check engine light MERCEDES-BENZ SPRINTER 2006 Workshop Manual

[x] Cancel search | Manufacturer: MERCEDES-BENZ, Model Year: 2006, Model line: SPRINTER, Model: MERCEDES-BENZ SPRINTER 2006Pages: 2305, PDF Size: 48.12 MB

Page 1742 of 2305

SPECIFICATIONS - TORQUE CHART

TORQUE SPECIFICATIONS

DESCRIPTION N´m Ft. Lbs. In. Lbs.

Power Steering Pump To

Timing Case Cover/Sup-

port21 15 185

High Pressure Flexible

Hose To Power Steering

Pump38 28 336

Power Steering Pulley To

Pump30 22 265

FLUID

STANDARD PROCEDURE

POWER STEERING PUMP FILL AND BLEED

PROCEDURE

(1) Remove the cap from the fluid reservoir.

Check cap seal for damage and replace if

needed.

(2) Fill the power steering pump with approved

fluid (Refer to LUBRICATION & MAINTENANCE/

FLUID TYPES - DESCRIPTION).Do not fill fluid

beyond the MAX mark.

(3) Raise the vehicles front wheels off the ground.

(4) With the engine off turn the steering wheel

from right to left.Perform this step until all the

bubble formations can no longer be seen in the

power steering reservoir.

(5) Start the engine and turn the steering wheel

with the engine at idle speed then shut the engine off

and check for correct oil level and no bubble in the

system.

(6) Reinstall power steering cap tightly.

(7) Test the system for leaks and proper operation.

FLUID COOLER TUBE

REMOVAL

(1) Siphon as much power steering fluid as possi-

ble out of the reservoir.

(2) Remove the grille (Refer to 23 - BODY/EXTE-

RIOR/GRILLE - REMOVAL).

(3) Remove the left headlight assembly.

(4) Disconnect the return lines from the cooler

tube.

(5) Remove the radiator clips (2).

(6) Remove the heat shield bolt for the turbo at

the core support.

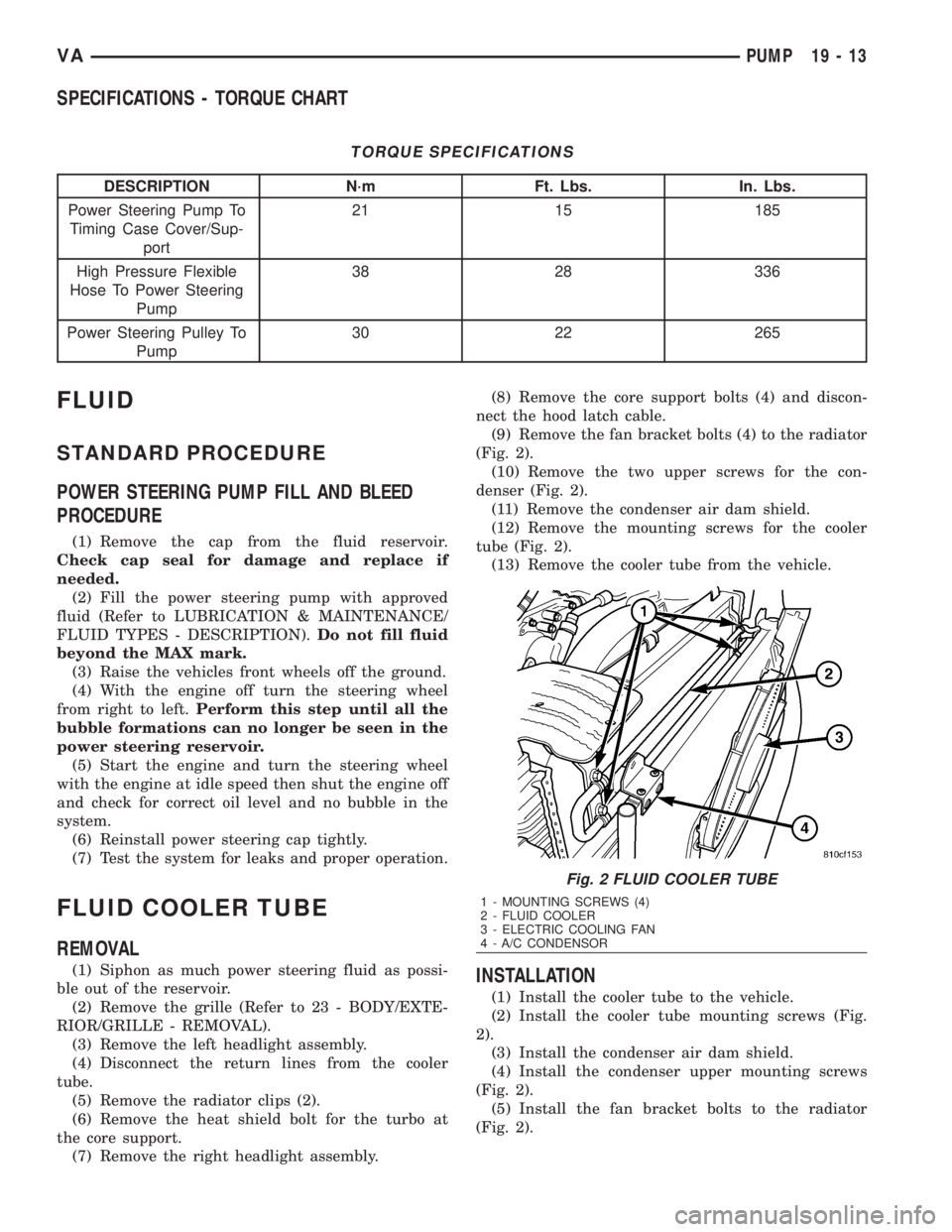

(7) Remove the right headlight assembly.(8) Remove the core support bolts (4) and discon-

nect the hood latch cable.

(9) Remove the fan bracket bolts (4) to the radiator

(Fig. 2).

(10) Remove the two upper screws for the con-

denser (Fig. 2).

(11) Remove the condenser air dam shield.

(12) Remove the mounting screws for the cooler

tube (Fig. 2).

(13) Remove the cooler tube from the vehicle.INSTALLATION

(1) Install the cooler tube to the vehicle.

(2) Install the cooler tube mounting screws (Fig.

2).

(3) Install the condenser air dam shield.

(4) Install the condenser upper mounting screws

(Fig. 2).

(5) Install the fan bracket bolts to the radiator

(Fig. 2).

Fig. 2 FLUID COOLER TUBE

1 - MOUNTING SCREWS (4)

2 - FLUID COOLER

3 - ELECTRIC COOLING FAN

4 - A/C CONDENSOR

VAPUMP 19 - 13

Page 1789 of 2305

(16) Disconnect ground strap and tie back to one

side.

