oil type MERCEDES-BENZ SPRINTER 2006 Owner's Guide

[x] Cancel search | Manufacturer: MERCEDES-BENZ, Model Year: 2006, Model line: SPRINTER, Model: MERCEDES-BENZ SPRINTER 2006Pages: 2305, PDF Size: 48.12 MB

Page 1950 of 2305

will remain stationary during the repair. Misalign-

ment can cause stress in the repair areas and can

result in future failure.

VISUAL INSPECTION

Composite materials can mask the severity of an

accident. Adhesive bond lines, interior structure of

the doors, and steel structures need to be inspected

carefully to get a true damage assessment. Close

inspection may require partial removal of interior

trim or inner panels.

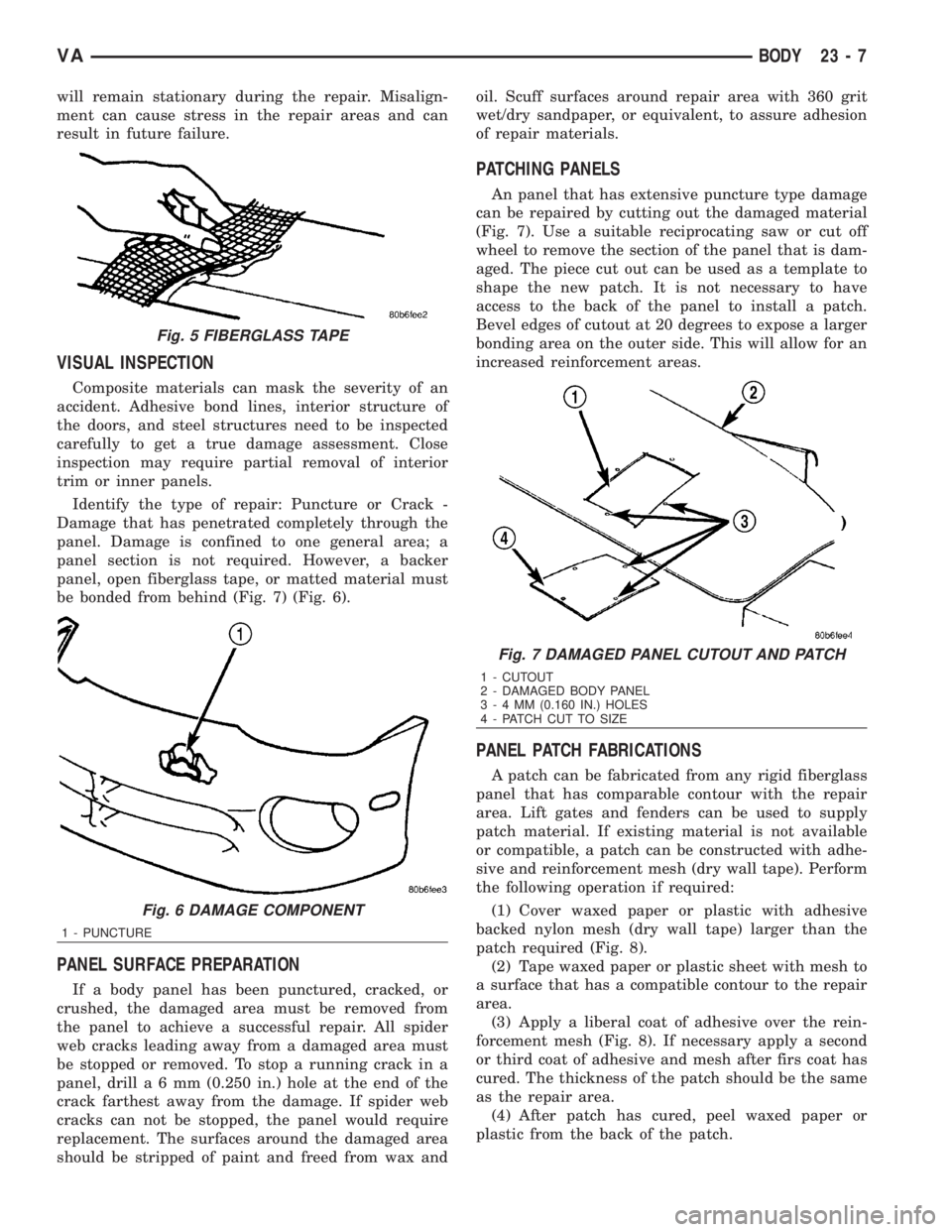

Identify the type of repair: Puncture or Crack -

Damage that has penetrated completely through the

panel. Damage is confined to one general area; a

panel section is not required. However, a backer

panel, open fiberglass tape, or matted material must

be bonded from behind (Fig. 7) (Fig. 6).

PANEL SURFACE PREPARATION

If a body panel has been punctured, cracked, or

crushed, the damaged area must be removed from

the panel to achieve a successful repair. All spider

web cracks leading away from a damaged area must

be stopped or removed. To stop a running crack in a

panel, drilla6mm(0.250 in.) hole at the end of the

crack farthest away from the damage. If spider web

cracks can not be stopped, the panel would require

replacement. The surfaces around the damaged area

should be stripped of paint and freed from wax andoil. Scuff surfaces around repair area with 360 grit

wet/dry sandpaper, or equivalent, to assure adhesion

of repair materials.

PATCHING PANELS

An panel that has extensive puncture type damage

can be repaired by cutting out the damaged material

(Fig. 7). Use a suitable reciprocating saw or cut off

wheel to remove the section of the panel that is dam-

aged. The piece cut out can be used as a template to

shape the new patch. It is not necessary to have

access to the back of the panel to install a patch.

Bevel edges of cutout at 20 degrees to expose a larger

bonding area on the outer side. This will allow for an

increased reinforcement areas.

PANEL PATCH FABRICATIONS

A patch can be fabricated from any rigid fiberglass

panel that has comparable contour with the repair

area. Lift gates and fenders can be used to supply

patch material. If existing material is not available

or compatible, a patch can be constructed with adhe-

sive and reinforcement mesh (dry wall tape). Perform

the following operation if required:

(1) Cover waxed paper or plastic with adhesive

backed nylon mesh (dry wall tape) larger than the

patch required (Fig. 8).

(2) Tape waxed paper or plastic sheet with mesh to

a surface that has a compatible contour to the repair

area.

(3) Apply a liberal coat of adhesive over the rein-

forcement mesh (Fig. 8). If necessary apply a second

or third coat of adhesive and mesh after firs coat has

cured. The thickness of the patch should be the same

as the repair area.

(4) After patch has cured, peel waxed paper or

plastic from the back of the patch.

