clock MERCEDES-BENZ SPRINTER 2006 Owner's Guide

[x] Cancel search | Manufacturer: MERCEDES-BENZ, Model Year: 2006, Model line: SPRINTER, Model: MERCEDES-BENZ SPRINTER 2006Pages: 2305, PDF Size: 48.12 MB

Page 931 of 2305

equipped, the ambient temperature indication can be

toggled with the clock indication on the right side of

the multi-function indicator Liquid Crystal Display

(LCD) located near the lower edge of the instrument

cluster, directly below the speedometer. The ambient

temperature indication consists of a numeric value

with a ª+º (plus) or ª2º (minus) prefix, and the unit

of measure is identified with the characters ªÉCº

(Canadian vehicles only) or ªÉFº (United States vehi-

cles only) located directly above the temperature

indication. The indications of the ambient tempera-

ture indicator are not visible when the LCD is not

illuminated. When illuminated the indications

appear as dark characters and icons silhouetted

against an amber field. When the exterior lighting is

turned Off, the display is illuminated at maximum

brightness. When the exterior lighting is turned On

the display illumination level can be adjusted in con-

cert with the cluster general illumination lighting

using the ª+º (plus) and ª2º (minus) multi-function

indicator push buttons. The ambient temperature

indicator is serviced as a unit with the instrument

cluster.

OPERATION

The optional ambient temperature indicator gives

an indication to the vehicle operator of the outside

air temperature. This indicator is controlled by the

instrument cluster microprocessor based upon cluster

programming and a hard wired input received by the

cluster from the ambient temperature sensor. The

ambient temperature indicator is completely con-

trolled by the instrument cluster logic circuit, and

that logic will allow this indicator to operate when-

ever the multi-function indicator Liquid Crystal Dis-

play (LCD) is activated. Therefore, the ambient

temperature indicator remains functional regardless

of the ignition switch position.

The vehicle operator can choose to have the ambi-

ent temperature indicator displayed instead of the

clock information, but the clock and ambient temper-

ature indicator cannot be displayed at the same time.

The clock or ambient temperature indicator display

option is selected using the multi-function indicator

clock switch on the instrument cluster circuit board.

This switch is actuated manually by depressing the

clock switch push button that extends through the

lower edge of the cluster lens below the left end of

the multi-function indicator. Actuating this switch

momentarily will toggle the display between the

clock and ambient temperature indicator modes.

Actuating this switch twice within about one second

will cause the display to toggle, but then automati-

cally revert to the originally selected mode after

about twenty seconds.

The ambient temperature sensor located below the

front bumper is a Negative Temperature Coefficient

(NTC) thermistor. The internal resistance of the sen-sor is reduced as the ambient temperature rises. The

instrument cluster continually monitors the resis-

tance through the sensor to determine the tempera-

ture value to be displayed. The current value is

displayed immediately after the LCD is activated.

The display value will remain static regardless of

decreases in the sensor resistance (temperature ris-

ing) below vehicle speeds of 10 to 15 kilometers-per-

hour (6 to 9 miles-per-hour). Decreases in the sensor

resistance above 15 kilometers-per-hour (9 miles-per-

hour) and increases the sensor resistance (tempera-

ture falling) regardless of vehicle speed are displayed

subject to a sixty second delay.

The ambient temperature sensor is connected to

the instrument cluster in series between the ambient

temperature sensor return and sense circuits. The

ambient temperature sensor and the return and

sense circuits to the instrument cluster can be diag-

nosed using conventional diagnostic tools and meth-

ods. For proper diagnosis of the instrument cluster

circuitry that controls the ambient temperature indi-

cator, a diagnostic scan tool is required. Refer to the

appropriate diagnostic information.BRAKE INDICATOR

DESCRIPTION

A brake indicator is standard equipment on all

instrument clusters. The brake indicator is located

near the lower edge of the instrument cluster, to the

left of the multi-function indicator display. In vehi-

cles built for the United States market, the brake

indicator consists of a stencil-like cutout of the word

ªBRAKEº in the opaque layer of the instrument clus-

ter overlay. In vehicles built for the Canadian mar-

ket, the brake indicator consists of the International

Control and Display Symbol icon for ªBrake Failureº

imprinted within a rectangular cutout in the opaque

layer of the instrument cluster overlay. In either

case, the dark outer layer of the overlay prevents the

indicator from being clearly visible when it is not

illuminated. A red Light Emitting Diode (LED)

behind the cutout in the opaque layer of the overlay

causes the ªBRAKEº text to appear in red, or the

icon to appear silhouetted against a red field through

the translucent outer layer of the overlay when the

indicator is illuminated from behind by the LED,

which is soldered onto the instrument cluster elec-

tronic circuit board. The brake indicator is serviced

as a unit with the instrument cluster.

OPERATION

The brake indicator gives an indication to the vehi-

cle operator when there are certain brake hydraulic

system malfunctions as indicated by a low brake

hydraulic fluid level condition, or when there is a

problem in the electronic brake force distribution

8J - 12 INSTRUMENT CLUSTERVA

Page 933 of 2305

or until the ignition switch is turned to the Off posi-

tion, whichever occurs first.

A brake wear sensor located at each wheel provides

a hard wired ground input to the instrument cluster

circuitry through the brake wear sense circuit when-

ever the brake linings for that wheel have exceeded

their wear limits. The four normally open brake wear

sensors are connected in parallel between ground and

instrument cluster. The brake wear sensors and their

input circuit to the instrument cluster can be diag-

nosed using conventional diagnostic tools and meth-

ods. For proper diagnosis of the instrument cluster

circuitry that controls the brake wear indicator, a

diagnostic scan tool is required. Refer to the appro-

priate diagnostic information.

CHARGING INDICATOR

DESCRIPTION

A charging indicator is standard equipment on all

instrument clusters. The charging indicator is located

near the lower edge of the instrument cluster, to the

left of the multi-function indicator display. The

charging indicator consists of the International Con-

trol and Display Symbol icon for ªBattery Charging

Conditionº imprinted within a rectangular cutout in

the opaque layer of the instrument cluster overlay.

The dark outer layer of the overlay prevents the indi-

cator from being clearly visible when it is not illumi-

nated. A red Light Emitting Diode (LED) behind the

cutout in the opaque layer of the overlay causes the

icon to appear silhouetted against a red field through

the translucent outer layer of the overlay when the

indicator is illuminated from behind by the LED,

which is soldered onto the instrument cluster elec-

tronic circuit board. The charging indicator is ser-

viced as a unit with the instrument cluster.

OPERATION

The charging indicator gives an indication to the

vehicle operator when the electrical system voltage is

too low. This indicator is controlled by a transistor on

the instrument cluster circuit board based upon clus-

ter programming and a hard wired input from the

generator. The charging indicator Light Emitting

Diode (LED) is completely controlled by the instru-

ment cluster logic circuit, and that logic will only

allow this indicator to operate when the instrument

cluster detects that the ignition switch is in the On

position. Therefore, the LED will always be off when

the ignition switch is in any position except On. The

LED only illuminates when it is provided a path to

ground by the instrument cluster transistor. The

instrument cluster will turn on the charging indica-

tor for the following reasons:

²Bulb Test- Each time the ignition switch is

turned to the On position with the engine not run-ning the charging indicator is illuminated by the

instrument cluster as a bulb test.

²Generator Input- Each time the cluster

detects that the voltage of the generator input is 12.7

volts or lower while the engine is running, the charg-

ing indicator will be illuminated. The indicator

remains illuminated until the cluster detects that the

voltage of the generator input is above 12.7 volts, or

until the ignition switch is turned to the Off position,

whichever occurs first.

