run flat MERCEDES-BENZ SPRINTER 2006 Service Manual

[x] Cancel search | Manufacturer: MERCEDES-BENZ, Model Year: 2006, Model line: SPRINTER, Model: MERCEDES-BENZ SPRINTER 2006Pages: 2305, PDF Size: 48.12 MB

Page 722 of 2305

(6) Start the engine in the vehicle which has the

booster battery, let the engine idle a few minutes,

then start the engine in the vehicle with the dis-

charged battery.

CAUTION: Do not crank starter motor on disabled

vehicle for more than 15 seconds, starter will over-

heat and could fail.

(7) Allow battery in disabled vehicle to charge to

at least 12.4 volts (75% charge) before attempting to

start engine. If engine does not start within 15 sec-

onds, stop cranking engine and allow starter to cool

(15 min.), before cranking again.

DISCONNECT CABLE CLAMPS AS FOLLOWS:

²Disconnect BLACK cable clamp from engine

ground on disabled vehicle.

²When using a Booster vehicle, disconnect

BLACK cable clamp from battery negative terminal.

Disconnect RED cable clamp from battery positive

terminal.

²Disconnect RED cable clamp from battery posi-

tive terminal on disabled vehicle.

TOWING

STANDARD PROCEDURE - TOWING

WARNING: Do not tow the vehicle if the key cannot

be turned in the ignition lock. If the key cannot be

turned, the ignition lock remains locked and the

vehicle cannot be steered. With the engine not run-

ning there is no power assistance for the braking

and steering systems. In this case, it is important to

keep in mind that a considerably higher degree of

effort is necessary to brake and steer the vehicle.

The vehicle must not be towed with the front axle

raised and the key in position 2 in the ignition lock

as the drive wheels could then lock due to the

acceleration skid control (ASR)

If the Engine is Damaged

For towing distances up to 30 miles (about 50

km)

²Shift selector lever in ªNº position.

²Do not exceed a towing speed of 30 m.p.h. (50

km/h).

For towing distances greater than 30 mile

(about 50 km)

²Remove the propeller shafts leading to the drive

axles. The vehicle can be towed without restriction.

If the Transmission is Damaged

²Remove the propeller shafts leading to the drive

axles. The vehicle can be towed without restriction.

If the Front Axle is Damaged

²Raise the front axle.

²Observe the same towing restrictions as for

engine damage.

If the Rear Axle is Damaged

²Raise the rear axle.

NOTE: Comply with local legal regulations regard-

ing towing vehicles.

SAFETY PRECAUTIONS

NOTE: The following safety precautions must be

observed when towing a vehicle.

²Secure loose and protruding parts.

²Always use a safety chain system that is inde-

pendent of the lifting and towing equipment.

²Do not allow towing equipment to contact the

disabled vehicle's fuel tank.

²Do not allow anyone under the disabled vehicle

while it is lifted by the towing device.

²Do not allow passengers to ride in a vehicle

being towed.

²Always observe state and local laws regarding

towing regulations.

²Do not tow a vehicle in a manner that could

jeopardize the safety of the operator, pedestrians or

other motorists.

²Do not attach tow chains, T-hooks, J-hooks, or a

tow sling to a bumper, steering linkage, drive shafts

or a non-reinforced frame hole.

²Remove exhaust pipe tips that interfere with the

tow sling and crossbar

²Padding should be placed between the tow sling/

crossbar and any painted surfaces

²When placing tow hooks on the rear axle, posi-

tion them so they do not damage the brake tubing or

hoses

²Do not tow the vehicle by connecting to the front

or rear shock absorbers

²Do not tow a heavily loaded vehicle. Damage to

the vehicle may result. Use a flatbed device to trans-

port a loaded vehicle.

GROUND CLEARANCE

CAUTION: If vehicle is towed with wheels removed,

install lug nuts to retain brake drums.

A towed vehicle should be raised until lifted wheels

are a minimum 100 mm (4 in) from the ground. Be

sure there is adequate ground clearance at the oppo-

site end of the vehicle, especially when towing over

rough terrain, steep rises in the road or if the vehicle

is equipped with air dams, spoilers, and/or ground

VALUBRICATION & MAINTENANCE 0 - 7

Page 749 of 2305

RUNOUT SPECIFICATIONS

Front of Shaft 0.020 in. (0.50 mm)

Center of Shaft 0.025 in. (0.63 mm)

Rear of Shaft 0.020 in. (0.50 mm)

note:

Measure front/rear runout approximately 76 mm (3

in.) from the weld seam at each end of the shaft

tube for tube lengths over 30 inches. For tube

lengths under 30 inches, the maximum allowed

runout is 0.50 mm (0.020 in.) for the full length of

the tube.

STANDARD PROCEDURE

PROPELLER SHAFT ANGLE

This procedure applies the front and rear propeller

shafts.

(1) Place vehicle in netural.

(2) Raise and support vehicle at the axles as level

as possible.

(3) Remove universal joint snap rings if equipped,

so Inclinometer 7663 base sits flat.

(4) Rotate shaft until transmission case output

yoke bearing is facing downward.

NOTE: Always make measurements from front to

rear and from the same side of the vehicle.

(5) Place Inclinometer 7663 on yoke bearing (A)

parallel to the shaft. Center bubble in sight glass and

record measurement.

This measurement will give you the transmis-

sion yoke Output Angle (A).

(6) Rotate propeller shaft 90 degrees and place

inclinometer on yoke bearing parallel to the shaft.