Fig. 5 FIBERGLASS TAPE

Fig. 6 DAMAGE COMPONENT

1 - PUNCTURE

Fig. 7 DAMAGED PANEL CUTOUT AND PATCH

1 - CUTOUT

2 - DAMAGED BODY PANEL

3-4MM(0.160 IN.) HOLES

4 - PATCH CUT TO SIZE

VABODY 23 - 7

Page 2046 of 2305

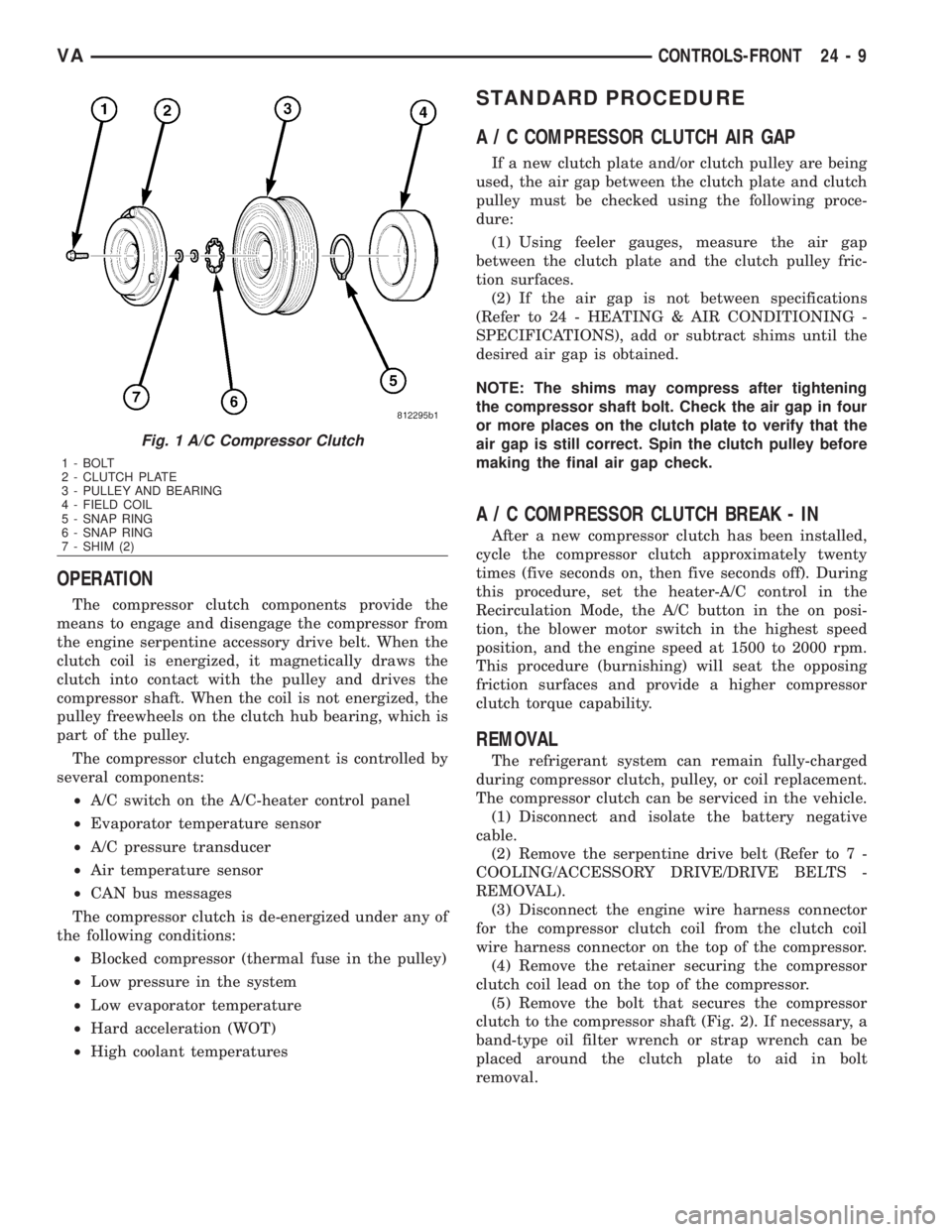

OPERATION

The compressor clutch components provide the

means to engage and disengage the compressor from

the engine serpentine accessory drive belt. When the

clutch coil is energized, it magnetically draws the

clutch into contact with the pulley and drives the

compressor shaft. When the coil is not energized, the

pulley freewheels on the clutch hub bearing, which is

part of the pulley.

The compressor clutch engagement is controlled by

several components:

²A/C switch on the A/C-heater control panel

²Evaporator temperature sensor

²A/C pressure transducer

²Air temperature sensor

²CAN bus messages

The compressor clutch is de-energized under any of

the following conditions:

²Blocked compressor (thermal fuse in the pulley)

²Low pressure in the system

²Low evaporator temperature

²Hard acceleration (WOT)

²High coolant temperatures

STANDARD PROCEDURE

A / C COMPRESSOR CLUTCH AIR GAP

If a new clutch plate and/or clutch pulley are being

used, the air gap between the clutch plate and clutch

pulley must be checked using the following proce-

dure:

(1) Using feeler gauges, measure the air gap

between the clutch plate and the clutch pulley fric-

tion surfaces.

(2) If the air gap is not between specifications

(Refer to 24 - HEATING & AIR CONDITIONING -

SPECIFICATIONS), add or subtract shims until the

desired air gap is obtained.

NOTE: The shims may compress after tightening

the compressor shaft bolt. Check the air gap in four

or more places on the clutch plate to verify that the

air gap is still correct. Spin the clutch pulley before

making the final air gap check.

A / C COMPRESSOR CLUTCH BREAK - IN

After a new compressor clutch has been installed,

cycle the compressor clutch approximately twenty

times (five seconds on, then five seconds off). During

this procedure, set the heater-A/C control in the

Recirculation Mode, the A/C button in the on posi-

tion, the blower motor switch in the highest speed

position, and the engine speed at 1500 to 2000 rpm.

This procedure (burnishing) will seat the opposing

friction surfaces and provide a higher compressor

clutch torque capability.

REMOVAL

The refrigerant system can remain fully-charged

during compressor clutch, pulley, or coil replacement.

The compressor clutch can be serviced in the vehicle.

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the serpentine drive belt (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

REMOVAL).

(3) Disconnect the engine wire harness connector

for the compressor clutch coil from the clutch coil

wire harness connector on the top of the compressor.

(4) Remove the retainer securing the compressor

clutch coil lead on the top of the compressor.

(5) Remove the bolt that secures the compressor

clutch to the compressor shaft (Fig. 2). If necessary, a

band-type oil filter wrench or strap wrench can be

placed around the clutch plate to aid in bolt

removal.

Fig. 1 A/C Compressor Clutch

1 - BOLT

2 - CLUTCH PLATE

3 - PULLEY AND BEARING

4 - FIELD COIL

5 - SNAP RING

6 - SNAP RING

7 - SHIM (2)

VACONTROLS-FRONT 24 - 9

Page 2049 of 2305

front cover of the compressor. Be certain that the

snap ring is properly fully and properly seated in the

groove.

(6) If the original clutch plate and clutch pulley

are to be reused, reinstall the original shim(s) on the

compressor shaft against the shoulder. If a new

clutch plate and/or clutch pulley are being used,

install a trial stack of shims 1.0 mm (0.040 in.) thick

on the compressor shaft against the shoulder.

(7) Install the clutch plate onto the compressor

shaft.

(8) Install and tighten the compressor shaft bolt. If

necessary, a band-type oil filter wrench or a strap

wrench can be placed around the clutch plate to aid

in bolt tightening. Tighten the bolt to 17.5 N´m (155

in. lbs.).

NOTE: The shims may compress after tightening

the shaft bolt. Check the air gap in four or more

places to verify the air gap is still correct. Spin the

pulley before performing a final check of the air

gap.

(9) If a new clutch plate and/or clutch pulley are

being installed, the air gap between the clutch plate

and clutch pulley must be checked (Refer to 24 -

HEATING & AIR CONDITIONING/CONTROLS/A/C

COMPRESSOR CLUTCH - STANDARD PROCE-

DURE).

(10) Install the retainer that secures the compres-

sor clutch coil lead to the top of the compressor.

(11) Reconnect the engine wire harness connector

to the clutch coil lead on the top of the compressor.

(12) Reinstall the serpentine accessory drive belt

(Refer to 7 - COOLING/ACCESSORY DRIVE/DRIVE

BELTS - INSTALLATION).

(13) Reconnect the battery negative cable.

(14) If a new clutch plate and/or clutch pulley are

being installed, the new clutch components must be

burnished (Refer to 24 - HEATING & AIR CONDI-

TIONING/CONTROLS/A/C COMPRESSOR CLUTCH

- STANDARD PROCEDURE).

A / C COMPRESSOR CLUTCH

COIL

DIAGNOSIS AND TESTING

A / C COMPRESSOR CLUTCH COIL

The air conditioning compressor clutch coil electri-

cal circuit is controlled by the ATC control module

which is integral to the heater-A/C control. Begin

testing of a suspected compressor clutch coil problem

by performing the ATC Function Test using the

DRBIIItscan tool.PRELIMINARY CHECKS

(1) If no diagnostic trouble codes (DTCs) are found

in the A/C-heater control or the powertrain control

module (PCM), go to Step 2. If any DTCs are found,

repair as required.