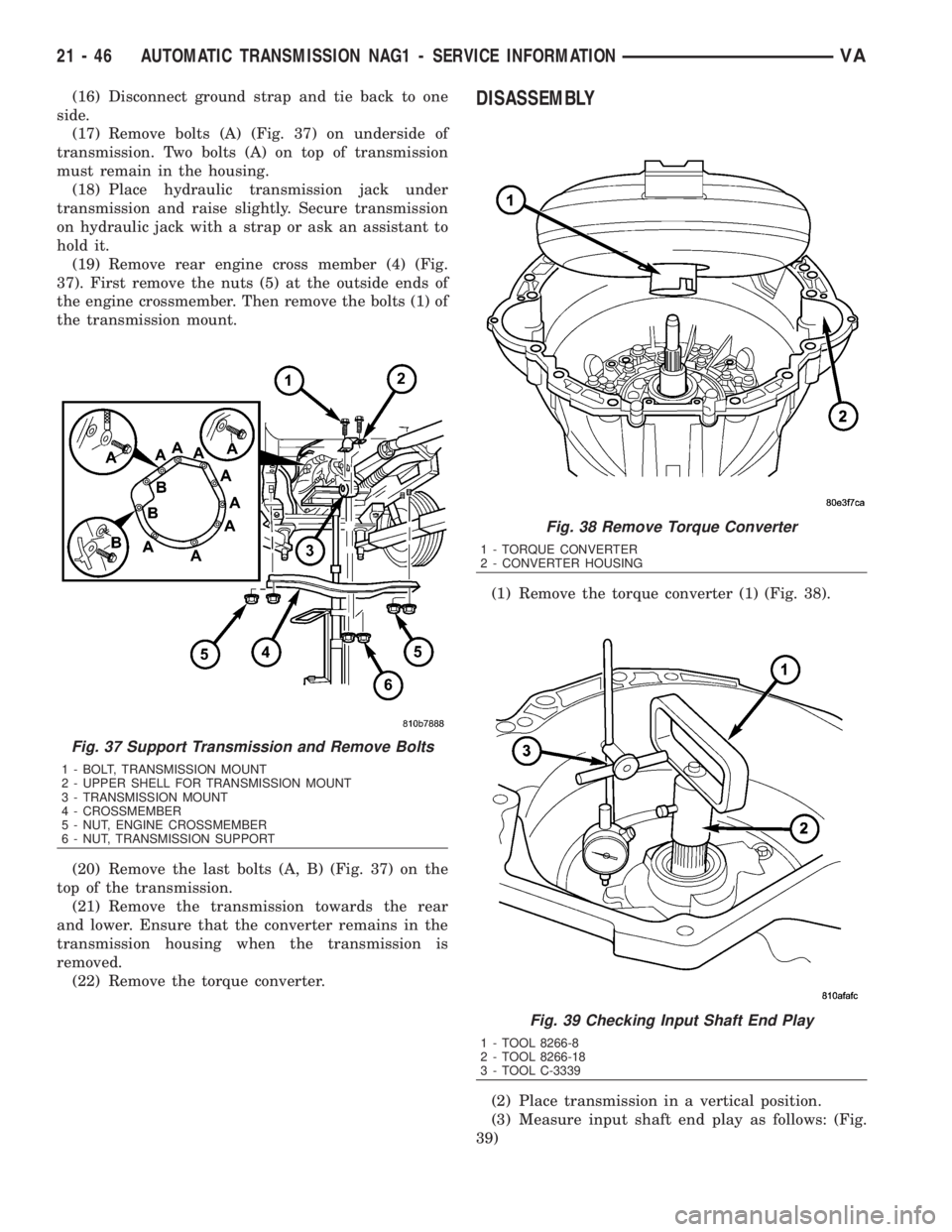

(17) Remove bolts (A) (Fig. 37) on underside of

transmission. Two bolts (A) on top of transmission

must remain in the housing.

(18) Place hydraulic transmission jack under

transmission and raise slightly. Secure transmission

on hydraulic jack with a strap or ask an assistant to

hold it.

(19) Remove rear engine cross member (4) (Fig.

37). First remove the nuts (5) at the outside ends of

the engine crossmember. Then remove the bolts (1) of

the transmission mount.

(20) Remove the last bolts (A, B) (Fig. 37) on the

top of the transmission.

(21) Remove the transmission towards the rear

and lower. Ensure that the converter remains in the

transmission housing when the transmission is

removed.

(22) Remove the torque converter.DISASSEMBLY

(1) Remove the torque converter (1) (Fig. 38).

(2) Place transmission in a vertical position.

(3) Measure input shaft end play as follows: (Fig.

39)

Fig. 37 Support Transmission and Remove Bolts

1 - BOLT, TRANSMISSION MOUNT

2 - UPPER SHELL FOR TRANSMISSION MOUNT

3 - TRANSMISSION MOUNT

4 - CROSSMEMBER

5 - NUT, ENGINE CROSSMEMBER

6 - NUT, TRANSMISSION SUPPORT

Fig. 38 Remove Torque Converter

1 - TORQUE CONVERTER

2 - CONVERTER HOUSING

Fig. 39 Checking Input Shaft End Play

1 - TOOL 8266-8

2 - TOOL 8266-18

3 - TOOL C-3339

21 - 46 AUTOMATIC TRANSMISSION NAG1 - SERVICE INFORMATIONVA

Page 1911 of 2305

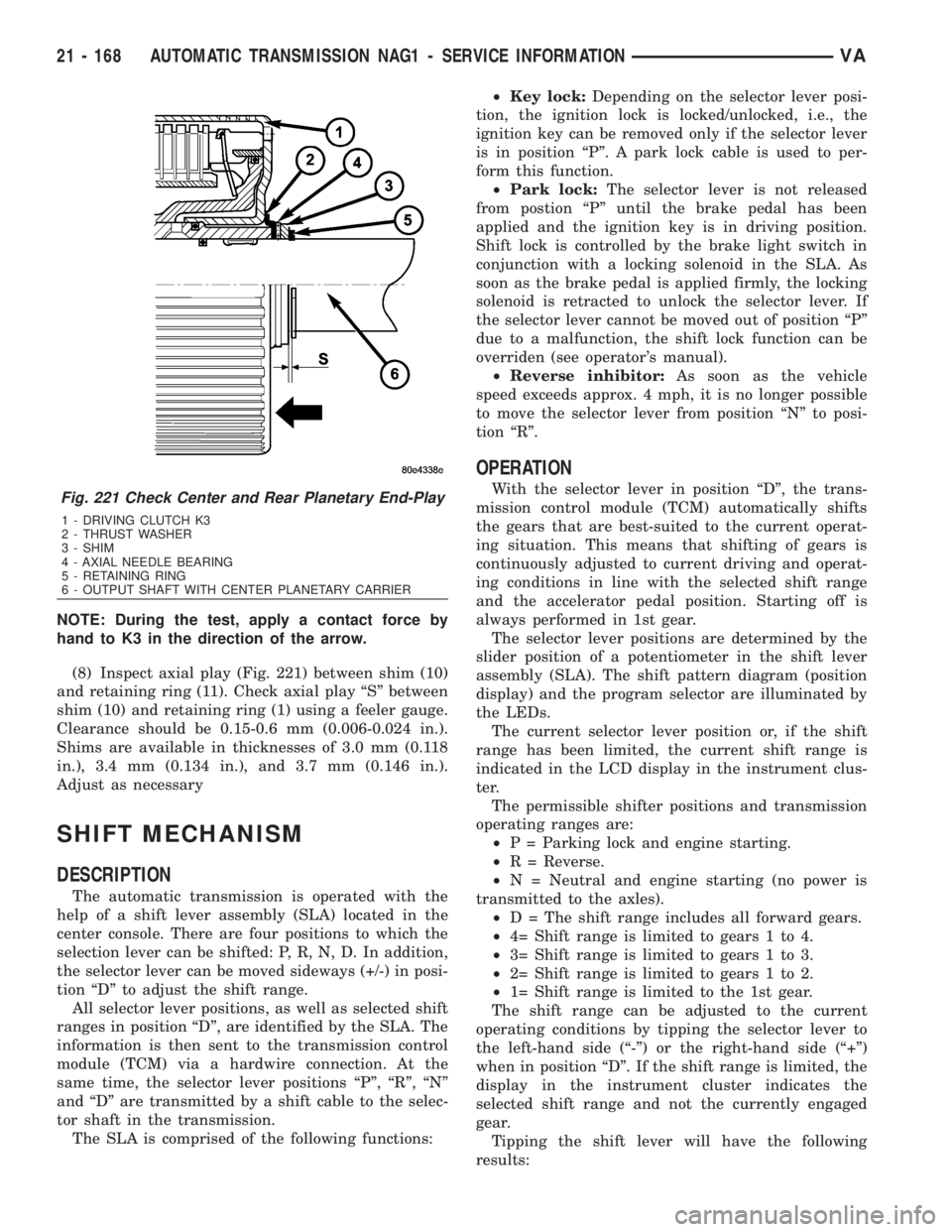

NOTE: During the test, apply a contact force by

hand to K3 in the direction of the arrow.