Center bubble in sight glass and record measure-

ment. This measurement can also be taken at the

rear end of the shaft.

This measurement will give you the Propeller

Shaft Angle (C).

(7) Rotate propeller shaft 90 degrees and place

inclinometer on companion flange yoke bearing par-

allel to the shaft. Center bubble in sight glass and

record measurement.

This measurement will give you the Pinion

Flange Input Angle (B).

(8) Subtract smaller figure from larger (C minus

A) to obtain TransmissionOutput Operating

Angle.

(9) Subtract smaller figure from larger (C minus

B) to obtain axleInput Operating Angle.

Refer to rules and example in (Fig. 4) for addi-

tional information.

RULES

²Good cancellation of U-joint operating angles

should be within 1degree.

²Operating angles should be less than 3 degrees.

²At least 1/2 of one degree continuous operating

(propeller shaft) angle.

3 - 4 PROPELLER SHAFTVA

Page 791 of 2305

POWER BRAKE BOOSTER

DESCRIPTION.........................19

OPERATION...........................19

REMOVAL.............................20

INSTALLATION.........................20

ROTORS

REMOVAL

REMOVAL - FRONT (SRW)..............20

REMOVAL - REAR (SRW)...............20

REMOVAL - FRONT (DRW)..............21

REMOVAL - REAR (DRW)...............21

INSTALLATION

INSTALLATION - FRONT (SRW)..........22

INSTALLATION - REAR (SRW)...........22

INSTALLATION - FRONT (DRW)..........22

INSTALLATION - REAR (DRW)...........22

SUPPORT PLATE

REMOVAL - REAR......................23

INSTALLATION - REAR...................23

PARKING BRAKE

SPECIFICATIONS

TORQUE CHART......................23

SPECIAL TOOLS

PARK BRAKE........................24

CABLE TENSIONER

REMOVAL.............................24INSTALLATION.........................24

CABLES

REMOVAL

REMOVAL - FRONT....................24

REMOVAL - REAR.....................25

INSTALLATION

INSTALLATION - FRONT................25

INSTALLATION - REAR.................26

ADJUSTMENTS

ADJUSTMENT - PARKING BRAKE CABLES . 26

LEVER

REMOVAL.............................26

INSTALLATION.........................27

SHOES

REMOVAL

REMOVAL - (SRW)....................27

REMOVAL - (DRW)....................27

CLEANING - REAR DRUM IN HAT BRAKE....28

INSTALLATION

INSTALLATION - (SRW).................28

INSTALLATION - (DRW).................28

ADJUSTMENTS

ADJUSTMENT........................28

BRAKES - BASE

DIAGNOSIS AND TESTING - BASE BRAKE SYS-

TEM

Base brake components consist of the brake pads,

calipers, brake drum in hat rotor in the rear, rotors,

brake lines, master cylinder, booster, and parking

brake components.

Brake diagnosis involves determining if the prob-

lem is related to a mechanical, hydraulic, or vacuum

operated component.

The first diagnosis step is the preliminary check.

PRELIMINARY BRAKE CHECK

(1) Check condition of tires and wheels. Damaged

wheels and worn, damaged, or underinflated tires

can cause pull, shudder, vibration, and a condition

similar to grab.

(2) If complaint was based on noise when braking,

check suspension components. Jounce front and rear

of vehicle and listen for noise that might be caused

by loose, worn or damaged suspension or steering

components.

(3) Inspect brake fluid level and condition. Note

that the brake reservoir fluid level will decrease in

proportion to normal lining wear.Also note that

brake fluid tends to darken over time. This is

normal and should not be mistaken for contam-

ination.(a) If fluid level is abnormally low, look for evi-

dence of leaks at calipers, wheel cylinders, brake

lines, and master cylinder.

(b) If fluid appears contaminated, drain out a

sample to examine. System will have to be flushed

if fluid is separated into layers, or contains a sub-

stance other than brake fluid. The system seals

and cups will also have to be replaced after flush-

ing. Use clean brake fluid to flush the system.

(4) Check parking brake operation. Verify free

movement and full release of cables and pedal. Also

note if vehicle was being operated with parking

brake partially applied.

(5) Check brake pedal operation. Verify that pedal

does not bind and has adequate free play. If pedal

lacks free play, check pedal and power booster for

being loose or for bind condition. Do not road test

until condition is corrected.

(6) Check booster vacuum check valve and hose.

(7) If components checked appear OK, road test

the vehicle.

ROAD TESTING

(1) If complaint involved low brake pedal, pump

pedal and note if it comes back up to normal height.

(2) Check brake pedal response with transmission

in Neutral and engine running. Pedal should remain

firm under constant foot pressure.

5 - 2 BRAKES - BASEVA

Page 997 of 2305

STANDARD PROCEDURE

STANDARD PROCEDURE - HANDLING NON -

DEPLOYED SUPPLEMENTAL RESTRAINTS

At no time should any source of electricity be per-

mitted near the inflator on the back of a non-de-

ployed airbag or seat belt tensioner. When carrying a

non-deployed airbag, the trim cover or airbag cushion

side of the unit should be pointed away from the

body to minimize injury in the event of an accidental

deployment. If the airbag unit is placed on a bench or

any other surface, the trim cover or airbag cushion

side of the unit should be face up to minimize move-

ment in the event of an accidental deployment. When

handling a non-deployed seat belt tensioner, take

proper care to keep fingers out from under the

retractor cover and away from the seat belt webbing

where it exits from the retractor cover. In addition,

the supplemental restraint system should be dis-

armed whenever any steering wheel, steering col-

umn, seat belt tensioner, airbag, impact sensor, or

instrument panel components require diagnosis or

service. Failure to observe this warning could result

in accidental deployment and possible personal

injury.

