oil type MERCEDES-BENZ SPRINTER 2006 User Guide

[x] Cancel search | Manufacturer: MERCEDES-BENZ, Model Year: 2006, Model line: SPRINTER, Model: MERCEDES-BENZ SPRINTER 2006Pages: 2305, PDF Size: 48.12 MB

Page 883 of 2305

SPECIAL TOOLS

GENERATOR

DESCRIPTION

The generator is belt-driven by the engine using a

serpentine-type drive belt. It is serviced only as a

complete assembly. If the generator fails for any rea-

son, the entire assembly must be replaced.

On certain engines, the decoupler pulley may be

replaced separately.

OPERATION

As the energized rotor begins to rotate within the

generator, the spinning magnetic field induces a cur-

rent into the windings of the stator coil. Once the

generator begins producing sufficient current, it also

provides the current needed to energize the rotor.

The stator winding connections deliver the induced

AC current to 3 positive and 3 negative diodes for

rectification. From the diodes, rectified DC current isdelivered to the vehicle electrical system through the

generator battery terminal.

Although the generators appear the same exter-

nally, different generators with different output rat-

ings are used on this vehicle. Be certain that the

replacement generator has the same output rating

and part number as the original unit. Refer to Spec-

ifications and see Generator Ratings for amperage

ratings and part numbers.

Noise emitting from the generator may be caused

by: worn, loose or defective bearings; a loose or defec-

tive drive pulley (decoupler pulley); incorrect, worn,

damaged or misadjusted fan drive belt; loose mount-

ing bolts; a misaligned drive pulley or a defective sta-

tor or diode.

An instrument panel mounted, battery charge indi-

cator lamp is used. When the key is in the on posi-

tion, the lamp will be illuminated. This is done as a

bulb check. If this lamp remains illuminated while

the engine is running, a Diagnostic Trouble Code

(DTC) has been detected for the charging system.

REMOVAL

CAUTION: DISCONNECT NEGATIVE CABLE FROM

BATTERY BEFORE REMOVING BATTERY OUTPUT

WIRE FROM GENERATOR. FAILURE TO DO SO

CAN RESULT IN INJURY.

CAUTION: Never force a belt over a pulley rim

using a screwdriver. The synthetic fiber of the belt

can be damaged.

CAUTION: When installing a serpentine accessory

drive belt, the belt MUST be routed correctly. The

water pump will be rotating in the wrong direction if

the belt is installed incorrectly, causing the engine

to overheat. Refer to belt routing label in engine

compartment, or refer to Belt Schematics in Cooling

System.

(1) Disconnect and isolate negative battery cable.

(2) Remove generator drive belt. Refer to Cooling

System for procedure.

(3) Raise and support vehicle.

(4) Remove protective plastic cover from B+ stud

at top of generator.

(5) Remove nut securing battery output cable to

B+ terminal at top of generator.

(6) Unplug field terminal connector at rear of gen-

erator.

(7) Remove 4 generator mounting bolts (Torx-style

#12 bit) (Fig. 1).

(8) Remove generator from lower side of vehicle.

GENERATOR DECOUPLER TOOL #8433

GENERATOR DECOUPLER TOOL #8823

8F - 18 CHARGING SYSTEMVA

Page 893 of 2305

STARTING SYSTEM

TABLE OF CONTENTS

page page

STARTING SYSTEM

DESCRIPTION.........................28

OPERATION...........................28

DIAGNOSIS AND TESTING - STARTING

SYSTEM............................29

SPECIFICATIONS

TORQUE - STARTER - DIESEL...........33

SPECIFICATIONS - STARTER MOTOR -

DIESEL.............................33STARTER MOTOR

DIAGNOSIS AND TESTING - STARTER

MOTOR .............................33

REMOVAL.............................34

INSTALLATION.........................35

STARTER MOTOR RELAY

DESCRIPTION.........................35

REMOVAL.............................35

INSTALLATION.........................36

STARTING SYSTEM

DESCRIPTION

The starting system consists of:

²Starter relay

²Starter motor (including an integral starter sole-

noid)

Other components to be considered as part of start-

ing system are:

²Battery

²Battery cables

²Ignition switch and key lock cylinder

²Park/neutral position switch (automatic trans-

mission)

²Wire harnesses and connections.

The Battery, Starting, and Charging systems oper-

ate in conjunction with one another, and must be

tested as a complete system. For correct operation of

starting/charging systems, all components used in

these 3 systems must perform within specifications.

When attempting to diagnose any of these systems, it

is important that you keep their interdependency in

mind.

The diagnostic procedures used in each of these

groups include the most basic conventional diagnostic

methods, to the more sophisticated On-Board Diag-

nostics (OBD) built into the Engine Control Module

(ECM). Use of an induction-type milliampere amme-

ter, volt/ohmmeter, battery charger, carbon pile rheo-

stat (load tester), and 12-volt test lamp may be

required.

Certain starting system components are monitored

by the ECM and may produce a Diagnostic Trouble

Code (DTC).

OPERATION

The starting system components form two separate

circuits. A high-amperage feed circuit that feeds the

starter motor high-amperage, and a low-amperagecontrol circuit that operates on less than 20 amperes.

The high-amperage feed circuit components include

the battery, the battery cables, the contact disc por-

tion of the starter solenoid, and the starter motor

itself. The low-amperage control circuit components

include the ignition switch, the park/neutral position

switch (automatic transmission), the starter relay,

the electromagnetic windings of the starter solenoid,

and the connecting wire harness components.

If the vehicle is equipped with an automatic trans-

mission, battery voltage is supplied through the low-

amperage control circuit to the coil battery terminal

of the starter relay when the ignition switch is

turned to the momentary Start position. The park/

neutral position switch is installed in series between

the starter relay coil ground terminal and ground.

This normally open switch prevents the starter relay

from being energized and the starter motor from

operating unless the automatic transmission gear

selector is in the Neutral or Park positions.

When the starter relay coil is energized, the nor-

mally open relay contacts close. The relay contacts

connect the relay common feed terminal to the relay

normally open terminal. The closed relay contacts

energize the starter solenoid coil windings.

The energized solenoid pull-in coil pulls in the sole-

noid plunger. The solenoid plunger pulls the shift

lever in the starter motor. This engages the starter

overrunning clutch and pinion gear with the starter

ring gear on the manual transmission flywheel or on

the automatic transmission torque converter or

torque converter drive plate.

