flat tire MERCEDES-BENZ SPRINTER 2012 MY12 Operator’s Manual

[x] Cancel search | Manufacturer: MERCEDES-BENZ, Model Year: 2012, Model line: SPRINTER, Model: MERCEDES-BENZ SPRINTER 2012Pages: 292, PDF Size: 6.75 MB

Page 228 of 292

X

Hook tire sealant bottle 006F into the upper

vent hole in the wheel using hook 0072.

X Push angled connecting piece 0074 located

on the hose of tire sealant filler bottle 006F

as far

as

it will go on to valve core extractor

0071 and fix it in place.

X Make sure that the pressure release screw

on pressure gauge 0086 is closed.

X Connect connector 0087 to the 12 V socket

(12 V, 25 A, 300 W) on the center console

(Y page 133).

! Only use the 12 V socket on the center

console to connect the electric air pump.

You could otherwise damage the vehicle's

electrics.

X Start the engine.

X Press I on tire inflation compressor

switch 0046.

The tire inflation compressor is activated.

The tire

sealant

is then pumped into the tire

and the tire pressure is increased. Let the

tire inflation compressor run for at least 10

minutes until tire sealant bottle 006F is

completely empty and the tire pressure is

at least 43.5 psi (3.0 bar).

! Do not

run

the electric air pump for longer

than 20 minutes without a break; otherwise

it may overheat.

The air pump can be used again once it has

cooled down.

X Inflate the tire using the tire inflation

compressor until the recommended tire

pressure ( Y page 281) is reached.

X Then, press 0 on tire inflation compressor

switch 0046.

The tire inflation compressor is

deactivated.

X Slide knob 0073 quickly to the stop in valve

core extractor 0071.

X Turn knob 0073 clockwise

until

the valve core

is firmly screwed into tire valve 0075.i

Do not pull the valve core extractor from

the tire valve while the valve core is

unscrewed from the

tire valve. Tire sealant

could otherwise escape and make you

dirty.

The tire sealant is water-soluble. If tire

sealant escapes, you can wash it away with

water.

X Pull knob 0073 out of valve core extractor

0071 as far as it will go.

X Unscrew valve core extractor 0071 counter-

clockwise from tire valve 0075.

X Screw valve extension 0070 onto tire valve

0075 and tighten it.

X Screw the valve cap onto valve extension

0070.

After filling with tire sealant, ( Y page 228).

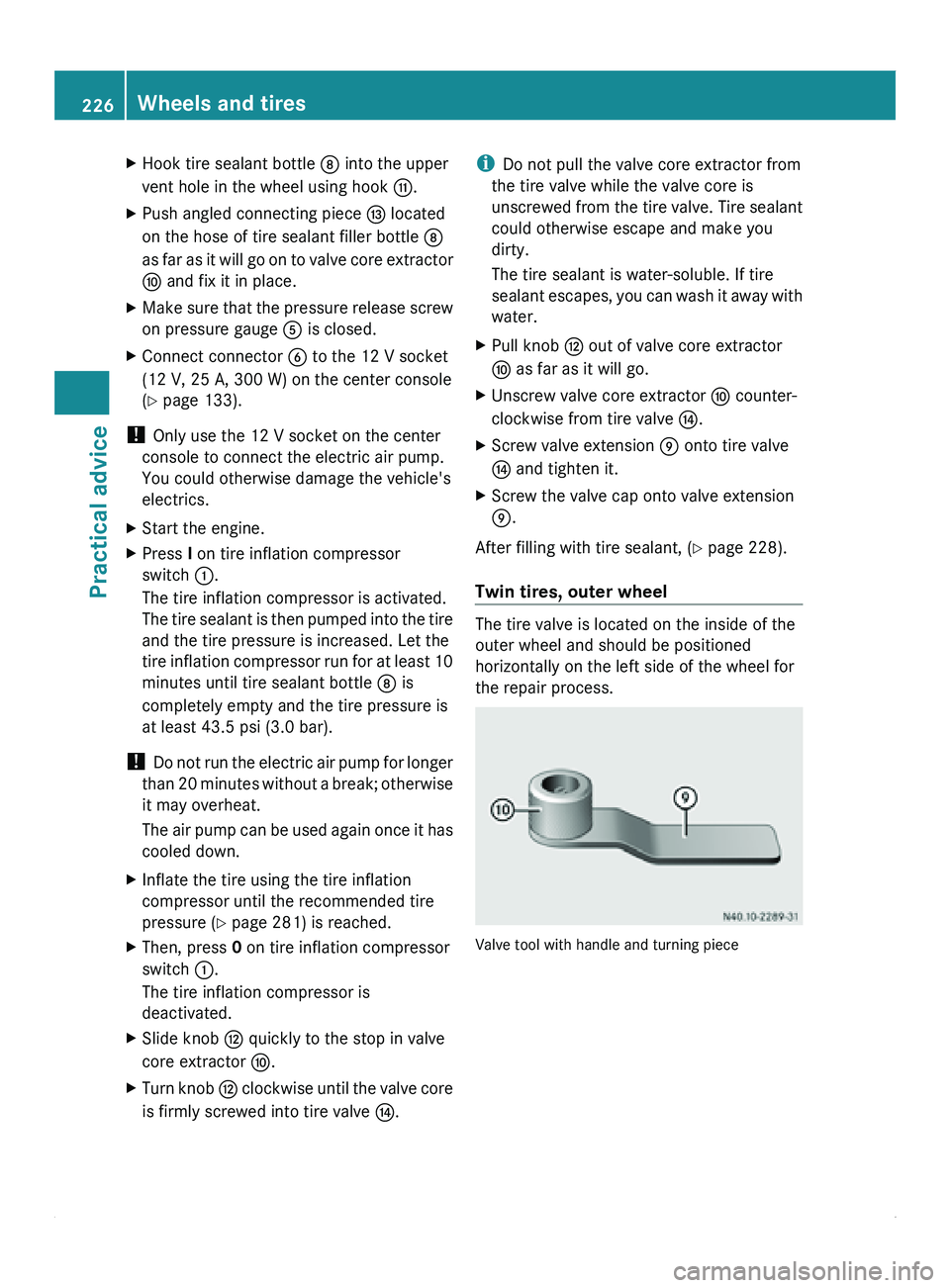

Twin tires, outer wheel The tire valve is located on the inside of the

outer wheel and should be positioned

horizontally on the left side of the wheel for

the repair process.