All damaged, faulty or non-deployed airbags and

seat belt tensioners which are replaced on vehicles

are to be handled and disposed of properly. If an air-

bag or seat belt tensioner unit is faulty or damaged

and non-deployed, refer to the Hazardous Substance

Control System for proper disposal. Dispose of all

non-deployed and deployed airbags and seat belt ten-

sioners in a manner consistent with state, provincial,

local and federal regulations.

SUPPLEMENTAL RESTRAINT STORAGE

Airbags and seat belt tensioners must be stored in

their original, special container until they are used

for service. Also, they must be stored in a clean, dry

environment; away from sources of extreme heat,

sparks, and high electrical energy. Always place or

store any airbag on a surface with its trim cover or

airbag cushion side facing up, to minimize movement

in case of an accidental deployment.

STANDARD PROCEDURE - SERVICE AFTER A

SUPPLEMENTAL RESTRAINT DEPLOYMENT

Any vehicle which is to be returned to use follow-

ing a supplemental restraint deployment, must have

the deployed restraints replaced. In addition, if the

driver airbag has been deployed, the clockspring and

the steering wheel must be replaced. If the passenger

airbag has been deployed, the instrument panel must

be replaced. The seat belt tensioners are deployed by

the same signal that deploys the driver and passen-

ger airbags and must also be replaced if either front

airbag has been deployed. These components are notintended for reuse and will be damaged or weakened

as a result of a supplemental restraint deployment,

which may or may not be obvious during a visual

inspection.

It is also critical that the mounting surfaces and/or

mounting brackets for the Airbag Control Module

(ACM) and the side impact sensors be closely

inspected and restored to their original conditions fol-

lowing any vehicle impact damage. Because the ACM

and each impact sensor are used by the supplemental

restraint system to monitor or confirm the direction

and severity of a vehicle impact, improper orientation

or insecure fastening of these components may cause

airbags not to deploy when required, or to deploy

when not required.

All other vehicle components should be closely

inspected following any supplemental restraint

deployment, but are to be replaced only as required

by the extent of the visible damage incurred.

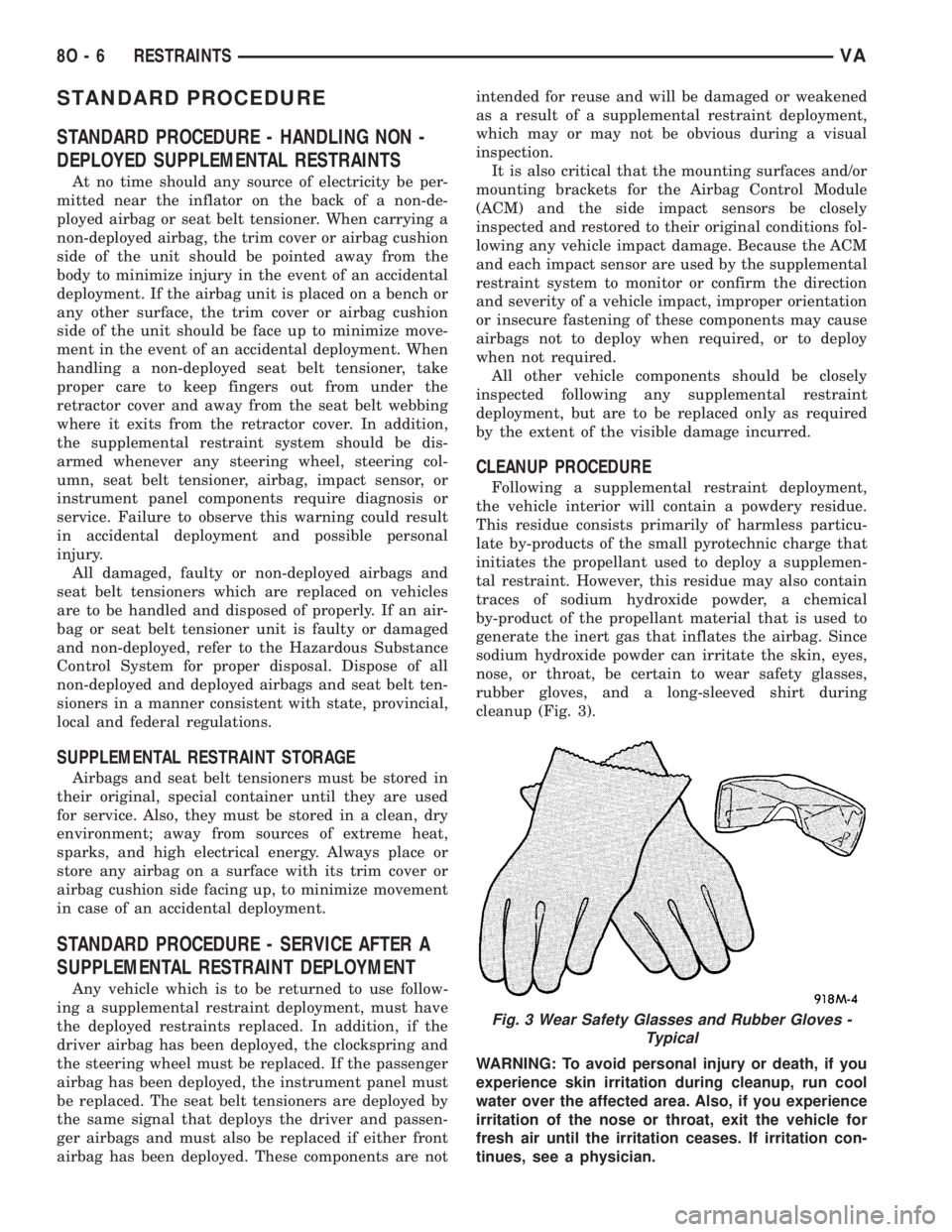

CLEANUP PROCEDURE

Following a supplemental restraint deployment,

the vehicle interior will contain a powdery residue.