(2) If the A/C compressor clutch still will not

engage, verify the refrigerant charge level (Refer to

24 - HEATING & AIR CONDITIONING/PLUMBING

- DIAGNOSIS AND TESTING - REFRIGERANT

SYSTEM LEAKS). If the refrigerant charge level is

OK, go to TESTS. If the refrigerant charge level is

not OK, adjust the refrigerant charge as required.

TESTS

(1) Verify the battery state of charge (Refer to 8 -

ELECTRICAL/BATTERY SYSTEM/BATTERY -

DIAGNOSIS AND TESTING).

(2) Connect an ammeter (0 to 10 ampere scale

selected) in series with the clutch coil feed terminal.

Connect a voltmeter (0 to 20 volt scale selected) to

measure voltage across the battery and the clutch

coil.

(3) With the A/C-heater control in the A/C mode

and the blower motor at low speed, start the engine

and allow it to run at a normal idle speed.

(4) The A/C compressor clutch should engage

immediately, and the clutch coil supply voltage

should be within two volts of the battery voltage. If

the coil supply voltage is OK, go to Step 5. If the coil

supply voltage is not within two volts of battery volt-

age, test the clutch coil feed circuit for excessive volt-

age drop and repair as necessary.

(5) For the acceptable A/C clutch coil current draw

specifications refer to 24 - HEATING & AIR CONDI-

TIONING - SPECIFICATIONS. Specifications apply

for a work area temperature of 21É C (70É F). If volt-

age is more than 12.5 volts, add electrical loads by

turning on electrical accessories until voltage reads

below 12.5 volts.

(a) If the A/C clutch coil current reading is zero,

the coil is open and must be replaced.

(b) If the A/C clutch coil current reading is above

specifications, the coil is shorted and must be

replaced.

A / C HEATER CONTROL

DESCRIPTION

This ATC system uses a combination of electrical

and mechanical controls. These controls provide the

vehicle operator with a number of setting options to

help control the climate and comfort within the vehi-

cle.

The A/C-heater control is located on the instrument

panel inboard of the steering column and below the

24 - 12 CONTROLS-FRONTVA

Page 2061 of 2305

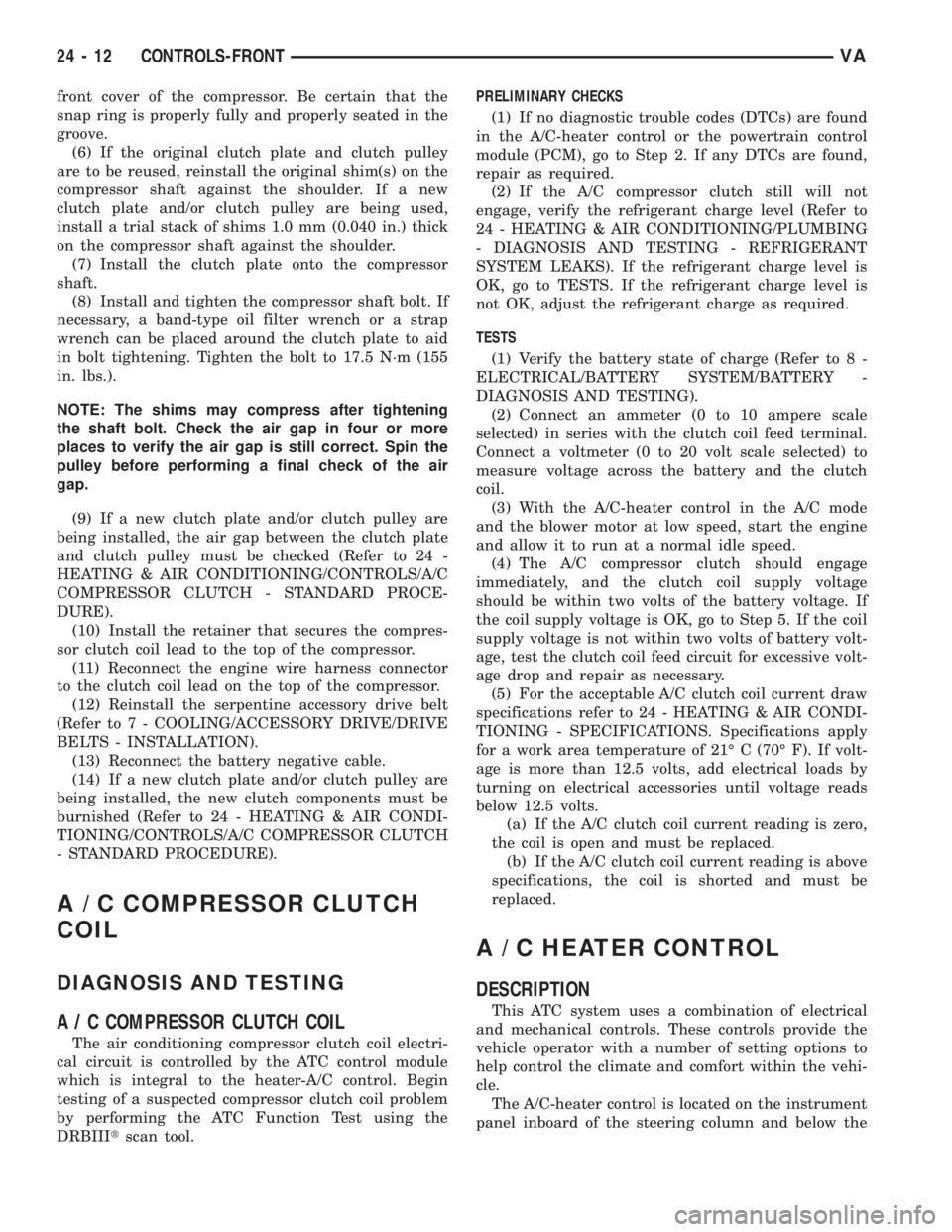

CONTROLS - REAR

TABLE OF CONTENTS

page page

A/C CLUTCH RELAY

DESCRIPTION.........................24

OPERATION...........................25

REMOVAL.............................25

INSTALLATION.........................26

A/C CONDENSER FAN RELAY

DESCRIPTION.........................26

OPERATION...........................26

REMOVAL.............................27

INSTALLATION.........................28

A/C CONTROL MODULE

DESCRIPTION.........................28

OPERATION...........................28

REMOVAL.............................29

INSTALLATION.........................30

A/C HIGH PRESSURE SWITCH

DESCRIPTION.........................30

OPERATION...........................30

REMOVAL.............................31

INSTALLATION.........................31

A/C LOW PRESSURE SWITCH

DESCRIPTION.........................32

OPERATION...........................32

REMOVAL.............................32

INSTALLATION.........................33

BLOWER MOTOR RELAY

DESCRIPTION.........................33

OPERATION...........................33

REMOVAL.............................34

INSTALLATION.........................35

BLOWER MOTOR SWITCH

DESCRIPTION.........................35

OPERATION...........................35

DIAGNOSIS AND TESTING

REAR BLOWER MOTOR SWITCH.........36REMOVAL.............................36

INSTALLATION.........................37

EVAPORATOR TEMPERATURE SENSOR

DESCRIPTION.........................37

OPERATION...........................37

REMOVAL.............................37

INSTALLATION.........................38

TEMPERATURE CONTROL

DESCRIPTION.........................38

OPERATION...........................38

DIAGNOSIS AND TESTING

REAR A/C TEMPERATURE CONTROL.....39

REMOVAL.............................39

INSTALLATION.........................40

TEMPERATURE SENSOR

DESCRIPTION.........................40

OPERATION...........................40

DIAGNOSIS AND TESTING

REAR TEMPERATURE SENSOR..........40

REMOVAL.............................40

INSTALLATION.........................41

SUPPRESSOR FILTER - REAR BLOWER

MOTOR

DESCRIPTION.........................41

OPERATION...........................41

REMOVAL.............................42

INSTALLATION.........................43

SUPPRESSOR FILTER - REAR CONDENSER

FA N

DESCRIPTION.........................43

OPERATION...........................44

REMOVAL.............................44

INSTALLATION.........................44

A / C CLUTCH RELAY

DESCRIPTION

The rear A/C clutch relay for the rear A/C system

is an International Standards Organization (ISO)-

type relay (Fig. 1). Relays conforming to the ISO

specifications have common physical dimensions, cur-

rent capacities, terminal functions and patterns. The

rear A/C clutch relay is an electromechanical device

that uses a low current input controlled by the rear

A/C control module to control the high current output

to the A/C clutch field coil for the rear A/C system.The rear A/C clutch relay is located in the relay

block in the rear A/C evaporator housing.

