.........................50

FUEL FILL DOOR

REMOVAL

(1) Open passenger compartment door.

(2) Open fuel fill door.

(3) Using a trim stick C-4755 or equivalent, dis-

connect the filler cap tether.

(4) Remove two bolts and remove filler door.

INSTALLATION

(1) Install the door and bolts.

(2) Connect filler cap tether.

(3) Close doors.

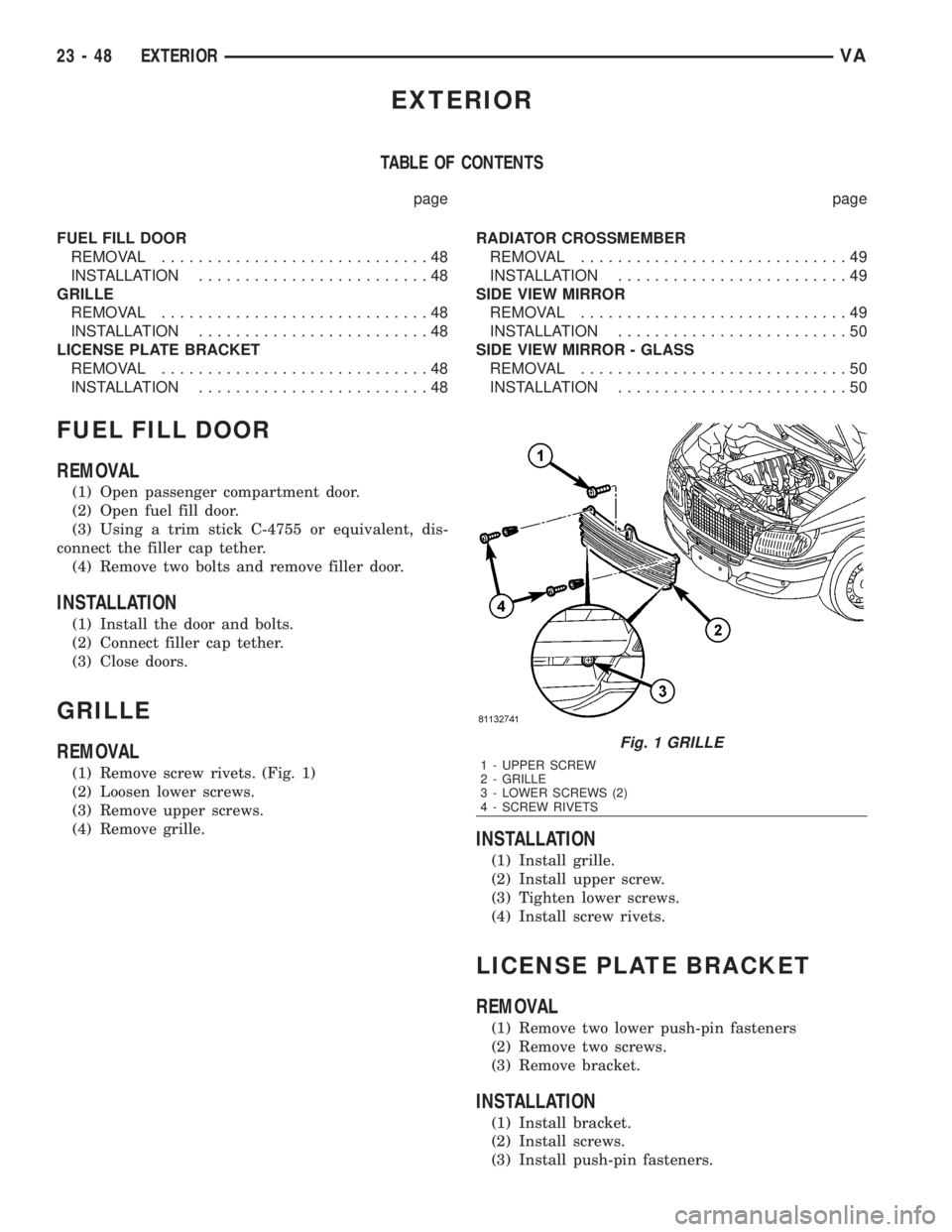

GRILLE

REMOVAL

(1) Remove screw rivets. (Fig. 1)

(2) Loosen lower screws.