The generator provides a hard wired input to the

instrument cluster circuitry on the engine running

(D+) circuit. If the instrument cluster turns on the

indicator while the engine is running, it may indicate

that the charging system requires service. The gener-

ator input circuit to the instrument cluster can be

diagnosed using conventional diagnostic tools and

methods. For proper diagnosis of the charging sys-

tem, or the instrument cluster circuitry that controls

the charging indicator, a diagnostic scan tool is

required. Refer to the appropriate diagnostic infor-

mation.

CLOCK

DESCRIPTION

An electronic digital clock is standard equipment

on all instrument clusters. In vehicles equipped with

the optional ambient temperature indicator, the clock

indication can be toggled with the ambient tempera-

ture indication on the right side of the multi-function

indicator Liquid Crystal Display (LCD) located near

the lower edge of the instrument cluster, directly

below the speedometer. The clock provides a 12 hour-

based, digital indication of the current hours and

minutes. The indications of the clock are not visible

when the LCD is not illuminated. When illuminated

the indications appear as dark characters silhouetted

against an amber field. When the exterior lighting is

turned Off, the display is illuminated at maximum

brightness. When the exterior lighting is turned On

the display illumination level can be adjusted in con-

cert with the cluster general illumination lighting

using the ª+º (plus) and ª2º (minus) multi-function

indicator push buttons. The clock is serviced as a

unit with the instrument cluster.

OPERATION

The clock gives an indication to the vehicle opera-

tor of the current time. The electronic digital clock is

controlled by the instrument cluster microprocessor

based upon cluster programming. The clock display is

completely controlled by the instrument cluster logic

circuit, and that logic will only allow this indication

to be viewed when the multi-function indicator Liq-

uid Crystal Display (LCD) is activated. However, the

8J - 14 INSTRUMENT CLUSTERVA

Page 934 of 2305

clock remains functional regardless of the ignition

switch position.

The vehicle operator can choose to have the

optional ambient temperature indicator displayed

instead of the clock information, but the clock and

ambient temperature indicator cannot be displayed

at the same time. The clock or ambient temperature

indicator display option is selected using the multi-

function indicator clock switch on the instrument

cluster circuit board. This switch is actuated manu-

ally by depressing the clock switch push button that

extends through the lower edge of the cluster lens

below the left end of the multi-function indicator.

Actuating this switch momentarily will toggle the

display between the clock and ambient temperature

indicator modes. Actuating this switch twice within

about one second will cause the display to toggle, but

then automatically revert to the originally selected

mode after about twenty seconds.

See the owner's manual in the vehicle glove box for

more information on the features, use, operation and

setting procedures for the clock. For proper testing of

the instrument cluster circuitry that controls the

clock functions, a diagnostic scan tool is required.

Refer to the appropriate diagnostic information.

COOLANT LOW INDICATOR

DESCRIPTION

A coolant low indicator is standard equipment on

all instrument clusters. The coolant low indicator is

located near the lower edge of the instrument cluster,

to the left of the multi-function indicator display. The

coolant low indicator consists of the International

Control and Display Symbol icon for ªLow Engine

Coolantº imprinted within a rectangular cutout in

the opaque layer of the instrument cluster overlay.

The dark outer layer of the overlay prevents the indi-

cator from being clearly visible when it is not illumi-

nated. A red Light Emitting Diode (LED) behind the

cutout in the opaque layer of the overlay causes the

icon to appear silhouetted against a red field through

the translucent outer layer of the overlay when the

indicator is illuminated from behind by the LED,

which is soldered onto the instrument cluster elec-

tronic circuit board. The coolant low indicator is ser-

viced as a unit with the instrument cluster.

OPERATION

The coolant low indicator gives an indication to the

vehicle operator when the engine coolant level is low.

This indicator is controlled by a transistor on the

instrument cluster circuit board based upon cluster

programming and a hard wired input received by the

cluster from the engine coolant level switch. The cool-

ant low indicator Light Emitting Diode (LED) is com-

pletely controlled by the instrument cluster logiccircuit, and that logic will only allow this indicator to

operate when the instrument cluster detects that the

ignition switch is in the On position. Therefore, the

LED will always be off when the ignition switch is in

any position except On. The LED only illuminates

when it is provided a path to ground by the instru-

ment cluster transistor. The instrument cluster will

turn on the coolant low indicator for the following

reasons:

²Bulb Test- Each time the ignition switch is

turned to the On position the coolant low indicator is

illuminated for about two seconds as a bulb test.

²Engine Coolant Level Switch Input- Each

time the cluster detects an appropriate input on the

low coolant fluid level sense circuit (engine coolant

level switch resistance low = engine coolant level low)

while the ignition switch is in the On position, the

coolant low indicator will be illuminated. The indica-

tor remains illuminated until the low coolant fluid

level sense input to the cluster changes (engine cool-

ant level switch resistance high = engine coolant

level full), or until the ignition switch is turned to

the Off position, whichever occurs first. The engine

coolant level switch also features a diagnostic resis-

tor connected in parallel between the switch input

and output to provide the cluster with verification

that the low coolant fluid level sense circuit is not

open or shorted.

The engine coolant level switch integral to the cool-

ant bottle provides a hard wired input to the instru-

ment cluster circuitry through the low coolant fluid

level sense circuit. The engine coolant level switch

and the low coolant fluid level sense circuit to the

instrument cluster can be diagnosed using conven-

tional diagnostic tools and methods. For proper diag-

nosis of the instrument cluster circuitry that controls

the coolant low indicator, a diagnostic scan tool is

required. Refer to the appropriate diagnostic infor-

mation.

ENGINE TEMPERATURE

GAUGE

DESCRIPTION

An engine coolant temperature gauge is standard

equipment on all instrument clusters. The engine

coolant temperature gauge is located in the upper

right corner of the instrument cluster, to the right of

the speedometer. The engine coolant temperature

gauge consists of a movable gauge needle or pointer

controlled by the instrument cluster circuitry and a

fixed 45 degree scale on the cluster overlay that

reads left-to-right from 120É C to 40É C for Canadian

vehicles, or from 250É F to 110É F for United States

vehicles. An International Control and Display Sym-

bol icon for ªEngine Coolant Temperatureº is located

VAINSTRUMENT CLUSTER 8J - 15

Page 939 of 2305

through the fuel level sense circuit. The fuel level

sensor is a potentiometer that changes resistance

according to the fuel level. As the fuel level

decreases, the resistance through the fuel level sen-

sor increases. The instrument cluster applies a fuel

tank characteristic curve and fuel tank reserve valve

setting to the fuel level sensor input, which must be

configured when the cluster is initialized. These

characteristics determine the algorithm the cluster

uses to display the fuel level data on the fuel gauge

and the control for the low fuel warning indicator.

The fuel level sensor and the fuel level sense circuit

to the instrument cluster can be diagnosed using con-

ventional diagnostic tools and methods. For proper

diagnosis of the instrument cluster circuitry that con-

trols the fuel gauge, a diagnostic scan tool is

required. Refer to the appropriate diagnostic infor-

mation.

LOW OIL LEVEL INDICATOR

DESCRIPTION

A low oil level indicator is standard equipment on

all instrument clusters. The low oil level indicator is

located near the lower edge of the instrument cluster,

to the left of the multi-function indicator display. The

low oil level indicator consists of the International

Control and Display Symbol icon for ªEngine Oilº

imprinted within a rectangular cutout in the opaque

layer of the instrument cluster overlay. The dark

outer layer of the overlay prevents the indicator from

being clearly visible when it is not illuminated. A red

Light Emitting Diode (LED) behind the cutout in the

opaque layer of the overlay causes the icon to appear

silhouetted against a red field through the translu-

cent outer layer of the overlay when the indicator is

illuminated from behind by the LED, which is sol-

dered onto the instrument cluster electronic circuit

board. The low oil level indicator is serviced as a unit

with the instrument cluster.