As the solenoid plunger reaches the end of its

travel, the solenoid contact disc completes the high-

amperage starter feed circuit and energizes the sole-

noid plunger hold-in coil. Current now flows between

the solenoid battery terminal and the starter motor,

energizing the starter.

Once the engine starts, the overrunning clutch pro-

tects the starter motor from damage by allowing the

8F - 28 STARTING SYSTEMVA

Page 898 of 2305

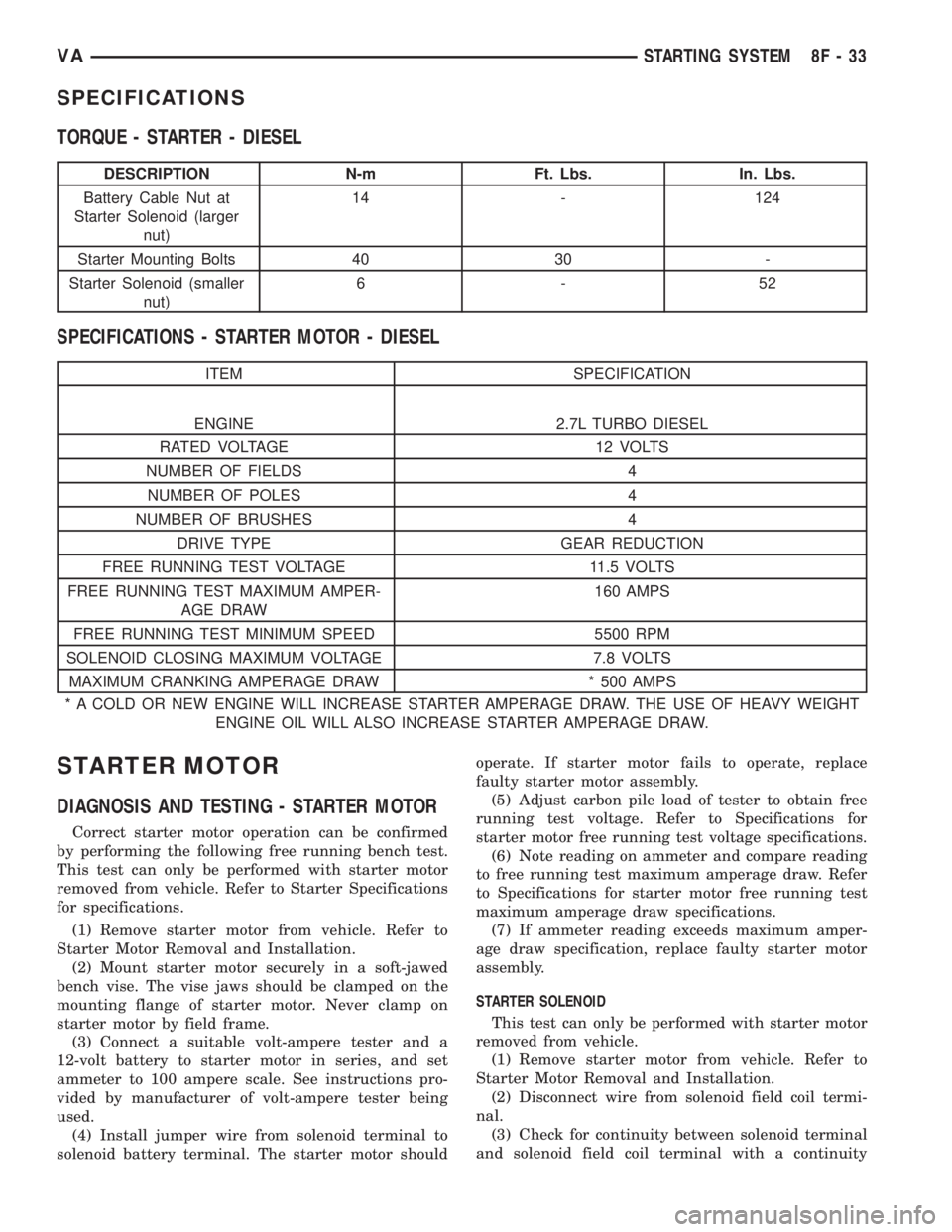

SPECIFICATIONS

TORQUE - STARTER - DIESEL

DESCRIPTION N-m Ft. Lbs. In. Lbs.

Battery Cable Nut at

Starter Solenoid (larger

nut)14 - 124

Starter Mounting Bolts 40 30 -

Starter Solenoid (smaller

nut)6-52

SPECIFICATIONS - STARTER MOTOR - DIESEL

ITEM SPECIFICATION

ENGINE 2.7L TURBO DIESEL

RATED VOLTAGE 12 VOLTS

NUMBER OF FIELDS 4

NUMBER OF POLES 4

NUMBER OF BRUSHES 4

DRIVE TYPE GEAR REDUCTION

FREE RUNNING TEST VOLTAGE 11.5 VOLTS

FREE RUNNING TEST MAXIMUM AMPER-

AGE DRAW160 AMPS

FREE RUNNING TEST MINIMUM SPEED 5500 RPM

SOLENOID CLOSING MAXIMUM VOLTAGE 7.8 VOLTS

MAXIMUM CRANKING AMPERAGE DRAW * 500 AMPS

* A COLD OR NEW ENGINE WILL INCREASE STARTER AMPERAGE DRAW. THE USE OF HEAVY WEIGHT

ENGINE OIL WILL ALSO INCREASE STARTER AMPERAGE DRAW.

STARTER MOTOR

DIAGNOSIS AND TESTING - STARTER MOTOR

Correct starter motor operation can be confirmed

by performing the following free running bench test.

This test can only be performed with starter motor

removed from vehicle. Refer to Starter Specifications

for specifications.

(1) Remove starter motor from vehicle. Refer to

Starter Motor Removal and Installation.

(2) Mount starter motor securely in a soft-jawed

bench vise. The vise jaws should be clamped on the

mounting flange of starter motor. Never clamp on

starter motor by field frame.

(3) Connect a suitable volt-ampere tester and a

12-volt battery to starter motor in series, and set

ammeter to 100 ampere scale. See instructions pro-

vided by manufacturer of volt-ampere tester being

used.