(3) Remove upper screws.

(4) Remove grille.

INSTALLATION

(1) Install grille.

(2) Install upper screw.

(3) Tighten lower screws.

(4) Install screw rivets.

LICENSE PLATE BRACKET

REMOVAL

(1) Remove two lower push-pin fasteners

(2) Remove two screws.

(3) Remove bracket.

INSTALLATION

(1) Install bracket.

(2) Install screws.

(3) Install push-pin fasteners.

Fig. 1 GRILLE

1 - UPPER SCREW

2 - GRILLE

3 - LOWER SCREWS (2)

4 - SCREW RIVETS

23 - 48 EXTERIORVA

Page 2137 of 2305

CAUTION: Use only the specified O-rings as they

are made of a special material for the R-134a sys-

tem. The use of any other O-rings may allow the

connection to leak intermittently during vehicle

operation.

(4) Lubricate the male fitting and O-rings, and the

inside of the female fitting with clean R-134a refrig-

erant oil. Use only refrigerant oil of the type recom-

mended for the compressor in the vehicle.

(5) Fit the female half of the coupler fitting over

the male half of the fitting.

(6) Push together firmly on the two halves of the

coupler fitting until the garter spring in the cage on

the male half of the fitting snaps over the flanged

end on the female half of the fitting.

(7) Ensure that the spring-lock coupler is fully

engaged by trying to separate the two coupler halves.

This is done by pulling the refrigerant lines on either

side of the coupler away from each other.

(8) Reinstall the secondary retaining clip over the

spring-lock coupler cage.

(9) Evacuate the refrigerant system (Refer to 24 -

HEATING & AIR CONDITIONING/PLUMBING -

STANDARD PROCEDURE - REFRIGERANT SYS-

TEM EVACUATE).

(10) Charge the refrigerant system (Refer to 24 -

HEATING & AIR CONDITIONING/PLUMBING -

STANDARD PROCEDURE - REFRIGERANT SYS-

TEM CHARGE).

UNDERBODY LINES

REMOVAL

WARNING: Refer to the applicable warnings and

cautions for this system before performing the fol-

lowing operation (Refer to 24 - HEATING & AIR

CONDITIONING/PLUMBING - WARNINGS) and (Refer

to 24 - HEATING & AIR CONDITIONING/PLUMBING -

CAUTIONS). Failure to follow the warnings and cau-

tions could result in possible personal injury or

death.

NOTE: The underbody refrigerant lines for the

optional rear A/C system are serviced in five sec-

tions. Two sections are connected the A/C compres-

sor. Two sections of the underbody suction line

(low-side) are connected together by a tapping

block with an O-ring seal. The underbody A/C dis-

charge line uses a spring-lock type refrigerant line

coupler with an O-ring seal.

