check engine light MERCEDES-BENZ SPRINTER 2006 User Guide

[x] Cancel search | Manufacturer: MERCEDES-BENZ, Model Year: 2006, Model line: SPRINTER, Model: MERCEDES-BENZ SPRINTER 2006Pages: 2305, PDF Size: 48.12 MB

Page 362 of 2305

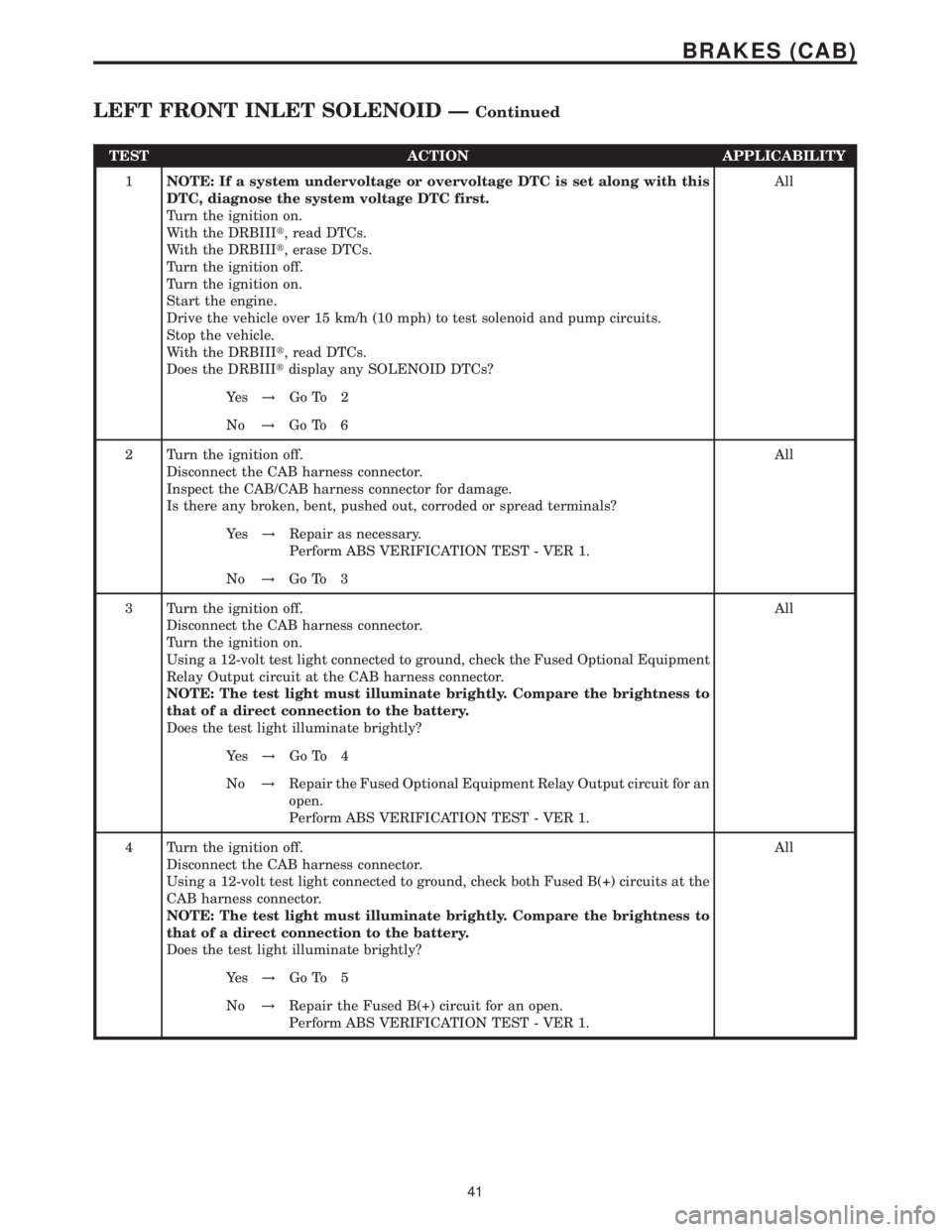

TEST ACTION APPLICABILITY

1NOTE: If a system undervoltage or overvoltage DTC is set along with this

DTC, diagnose the system voltage DTC first.

Turn the ignition on.

With the DRBIIIt, read DTCs.

With the DRBIIIt, erase DTCs.

Turn the ignition off.

Turn the ignition on.

Start the engine.

Drive the vehicle over 15 km/h (10 mph) to test solenoid and pump circuits.

Stop the vehicle.

With the DRBIIIt, read DTCs.

Does the DRBIIItdisplay any SOLENOID DTCs?All

Ye s!Go To 2

No!Go To 6

2 Turn the ignition off.

Disconnect the CAB harness connector.

Inspect the CAB/CAB harness connector for damage.

Is there any broken, bent, pushed out, corroded or spread terminals?All

Ye s!Repair as necessary.

Perform ABS VERIFICATION TEST - VER 1.

No!Go To 3

3 Turn the ignition off.

Disconnect the CAB harness connector.

Turn the ignition on.

Using a 12-volt test light connected to ground, check the Fused Optional Equipment

Relay Output circuit at the CAB harness connector.

NOTE: The test light must illuminate brightly. Compare the brightness to

that of a direct connection to the battery.

Does the test light illuminate brightly?All

Ye s!Go To 4

No!Repair the Fused Optional Equipment Relay Output circuit for an

open.

Perform ABS VERIFICATION TEST - VER 1.

4 Turn the ignition off.

Disconnect the CAB harness connector.

Using a 12-volt test light connected to ground, check both Fused B(+) circuits at the

CAB harness connector.

NOTE: The test light must illuminate brightly. Compare the brightness to

that of a direct connection to the battery.

Does the test light illuminate brightly?All

Ye s!Go To 5

No!Repair the Fused B(+) circuit for an open.

Perform ABS VERIFICATION TEST - VER 1.

41

BRAKES (CAB)