(4) Install jumper wire from solenoid terminal to

solenoid battery terminal. The starter motor shouldoperate. If starter motor fails to operate, replace

faulty starter motor assembly.

(5) Adjust carbon pile load of tester to obtain free

running test voltage. Refer to Specifications for

starter motor free running test voltage specifications.

(6) Note reading on ammeter and compare reading

to free running test maximum amperage draw. Refer

to Specifications for starter motor free running test

maximum amperage draw specifications.

(7) If ammeter reading exceeds maximum amper-

age draw specification, replace faulty starter motor

assembly.

STARTER SOLENOID

This test can only be performed with starter motor

removed from vehicle.

(1) Remove starter motor from vehicle. Refer to

Starter Motor Removal and Installation.

(2) Disconnect wire from solenoid field coil termi-

nal.

(3) Check for continuity between solenoid terminal

and solenoid field coil terminal with a continuity

VASTARTING SYSTEM 8F - 33

Page 904 of 2305

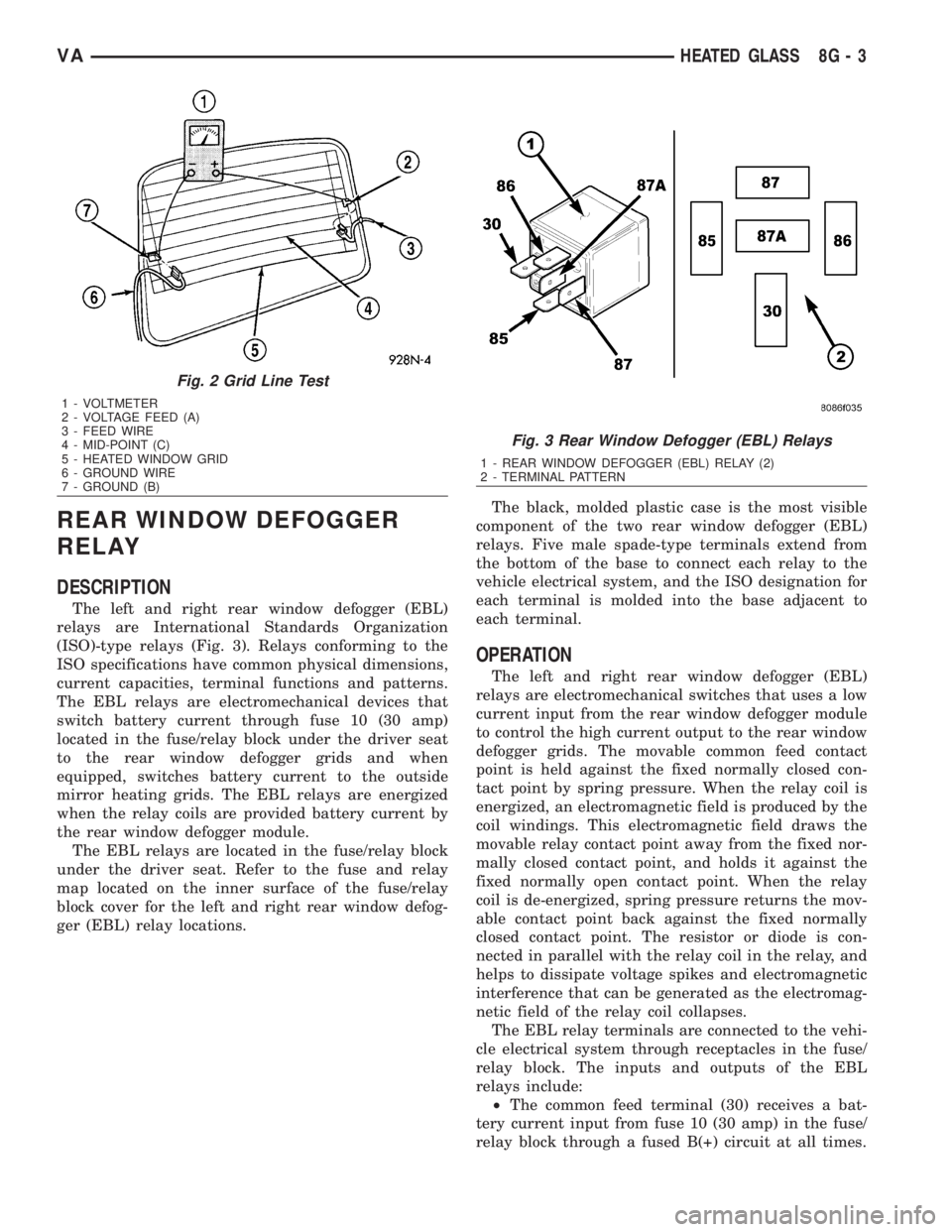

REAR WINDOW DEFOGGER

RELAY

DESCRIPTION

The left and right rear window defogger (EBL)

relays are International Standards Organization

(ISO)-type relays (Fig. 3). Relays conforming to the

ISO specifications have common physical dimensions,

current capacities, terminal functions and patterns.

The EBL relays are electromechanical devices that

switch battery current through fuse 10 (30 amp)

located in the fuse/relay block under the driver seat

to the rear window defogger grids and when

equipped, switches battery current to the outside

mirror heating grids. The EBL relays are energized

when the relay coils are provided battery current by

the rear window defogger module.

The EBL relays are located in the fuse/relay block

under the driver seat. Refer to the fuse and relay

map located on the inner surface of the fuse/relay

block cover for the left and right rear window defog-

ger (EBL) relay locations.The black, molded plastic case is the most visible

component of the two rear window defogger (EBL)

relays. Five male spade-type terminals extend from

the bottom of the base to connect each relay to the

vehicle electrical system, and the ISO designation for

each terminal is molded into the base adjacent to

each terminal.

OPERATION

The left and right rear window defogger (EBL)

relays are electromechanical switches that uses a low

current input from the rear window defogger module

to control the high current output to the rear window

defogger grids. The movable common feed contact

point is held against the fixed normally closed con-

tact point by spring pressure. When the relay coil is

energized, an electromagnetic field is produced by the

coil windings. This electromagnetic field draws the

movable relay contact point away from the fixed nor-

mally closed contact point, and holds it against the

fixed normally open contact point. When the relay

coil is de-energized, spring pressure returns the mov-

able contact point back against the fixed normally

closed contact point. The resistor or diode is con-

nected in parallel with the relay coil in the relay, and

helps to dissipate voltage spikes and electromagnetic

interference that can be generated as the electromag-

netic field of the relay coil collapses.

