tire pressure MERCEDES-BENZ SPRINTER 2012 MY12 Operator’s Manual

[x] Cancel search | Manufacturer: MERCEDES-BENZ, Model Year: 2012, Model line: SPRINTER, Model: MERCEDES-BENZ SPRINTER 2012Pages: 292, PDF Size: 6.75 MB

Page 197 of 292

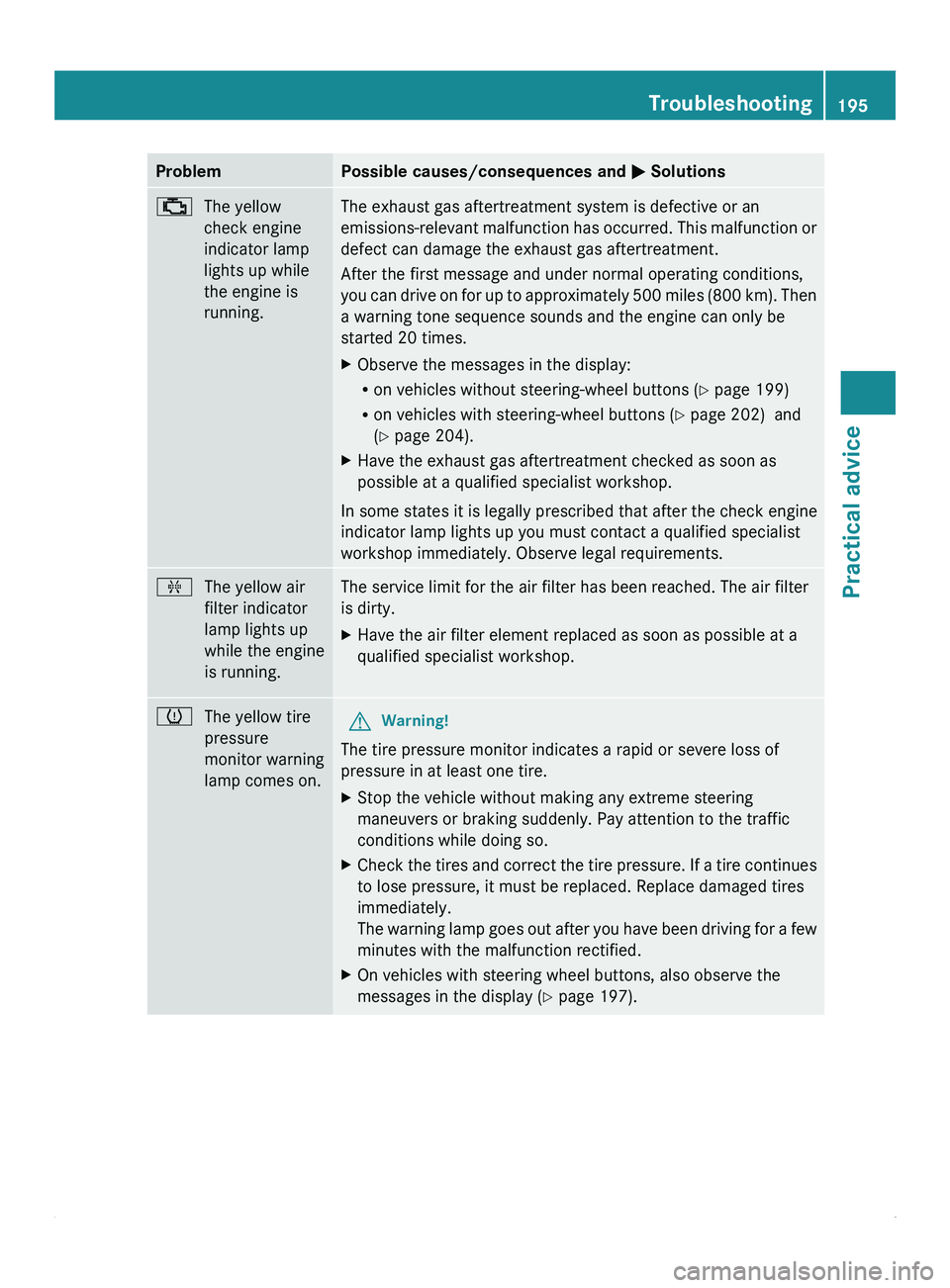

Problem Possible causes/consequences and

0050 Solutions00BB

The yellow

check engine

indicator lamp

lights up while

the engine is

running. The exhaust gas aftertreatment system is defective or an

emissions-relevant malfunction has

occurred. This malfunction or

defect can damage the exhaust gas aftertreatment.

After the first message and under normal operating conditions,

you can drive on for up to approximately 500 miles (800 km). Then

a warning tone sequence sounds and the engine can only be

started 20 times.

X Observe the messages in the display:

R

on vehicles without steering-wheel buttons (Y page 199)

R on vehicles with steering-wheel buttons (Y page 202) and

(Y page 204).

X Have the exhaust gas aftertreatment checked as soon as

possible at a qualified specialist workshop.

In some states it is legally prescribed that after the check engine

indicator lamp lights up you must contact a qualified specialist

workshop immediately. Observe legal requirements. 00AB

The yellow air

filter indicator

lamp lights up

while the engine

is running. The service limit for the air filter has been reached. The air filter

is dirty.

X

Have the air filter element replaced as soon as possible at a

qualified specialist workshop. 0077

The yellow tire

pressure

monitor warning

lamp comes on. G

Warning!

The tire pressure monitor indicates a rapid or severe loss of

pressure in at least one tire.

X Stop the vehicle without making any extreme steering

maneuvers or braking suddenly. Pay attention to the traffic

conditions while doing so.

X Check the tires and correct the tire pressure. If a tire continues

to lose pressure, it must be replaced. Replace damaged tires

immediately.

The warning lamp

goes out after you have been driving for a few

minutes with the malfunction rectified.

