engine MERCEDES-BENZ SPRINTER 2006 Workshop Manual

[x] Cancel search | Manufacturer: MERCEDES-BENZ, Model Year: 2006, Model line: SPRINTER, Model: MERCEDES-BENZ SPRINTER 2006Pages: 2305, PDF Size: 48.12 MB

Page 280 of 2305

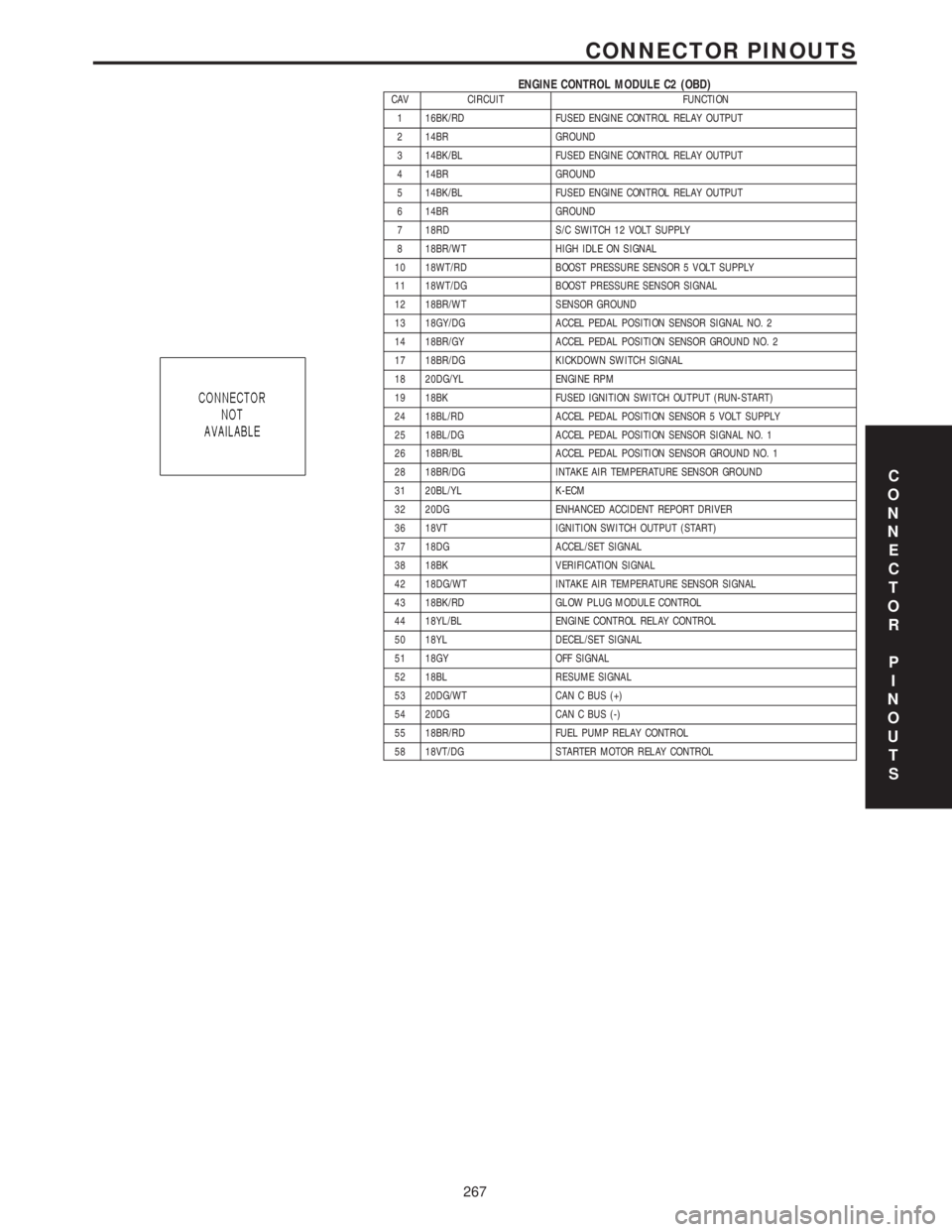

ENGINE CONTROL MODULE C2 (OBD)CAV CIRCUIT FUNCTION

1 16BK/RD FUSED ENGINE CONTROL RELAY OUTPUT

2 14BR GROUND

3 14BK/BL FUSED ENGINE CONTROL RELAY OUTPUT

4 14BR GROUND

5 14BK/BL FUSED ENGINE CONTROL RELAY OUTPUT

6 14BR GROUND

7 18RD S/C SWITCH 12 VOLT SUPPLY

8 18BR/WT HIGH IDLE ON SIGNAL

10 18WT/RD BOOST PRESSURE SENSOR 5 VOLT SUPPLY

11 18WT/DG BOOST PRESSURE SENSOR SIGNAL

12 18BR/WT SENSOR GROUND

13 18GY/DG ACCEL PEDAL POSITION SENSOR SIGNAL NO. 2

14 18BR/GY ACCEL PEDAL POSITION SENSOR GROUND NO. 2

17 18BR/DG KICKDOWN SWITCH SIGNAL

18 20DG/YL ENGINE RPM

19 18BK FUSED IGNITION SWITCH OUTPUT (RUN-START)

24 18BL/RD ACCEL PEDAL POSITION SENSOR 5 VOLT SUPPLY

25 18BL/DG ACCEL PEDAL POSITION SENSOR SIGNAL NO. 1

26 18BR/BL ACCEL PEDAL POSITION SENSOR GROUND NO. 1

28 18BR/DG INTAKE AIR TEMPERATURE SENSOR GROUND

31 20BL/YL K-ECM

32 20DG ENHANCED ACCIDENT REPORT DRIVER

36 18VT IGNITION SWITCH OUTPUT (START)

37 18DG ACCEL/SET SIGNAL

38 18BK VERIFICATION SIGNAL

42 18DG/WT INTAKE AIR TEMPERATURE SENSOR SIGNAL

43 18BK/RD GLOW PLUG MODULE CONTROL

44 18YL/BL ENGINE CONTROL RELAY CONTROL

50 18YL DECEL/SET SIGNAL

51 18GY OFF SIGNAL

52 18BL RESUME SIGNAL

53 20DG/WT CAN C BUS (+)

54 20DG CAN C BUS (-)