The EBL relay terminals are connected to the vehi-

cle electrical system through receptacles in the fuse/

relay block. The inputs and outputs of the EBL

relays include:

²The common feed terminal (30) receives a bat-

tery current input from fuse 10 (30 amp) in the fuse/

relay block through a fused B(+) circuit at all times.

Fig. 2 Grid Line Test

1 - VOLTMETER

2 - VOLTAGE FEED (A)

3 - FEED WIRE

4 - MID-POINT (C)

5 - HEATED WINDOW GRID

6 - GROUND WIRE

7 - GROUND (B)

Fig. 3 Rear Window Defogger (EBL) Relays

1 - REAR WINDOW DEFOGGER (EBL) RELAY (2)

2 - TERMINAL PATTERN

VAHEATED GLASS 8G - 3

Page 914 of 2305

The heated seat relay cannot be repaired or

adjusted and, if faulty or damaged, it must be

replaced.

OPERATION

The ISO relay consists of an electromagnetic coil, a

resistor or diode, and three (two fixed and one mov-

able) electrical contacts. The movable (common feed)

relay contact is held against one of the fixed contacts

(normally closed) by spring pressure. When the elec-

tromagnetic coil is energized, it draws the movable

contact away from the normally closed fixed contact,

and holds it against the other (normally open) fixed

contact. When the electromagnetic coil is de-ener-

gized, spring pressure returns the movable contact to

the normally closed position. The resistor or diode is

connected in parallel with the electromagnetic coil in

the relay, and helps to dissipate voltage spikes that

are produced when the coil is de-energized.

DIAGNOSIS AND TESTING - HEATED SEAT

RELAY

The heated seat relay is located in the Fuse Block,

under the drivers seat. Refer toWiringfor the loca-

tion of complete heated seat system wiring diagrams.

(1) Remove the heated seat relay from the fuse

block.

(2) A relay in the de-energized position should

have continuity between terminals 87A and 30, and

no continuity between terminals 87 and 30. If OK, go

to Step 3. If not OK, replace the faulty relay.

(3) Resistance between terminals 85 and 86 (elec-

tromagnet) should be 75 5 ohms. If OK, go to Step

4. If not OK, replace the faulty relay.

(4) Connect a battery to terminals 85 and 86.

There should now be continuity between terminals

30 and 87, and no continuity between terminals 87A

and 30. If OK, check the relay supply circuits. If not

OK, replace the faulty relay.

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) The heated seat relay is located in the fuse

block, under the drivers seat. Refer to wiring for

detailed location.

(3) Grasp the heated seat relay firmly and pull it

straight out from the fuse block. A slight rocking

motion will aid in removal.

INSTALLATION

(1) Grasp the heated seat relay firmly and push it

straight in the fuse block.

(2) Reconnect the battery negative cable.

HEATED SEAT SENSOR

DESCRIPTION

The heated seat temperature sensor is a Negative

Temperature Coefficient (NTC) thermistor. One tem-

perature sensor is used for each seat. The sensor is

located in the seat cushion heating element for all

models.

The heated seat sensor cannot be adjusted or

repaired and if it is found to be faulty, the complete

heated seat element must be replaced.

DIAGNOSIS AND TESTING - HEATED SEAT

SENSOR

For complete circuit diagrams, refer toWiring.

NOTE: Any resistance values (ohmsV) given in the

following text are supplied using the automatic

range generated by a FLUKETautomotive meter. If

another type of measuring device is used the val-

ues generated may not be the same as the results

shown here, or may have to be converted to the

range used here.

(1) Backprobe the heated seat relay wire harness

connector, do not disconnect. Using an voltmeter,

check the voltage of the seat temperature sensor

input cavity of the heated seat relay wire harness

connector. The seat sensor input voltage should be

between 1.7 volts and 3.0 volts with the system ON.

If OK, sensor is OK at this time. If not OK, replace

the faulty seat cushion heating element and sensor

assembly.

PASSENGER HEATED SEAT

SWITCH

DESCRIPTION

The heated seat switches are located on the instru-

ment panel, in the accessory switch bezel. The two,

momentary rocker type switches provide a signal to

the Heated Seat Relay through separate hard wired

circuits. Each switch contains two light emitting

diodes (LED), one for each High and Low setting to

let the occupant know that the seat heater system is

on.

The heated seat switches and their LED's cannot

be repaired. If either switch is faulty or damaged the

entire switch must be replaced.

OPERATION

There are three modes that can be selected with

each of the heated seat switches: Off, Low, and High.

When the top of the switch rocker is depressed, the

low mode is selected and the low mode LED indicator

illuminates. Depressing the top of the switch rocker a

VAHEATED SEATS 8G - 13

Page 922 of 2305

Located between the rear cover and the cluster

hood is the cluster housing. The molded plastic clus-

ter housing serves as the carrier for the cluster elec-

tronic circuit board and circuitry, the cluster

connector receptacles, the gauges, a Light Emitting

Diode (LED) for each cluster indicator and general

illumination lamp, the multi-function indicator LCD

unit, electronic tone generators, the cluster overlay,

the gauge pointers, the multi-function indicator

switches and the four switch push buttons.

The cluster overlay is a laminated plastic unit. The

dark, visible, outer surface of the overlay is marked

with all of the gauge dial faces and graduations, but

this layer is also translucent. The darkness of this

outer layer prevents the cluster from appearing clut-

tered or busy by concealing the cluster indicators

that are not illuminated, while the translucence of

this layer allows those indicators and icons that are

illuminated to be readily visible. The underlying

layer of the overlay is opaque and allows light from

the LED for each of the various indicators and illu-

mination lamps behind it to be visible through the

outer layer of the overlay only through predeter-

mined cutouts. A rectangular opening in the overlay

at the base of the speedometer provides a window

through which the illuminated multi-function indica-

tor LCD unit can be viewed.

Several versions of the EMIC module are offered

on this model. These versions accommodate all of the

variations of optional equipment and regulatory

requirements for the various markets in which the

vehicle will be offered. The microprocessor-based

EMIC utilizes integrated circuitry, Electrically Eras-

able Programmable Read Only Memory (EEPROM)

type memory storage, information carried on the

Controller Area Network (CAN) data bus, along with

several hard wired analog and multiplexed inputs to

monitor systems, sensors and switches throughout

the vehicle.