X On vehicles with steering wheel buttons, also observe the

messages in the display ( Y page 197). Troubleshooting

195

Practical advice Z

Page 198 of 292

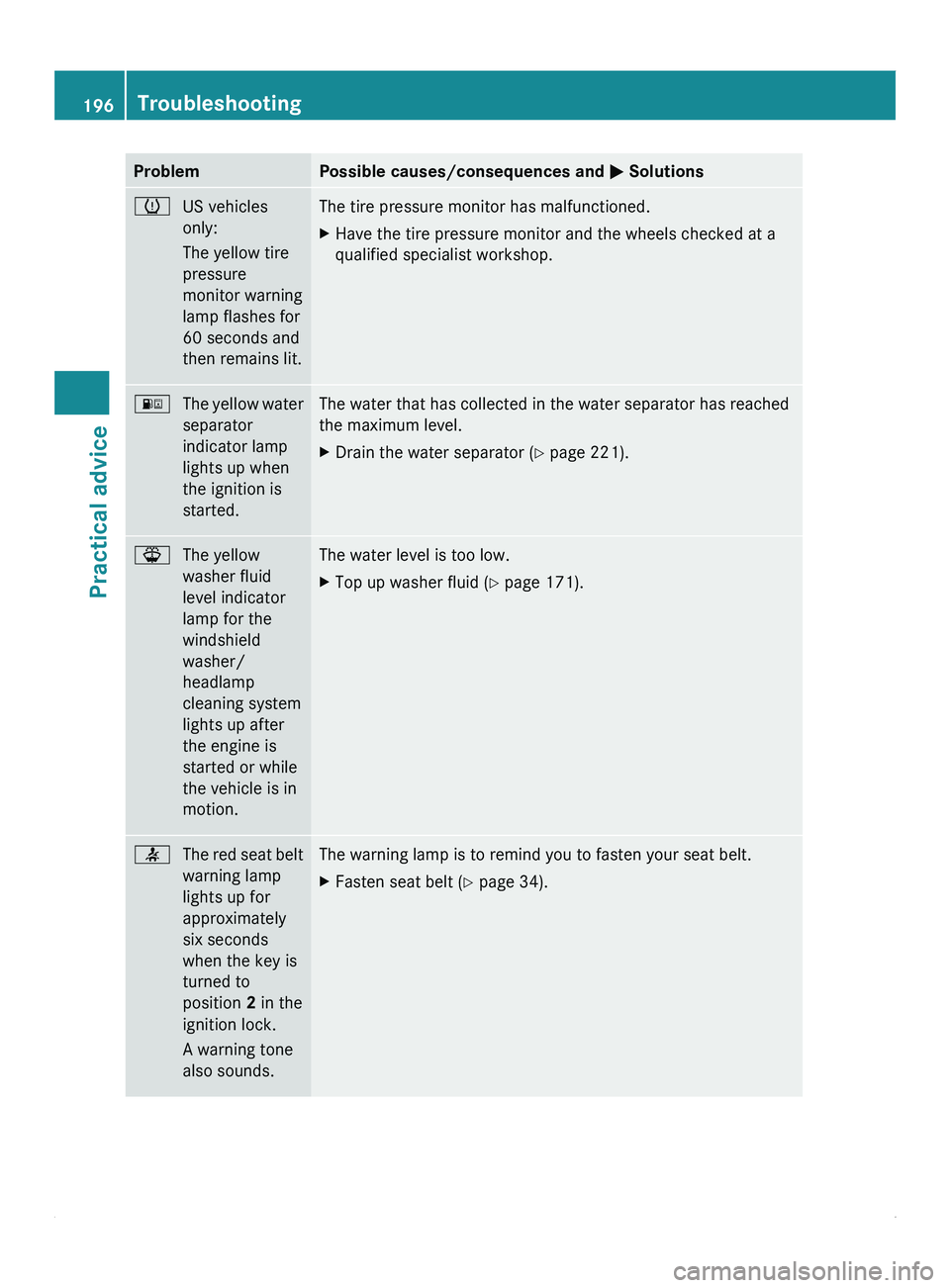

Problem Possible causes/consequences and

0050 Solutions0077

US vehicles

only:

The yellow tire

pressure

monitor warning

lamp flashes for

60 seconds and

then remains lit. The tire pressure monitor has malfunctioned.

X

Have the tire pressure monitor and the wheels checked at a

qualified specialist workshop. 00BA

The yellow water

separator

indicator lamp

lights up when

the ignition is

started. The water that has collected in the water separator has reached

the maximum level.

X

Drain the water separator ( Y page 221).00BD

The yellow

washer fluid

level indicator

lamp for the

windshield

washer/

headlamp

cleaning system

lights up after

the engine is

started or while

the vehicle is in

motion. The water level is too low.

X

Top up washer fluid ( Y page 171).0082

The red seat belt

warning lamp

lights up for

approximately

six seconds

when the key is

turned to

position 2 in the

ignition lock.

A warning tone

also sounds. The warning lamp is to remind you to fasten your seat belt.