Valve tool with handle and turning piece226

Wheels and tires

Practical advice

Page 229 of 292

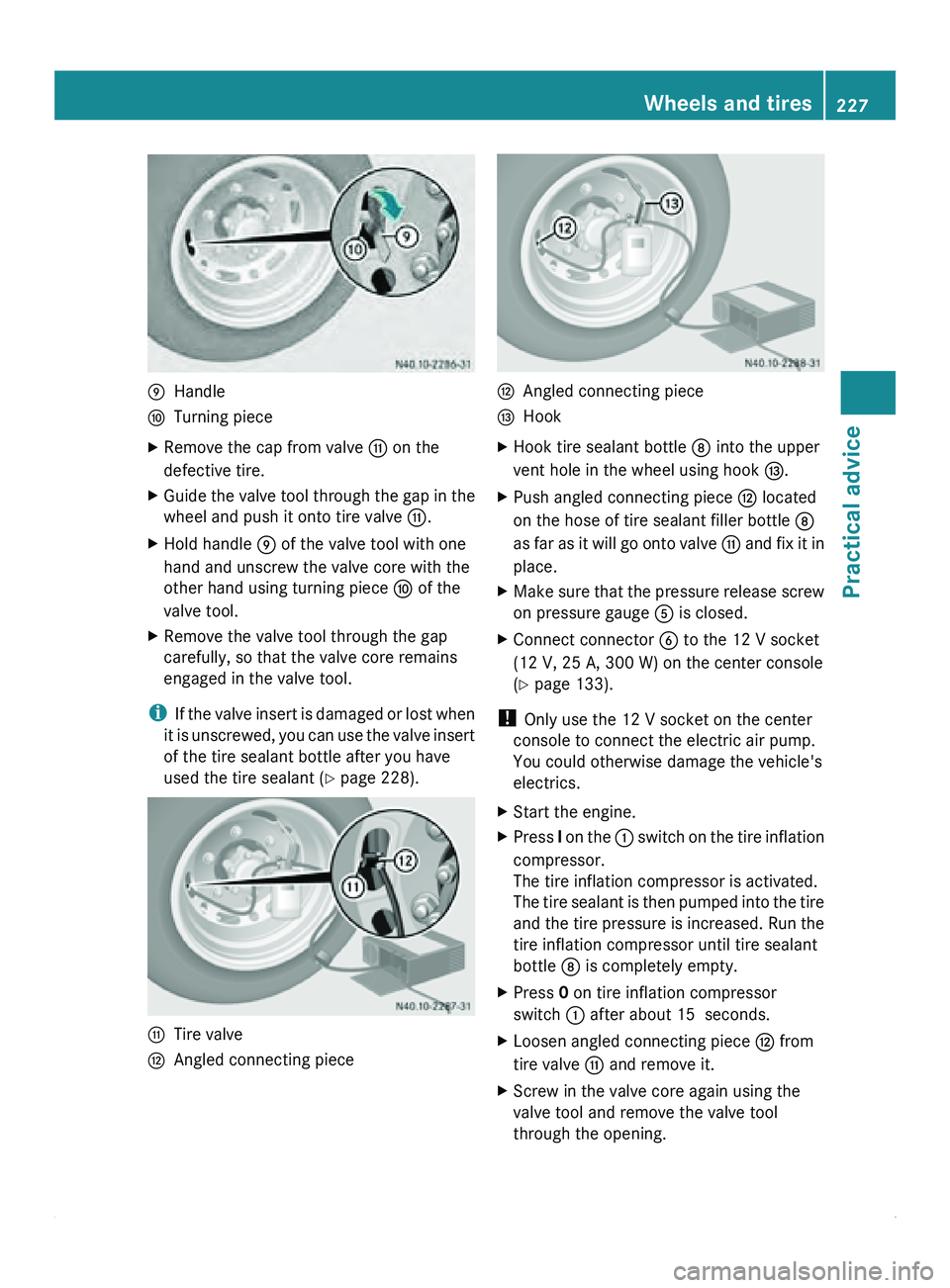

0070

Handle

0071 Turning piece

X Remove the cap from valve 0072 on the

defective tire.

X Guide the valve tool through the gap in the

wheel and push it onto tire valve 0072.

X Hold handle 0070 of the valve tool with one

hand and unscrew the valve core with the

other hand using turning piece 0071 of the

valve tool.

X Remove the valve tool through the gap

carefully, so that the valve core remains

engaged in the valve tool.

i If the

valve

insert is damaged or lost when

it is unscrewed, you can use the valve insert

of the tire sealant bottle after you have

used the tire sealant ( Y page 228).0072

Tire valve

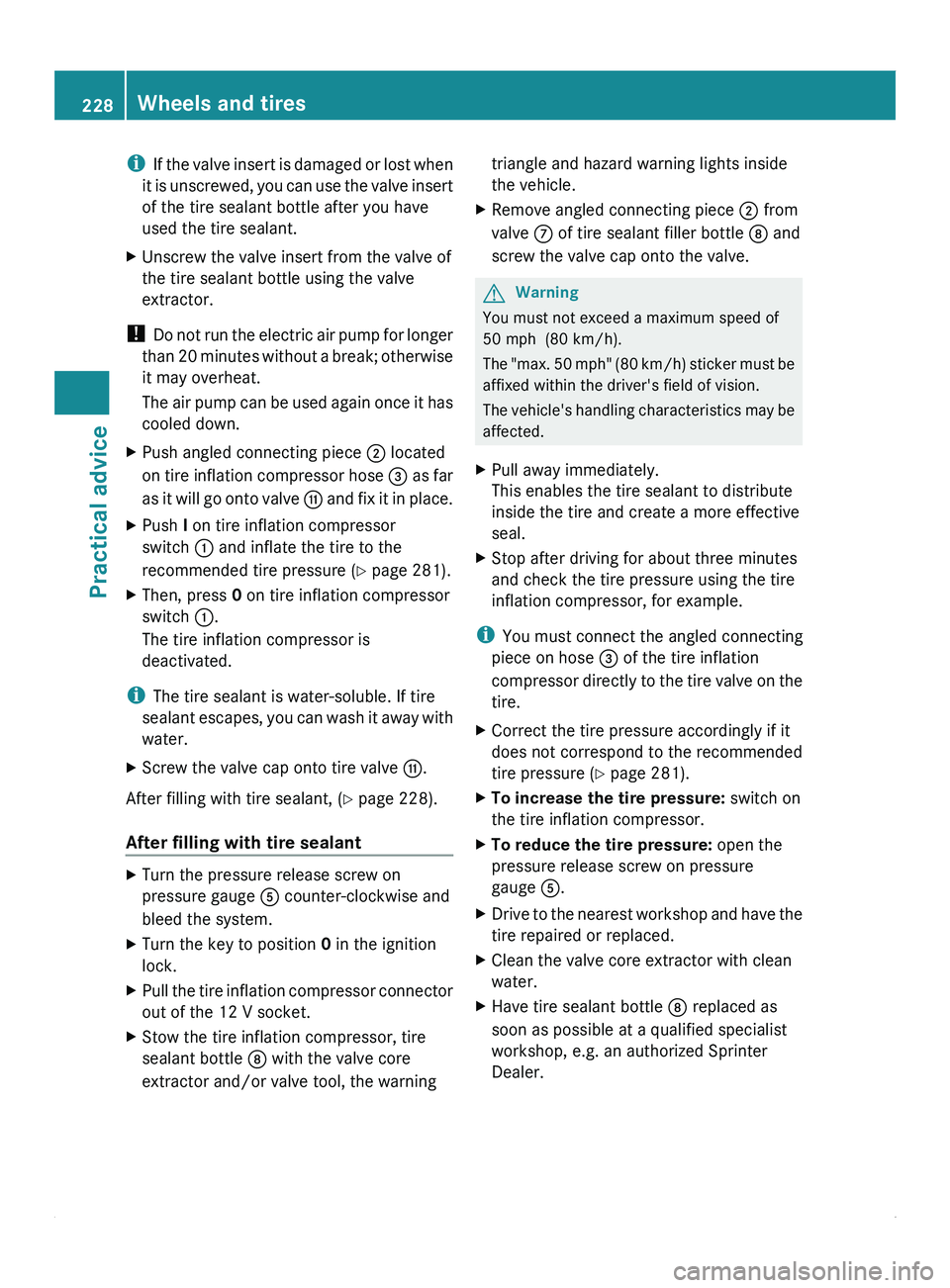

0073 Angled connecting piece 0073

Angled connecting piece

0074 Hook

X Hook tire sealant bottle 006F into the upper

vent hole in the wheel using hook 0074.