In response to those inputs, the hardware and soft-

ware of the EMIC allow it to control and integrate

many electronic functions and features of the vehicle

through both hard wired outputs and the transmis-

sion of electronic message outputs to other electronic

modules in the vehicle over the CAN data bus. (Refer

to 8 - ELECTRICAL/ELECTRONIC CONTROL

MODULES/COMMUNICATION - DESCRIPTION -

CAN BUS).

Besides typical instrument cluster gauge and indi-

cator support, the electronic functions and features

that the EMIC supports or controls include the fol-

lowing:

²Active Service System- In vehicles equipped

with the Active Service SYSTem (ASSYST) engine oil

maintenance indicator option, the EMIC electronic

circuit board includes a second dedicated micropro-

cessor. This second microprocessor evaluates various

data including time, mileage, and driving conditionsto calculate the required engine oil service intervals,

and provides both visual and audible alerts to the

vehicle operator when certain engine oil maintenance

services are required.

²Audible Warnings- The EMIC electronic cir-

cuit board is equipped with an audible tone generator

and programming that allows it to provide various

audible alerts to the vehicle operator, including buzz-

ing and chime tones. An audible contactless elec-

tronic relay is also soldered onto the circuit board to

produce audible clicks that is synchronized with turn

signal indicator flashing to emulate the sounds of a

conventional turn signal or hazard warning flasher.

These audible clicks can occur at one of two rates to

emulate both normal and bulb-out turn or hazard

flasher operation. (Refer to 8 - ELECTRICAL/

CHIME/BUZZER - DESCRIPTION).

²Panel Lamps Dimming Control- The EMIC

provides a hard wired 12-volt Pulse-Width Modulated

(PWM) output that synchronizes the dimming level

of all panel lamps dimmer controlled lamps with that

of the cluster general illumination lamps and multi-

function indicator.

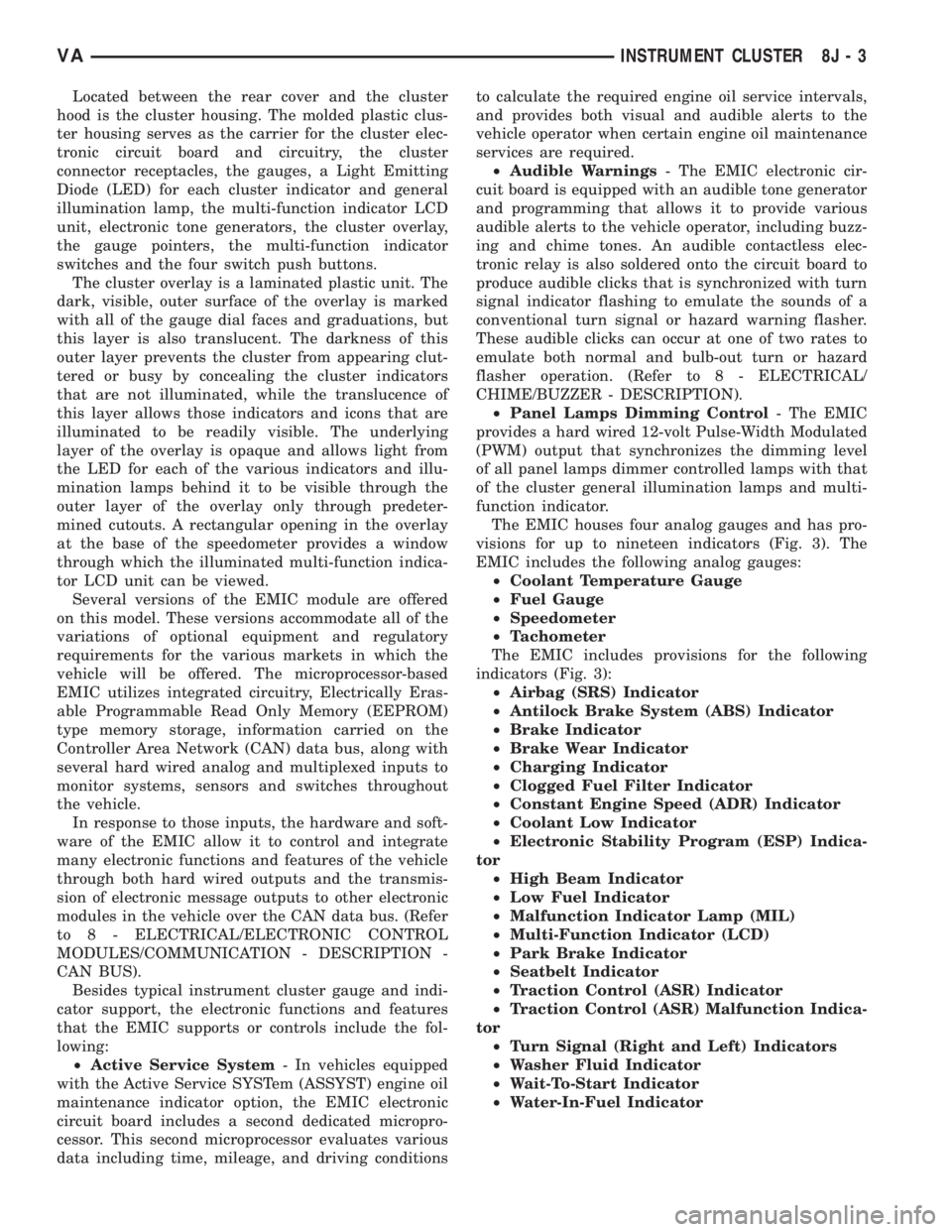

The EMIC houses four analog gauges and has pro-

visions for up to nineteen indicators (Fig. 3). The

EMIC includes the following analog gauges:

²Coolant Temperature Gauge

²Fuel Gauge

²Speedometer

²Tachometer

The EMIC includes provisions for the following

indicators (Fig. 3):

²Airbag (SRS) Indicator

²Antilock Brake System (ABS) Indicator

²Brake Indicator

²Brake Wear Indicator

²Charging Indicator

²Clogged Fuel Filter Indicator

²Constant Engine Speed (ADR) Indicator

²Coolant Low Indicator

²Electronic Stability Program (ESP) Indica-

tor

²High Beam Indicator

²Low Fuel Indicator

²Malfunction Indicator Lamp (MIL)

²Multi-Function Indicator (LCD)

²Park Brake Indicator

²Seatbelt Indicator

²Traction Control (ASR) Indicator

²Traction Control (ASR) Malfunction Indica-

tor

²Turn Signal (Right and Left) Indicators

²Washer Fluid Indicator

²Wait-To-Start Indicator

²Water-In-Fuel Indicator

VAINSTRUMENT CLUSTER 8J - 3

Page 923 of 2305

Except for the indications provided within the

multi-function indicator LCD unit, each indicator in

the EMIC is illuminated by a dedicated LED that is

soldered onto the EMIC electronic circuit board.

