heating MERCEDES-BENZ SPRINTER 2006 Repair Manual

[x] Cancel search | Manufacturer: MERCEDES-BENZ, Model Year: 2006, Model line: SPRINTER, Model: MERCEDES-BENZ SPRINTER 2006Pages: 2305, PDF Size: 48.12 MB

Page 189 of 2305

TEST ACTION APPLICABILITY

2 Turn the ignition off.

NOTE: Check connectors - Clean/repair as necessary.

Disconnect the Automatic Temperature Control (ATC) C1 harness connector.

Turn the ignition on.

Measure the voltage of the Water Cycle Valve Control circuit.

Is the voltage above 0.2 volts?All

Ye s!Repair the Water Cycle Valve Control circuit for a short to voltage.

Perform BODY VERIFICATION TEST - VER 1.

No!Replace the Automatic Temperature Control (ATC) in accordance

with the Service Information.

Perform BODY VERIFICATION TEST - VER 1.

3 Turn the ignition off.

NOTE: Check connectors - Clean/repair as necessary.

Disconnect the Automatic Temperature Control (ATC) C1 harness connector.

Disconnect the Water Cycle Valve harness connector.

Measure the resistance of the Water Cycle Valve Control circuit between the

Automatic Temperature Control (ATC) C1 harness connector and the Water Cycle

Valve harness connector.

Is the resistance below 5.0 ohms?All

Ye s!Go To 4

No!Repair the Water Cycle Valve Control circuit for an open.

Perform BODY VERIFICATION TEST - VER 1.

4 Turn the ignition off.

NOTE: Check connectors - Clean/repair as necessary.

Disconnect the Water Cycle Valve harness connector.

Measure the resistance between ground and the Ground circuit.

Is the resistance below 5.0 ohms?All

Ye s!Replace the Automatic Temperature Control (ATC) in accordance

with the Service Information.

Perform BODY VERIFICATION TEST - VER 1.

No!Repair the Ground circuit for an open.

Perform BODY VERIFICATION TEST - VER 1.

176

HEATING & A/C

WATER CYCLE VALVE CONTROL HIGH OR OPEN (ACTIVE) ÐContinued

Page 190 of 2305

Symptom:

WATER CYCLE VALVE CONTROL SHORTED LOW (ACTIVE)

POSSIBLE CAUSES

WATER CYCLE VALVE CONTROL CIRCUIT SHORTED TO GROUND

WATER CYCLE VALVE CONTROL CIRCUIT SHORTED TO GROUND CIRCUIT

WATER CYCLE VALVE CONTROL CIRCUIT SHORTED TO SENSOR GROUND CIRCUIT

AUTOMATIC TEMPERATURE CONTROL (ATC)

WATER CYCLE VALVE

TEST ACTION APPLICABILITY

1 Turn the ignition off.

Disconnect the Water Cycle Valve harness connector.

Disconnect the Automatic Temperature Control (ATC) C1 harness connector.

Measure the resistance between ground and the Water Cycle Valve Control circuit.

Is the resistance below 10k ohms?All

Ye s!Repair the Water Cycle Valve Control circuit for a short to ground.

Perform BODY VERIFICATION TEST - VER 1.

No!Go To 2

2 Turn the ignition off.

Disconnect the Water Cycle Valve harness connector.

Disconnect the Automatic Temperature Control (ATC) C1 harness connector.

Measure the resistance between the Water Cycle Valve Control circuit and the

Ground circuit in the Automatic Temperature Control C1 harness connector.

Is the resistance below 10k ohms?All

Ye s!Repair the Water Cycle Valve Control circuit for a short to the

Ground circuit.

Perform BODY VERIFICATION TEST - VER 1.

No!Go To 3

3 Turn the ignition off.

Disconnect the Water Cycle Valve harness connector.

Disconnect the Automatic Temperature Control (ATC) C1 harness connector.

Measure the resistance between the Water Cycle Valve Control circuit and the Sensor

Ground circuit in the Automatic Temperature Control C1 harness connector.

Is the resistance below 10k ohms?All

Ye s!Repair the Water Cycle Valve Control circuit for a short to the

Sensor Ground circuit.

Perform BODY VERIFICATION TEST - VER 1.

No!Go To 4

177

HEATING & A/C

Page 191 of 2305

TEST ACTION APPLICABILITY

4 Turn the ignition off.

NOTE: Check connectors - Clean/repair as necessary.

Reconnect the Automatic Temperature Control (ATC) C1 harness connector.

Press the Residual Engine Heat Utilization (REST) switch off.

Disconnect the Water Cycle Valve harness connector.

Connect a 12-volt test light between the Water Cycle Valve Control circuit and the

Ground circuit in the Water Cycle Valve harness connector. The test light should

operate as follows:

With the Residual Engine Heat Utilization (REST) switch off, the test light should

not illuminate.

Press the Residual Engine Heat Utilization (REST) switch on.

With the Blend control set to Full Cold, the test light should illuminate brightly and

continuously.

With the Blend control set to one position below the half Cold/Hot setting, the test

light should illuminate brightly and blink at a slow continuous rate.

With the Blend control set to the half Cold/Hot setting or above, the test light should

be off.