OPERATION

The low oil level indicator gives an indication to

the vehicle operator when the engine oil level is low.

This indicator is controlled by a transistor on the

instrument cluster electronic circuit board based

upon cluster programming and electronic messages

received by the cluster from the Engine Control Mod-

ule (ECM) over the Controller Area Network (CAN)

data bus. The low oil level indicator Light Emitting

Diode (LED) is completely controlled by the instru-

ment cluster logic circuit, and that logic will only

allow this indicator to operate when the instrument

cluster detects that the ignition switch is in the On

position. Therefore, the LED will always be off when

the ignition switch is in any position except On. The

LED only illuminates when it is provided a path toground by the instrument cluster transistor. The

instrument cluster will turn on the low oil level indi-

cator for the following reasons:

²Bulb Test- Each time the ignition switch is

turned to the On position the low oil level indicator

is illuminated for about two seconds as a bulb test.

²Engine Oil Level Low Message- Once the

engine has been started, each time the cluster

receives a message from the ECM indicating that the

engine oil level is at or near the ªMinimumº mark on

the dipstick, the low oil level indicator is illuminated.

The indicator remains illuminated briefly at first, but

will remain illuminated for longer periods as subse-

quent messages indicate that the oil level has

dropped further. Eventually, the indicator will

remain illuminated solid until the engine oil level is

corrected, or until the ignition switch is turned to the

Off position, whichever occurs first.

The instrument cluster also supplements the oil

level indicator by displaying an engine oil icon along

with alpha-numeric messages in the multi-function

indicator Liquid Crystal Display (LCD) advising the

vehicle operator how much oil is required to correct

the engine oil level, and when the ªMaximumº engine

oil level has been exceeded. See the owner's manual

in the vehicle glove box for more information on this

feature.

The ECM continually monitors the engine oil level

and temperature sensor to determine the engine oil

level. The ECM then sends the proper engine oil

level messages to the instrument cluster. If the

instrument cluster turns on the indicator after the

bulb test, even after the engine oil level is sufficient,

it may indicate that the engine or the engine oiling

system requires service. For proper diagnosis of the

engine oil level and temperature sensor, the ECM,

the CAN data bus, or the electronic message inputs

to the instrument cluster that control the low oil

level indicator, a diagnostic scan tool is required.

Refer to the appropriate diagnostic information.

MAINTENANCE INDICATOR

DESCRIPTION

An Active Service SYSTem (ASSYST) engine oil

maintenance indicator is optional equipment on all

instrument clusters. In vehicles so equipped, a sec-

ond, dedicated ASSYST microprocessor is integral to

the cluster electronic circuit board. The ASSYST indi-

cations are displayed and can be toggled with the

clock indication on the right side of the multi-func-

tion indicator Liquid Crystal Display (LCD) located

near the lower edge of the instrument cluster,

directly below the speedometer. The ASSYST displays

include numeric values combined with several icons

to indicate actual engine oil level, and reminders in

time (days) or distance (miles or kilometers) until the

8J - 20 INSTRUMENT CLUSTERVA

Page 940 of 2305

next required engine oil maintenance is anticipated.

ASSYST also provides several audible indications

using the electronic tone generator on the instrument

cluster circuit board to supplement these visual dis-

plays.

The indications of the ASSYST engine oil mainte-

nance indicator are not visible when the LCD is not

illuminated. When illuminated, the ASSYST indica-

tions appear as dark characters and icons silhouetted

against an amber field. When the exterior lighting is

turned Off, the display is illuminated at maximum

brightness. When the exterior lighting is turned On,

the display illumination level can be adjusted in con-

cert with the cluster general illumination lighting

using the ª+º (plus) and ª2º (minus) multi-function

indicator push buttons. The ASSYST engine oil main-

tenance indicator is serviced as a unit with the

instrument cluster.

OPERATION

The ASSYST engine oil maintenance indicator

microprocessor uses numerous criteria besides time

and mileage to evaluate vehicle maintenance require-

ments. Time data is taken from the electronic digital

clock integral to the instrument cluster. Vehicle dis-

tance data is obtained from the Controller Antilock

Brake (CAB) over the Controller Area Network

(CAN) data bus. Coolant temperature, engine oil

temperature, engine oil level, engine oil quality,

engine speed, and engine load data are obtained from

the Engine Control Module (ECM) over the CAN

data bus. Using all of the available data and internal

programming, the ASSYST microprocessor then cal-

culates the estimated time and distance to the next

required engine oil maintenance interval. The

ASSYST uses the multi-function indicator LCD to

display that data and, when necessary, issues audible

alerts to the vehicle operator through the electronic

tone generator on the cluster circuit board.

See the owner's manual in the vehicle glove box for

more information on the features, use, operation and

resetting procedures for the ASSYST maintenance

computer. Proper diagnosis and testing of the

ASSYST engine oil maintenance computer, the CAN

data bus and the electronic data bus message inputs

to the EMIC that are used by the ASSYST computer

for its calculations requires the use of a diagnostic

scan tool. Refer to the appropriate diagnostic infor-

mation.

MALFUNCTION INDICATOR

LAMP (MIL)

DESCRIPTION

A Malfunction Indicator Lamp (MIL) is standard

equipment on all instrument clusters. The MIL islocated near the lower edge of the instrument cluster,

to the right of the multi-function indicator display.

The MIL consists of the International Control and

Display Symbol icon for ªEngineº imprinted within a

rectangular cutout in the opaque layer of the instru-

ment cluster overlay. The dark outer layer of the

overlay prevents the indicator from being clearly vis-

ible when it is not illuminated. An amber Light

Emitting Diode (LED) behind the cutout in the

opaque layer of the overlay causes the icon to appear

silhouetted against an amber field through the trans-

lucent outer layer of the overlay when the indicator

is illuminated from behind by the LED, which is sol-

dered onto the instrument cluster electronic circuit

board. The MIL is serviced as a unit with the instru-

ment cluster.

OPERATION

The Malfunction Indicator Lamp (MIL) gives an

indication to the vehicle operator when the Engine

Control Module (ECM) has recorded a Diagnostic

Trouble Code (DTC) for an On-Board Diagnostics II

(OBDII) emissions-related circuit or component mal-

function. The MIL is controlled by a transistor on the

instrument cluster circuit board based upon cluster

programming and electronic messages received by

the cluster from the ECM over the Controller Area

Network (CAN) data bus. The MIL Light Emitting

Diode (LED) is completely controlled by the instru-

ment cluster logic circuit, and that logic will only

allow this indicator to operate when the instrument

cluster detects that the ignition switch is in the On

position. Therefore, the LED will always be off when

the ignition switch is in any position except On. The

LED only illuminates when it is provided a path to

ground by the instrument cluster transistor. The

instrument cluster will turn on the MIL for the fol-

lowing reasons:

²Bulb Test- Each time the ignition switch is

turned to the On position the MIL is illuminated as a

bulb test. The indicator will remain illuminated until

the engine is started, or until the ignition switch is

turned to the Off position, whichever occurs first.

²MIL Lamp-On Message- Each time the clus-

ter receives a MIL lamp-on message from the ECM,

the indicator will be illuminated. The indicator will

remain illuminated until the detected fault is

repaired, or until the ignition switch is turned to the

Off position, whichever occurs first. For more infor-

mation on the ECM and the DTC set and reset

parameters, (Refer to 25 - EMISSIONS CONTROL -

OPERATION).