LEFT FRONT INLET SOLENOID ÐContinued

Page 396 of 2305

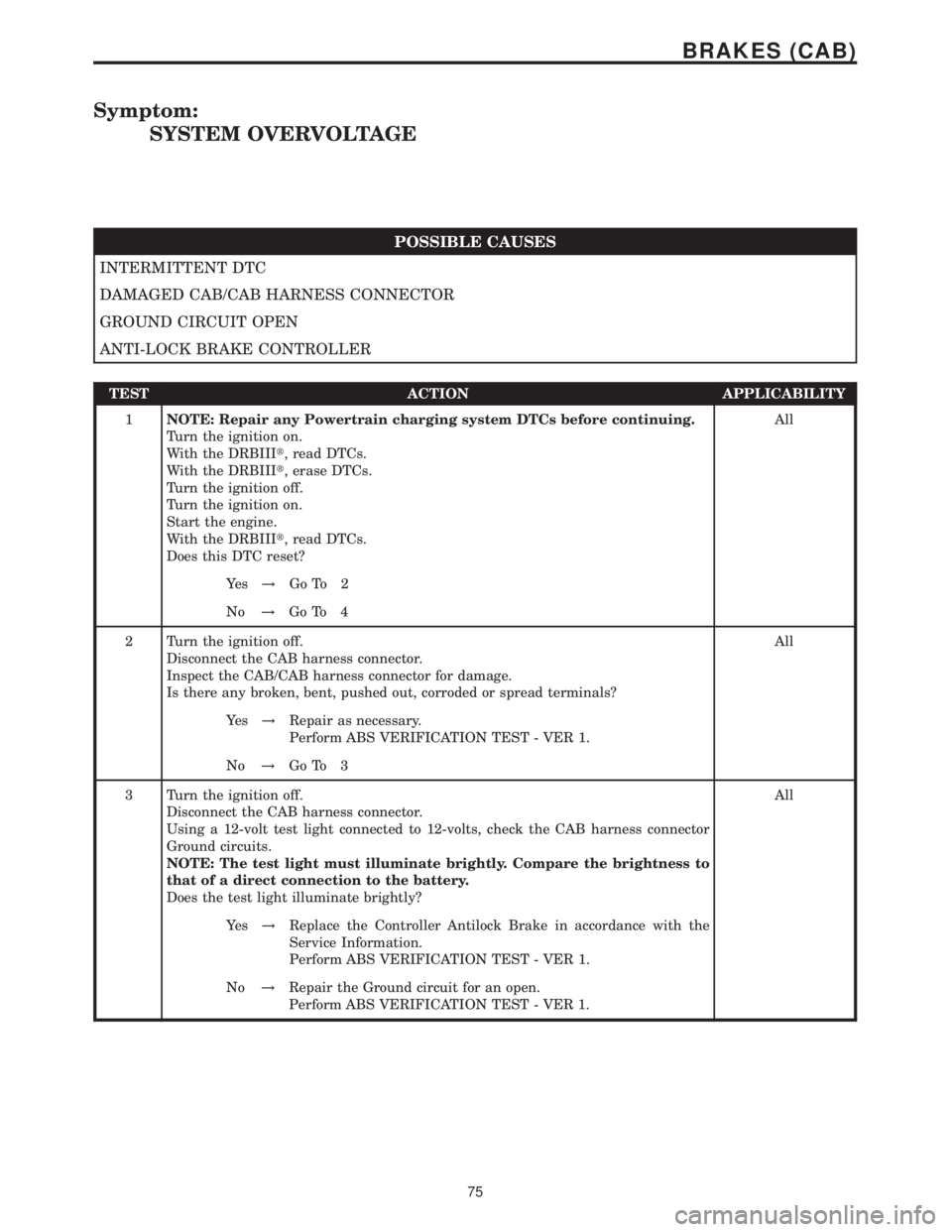

Symptom:

SYSTEM OVERVOLTAGE

POSSIBLE CAUSES

INTERMITTENT DTC

DAMAGED CAB/CAB HARNESS CONNECTOR

GROUND CIRCUIT OPEN

ANTI-LOCK BRAKE CONTROLLER

TEST ACTION APPLICABILITY

1NOTE: Repair any Powertrain charging system DTCs before continuing.

Turn the ignition on.

With the DRBIIIt, read DTCs.

With the DRBIIIt, erase DTCs.

Turn the ignition off.

Turn the ignition on.

Start the engine.

With the DRBIIIt, read DTCs.

Does this DTC reset?All

Ye s!Go To 2

No!Go To 4

2 Turn the ignition off.

Disconnect the CAB harness connector.

Inspect the CAB/CAB harness connector for damage.

Is there any broken, bent, pushed out, corroded or spread terminals?All

Ye s!Repair as necessary.

Perform ABS VERIFICATION TEST - VER 1.

No!Go To 3

3 Turn the ignition off.

Disconnect the CAB harness connector.

Using a 12-volt test light connected to 12-volts, check the CAB harness connector

Ground circuits.

NOTE: The test light must illuminate brightly. Compare the brightness to

that of a direct connection to the battery.

Does the test light illuminate brightly?All

Ye s!Replace the Controller Antilock Brake in accordance with the

Service Information.

Perform ABS VERIFICATION TEST - VER 1.

No!Repair the Ground circuit for an open.

Perform ABS VERIFICATION TEST - VER 1.

75

BRAKES (CAB)

Page 398 of 2305

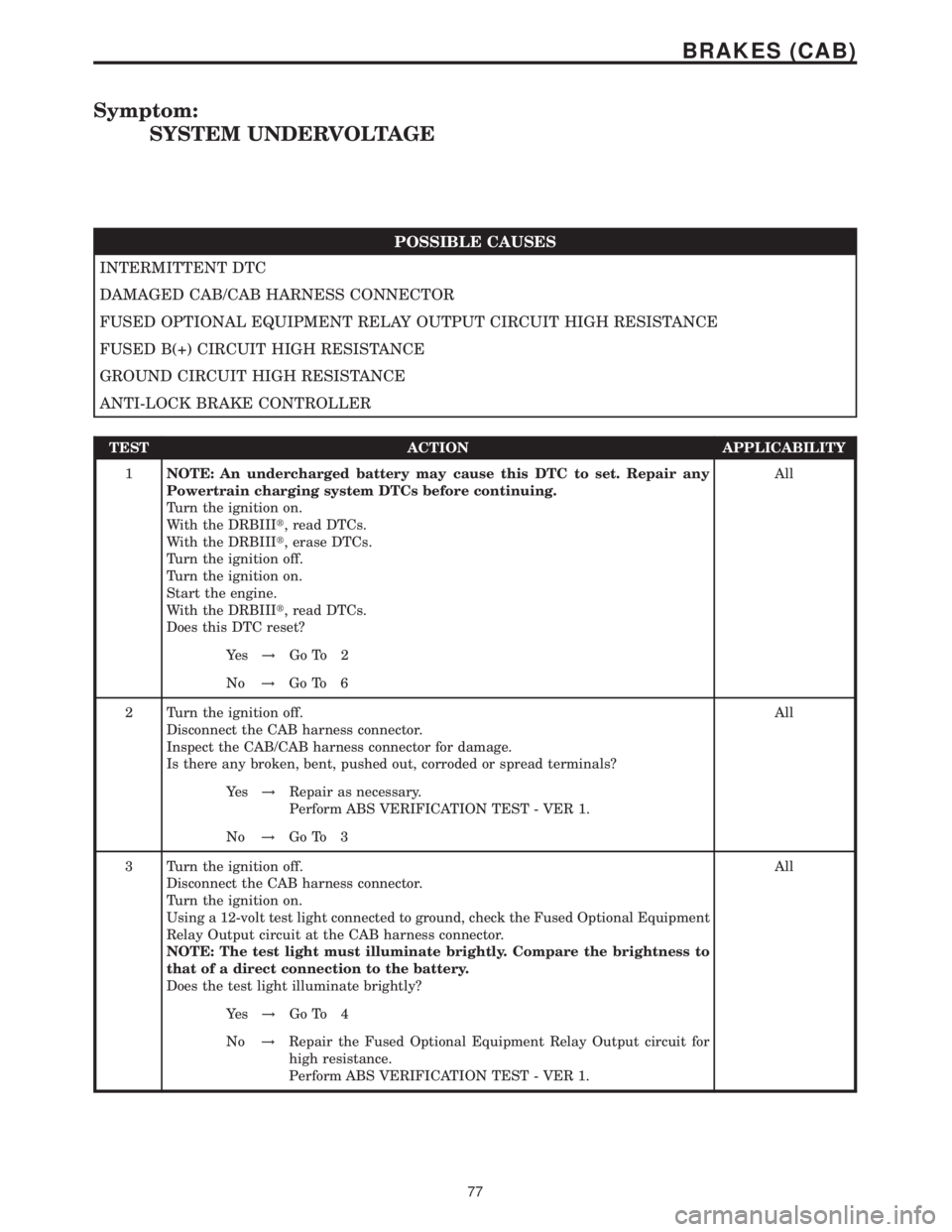

Symptom:

SYSTEM UNDERVOLTAGE

POSSIBLE CAUSES

INTERMITTENT DTC

DAMAGED CAB/CAB HARNESS CONNECTOR

FUSED OPTIONAL EQUIPMENT RELAY OUTPUT CIRCUIT HIGH RESISTANCE

FUSED B(+) CIRCUIT HIGH RESISTANCE

GROUND CIRCUIT HIGH RESISTANCE

ANTI-LOCK BRAKE CONTROLLER

TEST ACTION APPLICABILITY

1NOTE: An undercharged battery may cause this DTC to set. Repair any

Powertrain charging system DTCs before continuing.