This residue consists primarily of harmless particu-

late by-products of the small pyrotechnic charge that

initiates the propellant used to deploy a supplemen-

tal restraint. However, this residue may also contain

traces of sodium hydroxide powder, a chemical

by-product of the propellant material that is used to

generate the inert gas that inflates the airbag. Since

sodium hydroxide powder can irritate the skin, eyes,

nose, or throat, be certain to wear safety glasses,

rubber gloves, and a long-sleeved shirt during

cleanup (Fig. 3).

WARNING: To avoid personal injury or death, if you

experience skin irritation during cleanup, run cool

water over the affected area. Also, if you experience

irritation of the nose or throat, exit the vehicle for

fresh air until the irritation ceases. If irritation con-

tinues, see a physician.

Fig. 3 Wear Safety Glasses and Rubber Gloves -

Typical

8O - 6 RESTRAINTSVA

Page 1928 of 2305

TIRES / WHEELS

TABLE OF CONTENTS

page page

TIRES/WHEELS

DIAGNOSIS AND TESTING - TIRE AND

WHEEL RUNOUT......................1

STANDARD PROCEDURE

STANDARD PROCEDURE - MATCH

MOUNTING...........................2

STANDARD PROCEDURE - TIRE AND

WHEEL BALANCE......................4

STANDARD PROCEDURE - TIRE ROTATION . 6

SPECIFICATIONS

TORQUE CHART......................7

TIRES

DESCRIPTION

DESCRIPTION - TIRES..................7

DESCRIPTION - RADIAL ± PLY TIRES......7

DESCRIPTION - TIRE PRESSURE FOR

HIGH SPEEDS.........................8

DESCRIPTION - REPLACEMENT TIRES.....8

DESCRIPTION - TIRE INFLATION

PRESSURES..........................8

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - PRESSURE

GAUGES.............................9

DIAGNOSIS AND TESTING - TIRE NOISE

OR VIBRATION........................9

DIAGNOSIS AND TESTING - TREAD WEAR

INDICATORS..........................9DIAGNOSIS AND TESTING - TIRE WEAR

PATTERNS...........................9

DIAGNOSIS AND TESTING - TIRE/VEHICLE

LEAD...............................10

STANDARD PROCEDURE - REPAIRING

LEAKS..............................12