X Push angled connecting piece 0073 located

on the hose of tire sealant filler bottle 006F

as far

as

it will go onto valve 0072 and fix it in

place.

X Make sure that the pressure release screw

on pressure gauge 0086 is closed.

X Connect connector 0087 to the 12 V socket

(12 V, 25 A, 300 W) on the center console

(Y page 133).

! Only use the 12 V socket on the center

console to connect the electric air pump.

You could otherwise damage the vehicle's

electrics.

X Start the engine.

X Press I on the 0046

switch on the tire inflation

compressor.

The tire inflation compressor is activated.

The tire sealant is then pumped into the tire

and the tire pressure is increased. Run the

tire inflation compressor until tire sealant

bottle 006F is completely empty.

X Press 0 on tire inflation compressor

switch 0046 after about 15 seconds.

X Loosen angled connecting piece 0073 from

tire valve 0072 and remove it.

X Screw in the valve core again using the

valve tool and remove the valve tool

through the opening. Wheels and tires

227

Practical advice Z

Page 230 of 292

i

If the valve

insert is damaged or lost when

it is unscrewed, you can use the valve insert

of the tire sealant bottle after you have

used the tire sealant.

X Unscrew the valve insert from the valve of

the tire sealant bottle using the valve

extractor.

! Do not run

the electric air pump for longer

than 20 minutes without a break; otherwise

it may overheat.

The air pump can be used again once it has

cooled down.

X Push angled connecting piece 0047 located

on tire inflation

compressor hose 008A as far

as it will go onto valve 0072 and fix it in place.

X Push I on tire inflation compressor

switch 0046 and inflate the tire to the

recommended tire pressure ( Y page 281).

X Then, press 0 on tire inflation compressor

switch 0046.

The tire inflation compressor is

deactivated.

i The tire sealant is water-soluble. If tire

sealant escapes,

you

can wash it away with

water.

X Screw the valve cap onto tire valve 0072.

After filling with tire sealant, ( Y page 228).

After filling with tire sealant X

Turn the pressure release screw on

pressure gauge 0086 counter-clockwise and

bleed the system.

X Turn the key to position 0 in the ignition

lock.

X Pull the tire inflation compressor connector

out of the 12 V socket.

X Stow the tire inflation compressor, tire

sealant bottle 006F with the valve core

extractor and/or valve tool, the warning triangle and hazard warning lights inside

the vehicle.

X Remove angled connecting piece 0047 from

valve 006E of tire sealant filler bottle 006F and

screw the valve cap onto the valve. G

Warning

You must not exceed a maximum speed of

50 mph (80 km/h) .

The "max.

50 mph" (80 km/h) sticker must be

affixed within the driver's field of vision.

The vehicle's handling characteristics may be

affected.

X Pull away immediately.

This enables the tire sealant to distribute

inside the tire and create a more effective

seal.

X Stop after driving for about three minutes

and check the tire pressure using the tire

inflation compressor, for example.

i You must connect the angled connecting

piece on hose 008A of the tire inflation

compressor directly to

the tire valve on the

tire.

X Correct the tire pressure accordingly if it

does not correspond to the recommended

tire pressure ( Y page 281).

X To increase the tire pressure: switch on

the tire inflation compressor.

X To reduce the tire pressure: open the

pressure release screw on pressure

gauge 0086.

X Drive to the nearest workshop and have the

tire repaired or replaced.

X Clean the valve core extractor with clean

water.

X Have tire sealant bottle 006F replaced as

soon as possible at a qualified specialist

workshop, e.g. an authorized Sprinter

Dealer.228

Wheels and tires

Practical advice

Page 231 of 292

G

Warning

If the minimum tire pressure of 43.5 psi

(3 bar) still cannot

be achieved, the tire is too

badly damaged.

Do not drive any further. Consult a qualified

specialist workshop which has the necessary

specialist knowledge and tools to carry out

the work required.

For this reason, we recommend an authorized

Sprinter Dealer. In particular, work relevant to

safety or on safety-related systems must be

carried out at a qualified specialist workshop.

0040Environmental note

Have the used tire sealant disposed of at a

qualified specialist workshop, e.g. an

authorized Sprinter Dealer.

! Have the tire sealant bottle replaced

every eight years at a qualified specialist

workshop, e.g. an authorized Sprinter

Dealer. Changing a

wheel in the event of a flat

tire G

Warning

To avoid the risk of serious or even fatal injury

and to avoid damage to the vehicle, observe

the following:

R the vehicle's jack is intended only to raise

the vehicle for

a short time when changing

a wheel.

R position the jack on the appropriate jacking

point only. Make sure that the jack is

correctly positioned under the jacking point

before raising the vehicle.

R the jack must be placed on a firm, flat

surface.

R before raising the vehicle, you should also

secure it against rolling away, e.g. by

placing chocks under the wheels. Never

release the parking brake while the vehicle

is raised. R

make sure that the distance between the

underside

of the

tires and the ground does

not exceed 1.2 in (3 cm). The vehicle could

otherwise slip off the jack or tip over.

R never place your hands or feet under the

raised vehicle.

R never start the engine, and prevent other

jolts or vibrations while the vehicle is

raised. The vehicle could otherwise slip off

the jack.

Preparing to change a wheel X

Prepare the vehicle as described

(Y

page 222).

X Secure the vehicle against rolling away

using chocks or similar items.

Use the chock ( Y

page 183) to do so. G

Warning

The vehicle

could slip off the jack on uphill and

downhill gradients.

To avoid the risk of causing serious or even

fatal injury or damage to the vehicle, do not

change wheels on uphill and downhill

gradients.

On a level road:

X Place chocks in front of and behind the

wheel which is diagonally opposite the

wheel you wish to change.

X Take the vehicle tool kit and the jack from

the footwell on the co-driver's side

(Y page 182).

X Remove the spare wheel from the spare

wheel bracket ( Y page 185).

X On wheels with wheel bolts, remove the

hub cap.

X Assemble the lug wrench extension using

the middle rod

and the rod with the largest

diameter from the three-piece jack pump

lever.