Turn the ignition on.

With the DRBIIIt, read DTCs.

With the DRBIIIt, erase DTCs.

Turn the ignition off.

Turn the ignition on.

Start the engine.

With the DRBIIIt, read DTCs.

Does this DTC reset?All

Ye s!Go To 2

No!Go To 6

2 Turn the ignition off.

Disconnect the CAB harness connector.

Inspect the CAB/CAB harness connector for damage.

Is there any broken, bent, pushed out, corroded or spread terminals?All

Ye s!Repair as necessary.

Perform ABS VERIFICATION TEST - VER 1.

No!Go To 3

3 Turn the ignition off.

Disconnect the CAB harness connector.

Turn the ignition on.

Using a 12-volt test light connected to ground, check the Fused Optional Equipment

Relay Output circuit at the CAB harness connector.

NOTE: The test light must illuminate brightly. Compare the brightness to

that of a direct connection to the battery.

Does the test light illuminate brightly?All

Ye s!Go To 4

No!Repair the Fused Optional Equipment Relay Output circuit for

high resistance.

Perform ABS VERIFICATION TEST - VER 1.

77

BRAKES (CAB)

Page 431 of 2305

3.3.4 HANDLING NO TROUBLE CODE

PROBLEMS

After reading Section 3.0 (System Description

and Functional Operation), you should have a bet-

ter understanding of the theory and operation of the

on-board diagnostics and how this relates to the

diagnosis of a vehicle that may have a driveability-

related symptom or complaint. When there are no

trouble codes present, refer to the no trouble code

(*) tests.

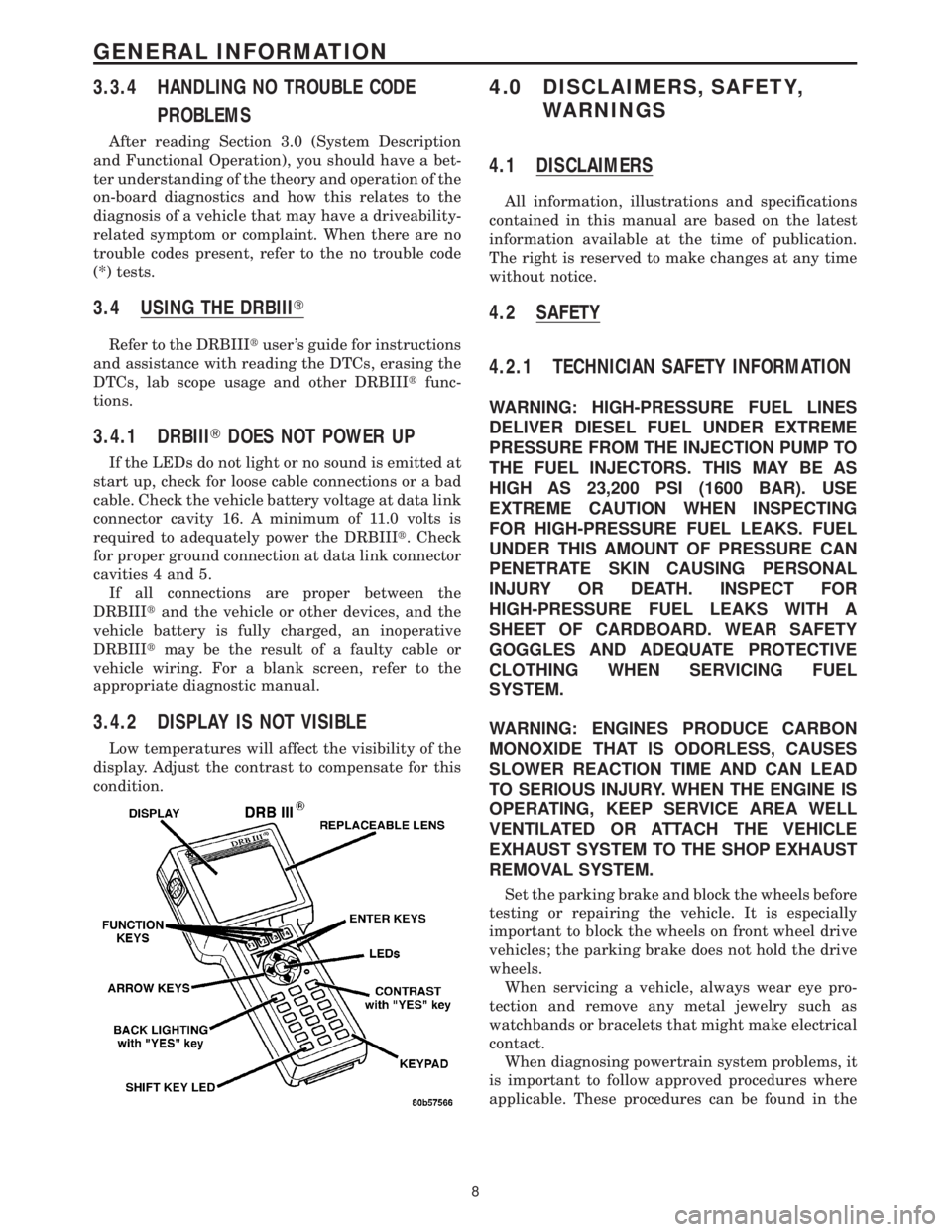

3.4 USING THE DRBIIIT

Refer to the DRBIIItuser 's guide for instructions

and assistance with reading the DTCs, erasing the

DTCs, lab scope usage and other DRBIIItfunc-

tions.

3.4.1 DRBIIITDOES NOT POWER UP

If the LEDs do not light or no sound is emitted at

start up, check for loose cable connections or a bad

cable. Check the vehicle battery voltage at data link

connector cavity 16. A minimum of 11.0 volts is

required to adequately power the DRBIIIt. Check

for proper ground connection at data link connector

cavities 4 and 5.

If all connections are proper between the

DRBIIItand the vehicle or other devices, and the

vehicle battery is fully charged, an inoperative

DRBIIItmay be the result of a faulty cable or

vehicle wiring. For a blank screen, refer to the

appropriate diagnostic manual.

3.4.2 DISPLAY IS NOT VISIBLE

Low temperatures will affect the visibility of the

display. Adjust the contrast to compensate for this

condition.

4.0 DISCLAIMERS, SAFETY,

WARNINGS

4.1 DISCLAIMERS

All information, illustrations and specifications

contained in this manual are based on the latest

information available at the time of publication.

The right is reserved to make changes at any time

without notice.