Cluster illumination is accomplished by dimmable

LED back lighting, which illuminates the gauges for

visibility when the exterior lighting is turned on. The

cluster general illumination LED units are also sol-

dered onto the EMIC electronic circuit board. The

LED units are not available for service replacement

and, if damaged or faulty, the entire EMIC must be

replaced.Hard wired circuitry connects the EMIC to the

electrical system of the vehicle. These hard wired cir-

cuits are integral to the vehicle wire harnesses,

which are routed throughout the vehicle and retained

by many different methods. These circuits may be

connected to each other, to the vehicle electrical sys-

tem and to the EMIC through the use of a combina-

tion of soldered splices, splice block connectors, and

many different types of wire harness terminal con-

nectors and insulators. Refer to the appropriate wir-

ing information. The wiring information includes

wiring diagrams, proper wire and connector repair

Fig. 3 Gauges & Indicators

1 - AIRBAG INDICATOR 16 - SEATBELT INDICATOR

2 - TACHOMETER 17 - ABS INDICATOR

3 - LEFT TURN INDICATOR 18 - MULTI-FUNCTION INDICATOR PLUS/MINUS SWITCH

PUSH BUTTONS

4 - SPEEDOMETER 19 - MULTI-FUNCTION INDICATOR (INCLUDES: CLOCK, GEAR

SELECTOR INDICATOR, ODOMETER, TRIP ODOMETER, EN-

GINE OIL LEVEL DATA, AMBIENT TEMPERATURE INDICATOR

[OPTIONAL], & ACTIVE SERVICE SYSTEM [ASSYST] ENGINE

OIL MAINTENANCE INDICATOR [OPTIONAL])

5 - TRACTION CONTROL INDICATOR 20 - MULTI-FUNCTION INDICATOR MODE (MILES [KILOME-

TERS]/TIME) SWITCH PUSH BUTTONS

6 - RIGHT TURN INDICATOR 21 - COOLANT LOW INDICATOR

7 - ENGINE TEMPERATURE GAUGE 22 - BRAKE INDICATOR

8 - FUEL GAUGE 23 - OIL LEVEL INDICATOR

9 - WAIT-TO-START INDICATOR 24 - BRAKE WEAR INDICATOR

10 - WASHER FLUID INDICATOR (OPTIONAL) 25 - WATER-IN-FUEL INDICATOR

11 - CONSTANT ENGINE SPEED (ADR) INDICATOR (OPTION-

AL)26 - CHARGING INDICATOR

12 - LOW FUEL INDICATOR 27 - HIGH BEAM INDICATOR

13 - TRACTION CONTROL MALFUNCTION INDICATOR 28 - PARK BRAKE INDICATOR

14 - MALFUNCTION INDICATOR LAMP 29 - FUEL FILTER CLOGGED INDICATOR

15 - ELECTRONIC STABILITY PROGRAM (ESP) INDICATOR

(OPTIONAL)

8J - 4 INSTRUMENT CLUSTERVA

Page 978 of 2305

right rear door is standard equipment on wagon mod-

els. The sliding and rear door jamb switches are not

available for van models.

²Entry/Exit Lamp- An entry/exit lamp to illu-

minate each front and sliding side door step well is

optional equipment on wagon models.

²Time Delay Relay- Vehicles equipped with the

optional remote cargo lamp switches also have a time

delay relay located in the electrical center within the

driver side front seat riser.

Hard wired circuitry connects the interior lighting

system components to the electrical system of the

vehicle. These hard wired circuits are integral to sev-

eral wire harnesses, which are routed throughout the

vehicle and retained by many different methods.

These circuits may be connected to each other, to the

vehicle electrical system and to the interior lighting

system components through the use of a combination

of soldered splices, splice block connectors, and many

different types of wire harness terminal connectors

and insulators. Refer to the appropriate wiring infor-

mation. The wiring information includes wiring dia-

grams, proper wire and connector repair procedures,

further details on wire harness routing and reten-

tion, as well as pin-out and location views for the

various wire harness connectors, splices and grounds.

OPERATION

The interior lighting systems can be divided into

two general classifications based upon the circuit

that controls their operation: The interior lighting

circuit, or the exterior lighting circuit. The hard

wired circuits and components of the interior lighting

systems may be diagnosed and tested using conven-

tional diagnostic tools and procedures.

INTERIOR LIGHTING CIRCUIT

Depending upon the vehicle model (van or wagon)

and the selected vehicle options the interior lighting

circuit may include dome/cargo lamps located over-

head in the front and rear of the vehicle, a dome/

reading lamp located in the header area above the

windshield between the sun visors, and entry/exit

lamps located in the front and sliding side door step

wells.

WAGON MODELS

In all wagon models, the lamps in the interior

lighting circuit are provided with battery current at

all times by a fuse in the fuse block beneath the

steering column. The front, side, and rear door jamb

switches control a ground path for each of these

lamps, except for the optional reading lamp. If the

lamp has an optional integral switch, that switch has

three separate positions. The first position provides a

ground path independent of the door jamb switches

to turn the lamp On. The second, or center position

allows the door jamb switches to control the lamp.The third position segregates that lamp from the

door jamb switch input, turning the lamp Off. In the

case of the optional dome/reading lamp, the integral

lamp switch has a fourth position which will illumi-

nate only the reading lamp bulb.

