cooling MERCEDES-BENZ SPRINTER 2006 Service Manual

[x] Cancel search | Manufacturer: MERCEDES-BENZ, Model Year: 2006, Model line: SPRINTER, Model: MERCEDES-BENZ SPRINTER 2006Pages: 2305, PDF Size: 48.12 MB

Page 106 of 2305

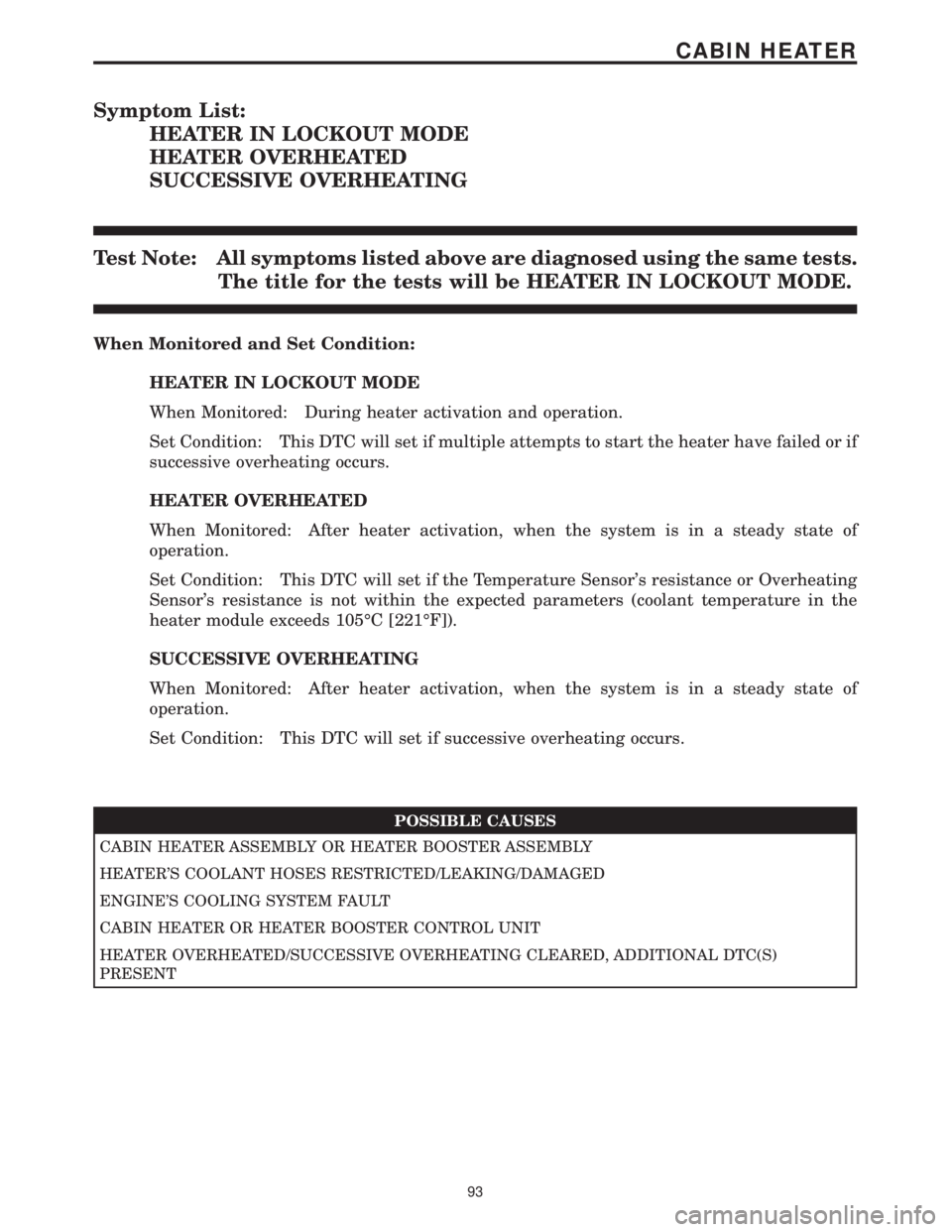

Symptom List:

HEATER IN LOCKOUT MODE

HEATER OVERHEATED

SUCCESSIVE OVERHEATING

Test Note: All symptoms listed above are diagnosed using the same tests.

The title for the tests will be HEATER IN LOCKOUT MODE.

When Monitored and Set Condition:

HEATER IN LOCKOUT MODE

When Monitored: During heater activation and operation.

Set Condition: This DTC will set if multiple attempts to start the heater have failed or if

successive overheating occurs.

HEATER OVERHEATED

When Monitored: After heater activation, when the system is in a steady state of

operation.

Set Condition: This DTC will set if the Temperature Sensor's resistance or Overheating

Sensor's resistance is not within the expected parameters (coolant temperature in the

heater module exceeds 105ÉC [221ÉF]).

SUCCESSIVE OVERHEATING

When Monitored: After heater activation, when the system is in a steady state of

operation.

Set Condition: This DTC will set if successive overheating occurs.

POSSIBLE CAUSES

CABIN HEATER ASSEMBLY OR HEATER BOOSTER ASSEMBLY

HEATER'S COOLANT HOSES RESTRICTED/LEAKING/DAMAGED

ENGINE'S COOLING SYSTEM FAULT

CABIN HEATER OR HEATER BOOSTER CONTROL UNIT

HEATER OVERHEATED/SUCCESSIVE OVERHEATING CLEARED, ADDITIONAL DTC(S)