24 - 24 CONTROLS - REARVA

Page 2063 of 2305

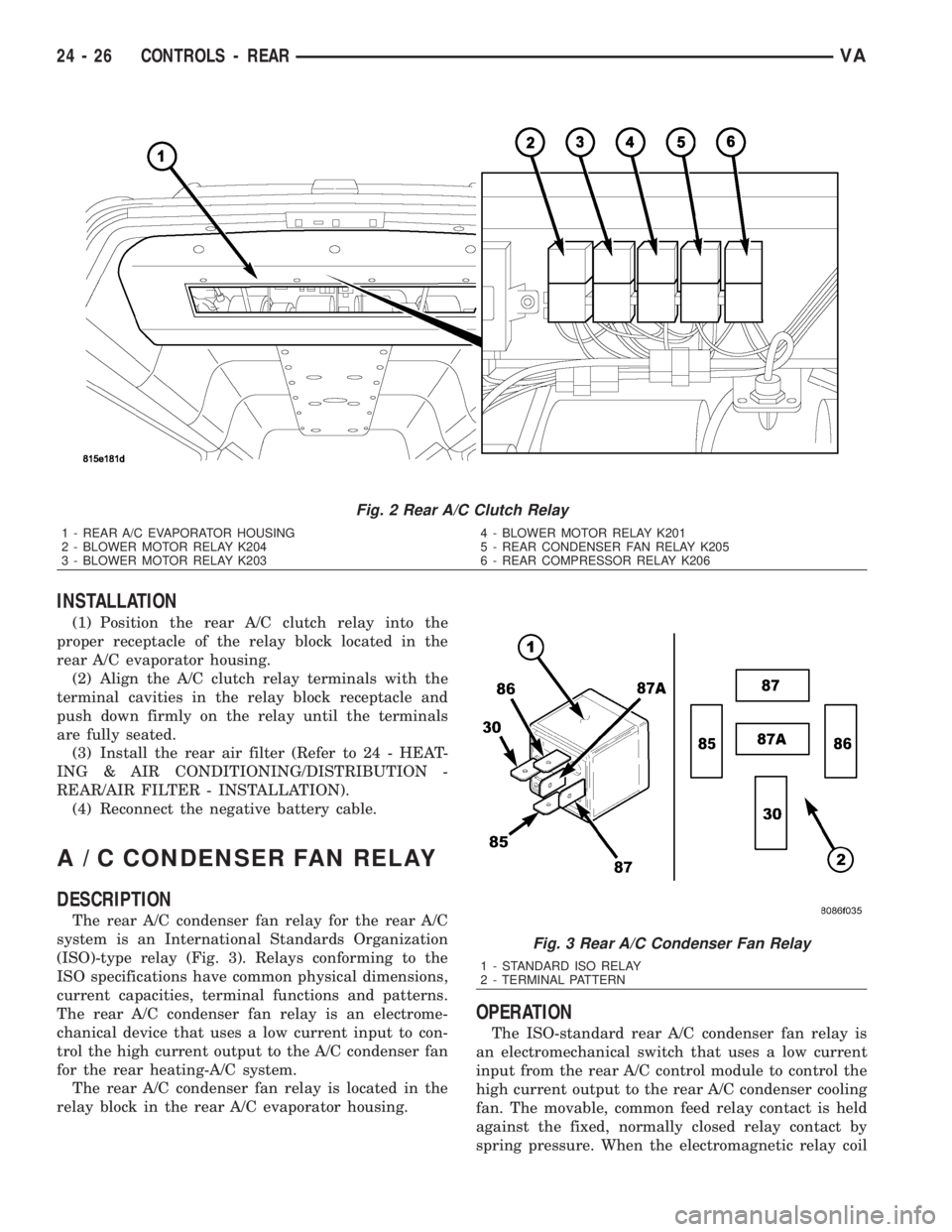

INSTALLATION

(1) Position the rear A/C clutch relay into the

proper receptacle of the relay block located in the

rear A/C evaporator housing.

(2) Align the A/C clutch relay terminals with the

terminal cavities in the relay block receptacle and

push down firmly on the relay until the terminals

are fully seated.

(3) Install the rear air filter (Refer to 24 - HEAT-

ING & AIR CONDITIONING/DISTRIBUTION -

REAR/AIR FILTER - INSTALLATION).

(4) Reconnect the negative battery cable.

A / C CONDENSER FAN RELAY

DESCRIPTION

The rear A/C condenser fan relay for the rear A/C

system is an International Standards Organization

(ISO)-type relay (Fig. 3). Relays conforming to the

ISO specifications have common physical dimensions,

current capacities, terminal functions and patterns.

The rear A/C condenser fan relay is an electrome-

chanical device that uses a low current input to con-

trol the high current output to the A/C condenser fan

for the rear heating-A/C system.

The rear A/C condenser fan relay is located in the

relay block in the rear A/C evaporator housing.