VAN MODELS

Unless a van model is equipped with an optional

remote cargo lamp switch, all of the lamps in the

interior lighting circuit operate the same way as the

wagon models except that there are only two door

jamb switches, one for each front door. If the vehicle

is equipped with an optional remote cargo lamp

switch, the lamps in the rear of the vehicle on the

interior lighting circuit are provided with battery

current by the time delay relay. The time delay relay

is a smart relay containing active electronic elements

that comprise an electronic timer logic circuit. When

the remote cargo lamp switches provide the proper

input to the time delay relay, the relay logic responds

by energizing the relay control coil. The energized

relay control coil provides battery current to all of

the lamps on the rear interior lighting circuit and to

the indicator Light-Emitting Diode (LED) units in

the remote cargo switches causing each to illuminate.

If a remote cargo lamp switch remains On for more

than about fifteen minutes, the time delay relay will

then automatically de-energize the rear interior

lighting circuits until the remote cargo lamp switch

is cycled Off and then back On.

EXTERIOR LIGHTING CIRCUIT

The exterior lighting circuit provides battery cur-

rent to the optional ash receiver/cigar lighter lamp

and to the illumination Light-Emitting Diode (LED)

unit within the remote cargo lamp switch in the

instrument panel accessory switch bezel whenever

the exterior lamps are turned On.

SPECIFICATIONS - INTERIOR LIGHTING

VALAMPS/LIGHTING - INTERIOR 8L - 29

Page 1077 of 2305

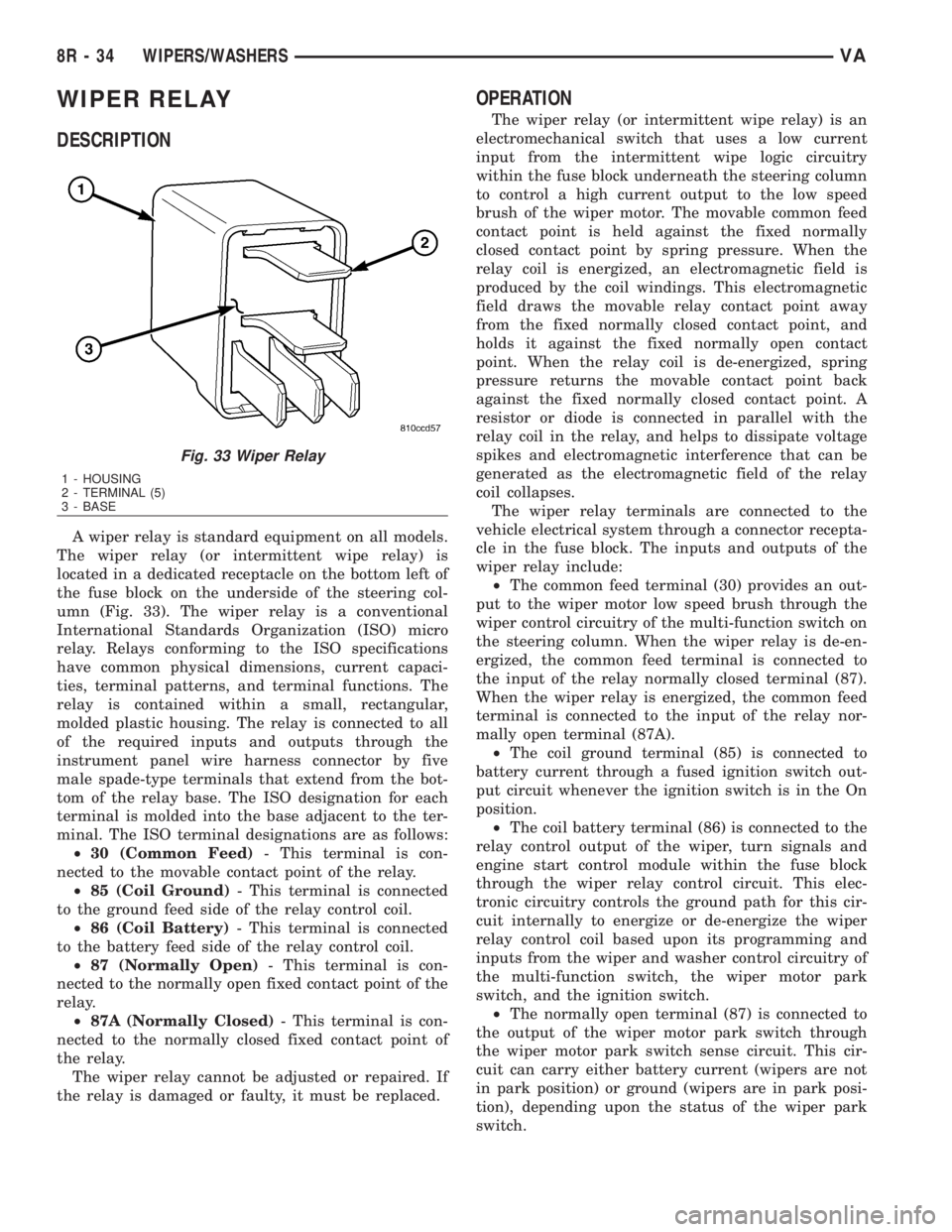

WIPER RELAY

DESCRIPTION

A wiper relay is standard equipment on all models.

The wiper relay (or intermittent wipe relay) is

located in a dedicated receptacle on the bottom left of

the fuse block on the underside of the steering col-

umn (Fig. 33). The wiper relay is a conventional

International Standards Organization (ISO) micro

relay. Relays conforming to the ISO specifications

have common physical dimensions, current capaci-

ties, terminal patterns, and terminal functions. The

relay is contained within a small, rectangular,

molded plastic housing. The relay is connected to all

of the required inputs and outputs through the

instrument panel wire harness connector by five

male spade-type terminals that extend from the bot-

tom of the relay base. The ISO designation for each

terminal is molded into the base adjacent to the ter-

minal. The ISO terminal designations are as follows:

²30 (Common Feed)- This terminal is con-

nected to the movable contact point of the relay.

²85 (Coil Ground)- This terminal is connected

to the ground feed side of the relay control coil.

²86 (Coil Battery)- This terminal is connected

to the battery feed side of the relay control coil.

²87 (Normally Open)- This terminal is con-

nected to the normally open fixed contact point of the

relay.

²87A (Normally Closed)- This terminal is con-

nected to the normally closed fixed contact point of

the relay.

The wiper relay cannot be adjusted or repaired. If

the relay is damaged or faulty, it must be replaced.