PRESENT

93

CABIN HEATER

Page 107 of 2305

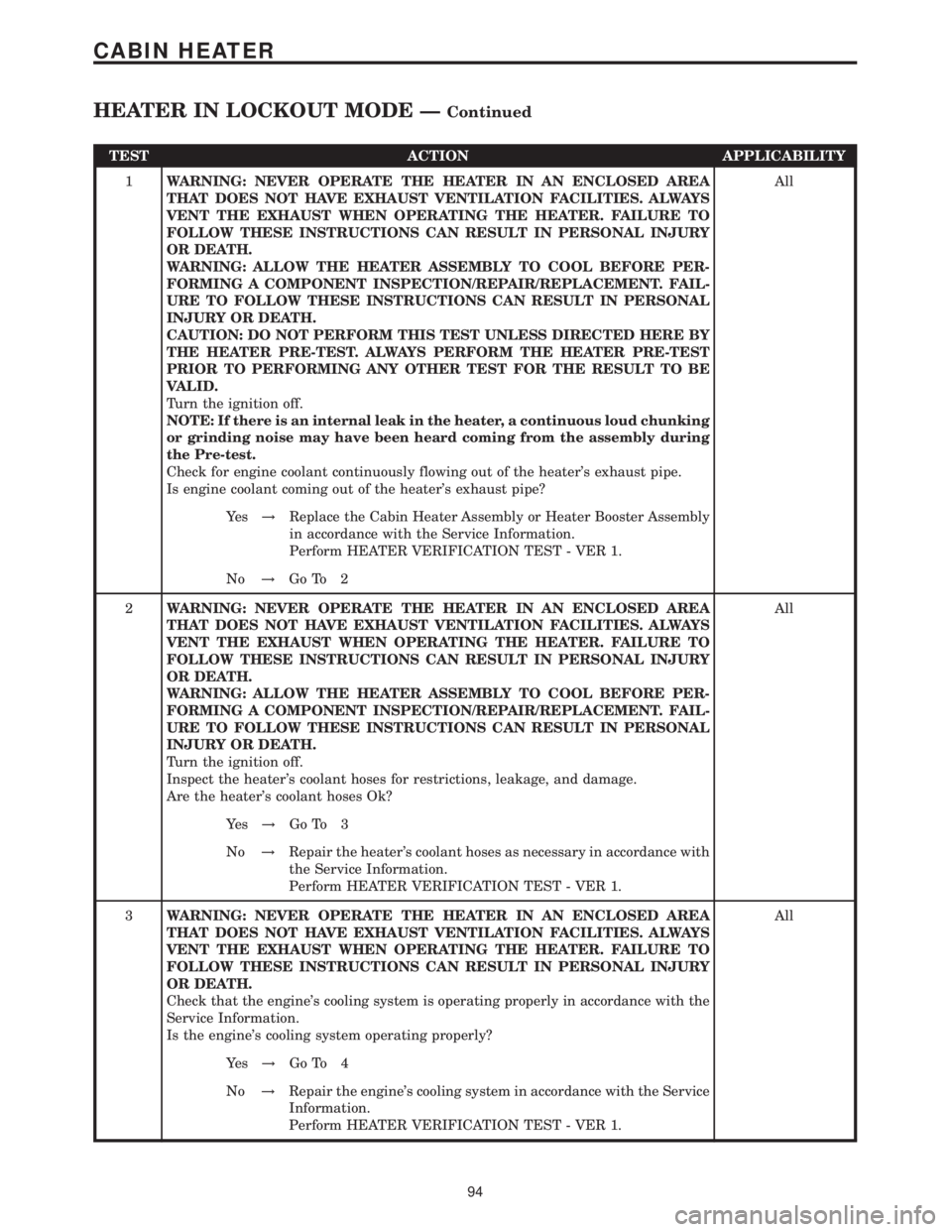

TEST ACTION APPLICABILITY

1WARNING: NEVER OPERATE THE HEATER IN AN ENCLOSED AREA

THAT DOES NOT HAVE EXHAUST VENTILATION FACILITIES. ALWAYS

VENT THE EXHAUST WHEN OPERATING THE HEATER. FAILURE TO

FOLLOW THESE INSTRUCTIONS CAN RESULT IN PERSONAL INJURY

OR DEATH.

WARNING: ALLOW THE HEATER ASSEMBLY TO COOL BEFORE PER-

FORMING A COMPONENT INSPECTION/REPAIR/REPLACEMENT. FAIL-

URE TO FOLLOW THESE INSTRUCTIONS CAN RESULT IN PERSONAL

INJURY OR DEATH.

CAUTION: DO NOT PERFORM THIS TEST UNLESS DIRECTED HERE BY

THE HEATER PRE-TEST. ALWAYS PERFORM THE HEATER PRE-TEST

PRIOR TO PERFORMING ANY OTHER TEST FOR THE RESULT TO BE

VALID.

Turn the ignition off.

NOTE: If there is an internal leak in the heater, a continuous loud chunking

or grinding noise may have been heard coming from the assembly during

the Pre-test.

Check for engine coolant continuously flowing out of the heater's exhaust pipe.

Is engine coolant coming out of the heater's exhaust pipe?All

Ye s!Replace the Cabin Heater Assembly or Heater Booster Assembly

in accordance with the Service Information.

Perform HEATER VERIFICATION TEST - VER 1.

No!Go To 2

2WARNING: NEVER OPERATE THE HEATER IN AN ENCLOSED AREA

THAT DOES NOT HAVE EXHAUST VENTILATION FACILITIES. ALWAYS

VENT THE EXHAUST WHEN OPERATING THE HEATER. FAILURE TO

FOLLOW THESE INSTRUCTIONS CAN RESULT IN PERSONAL INJURY

OR DEATH.

WARNING: ALLOW THE HEATER ASSEMBLY TO COOL BEFORE PER-

FORMING A COMPONENT INSPECTION/REPAIR/REPLACEMENT. FAIL-

URE TO FOLLOW THESE INSTRUCTIONS CAN RESULT IN PERSONAL

INJURY OR DEATH.

Turn the ignition off.

Inspect the heater's coolant hoses for restrictions, leakage, and damage.

Are the heater's coolant hoses Ok?All

Ye s!Go To 3

No!Repair the heater's coolant hoses as necessary in accordance with

the Service Information.

Perform HEATER VERIFICATION TEST - VER 1.

3WARNING: NEVER OPERATE THE HEATER IN AN ENCLOSED AREA

THAT DOES NOT HAVE EXHAUST VENTILATION FACILITIES. ALWAYS

VENT THE EXHAUST WHEN OPERATING THE HEATER. FAILURE TO

FOLLOW THESE INSTRUCTIONS CAN RESULT IN PERSONAL INJURY

OR DEATH.

Check that the engine's cooling system is operating properly in accordance with the

Service Information.

Is the engine's cooling system operating properly?All

Ye s!Go To 4

No!Repair the engine's cooling system in accordance with the Service

Information.

Perform HEATER VERIFICATION TEST - VER 1.