55 18BR/RD FUEL PUMP RELAY CONTROL

58 18VT/DG STARTER MOTOR RELAY CONTROL

C

O

N

N

E

C

T

O

R

P

I

N

O

U

T

S

267

CONNECTOR PINOUTS

Page 281 of 2305

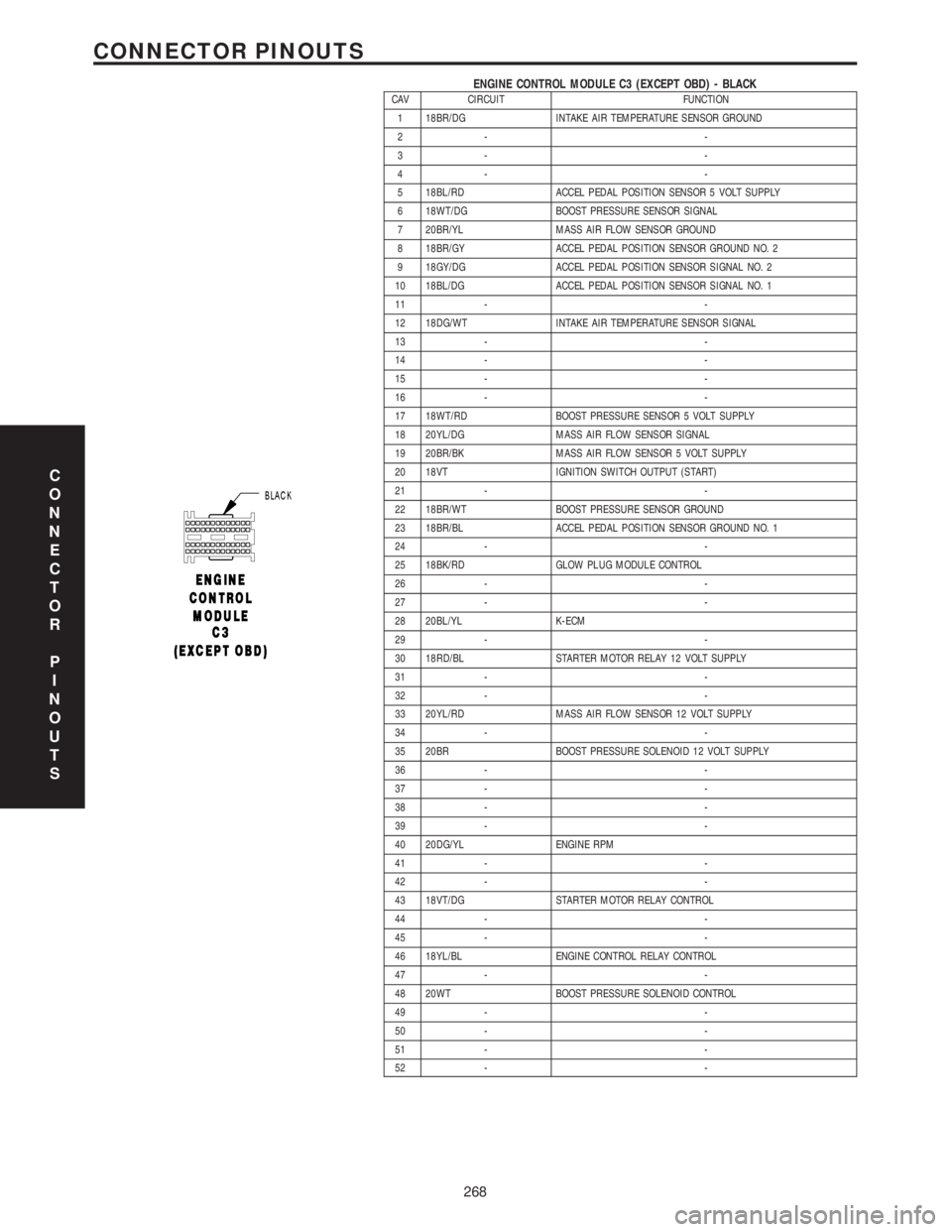

ENGINE CONTROL MODULE C3 (EXCEPT OBD) - BLACKCAV CIRCUIT FUNCTION

1 18BR/DG INTAKE AIR TEMPERATURE SENSOR GROUND

2- -

3- -

4- -

5 18BL/RD ACCEL PEDAL POSITION SENSOR 5 VOLT SUPPLY

6 18WT/DG BOOST PRESSURE SENSOR SIGNAL

7 20BR/YL MASS AIR FLOW SENSOR GROUND

8 18BR/GY ACCEL PEDAL POSITION SENSOR GROUND NO. 2

9 18GY/DG ACCEL PEDAL POSITION SENSOR SIGNAL NO. 2

10 18BL/DG ACCEL PEDAL POSITION SENSOR SIGNAL NO. 1

11 - -

12 18DG/WT INTAKE AIR TEMPERATURE SENSOR SIGNAL

13 - -

14 - -

15 - -

16 - -

17 18WT/RD BOOST PRESSURE SENSOR 5 VOLT SUPPLY

18 20YL/DG MASS AIR FLOW SENSOR SIGNAL

19 20BR/BK MASS AIR FLOW SENSOR 5 VOLT SUPPLY

20 18VT IGNITION SWITCH OUTPUT (START)