(8) Inspect axial play (Fig. 221) between shim (10)

and retaining ring (11). Check axial play ªSº between

shim (10) and retaining ring (1) using a feeler gauge.

Clearance should be 0.15-0.6 mm (0.006-0.024 in.).

Shims are available in thicknesses of 3.0 mm (0.118

in.), 3.4 mm (0.134 in.), and 3.7 mm (0.146 in.).

Adjust as necessary

SHIFT MECHANISM

DESCRIPTION

The automatic transmission is operated with the

help of a shift lever assembly (SLA) located in the

center console. There are four positions to which the

selection lever can be shifted: P, R, N, D. In addition,

the selector lever can be moved sideways (+/-) in posi-

tion ªDº to adjust the shift range.

All selector lever positions, as well as selected shift

ranges in position ªDº, are identified by the SLA. The

information is then sent to the transmission control

module (TCM) via a hardwire connection. At the

same time, the selector lever positions ªPº, ªRº, ªNº

and ªDº are transmitted by a shift cable to the selec-

tor shaft in the transmission.

The SLA is comprised of the following functions:²Key lock:Depending on the selector lever posi-

tion, the ignition lock is locked/unlocked, i.e., the

ignition key can be removed only if the selector lever

is in position ªPº. A park lock cable is used to per-

form this function.

²Park lock:The selector lever is not released

from postion ªPº until the brake pedal has been

applied and the ignition key is in driving position.

Shift lock is controlled by the brake light switch in

conjunction with a locking solenoid in the SLA. As

soon as the brake pedal is applied firmly, the locking

solenoid is retracted to unlock the selector lever. If

the selector lever cannot be moved out of position ªPº

due to a malfunction, the shift lock function can be

overriden (see operator's manual).

²Reverse inhibitor:As soon as the vehicle

speed exceeds approx. 4 mph, it is no longer possible

to move the selector lever from position ªNº to posi-

tion ªRº.

OPERATION

With the selector lever in position ªDº, the trans-

mission control module (TCM) automatically shifts

the gears that are best-suited to the current operat-

ing situation. This means that shifting of gears is

continuously adjusted to current driving and operat-

ing conditions in line with the selected shift range

and the accelerator pedal position. Starting off is

always performed in 1st gear.

The selector lever positions are determined by the

slider position of a potentiometer in the shift lever

assembly (SLA). The shift pattern diagram (position

display) and the program selector are illuminated by

the LEDs.

The current selector lever position or, if the shift

range has been limited, the current shift range is

indicated in the LCD display in the instrument clus-

ter.

The permissible shifter positions and transmission

operating ranges are:

²P = Parking lock and engine starting.

²R = Reverse.

²N = Neutral and engine starting (no power is

transmitted to the axles).

²D = The shift range includes all forward gears.

²4= Shift range is limited to gears 1 to 4.

²3= Shift range is limited to gears 1 to 3.

²2= Shift range is limited to gears 1 to 2.

²1= Shift range is limited to the 1st gear.

The shift range can be adjusted to the current

operating conditions by tipping the selector lever to

the left-hand side (ª-º) or the right-hand side (ª+º)

when in position ªDº. If the shift range is limited, the

display in the instrument cluster indicates the

selected shift range and not the currently engaged

gear.

Tipping the shift lever will have the following

results:Fig. 221 Check Center and Rear Planetary End-Play

1 - DRIVING CLUTCH K3

2 - THRUST WASHER

3 - SHIM

4 - AXIAL NEEDLE BEARING

5 - RETAINING RING

6 - OUTPUT SHAFT WITH CENTER PLANETARY CARRIER

21 - 168 AUTOMATIC TRANSMISSION NAG1 - SERVICE INFORMATIONVA

Page 2042 of 2305

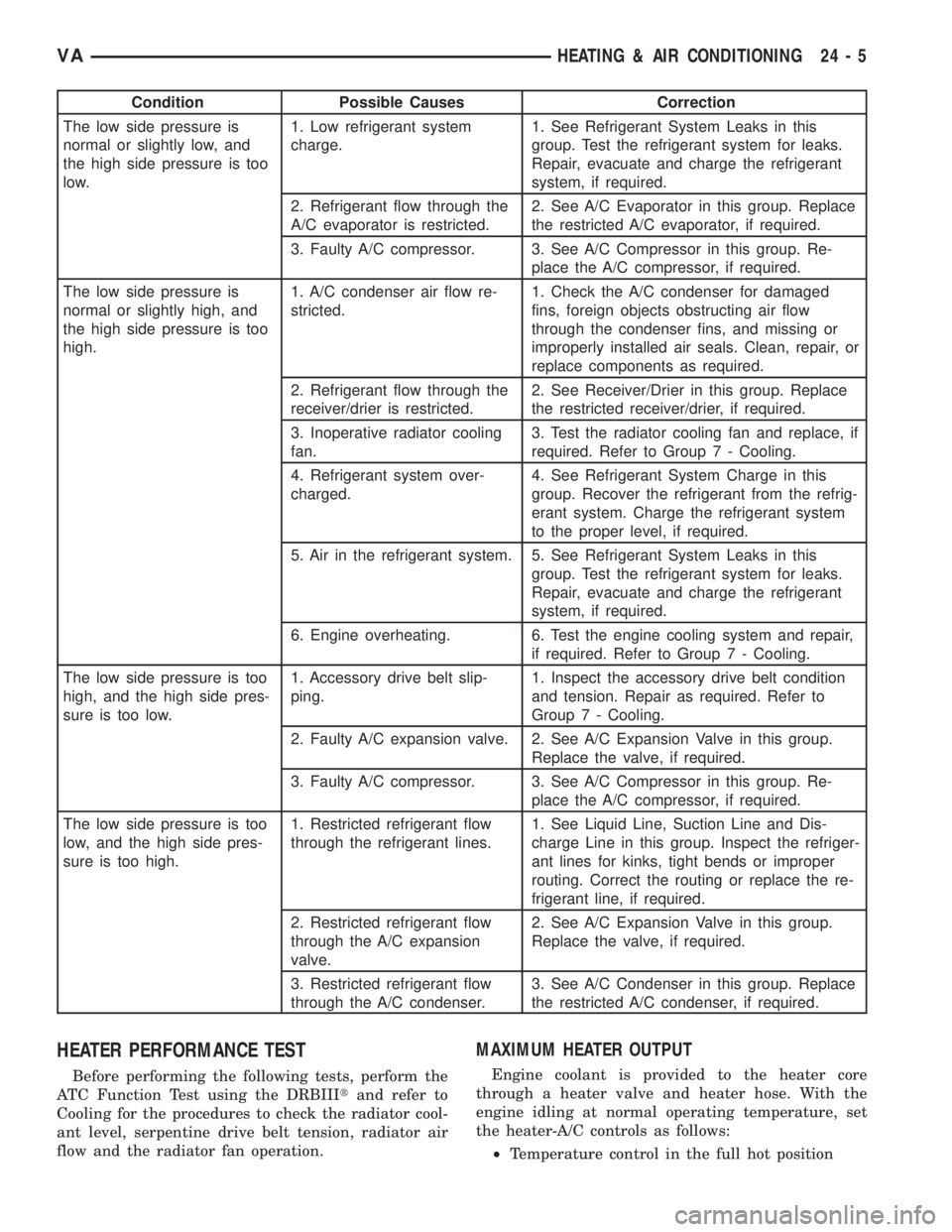

Condition Possible Causes Correction

The low side pressure is

normal or slightly low, and

the high side pressure is too

low.1. Low refrigerant system

charge.1. See Refrigerant System Leaks in this

group. Test the refrigerant system for leaks.