94

CABIN HEATER

HEATER IN LOCKOUT MODE ÐContinued

Page 108 of 2305

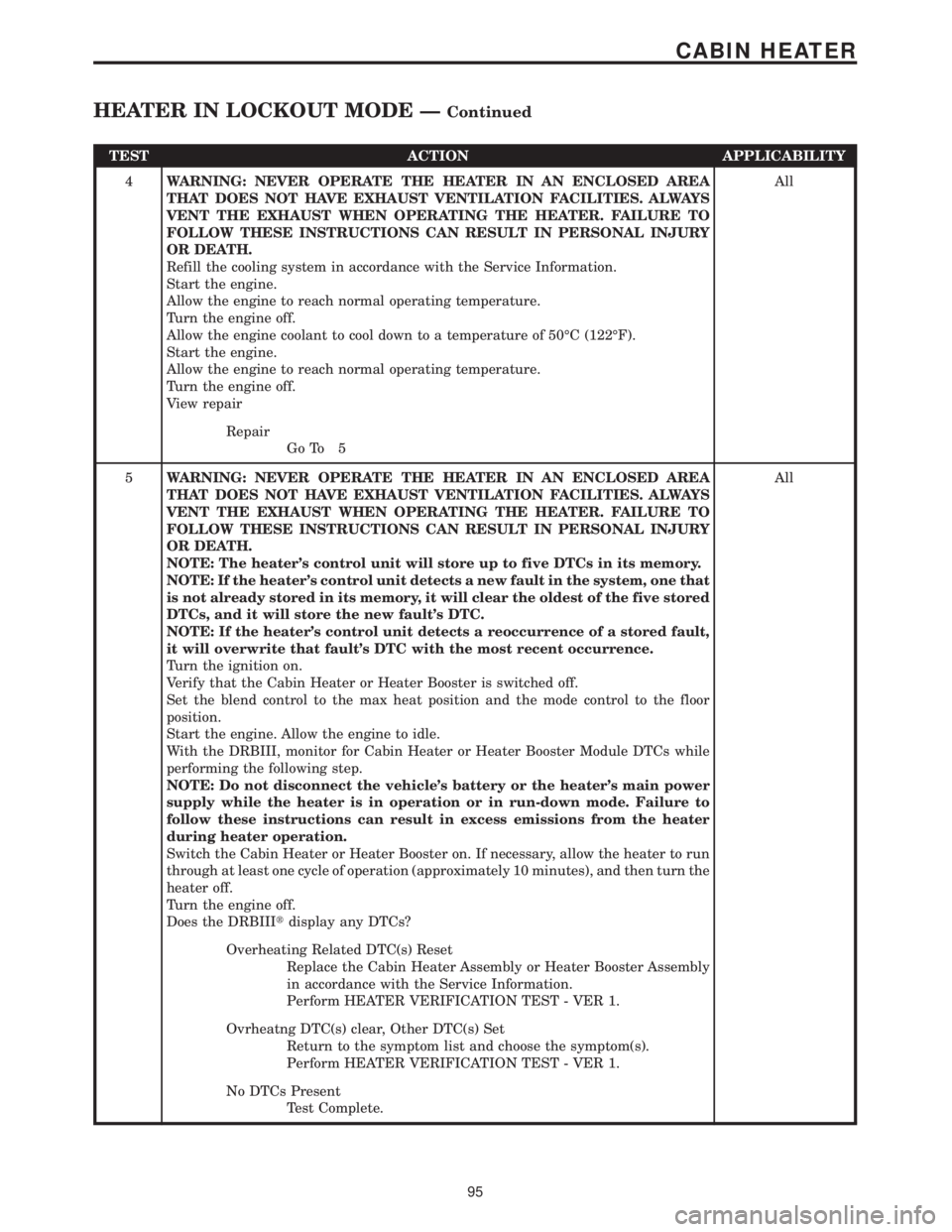

TEST ACTION APPLICABILITY

4WARNING: NEVER OPERATE THE HEATER IN AN ENCLOSED AREA

THAT DOES NOT HAVE EXHAUST VENTILATION FACILITIES. ALWAYS

VENT THE EXHAUST WHEN OPERATING THE HEATER. FAILURE TO

FOLLOW THESE INSTRUCTIONS CAN RESULT IN PERSONAL INJURY

OR DEATH.

Refill the cooling system in accordance with the Service Information.

Start the engine.

Allow the engine to reach normal operating temperature.

Turn the engine off.

Allow the engine coolant to cool down to a temperature of 50ÉC (122ÉF).

Start the engine.

Allow the engine to reach normal operating temperature.

Turn the engine off.

View repairAll

Repair

Go To 5

5WARNING: NEVER OPERATE THE HEATER IN AN ENCLOSED AREA

THAT DOES NOT HAVE EXHAUST VENTILATION FACILITIES. ALWAYS

VENT THE EXHAUST WHEN OPERATING THE HEATER. FAILURE TO

FOLLOW THESE INSTRUCTIONS CAN RESULT IN PERSONAL INJURY

OR DEATH.

NOTE: The heater's control unit will store up to five DTCs in its memory.

NOTE: If the heater's control unit detects a new fault in the system, one that

is not already stored in its memory, it will clear the oldest of the five stored

DTCs, and it will store the new fault's DTC.

NOTE: If the heater's control unit detects a reoccurrence of a stored fault,

it will overwrite that fault's DTC with the most recent occurrence.

Turn the ignition on.

Verify that the Cabin Heater or Heater Booster is switched off.

Set the blend control to the max heat position and the mode control to the floor

position.

Start the engine. Allow the engine to idle.

With the DRBIII, monitor for Cabin Heater or Heater Booster Module DTCs while

performing the following step.

NOTE: Do not disconnect the vehicle's battery or the heater's main power

supply while the heater is in operation or in run-down mode. Failure to

follow these instructions can result in excess emissions from the heater

during heater operation.

Switch the Cabin Heater or Heater Booster on. If necessary, allow the heater to run

through at least one cycle of operation (approximately 10 minutes), and then turn the

heater off.

Turn the engine off.

Does the DRBIIItdisplay any DTCs?All

Overheating Related DTC(s) Reset

Replace the Cabin Heater Assembly or Heater Booster Assembly

in accordance with the Service Information.

Perform HEATER VERIFICATION TEST - VER 1.

Ovrheatng DTC(s) clear, Other DTC(s) Set

Return to the symptom list and choose the symptom(s).

Perform HEATER VERIFICATION TEST - VER 1.

No DTCs Present

Test Complete.

95

CABIN HEATER

HEATER IN LOCKOUT MODE ÐContinued

Page 259 of 2305

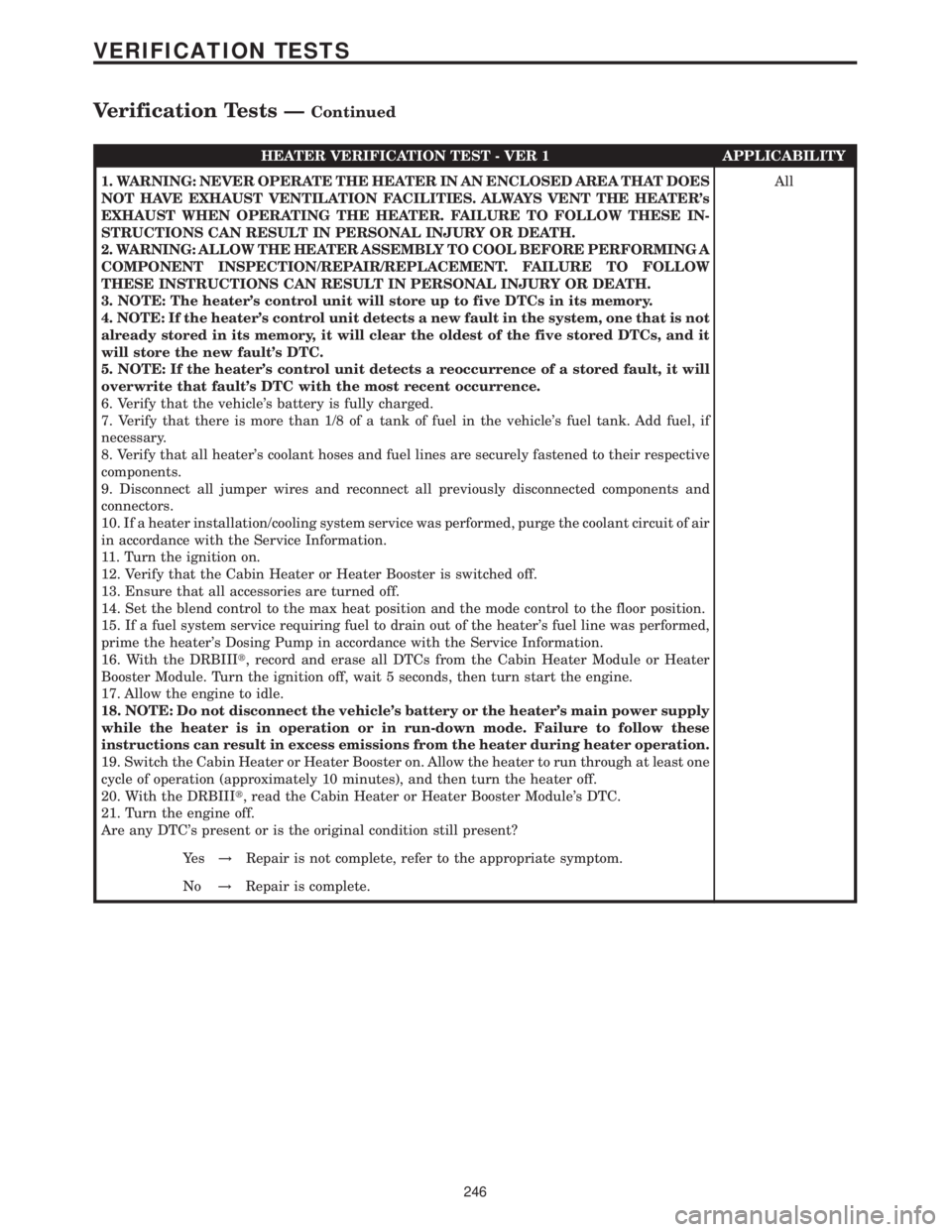

HEATER VERIFICATION TEST - VER 1 APPLICABILITY

1. WARNING: NEVER OPERATE THE HEATER IN AN ENCLOSED AREA THAT DOES

NOT HAVE EXHAUST VENTILATION FACILITIES. ALWAYS VENT THE HEATER's

EXHAUST WHEN OPERATING THE HEATER. FAILURE TO FOLLOW THESE IN-

STRUCTIONS CAN RESULT IN PERSONAL INJURY OR DEATH.