21 - -

22 18BR/WT BOOST PRESSURE SENSOR GROUND

23 18BR/BL ACCEL PEDAL POSITION SENSOR GROUND NO. 1

24 - -

25 18BK/RD GLOW PLUG MODULE CONTROL

26 - -

27 - -

28 20BL/YL K-ECM

29 - -

30 18RD/BL STARTER MOTOR RELAY 12 VOLT SUPPLY

31 - -

32 - -

33 20YL/RD MASS AIR FLOW SENSOR 12 VOLT SUPPLY

34 - -

35 20BR BOOST PRESSURE SOLENOID 12 VOLT SUPPLY

36 - -

37 - -

38 - -

39 - -

40 20DG/YL ENGINE RPM

41 - -

42 - -

43 18VT/DG STARTER MOTOR RELAY CONTROL

44 - -

45 - -

46 18YL/BL ENGINE CONTROL RELAY CONTROL

47 - -

48 20WT BOOST PRESSURE SOLENOID CONTROL

49 - -

50 - -

51 - -

52 - -

C

O

N

N

E

C

T

O

R

P

I

N

O

U

T

S

268

CONNECTOR PINOUTS

Page 284 of 2305

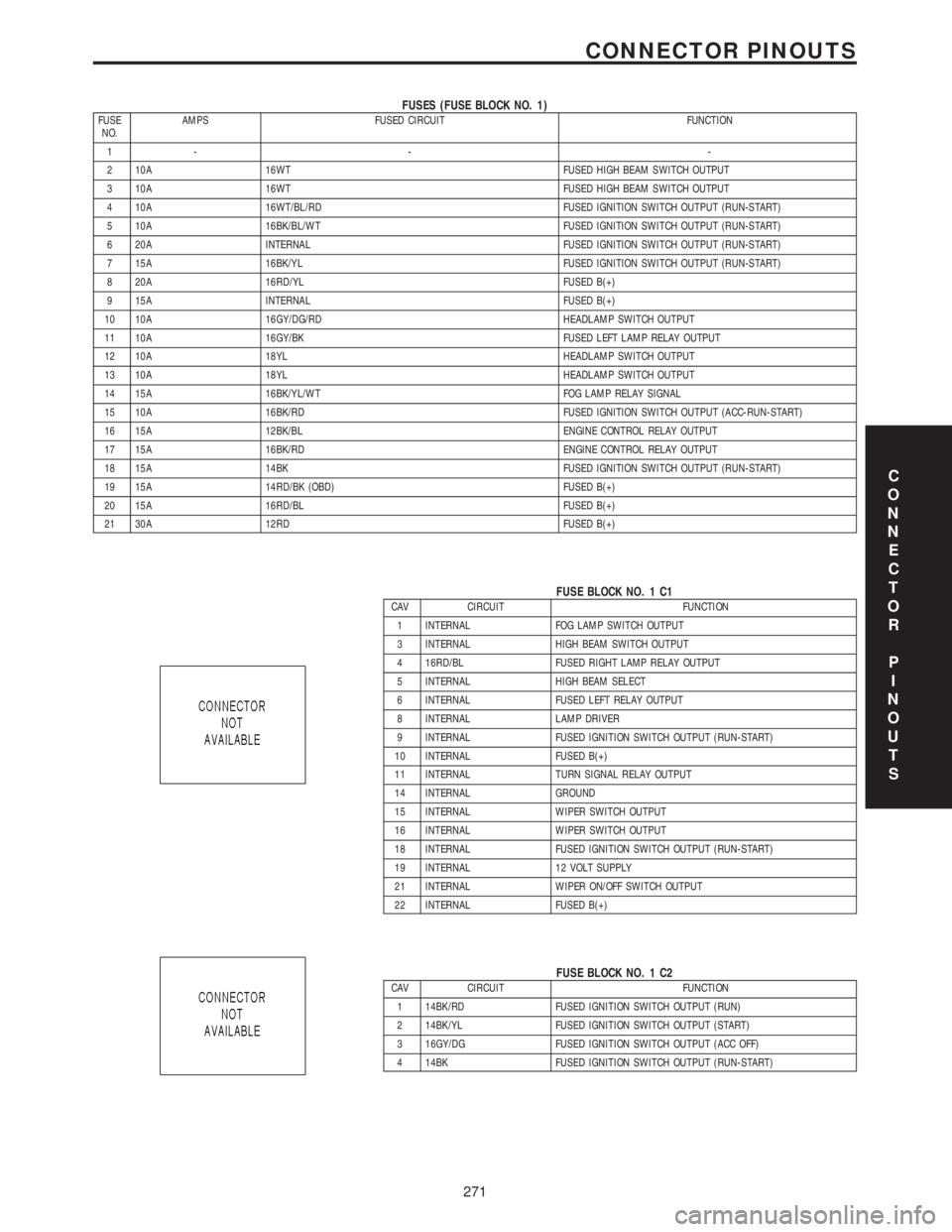

FUSES (FUSE BLOCK NO. 1)FUSE

NO.AMPS FUSED CIRCUIT FUNCTION

1- - -

2 10A 16WT FUSED HIGH BEAM SWITCH OUTPUT

3 10A 16WT FUSED HIGH BEAM SWITCH OUTPUT

4 10A 16WT/BL/RD FUSED IGNITION SWITCH OUTPUT (RUN-START)

5 10A 16BK/BL/WT FUSED IGNITION SWITCH OUTPUT (RUN-START)

6 20A INTERNAL FUSED IGNITION SWITCH OUTPUT (RUN-START)

7 15A 16BK/YL FUSED IGNITION SWITCH OUTPUT (RUN-START)

8 20A 16RD/YL FUSED B(+)

9 15A INTERNAL FUSED B(+)

10 10A 16GY/DG/RD HEADLAMP SWITCH OUTPUT

11 10A 16GY/BK FUSED LEFT LAMP RELAY OUTPUT

12 10A 18YL HEADLAMP SWITCH OUTPUT

13 10A 18YL HEADLAMP SWITCH OUTPUT

14 15A 16BK/YL/WT FOG LAMP RELAY SIGNAL

15 10A 16BK/RD FUSED IGNITION SWITCH OUTPUT (ACC-RUN-START)

16 15A 12BK/BL ENGINE CONTROL RELAY OUTPUT

17 15A 16BK/RD ENGINE CONTROL RELAY OUTPUT

18 15A 14BK FUSED IGNITION SWITCH OUTPUT (RUN-START)

19 15A 14RD/BK (OBD) FUSED B(+)

20 15A 16RD/BL FUSED B(+)

21 30A 12RD FUSED B(+)

FUSE BLOCK NO. 1 C1CAV CIRCUIT FUNCTION

1 INTERNAL FOG LAMP SWITCH OUTPUT

3 INTERNAL HIGH BEAM SWITCH OUTPUT

4 16RD/BL FUSED RIGHT LAMP RELAY OUTPUT

5 INTERNAL HIGH BEAM SELECT

6 INTERNAL FUSED LEFT RELAY OUTPUT

8 INTERNAL LAMP DRIVER

9 INTERNAL FUSED IGNITION SWITCH OUTPUT (RUN-START)

10 INTERNAL FUSED B(+)

11 INTERNAL TURN SIGNAL RELAY OUTPUT

14 INTERNAL GROUND

15 INTERNAL WIPER SWITCH OUTPUT

16 INTERNAL WIPER SWITCH OUTPUT

18 INTERNAL FUSED IGNITION SWITCH OUTPUT (RUN-START)

19 INTERNAL 12 VOLT SUPPLY

21 INTERNAL WIPER ON/OFF SWITCH OUTPUT

22 INTERNAL FUSED B(+)

FUSE BLOCK NO. 1 C2CAV CIRCUIT FUNCTION

1 14BK/RD FUSED IGNITION SWITCH OUTPUT (RUN)

2 14BK/YL FUSED IGNITION SWITCH OUTPUT (START)

3 16GY/DG FUSED IGNITION SWITCH OUTPUT (ACC OFF)

4 14BK FUSED IGNITION SWITCH OUTPUT (RUN-START)

C

O

N

N

E

C

T

O

R

P

I

N

O

U

T

S

271

CONNECTOR PINOUTS

Page 285 of 2305

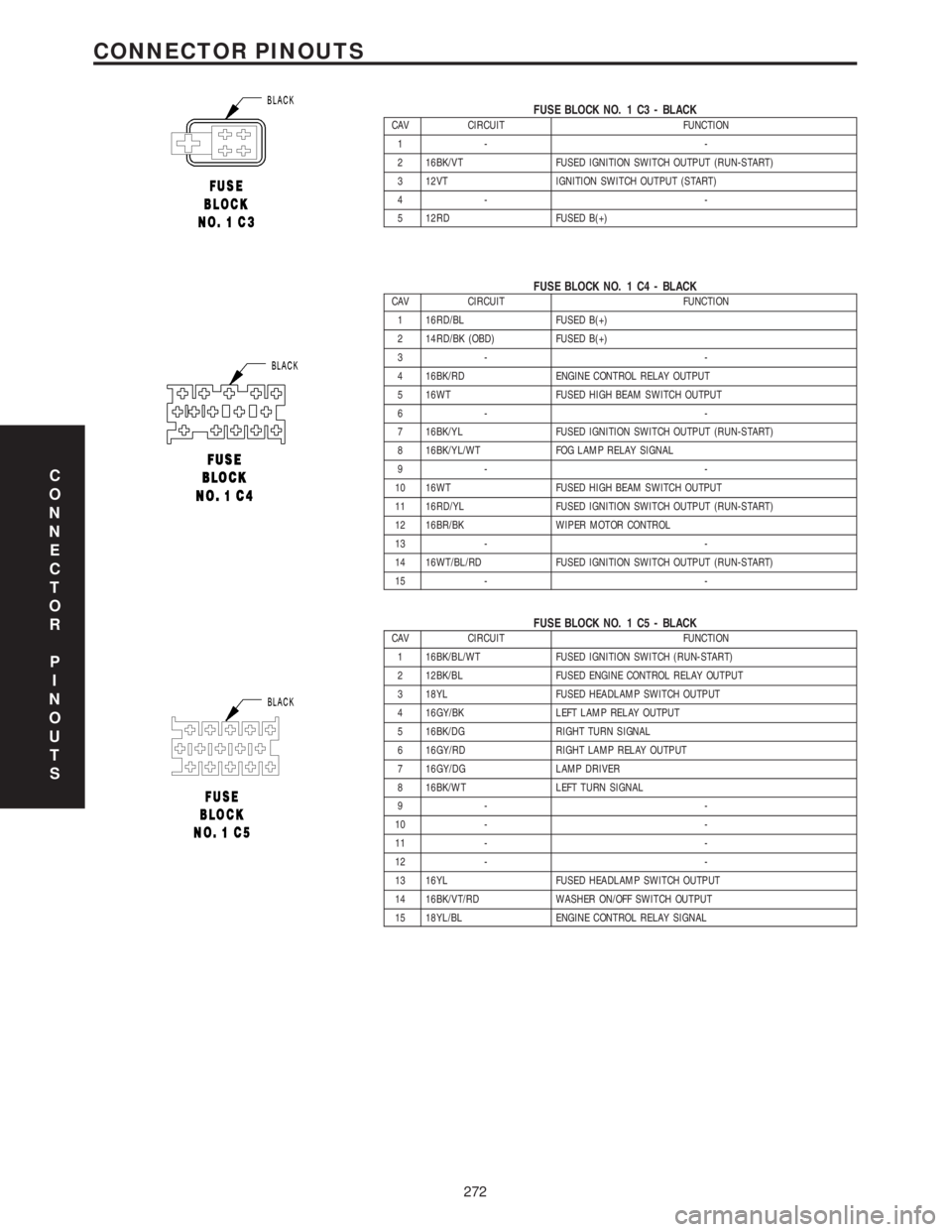

FUSE BLOCK NO. 1 C3 - BLACKCAV CIRCUIT FUNCTION

1- -

2 16BK/VT FUSED IGNITION SWITCH OUTPUT (RUN-START)