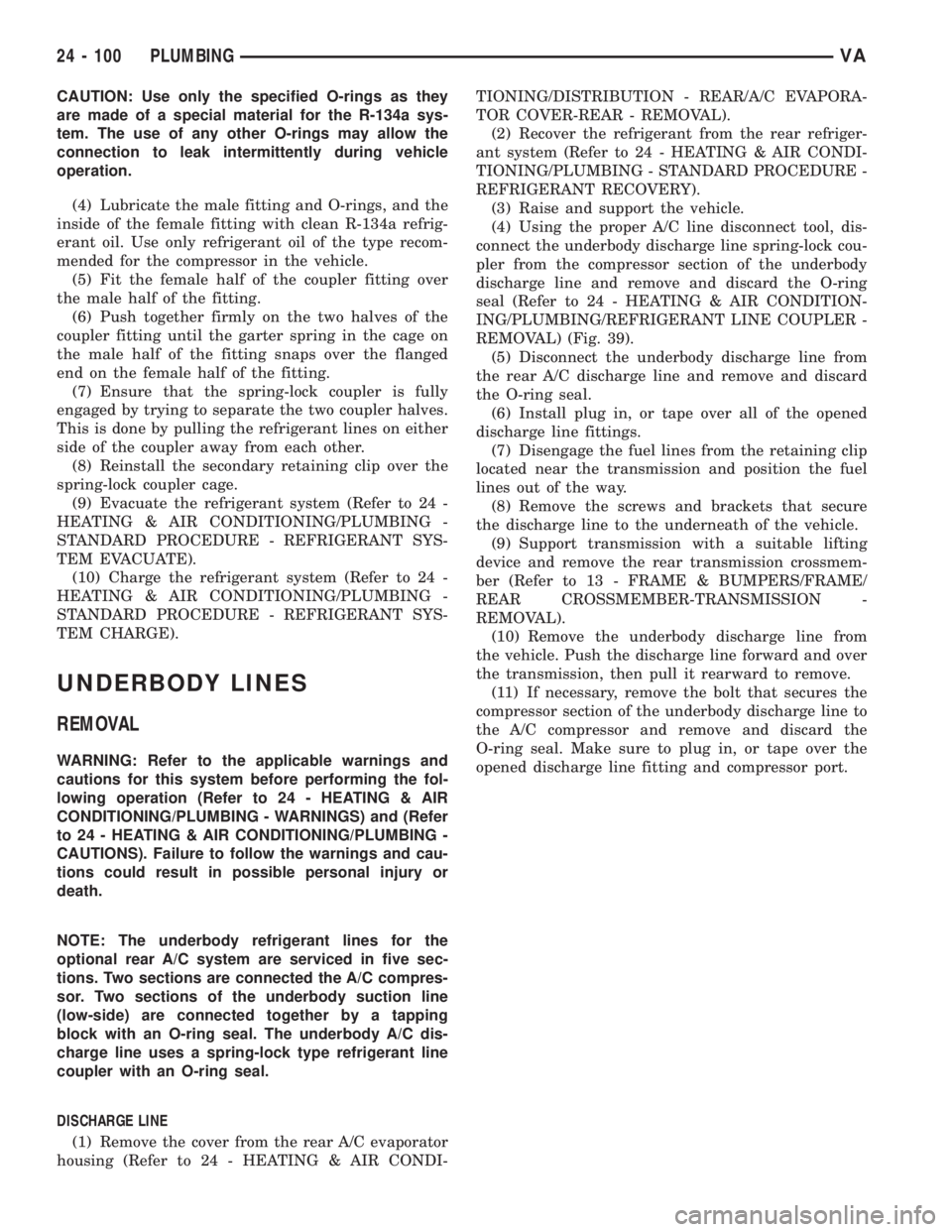

DISCHARGE LINE

(1) Remove the cover from the rear A/C evaporator

housing (Refer to 24 - HEATING & AIR CONDI-TIONING/DISTRIBUTION - REAR/A/C EVAPORA-

TOR COVER-REAR - REMOVAL).

(2) Recover the refrigerant from the rear refriger-

ant system (Refer to 24 - HEATING & AIR CONDI-

TIONING/PLUMBING - STANDARD PROCEDURE -

REFRIGERANT RECOVERY).

(3) Raise and support the vehicle.

(4) Using the proper A/C line disconnect tool, dis-

connect the underbody discharge line spring-lock cou-

pler from the compressor section of the underbody

discharge line and remove and discard the O-ring

seal (Refer to 24 - HEATING & AIR CONDITION-

ING/PLUMBING/REFRIGERANT LINE COUPLER -

REMOVAL) (Fig. 39).

(5) Disconnect the underbody discharge line from

the rear A/C discharge line and remove and discard

the O-ring seal.

(6) Install plug in, or tape over all of the opened

discharge line fittings.

(7) Disengage the fuel lines from the retaining clip

located near the transmission and position the fuel

lines out of the way.

(8) Remove the screws and brackets that secure

the discharge line to the underneath of the vehicle.

(9) Support transmission with a suitable lifting

device and remove the rear transmission crossmem-

ber (Refer to 13 - FRAME & BUMPERS/FRAME/

REAR CROSSMEMBER-TRANSMISSION -

REMOVAL).

(10) Remove the underbody discharge line from

the vehicle. Push the discharge line forward and over

the transmission, then pull it rearward to remove.

(11) If necessary, remove the bolt that secures the

compressor section of the underbody discharge line to

the A/C compressor and remove and discard the

O-ring seal. Make sure to plug in, or tape over the

opened discharge line fitting and compressor port.