2. WARNING: ALLOW THE HEATER ASSEMBLY TO COOL BEFORE PERFORMING A

COMPONENT INSPECTION/REPAIR/REPLACEMENT. FAILURE TO FOLLOW

THESE INSTRUCTIONS CAN RESULT IN PERSONAL INJURY OR DEATH.

3. NOTE: The heater's control unit will store up to five DTCs in its memory.

4. NOTE: If the heater's control unit detects a new fault in the system, one that is not

already stored in its memory, it will clear the oldest of the five stored DTCs, and it

will store the new fault's DTC.

5. NOTE: If the heater's control unit detects a reoccurrence of a stored fault, it will

overwrite that fault's DTC with the most recent occurrence.

6. Verify that the vehicle's battery is fully charged.

7. Verify that there is more than 1/8 of a tank of fuel in the vehicle's fuel tank. Add fuel, if

necessary.

8. Verify that all heater's coolant hoses and fuel lines are securely fastened to their respective

components.

9. Disconnect all jumper wires and reconnect all previously disconnected components and

connectors.

10. If a heater installation/cooling system service was performed, purge the coolant circuit of air

in accordance with the Service Information.

11. Turn the ignition on.

12. Verify that the Cabin Heater or Heater Booster is switched off.

13. Ensure that all accessories are turned off.

14. Set the blend control to the max heat position and the mode control to the floor position.

15. If a fuel system service requiring fuel to drain out of the heater's fuel line was performed,

prime the heater's Dosing Pump in accordance with the Service Information.

16. With the DRBIIIt, record and erase all DTCs from the Cabin Heater Module or Heater

Booster Module. Turn the ignition off, wait 5 seconds, then turn start the engine.

17. Allow the engine to idle.

18. NOTE: Do not disconnect the vehicle's battery or the heater's main power supply

while the heater is in operation or in run-down mode. Failure to follow these

instructions can result in excess emissions from the heater during heater operation.

19. Switch the Cabin Heater or Heater Booster on. Allow the heater to run through at least one

cycle of operation (approximately 10 minutes), and then turn the heater off.

20. With the DRBIIIt, read the Cabin Heater or Heater Booster Module's DTC.

21. Turn the engine off.

Are any DTC's present or is the original condition still present?All

Ye s!Repair is not complete, refer to the appropriate symptom.

No!Repair is complete.

246

VERIFICATION TESTS

Verification Tests ÐContinued

Page 425 of 2305

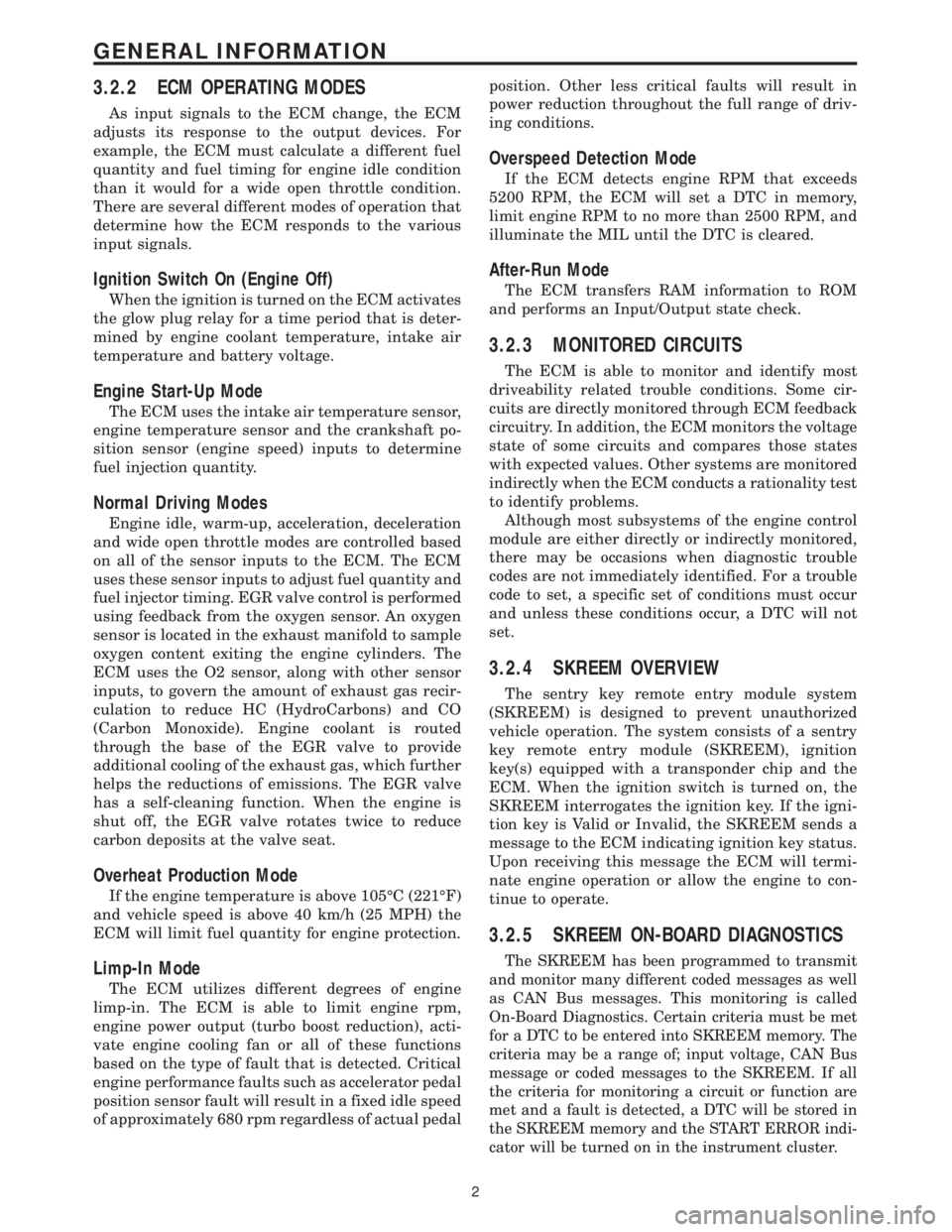

3.2.2 ECM OPERATING MODES

As input signals to the ECM change, the ECM

adjusts its response to the output devices. For

example, the ECM must calculate a different fuel

quantity and fuel timing for engine idle condition

than it would for a wide open throttle condition.

There are several different modes of operation that

determine how the ECM responds to the various

input signals.

Ignition Switch On (Engine Off)

When the ignition is turned on the ECM activates

the glow plug relay for a time period that is deter-

mined by engine coolant temperature, intake air

temperature and battery voltage.

Engine Start-Up Mode

The ECM uses the intake air temperature sensor,

engine temperature sensor and the crankshaft po-

sition sensor (engine speed) inputs to determine

fuel injection quantity.