4.2 SAFETY

4.2.1 TECHNICIAN SAFETY INFORMATION

WARNING: HIGH-PRESSURE FUEL LINES

DELIVER DIESEL FUEL UNDER EXTREME

PRESSURE FROM THE INJECTION PUMP TO

THE FUEL INJECTORS. THIS MAY BE AS

HIGH AS 23,200 PSI (1600 BAR). USE

EXTREME CAUTION WHEN INSPECTING

FOR HIGH-PRESSURE FUEL LEAKS. FUEL

UNDER THIS AMOUNT OF PRESSURE CAN

PENETRATE SKIN CAUSING PERSONAL

INJURY OR DEATH. INSPECT FOR

HIGH-PRESSURE FUEL LEAKS WITH A

SHEET OF CARDBOARD. WEAR SAFETY

GOGGLES AND ADEQUATE PROTECTIVE

CLOTHING WHEN SERVICING FUEL

SYSTEM.

WARNING: ENGINES PRODUCE CARBON

MONOXIDE THAT IS ODORLESS, CAUSES

SLOWER REACTION TIME AND CAN LEAD

TO SERIOUS INJURY. WHEN THE ENGINE IS

OPERATING, KEEP SERVICE AREA WELL

VENTILATED OR ATTACH THE VEHICLE

EXHAUST SYSTEM TO THE SHOP EXHAUST

REMOVAL SYSTEM.

Set the parking brake and block the wheels before

testing or repairing the vehicle. It is especially

important to block the wheels on front wheel drive

vehicles; the parking brake does not hold the drive

wheels.

When servicing a vehicle, always wear eye pro-

tection and remove any metal jewelry such as

watchbands or bracelets that might make electrical

contact.

When diagnosing powertrain system problems, it

is important to follow approved procedures where

applicable. These procedures can be found in the

8

GENERAL INFORMATION

Page 435 of 2305

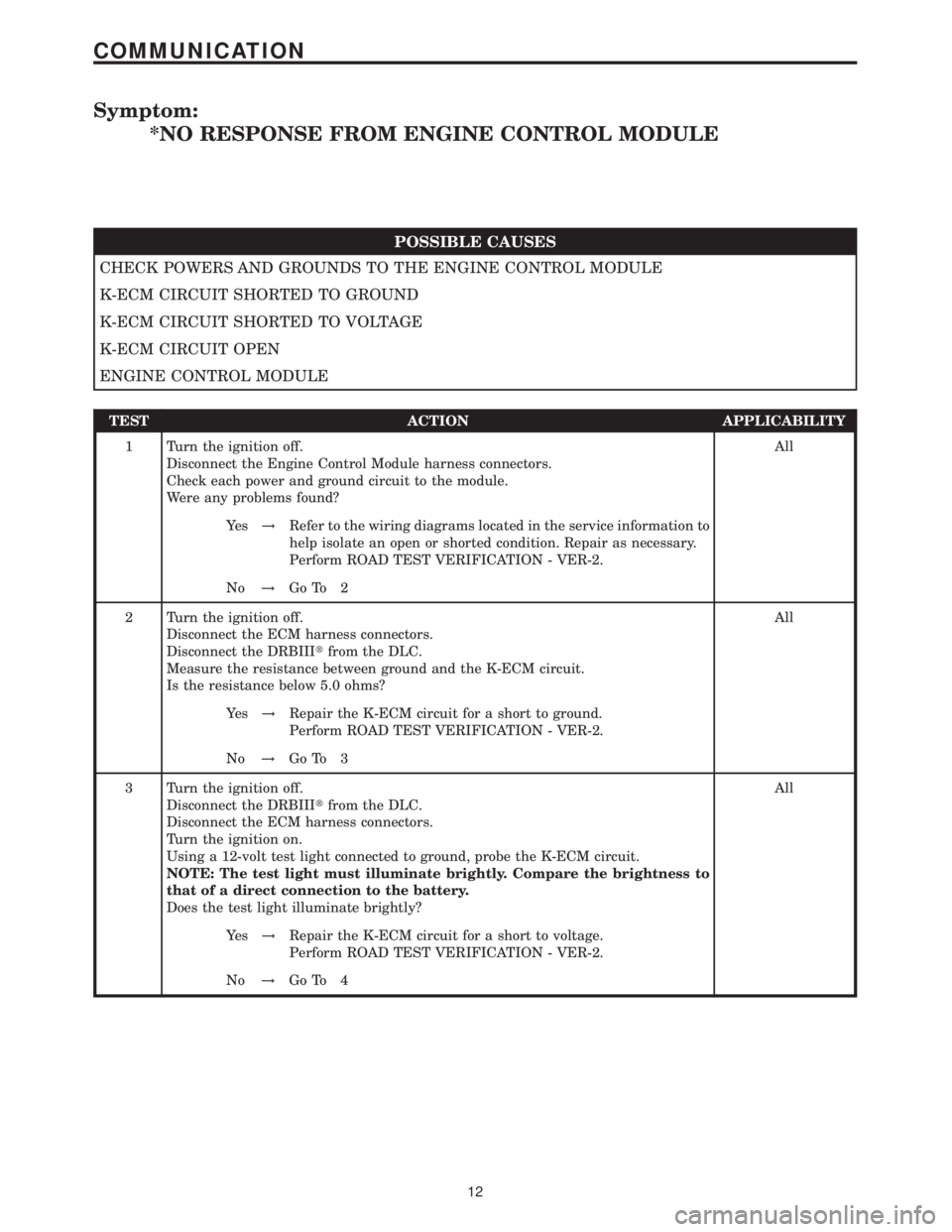

Symptom:

*NO RESPONSE FROM ENGINE CONTROL MODULE

POSSIBLE CAUSES

CHECK POWERS AND GROUNDS TO THE ENGINE CONTROL MODULE

K-ECM CIRCUIT SHORTED TO GROUND

K-ECM CIRCUIT SHORTED TO VOLTAGE

K-ECM CIRCUIT OPEN

ENGINE CONTROL MODULE

TEST ACTION APPLICABILITY

1 Turn the ignition off.

Disconnect the Engine Control Module harness connectors.

Check each power and ground circuit to the module.

Were any problems found?All

Ye s!Refer to the wiring diagrams located in the service information to

help isolate an open or shorted condition. Repair as necessary.

Perform ROAD TEST VERIFICATION - VER-2.

No!Go To 2

2 Turn the ignition off.

Disconnect the ECM harness connectors.

Disconnect the DRBIIItfrom the DLC.

Measure the resistance between ground and the K-ECM circuit.

Is the resistance below 5.0 ohms?All

Ye s!Repair the K-ECM circuit for a short to ground.

Perform ROAD TEST VERIFICATION - VER-2.

No!Go To 3

3 Turn the ignition off.

Disconnect the DRBIIItfrom the DLC.

Disconnect the ECM harness connectors.

Turn the ignition on.

Using a 12-volt test light connected to ground, probe the K-ECM circuit.

NOTE: The test light must illuminate brightly. Compare the brightness to

that of a direct connection to the battery.

Does the test light illuminate brightly?All

Ye s!Repair the K-ECM circuit for a short to voltage.

Perform ROAD TEST VERIFICATION - VER-2.