Repair, evacuate and charge the refrigerant

system, if required.

2. Refrigerant flow through the

A/C evaporator is restricted.2. See A/C Evaporator in this group. Replace

the restricted A/C evaporator, if required.

3. Faulty A/C compressor. 3. See A/C Compressor in this group. Re-

place the A/C compressor, if required.

The low side pressure is

normal or slightly high, and

the high side pressure is too

high.1. A/C condenser air flow re-

stricted.1. Check the A/C condenser for damaged

fins, foreign objects obstructing air flow

through the condenser fins, and missing or

improperly installed air seals. Clean, repair, or

replace components as required.

2. Refrigerant flow through the

receiver/drier is restricted.2. See Receiver/Drier in this group. Replace

the restricted receiver/drier, if required.

3. Inoperative radiator cooling

fan.3. Test the radiator cooling fan and replace, if

required. Refer to Group 7 - Cooling.

4. Refrigerant system over-

charged.4. See Refrigerant System Charge in this

group. Recover the refrigerant from the refrig-

erant system. Charge the refrigerant system

to the proper level, if required.

5. Air in the refrigerant system. 5. See Refrigerant System Leaks in this

group. Test the refrigerant system for leaks.

Repair, evacuate and charge the refrigerant

system, if required.

6. Engine overheating. 6. Test the engine cooling system and repair,

if required. Refer to Group 7 - Cooling.

The low side pressure is too

high, and the high side pres-

sure is too low.1. Accessory drive belt slip-

ping.1. Inspect the accessory drive belt condition

and tension. Repair as required. Refer to

Group 7 - Cooling.

2. Faulty A/C expansion valve. 2. See A/C Expansion Valve in this group.

Replace the valve, if required.

3. Faulty A/C compressor. 3. See A/C Compressor in this group. Re-

place the A/C compressor, if required.

The low side pressure is too

low, and the high side pres-

sure is too high.1. Restricted refrigerant flow

through the refrigerant lines.1. See Liquid Line, Suction Line and Dis-

charge Line in this group. Inspect the refriger-

ant lines for kinks, tight bends or improper

routing. Correct the routing or replace the re-

frigerant line, if required.

2. Restricted refrigerant flow

through the A/C expansion

valve.2. See A/C Expansion Valve in this group.

Replace the valve, if required.

3. Restricted refrigerant flow

through the A/C condenser.3. See A/C Condenser in this group. Replace

the restricted A/C condenser, if required.

HEATER PERFORMANCE TEST

Before performing the following tests, perform the

ATC Function Test using the DRBIIItand refer to

Cooling for the procedures to check the radiator cool-

ant level, serpentine drive belt tension, radiator air

flow and the radiator fan operation.

MAXIMUM HEATER OUTPUT

Engine coolant is provided to the heater core

through a heater valve and heater hose. With the

engine idling at normal operating temperature, set

the heater-A/C controls as follows:

²Temperature control in the full hot position

VAHEATING & AIR CONDITIONING 24 - 5

Page 2043 of 2305

²Mode control in the floor heat position

²Blower motor control in the highest speed posi-

tion

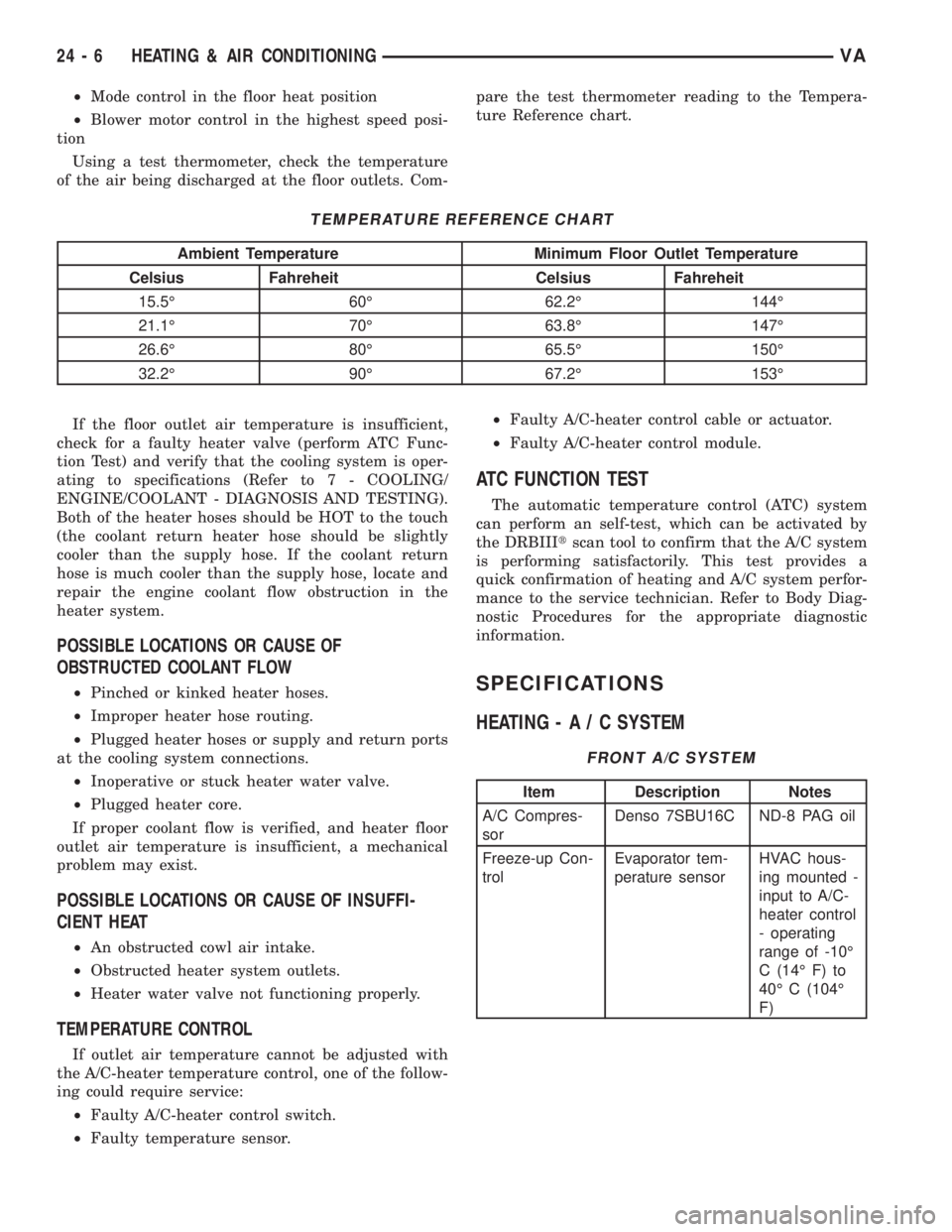

Using a test thermometer, check the temperature

of the air being discharged at the floor outlets. Com-pare the test thermometer reading to the Tempera-

ture Reference chart.

TEMPERATURE REFERENCE CHART

Ambient Temperature Minimum Floor Outlet Temperature

Celsius Fahreheit Celsius Fahreheit

15.5É 60É 62.2É 144É

21.1É 70É 63.8É 147É

26.6É 80É 65.5É 150É

32.2É 90É 67.2É 153É

If the floor outlet air temperature is insufficient,

check for a faulty heater valve (perform ATC Func-

tion Test) and verify that the cooling system is oper-

ating to specifications (Refer to 7 - COOLING/

ENGINE/COOLANT - DIAGNOSIS AND TESTING).

Both of the heater hoses should be HOT to the touch

(the coolant return heater hose should be slightly

cooler than the supply hose. If the coolant return

hose is much cooler than the supply hose, locate and

repair the engine coolant flow obstruction in the

heater system.