Normal Driving Modes

Engine idle, warm-up, acceleration, deceleration

and wide open throttle modes are controlled based

on all of the sensor inputs to the ECM. The ECM

uses these sensor inputs to adjust fuel quantity and

fuel injector timing. EGR valve control is performed

using feedback from the oxygen sensor. An oxygen

sensor is located in the exhaust manifold to sample

oxygen content exiting the engine cylinders. The

ECM uses the O2 sensor, along with other sensor

inputs, to govern the amount of exhaust gas recir-

culation to reduce HC (HydroCarbons) and CO

(Carbon Monoxide). Engine coolant is routed

through the base of the EGR valve to provide

additional cooling of the exhaust gas, which further

helps the reductions of emissions. The EGR valve

has a self-cleaning function. When the engine is

shut off, the EGR valve rotates twice to reduce

carbon deposits at the valve seat.

Overheat Production Mode

If the engine temperature is above 105ÉC (221ÉF)

and vehicle speed is above 40 km/h (25 MPH) the

ECM will limit fuel quantity for engine protection.

Limp-In Mode

The ECM utilizes different degrees of engine

limp-in. The ECM is able to limit engine rpm,

engine power output (turbo boost reduction), acti-

vate engine cooling fan or all of these functions

based on the type of fault that is detected. Critical

engine performance faults such as accelerator pedal

position sensor fault will result in a fixed idle speed

of approximately 680 rpm regardless of actual pedalposition. Other less critical faults will result in

power reduction throughout the full range of driv-

ing conditions.

Overspeed Detection Mode

If the ECM detects engine RPM that exceeds

5200 RPM, the ECM will set a DTC in memory,

limit engine RPM to no more than 2500 RPM, and

illuminate the MIL until the DTC is cleared.

After-Run Mode

The ECM transfers RAM information to ROM

and performs an Input/Output state check.

3.2.3 MONITORED CIRCUITS

The ECM is able to monitor and identify most

driveability related trouble conditions. Some cir-

cuits are directly monitored through ECM feedback

circuitry. In addition, the ECM monitors the voltage

state of some circuits and compares those states

with expected values. Other systems are monitored

indirectly when the ECM conducts a rationality test

to identify problems.

Although most subsystems of the engine control

module are either directly or indirectly monitored,

there may be occasions when diagnostic trouble

codes are not immediately identified. For a trouble

code to set, a specific set of conditions must occur

and unless these conditions occur, a DTC will not

set.

3.2.4 SKREEM OVERVIEW

The sentry key remote entry module system

(SKREEM) is designed to prevent unauthorized

vehicle operation. The system consists of a sentry

key remote entry module (SKREEM), ignition

key(s) equipped with a transponder chip and the

ECM. When the ignition switch is turned on, the

SKREEM interrogates the ignition key. If the igni-

tion key is Valid or Invalid, the SKREEM sends a

message to the ECM indicating ignition key status.

Upon receiving this message the ECM will termi-

nate engine operation or allow the engine to con-

tinue to operate.

3.2.5 SKREEM ON-BOARD DIAGNOSTICS

The SKREEM has been programmed to transmit

and monitor many different coded messages as well

as CAN Bus messages. This monitoring is called

On-Board Diagnostics. Certain criteria must be met

for a DTC to be entered into SKREEM memory. The

criteria may be a range of; input voltage, CAN Bus

message or coded messages to the SKREEM. If all

the criteria for monitoring a circuit or function are

met and a fault is detected, a DTC will be stored in

the SKREEM memory and the START ERROR indi-

cator will be turned on in the instrument cluster.

2

GENERAL INFORMATION

Page 463 of 2305

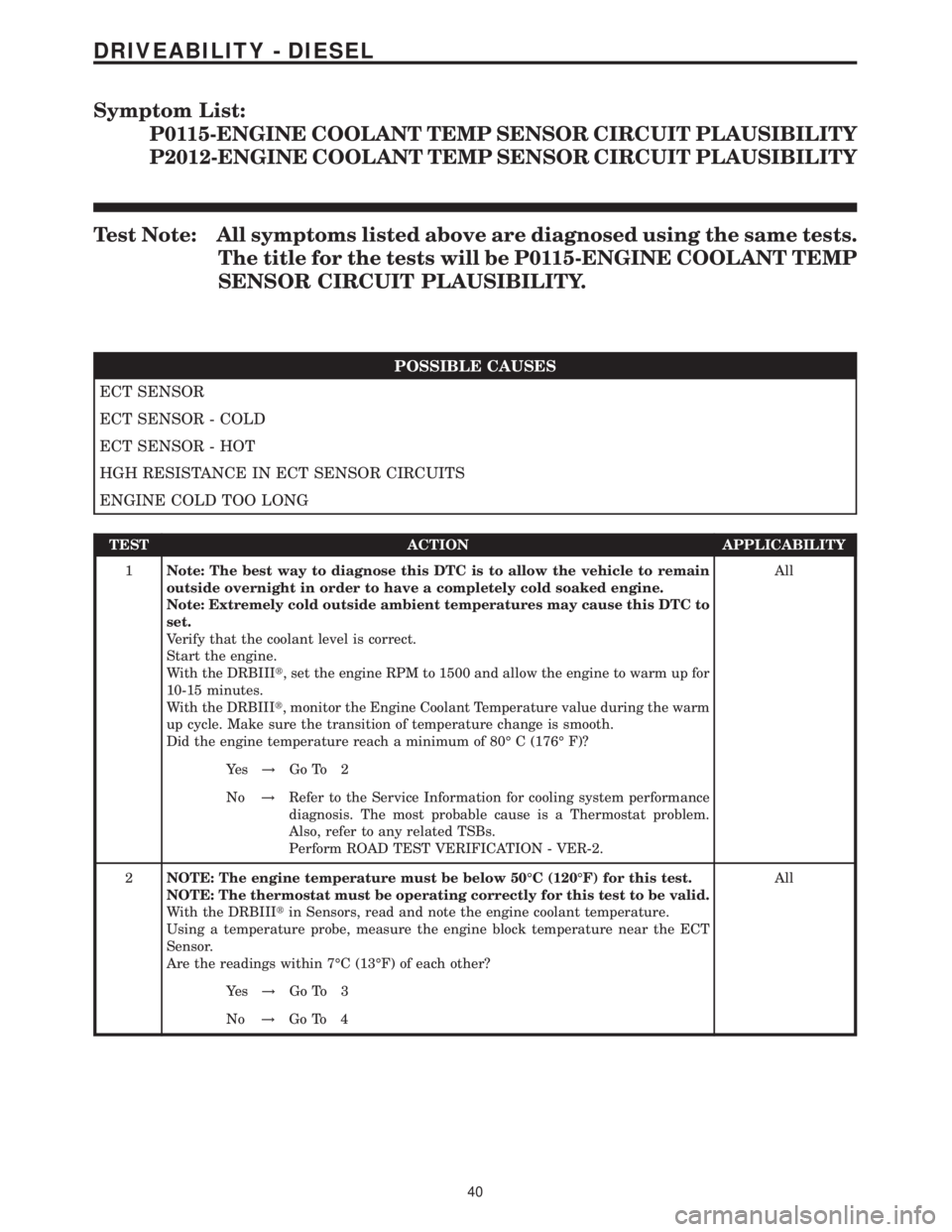

Symptom List:

P0115-ENGINE COOLANT TEMP SENSOR CIRCUIT PLAUSIBILITY

P2012-ENGINE COOLANT TEMP SENSOR CIRCUIT PLAUSIBILITY

Test Note: All symptoms listed above are diagnosed using the same tests.

The title for the tests will be P0115-ENGINE COOLANT TEMP

SENSOR CIRCUIT PLAUSIBILITY.