X

Fasten seat belt (Y page 34).196

TroubleshootingPractical advice

Page 201 of 292

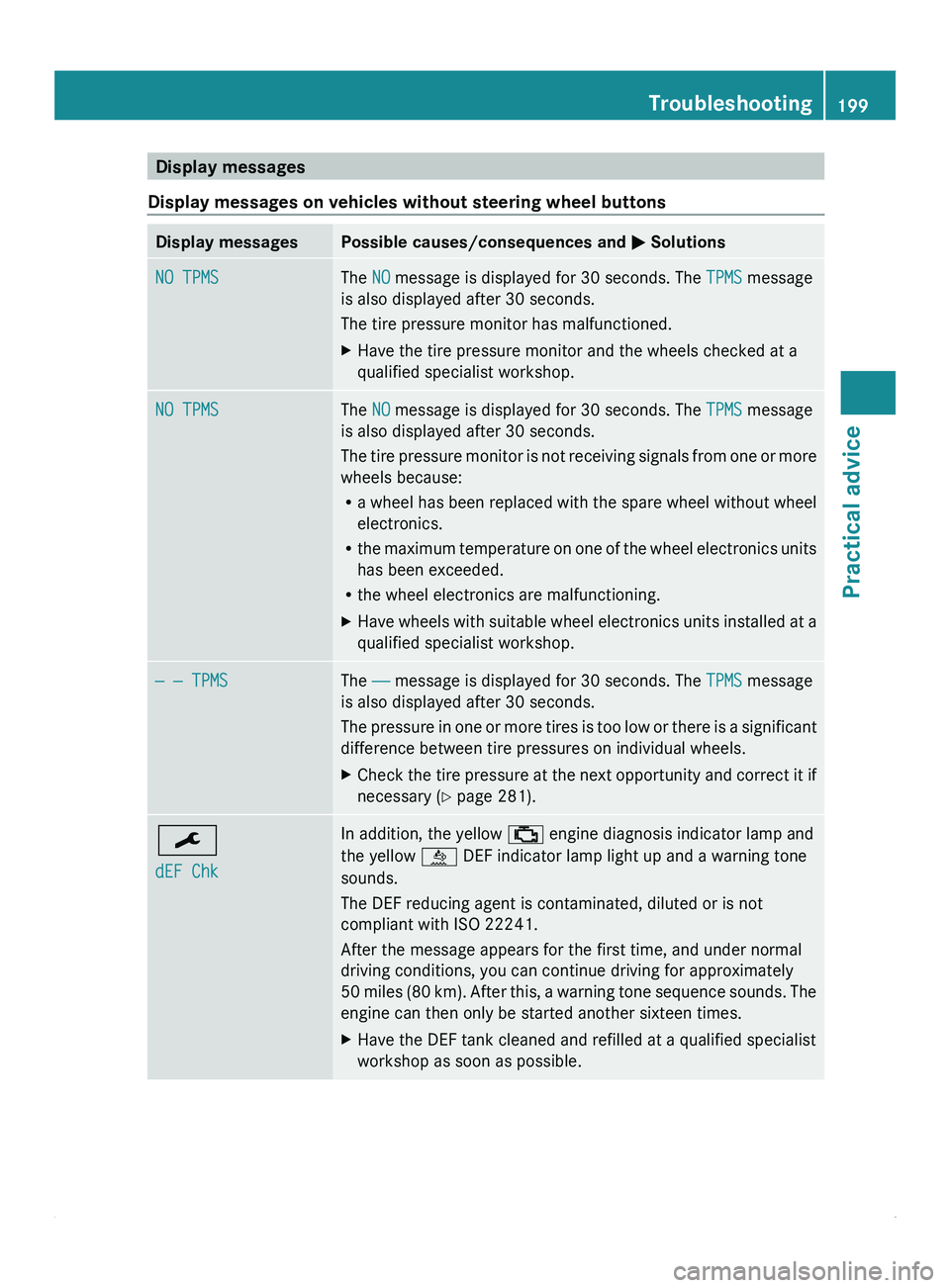

Display messages

Display messages on vehicles without steering wheel buttons Display messages Possible causes/consequences and

0050 SolutionsNO TPMS The NO message is displayed for 30 seconds. The

TPMS message

is also displayed after 30 seconds.

The tire pressure monitor has malfunctioned.

X Have the tire pressure monitor and the wheels checked at a

qualified specialist workshop. NO TPMS The NO message is displayed for 30 seconds. The

TPMS message

is also displayed after 30 seconds.

The tire pressure

monitor is not receiving signals from one or more

wheels because:

R a wheel has been replaced with the spare wheel without wheel

electronics.

R the maximum temperature on one of the wheel electronics units

has been exceeded.

R the wheel electronics are malfunctioning.

X Have wheels with suitable wheel electronics units installed at a

qualified specialist workshop. — — TPMS The ——

message is displayed for 30 seconds. The

TPMS message

is also displayed after 30 seconds.

The pressure in

one or more tires is too low or there is a significant

difference between tire pressures on individual wheels.

X Check the tire pressure at the next opportunity and correct it if

necessary ( Y page 281). 009B

dEF Chk In addition, the yellow

00BB engine diagnosis indicator lamp and

the yellow 00E4

DEF indicator lamp light up and a warning tone

sounds.

The DEF reducing agent is contaminated, diluted or is not

compliant with ISO 22241 .

After the message appears for the first time, and under normal

driving conditions, you can continue driving for approximately

50 miles

(80 km). After this, a warning tone sequence sounds. The

engine can then only be started another sixteen times.

X Have the DEF tank cleaned and refilled at a qualified specialist

workshop as soon as possible. Troubleshooting

199

Practical advice Z

Page 205 of 292

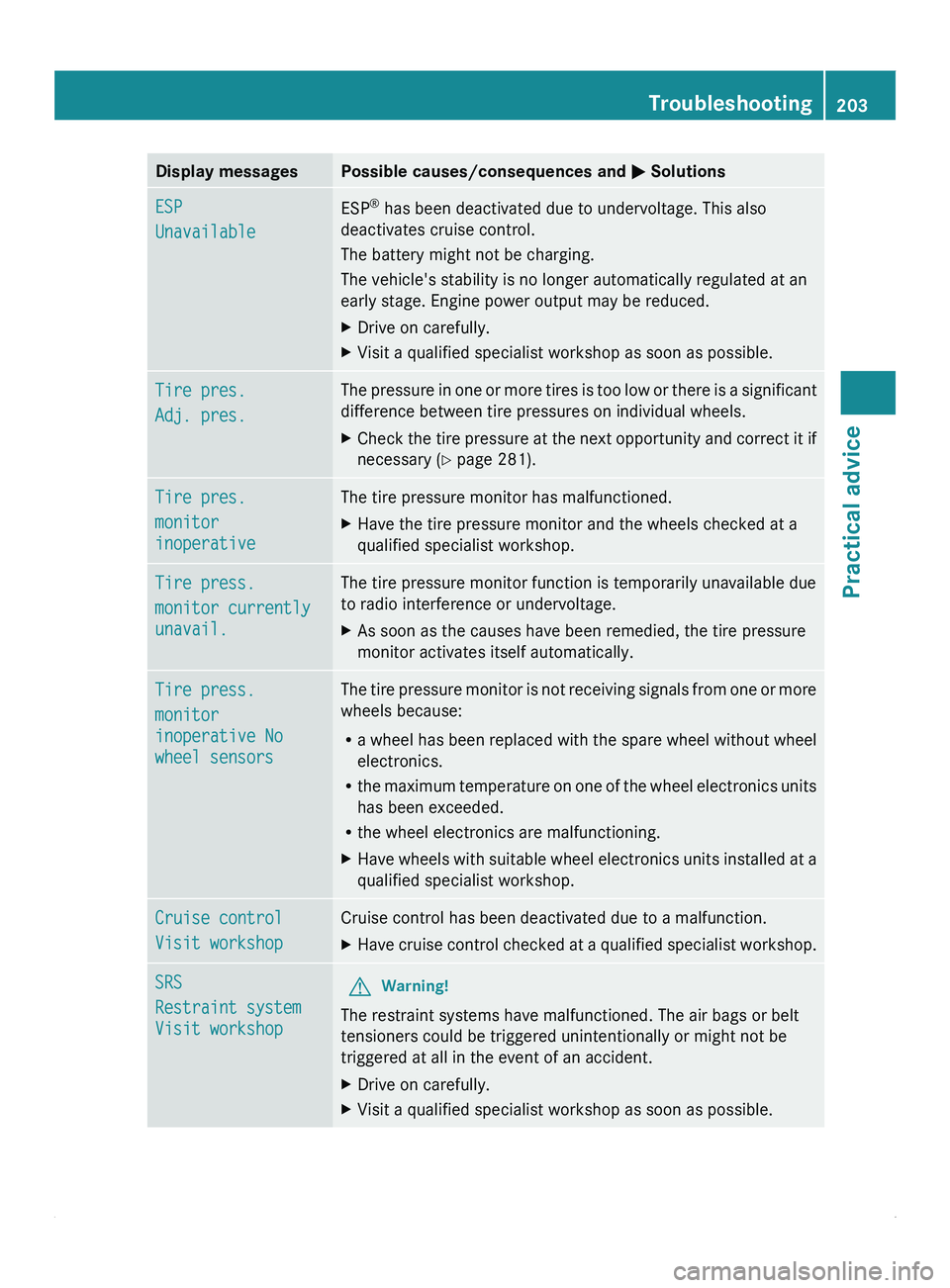

Display messages Possible causes/consequences and

0050 SolutionsESP

Unavailable

ESP

®

has been deactivated due to undervoltage. This also

deactivates cruise control.