Does the test light operate as specified?All

Ye s!Replace the Water Cycle Valve in accordance with the Service

Information.

Perform BODY VERIFICATION TEST - VER 1.

No!Replace the Automatic Temperature Control (ATC) in accordance

with the Service Information.

Perform BODY VERIFICATION TEST - VER 1.

178

HEATING & A/C

WATER CYCLE VALVE CONTROL SHORTED LOW (ACTIVE) ÐContinued

Page 263 of 2305

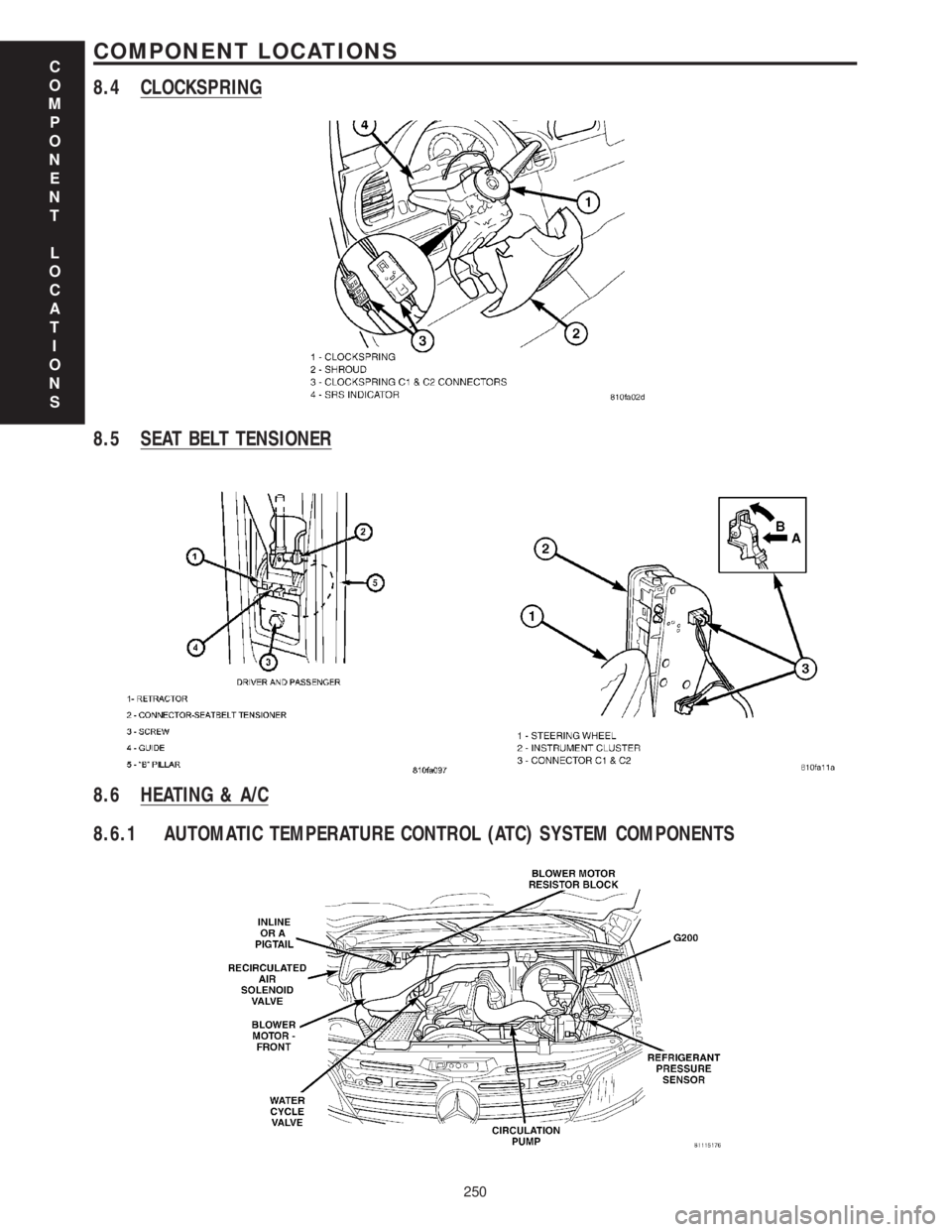

8.4 CLOCKSPRING

8.5 SEAT BELT TENSIONER

8.6 HEATING & A/C

8.6.1 AUTOMATIC TEMPERATURE CONTROL (ATC) SYSTEM COMPONENTS

C

O

M

P

O

N

E

N

T

L

O

C

A

T

I

O

N

S

250

COMPONENT LOCATIONS

Page 305 of 2305

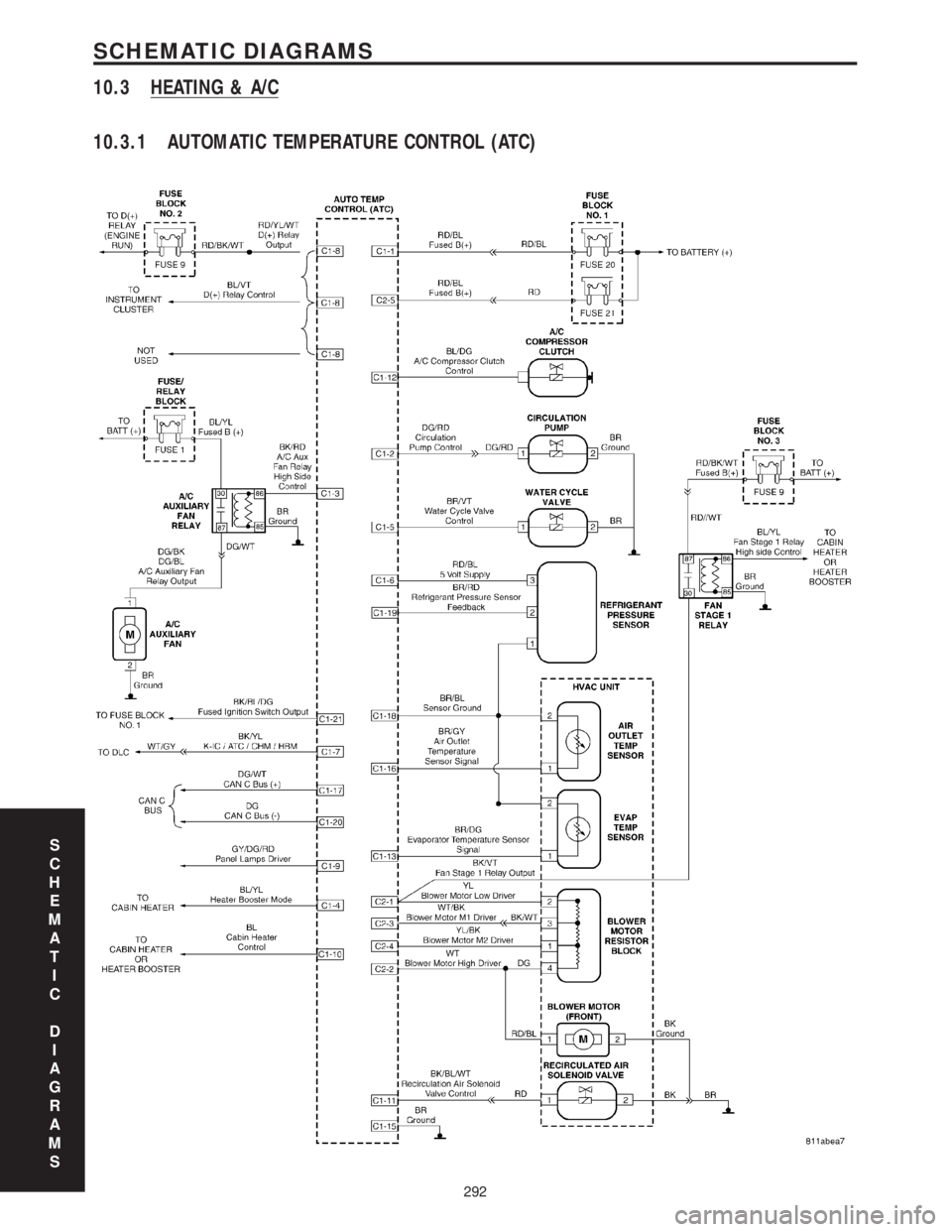

10.3 HEATING & A/C