POSSIBLE CAUSES

ECT SENSOR

ECT SENSOR - COLD

ECT SENSOR - HOT

HGH RESISTANCE IN ECT SENSOR CIRCUITS

ENGINE COLD TOO LONG

TEST ACTION APPLICABILITY

1Note: The best way to diagnose this DTC is to allow the vehicle to remain

outside overnight in order to have a completely cold soaked engine.

Note: Extremely cold outside ambient temperatures may cause this DTC to

set.

Verify that the coolant level is correct.

Start the engine.

With the DRBIIIt, set the engine RPM to 1500 and allow the engine to warm up for

10-15 minutes.

With the DRBIIIt, monitor the Engine Coolant Temperature value during the warm

up cycle. Make sure the transition of temperature change is smooth.

Did the engine temperature reach a minimum of 80É C (176É F)?All

Ye s!Go To 2

No!Refer to the Service Information for cooling system performance

diagnosis. The most probable cause is a Thermostat problem.

Also, refer to any related TSBs.

Perform ROAD TEST VERIFICATION - VER-2.

2NOTE: The engine temperature must be below 50ÉC (120ÉF) for this test.

NOTE: The thermostat must be operating correctly for this test to be valid.

With the DRBIIItin Sensors, read and note the engine coolant temperature.

Using a temperature probe, measure the engine block temperature near the ECT

Sensor.

Are the readings within 7ÉC (13ÉF) of each other?All

Ye s!Go To 3

No!Go To 4

40

DRIVEABILITY - DIESEL

Page 465 of 2305

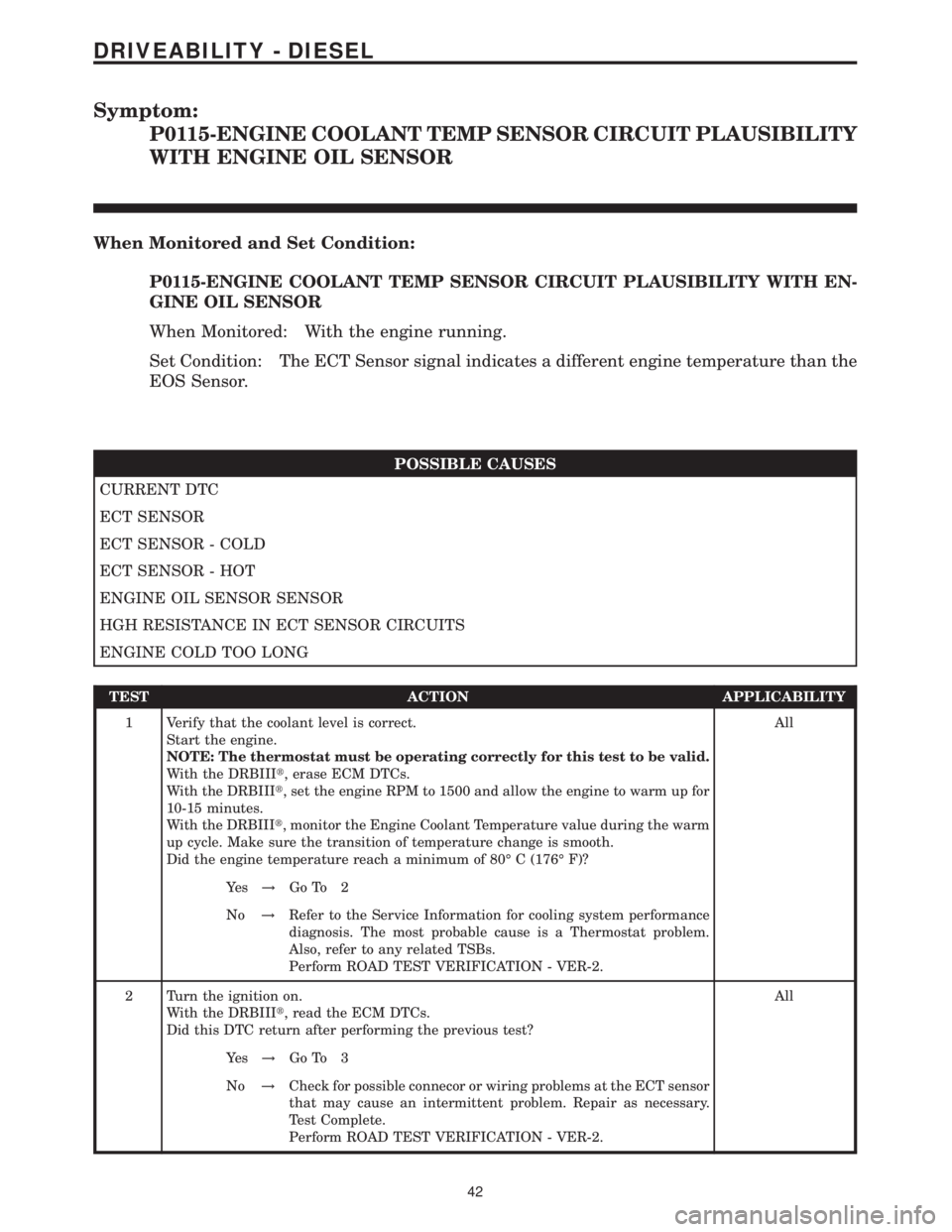

Symptom:

P0115-ENGINE COOLANT TEMP SENSOR CIRCUIT PLAUSIBILITY

WITH ENGINE OIL SENSOR

When Monitored and Set Condition:

P0115-ENGINE COOLANT TEMP SENSOR CIRCUIT PLAUSIBILITY WITH EN-

GINE OIL SENSOR

When Monitored: With the engine running.

Set Condition: The ECT Sensor signal indicates a different engine temperature than the

EOS Sensor.

POSSIBLE CAUSES

CURRENT DTC

ECT SENSOR

ECT SENSOR - COLD

ECT SENSOR - HOT

ENGINE OIL SENSOR SENSOR

HGH RESISTANCE IN ECT SENSOR CIRCUITS

ENGINE COLD TOO LONG

TEST ACTION APPLICABILITY

1 Verify that the coolant level is correct.

Start the engine.

NOTE: The thermostat must be operating correctly for this test to be valid.

With the DRBIIIt, erase ECM DTCs.

With the DRBIIIt, set the engine RPM to 1500 and allow the engine to warm up for

10-15 minutes.

With the DRBIIIt, monitor the Engine Coolant Temperature value during the warm

up cycle. Make sure the transition of temperature change is smooth.

Did the engine temperature reach a minimum of 80É C (176É F)?All

Ye s!Go To 2

No!Refer to the Service Information for cooling system performance

diagnosis. The most probable cause is a Thermostat problem.

Also, refer to any related TSBs.

Perform ROAD TEST VERIFICATION - VER-2.

2 Turn the ignition on.

With the DRBIIIt, read the ECM DTCs.

Did this DTC return after performing the previous test?All

Ye s!Go To 3

No!Check for possible connecor or wiring problems at the ECT sensor

that may cause an intermittent problem. Repair as necessary.

Test Complete.

Perform ROAD TEST VERIFICATION - VER-2.