24 - 100 PLUMBINGVA

Page 2138 of 2305

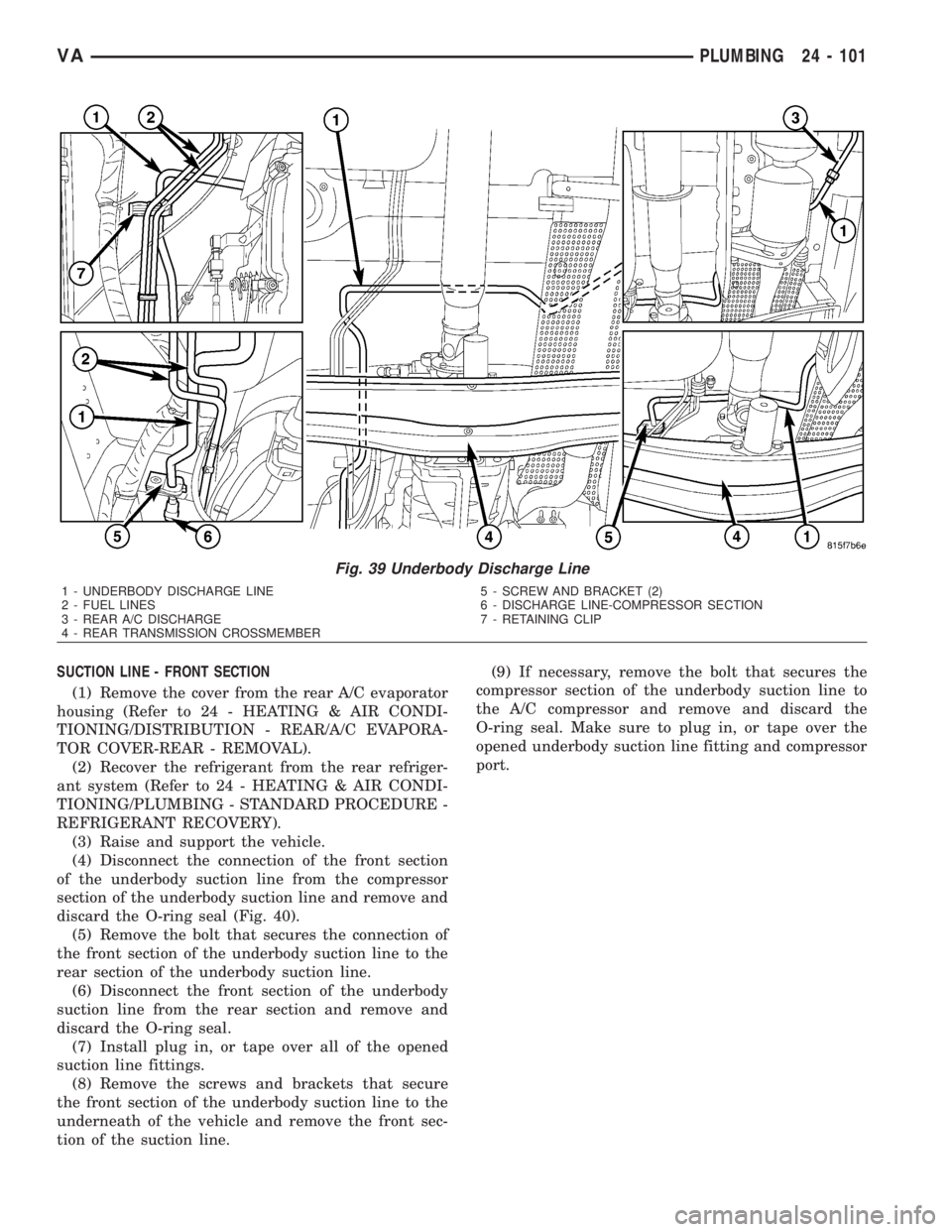

SUCTION LINE - FRONT SECTION

(1) Remove the cover from the rear A/C evaporator

housing (Refer to 24 - HEATING & AIR CONDI-

TIONING/DISTRIBUTION - REAR/A/C EVAPORA-

TOR COVER-REAR - REMOVAL).

(2) Recover the refrigerant from the rear refriger-

ant system (Refer to 24 - HEATING & AIR CONDI-

TIONING/PLUMBING - STANDARD PROCEDURE -

REFRIGERANT RECOVERY).

(3) Raise and support the vehicle.