The battery might not be charging.

The vehicle's stability is no longer automatically regulated at an

early stage. Engine power output may be reduced.

X Drive on carefully.

X Visit a qualified specialist workshop as soon as possible. Tire pres.

Adj. pres. The pressure in one or more tires is too low or there is a significant

difference between tire pressures on individual wheels.

X

Check the tire pressure at the next opportunity and correct it if

necessary ( Y page 281). Tire pres.

monitor

inoperative The tire pressure monitor has malfunctioned.

X

Have the tire pressure monitor and the wheels checked at a

qualified specialist workshop. Tire press.

monitor currently

unavail. The tire pressure monitor function is temporarily unavailable due

to radio interference or undervoltage.

X

As soon as the causes have been remedied, the tire pressure

monitor activates itself automatically. Tire press.

monitor

inoperative No

wheel sensors The tire pressure monitor is not receiving signals from one or more

wheels because:

R

a wheel has

been replaced with the spare wheel without wheel

electronics.

R the maximum temperature on one of the wheel electronics units

has been exceeded.

R the wheel electronics are malfunctioning.

X Have wheels with suitable wheel electronics units installed at a

qualified specialist workshop. Cruise control

Visit workshop Cruise control has been deactivated due to a malfunction.

X

Have cruise control checked at a qualified specialist workshop. SRS

Restraint system

Visit workshop

G

Warning!

The restraint systems have malfunctioned. The air bags or belt

tensioners could be triggered unintentionally or might not be

triggered at all in the event of an accident.

X Drive on carefully.

X Visit a qualified specialist workshop as soon as possible. Troubleshooting

203

Practical advice Z

Page 210 of 292

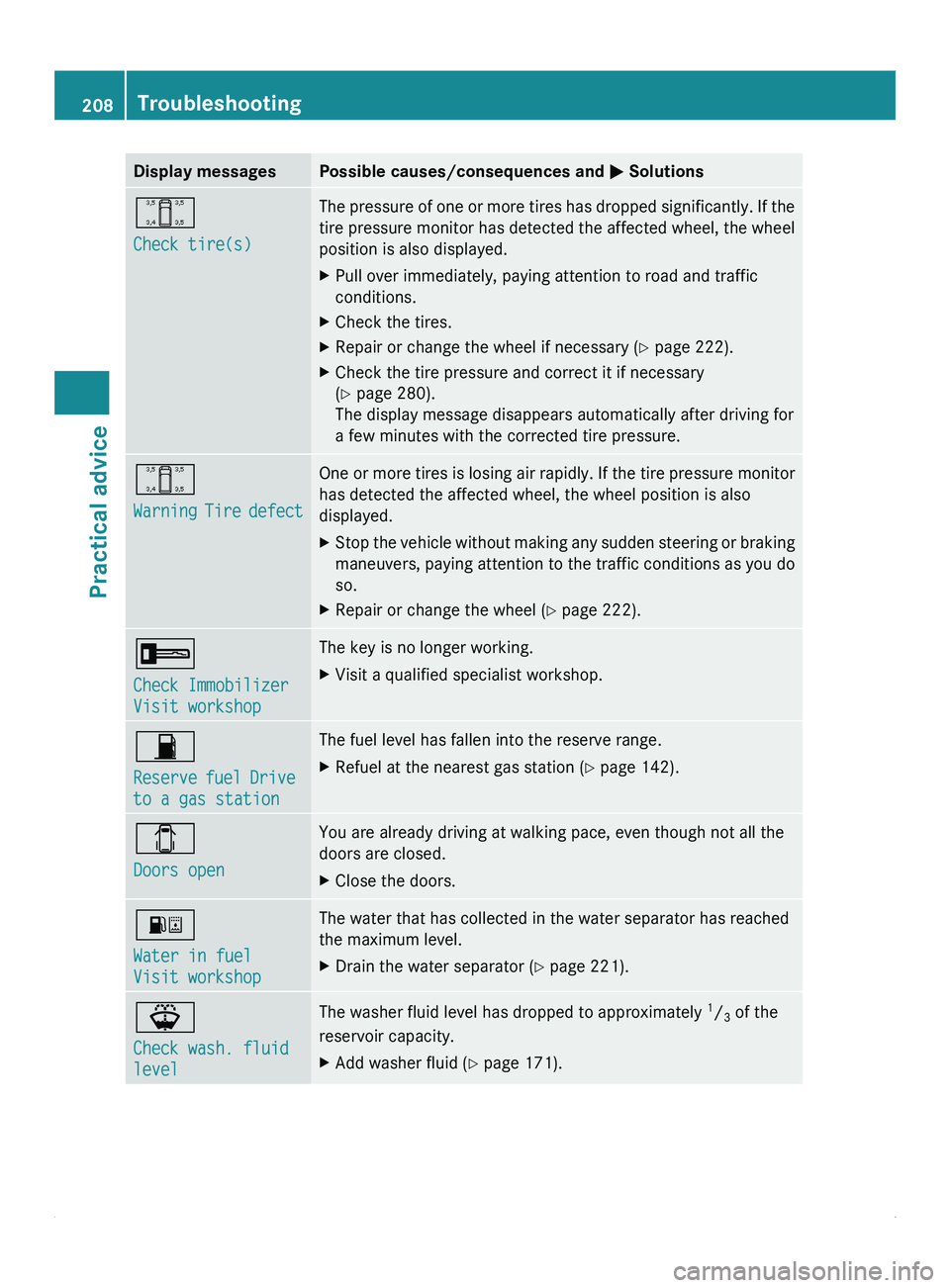

Display messages Possible causes/consequences and

0050 Solutions0063

Check tire(s) The pressure of one or more tires has dropped significantly. If the

tire pressure monitor

has detected the affected wheel, the wheel

position is also displayed.

X Pull over immediately, paying attention to road and traffic

conditions.

X Check the tires.

X Repair or change the wheel if necessary ( Y page 222).

X Check the tire pressure and correct it if necessary

(Y page 280).

The display message disappears automatically after driving for

a few minutes with the corrected tire pressure. 0063

Warning Tire

defect One or more tires is losing air rapidly. If the tire pressure monitor

has detected the affected wheel, the wheel position is also

displayed.