²Communication Error- If the cluster receives

no lamp-on or lamp-off message from the ECM, the

MIL is illuminated by the instrument cluster. The

indicator remains controlled and illuminated by the

cluster until a valid lamp-on or lamp-off message is

received from the ECM.

VAINSTRUMENT CLUSTER 8J - 21

Page 941 of 2305

The ECM continually monitors the fuel and emis-

sions system circuits and sensors to decide whether

the system is in good operating condition. The ECM

then sends the proper lamp-on or lamp-off messages

to the instrument cluster. If the instrument cluster

turns on the MIL after the bulb test, it may indicate

that a malfunction has occurred and that the fuel

and emissions systems may require service. For

proper diagnosis of the fuel and emissions systems,

the ECM, the CAN data bus, or the electronic mes-

sage inputs to the instrument cluster that control the

MIL, a diagnostic scan tool is required. Refer to the

appropriate diagnostic information.

MULTI - FUNCTION INDICA-

TOR

DESCRIPTION

A multi-function indicator is standard equipment

on all instrument clusters. The multi-function indica-

tor is located near the lower edge of the instrument

cluster, directly below the speedometer. The multi-

function indicator consists of a Liquid Crystal Dis-

play (LCD) unit and four push button-controlled

switches that are soldered onto the instrument clus-

ter electronic circuit board. The LCD is visible

through a large rectangular cutout in the instrument

cluster overlay, while the four switch push buttons

extend through a black plastic switch bezel located

on the cluster lens directly below the LCD. The four

multi-function indicator push buttons allow the vehi-

cle operator to configure and adjust several of the

display features. The buttons are labeled from left to

right: ªmiº (miles) or ªkmº (kilometers), an icon

depicting an analog clock face (clock), ª2º (minus),

and ª+º (plus).

The multi-function indicator LCD displays both

alpha-numeric characters and numerous icons to pro-

vide information to the vehicle operator. The indica-

tions of the multi-function indicator are not visible

when the LCD is not illuminated. When illuminated

the indications appear as dark characters and icons

silhouetted against an amber field. When the exterior

lighting is turned Off, the display is illuminated at

maximum brightness. When the exterior lighting is

turned On the display illumination level can be

adjusted in concert with the cluster general illumina-

tion lighting using the ª+º (plus) and ª2º (minus)

multi-function indicator push buttons. The multi-

function indicator LCD unit and push button

switches are serviced as a unit with the instrument

cluster.

OPERATION

The multi-function indicator has several display

capabilities including odometer, trip odometer, clock,engine oil level data, gear selector indicator

(PRNDL), certain diagnostic information and, on

vehicles so equipped, an optional Active Service SYS-

Tem (ASSYST) engine oil maintenance indicator and

an optional outside ambient temperature indicator.

The multi-function indicator is completely controlled

by the instrument cluster logic circuit, and that logic

will allow this indication to be viewed whenever the

multi-function indicator Liquid Crystal Display

(LCD) is activated. Therefore, the indicator remains

functional regardless of the ignition switch position.

With the ignition switch in the Off or Accessory posi-

tions and the key removed from the ignition lock cyl-

inder, the display is activated when the park lamps

are turned On or, for about thirty seconds after any

one of the multi-function indicator switch push but-

tons is depressed. Otherwise, the display unit is

active for about thirty seconds after the key is

inserted into the ignition lock cylinder, and inactive

about thirty seconds after the key is removed from

the ignition lock cylinder.

The multi-function indicator ªmiº (miles) or

ªkmº(kilometers) switch push button is used to con-

trol the odometer/trip odometer display modes. The

multi-function indicator clock switch push button is

used to control the clock/outside temperature display

modes. The multi-function indicator ª+º (plus) and

ª2º (minus) switch push buttons are used to adjust

the cluster general illumination dimming level, the

clock, and other cluster settings. See the owner's

manual in the vehicle glove box for more information

on the features, use, operation and setting proce-

dures for the various standard and optional multi-

function indicator displays.

Proper testing of the multi-function indicator LCD

unit, the CAN data bus and the electronic data bus

message inputs to the instrument cluster that control

some of the multi-function indicator functions

requires the use of a diagnostic scan tool. Refer to

the appropriate diagnostic information. Additional

details for the odometer/trip odometer, the clock, the

gear selector indicator, the ambient temperature indi-

cator and the ASSYST warning and reminder func-

tions of the multi-function indicator may be found

elsewhere in this service information.

ODOMETER

DESCRIPTION

An odometer and trip odometer are standard

equipment in all instrument clusters. The odometer

and trip odometer values are displayed on the left

side of the multi-function indicator Liquid Crystal

Display (LCD). The LCD is soldered onto the cluster

electronic circuit board and is visible through a win-

dow with a clear lens located near the lower edge of

8J - 22 INSTRUMENT CLUSTERVA

Page 955 of 2305

(5) Remove the backup lamp bulb from the tail

lamp socket plate.