POSSIBLE LOCATIONS OR CAUSE OF

OBSTRUCTED COOLANT FLOW

²Pinched or kinked heater hoses.

²Improper heater hose routing.

²Plugged heater hoses or supply and return ports

at the cooling system connections.

²Inoperative or stuck heater water valve.

²Plugged heater core.

If proper coolant flow is verified, and heater floor

outlet air temperature is insufficient, a mechanical

problem may exist.

POSSIBLE LOCATIONS OR CAUSE OF INSUFFI-

CIENT HEAT

²An obstructed cowl air intake.

²Obstructed heater system outlets.

²Heater water valve not functioning properly.

TEMPERATURE CONTROL

If outlet air temperature cannot be adjusted with

the A/C-heater temperature control, one of the follow-

ing could require service:

²Faulty A/C-heater control switch.

²Faulty temperature sensor.²Faulty A/C-heater control cable or actuator.

²Faulty A/C-heater control module.

ATC FUNCTION TEST

The automatic temperature control (ATC) system

can perform an self-test, which can be activated by

the DRBIIItscan tool to confirm that the A/C system

is performing satisfactorily. This test provides a

quick confirmation of heating and A/C system perfor-

mance to the service technician. Refer to Body Diag-

nostic Procedures for the appropriate diagnostic

information.

SPECIFICATIONS

HEATING-A/CSYSTEM

FRONT A/C SYSTEM

Item Description Notes

A/C Compres-

sorDenso 7SBU16C ND-8 PAG oil

Freeze-up Con-

trolEvaporator tem-

perature sensorHVAC hous-

ing mounted -

input to A/C-

heater control

- operating

range of -10É

C (14É F) to

40É C (104É

F)