10.3.1 AUTOMATIC TEMPERATURE CONTROL (ATC)

S

C

H

E

M

A

T

I

C

D

I

A

G

R

A

M

S

292

SCHEMATIC DIAGRAMS

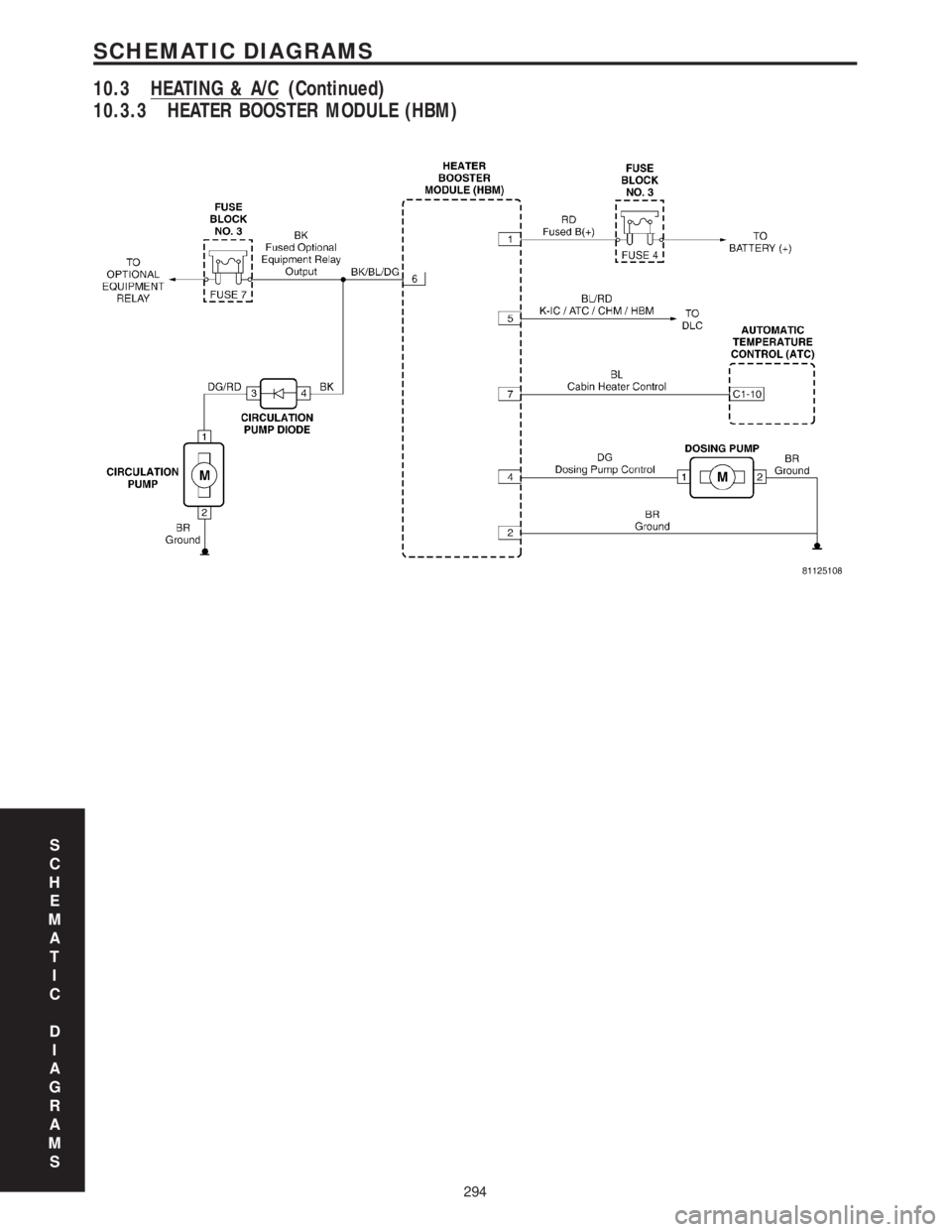

Page 307 of 2305

10.3.3 HEATER BOOSTER MODULE (HBM)

S

C

H

E

M

A

T

I

C

D

I

A

G

R

A

M

S

294

SCHEMATIC DIAGRAMS

10.3 HEATING & A/C (Continued)

Page 354 of 2305

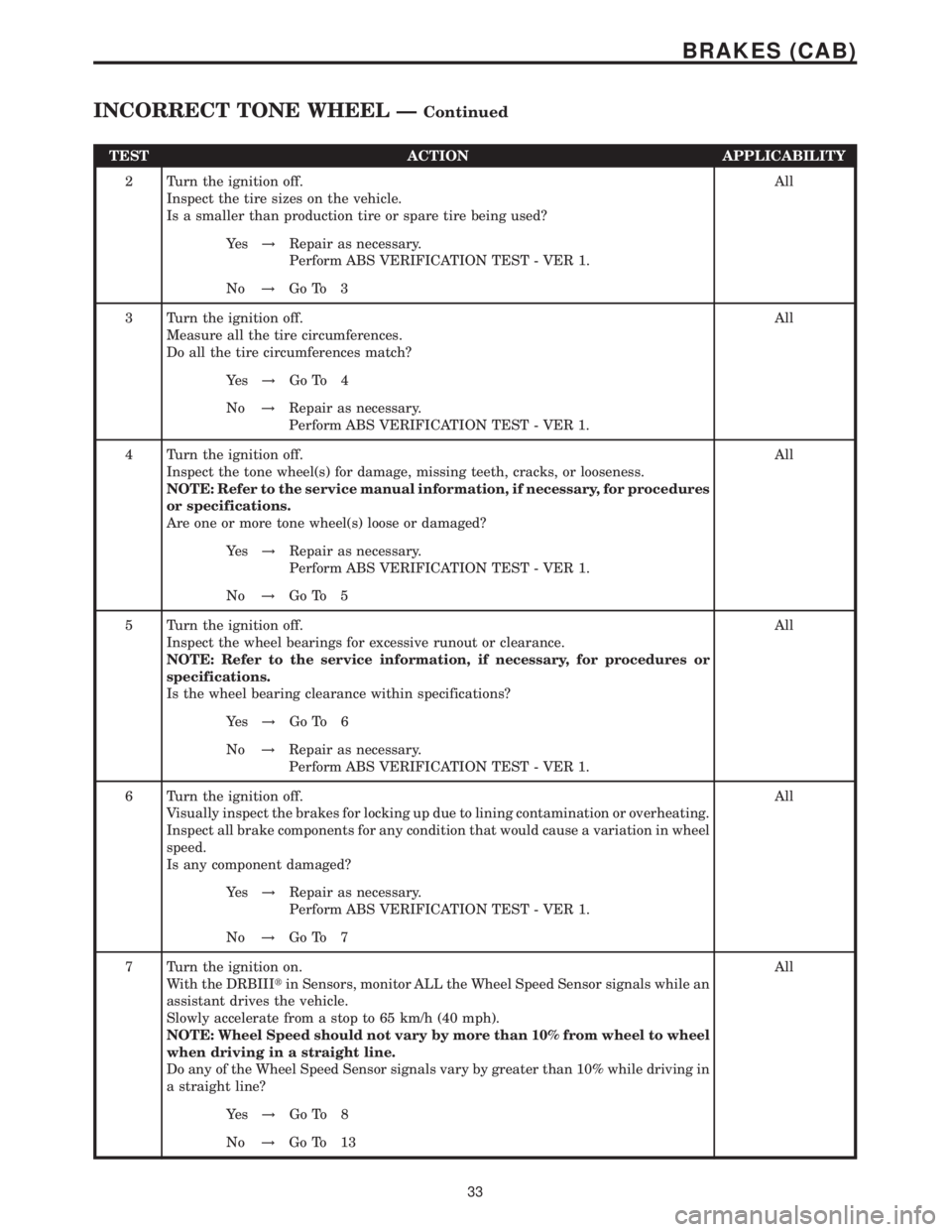

TEST ACTION APPLICABILITY

2 Turn the ignition off.

Inspect the tire sizes on the vehicle.

Is a smaller than production tire or spare tire being used?All

Ye s!Repair as necessary.

Perform ABS VERIFICATION TEST - VER 1.

No!Go To 3

3 Turn the ignition off.

Measure all the tire circumferences.

Do all the tire circumferences match?All

Ye s!Go To 4