3 12VT IGNITION SWITCH OUTPUT (START)

4- -

5 12RD FUSED B(+)

FUSE BLOCK NO. 1 C4 - BLACKCAV CIRCUIT FUNCTION

1 16RD/BL FUSED B(+)

2 14RD/BK (OBD) FUSED B(+)

3- -

4 16BK/RD ENGINE CONTROL RELAY OUTPUT

5 16WT FUSED HIGH BEAM SWITCH OUTPUT

6- -

7 16BK/YL FUSED IGNITION SWITCH OUTPUT (RUN-START)

8 16BK/YL/WT FOG LAMP RELAY SIGNAL

9- -

10 16WT FUSED HIGH BEAM SWITCH OUTPUT

11 16RD/YL FUSED IGNITION SWITCH OUTPUT (RUN-START)

12 16BR/BK WIPER MOTOR CONTROL

13 - -

14 16WT/BL/RD FUSED IGNITION SWITCH OUTPUT (RUN-START)

15 - -

FUSE BLOCK NO. 1 C5 - BLACKCAV CIRCUIT FUNCTION

1 16BK/BL/WT FUSED IGNITION SWITCH (RUN-START)

2 12BK/BL FUSED ENGINE CONTROL RELAY OUTPUT

3 18YL FUSED HEADLAMP SWITCH OUTPUT

4 16GY/BK LEFT LAMP RELAY OUTPUT

5 16BK/DG RIGHT TURN SIGNAL

6 16GY/RD RIGHT LAMP RELAY OUTPUT

7 16GY/DG LAMP DRIVER

8 16BK/WT LEFT TURN SIGNAL

9- -

10 - -

11 - -

12 - -

13 16YL FUSED HEADLAMP SWITCH OUTPUT

14 16BK/VT/RD WASHER ON/OFF SWITCH OUTPUT

15 18YL/BL ENGINE CONTROL RELAY SIGNAL

C

O

N

N

E

C

T

O

R

P

I

N

O

U

T

S

272

CONNECTOR PINOUTS

Page 292 of 2305

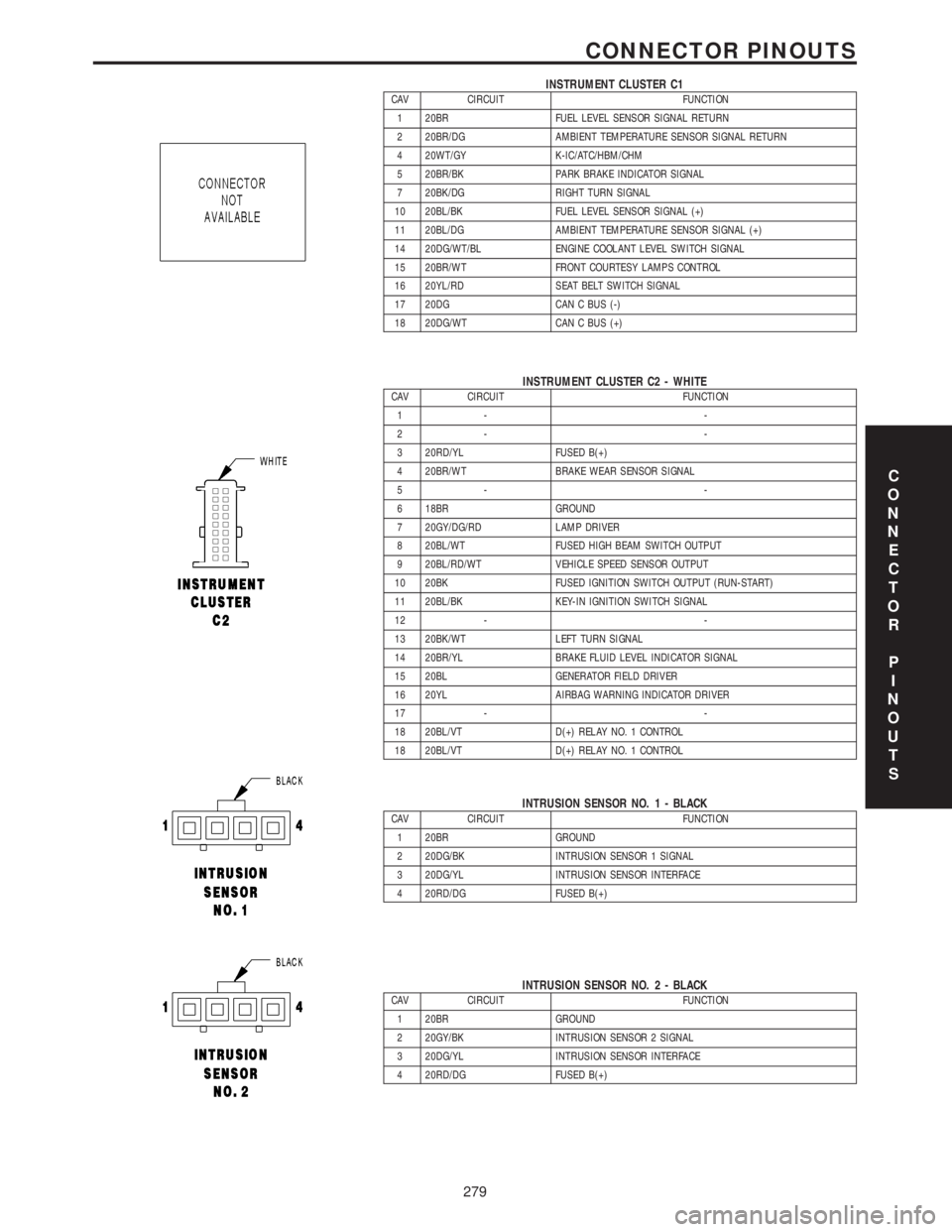

INSTRUMENT CLUSTER C1CAV CIRCUIT FUNCTION

1 20BR FUEL LEVEL SENSOR SIGNAL RETURN

2 20BR/DG AMBIENT TEMPERATURE SENSOR SIGNAL RETURN

4 20WT/GY K-IC/ATC/HBM/CHM

5 20BR/BK PARK BRAKE INDICATOR SIGNAL

7 20BK/DG RIGHT TURN SIGNAL

10 20BL/BK FUEL LEVEL SENSOR SIGNAL (+)

11 20BL/DG AMBIENT TEMPERATURE SENSOR SIGNAL (+)

14 20DG/WT/BL ENGINE COOLANT LEVEL SWITCH SIGNAL

15 20BR/WT FRONT COURTESY LAMPS CONTROL

16 20YL/RD SEAT BELT SWITCH SIGNAL

17 20DG CAN C BUS (-)

18 20DG/WT CAN C BUS (+)

INSTRUMENT CLUSTER C2 - WHITECAV CIRCUIT FUNCTION

1- -

2- -

3 20RD/YL FUSED B(+)