24 - 6 HEATING & AIR CONDITIONINGVA

Page 2158 of 2305

INDEX

ABS INDICATOR.......................8J-9ACCELERATOR PEDAL POSITION SENSOR. . . 14-32

ACCESSORY SWITCH BEZEL............23-56

ADR INDICATOR.....................8J-10

AIR CLEANER ELEMENT................9-21

AIR CLEANER HOUSING................9-21

AIR FILTER ....................24-45, 24-58

AIR OUTLET TEMPERATURE SENSOR....24-16

AIR OUTLETS.......................24-45

AIRBAG CONTROL MODULE.............8O-8

AIRBAG INDICATOR...................8J-11

ALB CONTROLLER....................5-16

ALB LEVER..........................5-16

AMBIENT TEMPERATURE INDICATOR.....8J-11

AMBIENT TEMPERATURE SENSOR.......24-17

ANTENNA BODY & CABLE..............8A-1

ARMREST..........................23-79

ASH RECEIVER......................23-57

ASH RECEIVER / CIGAR LIGHTER LAMP

UNIT..............................8L-30

ASSIST HANDLE.....................23-71

AUDIO..............................8A-1

AUTOMATIC TRANSMISSION NAG1 -

SERVICE INFORMATION................21-3

A - PILLAR TRIM.....................23-70

A / C CLUTCH RELAY.................24-24

A / C COMPRESSOR CLUTCH COIL.......24-12

A / C COMPRESSOR CLUTCH............24-8

A / C COMPRESSOR..................24-66

A / C CONDENSER COVER.............24-52

A / C CONDENSER FAN RELAY..........24-26

A / C CONDENSER HOUSING...........24-52

A / C CONDENSER....................24-69

A / C CONTROL MODULE..............24-28

A / C DISCHARGE LINE................24-71

A / C EVAPORATOR COVER.............24-55

A / C EVAPORATOR HOUSING...........24-55

A / C EVAPORATOR...................24-72

A / C EXPANSION VALVE...............24-73

A / C HEATER CONTROL...............24-12

A / C HIGH PRESSURE SWITCH.........24-30

A / C LOW PRESSURE SWITCH.........24-32

A / C PRESSURE TRANSDUCER.........24-14

BACKLITE - BULKHEAD TRIM PANEL.....23-84

BACKUP LAMP BULB..................8L-5

BASECOAT / CLEARCOAT FINISH........23-77

BATTERY CABLES....................8F-14

BATTERY HOLDDOWN.................8F-13

BATTERY SYSTEM.....................8F-1

BATTERY TRAY......................8F-16

BATTERY............................8F-6

BEARINGS - DIFFERENTIAL CASE.........3-38

BEARING / SEAL - AXLE HUB............3-28

BEARING / SEAL - AXLE................3-24

BELT TENSIONERS.....................7-5

BLOWER MOTOR RELAY...............24-33

BLOWER MOTOR RESISTOR............24-17

BLOWER MOTOR SWITCH........24-19, 24-35

BLOWER MOTOR...............24-47, 24-58

BODY...............................23-1

BOOST PRESSURE SENSOR............14-33

BRAKE INDICATOR...................8J-12

BRAKE LAMP SWITCH.................8L-6

BRAKE LINES.........................5-8

BRAKE PADS / SHOES...................5-8

BRAKE WEAR INDICATOR..............8J-13

BRAKES - ABS........................5-30

BRAKES - BASE........................5-2

BRAKE / PARK LAMP BULB.............8L-7

BULKHEAD TRIM PANEL...............23-72

BUMPERS...........................13-1

BUSHINGS............................2-3

B - PILLAR TRIM.....................23-71

CABIN HEATER.....................24-104

CABLE TENSIONER....................5-24

CABLE..............................8P-2

CABLES.............................5-24

CAMSHAFT POSITION SENSOR..........14-33

CAMSHAFT(S)........................9-28

CARGO LAMP SWITCH................8L-31

CARGO / DOME LAMP BULB............8L-30

CARGO / DOME LAMP UNIT............8L-31

CARPETS AND FLOOR MATS...........23-72

CATALYTIC CONVERTER

................11-3

CENTER BEARING

......................3-9

CENTER HIGH MOUNTED STOP LAMP BULB. . . 8L-8CENTER HIGH MOUNTED STOP LAMP UN.....8L-8

CENTER ROLLER ARM

................23-36CENTER TRACK......................23-37

CENTRAL TIMER MODULE..............8E-1

CHARGE AIR COOLER AND PLUMBING....11-4

CHARGING INDICATOR................8J-14

CHARGING SYSTEM..................8F-17

CHECK VALVE.......................8R-11

CHECK.......................23-13, 23-23

CHIME / BUZZER......................8B-1

CIGAR LIGHTER OUTLET............8W-97-1

CIRCUIT BREAKER.................8W-97-2

CLEARANCE LAMP BULB...............8L-9

CLEARANCE LAMP UNIT................8L-9

CLOCK.............................8J-14

CLOCKSPRING......................8O-12

CLUSTER BEZEL.....................23-55

COLUMN............................19-4

CONNECTOR.......................Intro.-9

CONNECTOR/GROUND/SPLICE

LOCATION........................8W-91-1

CONTROLLER ANTILOCK BRAKE.........8E-3

COOLANT LEVEL SENSOR...............7-13

COOLANT LOW INDICATOR.............8J-15

COOLANT............................7-9

COOLING.............................7-1

COWL TRIM........................23-73

CRANKCASE VENTILATION BREATHER......25-2

CRANKCASE VENTILATION HEATER.......25-1

CRANKSHAFT OIL SEAL - FRONT.........9-42

CRANKSHAFT OIL SEAL - REAR..........9-41

CRANKSHAFT POSITION SENSOR........14-35

CRANKSHAFT........................9-39

CUP HOLDER........................23-57

CYLINDER HEAD COVER(S).............9-33

CYLINDER HEAD......................9-22

DAYTIME RUNNING LAMP RELAY.......8L-10

DEFROSTER DUCTS..................24-47

DIFFERENTIAL........................3-31

DIODE............................Intro.-9

DISC BRAKE CALIPER ADAPTER.........5-14

DISC BRAKE CALIPERS.................5-11

DOME LAMP / INTRUSION SENSOR

BULB..............................8L-33

DOME LAMP / INTRUSION SENSOR......8L-33

DOME / READING LAMP BULB..........8L-32

DOME / READING LAMP UNIT..........8L-32

DOOR GLASS............23-15, 23-30, 23-46

DOOR JAMB SWITCH.................8L-34

DOOR LOCK MOTOR...................8N-1

DOOR OPENING SEALS................23-90

DOOR........................23-14, 23-23

DRIVE BELTS..........................7-5

DRIVER AIRBAG.....................8O-16

DRIVER HEATED SEAT SWITCH.........8G-11

D - PILLAR TRIM.....................23-73

ELECTRIC COOLANT PUMP.............24-75

ELECTRICAL.........................5-30

ELECTROHYDRAULIC UNIT............21-105

ENGINE BLOCK HEATER................7-14

ENGINE BLOCK.......................9-37

ENGINE CONTROL MODULE.............8E-3

ENGINE COOLANT TEMP SENSOR........7-15

ENGINE COOLANT THERMOSTAT.........7-16

ENGINE CRADLE CROSSMEMBER........13-8

ENGINE TEMPERATURE GAUGE.........8J-15

ENGINE..............................9-2

ENTRY / EXIT LAMP BULB.............8L-34

ENTRY / EXIT LAMP UNIT..............8L-35

ESP INDICATOR......................8J-16

EVAPORATOR TEMPERATURE

SENSOR......................24-19, 24-37

EXHAUST GAS RECIRCULATION..........25-4

EXHAUST MANIFOLD..................9-68

EXHAUST PIPE.......................11-3

EXHAUST SYSTEM....................11-1

EXHAUST TUBE.....................24-105

EXTERIOR HANDLE.......23-16, 23-31, 23-35

FAN DRIVE VISCOUS CLUTCH...........7-17

FASTENER IDENTIFICATION...........Intro.-3

FASTENER USAGE...................Intro.-6

FINESSE SANDING / BUFFING & POLISH . . 23-78

FLOOR DISTRIBUTION DUCTS..........24-47

FLUID AND FILTER..................21-131

FLUID CAPACITIES.....................0-5

FLUID COOLER TUBE

.................19-13

FLUID FILL / CHECK LOCATIONS

..........0-5

FLUID RESERVOIR

....................5-15

FLUID TYPES

..........................0-1

FLYWHEEL

...........................9-43FOG LAMP BULB.....................8L-10

FOG LAMP RELAY....................8L-11

FOG LAMP SWITCH...................8L-12

FRAME..............................13-3

FREEWHEELING CLUTCH.............21-135

FRONT BUMPER - STEPS...............13-2

FRONT DOOR INNER BELT

WEATHERSTRIP.....................23-90

FRONT DOOR OUTER BELT

WEATHERSTRIP.....................23-90

FRONT FASCIA.......................13-2

FRONT LAMP UNIT...................8L-13

FRONT POSITION LAMP BULB..........8L-14

FRONT SEAT BELT & RETRACTOR.......8O-20

FRONT SEAT BELT BUCKLE............8O-23

FRONT TURN / PARK / SIDE MARKER

LAMP BULB.........................8L-15

FRONT WHEEL SPEED SENSOR..........5-31

FRONT...............................2-1

FUEL DELIVERY.......................14-6

FUEL DOSING PUMP.................24-106

FUEL DRAIN TUBES..................14-10

FUEL FILL DOOR.....................23-48

FUEL FILTER CLOGGED INDICATOR......8J-17

FUEL FILTER........................14-10

FUEL GAUGE........................8J-17

FUEL INJECTOR.......................14-35

FUEL LEVEL SENDING UNIT / SENSOR....14-28

FUEL LINE.........................24-107

FUEL LINES.........................14-11

FUEL PRESSURE SENSOR.............14-39

FUEL PRESSURE SOLENOID............14-40

FUEL PUMP MODULE.................14-18

FUEL PUMP.........................14-13

FUEL QUANTITY CONTROL VALVE.......14-21

FUEL RAIL PRESSURE SENSOR.........14-12

FUEL RAIL..........................14-22

FUEL SYSTEM........................14-1

FUEL TANK.........................14-23

FUEL TEMPERATURE SENSOR..........14-42

FUSE BLOCK #1...................8W-97-2

FUSE BLOCK #2...................8W-97-3

GAP AND FLUSH.....................23-91

GEAR SELECTOR INDICATOR...........8J-18

GEAR...............................19-7

GEARSHIFT CABLE..................21-138

GEAR - PINION / RING.................3-41

GENERATOR DECOUPLER PULLEY.......8F-19

GENERATOR........................8F-18

GLOVE BOX.........................23-58

GLOW PLUG RELAY....................8I-1

GLOW PLUG..........................8I-1

GRILLE............................23-48

HCU (HYDRAULIC CONTROL UNIT).......5-36

HEADLAMP LEVELING MOTOR..........8L-16

HEADLAMP LEVELING SWITCH.........8L-17

HEADLINER.........................23-73

HEADREST..........................23-79

HEATED GLASS.......................8G-1

HEATED MIRRORS....................8G-9

HEATED SEAT ELEMENT...............8G-12

HEATED SEAT RELAY.................8G-12

HEATED SEAT SENSOR................8G-13

HEATED SEATS ......................8G-10

HEATER CORE.......................24-76

HEATER UNIT......................24-110

HEATING & AIR CONDITIONING..........24-1

HIGH BEAM HEADLAMP BULB..........8L-18

HIGH BEAM INDICATOR...............8J-19

HINGE..................23-17, 23-32, 23-51

HOISTING............................0-5

HOLDING CLUTCH B1................21-143

HOLDING CLUTCH B2................21-148

HOLDING CLUTCHES.................21-141

HOOD.............................23-51

HORN SWITCH.......................8H-1

HORN..............................8H-1

HOSES.............................19-14

HUB / BEARING........................2-4

HVAC HOUSING......................24-48

HYDRAULIC / MECHANICAL..............5-5

IGNITION CONTROL....................8I-1

INLET HOSE........................24-111

INPUT CLUTCH K1

...................21-92

INPUT CLUTCH K2

...................21-97

INPUT CLUTCH K3

..................21-102

INPUT CLUTCHES

....................21-90

INPUT SPEED SENSORS

..............21-153

VAINDEX 1

Description Group-Page Description Group-Page Description Group-Page

Page 2167 of 2305

The NAG1 will default in the current gear position

if a DTC is detected, then after a key cycle or shift

to park the transmission will go into Limp-in, which

is mechanical 2nd gear. Some DTC's may allow the

transmission to resume normal operation (recover)

if the detected problem goes away. Permanent

limp-in DTC will recover when the key is cycled, but

if the same DTC is detected for three key cycles the

system will not recover and the DTC must be

cleared from the TCM with the DRBIII scan tool.

Once the DRBIIItis in the Transmission portion

of the diagnostic program, it constantly monitors

the TCM to see if the system is in limp-in mode. If

the transmission is in limp-in mode, the DRBIIIt

will flash the red LED.

3.2.1 CONTROLLER MODES OF

OPERATION

Permanent limp-in mode

When the TCM determines there is a non-

recoverable condition present that will not allow

proper transmission operation, it will place the

transmission in permanent limp-in mode. When the

condition occurs the TCM will turn off all solenoids

as well as the solenoid supply output circuit. If this

occurs while the vehicle is moving, the transmission

will remain in the current gear until the ignition is

turned off or shifter is placed in the9P9position.

Once the shifter has been placed in9P9the Trans-

mission will only allow 2nd gear operation. If the

problem occurs while the vehicle is not moving the

transmission will only allow 2nd gear operation.