X Starting with the middle rod, slide the lug

wrench extension as far as it will go onto

the lug wrench. Wheels and tires

229

Practical advice Z

Page 232 of 292

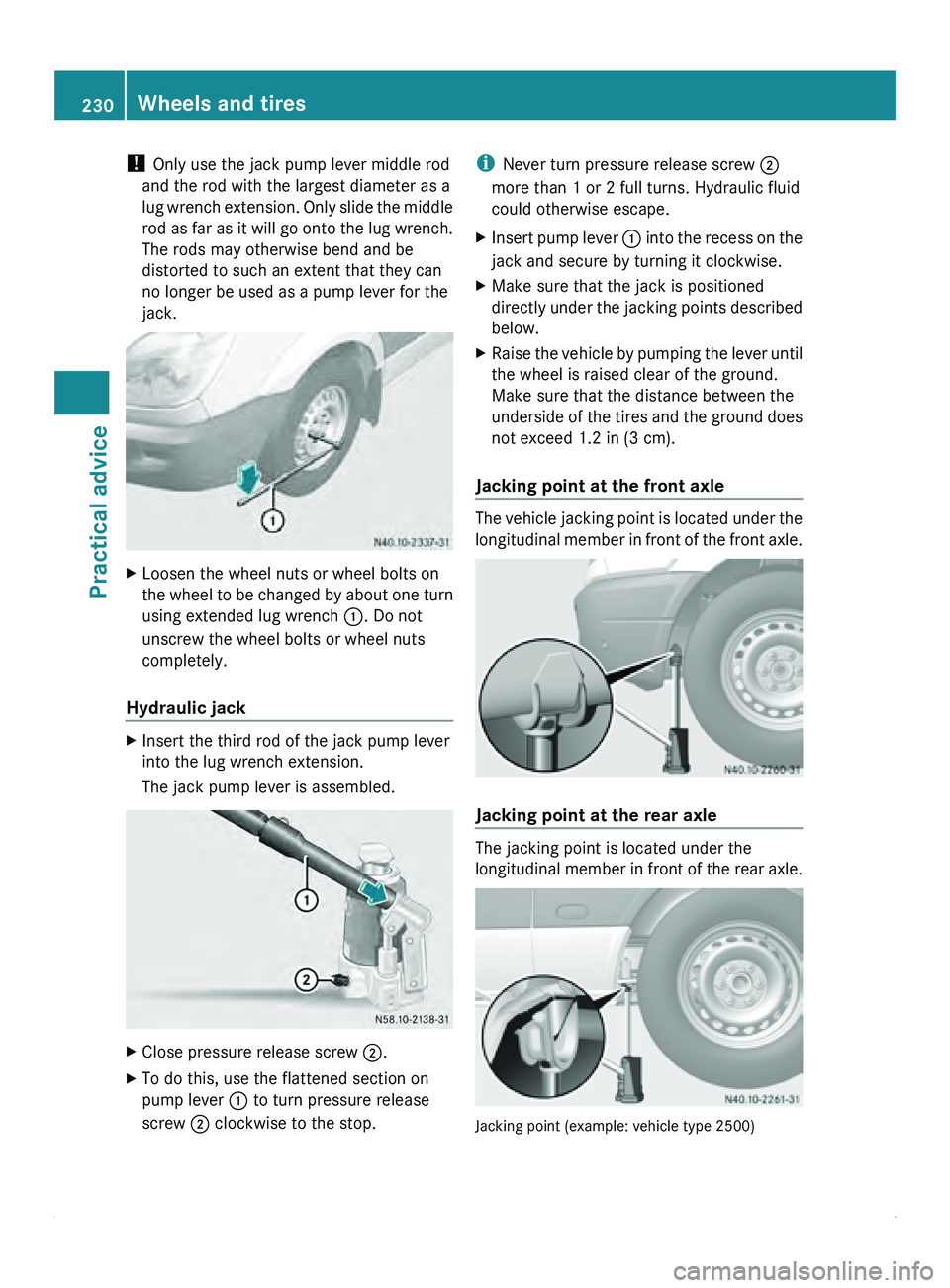

!

Only use the jack pump lever middle rod

and the rod with the largest diameter as a

lug wrench extension.

Only slide the middle

rod as far as it will go onto the lug wrench.

The rods may otherwise bend and be

distorted to such an extent that they can

no longer be used as a pump lever for the

jack. X

Loosen the wheel nuts or wheel bolts on

the wheel to

be changed by about one turn

using extended lug wrench 0046. Do not

unscrew the wheel bolts or wheel nuts

completely.

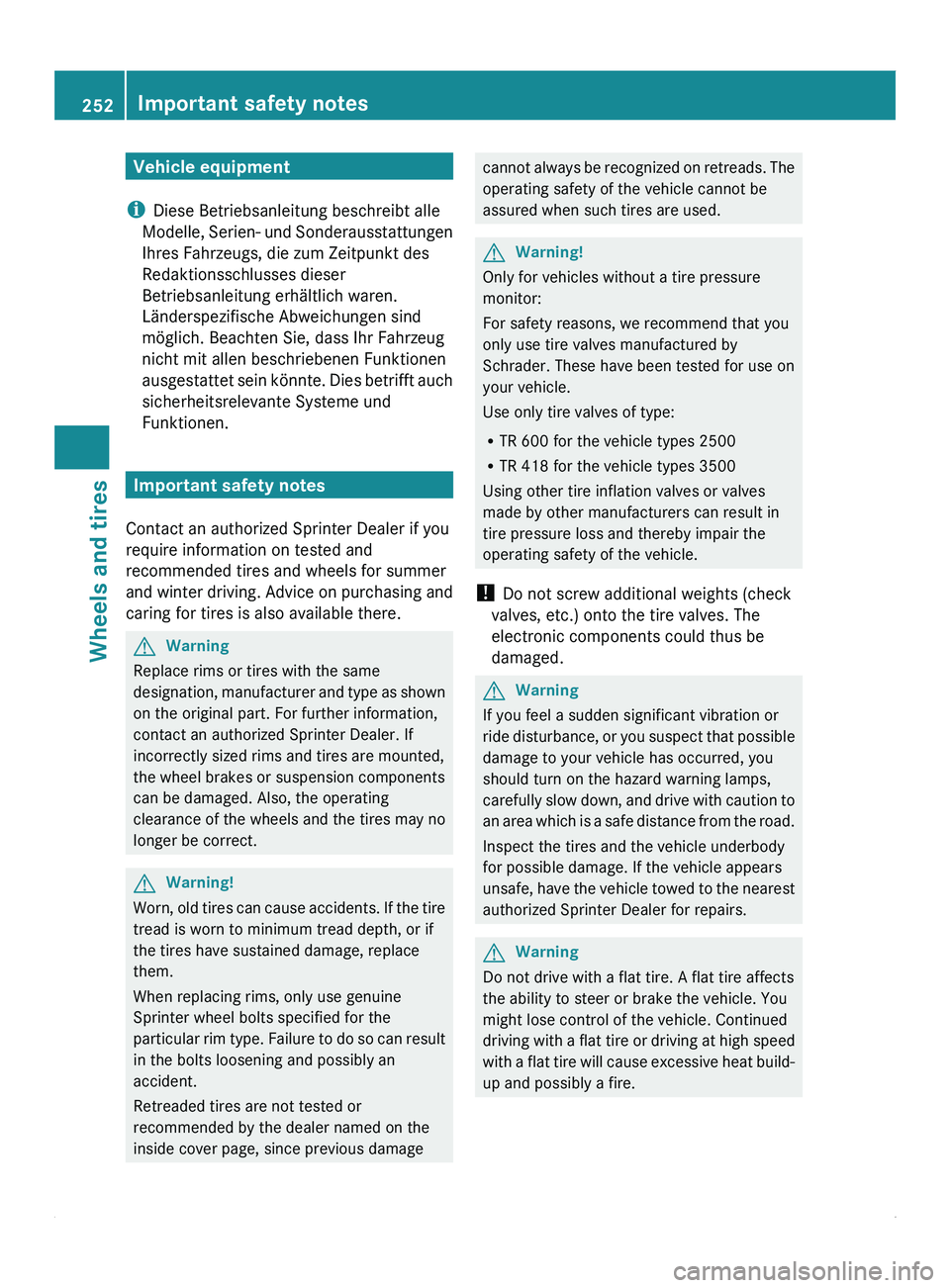

Hydraulic jack X

Insert the third rod of the jack pump lever

into the lug wrench extension.