No!Repair as necessary.

Perform ABS VERIFICATION TEST - VER 1.

4 Turn the ignition off.

Inspect the tone wheel(s) for damage, missing teeth, cracks, or looseness.

NOTE: Refer to the service manual information, if necessary, for procedures

or specifications.

Are one or more tone wheel(s) loose or damaged?All

Ye s!Repair as necessary.

Perform ABS VERIFICATION TEST - VER 1.

No!Go To 5

5 Turn the ignition off.

Inspect the wheel bearings for excessive runout or clearance.

NOTE: Refer to the service information, if necessary, for procedures or

specifications.

Is the wheel bearing clearance within specifications?All

Ye s!Go To 6

No!Repair as necessary.

Perform ABS VERIFICATION TEST - VER 1.

6 Turn the ignition off.

Visually inspect the brakes for locking up due to lining contamination or overheating.

Inspect all brake components for any condition that would cause a variation in wheel

speed.

Is any component damaged?All

Ye s!Repair as necessary.

Perform ABS VERIFICATION TEST - VER 1.

No!Go To 7

7 Turn the ignition on.

With the DRBIIItin Sensors, monitor ALL the Wheel Speed Sensor signals while an

assistant drives the vehicle.

Slowly accelerate from a stop to 65 km/h (40 mph).

NOTE: Wheel Speed should not vary by more than 10% from wheel to wheel

when driving in a straight line.

Do any of the Wheel Speed Sensor signals vary by greater than 10% while driving in

a straight line?All

Ye s!Go To 8

No!Go To 13

33

BRAKES (CAB)