Temporary limp-in mode

This mode is the same as the permanent limp-in

mode except if the condition is no longer present the

system will resume normal operation. (Recoverable

DTC)

Undervoltage limp-in mode

When the TCM detects that system voltage has

dropped below 8.5 volts it will disable voltage de-

pendant diagnostics and place the transmission in

the temporary limp-in mode. When the TCM senses

that the voltage has risen above 9.0 volts, normal

transmission operation will be resumed.

Hardware Error Mode

When the TCM detects a major internal error the

transmission will be placed in the permanent

limp-in mode and cease all communication over the

CAN bus. Once the TCM has entered this mode

normal transmission operation will not resume un-

til all DTC's are cleared from the TCM.

Loss of Drive

If the TCM detects a situation that has resulted or

may result in engine or transmission failure, the

transmission will be placed in the neutral position.Improper Ratio, Input Sensor Overspeed, or Engine

Overspeed DTC's will cause the loss of drive.

Controlled Limp-in Mode

When a failure condition does not require the TCM

to shut down the solenoid supply, but the failure is

of a degree where the TCM will place the transmis-

sion into a predefined gear, there will be several

shift performance issues. Examples of this are, with

the transmission slipping the controller will at-

tempt to place the transmission into third gear and

maintain third gear for all forward drive conditions.

Another example is some of the CAN bus message

issues if the TCM does not receive required infor-

mation from the Engine Controller, then default

values are used which may result in poor transmis-

sion shift performance.

3.2.2 MIL ILLUMINATION

For failures detected by the Transmission Con-

troller that result in the controller placing the

transmission into a limp-in mode, except for System

Overvoltage and System Undervoltage DTCs, the

MIL will be illuminated. The Transmission Control

Module will inform the ECM over the CAN bus that

a failure has occurred. The ECM will illuminate the

MIL. If the condition is removed and the failure

becomes Stored (Intermittent), the Transmission

controller will stop reporting that the DTC is active

and the ECM will extinguish the MIL.

NOTE: The MIL will light when the problem is

first detected and it will not go off until the

next ignition cycle, after all problem

conditions have been checked for their

presence. This normally takes several

minutes of driving.

3.2.3 SOLENOIDS

1-2/4-5 solenoid -The 1-2/4-5 solenoid is activated

when the TCM determines that the transmission

must shift into or out of 2nd gear or 5th gear. The

solenoid is only activated during the shifting of the

transmission. When the solenoid is activated, hy-

draulic pressure is applied to the proper shift ele-

ments in the transmission to allow the desired shift.

Once the shift is completed, the solenoid is turned

off.

2-3 solenoid -The 2-3 solenoid is activated when

the TCM determines that the transmission must

shift into or out of 3rd gear. The solenoid is only

activated during the shifting of the transmission.

When the solenoid is activated hydraulic pressure

is applied to the proper shift elements in the trans-

mission to allow the desired shift. Once the shift is

completed, the solenoid is turned off.

2

GENERAL INFORMATION

Page 2168 of 2305

3-4 solenoid -The 3-4 solenoid is activated when

the TCM determines that the transmission must

shift into or out of 4th gear. The solenoid is only

activated during the shifting of the transmission.

When the solenoid is activated, hydraulic pressure

is applied to the proper shift elements in the trans-

mission to allow the desired shift. Once the shift is

completed, the solenoid is turned off.

TCC solenoid -The TCC solenoid is activated

when the TCM determines that the Torque con-

verter clutch should be activated. The TCC clutch is

a variable slip torque clutch that allows control of

torque converter slip from 5% to 95.5% of full TCC

engagement. The clutch is controlled by the TCC

solenoid which is pulse width modulated (PWM) to

provide the desired amount of slip.

Shift Pressure Solenoid -The Shift Pressure

Solenoid is activated when the TCM determines

that a transmission shift is required. The solenoid

is PWM controller to allow the proper amount of

hydraulic pressure to the shift elements. The sole-

noid is only activated during the shifting of the

transmission. When the solenoid is activated, hy-

draulic pressure is removed from the proper shift

elements to allow the desired shift. Once the shift is

completed, the solenoid is turned off.

Modulation pressure solenoid -The modulation

pressure is always active. The solenoid is pulse

width modulated (PWM) controlled and is used to

modulate the hydraulic system pressure to the

desired pressure.

3.2.4 TRANSMISSION COMPONENT

DESCRIPTIONS

Shift Assembly

The Shift Lever Selector transmits all selector lever

positions, as well as selected shift ranges to the

TCM over the CAN Bus. At the same time, the

selector lever positions P, R, N, and D are transmit-

ted by a cable to the selector lever shaft in the

transmission.

Brake shift inter-lock

To prevent unauthorized shifting out of the park

position, the Selector lever is locked in the Park

position until the ignition key is turned to the run

position and the brake pedal is pressed. This will

allow the driver to shift out of the park position.

Reverse Lamp Output

The Reverse Light Switch is integrated into the

shifter module and controls the reverse lights.

Reverse Inhibitor

The Shift Lever Assembly constantly monitors ABS

wheel speed to prevents an inadvertent selection of

reverse at speeds above approximately 6.4 Km/h(4MPH). The Reverse inhibitor is part of the Shift

Lever Assembly and is controlled by the Shift Lever

Assembly module.

Trans temp sensor - P/N Switch circuit

The TCM will detect the selector lever in park and

neutral positions. The TCM does this by monitoring

the Transmission temperature sensor signal along

with the shifter position signals. The P/N switch

contact is operated by a cam located in the trans-

mission which, opens a reed contact switch that is

wired in series with the transmission temperature

sensor. When the P/N contact switch is opened in

park and neutral, the TCM senses a high transmis-

sion temperature. Confirming the P/N switch sta-

tus. Note: In park or neutral, the TCM uses engine

temperature (to avoid setting a DTC). The TCM

sends a hardwired signal to the ECM that will allow

the ECM controlled start circuit to engage in P or N

only. The TCM also sends a P/N bus message to the

ECM to confirm the P/N switch status.

The Normal Transmission Temperature Sensor

resistance is between 500.0 and 2500.0 ohms.

The normal voltage limits for the transmis-

sion temperature sensor, are between 0.5 and

3.0 volts.

Input Speed Sensors

The NAG1 transmission has two input speed sen-

sors N2 and N3, both speed sensors are located on

the valve body and report DTC's for the input speed

sensors errors. The speed sensors are Hall Effect

speed sensors that are used by the TCM to calculate

the transmissions input speed. Since the input

speed could not be measured directly, two of the

drive elements are measured. Two input speed

sensors were required because both drive elements

are not active in all gears. The input sensors N2 and

N3 will report the same input speed in gears 2nd,

3rd or 4th. If the N2 and N3 input speed signals are

not the same in these gears then there is an issue

with the transmission and the DTC Input Sensors

Mismatch will be set.

The N3 input speed is not reported in1st and 5th

gears. The N2 sensor is not reported in Reverse.

The Input Speed Sensor Overspeed is a rationality

check that is intended to indicate a major transmis-

sion failure and will cause a loss of drive (place the

transmission in Neutral)

Output Speed Sensor (ABS signal)

The NAG1 transmission does not have an output

shaft speed sensor. The TCM uses the ABS (An-

tilock Brake System) Wheel Speed sensor informa-

tion, it receives over the CAN bus, to calculate the

transmissions output shaft speed. The TCM moni-

tors the ABS system for functionality and reports

ABS speed sensor and communication DTCs, which

will affect proper transmission operation.