OPERATION

The wiper relay (or intermittent wipe relay) is an

electromechanical switch that uses a low current

input from the intermittent wipe logic circuitry

within the fuse block underneath the steering column

to control a high current output to the low speed

brush of the wiper motor. The movable common feed

contact point is held against the fixed normally

closed contact point by spring pressure. When the

relay coil is energized, an electromagnetic field is

produced by the coil windings. This electromagnetic

field draws the movable relay contact point away

from the fixed normally closed contact point, and

holds it against the fixed normally open contact

point. When the relay coil is de-energized, spring

pressure returns the movable contact point back

against the fixed normally closed contact point. A

resistor or diode is connected in parallel with the

relay coil in the relay, and helps to dissipate voltage

spikes and electromagnetic interference that can be

generated as the electromagnetic field of the relay

coil collapses.

The wiper relay terminals are connected to the

vehicle electrical system through a connector recepta-

cle in the fuse block. The inputs and outputs of the

wiper relay include:

²The common feed terminal (30) provides an out-

put to the wiper motor low speed brush through the

wiper control circuitry of the multi-function switch on

the steering column. When the wiper relay is de-en-

ergized, the common feed terminal is connected to

the input of the relay normally closed terminal (87).

When the wiper relay is energized, the common feed

terminal is connected to the input of the relay nor-

mally open terminal (87A).

²The coil ground terminal (85) is connected to

battery current through a fused ignition switch out-

put circuit whenever the ignition switch is in the On

position.

²The coil battery terminal (86) is connected to the

relay control output of the wiper, turn signals and

engine start control module within the fuse block

through the wiper relay control circuit. This elec-

tronic circuitry controls the ground path for this cir-

cuit internally to energize or de-energize the wiper

relay control coil based upon its programming and

inputs from the wiper and washer control circuitry of

the multi-function switch, the wiper motor park

switch, and the ignition switch.

²The normally open terminal (87) is connected to

the output of the wiper motor park switch through

the wiper motor park switch sense circuit. This cir-

cuit can carry either battery current (wipers are not

in park position) or ground (wipers are in park posi-

tion), depending upon the status of the wiper park

switch.

Fig. 33 Wiper Relay

1 - HOUSING

2 - TERMINAL (5)

3 - BASE

8R - 34 WIPERS/WASHERSVA

Page 1571 of 2305

OPERATION

The cigar lighter consists of two major components:

a knob and heating element unit, and the cigar

lighter base or receptacle shell. The receptacle shell

is connected to ground, and an insulated contact in

the bottom of the shell is connected to battery cur-

rent. The cigar lighter receives battery voltage from a

fuse in the fuseblock only when the ignition switch is

in the Accessory or On positions.

The knob and heating element are encased within

a spring-loaded housing, which also features a sliding

protective heat shield. When the heating element is

inserted in the receptacle shell, the heating element

resistor coil is grounded through its housing to the

receptacle shell. If the cigar lighter knob is pushed

inward, the heat shield slides up toward the knob

exposing the heating element.

Two small spring-clip retainers are located on

either side of the insulated contact inside the bottom

of the receptacle shell. These clips engage and hold

the heating element against the insulated contact

long enough for the resistor coil to heat up and glow.

When the resistor coil becomes sufficiently heated,

excess heat radiates from the heating element caus-

ing the spring-clips to expand. Once the spring-clips

expand far enough to release the heating element,

the spring-loaded housing forces the knob and heat-

ing element to pop back outward to their relaxed

position. When the cigar lighter knob and element

are pulled out of the receptacle shell, the protective

heat shield slides downward on the housing so that

the heating element is recessed and shielded around

its circumference for safety.

DIAGNOSIS AND TESTING - CIGAR LIGHTER

OUTLET

For cigar lighter outlet diagnosis and testing pro-

cedures (Refer to 8 - ELECTRICAL/POWER DISTRI-

BUTION/POWER OUTLET - DIAGNOSIS AND

TESTING)

REMOVAL

For cigar lighter outlet removal procedure (Refer to

8 - ELECTRICAL/POWER DISTRIBUTION/POWER

OUTLET - REMOVAL).

CIRCUIT BREAKER

DESCRIPTION

Automatic resetting circuit breakers are used to

protect the power window voltage supply circuits.

These circuit breakers can protect the systems from a

short circuit, or from an overload condition caused byan obstructed or stuck power window regulator or

switch.

The circuit breaker cannot be repaired and, if

faulty or damaged, it must be replaced.

OPERATION

The circuit breaker contains a bi-metal strip sand-

wiched between two contacts forming the connection

in the circuit. An overload condition causes the

bi-metal strip to heat and bend to the open position,

disconnecting current flow to the circuit. Then as the

system overload or short circuit is removed, the

bi-metal strip cools, re-establishing contact to allow

current flow to the circuit.

DIAGNOSIS AND TESTING - CIRCUIT BREAKER

For complete circuit descriptions and diagrams,

refer toWiring.

(1) Locate the correct circuit breaker in the fuse-

block. Pull out the circuit breaker slightly, but be cer-

tain that the circuit breaker terminals still contact

the terminals in the fuseblock cavities.

(2) Connect the negative lead of a 12-volt DC volt-

meter to a good ground.

(3) With the voltmeter positive lead, check both

terminals of the circuit breaker for battery voltage.

If only one terminal has battery voltage, the circuit

breaker is faulty and must be replaced. If neither ter-

minal has battery voltage, repair the open circuit

from the Power Distribution Center as required.

FUSE BLOCK #1

DESCRIPTION

An electrical fuse block is concealed under the

driver side steering column. The fuse block serves to

distribute electrical current to many of the electrical

systems in the vehicle. The fuse block contains blade-

type mini fuses, relays and micro processors that

enable automatic control of some of the power distri-

bution circuits throughout the vehicle.

The molded plastic fuse block housing has an inte-

gral mounting bracket that is secured with screws to

the steering column. A finger recess is molded into

the cover for easy removal. A fuse layout map is

molded onto the back side of the cover to ensure

proper fuse identification.

The fuse block cannot be repaired, if the fuse block

is faulty or damaged or if any internal circuit is

faulty or damaged, the entire fuse block must be

replaced.

8W - 97 - 2 8W-97 POWER DISTRIBUTIONVA