(4) Disconnect the connection of the front section

of the underbody suction line from the compressor

section of the underbody suction line and remove and

discard the O-ring seal (Fig. 40).

(5) Remove the bolt that secures the connection of

the front section of the underbody suction line to the

rear section of the underbody suction line.

(6) Disconnect the front section of the underbody

suction line from the rear section and remove and

discard the O-ring seal.

(7) Install plug in, or tape over all of the opened

suction line fittings.

(8) Remove the screws and brackets that secure

the front section of the underbody suction line to the

underneath of the vehicle and remove the front sec-

tion of the suction line.(9) If necessary, remove the bolt that secures the

compressor section of the underbody suction line to

the A/C compressor and remove and discard the

O-ring seal. Make sure to plug in, or tape over the

opened underbody suction line fitting and compressor

port.

Fig. 39 Underbody Discharge Line

1 - UNDERBODY DISCHARGE LINE

2 - FUEL LINES

3 - REAR A/C DISCHARGE

4 - REAR TRANSMISSION CROSSMEMBER5 - SCREW AND BRACKET (2)

6 - DISCHARGE LINE-COMPRESSOR SECTION

7 - RETAINING CLIP

VAPLUMBING 24 - 101

Page 2139 of 2305

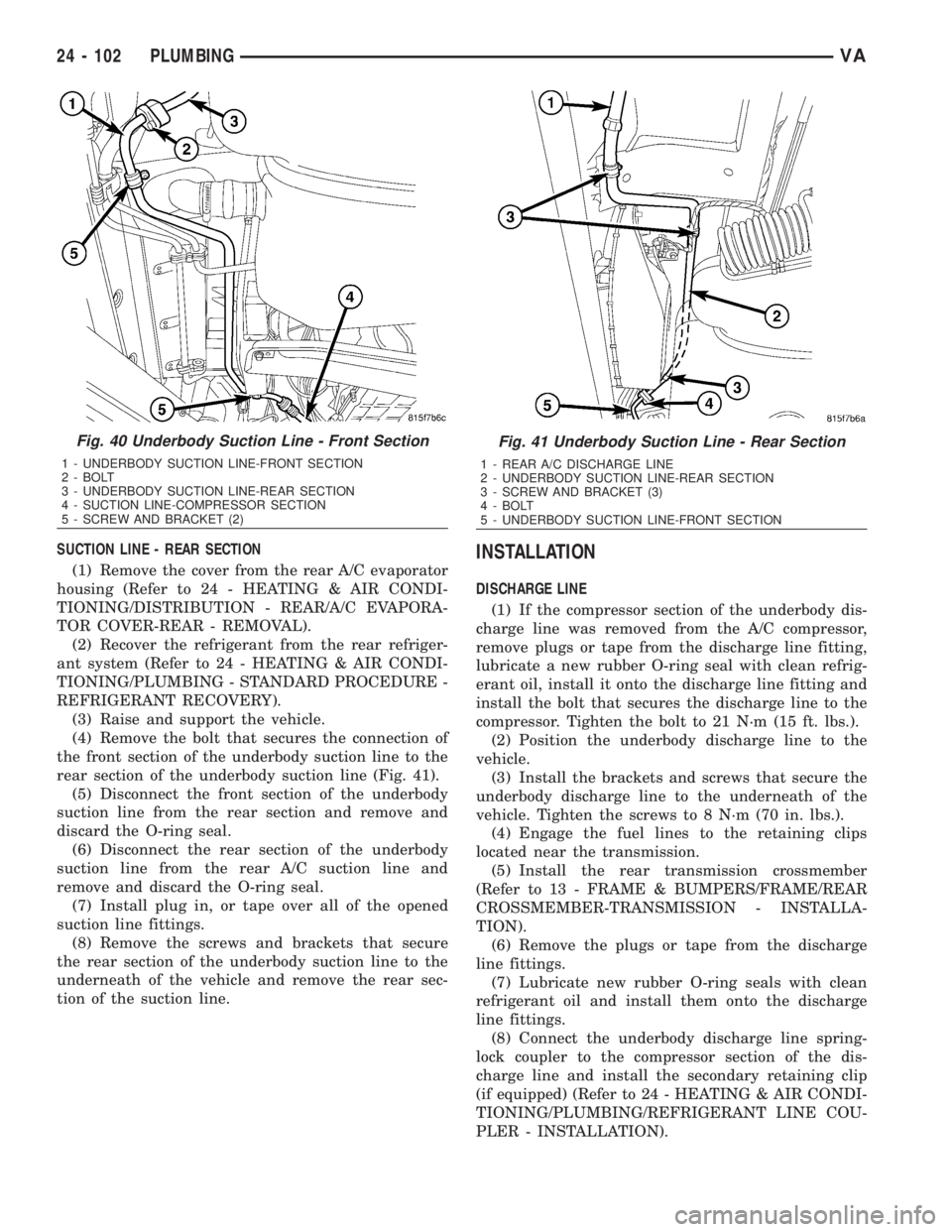

SUCTION LINE - REAR SECTION

(1) Remove the cover from the rear A/C evaporator

housing (Refer to 24 - HEATING & AIR CONDI-

TIONING/DISTRIBUTION - REAR/A/C EVAPORA-

TOR COVER-REAR - REMOVAL).

(2) Recover the refrigerant from the rear refriger-

ant system (Refer to 24 - HEATING & AIR CONDI-

TIONING/PLUMBING - STANDARD PROCEDURE -

REFRIGERANT RECOVERY).

(3) Raise and support the vehicle.

(4) Remove the bolt that secures the connection of

the front section of the underbody suction line to the

rear section of the underbody suction line (Fig. 41).

(5) Disconnect the front section of the underbody

suction line from the rear section and remove and

discard the O-ring seal.

(6) Disconnect the rear section of the underbody