4 20BR/WT BRAKE WEAR SENSOR SIGNAL

5- -

6 18BR GROUND

7 20GY/DG/RD LAMP DRIVER

8 20BL/WT FUSED HIGH BEAM SWITCH OUTPUT

9 20BL/RD/WT VEHICLE SPEED SENSOR OUTPUT

10 20BK FUSED IGNITION SWITCH OUTPUT (RUN-START)

11 20BL/BK KEY-IN IGNITION SWITCH SIGNAL

12 - -

13 20BK/WT LEFT TURN SIGNAL

14 20BR/YL BRAKE FLUID LEVEL INDICATOR SIGNAL

15 20BL GENERATOR FIELD DRIVER

16 20YL AIRBAG WARNING INDICATOR DRIVER

17 - -

18 20BL/VT D(+) RELAY NO. 1 CONTROL

18 20BL/VT D(+) RELAY NO. 1 CONTROL

INTRUSION SENSOR NO. 1 - BLACKCAV CIRCUIT FUNCTION

1 20BR GROUND

2 20DG/BK INTRUSION SENSOR 1 SIGNAL

3 20DG/YL INTRUSION SENSOR INTERFACE

4 20RD/DG FUSED B(+)

INTRUSION SENSOR NO. 2 - BLACKCAV CIRCUIT FUNCTION

1 20BR GROUND

2 20GY/BK INTRUSION SENSOR 2 SIGNAL

3 20DG/YL INTRUSION SENSOR INTERFACE

4 20RD/DG FUSED B(+)

C

O

N

N

E

C

T

O

R

P

I

N

O

U

T

S

279

CONNECTOR PINOUTS

Page 316 of 2305

DIAGNOSTIC TEST PROCEDURES — TELL US!

DaimlerChrysler Corporation is constantly working to provide the technician the best diagnostic manuals possible.

Your comments and recommendations regarding the diagnostic manuals and procedures are appreciated.

To best understand your suggestion, please complete the form giving us as much detail as possible.

ModelYearBody TypeEngine

TransmissionVehicle MileageMDH

Diagnostic ProcedureBook No.Page

Comments/recommendations (if necessary, draw sketch)

Name

Submitted by:

Address

City/State/Zip

Business Phone #

All comments become property of DaimlerChrysler Corporation and may be used without compensation.

Page 323 of 2305

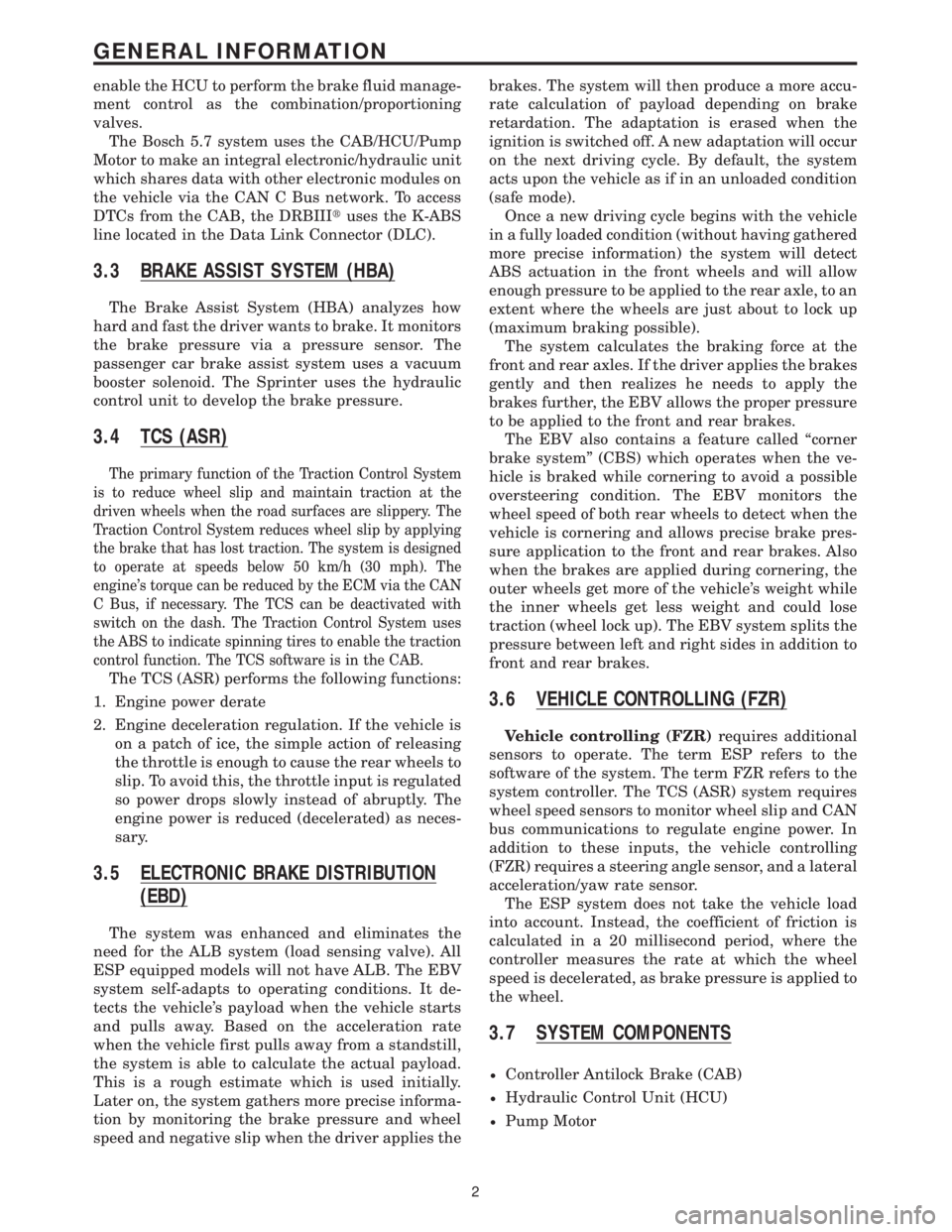

enable the HCU to perform the brake fluid manage-

ment control as the combination/proportioning

valves.

The Bosch 5.7 system uses the CAB/HCU/Pump

Motor to make an integral electronic/hydraulic unit

which shares data with other electronic modules on

the vehicle via the CAN C Bus network. To access

DTCs from the CAB, the DRBIIItuses the K-ABS

line located in the Data Link Connector (DLC).

3.3 BRAKE ASSIST SYSTEM (HBA)

The Brake Assist System (HBA) analyzes how

hard and fast the driver wants to brake. It monitors

the brake pressure via a pressure sensor. The

passenger car brake assist system uses a vacuum

booster solenoid. The Sprinter uses the hydraulic

control unit to develop the brake pressure.

3.4 TCS (ASR)

The primary function of the Traction Control System

is to reduce wheel slip and maintain traction at the

driven wheels when the road surfaces are slippery. The

Traction Control System reduces wheel slip by applying

the brake that has lost traction. The system is designed

to operate at speeds below 50 km/h (30 mph). The

engine's torque can be reduced by the ECM via the CAN

C Bus, if necessary. The TCS can be deactivated with

switch on the dash. The Traction Control System uses

the ABS to indicate spinning tires to enable the traction

control function. The TCS software is in the CAB.

The TCS (ASR) performs the following functions:

1. Engine power derate

2. Engine deceleration regulation. If the vehicle is

on a patch of ice, the simple action of releasing

the throttle is enough to cause the rear wheels to

slip. To avoid this, the throttle input is regulated

so power drops slowly instead of abruptly. The

engine power is reduced (decelerated) as neces-

sary.