42

DRIVEABILITY - DIESEL

Page 704 of 2305

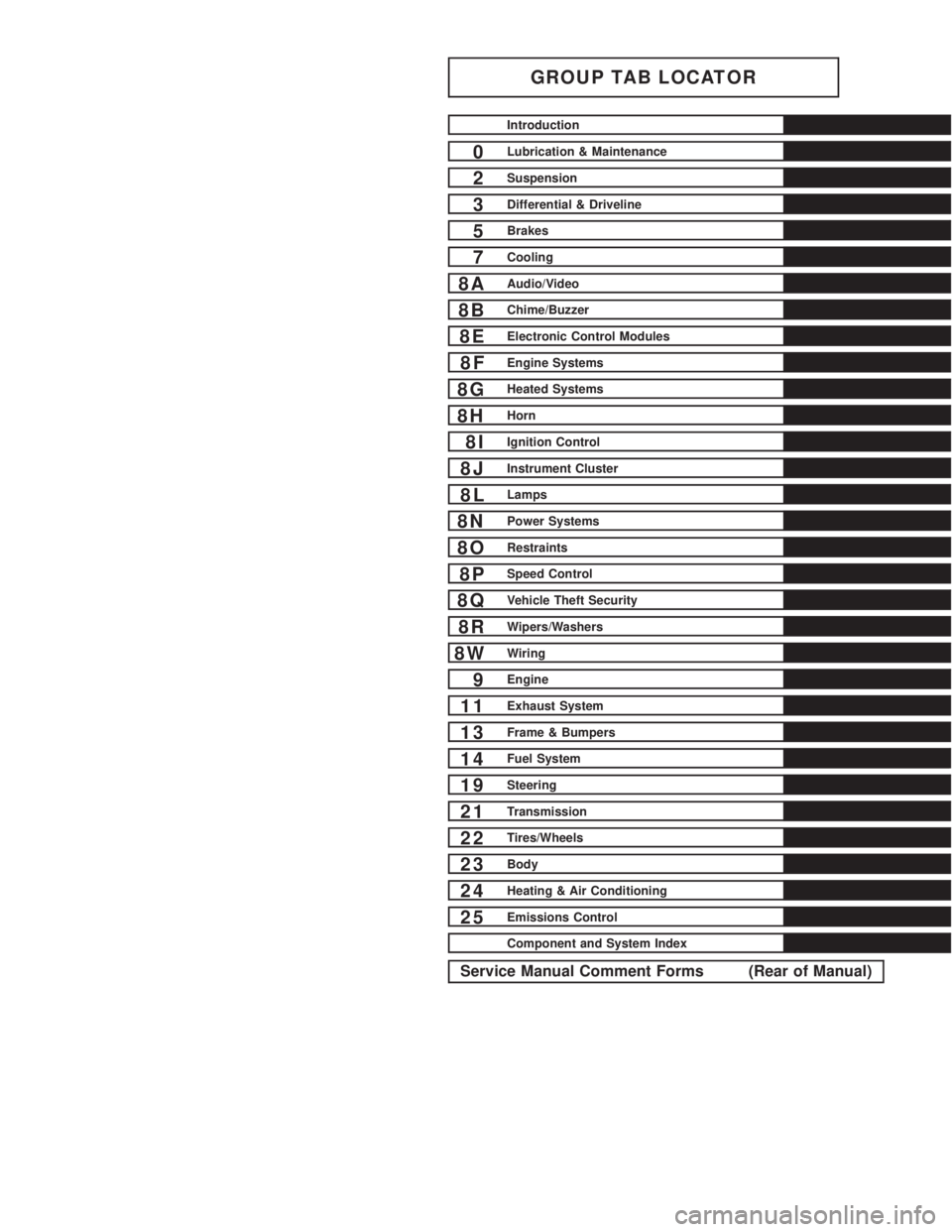

GROUP TAB LOCATOR

Introduction

0Lubrication & Maintenance

2Suspension

3Differential & Driveline

5Brakes

7Cooling

8AAudio/Video

8BChime/Buzzer

8EElectronic Control Modules

8FEngine Systems

8GHeated Systems

8HHorn

8IIgnition Control

8JInstrument Cluster

8LLamps

8NPower Systems

8ORestraints

8PSpeed Control

8QVehicle Theft Security

8RWipers/Washers

8WWiring

9Engine

11Exhaust System

13Frame & Bumpers

14Fuel System

19Steering

21Transmission

22Tires/Wheels

23Body

24Heating & Air Conditioning

25Emissions Control

Component and System Index

Service Manual Comment Forms (Rear of Manual)

Page 717 of 2305

AXLE FLUID

Use oils approved to MB 235.0 or 235.6, such as

Shell Spirax MB90, Caltex Hypoid LD, or MOPARt

part number 4874469, or equivalent. An API GL-5/

MIL-2105-E SAE 90 Hypoid Gear Oil may be substi-

tuted. Reduced axle durability may result if an

unapproved product is used.

BRAKE FLUID

Use brake fluid approved to MB 331.0, such as

Intac B026D, MOPARtBrake & Clutch Fluid, part

number 04549625AC, or equivalent. If the approved

product is not available, use a DOT 4 brake fluid:

minimum dry boiling point (ERBP) 500ÉF, minimum

wet boiling point (WERBP) 356ÉF, maximum viscos-

ity 1500 mm

2/s, conforming to FMVSS 116 and ISO

4925.

HOAT COOLANT

WARNING: ANTIFREEZE IS AN ETHYLENE-GLYCOL

BASE COOLANT AND IS HARMFUL IF SWAL-

LOWED OR INHALED. IF SWALLOWED, DRINK

TWO GLASSES OF WATER AND INDUCE VOMIT-

ING. IF INHALED, MOVE TO FRESH AIR AREA.

SEEK MEDICAL ATTENTION IMMEDIATELY. DO NOT

STORE IN OPEN OR UNMARKED CONTAINERS.

WASH SKIN AND CLOTHING THOROUGHLY AFTER

COMING IN CONTACT WITH ETHYLENE-GLYCOL.

KEEP OUT OF REACH OF CHILDREN. DISPOSE OF

GLYCOL BASE COOLANT PROPERLY, CONTACT

YOUR DEALER OR GOVERNMENT AGENCY FOR

LOCATION OF COLLECTION CENTER IN YOUR

AREA. DO NOT OPEN A COOLING SYSTEM WHEN

THE ENGINE IS AT OPERATING TEMPERATURE OR

HOT UNDER PRESSURE, PERSONAL INJURY CAN

RESULT. AVOID RADIATOR COOLING FAN WHEN

ENGINE COMPARTMENT RELATED SERVICE IS

PERFORMED, PERSONAL INJURY CAN RESULT.

CAUTION: Use of Propylene-Glycol based coolants

is not recommended, as they provide less freeze

protection and less corrosion protection.

The cooling system is designed around the coolant.

The coolant must accept heat from engine metal, in

the cylinder head area near the exhaust valves and

engine block. Then coolant carries the heat to the

radiator where the tube/fin radiator can transfer the

heat to the air.

The use of aluminum cylinder blocks, cylinder

heads, and water pumps requires special corrosion

protection. Use coolant approved to MB 325.0, such

as EURO Peak Coolant/Anti-freeze (OLD WORLD

INDUSTRIES), Zerex G05 or G48 (The Valvoline

Company), Glysantin G05 (BASF AG), MOPARtpart

number 05066386AA, or an equivalent Extended LifeCoolant with the HOAT inhibitor system. This cool-

ant offers the best engine cooling without corrosion

when mixed with 50% anti-freeze and 50% distilled

water to obtain a freeze point of -37ÉC (-34ÉF). If it

loses color or becomes contaminated, drain, flush,

and replace with fresh properly mixed coolant solu-

tion.

CAUTION: This coolant may not be mixed with any

other type of antifreeze. Mixing of coolants other

than specified (non-HOAT), may result in engine

damage that may not be covered under the new

vehicle warranty, and decreased corrosion protec-

tion.

CAUTION: Do not use coolant additives that are

claimed to improve engine cooling.