INSTALLATION

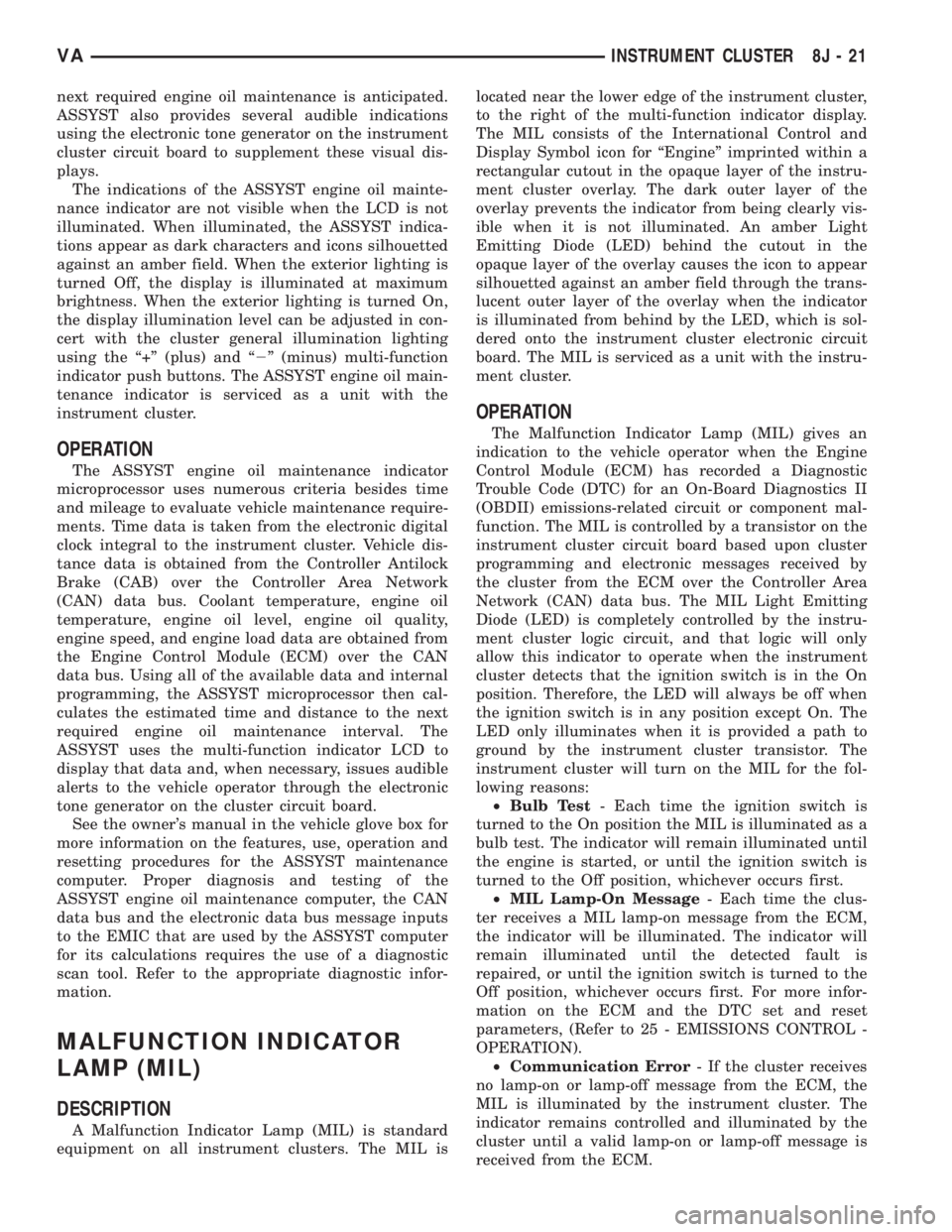

(1) Install the backup lamp bulb into the tail lamp

socket plate (Fig. 3).

(2) Align the socket plate with the mounting hole

in the inner rear pillar.

(3) Using hand pressure, push the socket plate

gently and evenly into the inner rear pillar mounting

hole until both latch tabs are fully engaged (Fig. 2).

(4) If the vehicle is so equipped, reinstall the trim

onto the inside of the right or left rear corner pillar.

(5) Reconnect the battery negative cable.

BRAKE LAMP SWITCH

REMOVAL

WARNING: To avoid personal injury or death, on

vehicles equipped with airbags, disable the supple-

mental restraint system before attempting any

steering wheel, steering column, airbag, seat belt

tensioner, or instrument panel component diagno-

sis or service. Disconnect and isolate the battery

negative (ground) cable, then wait two minutes for

the system capacitor to discharge before perform-

ing further diagnosis or service. This is the only

sure way to disable the supplemental restraint sys-

tem. Failure to take the proper precautions could

result in accidental airbag deployment.

(1) Disconnect and isolate the battery negative

cable.

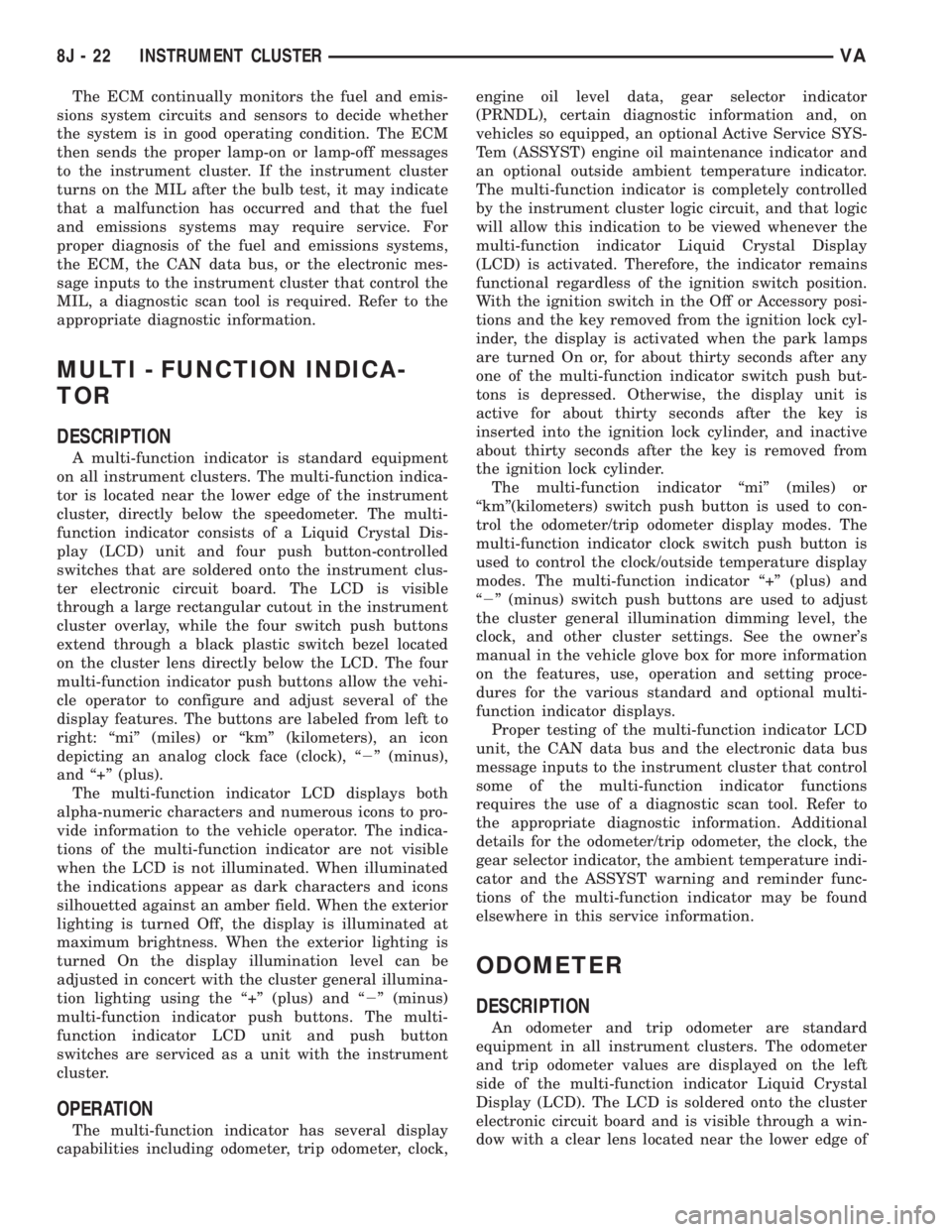

(2) Locate the brake lamp switch on the pedal

bracket underneath the instrument panel (Fig. 4).(3) Depress the locking tab on the brake lamp