X

Stop the vehicle without making any sudden steering or braking

maneuvers, paying attention

to the traffic conditions as you do

so.

X Repair or change the wheel (Y page 222). 0039

Check Immobilizer

Visit workshop The key is no longer working.

X

Visit a qualified specialist workshop. 00B7

Reserve fuel

Drive

to a gas station The fuel level has fallen into the reserve range.

X

Refuel at the nearest gas station ( Y page 142).003E

Doors open You are already driving at walking pace, even though not all the

doors are closed.

X

Close the doors. 00BA

Water in fuel

Visit workshop The water that has collected in the water separator has reached

the maximum level.

X

Drain the water separator ( Y page 221).00BD

Check wash. fluid

level The washer fluid level has dropped to approximately

1

/ 3 of the

reservoir capacity.

X Add washer fluid ( Y page 171).208

Troubleshooting

Practical advice

Page 224 of 292

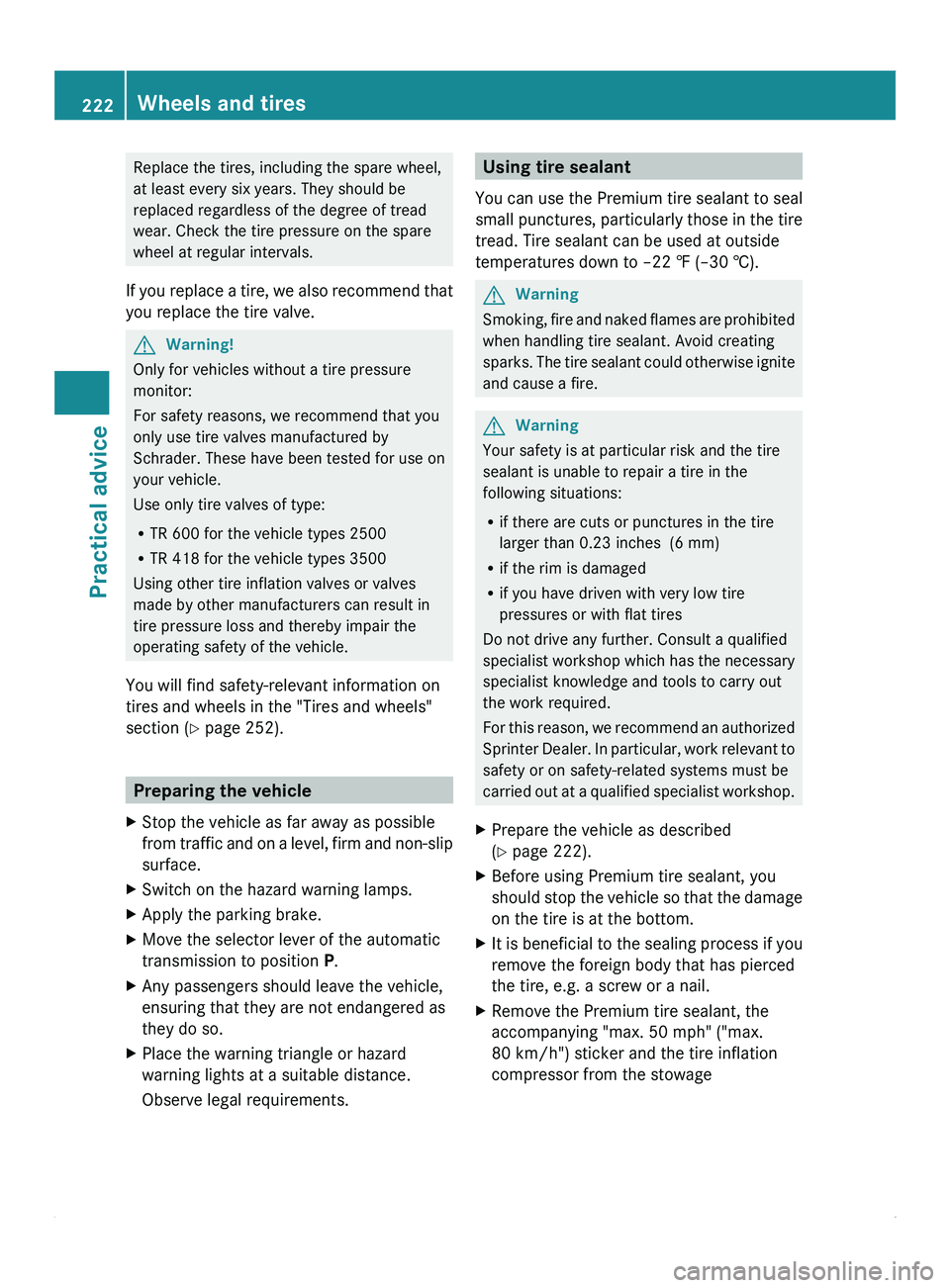

Replace the tires, including the spare wheel,

at least every six years. They should be

replaced regardless of the degree of tread

wear. Check the tire pressure on the spare

wheel at regular intervals.

If you replace

a tire, we also recommend that

you replace the tire valve. G

Warning!

Only for vehicles without a tire pressure

monitor:

For safety reasons, we recommend that you

only use tire valves manufactured by

Schrader. These have been tested for use on

your vehicle.

Use only tire valves of type:

R TR 600 for the vehicle types 2500

R TR 418 for the vehicle types 3500

Using other tire inflation valves or valves

made by other manufacturers can result in

tire pressure loss and thereby impair the

operating safety of the vehicle.

You will find safety-relevant information on

tires and wheels in the "Tires and wheels"

section ( Y page 252).Preparing the vehicle

X Stop the vehicle as far away as possible

from traffic and

on a level, firm and non-slip

surface.

X Switch on the hazard warning lamps.

X Apply the parking brake.

X Move the selector lever of the automatic

transmission to position P.

X Any passengers should leave the vehicle,

ensuring that they are not endangered as

they do so.

X Place the warning triangle or hazard

warning lights at a suitable distance.

Observe legal requirements. Using tire sealant

You can use

the Premium tire sealant to seal

small punctures, particularly those in the tire

tread. Tire sealant can be used at outside

temperatures down to –22 ‡ (–30 †). G

Warning

Smoking, fire

and naked flames are prohibited

when handling tire sealant. Avoid creating

sparks. The tire

sealant could otherwise ignite

and cause a fire. G

Warning

Your safety is at particular risk and the tire

sealant is unable to repair a tire in the

following situations:

R if there are cuts or punctures in the tire

larger than 0.23 inches (6 mm)

R if the rim is damaged

R if you have driven with very low tire

pressures or with flat tires

Do not drive any further. Consult a qualified

specialist workshop which

has the necessary

specialist knowledge and tools to carry out

the work required.