suction line from the rear A/C suction line and

remove and discard the O-ring seal.

(7) Install plug in, or tape over all of the opened

suction line fittings.

(8) Remove the screws and brackets that secure

the rear section of the underbody suction line to the

underneath of the vehicle and remove the rear sec-

tion of the suction line.INSTALLATION

DISCHARGE LINE

(1) If the compressor section of the underbody dis-

charge line was removed from the A/C compressor,

remove plugs or tape from the discharge line fitting,

lubricate a new rubber O-ring seal with clean refrig-

erant oil, install it onto the discharge line fitting and

install the bolt that secures the discharge line to the

compressor. Tighten the bolt to 21 N´m (15 ft. lbs.).

(2) Position the underbody discharge line to the

vehicle.

(3) Install the brackets and screws that secure the

underbody discharge line to the underneath of the

vehicle. Tighten the screws to 8 N´m (70 in. lbs.).

(4) Engage the fuel lines to the retaining clips

located near the transmission.

(5) Install the rear transmission crossmember

(Refer to 13 - FRAME & BUMPERS/FRAME/REAR

CROSSMEMBER-TRANSMISSION - INSTALLA-

TION).

(6) Remove the plugs or tape from the discharge

line fittings.

(7) Lubricate new rubber O-ring seals with clean

refrigerant oil and install them onto the discharge

line fittings.

(8) Connect the underbody discharge line spring-

lock coupler to the compressor section of the dis-

charge line and install the secondary retaining clip

(if equipped) (Refer to 24 - HEATING & AIR CONDI-

TIONING/PLUMBING/REFRIGERANT LINE COU-

PLER - INSTALLATION).

Fig. 40 Underbody Suction Line - Front Section

1 - UNDERBODY SUCTION LINE-FRONT SECTION

2 - BOLT

3 - UNDERBODY SUCTION LINE-REAR SECTION

4 - SUCTION LINE-COMPRESSOR SECTION

5 - SCREW AND BRACKET (2)

Fig. 41 Underbody Suction Line - Rear Section

1 - REAR A/C DISCHARGE LINE

2 - UNDERBODY SUCTION LINE-REAR SECTION

3 - SCREW AND BRACKET (3)