3.5 ELECTRONIC BRAKE DISTRIBUTION

(EBD)

The system was enhanced and eliminates the

need for the ALB system (load sensing valve). All

ESP equipped models will not have ALB. The EBV

system self-adapts to operating conditions. It de-

tects the vehicle's payload when the vehicle starts

and pulls away. Based on the acceleration rate

when the vehicle first pulls away from a standstill,

the system is able to calculate the actual payload.

This is a rough estimate which is used initially.

Later on, the system gathers more precise informa-

tion by monitoring the brake pressure and wheel

speed and negative slip when the driver applies thebrakes. The system will then produce a more accu-

rate calculation of payload depending on brake

retardation. The adaptation is erased when the

ignition is switched off. A new adaptation will occur

on the next driving cycle. By default, the system

acts upon the vehicle as if in an unloaded condition

(safe mode).

Once a new driving cycle begins with the vehicle

in a fully loaded condition (without having gathered

more precise information) the system will detect

ABS actuation in the front wheels and will allow

enough pressure to be applied to the rear axle, to an

extent where the wheels are just about to lock up

(maximum braking possible).

The system calculates the braking force at the

front and rear axles. If the driver applies the brakes

gently and then realizes he needs to apply the

brakes further, the EBV allows the proper pressure

to be applied to the front and rear brakes.

The EBV also contains a feature called ªcorner

brake systemº (CBS) which operates when the ve-

hicle is braked while cornering to avoid a possible

oversteering condition. The EBV monitors the

wheel speed of both rear wheels to detect when the

vehicle is cornering and allows precise brake pres-

sure application to the front and rear brakes. Also

when the brakes are applied during cornering, the

outer wheels get more of the vehicle's weight while

the inner wheels get less weight and could lose

traction (wheel lock up). The EBV system splits the

pressure between left and right sides in addition to

front and rear brakes.

3.6 VEHICLE CONTROLLING (FZR)

Vehicle controlling (FZR)requires additional

sensors to operate. The term ESP refers to the

software of the system. The term FZR refers to the

system controller. The TCS (ASR) system requires

wheel speed sensors to monitor wheel slip and CAN

bus communications to regulate engine power. In

addition to these inputs, the vehicle controlling

(FZR) requires a steering angle sensor, and a lateral

acceleration/yaw rate sensor.

The ESP system does not take the vehicle load

into account. Instead, the coefficient of friction is

calculated in a 20 millisecond period, where the

controller measures the rate at which the wheel

speed is decelerated, as brake pressure is applied to

the wheel.

3.7 SYSTEM COMPONENTS

²Controller Antilock Brake (CAB)

²Hydraulic Control Unit (HCU)

²Pump Motor

2

GENERAL INFORMATION

Page 324 of 2305

²Four Wheel Speed Sensors/Tone Wheel assem-

blies

²ABS warning indicator

²TCS (ASR) event indicator

²TCS (ASR) warning indicator

²Steering Angle Sensor

²Lateral Acceleration/Yaw Rate Sensor

²Brake Pressure Sensor

²ESP event indicator

²Brake Fluid Level switch

²Brake Switch (BS)

²Brake Lamp Switch (BLS)

²TCS Switch (TCSS)

²K - ABS

²CAN C Bus

²Fuses, grounds, and wiring

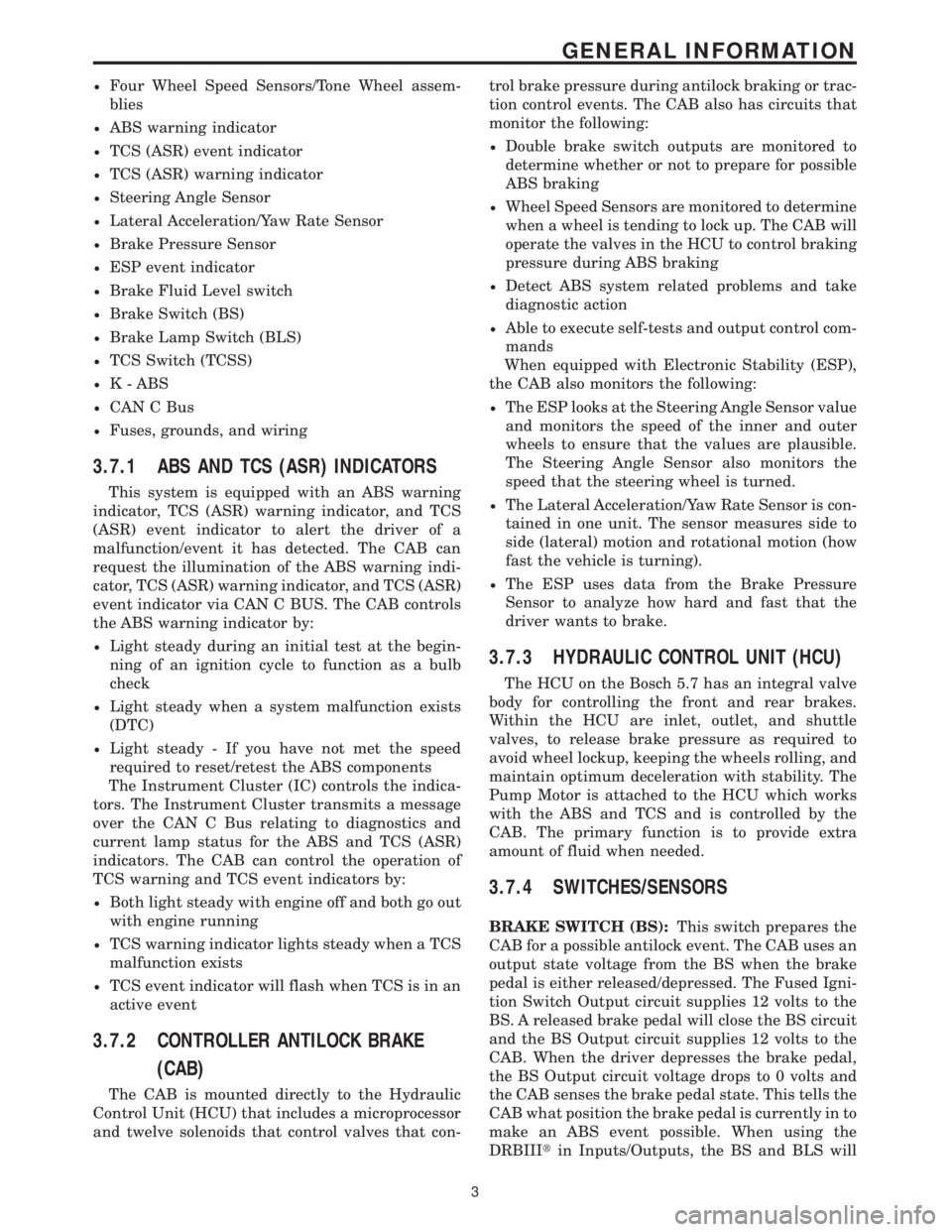

3.7.1 ABS AND TCS (ASR) INDICATORS

This system is equipped with an ABS warning

indicator, TCS (ASR) warning indicator, and TCS

(ASR) event indicator to alert the driver of a

malfunction/event it has detected. The CAB can

request the illumination of the ABS warning indi-

cator, TCS (ASR) warning indicator, and TCS (ASR)

event indicator via CAN C BUS. The CAB controls

the ABS warning indicator by:

²Light steady during an initial test at the begin-

ning of an ignition cycle to function as a bulb

check

²Light steady when a system malfunction exists

(DTC)