No!Go To 4

12

COMMUNICATION

Page 444 of 2305

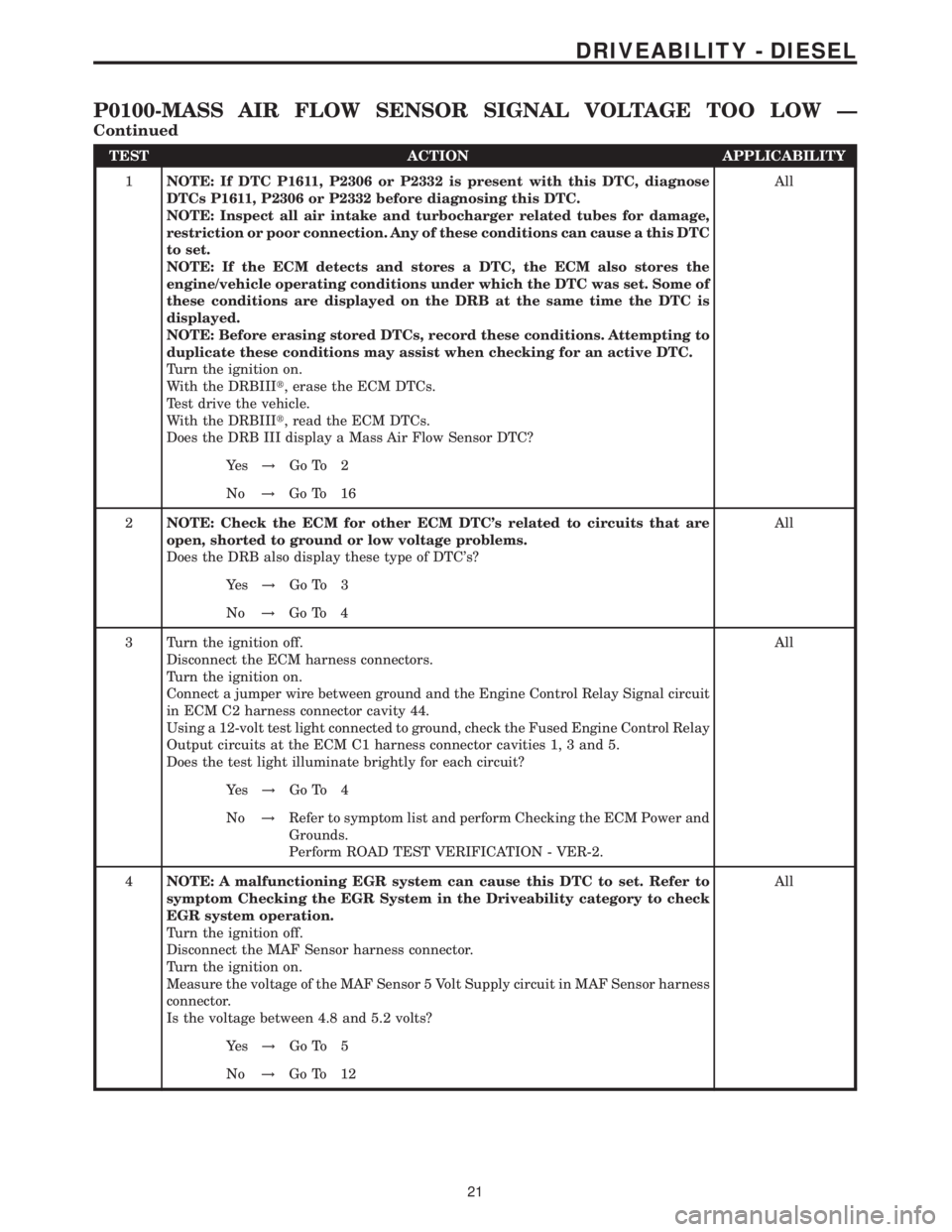

TEST ACTION APPLICABILITY

1NOTE: If DTC P1611, P2306 or P2332 is present with this DTC, diagnose

DTCs P1611, P2306 or P2332 before diagnosing this DTC.

NOTE: Inspect all air intake and turbocharger related tubes for damage,

restriction or poor connection. Any of these conditions can cause a this DTC

to set.

NOTE: If the ECM detects and stores a DTC, the ECM also stores the

engine/vehicle operating conditions under which the DTC was set. Some of

these conditions are displayed on the DRB at the same time the DTC is

displayed.

NOTE: Before erasing stored DTCs, record these conditions. Attempting to

duplicate these conditions may assist when checking for an active DTC.

Turn the ignition on.

With the DRBIIIt, erase the ECM DTCs.

Test drive the vehicle.

With the DRBIIIt, read the ECM DTCs.

Does the DRB III display a Mass Air Flow Sensor DTC?All

Ye s!Go To 2

No!Go To 16

2NOTE: Check the ECM for other ECM DTC's related to circuits that are

open, shorted to ground or low voltage problems.

Does the DRB also display these type of DTC's?All

Ye s!Go To 3

No!Go To 4

3 Turn the ignition off.

Disconnect the ECM harness connectors.

Turn the ignition on.

Connect a jumper wire between ground and the Engine Control Relay Signal circuit

in ECM C2 harness connector cavity 44.

Using a 12-volt test light connected to ground, check the Fused Engine Control Relay

Output circuits at the ECM C1 harness connector cavities 1, 3 and 5.

Does the test light illuminate brightly for each circuit?All

Ye s!Go To 4

No!Refer to symptom list and perform Checking the ECM Power and

Grounds.

Perform ROAD TEST VERIFICATION - VER-2.

4NOTE: A malfunctioning EGR system can cause this DTC to set. Refer to

symptom Checking the EGR System in the Driveability category to check

EGR system operation.

Turn the ignition off.

Disconnect the MAF Sensor harness connector.

Turn the ignition on.

Measure the voltage of the MAF Sensor 5 Volt Supply circuit in MAF Sensor harness

connector.