4 - BOLT

5 - UNDERBODY SUCTION LINE-FRONT SECTION

24 - 102 PLUMBINGVA

Page 2141 of 2305

CABIN HEATER

TABLE OF CONTENTS

page page

CABIN HEATER

DESCRIPTION........................104

OPERATION..........................104

DIAGNOSIS AND TESTING

SUPPLEMENTAL CABIN HEATER........104

EXHAUST TUBE

REMOVAL............................105

INSTALLATION........................106

FUEL DOSING PUMP

DESCRIPTION........................106

OPERATION..........................106

REMOVAL............................106

INSTALLATION........................107

FUEL LINE

STANDARD PROCEDURE

CLEANING.........................107REMOVAL............................108

INSTALLATION........................109

HEATER UNIT

REMOVAL

HEATER UNIT.......................110

WIRE HARNESS.....................110

INSTALLATION

HEATER UNIT.......................110

WIRE HARNESS.....................111

INLET HOSE

REMOVAL............................111

INSTALLATION........................112

CABIN HEATER

DESCRIPTION

Vehicles equipped with the diesel engine are also

equipped with a supplemental cabin heater. This

cabin heater is mounted under the vehicle and oper-

ates similar to an oil fired furnace. The heater burns

small amounts of fuel to provide additional heat to

the coolant. Coolant is routed from the engine, to the

supplemental cabin heater and then to the front

heater core. This provides additional heat to the pas-

senger compartment. The supplemental cabin heater

system is interfaced to the vehicles on-board com-

puter systems and DRBIIItdiagnostics.

The supplemental cabin heater has an electronic

control module that monitors the heat output of the

heater. The cabin heater operates at full load (5 kW),

half load or idle mode (no additional heat) depending

on engine coolant temperature.

OPERATION

The supplemental cabin heater is activated by

using the temperature control on the A/C-heater con-

trol. The supplemental cabin heater is activated

when the temperature control is set to/or above the

upper set point. The supplemental cabin heater can

operate in a full or partial load range as well as an

idle mode, all dependent on the engine coolant tem-

perature. The heater unit will also turn off if the

temperature control is set to less than the lower set

point. The supplemental cabin heater can take up to

three minutes to completely shut down when eitherthe heater temperature is set below the lower set

point or the vehicle ignition is turned off.

The supplemental cabin heater only operates when

the engine is running, the mileage exceeds 8 kilome-

ter (5 mph) and the fuel tank volume exceeds 1/8 of a

tank. The heater should start if the coolant temper-

ature is below 40É C (104É F).

NOTE: Do not apply a strong vacuum directly on

the supplemental cabin heater exhaust line. Place

the vacuum within 75 mm (3 inches) of the exhaust

port. Too strong of a vacuum can prevent the heater

from starting. The heater control module monitors

the blower speed and combustion during its start-

up.

DIAGNOSIS AND TESTING

SUPPLEMENTAL CABIN HEATER

Refer to the Symptoms Diagnosis table for basic

checks of the diesel fueled supplemental cabin heater.