²Light steady - If you have not met the speed

required to reset/retest the ABS components

The Instrument Cluster (IC) controls the indica-

tors. The Instrument Cluster transmits a message

over the CAN C Bus relating to diagnostics and

current lamp status for the ABS and TCS (ASR)

indicators. The CAB can control the operation of

TCS warning and TCS event indicators by:

²Both light steady with engine off and both go out

with engine running

²TCS warning indicator lights steady when a TCS

malfunction exists

²TCS event indicator will flash when TCS is in an

active event

3.7.2 CONTROLLER ANTILOCK BRAKE

(CAB)

The CAB is mounted directly to the Hydraulic

Control Unit (HCU) that includes a microprocessor

and twelve solenoids that control valves that con-trol brake pressure during antilock braking or trac-

tion control events. The CAB also has circuits that

monitor the following:

²Double brake switch outputs are monitored to

determine whether or not to prepare for possible

ABS braking

²Wheel Speed Sensors are monitored to determine

when a wheel is tending to lock up. The CAB will

operate the valves in the HCU to control braking

pressure during ABS braking

²Detect ABS system related problems and take

diagnostic action

²Able to execute self-tests and output control com-

mands

When equipped with Electronic Stability (ESP),

the CAB also monitors the following:

²The ESP looks at the Steering Angle Sensor value

and monitors the speed of the inner and outer

wheels to ensure that the values are plausible.

The Steering Angle Sensor also monitors the

speed that the steering wheel is turned.

²The Lateral Acceleration/Yaw Rate Sensor is con-

tained in one unit. The sensor measures side to

side (lateral) motion and rotational motion (how

fast the vehicle is turning).

²The ESP uses data from the Brake Pressure

Sensor to analyze how hard and fast that the

driver wants to brake.

3.7.3 HYDRAULIC CONTROL UNIT (HCU)

The HCU on the Bosch 5.7 has an integral valve

body for controlling the front and rear brakes.

Within the HCU are inlet, outlet, and shuttle

valves, to release brake pressure as required to

avoid wheel lockup, keeping the wheels rolling, and

maintain optimum deceleration with stability. The

Pump Motor is attached to the HCU which works

with the ABS and TCS and is controlled by the

CAB. The primary function is to provide extra

amount of fluid when needed.

3.7.4 SWITCHES/SENSORS

BRAKE SWITCH (BS):This switch prepares the

CAB for a possible antilock event. The CAB uses an

output state voltage from the BS when the brake

pedal is either released/depressed. The Fused Igni-

tion Switch Output circuit supplies 12 volts to the

BS. A released brake pedal will close the BS circuit

and the BS Output circuit supplies 12 volts to the

CAB. When the driver depresses the brake pedal,

the BS Output circuit voltage drops to 0 volts and

the CAB senses the brake pedal state. This tells the

CAB what position the brake pedal is currently in to

make an ABS event possible. When using the

DRBIIItin Inputs/Outputs, the BS and BLS will

3

GENERAL INFORMATION

Page 326 of 2305

ver: 2.14

date: 26 Jul93

file: key_iff.cc

date: Jul 26 1993

line: 548

err: 0x1

User-Requested COLD Boot

Press MORE to switch between this display

and the application screen.

Press F4 when done noting information.

3.9.1 DRBIIITDOES NOT POWER UP

(BLANK SCREEN)

If the LED's do not light or no sound is emitted at

start up, check for loose cable connections or a bad

cable. Check the vehicle battery voltage (data link

16-way connector cavity 16). A minimum of 11 volts

is required to adequately power the DRBIIIt. Also

check for a good ground at DLC.

If all connections are proper between the

DRBIIItand the vehicle or other devices, and the

vehicle battery is fully charged, an inoperative

DRBIIItmay be the result or a faulty cable or

vehicle wiring.

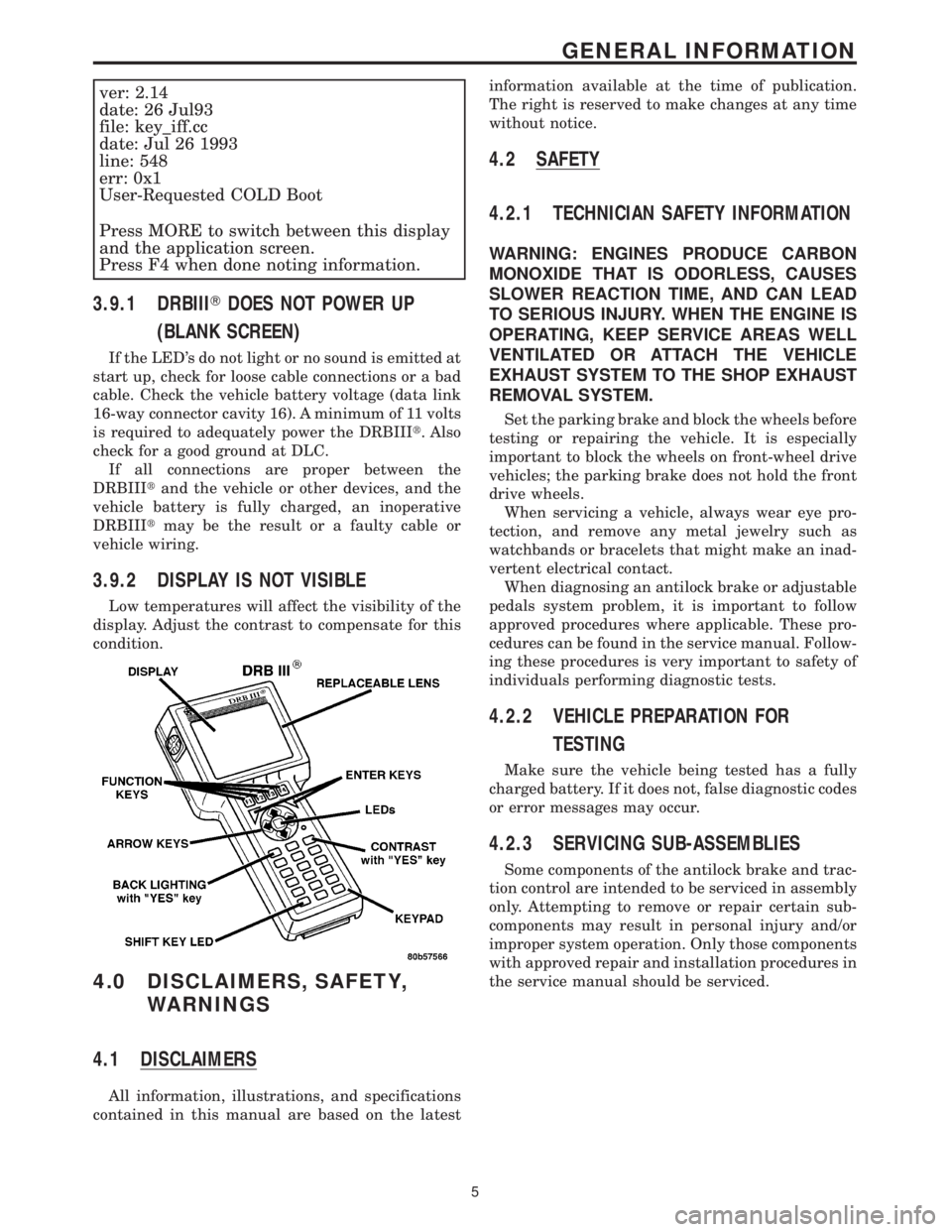

3.9.2 DISPLAY IS NOT VISIBLE

Low temperatures will affect the visibility of the

display. Adjust the contrast to compensate for this

condition.