OPERATION

The ISO-standard rear A/C condenser fan relay is

an electromechanical switch that uses a low current

input from the rear A/C control module to control the

high current output to the rear A/C condenser cooling

fan. The movable, common feed relay contact is held

against the fixed, normally closed relay contact by

spring pressure. When the electromagnetic relay coil

Fig. 2 Rear A/C Clutch Relay

1 - REAR A/C EVAPORATOR HOUSING

2 - BLOWER MOTOR RELAY K204

3 - BLOWER MOTOR RELAY K2034 - BLOWER MOTOR RELAY K201

5 - REAR CONDENSER FAN RELAY K205

6 - REAR COMPRESSOR RELAY K206

Fig. 3 Rear A/C Condenser Fan Relay

1 - STANDARD ISO RELAY

2 - TERMINAL PATTERN

24 - 26 CONTROLS - REARVA

Page 2070 of 2305

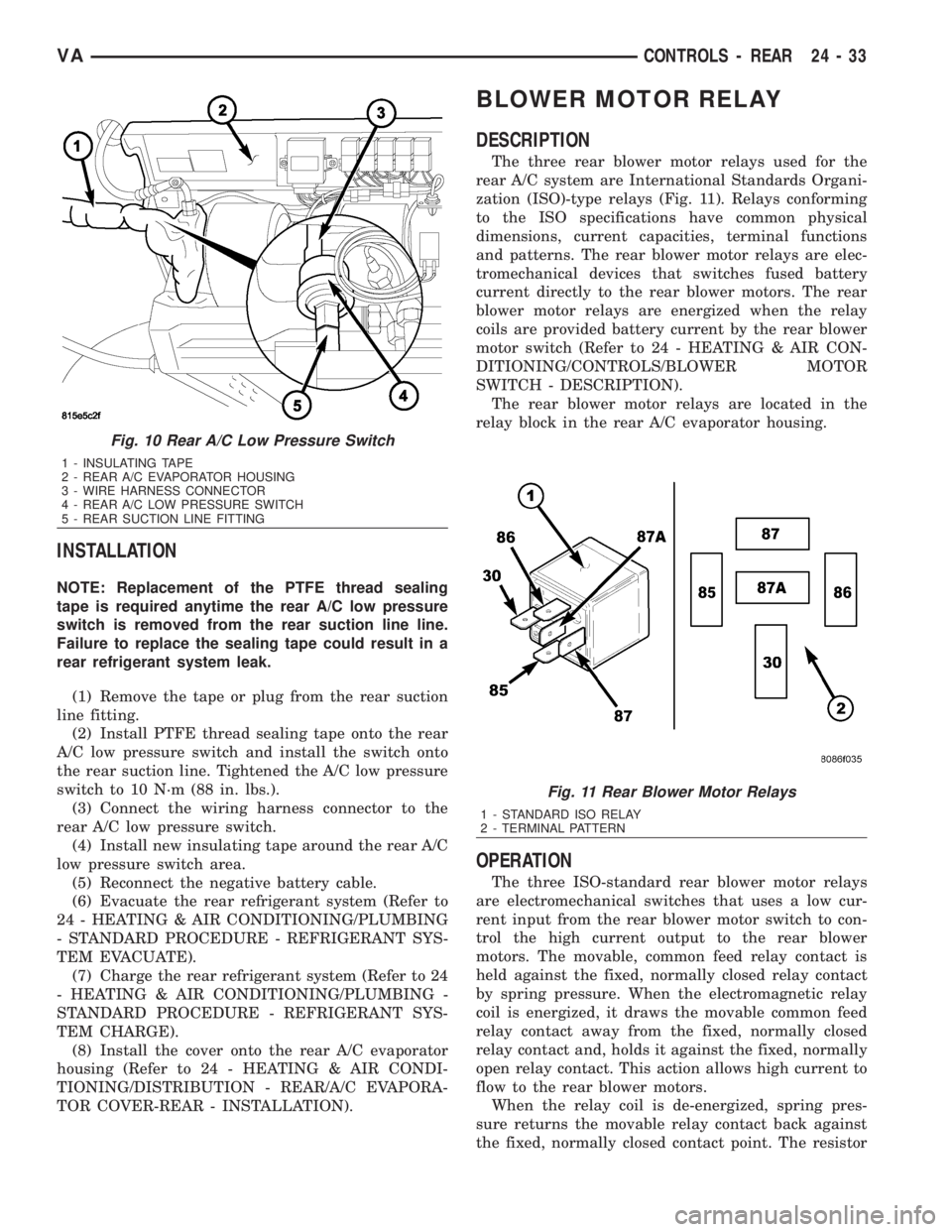

INSTALLATION

NOTE: Replacement of the PTFE thread sealing

tape is required anytime the rear A/C low pressure

switch is removed from the rear suction line line.

Failure to replace the sealing tape could result in a

rear refrigerant system leak.

(1) Remove the tape or plug from the rear suction

line fitting.

(2) Install PTFE thread sealing tape onto the rear

A/C low pressure switch and install the switch onto

the rear suction line. Tightened the A/C low pressure

switch to 10 N´m (88 in. lbs.).

(3) Connect the wiring harness connector to the

rear A/C low pressure switch.

(4) Install new insulating tape around the rear A/C

low pressure switch area.

(5) Reconnect the negative battery cable.

(6) Evacuate the rear refrigerant system (Refer to

24 - HEATING & AIR CONDITIONING/PLUMBING

- STANDARD PROCEDURE - REFRIGERANT SYS-

TEM EVACUATE).

(7) Charge the rear refrigerant system (Refer to 24

- HEATING & AIR CONDITIONING/PLUMBING -

STANDARD PROCEDURE - REFRIGERANT SYS-

TEM CHARGE).

(8) Install the cover onto the rear A/C evaporator

housing (Refer to 24 - HEATING & AIR CONDI-

TIONING/DISTRIBUTION - REAR/A/C EVAPORA-

TOR COVER-REAR - INSTALLATION).

BLOWER MOTOR RELAY

DESCRIPTION

The three rear blower motor relays used for the

rear A/C system are International Standards Organi-

zation (ISO)-type relays (Fig. 11). Relays conforming

to the ISO specifications have common physical

dimensions, current capacities, terminal functions

and patterns. The rear blower motor relays are elec-

tromechanical devices that switches fused battery

current directly to the rear blower motors. The rear

blower motor relays are energized when the relay

coils are provided battery current by the rear blower

motor switch (Refer to 24 - HEATING & AIR CON-

DITIONING/CONTROLS/BLOWER MOTOR

SWITCH - DESCRIPTION).

The rear blower motor relays are located in the

relay block in the rear A/C evaporator housing.

OPERATION

The three ISO-standard rear blower motor relays

are electromechanical switches that uses a low cur-

rent input from the rear blower motor switch to con-

trol the high current output to the rear blower

motors. The movable, common feed relay contact is

held against the fixed, normally closed relay contact

by spring pressure. When the electromagnetic relay

coil is energized, it draws the movable common feed

relay contact away from the fixed, normally closed

relay contact and, holds it against the fixed, normally

open relay contact. This action allows high current to

flow to the rear blower motors.

When the relay coil is de-energized, spring pres-

sure returns the movable relay contact back against

the fixed, normally closed contact point. The resistor

Fig. 10 Rear A/C Low Pressure Switch

1 - INSULATING TAPE

2 - REAR A/C EVAPORATOR HOUSING

3 - WIRE HARNESS CONNECTOR

4 - REAR A/C LOW PRESSURE SWITCH

5 - REAR SUCTION LINE FITTING

Fig. 11 Rear Blower Motor Relays

1 - STANDARD ISO RELAY

2 - TERMINAL PATTERN

VACONTROLS - REAR 24 - 33

Page 2091 of 2305

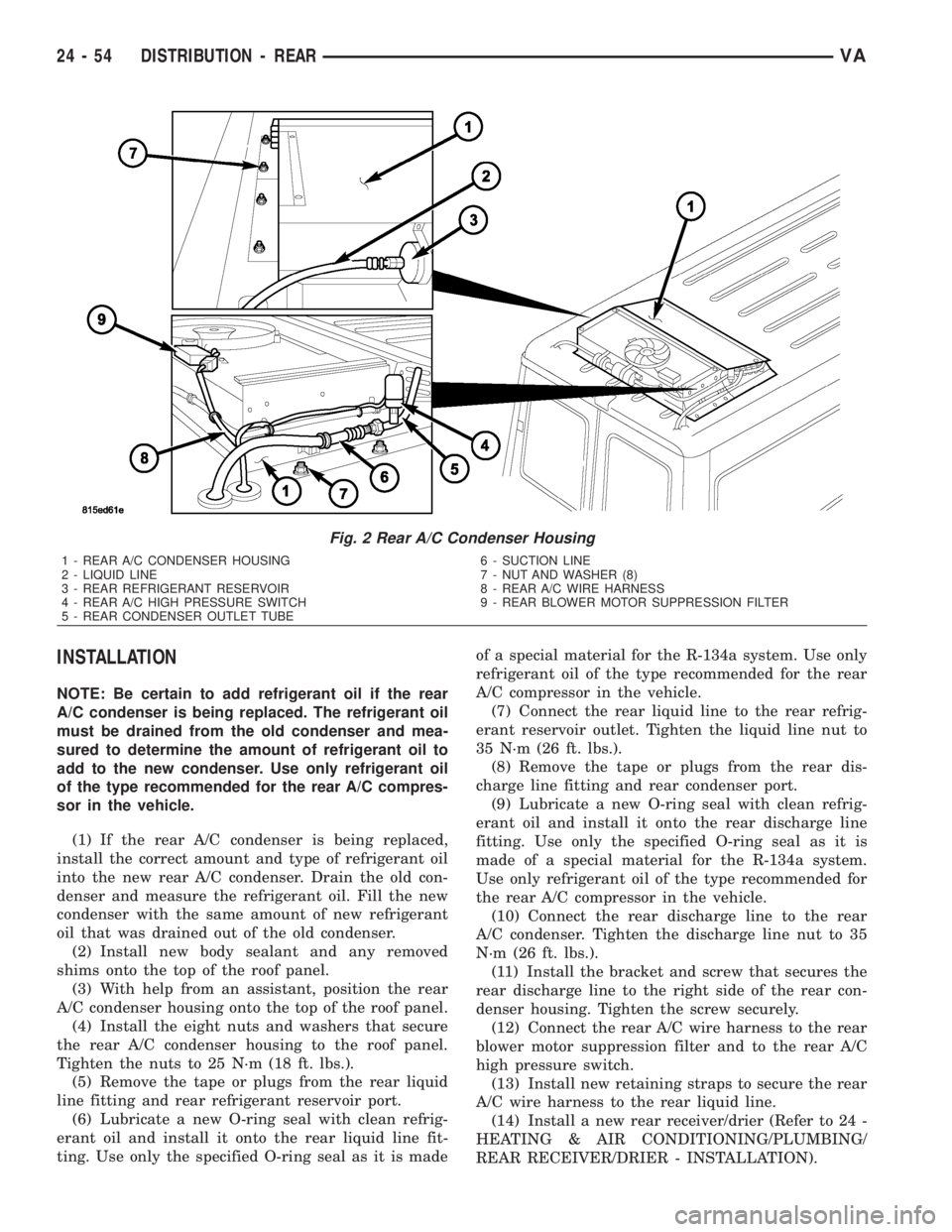

INSTALLATION

NOTE: Be certain to add refrigerant oil if the rear

A/C condenser is being replaced. The refrigerant oil

must be drained from the old condenser and mea-

sured to determine the amount of refrigerant oil to

add to the new condenser. Use only refrigerant oil

of the type recommended for the rear A/C compres-

sor in the vehicle.