The jack pump lever is assembled. X

Close pressure release screw 0047.

X To do this, use the flattened section on

pump lever 0046 to turn pressure release

screw 0047 clockwise to the stop. i

Never turn pressure release screw 0047

more than 1 or 2 full turns. Hydraulic fluid

could otherwise escape.

X Insert pump lever 0046 into the

recess on the

jack and secure by turning it clockwise.

X Make sure that the jack is positioned

directly under the

jacking points described

below.

X Raise the vehicle by pumping the lever until

the wheel is raised clear of the ground.

Make sure that the distance between the

underside of the

tires and the ground does

not exceed 1.2 in (3 cm).

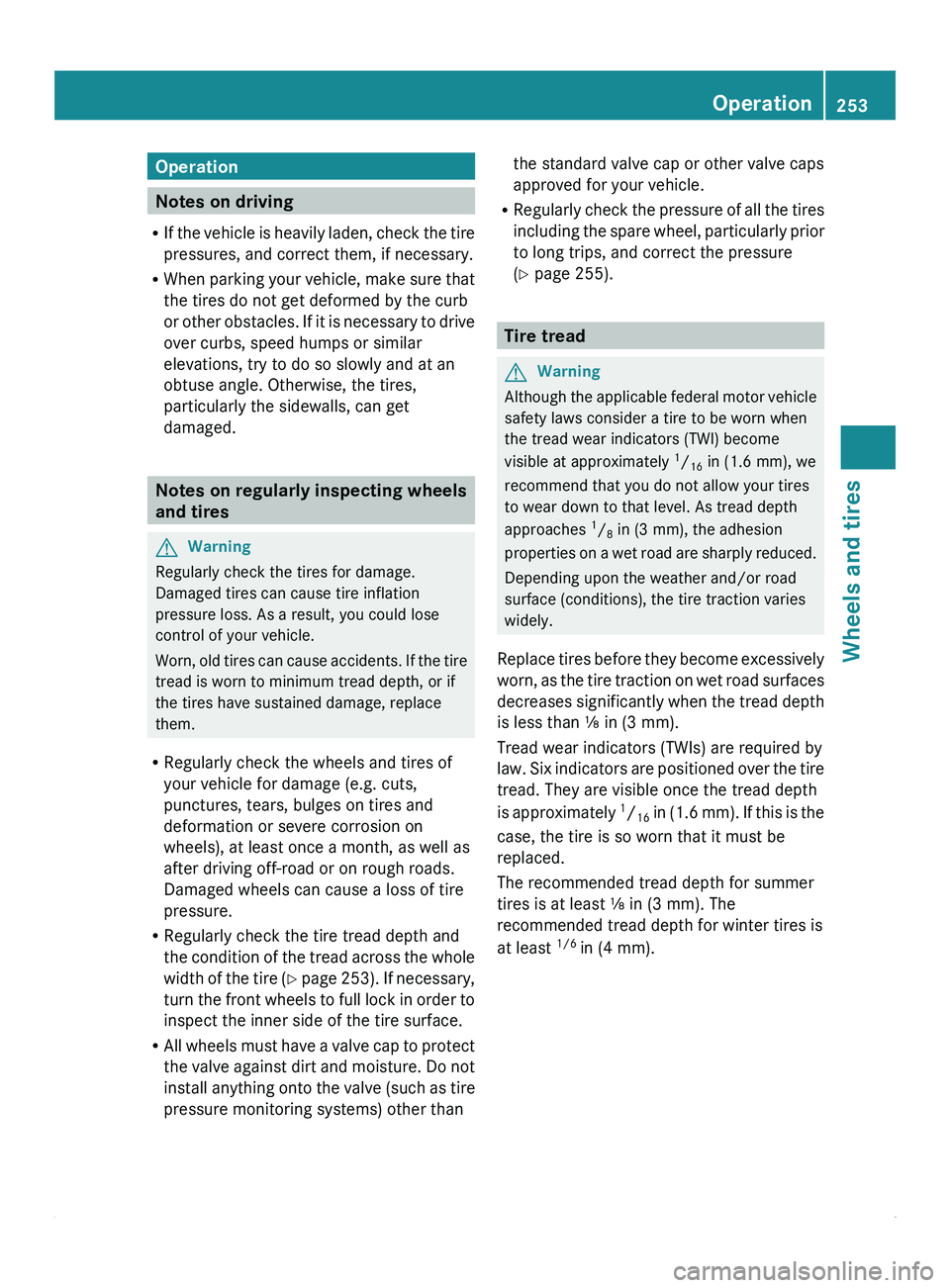

Jacking point at the front axle The vehicle jacking point is located under the

longitudinal member

in

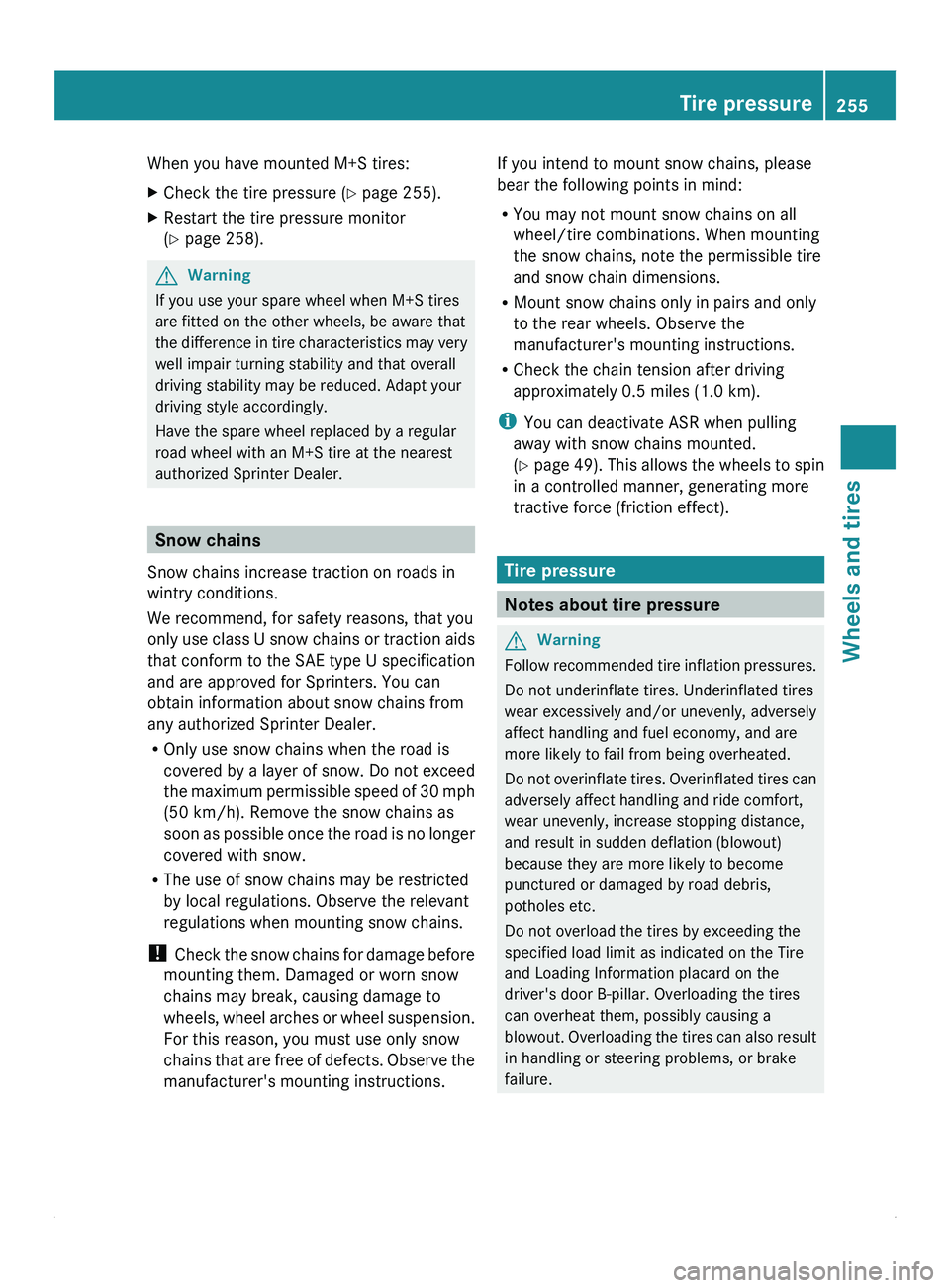

front of the front axle. Jacking point at the rear axle

The jacking point is located under the

longitudinal member

in

front of the rear axle. Jacking point (example: vehicle type 2500)230

Wheels and tires

Practical advice

Page 254 of 292

Vehicle equipment

i Diese Betriebsanleitung beschreibt alle

Modelle, Serien- und

Sonderausstattungen

Ihres Fahrzeugs, die zum Zeitpunkt des

Redaktionsschlusses dieser

Betriebsanleitung erhältlich waren.

Länderspezifische Abweichungen sind

möglich. Beachten Sie, dass Ihr Fahrzeug

nicht mit allen beschriebenen Funktionen

ausgestattet sein könnte. Dies betrifft auch

sicherheitsrelevante Systeme und

Funktionen. Important safety notes

Contact an authorized Sprinter Dealer if you

require information on tested and

recommended tires and wheels for summer

and winter driving.

Advice on purchasing and

caring for tires is also available there. G

Warning

Replace rims or tires with the same

designation, manufacturer and

type as shown

on the original part. For further information,

contact an authorized Sprinter Dealer. If

incorrectly sized rims and tires are mounted,

the wheel brakes or suspension components

can be damaged. Also, the operating

clearance of the wheels and the tires may no

longer be correct. G

Warning!

Worn, old

tires can cause accidents. If the tire

tread is worn to minimum tread depth, or if

the tires have sustained damage, replace

them.

When replacing rims, only use genuine

Sprinter wheel bolts specified for the

particular rim type.

Failure to do so can result

in the bolts loosening and possibly an

accident.

Retreaded tires are not tested or

recommended by the dealer named on the

inside cover page, since previous damage cannot always

be recognized on retreads. The

operating safety of the vehicle cannot be

assured when such tires are used. G

Warning!

Only for vehicles without a tire pressure

monitor:

For safety reasons, we recommend that you

only use tire valves manufactured by

Schrader. These have been tested for use on

your vehicle.

Use only tire valves of type:

R TR 600 for the vehicle types 2500

R TR 418 for the vehicle types 3500

Using other tire inflation valves or valves

made by other manufacturers can result in

tire pressure loss and thereby impair the

operating safety of the vehicle.

! Do not screw additional weights (check

valves, etc.) onto the tire valves. The

electronic components could thus be

damaged. G

Warning

If you feel a sudden significant vibration or

ride disturbance, or

you suspect that possible

damage to your vehicle has occurred, you

should turn on the hazard warning lamps,

carefully slow down, and drive with caution to

an area which is a safe distance from the road.

Inspect the tires and the vehicle underbody