Is the voltage between 4.8 and 5.2 volts?All

Ye s!Go To 5

No!Go To 12

21

DRIVEABILITY - DIESEL

P0100-MASS AIR FLOW SENSOR SIGNAL VOLTAGE TOO LOW Ð

Continued

Page 487 of 2305

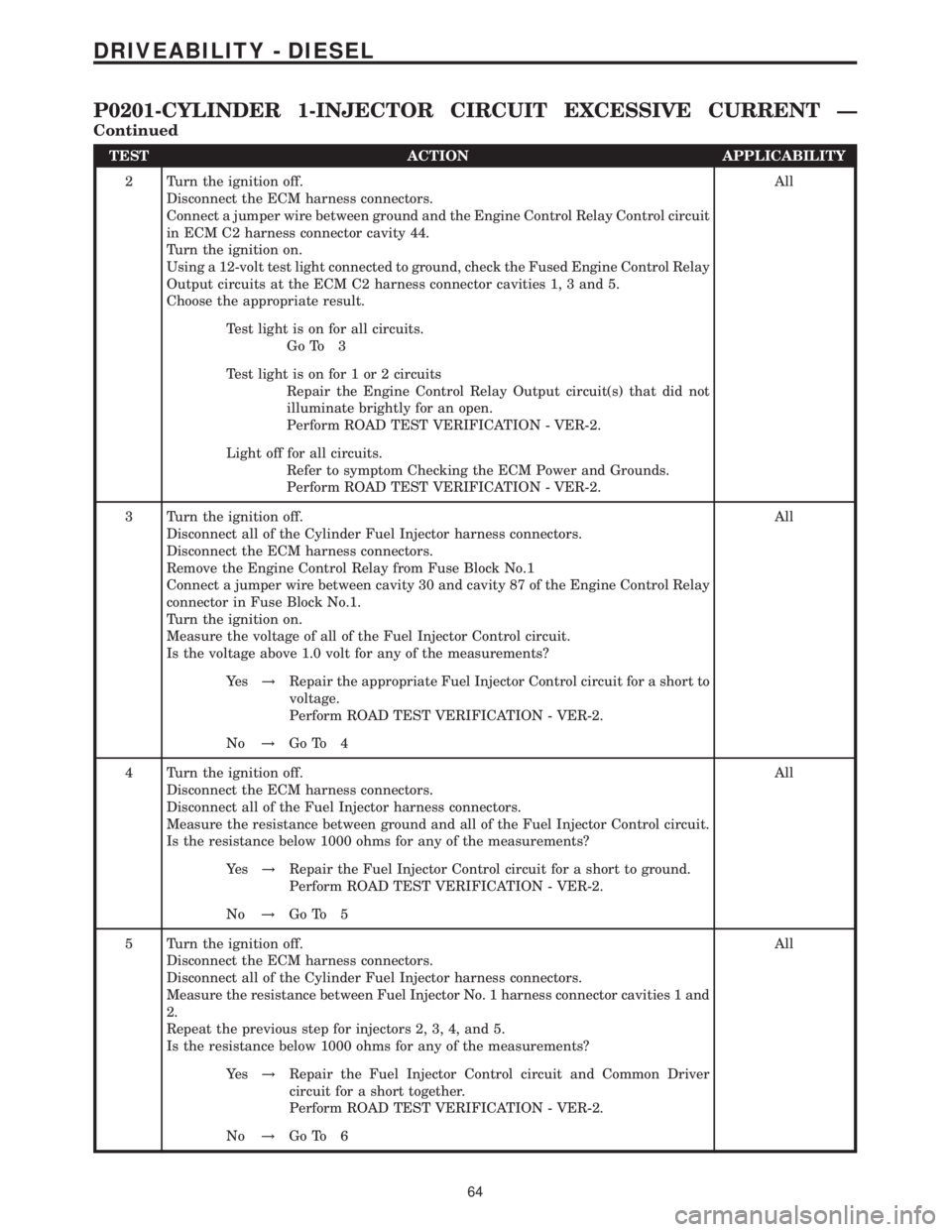

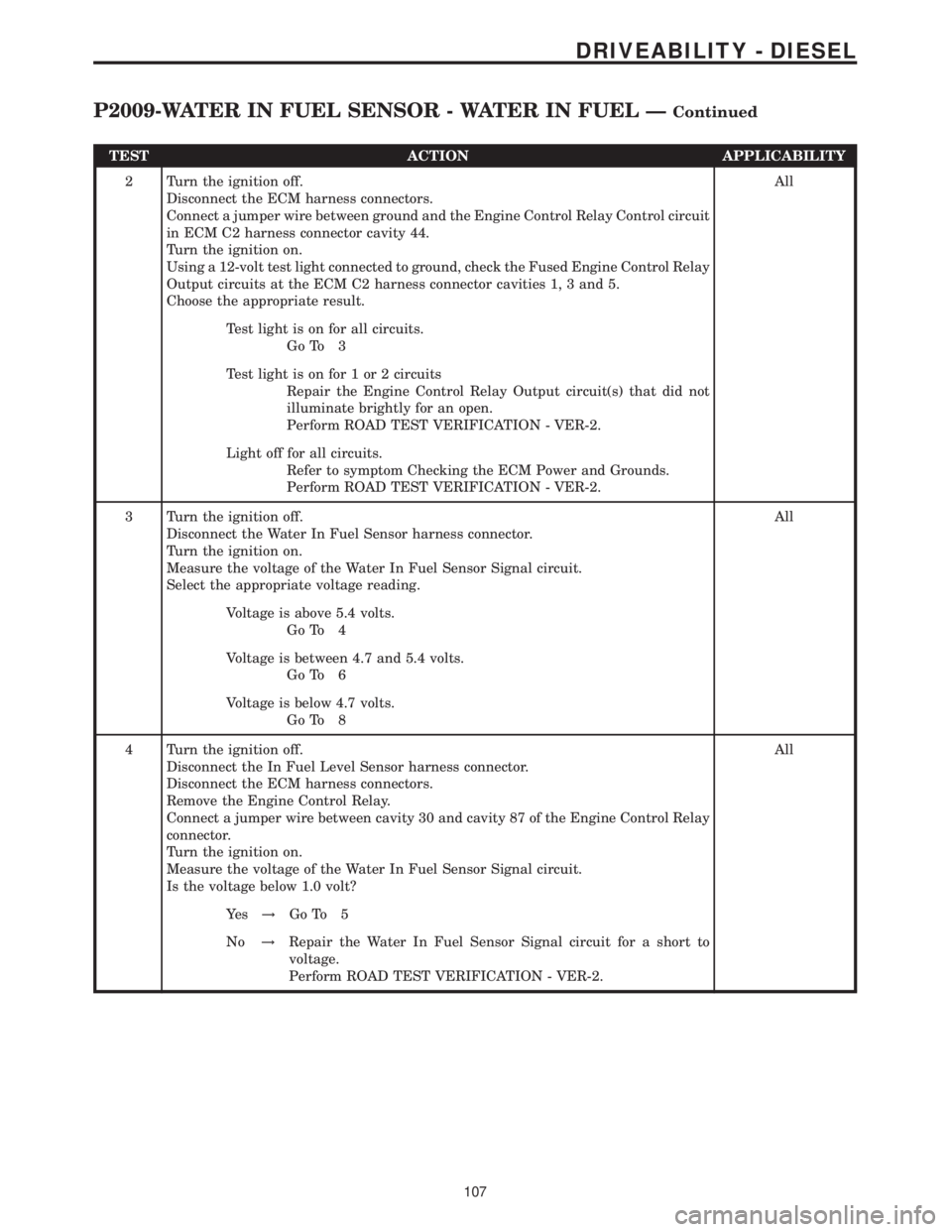

TEST ACTION APPLICABILITY

2 Turn the ignition off.

Disconnect the ECM harness connectors.

Connect a jumper wire between ground and the Engine Control Relay Control circuit

in ECM C2 harness connector cavity 44.

Turn the ignition on.

Using a 12-volt test light connected to ground, check the Fused Engine Control Relay

Output circuits at the ECM C2 harness connector cavities 1, 3 and 5.

Choose the appropriate result.All

Test light is on for all circuits.

Go To 3

Test light is on for 1 or 2 circuits

Repair the Engine Control Relay Output circuit(s) that did not

illuminate brightly for an open.

Perform ROAD TEST VERIFICATION - VER-2.

Light off for all circuits.

Refer to symptom Checking the ECM Power and Grounds.

Perform ROAD TEST VERIFICATION - VER-2.

3 Turn the ignition off.

Disconnect all of the Cylinder Fuel Injector harness connectors.

Disconnect the ECM harness connectors.

Remove the Engine Control Relay from Fuse Block No.1

Connect a jumper wire between cavity 30 and cavity 87 of the Engine Control Relay

connector in Fuse Block No.1.

Turn the ignition on.

Measure the voltage of all of the Fuel Injector Control circuit.

Is the voltage above 1.0 volt for any of the measurements?All

Ye s!Repair the appropriate Fuel Injector Control circuit for a short to

voltage.

Perform ROAD TEST VERIFICATION - VER-2.

No!Go To 4

4 Turn the ignition off.

Disconnect the ECM harness connectors.

Disconnect all of the Fuel Injector harness connectors.

Measure the resistance between ground and all of the Fuel Injector Control circuit.

Is the resistance below 1000 ohms for any of the measurements?All

Ye s!Repair the Fuel Injector Control circuit for a short to ground.