CLEANING............................12

SPECIFICATIONS

TIRES..............................12

SPARE TIRE CARRIER

REMOVAL.............................12

INSTALLATION.........................12

WHEELS

DESCRIPTION.........................13

OPERATION...........................13

DIAGNOSIS AND TESTING

WHEEL INSPECTION..................13

STANDARD PROCEDURE

STANDARD PROCEDURE - WHEEL

REPLACEMENT.......................13

STANDARD PROCEDURE - DUAL REAR

WHEEL INSTALLATION.................13

REMOVAL.............................14

INSTALLATION.........................15

TIRES / WHEELS

DIAGNOSIS AND TESTING - TIRE AND WHEEL

RUNOUT

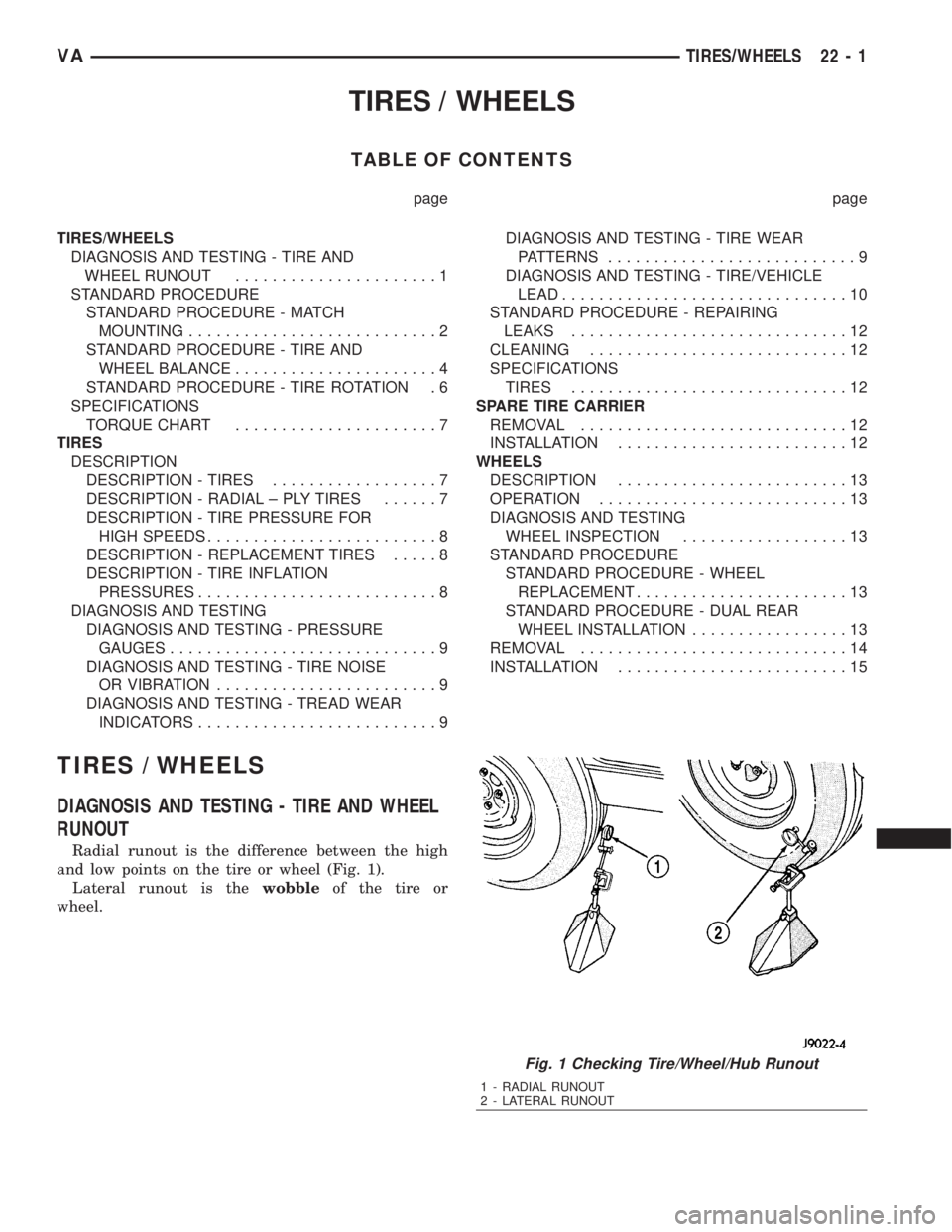

Radial runout is the difference between the high

and low points on the tire or wheel (Fig. 1).

Lateral runout is thewobbleof the tire or

wheel.

Fig. 1 Checking Tire/Wheel/Hub Runout

1 - RADIAL RUNOUT

2 - LATERAL RUNOUT

VATIRES/WHEELS 22 - 1

Page 1929 of 2305

Radial runout of more than 1.5 mm (.060 inch)

measured at the center line of the tread may cause

the vehicle to shake.

Lateral runout of more than 2.0 mm (.080 inch)

measured near the shoulder of the tire may cause the

vehicle to shake.

Sometimes radial runout can be reduced. Relocate

the wheel and tire assembly on the mounting studs

(See Method 1). If this does not reduce runout to an

acceptable level, the tire can be rotated on the wheel.

(See Method 2).

METHOD 1 (RELOCATE WHEEL ON HUB)

(1) Drive vehicle a short distance to eliminate tire

flat spotting from a parked position.

(2) Check wheel bearings and adjust if adjustable

or replace if necessary.

(3) Check the wheel mounting surface.

(4) Relocate wheel on the mounting, two studs

over from the original position.

(5) Tighten wheel nuts until all are properly

torqued, to eliminate brake distortion.

(6) Check radial runout. If still excessive, mark

tire sidewall, wheel, and stud at point of maximum

runout and proceed to Method 2.

METHOD 2 (RELOCATE TIRE ON WHEEL)

NOTE: Rotating the tire on wheel is particularly

effective when there is runout in both tire and

wheel.