for possible damage. If the vehicle appears

unsafe, have the vehicle towed to the nearest

authorized Sprinter Dealer for repairs. G

Warning

Do not drive with a flat tire. A flat tire affects

the ability to steer or brake the vehicle. You

might lose control of the vehicle. Continued

driving with a

flat tire or driving at high speed

with a flat tire will cause excessive heat build-

up and possibly a fire. 252

Important safety notes

Wheels and tires

Page 255 of 292

Operation

Notes on driving

R If the vehicle

is heavily laden, check the tire

pressures, and correct them, if necessary.

R When parking your vehicle, make sure that

the tires do not get deformed by the curb

or other obstacles. If it is necessary to drive

over curbs, speed humps or similar

elevations, try to do so slowly and at an

obtuse angle. Otherwise, the tires,

particularly the sidewalls, can get

damaged. Notes on regularly inspecting wheels

and tires

G

Warning

Regularly check the tires for damage.

Damaged tires can cause tire inflation

pressure loss. As a result, you could lose

control of your vehicle.

Worn, old tires

can cause accidents. If the tire

tread is worn to minimum tread depth, or if

the tires have sustained damage, replace

them.

R Regularly check the wheels and tires of

your vehicle for damage (e.g. cuts,

punctures, tears, bulges on tires and

deformation or severe corrosion on

wheels), at least once a month, as well as

after driving off-road or on rough roads.

Damaged wheels can cause a loss of tire

pressure.

R Regularly check the tire tread depth and

the condition of the tread across the whole

width of the tire (Y page 253). If necessary,

turn the front wheels to full lock in order to

inspect the inner side of the tire surface.

R All wheels must have a valve cap to protect

the valve against dirt and moisture. Do not

install anything onto the valve (such as tire

pressure monitoring systems) other than the standard valve cap or other valve caps

approved for your vehicle.

R Regularly check the

pressure of all the tires

including the spare wheel, particularly prior

to long trips, and correct the pressure

(Y page 255). Tire tread

G

Warning

Although the

applicable federal motor vehicle

safety laws consider a tire to be worn when

the tread wear indicators (TWI) become

visible at approximately 1

/ 16 in (1.6 mm), we

recommend that you do not allow your tires

to wear down to that level. As tread depth

approaches 1

/ 8 in (3 mm), the adhesion

properties on a

wet road are sharply reduced.

Depending upon the weather and/or road

surface (conditions), the tire traction varies

widely.

Replace tires before they become excessively

worn, as the tire traction on wet road surfaces

decreases significantly when the tread depth

is less than ⅛ in (3 mm).

Tread wear indicators (TWIs) are required by

law. Six indicators are positioned over the tire

tread. They are visible once the tread depth

is approximately 1

/ 16 in (1.6 mm). If this is the

case, the tire is so worn that it must be

replaced.

The recommended tread depth for summer

tires is at least ⅛ in (3 mm). The

recommended tread depth for winter tires is

at least 1/6

in (4 mm). Operation

253

Wheels and tires Z

Page 257 of 292

When you have mounted M+S tires:

X

Check the tire pressure (Y page 255).

X Restart the tire pressure monitor

(Y page 258). G

Warning

If you use your spare wheel when M+S tires

are fitted on the other wheels, be aware that

the difference in

tire characteristics may very

well impair turning stability and that overall

driving stability may be reduced. Adapt your

driving style accordingly.