Perform ROAD TEST VERIFICATION - VER-2.

No!Go To 5

5 Turn the ignition off.

Disconnect the ECM harness connectors.

Disconnect all of the Cylinder Fuel Injector harness connectors.

Measure the resistance between Fuel Injector No. 1 harness connector cavities 1 and

2.

Repeat the previous step for injectors 2, 3, 4, and 5.

Is the resistance below 1000 ohms for any of the measurements?All

Ye s!Repair the Fuel Injector Control circuit and Common Driver

circuit for a short together.

Perform ROAD TEST VERIFICATION - VER-2.

No!Go To 6

64

DRIVEABILITY - DIESEL

P0201-CYLINDER 1-INJECTOR CIRCUIT EXCESSIVE CURRENT Ð

Continued

Page 499 of 2305

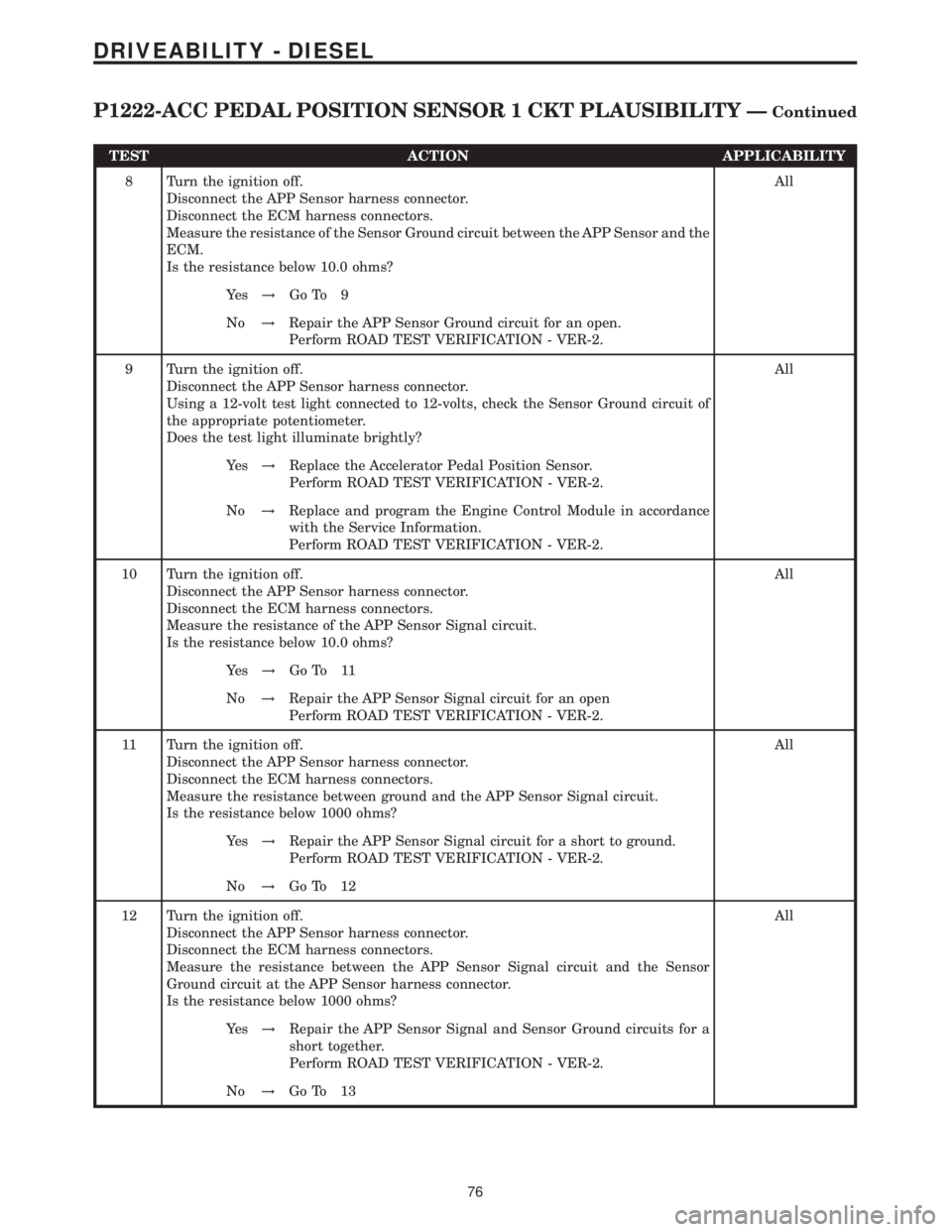

TEST ACTION APPLICABILITY

8 Turn the ignition off.

Disconnect the APP Sensor harness connector.

Disconnect the ECM harness connectors.

Measure the resistance of the Sensor Ground circuit between the APP Sensor and the

ECM.

Is the resistance below 10.0 ohms?All

Ye s!Go To 9

No!Repair the APP Sensor Ground circuit for an open.

Perform ROAD TEST VERIFICATION - VER-2.

9 Turn the ignition off.

Disconnect the APP Sensor harness connector.

Using a 12-volt test light connected to 12-volts, check the Sensor Ground circuit of

the appropriate potentiometer.

Does the test light illuminate brightly?All

Ye s!Replace the Accelerator Pedal Position Sensor.

Perform ROAD TEST VERIFICATION - VER-2.

No!Replace and program the Engine Control Module in accordance

with the Service Information.

Perform ROAD TEST VERIFICATION - VER-2.

10 Turn the ignition off.

Disconnect the APP Sensor harness connector.

Disconnect the ECM harness connectors.

Measure the resistance of the APP Sensor Signal circuit.

Is the resistance below 10.0 ohms?All

Ye s!Go To 11

No!Repair the APP Sensor Signal circuit for an open

Perform ROAD TEST VERIFICATION - VER-2.

11 Turn the ignition off.

Disconnect the APP Sensor harness connector.

Disconnect the ECM harness connectors.

Measure the resistance between ground and the APP Sensor Signal circuit.

Is the resistance below 1000 ohms?All

Ye s!Repair the APP Sensor Signal circuit for a short to ground.

Perform ROAD TEST VERIFICATION - VER-2.

No!Go To 12

12 Turn the ignition off.

Disconnect the APP Sensor harness connector.

Disconnect the ECM harness connectors.

Measure the resistance between the APP Sensor Signal circuit and the Sensor

Ground circuit at the APP Sensor harness connector.

Is the resistance below 1000 ohms?All

Ye s!Repair the APP Sensor Signal and Sensor Ground circuits for a

short together.

Perform ROAD TEST VERIFICATION - VER-2.

No!Go To 13

76

DRIVEABILITY - DIESEL

P1222-ACC PEDAL POSITION SENSOR 1 CKT PLAUSIBILITY ÐContinued

Page 530 of 2305

TEST ACTION APPLICABILITY

2 Turn the ignition off.

Disconnect the ECM harness connectors.

Connect a jumper wire between ground and the Engine Control Relay Control circuit

in ECM C2 harness connector cavity 44.

Turn the ignition on.

Using a 12-volt test light connected to ground, check the Fused Engine Control Relay

Output circuits at the ECM C2 harness connector cavities 1, 3 and 5.

Choose the appropriate result.All

Test light is on for all circuits.

Go To 3

Test light is on for 1 or 2 circuits

Repair the Engine Control Relay Output circuit(s) that did not

illuminate brightly for an open.