COOLANT PERFORMANCE

The required ethylene-glycol (antifreeze) and water

mixture depends upon climate and vehicle operating

conditions. The coolant performance of various mix-

tures follows:

Pure Water-Water can absorb more heat than a

mixture of water and ethylene-glycol. This is for pur-

pose of heat transfer only. Water also freezes at a

higher temperature and allows corrosion.

100 percent Ethylene-Glycol-The corrosion

inhibiting additives in ethylene-glycol need the pres-

ence of water to dissolve. Without water, additives

form deposits in system. These act as insulation

causing temperature to rise. The increased tempera-

ture can result in engine detonation. In addition, 100

percent ethylene-glycol freezes at -22ÉC (-8ÉF).

50/50 Ethylene-Glycol and Water-Is the recom-

mended mixture, it provides protection against freez-

ing to -37ÉC (-34ÉF). The antifreeze concentration

must alwaysbe a minimum of 44 percent, year-

round in all climates. If percentage is lower, engine

parts may be eroded by cavitation. Maximum protec-

tion against freezing is provided with a 68 percent

antifreeze concentration, which prevents freezing

down to -67.7ÉC (-90ÉF). A higher percentage will

freeze at a warmer temperature. Also, a higher per-

centage of antifreeze can cause the engine to over-

heat because specific heat of antifreeze is lower than

that of water.

CAUTION: Richer antifreeze mixtures cannot be

measured with normal field equipment and can

cause problems associated with 100 percent ethyl-

ene-glycol.

0 - 2 LUBRICATION & MAINTENANCEVA

Page 724 of 2305

SCOPE OF WORK FOR MAINTENANCE SERVICE

Oil Service

²Engine: Oil change and filter replacement

Check fluid levels of the following system, refill as neces-

sary.

²If fluid is lost, trace and eliminate cause - as a

separate order.

²Power-assisted steering

Lubrication work:

²Trailer tow hitch (original equipment)

Maintenance

²ASSYST maintenance computer reset

Function check

²Signalling system, warning and indicator lamps

²Headlamps, exterior lighting

²Windshield wipers, windshield washer system

Check for leaks and damage

²Check for abrasion points and ensure that lines

are correctly routed!

²All lines and hoses, sensor cables

²Rubber boots on front axle drive shafts, rubber

boots on front axle suspension ball joints, shock

absorbers

²Check fluid levels for the following systems, cor-

rect as necessary

NOTE: Should there be a loss of fluid which cannot

be explained by regular use, trace and eliminate the

cause.

²Engine cooling system. Check corrosion inhibi-

tor/antifreeze, refill as necessary.

²Hydraulic brake system

²Battery

²Windshield washer system

Engine

²Fuel filter renewal - Every oil service

²Air cleaner with maintenance indicator:

²Check degree of contamination.

²Air cleaner filter element renewed as necessary.

Chassis and body

²Trailer coupling: Check operation, play and

retaining fixtures

²Secondary rubber springs: Visual check

²Tire pressures: Correct as necessary, including

spare tire

²Check thickness of brake pads

²Brake test

²Check condition of steering mechanism

²Heating/ventilation dust filter renewal

ADDITIONAL MAINTENANCE WORK

Automatic transmission once only at 80,000 miles / 128000

km

²Oil and filter change

During every second maintenance service

²Air cleaner without maintenance indicator:

²Air cleaner filter element renewal

²Check poly-V-belt for wear and signs of damage

During every fourth maintenance service

²Change rear axle fluid

ADDITIONAL MAINTENANCE WORK AFTER YEARS

Every 2 years

²Change brake fluid.

Every 3 years

²Air cleaner filter element renewal (note installa-

tion date)

Every 15 years or 100,000 miles

²Coolant renewal

²Note coolant composition

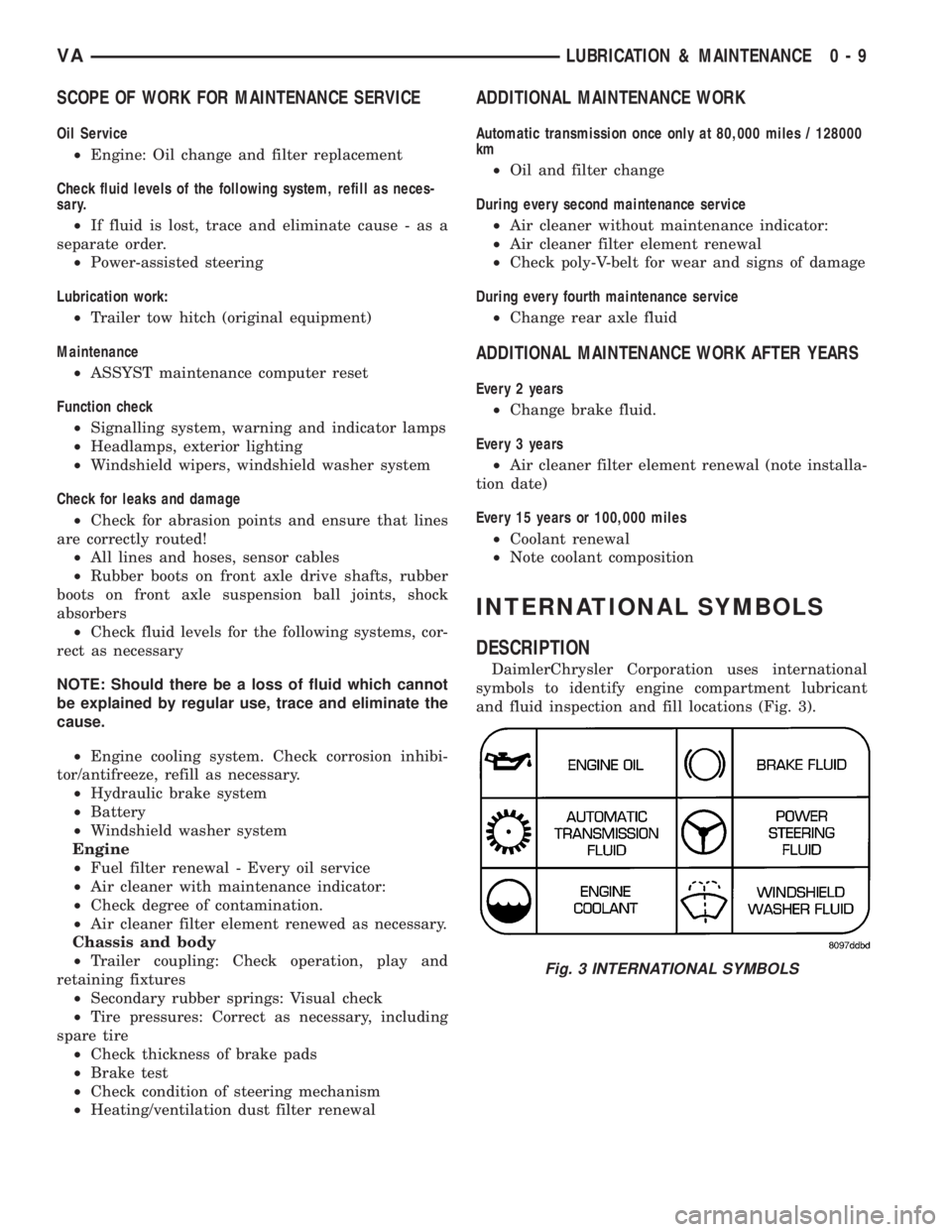

INTERNATIONAL SYMBOLS

DESCRIPTION

DaimlerChrysler Corporation uses international

symbols to identify engine compartment lubricant

and fluid inspection and fill locations (Fig. 3).

Fig. 3 INTERNATIONAL SYMBOLS

VALUBRICATION & MAINTENANCE 0 - 9