(1) If the rear A/C condenser is being replaced,

install the correct amount and type of refrigerant oil

into the new rear A/C condenser. Drain the old con-

denser and measure the refrigerant oil. Fill the new

condenser with the same amount of new refrigerant

oil that was drained out of the old condenser.

(2) Install new body sealant and any removed

shims onto the top of the roof panel.

(3) With help from an assistant, position the rear

A/C condenser housing onto the top of the roof panel.

(4) Install the eight nuts and washers that secure

the rear A/C condenser housing to the roof panel.

Tighten the nuts to 25 N´m (18 ft. lbs.).

(5) Remove the tape or plugs from the rear liquid

line fitting and rear refrigerant reservoir port.

(6) Lubricate a new O-ring seal with clean refrig-

erant oil and install it onto the rear liquid line fit-

ting. Use only the specified O-ring seal as it is madeof a special material for the R-134a system. Use only

refrigerant oil of the type recommended for the rear

A/C compressor in the vehicle.

(7) Connect the rear liquid line to the rear refrig-

erant reservoir outlet. Tighten the liquid line nut to

35 N´m (26 ft. lbs.).

(8) Remove the tape or plugs from the rear dis-

charge line fitting and rear condenser port.

(9) Lubricate a new O-ring seal with clean refrig-

erant oil and install it onto the rear discharge line

fitting. Use only the specified O-ring seal as it is

made of a special material for the R-134a system.

Use only refrigerant oil of the type recommended for

the rear A/C compressor in the vehicle.

(10) Connect the rear discharge line to the rear

A/C condenser. Tighten the discharge line nut to 35

N´m (26 ft. lbs.).

(11) Install the bracket and screw that secures the

rear discharge line to the right side of the rear con-

denser housing. Tighten the screw securely.

(12) Connect the rear A/C wire harness to the rear

blower motor suppression filter and to the rear A/C

high pressure switch.

(13) Install new retaining straps to secure the rear

A/C wire harness to the rear liquid line.

(14) Install a new rear receiver/drier (Refer to 24 -

HEATING & AIR CONDITIONING/PLUMBING/

REAR RECEIVER/DRIER - INSTALLATION).

Fig. 2 Rear A/C Condenser Housing

1 - REAR A/C CONDENSER HOUSING

2 - LIQUID LINE

3 - REAR REFRIGERANT RESERVOIR

4 - REAR A/C HIGH PRESSURE SWITCH

5 - REAR CONDENSER OUTLET TUBE6 - SUCTION LINE

7 - NUT AND WASHER (8)

8 - REAR A/C WIRE HARNESS

9 - REAR BLOWER MOTOR SUPPRESSION FILTER

24 - 54 DISTRIBUTION - REARVA

Page 2094 of 2305

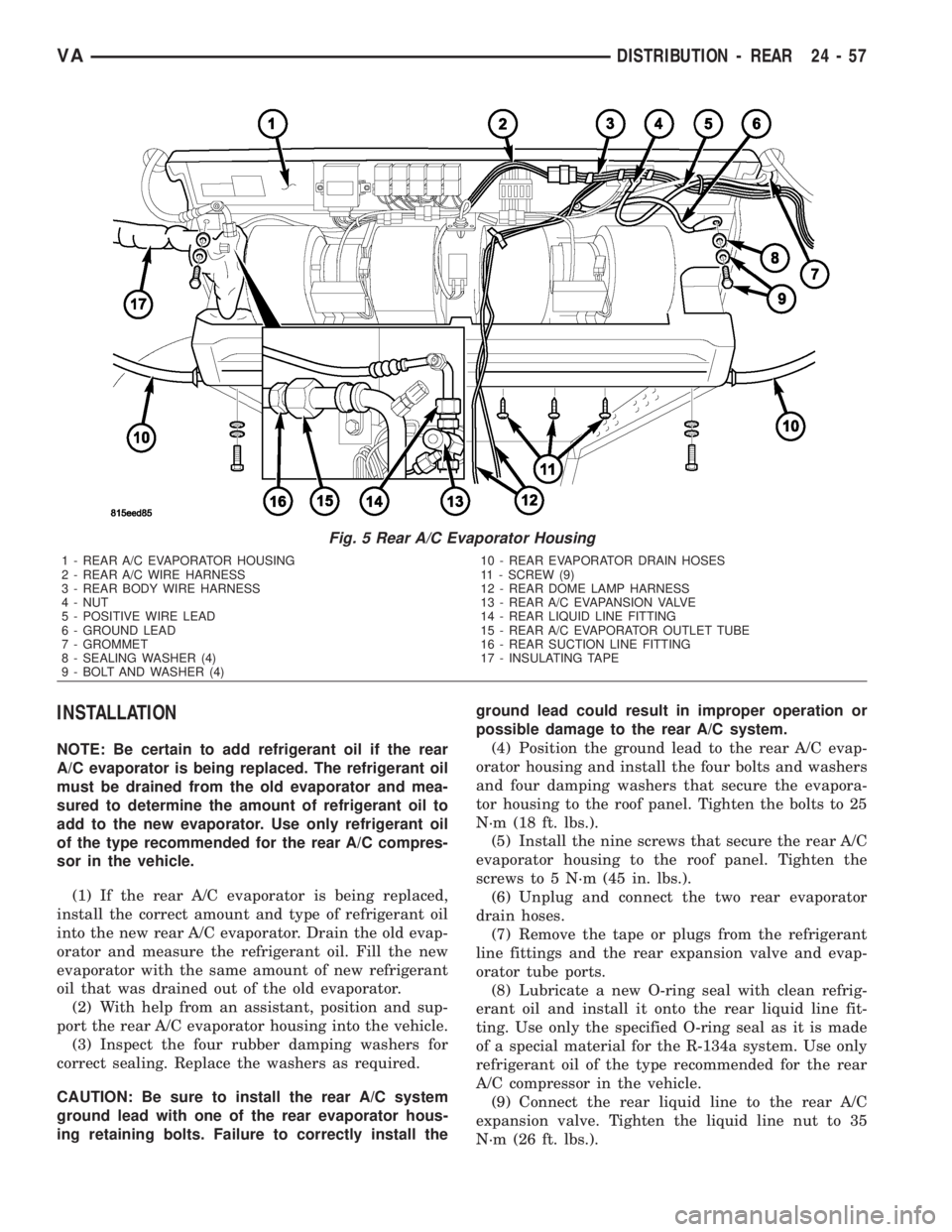

INSTALLATION

NOTE: Be certain to add refrigerant oil if the rear

A/C evaporator is being replaced. The refrigerant oil

must be drained from the old evaporator and mea-

sured to determine the amount of refrigerant oil to

add to the new evaporator. Use only refrigerant oil

of the type recommended for the rear A/C compres-

sor in the vehicle.

(1) If the rear A/C evaporator is being replaced,

install the correct amount and type of refrigerant oil

into the new rear A/C evaporator. Drain the old evap-

orator and measure the refrigerant oil. Fill the new

evaporator with the same amount of new refrigerant

oil that was drained out of the old evaporator.

(2) With help from an assistant, position and sup-

port the rear A/C evaporator housing into the vehicle.

(3) Inspect the four rubber damping washers for

correct sealing. Replace the washers as required.