For this reason, we recommend an authorized

Sprinter Dealer. In particular, work relevant to

safety or on safety-related systems must be

carried out at a qualified specialist workshop.

X Prepare the vehicle as described

(Y page 222).

X Before using Premium tire sealant, you

should stop the

vehicle so that the damage

on the tire is at the bottom.

X It is beneficial to the sealing process if you

remove the foreign body that has pierced

the tire, e.g. a screw or a nail.

X Remove the Premium tire sealant, the

accompanying "max. 50 mph" ("max.

80 km/h") sticker and the tire inflation

compressor from the stowage222

Wheels and tires

Practical advice

Page 225 of 292

compartment in the right-hand doorway

(Y page 184).

X Affix the sticker within the driver's field of

vision. G

Warning

It is essential to comply with the

manufacturer's safety notice

on the sticker on

the electric air pump and the tire sealant

bottle. You could otherwise fail to recognize

dangers and injure yourself and others. G

Warning

Tire sealant must not come into contact with

your skin, eyes or clothing. Do not inhale the

fumes.

R If tire sealant

comes into contact with your

eyes or skin, immediately rinse thoroughly

with clean water.

R Immediately change out of clothing that

has been in contact with tire sealant.

R If an allergic reaction occurs, consult a

doctor immediately.

Keep tire sealant away from children.

R If tire sealant is swallowed, immediately

rinse your mouth out thoroughly and drink

plenty of water.

R Do not induce vomiting. Consult a doctor

immediately.

i The tire sealant is water-soluble. If tire

sealant escapes, you can wash it away with

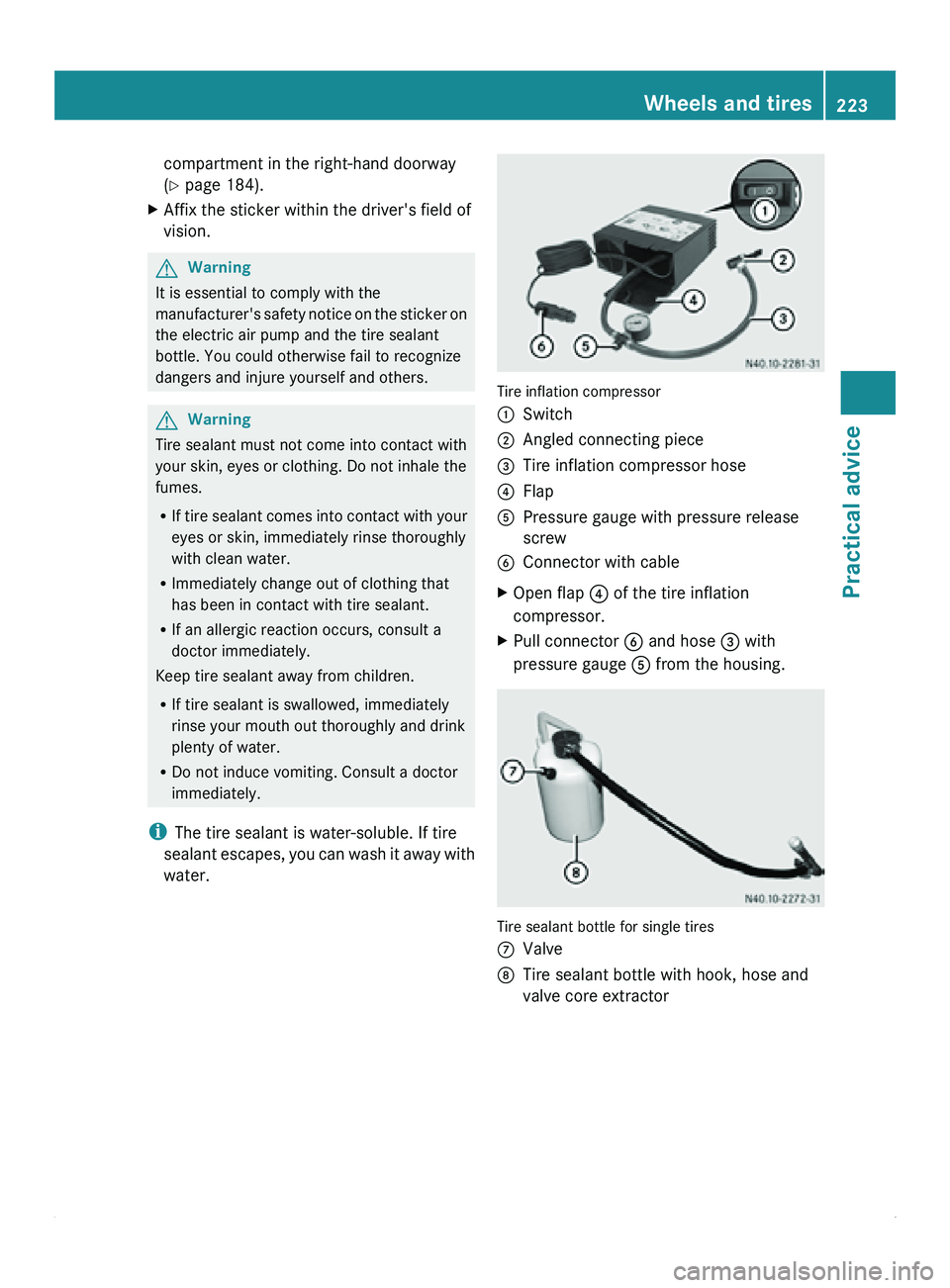

water. Tire inflation compressor

0046

Switch

0047 Angled connecting piece

008A Tire inflation compressor hose

0088 Flap

0086 Pressure gauge with pressure release

screw

0087 Connector with cable

X Open flap 0088 of the tire inflation

compressor.