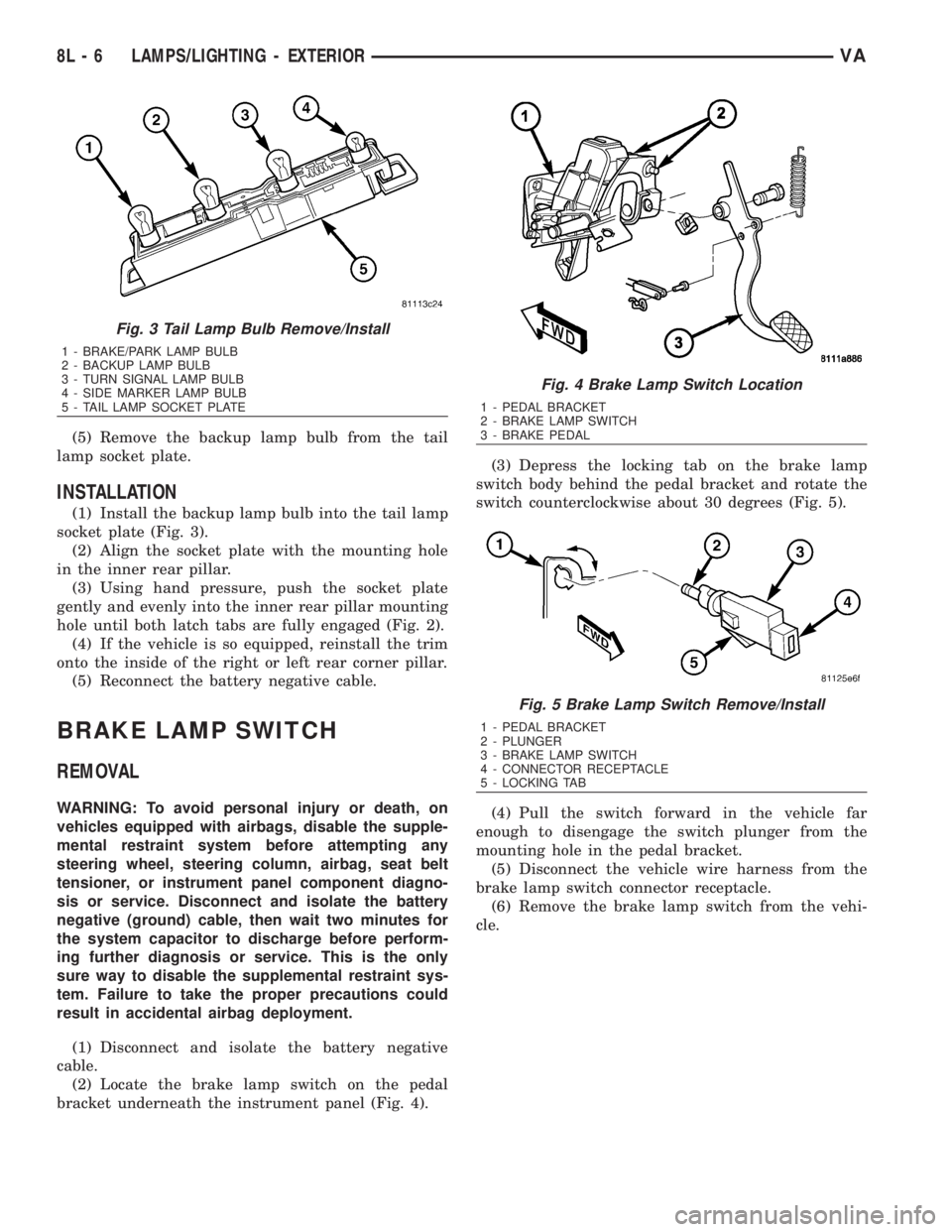

switch body behind the pedal bracket and rotate the

switch counterclockwise about 30 degrees (Fig. 5).

(4) Pull the switch forward in the vehicle far

enough to disengage the switch plunger from the

mounting hole in the pedal bracket.

(5) Disconnect the vehicle wire harness from the

brake lamp switch connector receptacle.

(6) Remove the brake lamp switch from the vehi-

cle.

Fig. 3 Tail Lamp Bulb Remove/Install

1 - BRAKE/PARK LAMP BULB

2 - BACKUP LAMP BULB

3 - TURN SIGNAL LAMP BULB

4 - SIDE MARKER LAMP BULB

5 - TAIL LAMP SOCKET PLATE

Fig. 4 Brake Lamp Switch Location

1 - PEDAL BRACKET

2 - BRAKE LAMP SWITCH

3 - BRAKE PEDAL

Fig. 5 Brake Lamp Switch Remove/Install

1 - PEDAL BRACKET

2 - PLUNGER

3 - BRAKE LAMP SWITCH

4 - CONNECTOR RECEPTACLE

5 - LOCKING TAB

8L - 6 LAMPS/LIGHTING - EXTERIORVA

Page 956 of 2305

INSTALLATION

WARNING: To avoid personal injury or death, on

vehicles equipped with airbags, disable the supple-

mental restraint system before attempting any

steering wheel, steering column, airbag, seat belt

tensioner, or instrument panel component diagno-

sis or service. Disconnect and isolate the battery

negative (ground) cable, then wait two minutes for

the system capacitor to discharge before perform-

ing further diagnosis or service. This is the only

sure way to disable the supplemental restraint sys-

tem. Failure to take the proper precautions could

result in accidental airbag deployment.

(1) Pull the plunger of the brake lamp switch out-

ward from the switch body to its travel limit (Fig. 5).

(2) Reconnect the vehicle wire harness to the

brake lamp switch connector receptacle.

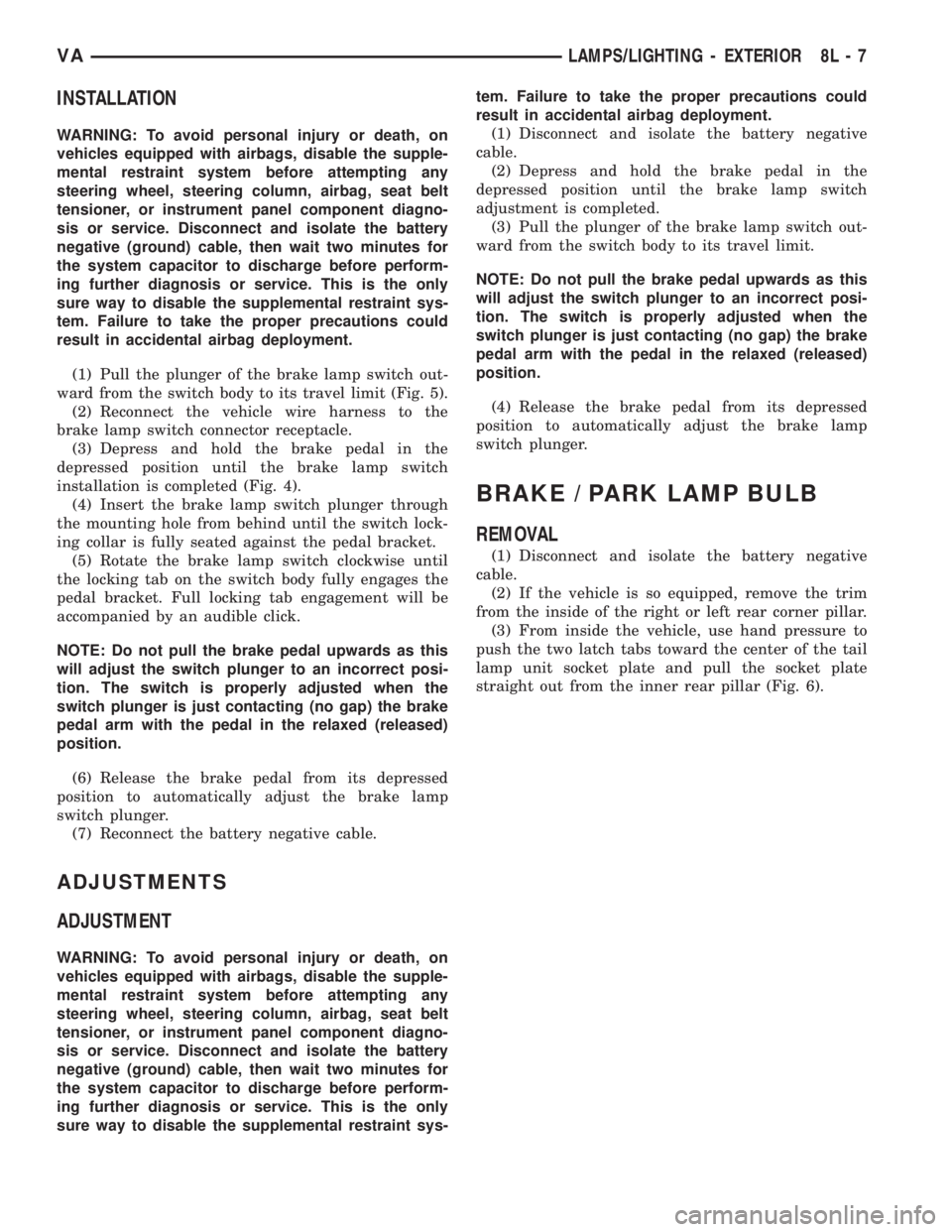

(3) Depress and hold the brake pedal in the

depressed position until the brake lamp switch

installation is completed (Fig. 4).