INCORRECT TONE WHEEL ÐContinued

Page 368 of 2305

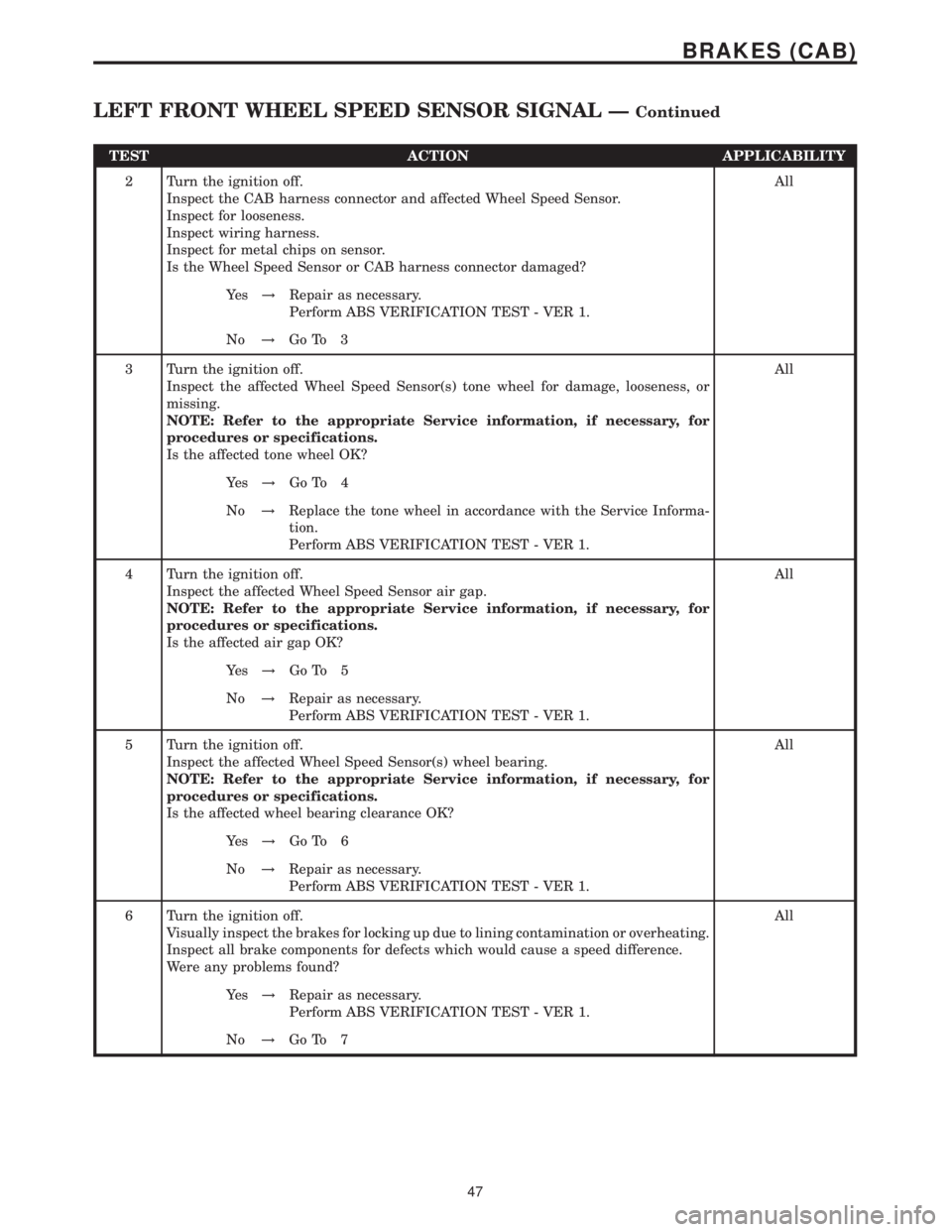

TEST ACTION APPLICABILITY

2 Turn the ignition off.

Inspect the CAB harness connector and affected Wheel Speed Sensor.

Inspect for looseness.

Inspect wiring harness.

Inspect for metal chips on sensor.

Is the Wheel Speed Sensor or CAB harness connector damaged?All

Ye s!Repair as necessary.

Perform ABS VERIFICATION TEST - VER 1.

No!Go To 3

3 Turn the ignition off.

Inspect the affected Wheel Speed Sensor(s) tone wheel for damage, looseness, or

missing.

NOTE: Refer to the appropriate Service information, if necessary, for

procedures or specifications.

Is the affected tone wheel OK?All

Ye s!Go To 4

No!Replace the tone wheel in accordance with the Service Informa-

tion.

Perform ABS VERIFICATION TEST - VER 1.

4 Turn the ignition off.

Inspect the affected Wheel Speed Sensor air gap.

NOTE: Refer to the appropriate Service information, if necessary, for

procedures or specifications.

Is the affected air gap OK?All

Ye s!Go To 5

No!Repair as necessary.

Perform ABS VERIFICATION TEST - VER 1.

5 Turn the ignition off.

Inspect the affected Wheel Speed Sensor(s) wheel bearing.

NOTE: Refer to the appropriate Service information, if necessary, for

procedures or specifications.

Is the affected wheel bearing clearance OK?All

Ye s!Go To 6

No!Repair as necessary.

Perform ABS VERIFICATION TEST - VER 1.

6 Turn the ignition off.

Visually inspect the brakes for locking up due to lining contamination or overheating.

Inspect all brake components for defects which would cause a speed difference.

Were any problems found?All

Ye s!Repair as necessary.

Perform ABS VERIFICATION TEST - VER 1.

No!Go To 7

47

BRAKES (CAB)