CAUTION: Be sure to install the rear A/C system

ground lead with one of the rear evaporator hous-

ing retaining bolts. Failure to correctly install theground lead could result in improper operation or

possible damage to the rear A/C system.

(4) Position the ground lead to the rear A/C evap-

orator housing and install the four bolts and washers

and four damping washers that secure the evapora-

tor housing to the roof panel. Tighten the bolts to 25

N´m (18 ft. lbs.).

(5) Install the nine screws that secure the rear A/C

evaporator housing to the roof panel. Tighten the

screws to 5 N´m (45 in. lbs.).

(6) Unplug and connect the two rear evaporator

drain hoses.

(7) Remove the tape or plugs from the refrigerant

line fittings and the rear expansion valve and evap-

orator tube ports.

(8) Lubricate a new O-ring seal with clean refrig-

erant oil and install it onto the rear liquid line fit-

ting. Use only the specified O-ring seal as it is made

of a special material for the R-134a system. Use only

refrigerant oil of the type recommended for the rear

A/C compressor in the vehicle.

(9) Connect the rear liquid line to the rear A/C

expansion valve. Tighten the liquid line nut to 35

N´m (26 ft. lbs.).

Fig. 5 Rear A/C Evaporator Housing

1 - REAR A/C EVAPORATOR HOUSING

2 - REAR A/C WIRE HARNESS

3 - REAR BODY WIRE HARNESS

4 - NUT

5 - POSITIVE WIRE LEAD

6 - GROUND LEAD

7 - GROMMET

8 - SEALING WASHER (4)

9 - BOLT AND WASHER (4)10 - REAR EVAPORATOR DRAIN HOSES

11 - SCREW (9)

12 - REAR DOME LAMP HARNESS

13 - REAR A/C EVAPANSION VALVE

14 - REAR LIQUID LINE FITTING

15 - REAR A/C EVAPORATOR OUTLET TUBE

16 - REAR SUCTION LINE FITTING

17 - INSULATING TAPE

VADISTRIBUTION - REAR 24 - 57

Page 2095 of 2305

(10) Lubricate a new O-ring seal with clean refrig-

erant oil and install it onto the rear suction line fit-

ting. Use only the specified O-ring seal as it is made

of a special material for the R-134a system. Use only

refrigerant oil of the type recommended for the rear

A/C compressor in the vehicle.

(11) Connect the rear suction line to the rear evap-

orator outlet tube. Tighten the suction line nut to 35

N´m (26 ft. lbs.).

(12) Install new insulating tape around the rear

evaporator connections.

(13) Install the positive wire lead onto the rear

A/C system terminal block and install the retaining

nut. Tighten the nut securely.

(14) Reposition the rear dome lamp harness and

install the retaining straps that secure the harness

to the rear A/C evaporator housing.

(15) Connect the rear A/C wire harness connector

to the rear body wire harness.

(16) Route the rear A/C wire harness up through

the roof panel and install the grommet.

(17) Connect the rear A/C wire harness to the rear

condenser fan suppression filter and the rear A/C

high pressure switch and install the retaining straps

that secure the wire harness to the rear liquid line.

(18) Reconnect the negative battery cable.

(19) Evacuate the rear refrigerant system (Refer to

24 - HEATING & AIR CONDITIONING/PLUMBING

- STANDARD PROCEDURE - REFRIGERANT SYS-

TEM EVACUATE).

(20) Charge the rear refrigerant system (Refer to

24 - HEATING & AIR CONDITIONING/PLUMBING

- STANDARD PROCEDURE - REFRIGERANT SYS-

TEM CHARGE).

(21) Install the cover onto the rear A/C evaporator

housing (Refer to 24 - HEATING & AIR CONDI-

TIONING/DISTRIBUTION - REAR/A/C EVAPORA-

TOR COVER-REAR - INSTALLATION).

(22) Install the cover onto the rear A/C condenser

housing (Refer to 24 - HEATING & AIR CONDI-

TIONING/DISTRIBUTION - REAR/A/C CON-

DENSER COVER - INSTALLATION).

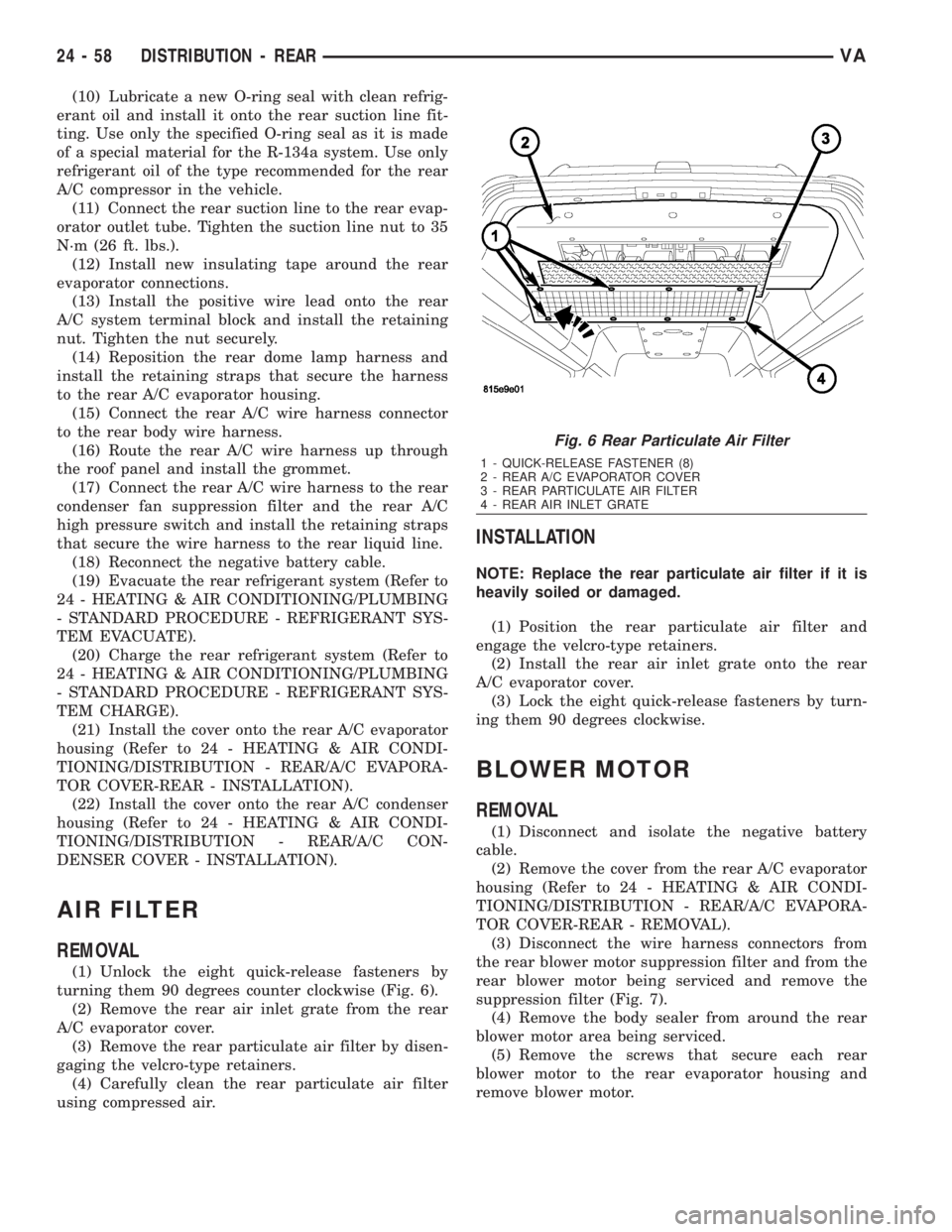

AIR FILTER

REMOVAL

(1) Unlock the eight quick-release fasteners by

turning them 90 degrees counter clockwise (Fig. 6).

(2) Remove the rear air inlet grate from the rear

A/C evaporator cover.

(3) Remove the rear particulate air filter by disen-

gaging the velcro-type retainers.

(4) Carefully clean the rear particulate air filter

using compressed air.