24 - 104 CABIN HEATERVA

Page 2142 of 2305

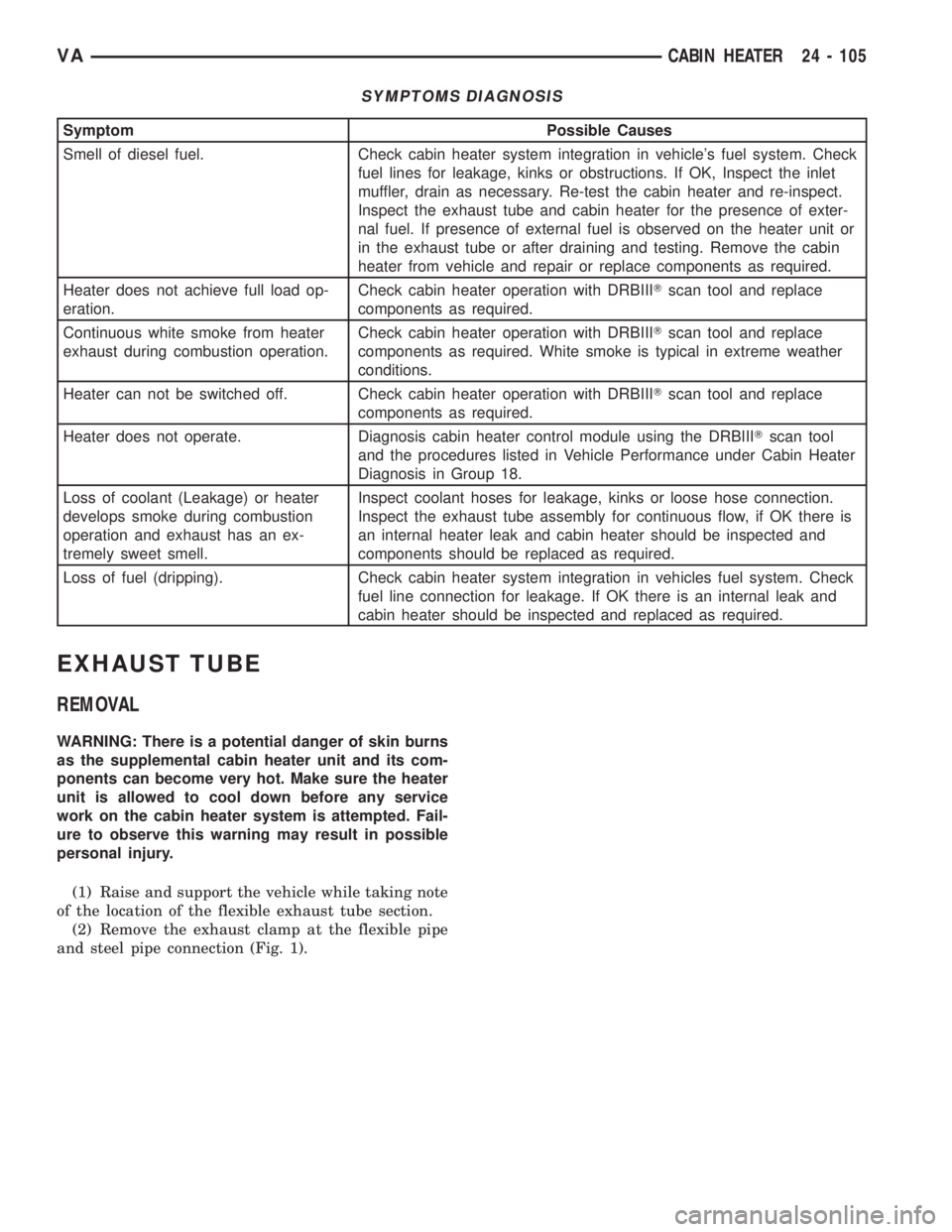

SYMPTOMS DIAGNOSIS

Symptom Possible Causes

Smell of diesel fuel. Check cabin heater system integration in vehicle's fuel system. Check

fuel lines for leakage, kinks or obstructions. If OK, Inspect the inlet

muffler, drain as necessary. Re-test the cabin heater and re-inspect.

Inspect the exhaust tube and cabin heater for the presence of exter-

nal fuel. If presence of external fuel is observed on the heater unit or

in the exhaust tube or after draining and testing. Remove the cabin

heater from vehicle and repair or replace components as required.

Heater does not achieve full load op-

eration.Check cabin heater operation with DRBIIITscan tool and replace

components as required.

Continuous white smoke from heater

exhaust during combustion operation.Check cabin heater operation with DRBIIITscan tool and replace

components as required. White smoke is typical in extreme weather

conditions.

Heater can not be switched off. Check cabin heater operation with DRBIIITscan tool and replace

components as required.

Heater does not operate. Diagnosis cabin heater control module using the DRBIIITscan tool

and the procedures listed in Vehicle Performance under Cabin Heater

Diagnosis in Group 18.

Loss of coolant (Leakage) or heater

develops smoke during combustion

operation and exhaust has an ex-

tremely sweet smell.Inspect coolant hoses for leakage, kinks or loose hose connection.

Inspect the exhaust tube assembly for continuous flow, if OK there is

an internal heater leak and cabin heater should be inspected and

components should be replaced as required.

Loss of fuel (dripping). Check cabin heater system integration in vehicles fuel system. Check

fuel line connection for leakage. If OK there is an internal leak and

cabin heater should be inspected and replaced as required.

EXHAUST TUBE

REMOVAL

WARNING: There is a potential danger of skin burns

as the supplemental cabin heater unit and its com-

ponents can become very hot. Make sure the heater

unit is allowed to cool down before any service

work on the cabin heater system is attempted. Fail-

ure to observe this warning may result in possible

personal injury.

(1) Raise and support the vehicle while taking note

of the location of the flexible exhaust tube section.

(2) Remove the exhaust clamp at the flexible pipe

and steel pipe connection (Fig. 1).

VACABIN HEATER 24 - 105