LEFT FRONT WHEEL SPEED SENSOR SIGNAL ÐContinued

Page 704 of 2305

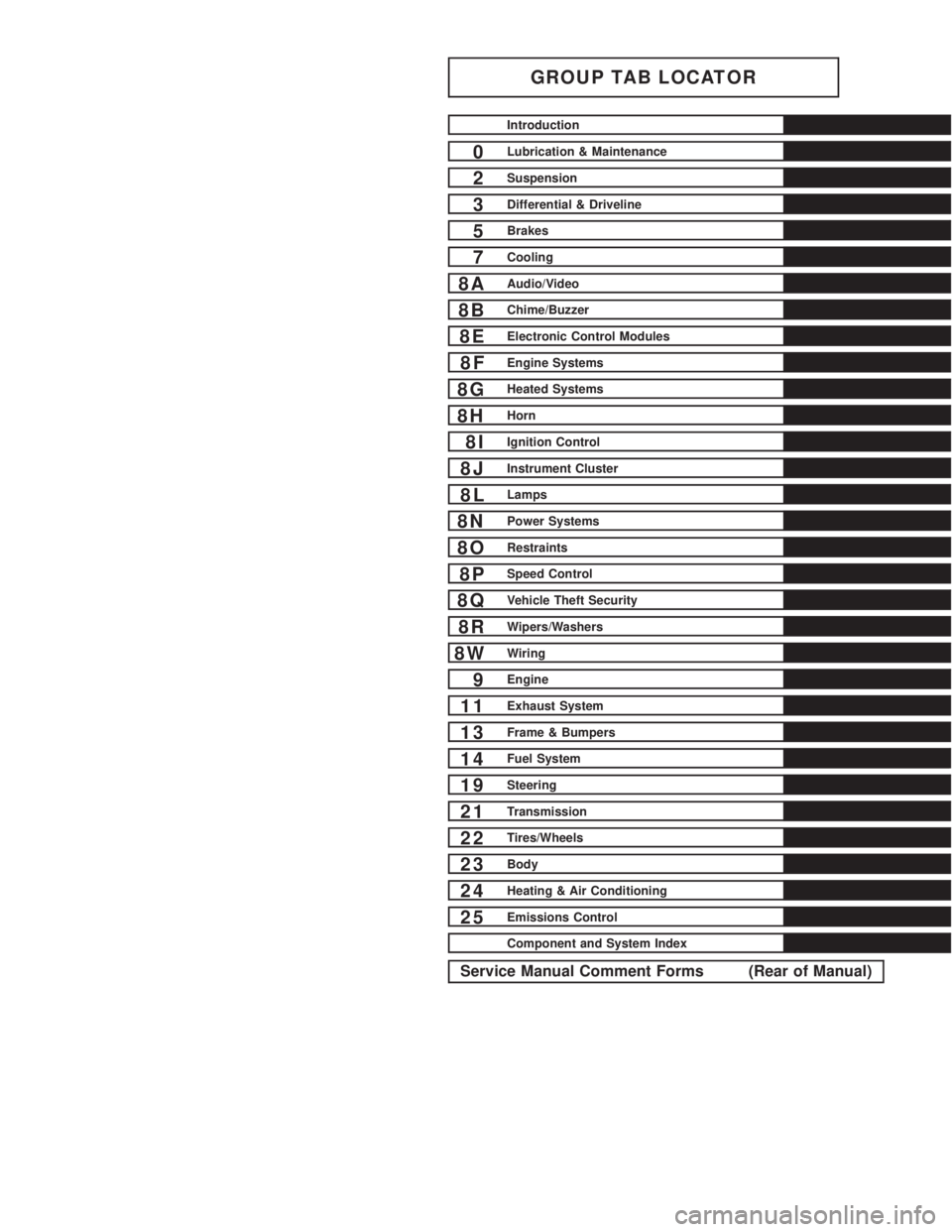

GROUP TAB LOCATOR

Introduction

0Lubrication & Maintenance

2Suspension

3Differential & Driveline

5Brakes

7Cooling

8AAudio/Video

8BChime/Buzzer

8EElectronic Control Modules

8FEngine Systems

8GHeated Systems

8HHorn

8IIgnition Control

8JInstrument Cluster

8LLamps

8NPower Systems

8ORestraints

8PSpeed Control

8QVehicle Theft Security

8RWipers/Washers

8WWiring

9Engine

11Exhaust System

13Frame & Bumpers

14Fuel System

19Steering

21Transmission

22Tires/Wheels

23Body

24Heating & Air Conditioning

25Emissions Control

Component and System Index

Service Manual Comment Forms (Rear of Manual)