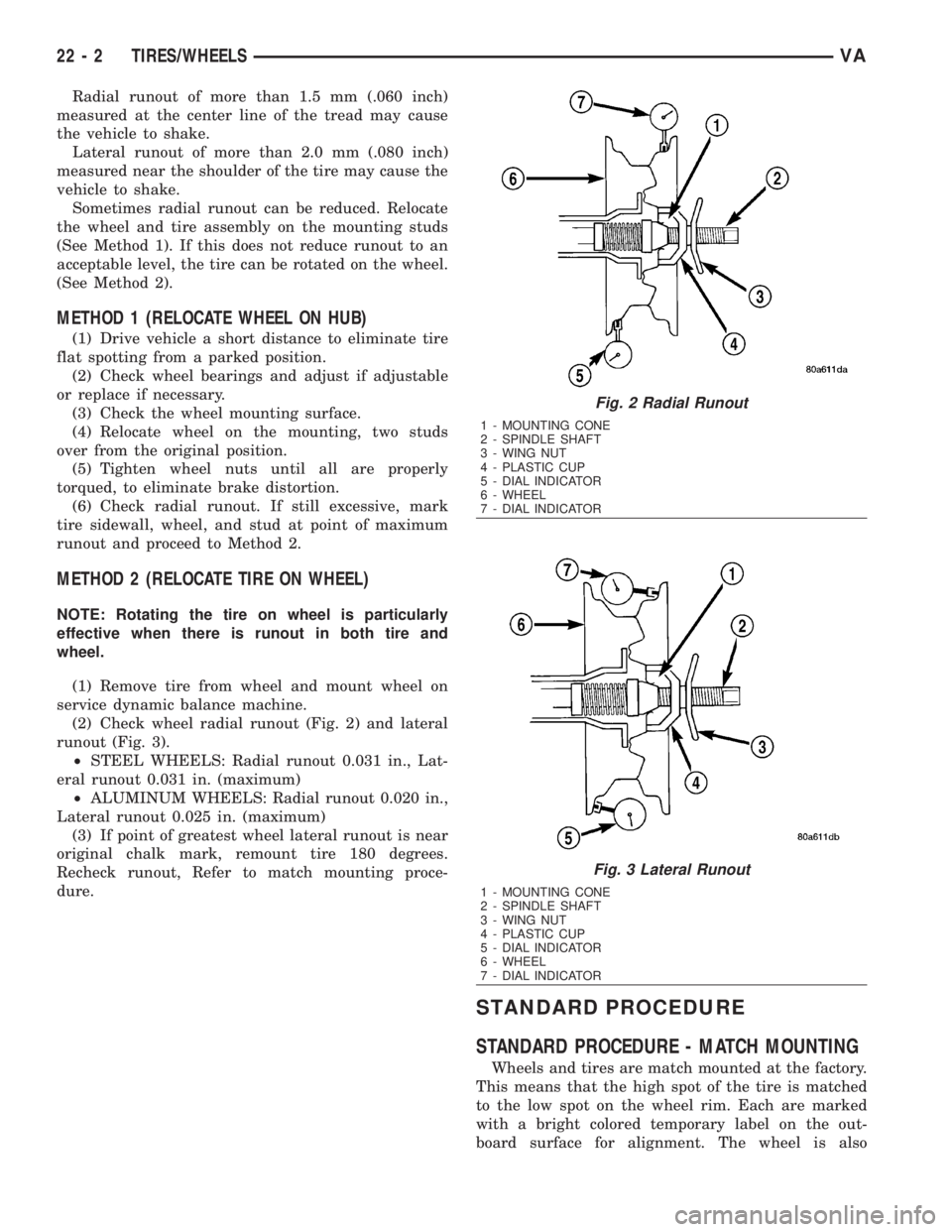

(1) Remove tire from wheel and mount wheel on

service dynamic balance machine.

(2) Check wheel radial runout (Fig. 2) and lateral

runout (Fig. 3).

²STEEL WHEELS: Radial runout 0.031 in., Lat-

eral runout 0.031 in. (maximum)

²ALUMINUM WHEELS: Radial runout 0.020 in.,

Lateral runout 0.025 in. (maximum)

(3) If point of greatest wheel lateral runout is near

original chalk mark, remount tire 180 degrees.

Recheck runout, Refer to match mounting proce-

dure.

STANDARD PROCEDURE

STANDARD PROCEDURE - MATCH MOUNTING

Wheels and tires are match mounted at the factory.

This means that the high spot of the tire is matched

to the low spot on the wheel rim. Each are marked

with a bright colored temporary label on the out-

board surface for alignment. The wheel is also

Fig. 2 Radial Runout

1 - MOUNTING CONE

2 - SPINDLE SHAFT

3 - WING NUT

4 - PLASTIC CUP

5 - DIAL INDICATOR

6 - WHEEL

7 - DIAL INDICATOR

Fig. 3 Lateral Runout

1 - MOUNTING CONE

2 - SPINDLE SHAFT

3 - WING NUT

4 - PLASTIC CUP

5 - DIAL INDICATOR

6 - WHEEL

7 - DIAL INDICATOR

22 - 2 TIRES/WHEELSVA

Page 1936 of 2305

²Vehicle drift

For proper tire pressure specification refer to the

Tire Inflation Pressure Chart provided with the vehi-

cles Owners Manual. A Certification Label on the

drivers side door pillar provides the minimum tire

and rim size for the vehicle. The label also list the

cold inflation pressure for these tires at full load

operation

Tire pressures have been chosen to provide safe

operation, vehicle stability, and a smooth ride. Tire

pressure should be checked cold once a month. Tire

pressure decreases as the ambient temperature

drops. Check tire pressure frequently when ambient

temperature varies widely.

Tire inflation pressures are cold inflation pressure.

The vehicle must sit for at least 3 hours to obtain the

correct cold inflation pressure reading. Or be driven

less than one mile after sitting for 3 hours. Tire

inflation pressures may increase from 2 to 6 pounds

per square inch (psi) during operation. Do not reduce

this normal pressure build-up.

WARNING: OVER OR UNDER INFLATED TIRES CAN

AFFECT VEHICLE HANDLING AND TREAD WEAR.

THIS MAY CAUSE THE TIRE TO FAIL SUDDENLY,

RESULTING IN LOSS OF VEHICLE CONTROL.

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - PRESSURE

GAUGES

A quality air pressure gauge is recommended to

check tire pressure. After checking the air pressure,

replace valve cap finger tight.

DIAGNOSIS AND TESTING - TIRE NOISE OR

VIBRATION

Radial-ply tires are sensitive to force impulses

caused by improper mounting, vibration, wheel

defects, or possibly tire imbalance.

To find out if tires are causing the noise or vibra-

tion, drive the vehicle over a smooth road at varying

speeds. Note the noise level during acceleration and

deceleration. The engine, differential and exhaust

noises will change as speed varies, while the tire

noise will usually remain constant.