(4) Insert the brake lamp switch plunger through

the mounting hole from behind until the switch lock-

ing collar is fully seated against the pedal bracket.

(5) Rotate the brake lamp switch clockwise until

the locking tab on the switch body fully engages the

pedal bracket. Full locking tab engagement will be

accompanied by an audible click.

NOTE: Do not pull the brake pedal upwards as this

will adjust the switch plunger to an incorrect posi-

tion. The switch is properly adjusted when the

switch plunger is just contacting (no gap) the brake

pedal arm with the pedal in the relaxed (released)

position.

(6) Release the brake pedal from its depressed

position to automatically adjust the brake lamp

switch plunger.

(7) Reconnect the battery negative cable.

ADJUSTMENTS

ADJUSTMENT

WARNING: To avoid personal injury or death, on

vehicles equipped with airbags, disable the supple-

mental restraint system before attempting any

steering wheel, steering column, airbag, seat belt

tensioner, or instrument panel component diagno-

sis or service. Disconnect and isolate the battery

negative (ground) cable, then wait two minutes for

the system capacitor to discharge before perform-

ing further diagnosis or service. This is the only

sure way to disable the supplemental restraint sys-tem. Failure to take the proper precautions could

result in accidental airbag deployment.

(1) Disconnect and isolate the battery negative

cable.

(2) Depress and hold the brake pedal in the

depressed position until the brake lamp switch

adjustment is completed.

(3) Pull the plunger of the brake lamp switch out-

ward from the switch body to its travel limit.

NOTE: Do not pull the brake pedal upwards as this

will adjust the switch plunger to an incorrect posi-

tion. The switch is properly adjusted when the

switch plunger is just contacting (no gap) the brake

pedal arm with the pedal in the relaxed (released)

position.

(4) Release the brake pedal from its depressed

position to automatically adjust the brake lamp

switch plunger.

BRAKE / PARK LAMP BULB

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) If the vehicle is so equipped, remove the trim

from the inside of the right or left rear corner pillar.

(3) From inside the vehicle, use hand pressure to

push the two latch tabs toward the center of the tail

lamp unit socket plate and pull the socket plate

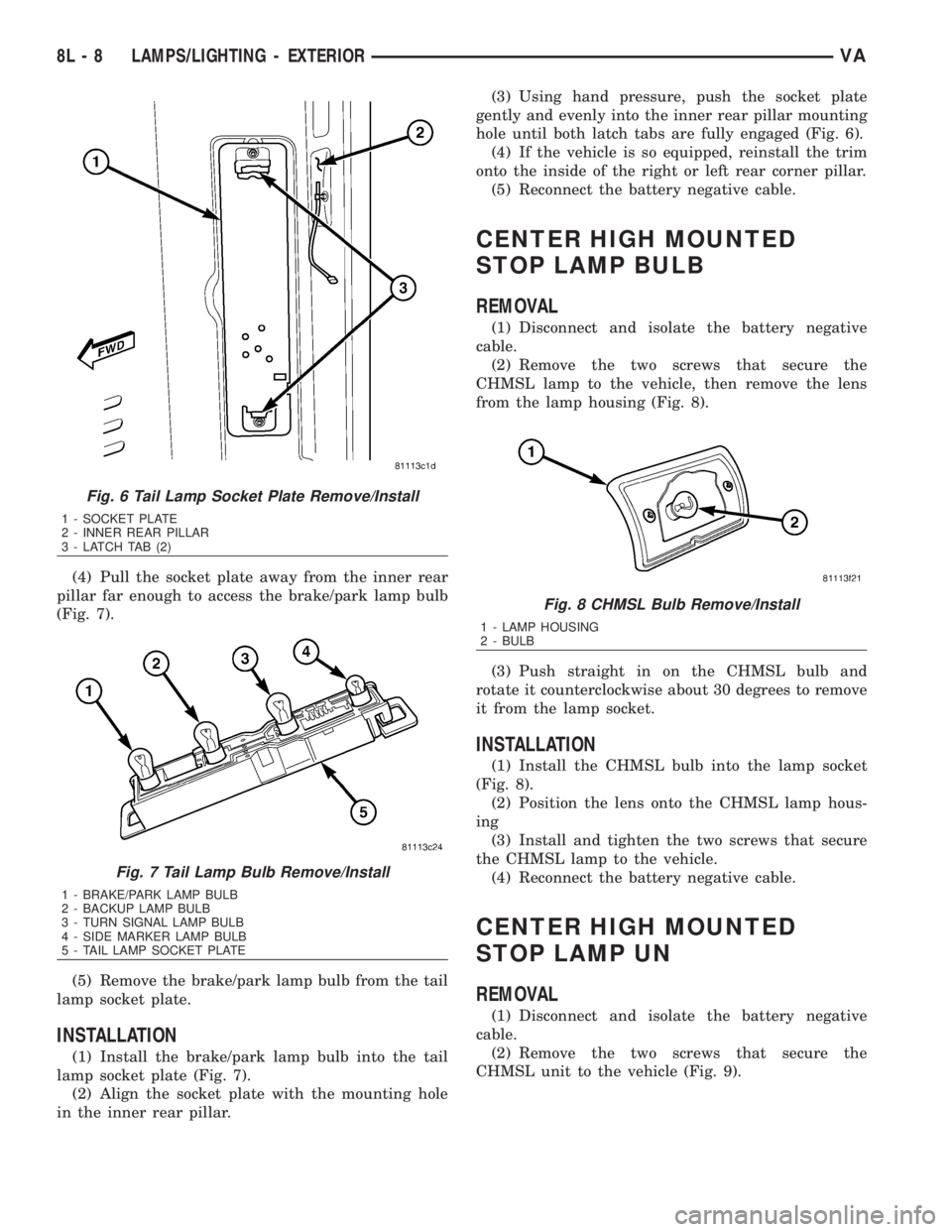

straight out from the inner rear pillar (Fig. 6).

VALAMPS/LIGHTING - EXTERIOR 8L - 7

Page 957 of 2305

(4) Pull the socket plate away from the inner rear

pillar far enough to access the brake/park lamp bulb

(Fig. 7).

(5) Remove the brake/park lamp bulb from the tail

lamp socket plate.

INSTALLATION

(1) Install the brake/park lamp bulb into the tail

lamp socket plate (Fig. 7).

(2) Align the socket plate with the mounting hole

in the inner rear pillar.(3) Using hand pressure, push the socket plate

gently and evenly into the inner rear pillar mounting

hole until both latch tabs are fully engaged (Fig. 6).

(4) If the vehicle is so equipped, reinstall the trim

onto the inside of the right or left rear corner pillar.

(5) Reconnect the battery negative cable.