Page 716 of 2305

LUBRICATION & MAINTENANCE

TABLE OF CONTENTS

page page

FLUID TYPES

DESCRIPTION

PARTS AND LUBRICANT

RECOMMENDATIONS...................1

AUTOMATIC TRANSMISSION FLUID - NAG1 . 1

AXLE FLUID..........................2

BRAKE FLUID.........................2

HOAT COOLANT.......................2

ENGINE OIL - DIESEL ENGINES...........3

FUEL REQUIREMENTS - DIESEL ENGINE . . . 4

POWER STEERING FLUID...............5

OPERATION - AUTOMATIC TRANSMISSION

FLUID...............................5

FLUID CAPACITIES

SPECIFICATIONS - FLUID CAPACITIES.......5FLUID FILL/CHECK LOCATIONS

INSPECTION - FLUID FILL/CHECK

LOCATIONS..........................5

HOISTING

STANDARD PROCEDURE - HOISTING........5

JUMP STARTING

STANDARD PROCEDURE - JUMP STARTING . . 6

TOWING

STANDARD PROCEDURE - TOWING.........7

MAINTENANCE SCHEDULES

DESCRIPTION..........................8

INTERNATIONAL SYMBOLS

DESCRIPTION..........................9

FLUID TYPES

DESCRIPTION

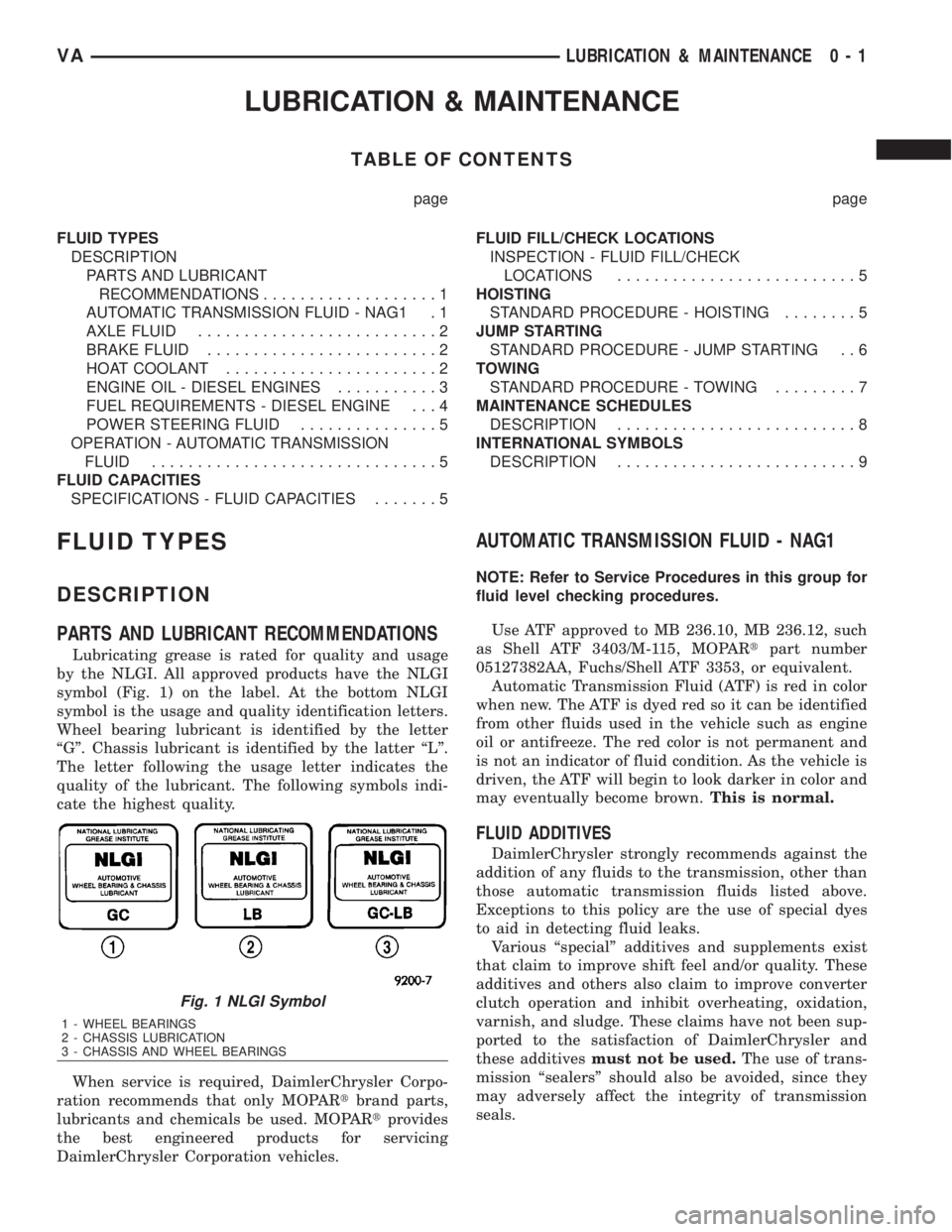

PARTS AND LUBRICANT RECOMMENDATIONS

Lubricating grease is rated for quality and usage

by the NLGI. All approved products have the NLGI

symbol (Fig. 1) on the label. At the bottom NLGI

symbol is the usage and quality identification letters.

Wheel bearing lubricant is identified by the letter

ªGº. Chassis lubricant is identified by the latter ªLº.

The letter following the usage letter indicates the

quality of the lubricant. The following symbols indi-

cate the highest quality.

When service is required, DaimlerChrysler Corpo-

ration recommends that only MOPARtbrand parts,

lubricants and chemicals be used. MOPARtprovides

the best engineered products for servicing

DaimlerChrysler Corporation vehicles.

AUTOMATIC TRANSMISSION FLUID - NAG1

NOTE: Refer to Service Procedures in this group for

fluid level checking procedures.

Use ATF approved to MB 236.10, MB 236.12, such

as Shell ATF 3403/M-115, MOPARtpart number

05127382AA, Fuchs/Shell ATF 3353, or equivalent.

Automatic Transmission Fluid (ATF) is red in color

when new. The ATF is dyed red so it can be identified

from other fluids used in the vehicle such as engine

oil or antifreeze. The red color is not permanent and

is not an indicator of fluid condition. As the vehicle is

driven, the ATF will begin to look darker in color and

may eventually become brown.This is normal.

FLUID ADDITIVES

DaimlerChrysler strongly recommends against the

addition of any fluids to the transmission, other than

those automatic transmission fluids listed above.

Exceptions to this policy are the use of special dyes

to aid in detecting fluid leaks.

Various ªspecialº additives and supplements exist

that claim to improve shift feel and/or quality. These

additives and others also claim to improve converter

clutch operation and inhibit overheating, oxidation,

varnish, and sludge. These claims have not been sup-

ported to the satisfaction of DaimlerChrysler and

these additivesmust not be used.The use of trans-

mission ªsealersº should also be avoided, since they

may adversely affect the integrity of transmission

seals.

Fig. 1 NLGI Symbol

1 - WHEEL BEARINGS

2 - CHASSIS LUBRICATION

3 - CHASSIS AND WHEEL BEARINGS

VALUBRICATION & MAINTENANCE 0 - 1