X Pull connector 0087 and hose 008A with

pressure gauge 0086 from the housing. Tire sealant bottle for single tires

006E

Valve

006F Tire sealant bottle with hook, hose and

valve core extractor Wheels and tires

223

Practical advice Z

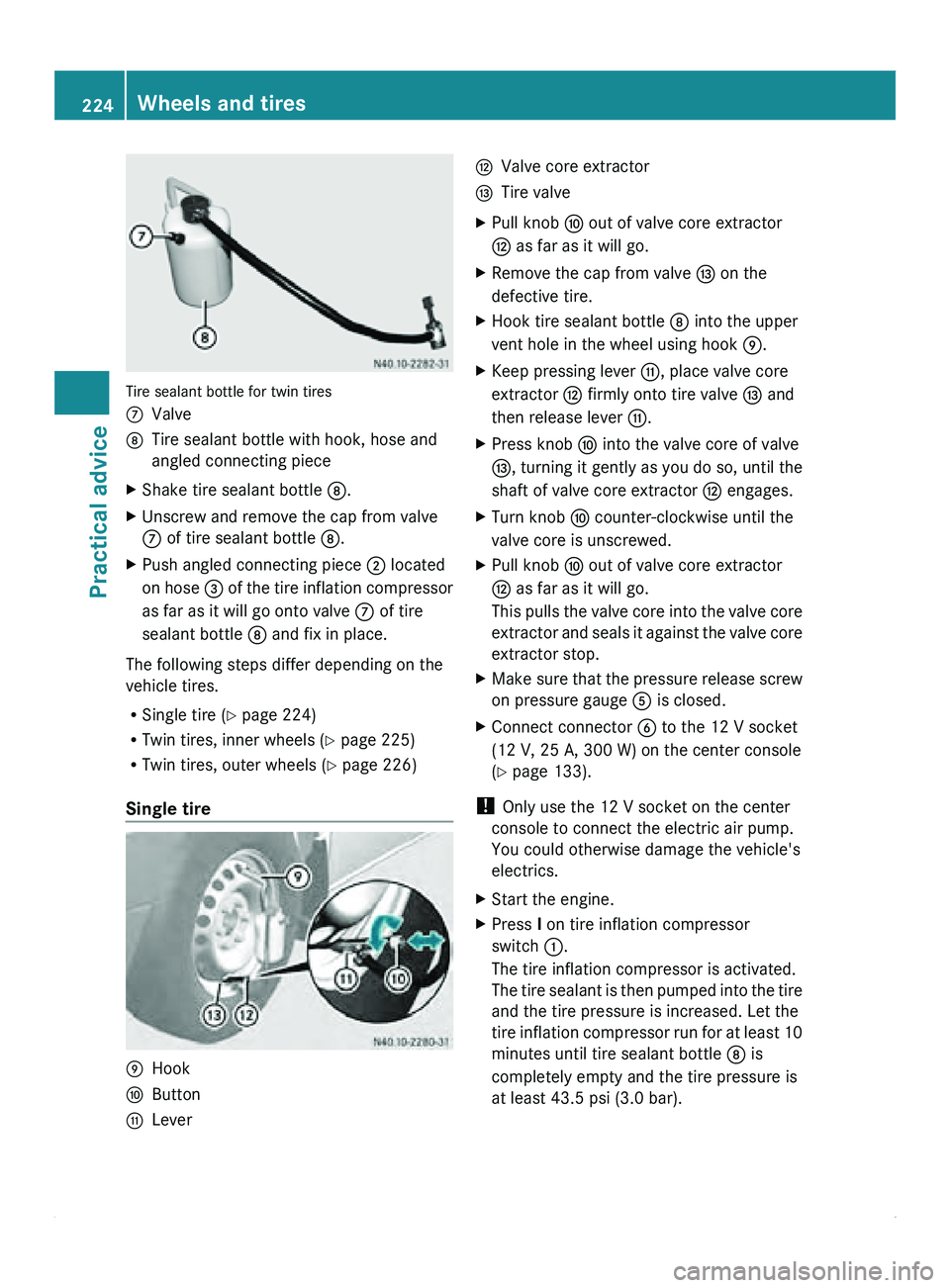

Page 226 of 292

Tire sealant bottle for twin tires

006E

Valve

006F Tire sealant bottle with hook, hose and

angled connecting piece

X Shake tire sealant bottle 006F.

X Unscrew and remove the cap from valve

006E of tire sealant bottle 006F.

X Push angled connecting piece 0047 located

on hose 008A

of the tire inflation compressor

as far as it will go onto valve 006E of tire

sealant bottle 006F and fix in place.

The following steps differ depending on the

vehicle tires.

R Single tire (Y page 224)

R Twin tires, inner wheels ( Y page 225)

R Twin tires, outer wheels (

Y page 226)

Single tire 0070

Hook

0071 Button

0072 Lever 0073

Valve core extractor

0074 Tire valve

X Pull knob 0071 out of valve core extractor

0073 as far as it will go.

X Remove the cap from valve 0074 on the

defective tire.

X Hook tire sealant bottle 006F into the upper

vent hole in the wheel using hook 0070.

X Keep pressing lever 0072, place valve core

extractor 0073 firmly onto tire valve 0074 and

then release lever 0072.

X Press knob 0071 into the valve core of valve

0074, turning it gently as you do so, until the

shaft of valve core extractor 0073 engages.

X Turn knob 0071 counter-clockwise until the

valve core is unscrewed.

X Pull knob 0071 out of valve core extractor

0073 as far as it will go.

This pulls

the

valve core into the valve core

extractor and seals it against the valve core

extractor stop.

X Make sure that the pressure release screw

on pressure gauge 0086 is closed.

X Connect connector 0087 to the 12 V socket

(12 V, 25 A, 300 W) on the center console

(Y page 133).

! Only use the 12 V socket on the center

console to connect the electric air pump.

You could otherwise damage the vehicle's

electrics.

X Start the engine.

X Press I on tire inflation compressor

switch 0046.

The tire inflation compressor is activated.

The tire sealant

is then pumped into the tire

and the tire pressure is increased. Let the

tire inflation compressor run for at least 10

minutes until tire sealant bottle 006F is

completely empty and the tire pressure is

at least 43.5 psi (3.0 bar). 224

Wheels and tires

Practical advice

Page 227 of 292

!

Do not run

the electric air pump for longer

than 20 minutes without a break; otherwise

it may overheat.

The air pump can be used again once it has

cooled down.

X Inflate the tire using the tire inflation

compressor until the recommended tire

pressure ( Y page 281) is reached.

X Then, press 0 on tire inflation compressor

switch 0046.

The tire inflation compressor is

deactivated.

X Slide knob 0071 quickly to the stop in valve

core extractor 0073.

X Turn knob 0071 clockwise

until

the valve core

is firmly screwed into tire valve 0074.

i Do not pull the valve core extractor from

the tire valve while the valve core is

unscrewed from

the

tire valve. Tire sealant

could otherwise escape and make you

dirty.

The tire sealant is water-soluble. If tire

sealant escapes, you can wash it away with

water.

X Press lever 0072 and pull

valve core extractor

0073 from tire valve 0074.

X Screw the valve cap onto tire valve 0074.

After filling with tire sealant, ( Y page 228).