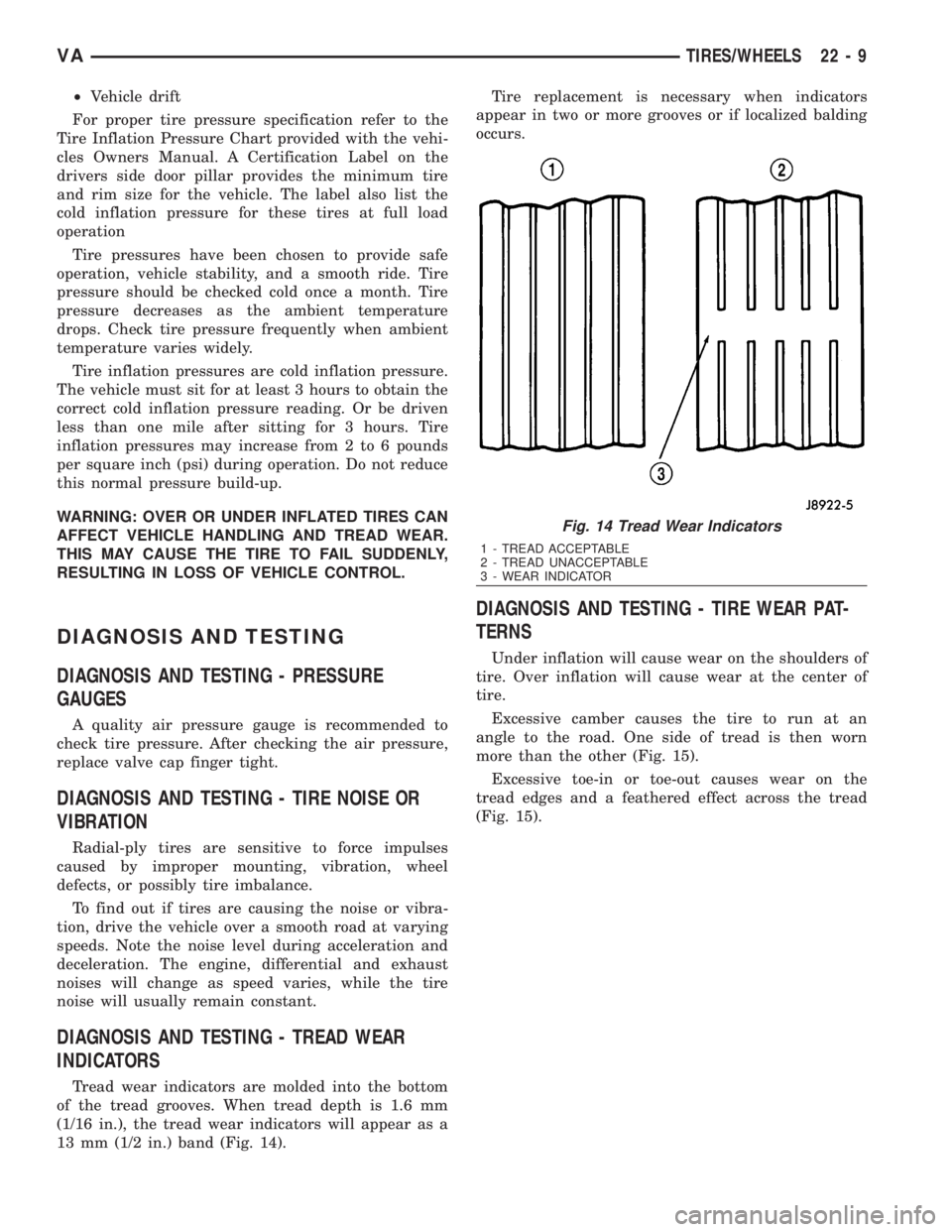

DIAGNOSIS AND TESTING - TREAD WEAR

INDICATORS

Tread wear indicators are molded into the bottom

of the tread grooves. When tread depth is 1.6 mm

(1/16 in.), the tread wear indicators will appear as a

13 mm (1/2 in.) band (Fig. 14).Tire replacement is necessary when indicators

appear in two or more grooves or if localized balding

occurs.

DIAGNOSIS AND TESTING - TIRE WEAR PAT-

TERNS

Under inflation will cause wear on the shoulders of

tire. Over inflation will cause wear at the center of

tire.

Excessive camber causes the tire to run at an

angle to the road. One side of tread is then worn

more than the other (Fig. 15).

Excessive toe-in or toe-out causes wear on the

tread edges and a feathered effect across the tread

(Fig. 15).

Fig. 14 Tread Wear Indicators

1 - TREAD ACCEPTABLE

2 - TREAD UNACCEPTABLE

3 - WEAR INDICATOR

VATIRES/WHEELS 22 - 9

Page 1940 of 2305

WHEELS

DESCRIPTION

Original equipment wheels are designed for the

specified Maximum Vehicle Capacity.

All models use steel or aluminum wheels.

Aluminum wheels require special balance weights

and alignment equipment.

(1) On vehicles equipped with dual rear wheels,

The slots in the wheel must be aligned to provide

access to the valve stem.