3

GENERAL INFORMATION

Page 2170 of 2305

Emergency running function

If DTCs occur, safe-driving conditions must be re-

tained but full functionality of the transmission will

be limited to avoid damaging the automatic trans-

mission. In the event of certain DTCs the TCM

switches to emergency running. The TCM will store

the appropriate DTC codes and solenoids will be

de-energized (turned off)

The transmission effects will be:

²The last gear shifted remains in that position

²The modulating pressure and shift pressure in-

crease to maximum value

²The torque converter clutch is disengaged

(turned off)

Shifting manually after a DTC detection

NOTE: The vehicle can still be shifted

manually to 2nd or reverse gear.

To accomplish these shifts you must

Stop the vehicle

Turn the ignition off

Start the engine

Place the selector lever into D for 2nd gear

Place the selector lever into R for reverse gear

The emergency running function is retained until

the DTC is eliminated or the stored DTC code is

erased.

Stored (Intermittent) DTCs can be reset by cy-

cling the ignition switch

3.3.3 TROUBLE CODE ERASURE

Diagnostic Trouble Codes can be erased in two

ways. The first is to erase the DTC with the DRBIII

or scan tool. The second is if the DTC is no longer

present, the DTC is reset by the TCM (after an

ignition cycle), which will place the DTC in an

intermittent status (Stored DTC).

When there are no diagnostic trouble codes

stored in memory, the DRBIIItwill display

(NO DTC's DETECTED(

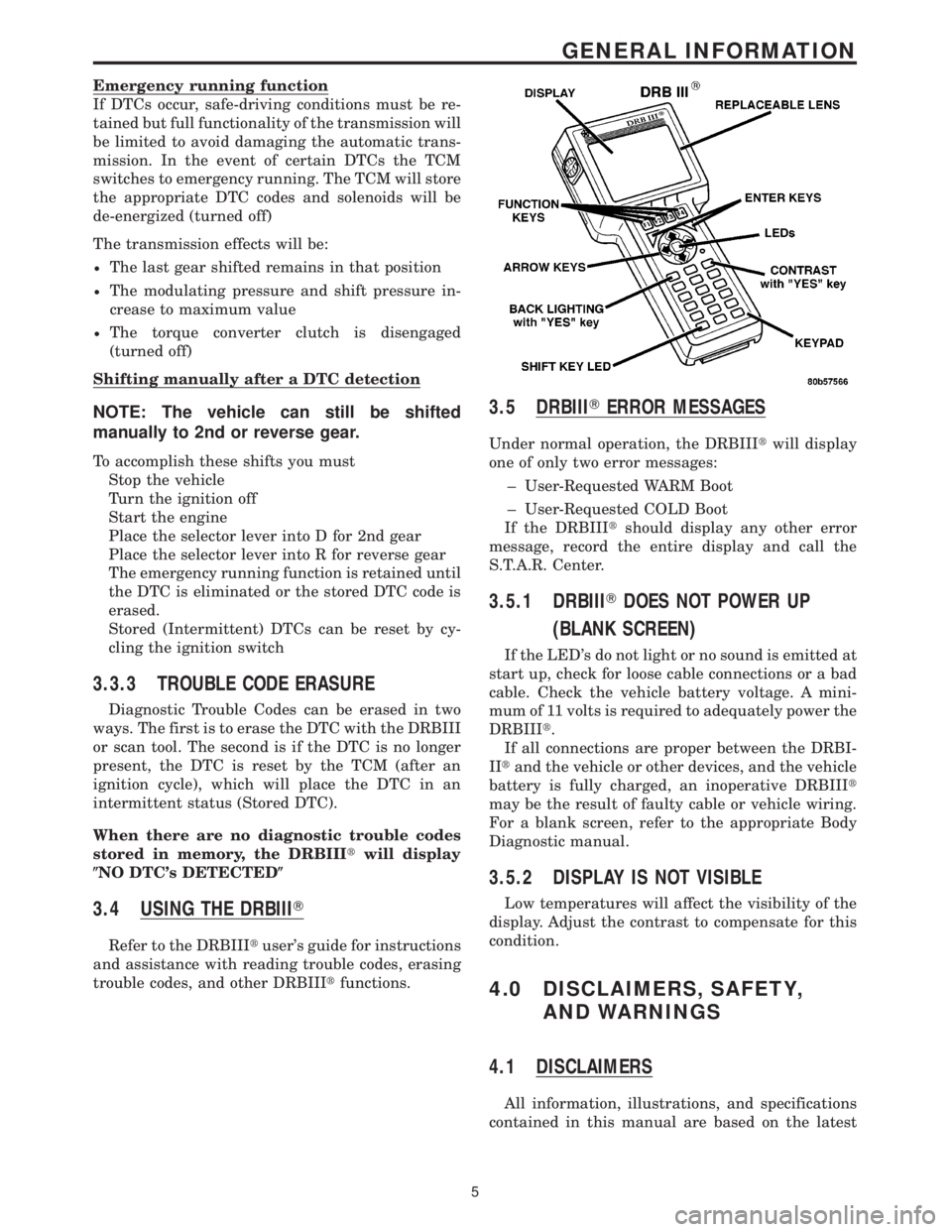

3.4 USING THE DRBIIIT

Refer to the DRBIIItuser's guide for instructions

and assistance with reading trouble codes, erasing

trouble codes, and other DRBIIItfunctions.

3.5 DRBIIITERROR MESSAGES

Under normal operation, the DRBIIItwill display

one of only two error messages:

± User-Requested WARM Boot

± User-Requested COLD Boot

If the DRBIIItshould display any other error

message, record the entire display and call the

S.T.A.R. Center.

3.5.1 DRBIIITDOES NOT POWER UP

(BLANK SCREEN)

If the LED's do not light or no sound is emitted at

start up, check for loose cable connections or a bad

cable. Check the vehicle battery voltage. A mini-

mum of 11 volts is required to adequately power the

DRBIIIt.

If all connections are proper between the DRBI-

IItand the vehicle or other devices, and the vehicle

battery is fully charged, an inoperative DRBIIIt

may be the result of faulty cable or vehicle wiring.

For a blank screen, refer to the appropriate Body

Diagnostic manual.

3.5.2 DISPLAY IS NOT VISIBLE

Low temperatures will affect the visibility of the

display. Adjust the contrast to compensate for this

condition.

4.0 DISCLAIMERS, SAFETY,

AND WARNINGS

4.1 DISCLAIMERS

All information, illustrations, and specifications

contained in this manual are based on the latest

5

GENERAL INFORMATION

Page 2180 of 2305

Symptom:

BACKUP LAMP CKT SHORT TO VOLTAGE OR OPEN

POSSIBLE CAUSES

BACKUP LAMP CIRCUIT OPEN

BACKUP LAMP CIRCUIT SHORT TO VOLTAGE

SHIFT LEVER ASSEMBLY

TEST ACTION APPLICABILITY

1 Start the engine.

While back probing, measure the voltage of the Backup Lamp circuit.

Is the voltage above 0.5 volts?All

Ye s!Go To 2

No!Go To 3

2 Turn the ignition off to the lock position.

Disconnect the Shift Lever Assembly harness connector.

Start the engine.

Measure the voltage of the Backup Lamp circuit in the Shift Lever Assembly harness

connector.

Is the voltage above 0.5 volts?All

Ye s!Repair the Backup Lamp circuit for a short to voltage.

No!Replace the Shift Lever Assembly per the Service Information.

3 Turn the ignition off to the lock position.

Disconnect the Shift Lever Assembly harness connector.

Remove the Backup Lamp bulb(s).

Connect a jumper wire between Shift Lever Assembly circuit and B(+).

Using a 12-volt test light connected to 12-volts, check the Backup Lamp circuit in the

Backup Lamp socket(s).

NOTE: The test light must illuminate brightly. Compare the brightness to

that of a direct connection to the battery.

Does the test light illuminate brightly?All

Ye s!Replace the Shift Lever Assembly per the Service Information.

No!Repair the Backup Lamp circuit for an open.

15

SHIFT LEVER ASSEMBLY