Have the spare wheel replaced by a regular

road wheel with an M+S tire at the nearest

authorized Sprinter Dealer. Snow chains

Snow chains increase traction on roads in

wintry conditions.

We recommend, for safety reasons, that you

only use class

U snow chains or traction aids

that conform to the SAE type U specification

and are approved for Sprinters. You can

obtain information about snow chains from

any authorized Sprinter Dealer.

R Only use snow chains when the road is

covered by a layer of snow. Do not exceed

the maximum permissible speed of 30 mph

(50 km/h). Remove the snow chains as

soon as possible once the road is no longer

covered with snow.

R The use of snow chains may be restricted

by local regulations. Observe the relevant

regulations when mounting snow chains.

! Check the snow chains for damage before

mounting them. Damaged or worn snow

chains may break, causing damage to

wheels, wheel arches or wheel suspension.

For this reason, you must use only snow

chains that are free of defects. Observe the

manufacturer's mounting instructions. If you intend to mount snow chains, please

bear the following points in mind:

R

You may not mount snow chains on all

wheel/tire combinations. When mounting

the snow chains, note the permissible tire

and snow chain dimensions.

R Mount snow chains only in pairs and only

to the rear wheels. Observe the

manufacturer's mounting instructions.

R Check the chain tension after driving

approximately 0.5 miles (1.0 km) .

i You can deactivate ASR when pulling

away with snow chains mounted.

(

Y page 49). This allows the wheels to spin

in a controlled manner, generating more

tractive force (friction effect). Tire pressure

Notes about tire pressure

G

Warning

Follow recommended tire inflation pressures.

Do not underinflate tires. Underinflated tires

wear excessively and/or unevenly, adversely

affect handling and fuel economy, and are

more likely to fail from being overheated.

Do not overinflate

tires. Overinflated tires can

adversely affect handling and ride comfort,

wear unevenly, increase stopping distance,

and result in sudden deflation (blowout)

because they are more likely to become

punctured or damaged by road debris,

potholes etc.

Do not overload the tires by exceeding the

specified load limit as indicated on the Tire

and Loading Information placard on the

driver's door B-pillar. Overloading the tires

can overheat them, possibly causing a

blowout. Overloading the tires can also result

in handling or steering problems, or brake

failure. Tire pressure

255Wheels and tires Z

Page 258 of 292

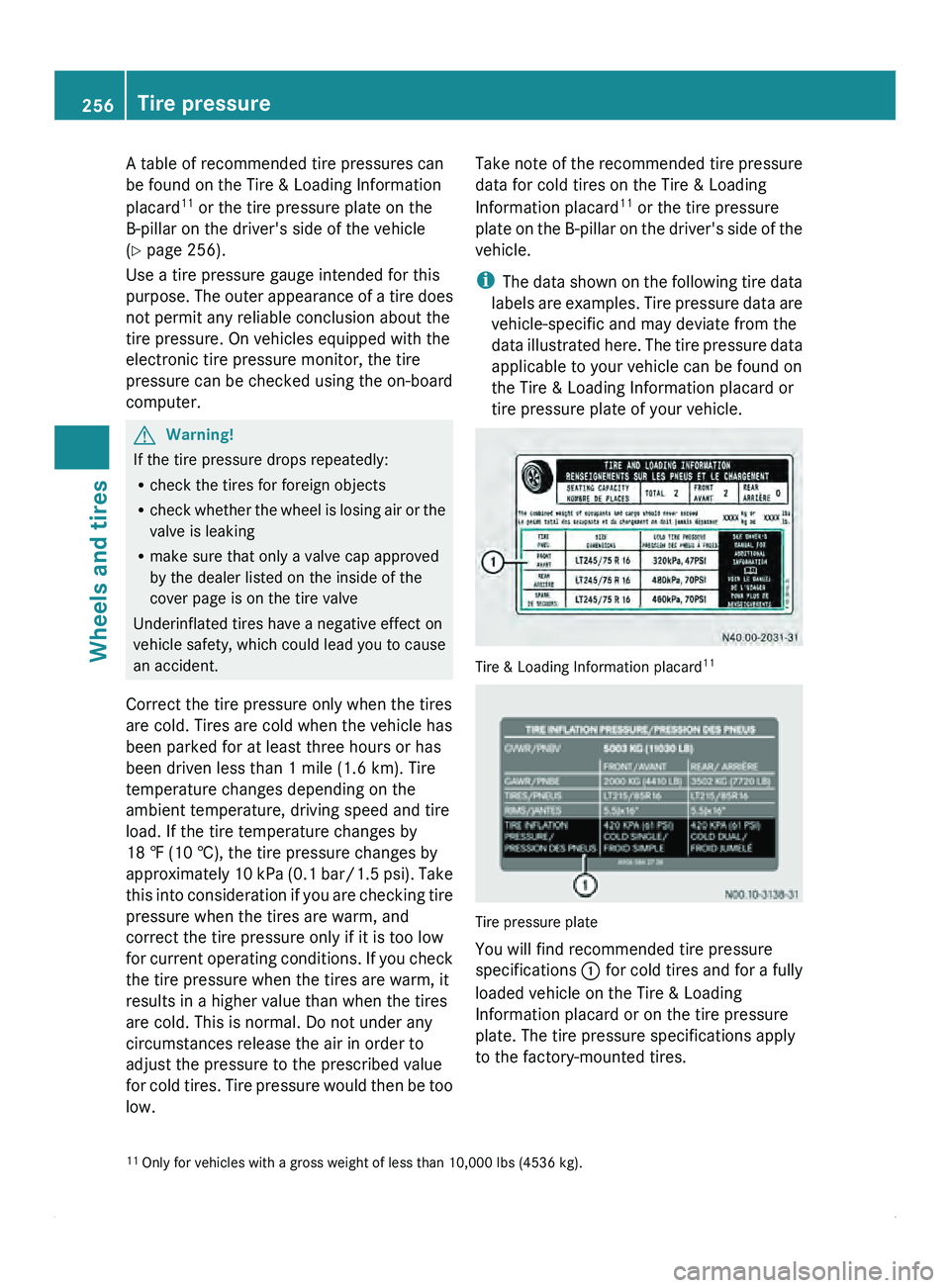

A table of recommended tire pressures can

be found on the Tire & Loading Information

placard

11

or the tire pressure plate on the

B-pillar on the driver's side of the vehicle

(Y page 256).

Use a tire pressure gauge intended for this

purpose. The outer

appearance of a tire does

not permit any reliable conclusion about the

tire pressure. On vehicles equipped with the

electronic tire pressure monitor, the tire

pressure can be checked using the on-board

computer. G

Warning!

If the tire pressure drops repeatedly:

R check the tires for foreign objects

R check whether the

wheel is losing air or the

valve is leaking

R make sure that only a valve cap approved

by the dealer listed on the inside of the

cover page is on the tire valve

Underinflated tires have a negative effect on

vehicle safety, which could lead you to cause

an accident.