Perform ROAD TEST VERIFICATION - VER-2.

Light off for all circuits.

Refer to symptom Checking the ECM Power and Grounds.

Perform ROAD TEST VERIFICATION - VER-2.

3 Turn the ignition off.

Disconnect the Water In Fuel Sensor harness connector.

Turn the ignition on.

Measure the voltage of the Water In Fuel Sensor Signal circuit.

Select the appropriate voltage reading.All

Voltage is above 5.4 volts.

Go To 4

Voltage is between 4.7 and 5.4 volts.

Go To 6

Voltage is below 4.7 volts.

Go To 8

4 Turn the ignition off.

Disconnect the In Fuel Level Sensor harness connector.

Disconnect the ECM harness connectors.

Remove the Engine Control Relay.

Connect a jumper wire between cavity 30 and cavity 87 of the Engine Control Relay

connector.

Turn the ignition on.

Measure the voltage of the Water In Fuel Sensor Signal circuit.

Is the voltage below 1.0 volt?All

Ye s!Go To 5

No!Repair the Water In Fuel Sensor Signal circuit for a short to

voltage.

Perform ROAD TEST VERIFICATION - VER-2.

107

DRIVEABILITY - DIESEL

P2009-WATER IN FUEL SENSOR - WATER IN FUEL ÐContinued

Page 543 of 2305

TEST ACTION APPLICABILITY

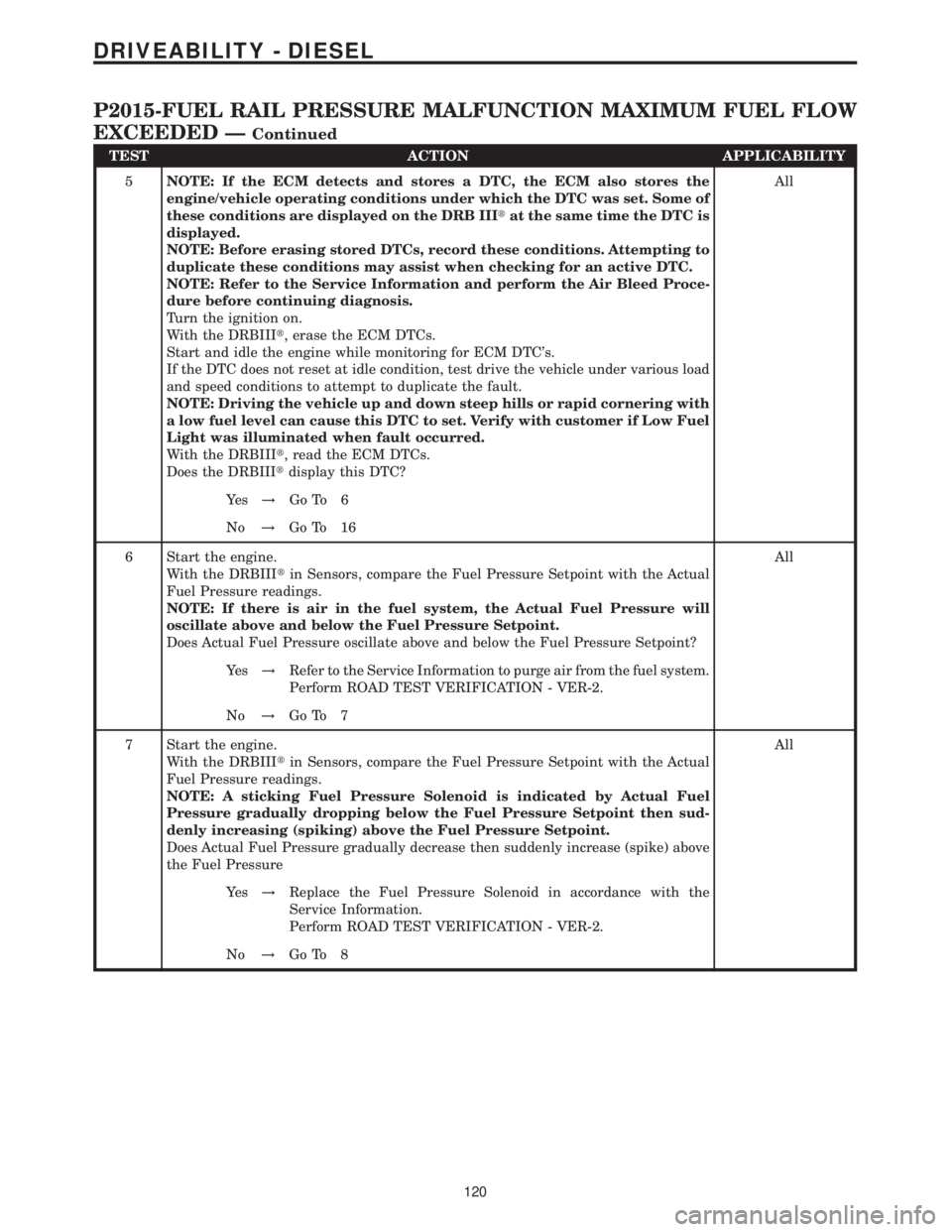

5NOTE: If the ECM detects and stores a DTC, the ECM also stores the

engine/vehicle operating conditions under which the DTC was set. Some of

these conditions are displayed on the DRB IIItat the same time the DTC is

displayed.

NOTE: Before erasing stored DTCs, record these conditions. Attempting to

duplicate these conditions may assist when checking for an active DTC.

NOTE: Refer to the Service Information and perform the Air Bleed Proce-

dure before continuing diagnosis.

Turn the ignition on.

With the DRBIIIt, erase the ECM DTCs.

Start and idle the engine while monitoring for ECM DTC's.

If the DTC does not reset at idle condition, test drive the vehicle under various load

and speed conditions to attempt to duplicate the fault.

NOTE: Driving the vehicle up and down steep hills or rapid cornering with

a low fuel level can cause this DTC to set. Verify with customer if Low Fuel

Light was illuminated when fault occurred.

With the DRBIIIt, read the ECM DTCs.

Does the DRBIIItdisplay this DTC?All

Ye s!Go To 6

No!Go To 16

6 Start the engine.

With the DRBIIItin Sensors, compare the Fuel Pressure Setpoint with the Actual

Fuel Pressure readings.

NOTE: If there is air in the fuel system, the Actual Fuel Pressure will

oscillate above and below the Fuel Pressure Setpoint.

Does Actual Fuel Pressure oscillate above and below the Fuel Pressure Setpoint?All

Ye s!Refer to the Service Information to purge air from the fuel system.

Perform ROAD TEST VERIFICATION - VER-2.

No!Go To 7

7 Start the engine.

With the DRBIIItin Sensors, compare the Fuel Pressure Setpoint with the Actual

Fuel Pressure readings.

NOTE: A sticking Fuel Pressure Solenoid is indicated by Actual Fuel

Pressure gradually dropping below the Fuel Pressure Setpoint then sud-

denly increasing (spiking) above the Fuel Pressure Setpoint.

Does Actual Fuel Pressure gradually decrease then suddenly increase (spike) above

the Fuel PressureAll

Ye s!Replace the Fuel Pressure Solenoid in accordance with the

Service Information.

Perform ROAD TEST VERIFICATION - VER-2.

No!Go To 8

120

DRIVEABILITY - DIESEL

P2015-FUEL RAIL PRESSURE MALFUNCTION MAXIMUM FUEL FLOW

EXCEEDED Ð

Continued