4.0 DISCLAIMERS, SAFETY,

WARNINGS

4.1 DISCLAIMERS

All information, illustrations, and specifications

contained in this manual are based on the latestinformation available at the time of publication.

The right is reserved to make changes at any time

without notice.

4.2 SAFETY

4.2.1 TECHNICIAN SAFETY INFORMATION

WARNING: ENGINES PRODUCE CARBON

MONOXIDE THAT IS ODORLESS, CAUSES

SLOWER REACTION TIME, AND CAN LEAD

TO SERIOUS INJURY. WHEN THE ENGINE IS

OPERATING, KEEP SERVICE AREAS WELL

VENTILATED OR ATTACH THE VEHICLE

EXHAUST SYSTEM TO THE SHOP EXHAUST

REMOVAL SYSTEM.

Set the parking brake and block the wheels before

testing or repairing the vehicle. It is especially

important to block the wheels on front-wheel drive

vehicles; the parking brake does not hold the front

drive wheels.

When servicing a vehicle, always wear eye pro-

tection, and remove any metal jewelry such as

watchbands or bracelets that might make an inad-

vertent electrical contact.

When diagnosing an antilock brake or adjustable

pedals system problem, it is important to follow

approved procedures where applicable. These pro-

cedures can be found in the service manual. Follow-

ing these procedures is very important to safety of

individuals performing diagnostic tests.

4.2.2 VEHICLE PREPARATION FOR

TESTING

Make sure the vehicle being tested has a fully

charged battery. If it does not, false diagnostic codes

or error messages may occur.

4.2.3 SERVICING SUB-ASSEMBLIES

Some components of the antilock brake and trac-

tion control are intended to be serviced in assembly

only. Attempting to remove or repair certain sub-

components may result in personal injury and/or

improper system operation. Only those components

with approved repair and installation procedures in

the service manual should be serviced.

5

GENERAL INFORMATION

Page 346 of 2305

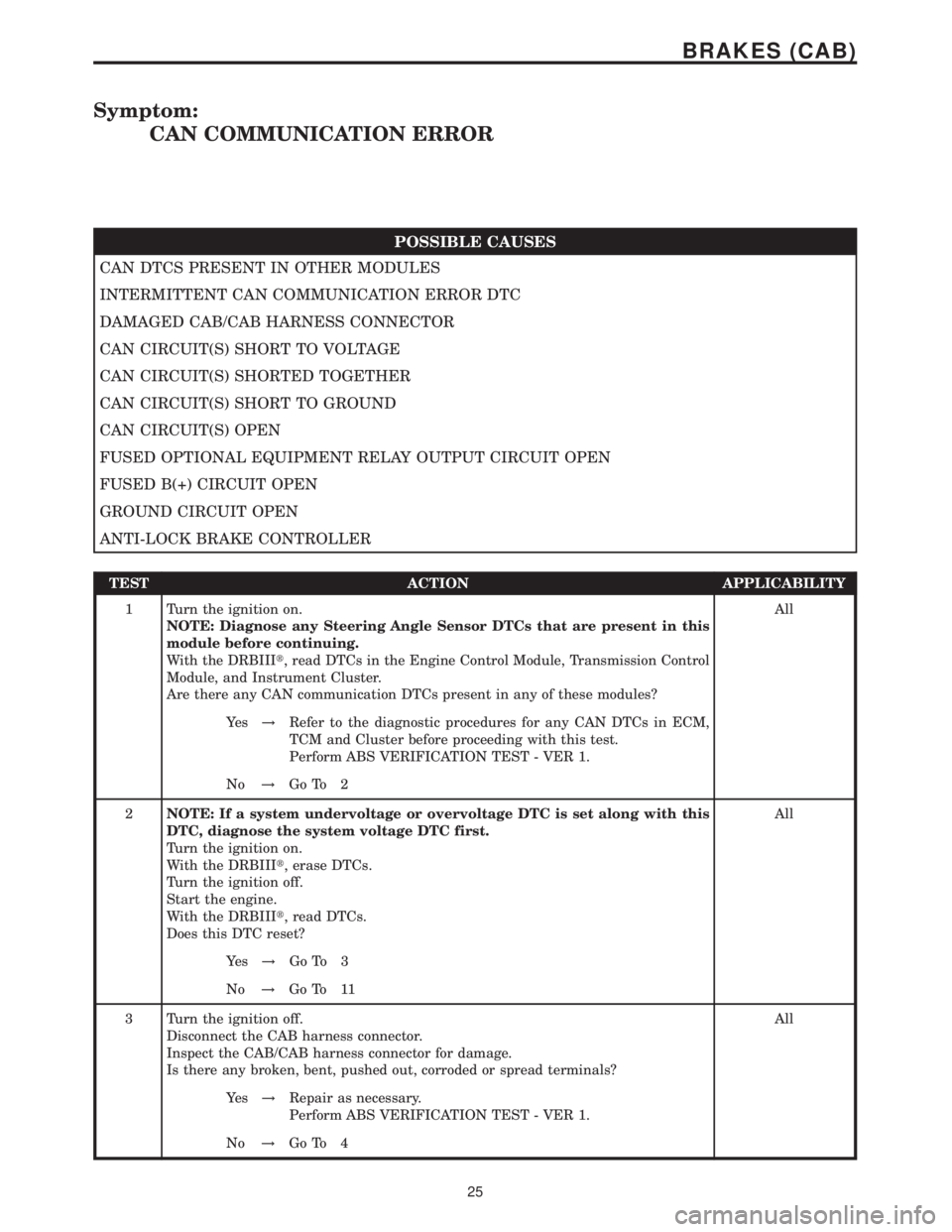

Symptom:

CAN COMMUNICATION ERROR

POSSIBLE CAUSES

CAN DTCS PRESENT IN OTHER MODULES

INTERMITTENT CAN COMMUNICATION ERROR DTC

DAMAGED CAB/CAB HARNESS CONNECTOR

CAN CIRCUIT(S) SHORT TO VOLTAGE

CAN CIRCUIT(S) SHORTED TOGETHER

CAN CIRCUIT(S) SHORT TO GROUND

CAN CIRCUIT(S) OPEN

FUSED OPTIONAL EQUIPMENT RELAY OUTPUT CIRCUIT OPEN

FUSED B(+) CIRCUIT OPEN

GROUND CIRCUIT OPEN

ANTI-LOCK BRAKE CONTROLLER

TEST ACTION APPLICABILITY

1 Turn the ignition on.

NOTE: Diagnose any Steering Angle Sensor DTCs that are present in this

module before continuing.

With the DRBIIIt, read DTCs in the Engine Control Module, Transmission Control

Module, and Instrument Cluster.

Are there any CAN communication DTCs present in any of these modules?All

Ye s!Refer to the diagnostic procedures for any CAN DTCs in ECM,

TCM and Cluster before proceeding with this test.

Perform ABS VERIFICATION TEST - VER 1.

No!Go To 2

2NOTE: If a system undervoltage or overvoltage DTC is set along with this

DTC, diagnose the system voltage DTC first.

Turn the ignition on.

With the DRBIIIt, erase DTCs.

Turn the ignition off.

Start the engine.

With the DRBIIIt, read DTCs.

Does this DTC reset?All

Ye s!Go To 3

No!Go To 11

3 Turn the ignition off.

Disconnect the CAB harness connector.

Inspect the CAB/CAB harness connector for damage.

Is there any broken, bent, pushed out, corroded or spread terminals?All

Ye s!Repair as necessary.

Perform ABS VERIFICATION TEST - VER 1.

No!Go To 4

25

BRAKES (CAB)