Correct the tire pressure only when the tires

are cold. Tires are cold when the vehicle has

been parked for at least three hours or has

been driven less than 1 mile (1.6 km). Tire

temperature changes depending on the

ambient temperature, driving speed and tire

load. If the tire temperature changes by

18 ‡ (10 †), the tire pressure changes by

approximately 10 kPa (0.1 bar/1.5 psi). Take

this into consideration if you are checking tire

pressure when the tires are warm, and

correct the tire pressure only if it is too low

for current operating conditions. If you check

the tire pressure when the tires are warm, it

results in a higher value than when the tires

are cold. This is normal. Do not under any

circumstances release the air in order to

adjust the pressure to the prescribed value

for cold tires. Tire pressure would then be too

low. Take note of the recommended tire pressure

data for cold tires on the Tire & Loading

Information placard

11

or the tire pressure

plate on the

B-pillar on the driver's side of the

vehicle.

i The data shown on the following tire data

labels are examples. Tire pressure data are

vehicle-specific and may deviate from the

data illustrated here. The tire pressure data

applicable to your vehicle can be found on

the Tire & Loading Information placard or

tire pressure plate of your vehicle. Tire & Loading Information placard

11 Tire pressure plate

You will find recommended tire pressure

specifications

0046 for cold

tires and for a fully

loaded vehicle on the Tire & Loading

Information placard or on the tire pressure

plate. The tire pressure specifications apply

to the factory-mounted tires.

11 Only for vehicles with a gross weight of less than 10,000 lbs (4536 kg).256

Tire pressure

Wheels and tires

Page 259 of 292

Tire pressure too low or too high

Underinflated tires G

Warning

Follow recommended tire inflation pressures.

Do not underinflate tires. Underinflated tires

wear excessively and/or unevenly, adversely

affect handling and fuel economy, and are

more likely to fail from being overheated.

Underinflated tires can:

R wear excessively and/or unevenly

R adversely affect fuel economy

R fail from being overheated

R adversely affect handling

Overinflated tires G

Warning

Follow recommended tire inflation pressures.

Do not overinflate

tires. Overinflated tires can

adversely affect handling and ride comfort,

wear unevenly, increase stopping distance,

and result in sudden deflation (blowout)

because they are more likely to become

punctured or damaged by road debris,

potholes etc.

Overinflated tires can:

R adversely affect handling

R wear excessively and/or unevenly

R be more likely to become damaged

R adversely affect ride comfort

R increase stopping distance

Maximum tire pressures G

Warning

Never exceed the maximum tire inflation

pressure. Follow recommended tire inflation

pressures.

Do not underinflate tires. Underinflated tires

wear excessively and/or unevenly, adversely affect handling and fuel economy, and are

more likely to fail from being overheated.

Do not

overinflate

tires. Overinflated tires can

adversely affect handling and ride comfort,

wear unevenly, increase stopping distance,

and result in sudden deflation (blowout)

because they are more likely to become

punctured or damaged by road debris,

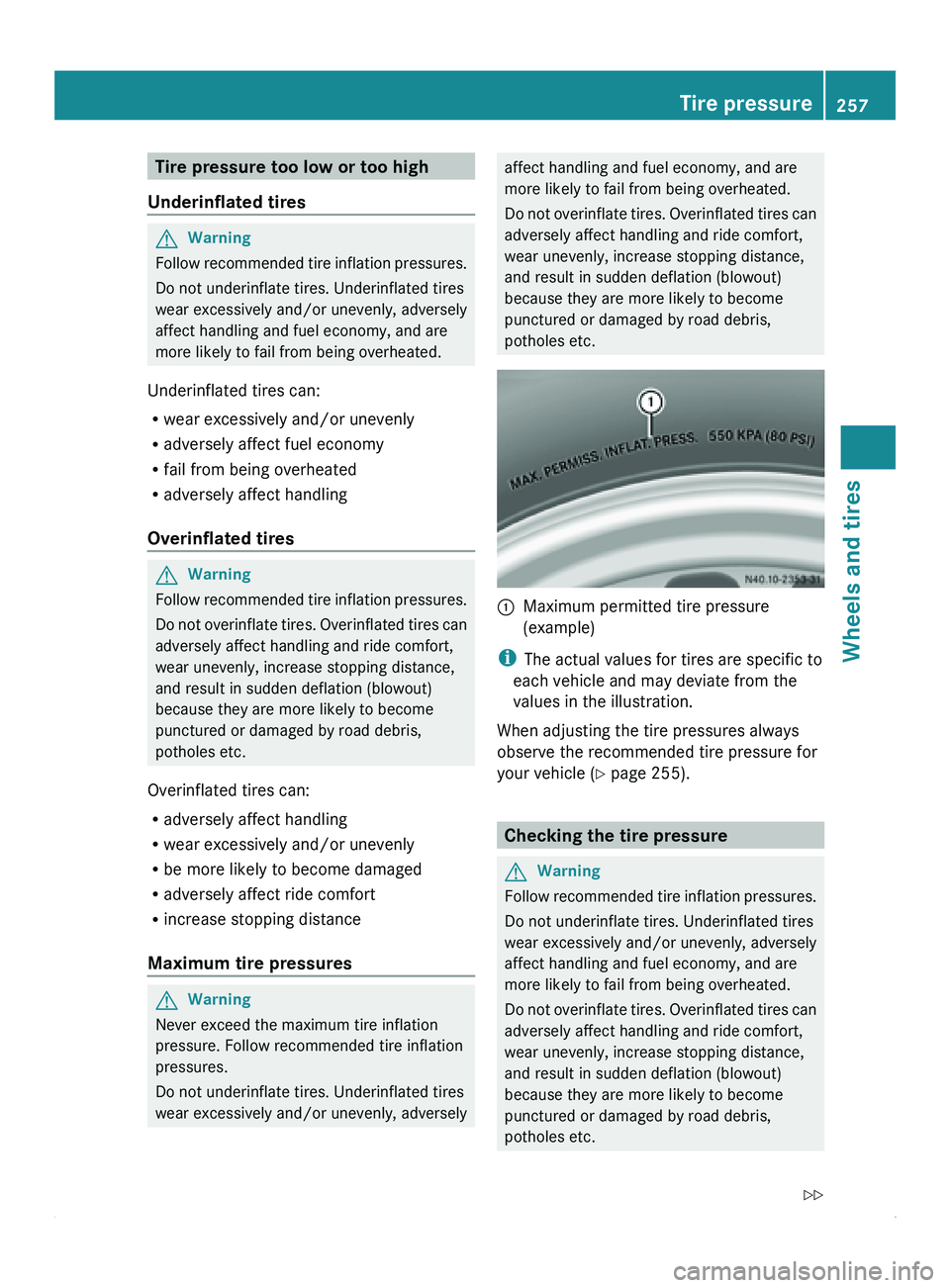

potholes etc. 0046

Maximum permitted tire pressure

(example)

i The actual values for tires are specific to

each vehicle and may deviate from the

values in the illustration.

When adjusting the tire pressures always

observe the recommended tire pressure for

your vehicle ( Y page 255). Checking the tire pressure

G

Warning

Follow recommended

tire inflation pressures.

Do not underinflate tires. Underinflated tires

wear excessively and/or unevenly, adversely

affect handling and fuel economy, and are

more likely to fail from being overheated.

Do not overinflate

tires. Overinflated tires can

adversely affect handling and ride comfort,

wear unevenly, increase stopping distance,

and result in sudden deflation (blowout)

because they are more likely to become

punctured or damaged by road debris,

potholes etc. Tire pressure

257

Wheels and tires

Z