CENTER HIGH MOUNTED

STOP LAMP BULB

REMOVAL

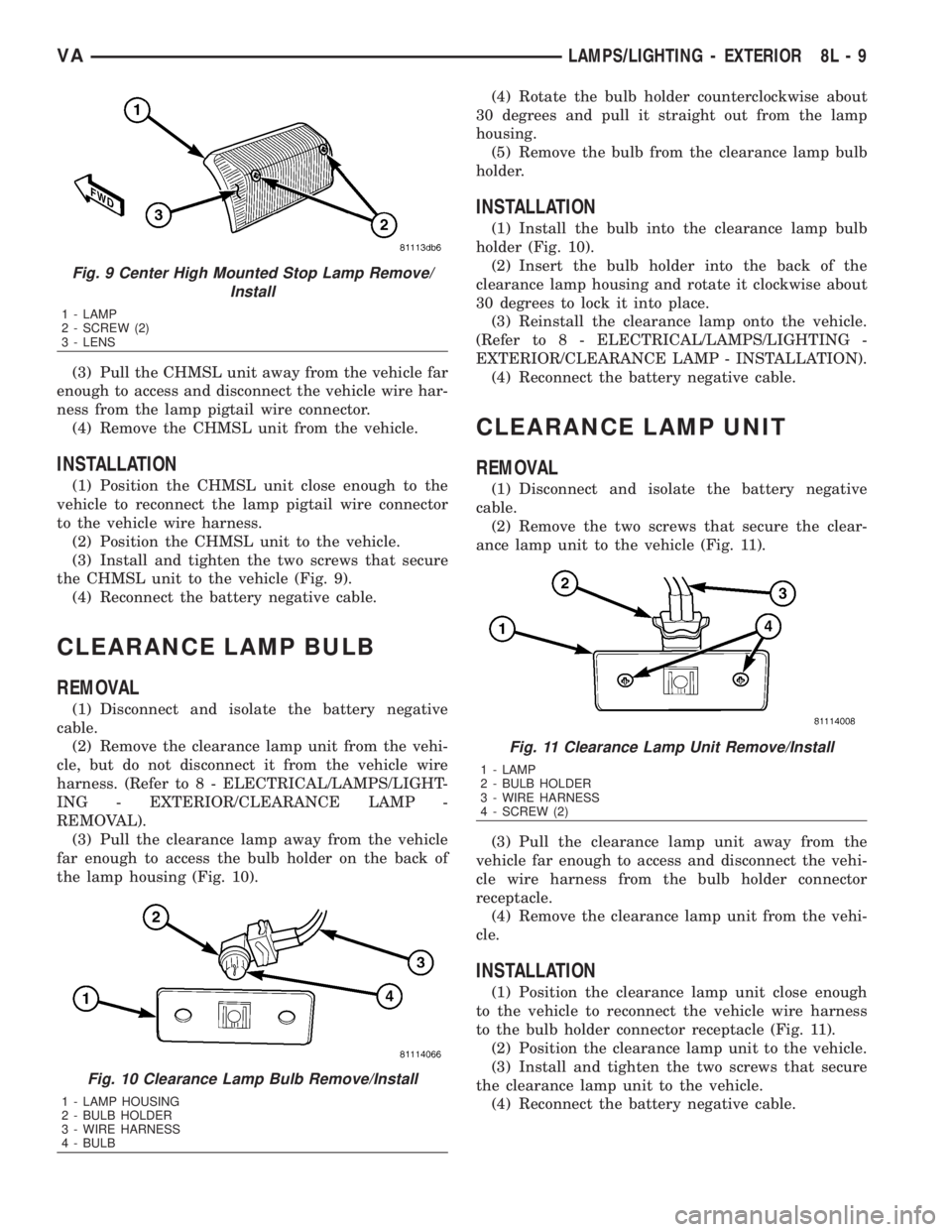

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the two screws that secure the

CHMSL lamp to the vehicle, then remove the lens

from the lamp housing (Fig. 8).

(3) Push straight in on the CHMSL bulb and

rotate it counterclockwise about 30 degrees to remove

it from the lamp socket.

INSTALLATION

(1) Install the CHMSL bulb into the lamp socket

(Fig. 8).

(2) Position the lens onto the CHMSL lamp hous-

ing

(3) Install and tighten the two screws that secure

the CHMSL lamp to the vehicle.

(4) Reconnect the battery negative cable.

CENTER HIGH MOUNTED

STOP LAMP UN

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the two screws that secure the

CHMSL unit to the vehicle (Fig. 9).

Fig. 6 Tail Lamp Socket Plate Remove/Install

1 - SOCKET PLATE

2 - INNER REAR PILLAR

3 - LATCH TAB (2)

Fig. 7 Tail Lamp Bulb Remove/Install

1 - BRAKE/PARK LAMP BULB

2 - BACKUP LAMP BULB

3 - TURN SIGNAL LAMP BULB

4 - SIDE MARKER LAMP BULB

5 - TAIL LAMP SOCKET PLATE

Fig. 8 CHMSL Bulb Remove/Install

1 - LAMP HOUSING

2 - BULB

8L - 8 LAMPS/LIGHTING - EXTERIORVA

Page 958 of 2305

(3) Pull the CHMSL unit away from the vehicle far

enough to access and disconnect the vehicle wire har-

ness from the lamp pigtail wire connector.

(4) Remove the CHMSL unit from the vehicle.

INSTALLATION

(1) Position the CHMSL unit close enough to the

vehicle to reconnect the lamp pigtail wire connector

to the vehicle wire harness.

(2) Position the CHMSL unit to the vehicle.

(3) Install and tighten the two screws that secure

the CHMSL unit to the vehicle (Fig. 9).

(4) Reconnect the battery negative cable.

CLEARANCE LAMP BULB

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the clearance lamp unit from the vehi-

cle, but do not disconnect it from the vehicle wire

harness. (Refer to 8 - ELECTRICAL/LAMPS/LIGHT-

ING - EXTERIOR/CLEARANCE LAMP -

REMOVAL).

(3) Pull the clearance lamp away from the vehicle

far enough to access the bulb holder on the back of

the lamp housing (Fig. 10).(4) Rotate the bulb holder counterclockwise about

30 degrees and pull it straight out from the lamp

housing.

(5) Remove the bulb from the clearance lamp bulb

holder.

INSTALLATION

(1) Install the bulb into the clearance lamp bulb

holder (Fig. 10).

(2) Insert the bulb holder into the back of the

clearance lamp housing and rotate it clockwise about

30 degrees to lock it into place.

(3) Reinstall the clearance lamp onto the vehicle.

(Refer to 8 - ELECTRICAL/LAMPS/LIGHTING -

EXTERIOR/CLEARANCE LAMP - INSTALLATION).

(4) Reconnect the battery negative cable.

CLEARANCE LAMP UNIT

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the two screws that secure the clear-

ance lamp unit to the vehicle (Fig. 11).

(3) Pull the clearance lamp unit away from the

vehicle far enough to access and disconnect the vehi-

cle wire harness from the bulb holder connector

receptacle.

(4) Remove the clearance lamp unit from the vehi-

cle.

INSTALLATION

(1) Position the clearance lamp unit close enough

to the vehicle to reconnect the vehicle wire harness

to the bulb holder connector receptacle (Fig. 11).

(2) Position the clearance lamp unit to the vehicle.

(3) Install and tighten the two screws that secure

the clearance lamp unit to the vehicle.

(4) Reconnect the battery negative cable.

Fig. 9 Center High Mounted Stop Lamp Remove/

Install

1 - LAMP

2 - SCREW (2)

3 - LENS

Fig. 10 Clearance Lamp Bulb Remove/Install

1 - LAMP HOUSING

2 - BULB HOLDER

3 - WIRE HARNESS

4 - BULB

Fig. 11 Clearance Lamp Unit Remove/Install

1 - LAMP

2 - BULB HOLDER

3 - WIRE HARNESS

4 - SCREW (2)

VALAMPS/LIGHTING - EXTERIOR 8L - 9