INSTALLATION

NOTE: Replace the rear particulate air filter if it is

heavily soiled or damaged.

(1) Position the rear particulate air filter and

engage the velcro-type retainers.

(2) Install the rear air inlet grate onto the rear

A/C evaporator cover.

(3) Lock the eight quick-release fasteners by turn-

ing them 90 degrees clockwise.

BLOWER MOTOR

REMOVAL

(1) Disconnect and isolate the negative battery

cable.

(2) Remove the cover from the rear A/C evaporator

housing (Refer to 24 - HEATING & AIR CONDI-

TIONING/DISTRIBUTION - REAR/A/C EVAPORA-

TOR COVER-REAR - REMOVAL).

(3) Disconnect the wire harness connectors from

the rear blower motor suppression filter and from the

rear blower motor being serviced and remove the

suppression filter (Fig. 7).

(4) Remove the body sealer from around the rear

blower motor area being serviced.

(5) Remove the screws that secure each rear

blower motor to the rear evaporator housing and

remove blower motor.

Fig. 6 Rear Particulate Air Filter

1 - QUICK-RELEASE FASTENER (8)

2 - REAR A/C EVAPORATOR COVER

3 - REAR PARTICULATE AIR FILTER

4 - REAR AIR INLET GRATE

24 - 58 DISTRIBUTION - REARVA

Page 2103 of 2305

(12)EXAMPLE:The ambient temperature is 21É

C (70É F). The evaporator inlet tube temperature is

12É C (54É F) and the evaporator outlet tube temper-

ature is 10É C (50É F). Subtract the inlet tube tem-

perature from the outlet tube temperature. The

difference is -2É C (-4É F). With a -2É C (-4É F) tem-

perature differential at 21É C (70É F) ambient tem-

perature, the system is fully charged.

(13) Add enough refrigerant to bring the refriger-

ant system up to a full charge.

(14) Remove the jumper wire from the low pres-

sure cycling clutch switch wire harness connector

and plug the connector back into the switch.

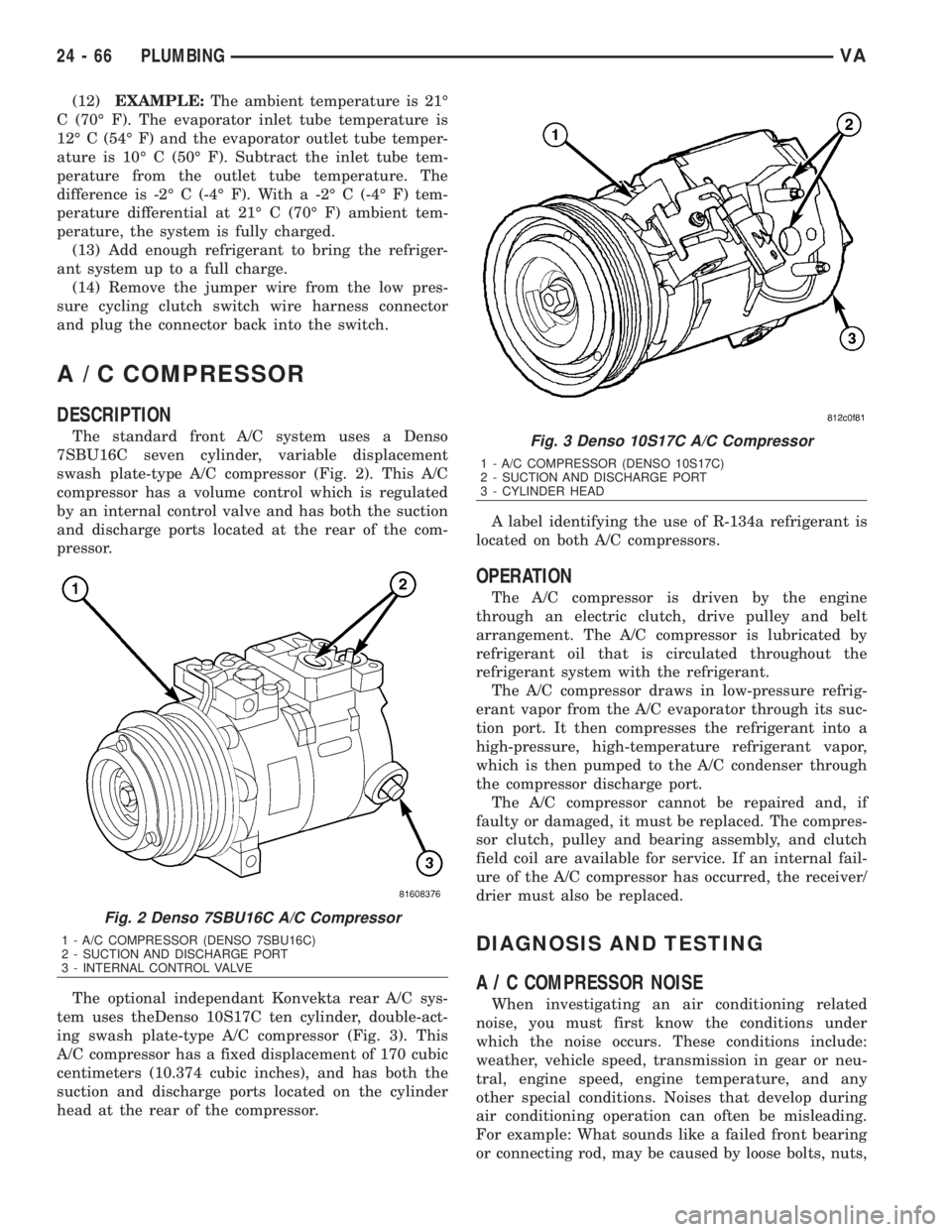

A / C COMPRESSOR

DESCRIPTION

The standard front A/C system uses a Denso

7SBU16C seven cylinder, variable displacement

swash plate-type A/C compressor (Fig. 2). This A/C

compressor has a volume control which is regulated

by an internal control valve and has both the suction

and discharge ports located at the rear of the com-

pressor.

The optional independant Konvekta rear A/C sys-

tem uses theDenso 10S17C ten cylinder, double-act-

ing swash plate-type A/C compressor (Fig. 3). This

A/C compressor has a fixed displacement of 170 cubic

centimeters (10.374 cubic inches), and has both the

suction and discharge ports located on the cylinder

head at the rear of the compressor.A label identifying the use of R-134a refrigerant is

located on both A/C compressors.

OPERATION

The A/C compressor is driven by the engine

through an electric clutch, drive pulley and belt

arrangement. The A/C compressor is lubricated by

refrigerant oil that is circulated throughout the

refrigerant system with the refrigerant.

The A/C compressor draws in low-pressure refrig-

erant vapor from the A/C evaporator through its suc-

tion port. It then compresses the refrigerant into a

high-pressure, high-temperature refrigerant vapor,

which is then pumped to the A/C condenser through

the compressor discharge port.

The A/C compressor cannot be repaired and, if

faulty or damaged, it must be replaced. The compres-

sor clutch, pulley and bearing assembly, and clutch

field coil are available for service. If an internal fail-

ure of the A/C compressor has occurred, the receiver/

drier must also be replaced.

DIAGNOSIS AND TESTING

A / C COMPRESSOR NOISE

When investigating an air conditioning related

noise, you must first know the conditions under

which the noise occurs. These conditions include:

weather, vehicle speed, transmission in gear or neu-

tral, engine speed, engine temperature, and any

other special conditions. Noises that develop during

air conditioning operation can often be misleading.

For example: What sounds like a failed front bearing

or connecting rod, may be caused by loose bolts, nuts,

Fig. 2 Denso 7SBU16C A/C Compressor

1 - A/C COMPRESSOR (DENSO 7SBU16C)

2 - SUCTION AND DISCHARGE PORT

3 - INTERNAL CONTROL VALVE

Fig. 3 Denso 10S17C A/C Compressor

1 - A/C COMPRESSOR (DENSO 10S17C)

2 - SUCTION AND DISCHARGE PORT

3 - CYLINDER HEAD

24 - 66 PLUMBINGVA