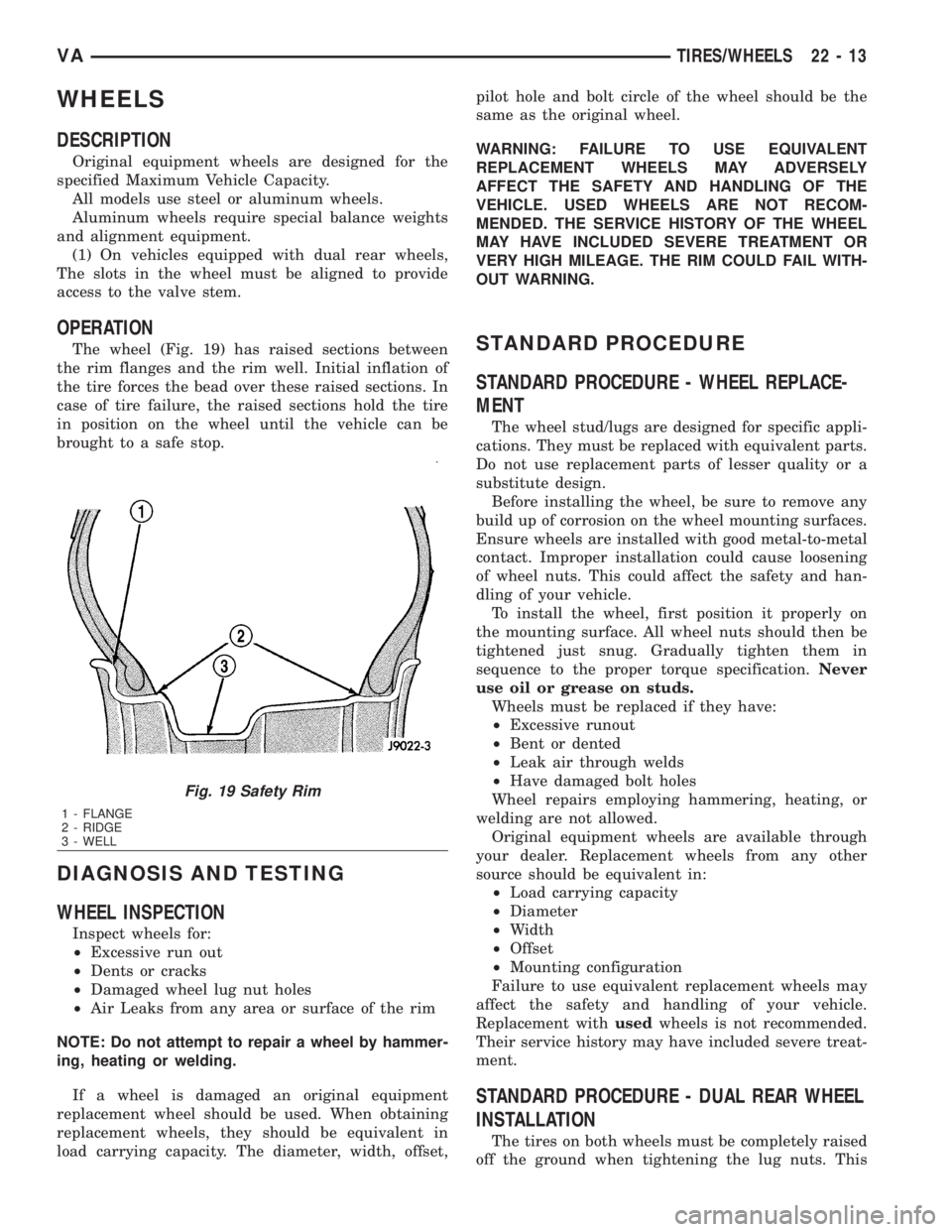

OPERATION

The wheel (Fig. 19) has raised sections between

the rim flanges and the rim well. Initial inflation of

the tire forces the bead over these raised sections. In

case of tire failure, the raised sections hold the tire

in position on the wheel until the vehicle can be

brought to a safe stop.

DIAGNOSIS AND TESTING

WHEEL INSPECTION

Inspect wheels for:

²Excessive run out

²Dents or cracks

²Damaged wheel lug nut holes

²Air Leaks from any area or surface of the rim

NOTE: Do not attempt to repair a wheel by hammer-

ing, heating or welding.

If a wheel is damaged an original equipment

replacement wheel should be used. When obtaining

replacement wheels, they should be equivalent in

load carrying capacity. The diameter, width, offset,pilot hole and bolt circle of the wheel should be the

same as the original wheel.

WARNING: FAILURE TO USE EQUIVALENT

REPLACEMENT WHEELS MAY ADVERSELY

AFFECT THE SAFETY AND HANDLING OF THE

VEHICLE. USED WHEELS ARE NOT RECOM-

MENDED. THE SERVICE HISTORY OF THE WHEEL

MAY HAVE INCLUDED SEVERE TREATMENT OR

VERY HIGH MILEAGE. THE RIM COULD FAIL WITH-

OUT WARNING.

STANDARD PROCEDURE

STANDARD PROCEDURE - WHEEL REPLACE-

MENT

The wheel stud/lugs are designed for specific appli-

cations. They must be replaced with equivalent parts.

Do not use replacement parts of lesser quality or a

substitute design.

Before installing the wheel, be sure to remove any

build up of corrosion on the wheel mounting surfaces.

Ensure wheels are installed with good metal-to-metal

contact. Improper installation could cause loosening

of wheel nuts. This could affect the safety and han-

dling of your vehicle.

To install the wheel, first position it properly on

the mounting surface. All wheel nuts should then be

tightened just snug. Gradually tighten them in

sequence to the proper torque specification.Never

use oil or grease on studs.

Wheels must be replaced if they have:

²Excessive runout

²Bent or dented

²Leak air through welds

²Have damaged bolt holes

Wheel repairs employing hammering, heating, or

welding are not allowed.

Original equipment wheels are available through

your dealer. Replacement wheels from any other

source should be equivalent in:

²Load carrying capacity

²Diameter

²Width

²Offset

²Mounting configuration

Failure to use equivalent replacement wheels may

affect the safety and handling of your vehicle.

Replacement withusedwheels is not recommended.

Their service history may have included severe treat-

ment.

STANDARD PROCEDURE - DUAL REAR WHEEL

INSTALLATION

The tires on both wheels must be completely raised

off the ground when tightening the lug nuts. This

Fig. 19 Safety Rim

1 - FLANGE

2 - RIDGE

3 - WELL

VATIRES/WHEELS 22 - 13