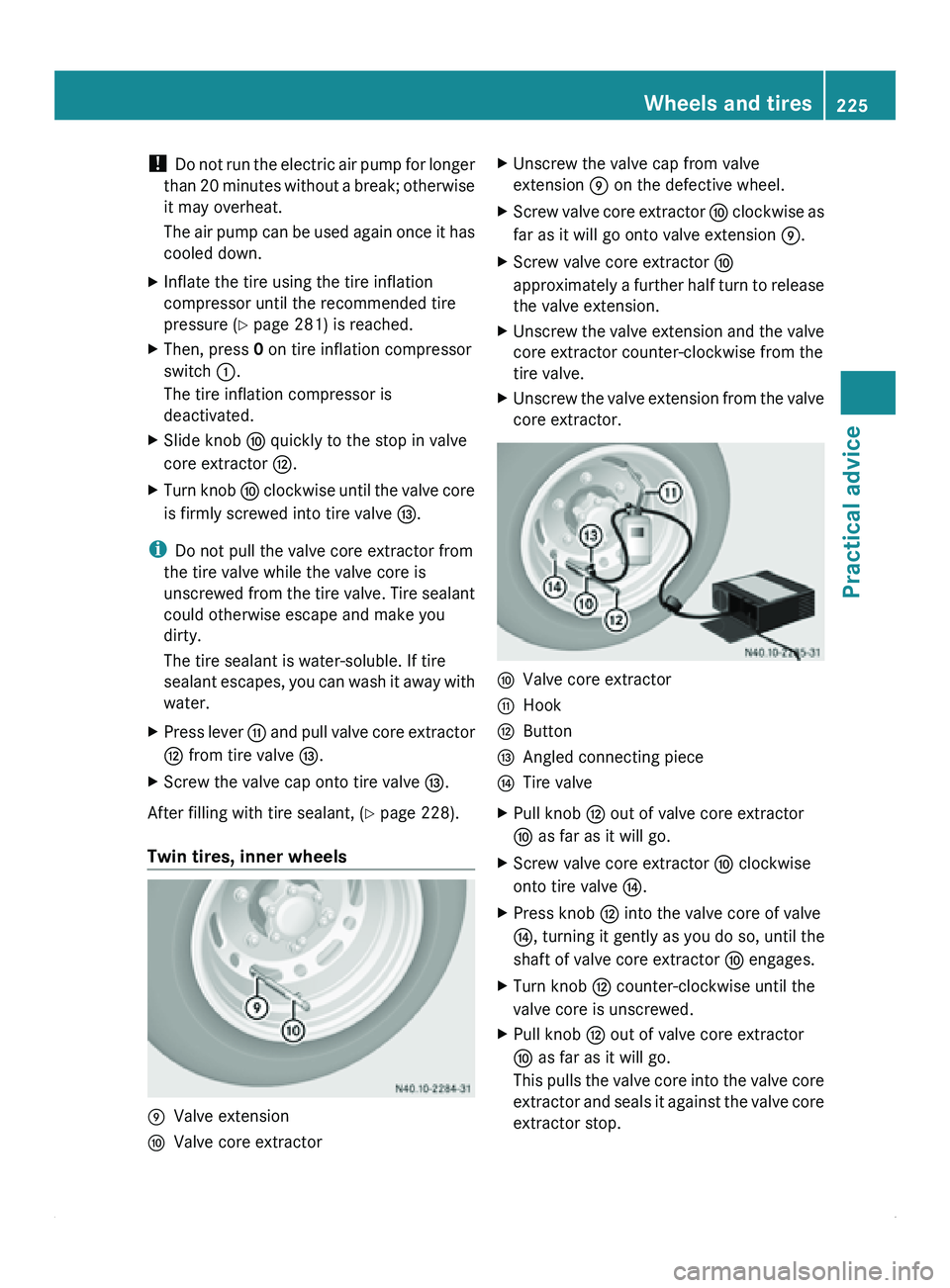

Twin tires, inner wheels 0070

Valve extension

0071 Valve core extractor X

Unscrew the valve cap from valve

extension 0070 on the defective wheel.

X Screw valve core extractor 0071

clockwise as

far as it will go onto valve extension 0070

.

X Screw valve core extractor 0071

approximately a

further

half turn to release

the valve extension.

X Unscrew the valve extension and the valve

core extractor counter-clockwise from the

tire valve.

X Unscrew the valve extension from the valve

core extractor. 0071

Valve core extractor

0072 Hook

0073 Button

0074 Angled connecting piece

0075 Tire valve

X Pull knob 0073 out of valve core extractor

0071 as far as it will go.

X Screw valve core extractor 0071 clockwise

onto tire valve 0075.

X Press knob 0073 into the valve core of valve

0075, turning it gently as you do so, until the

shaft of valve core extractor 0071 engages.

X Turn knob 0073 counter-clockwise until the

valve core is unscrewed.

X Pull knob 0073 out of valve core extractor

0071 as far as it will go.

This pulls

the

valve core into the valve core

extractor and seals it against the valve core

extractor stop. Wheels and tires

225

Practical advice Z

Page 228 of 292

X

Hook tire sealant bottle 006F into the upper

vent hole in the wheel using hook 0072.

X Push angled connecting piece 0074 located

on the hose of tire sealant filler bottle 006F

as far

as

it will go on to valve core extractor

0071 and fix it in place.

X Make sure that the pressure release screw

on pressure gauge 0086 is closed.

X Connect connector 0087 to the 12 V socket

(12 V, 25 A, 300 W) on the center console

(Y page 133).

! Only use the 12 V socket on the center

console to connect the electric air pump.

You could otherwise damage the vehicle's

electrics.

X Start the engine.

X Press I on tire inflation compressor

switch 0046.

The tire inflation compressor is activated.

The tire

sealant

is then pumped into the tire

and the tire pressure is increased. Let the

tire inflation compressor run for at least 10

minutes until tire sealant bottle 006F is

completely empty and the tire pressure is

at least 43.5 psi (3.0 bar).

! Do not

run

the electric air pump for longer

than 20 minutes without a break; otherwise

it may overheat.

The air pump can be used again once it has

cooled down.

X Inflate the tire using the tire inflation

compressor until the recommended tire

pressure ( Y page 281) is reached.

X Then, press 0 on tire inflation compressor

switch 0046.

The tire inflation compressor is

deactivated.

X Slide knob 0073 quickly to the stop in valve

core extractor 0071.

X Turn knob 0073 clockwise

until

the valve core

is firmly screwed into tire valve 0075.i

Do not pull the valve core extractor from

the tire valve while the valve core is

unscrewed from the

tire valve. Tire sealant

could otherwise escape and make you

dirty.

The tire sealant is water-soluble. If tire

sealant escapes, you can wash it away with

water.

X Pull knob 0073 out of valve core extractor

0071 as far as it will go.

X Unscrew valve core extractor 0071 counter-

clockwise from tire valve 0075.

X Screw valve extension 0070 onto tire valve

0075 and tighten it.

X Screw the valve cap onto valve extension

0070.

After filling with tire sealant, ( Y page 228).

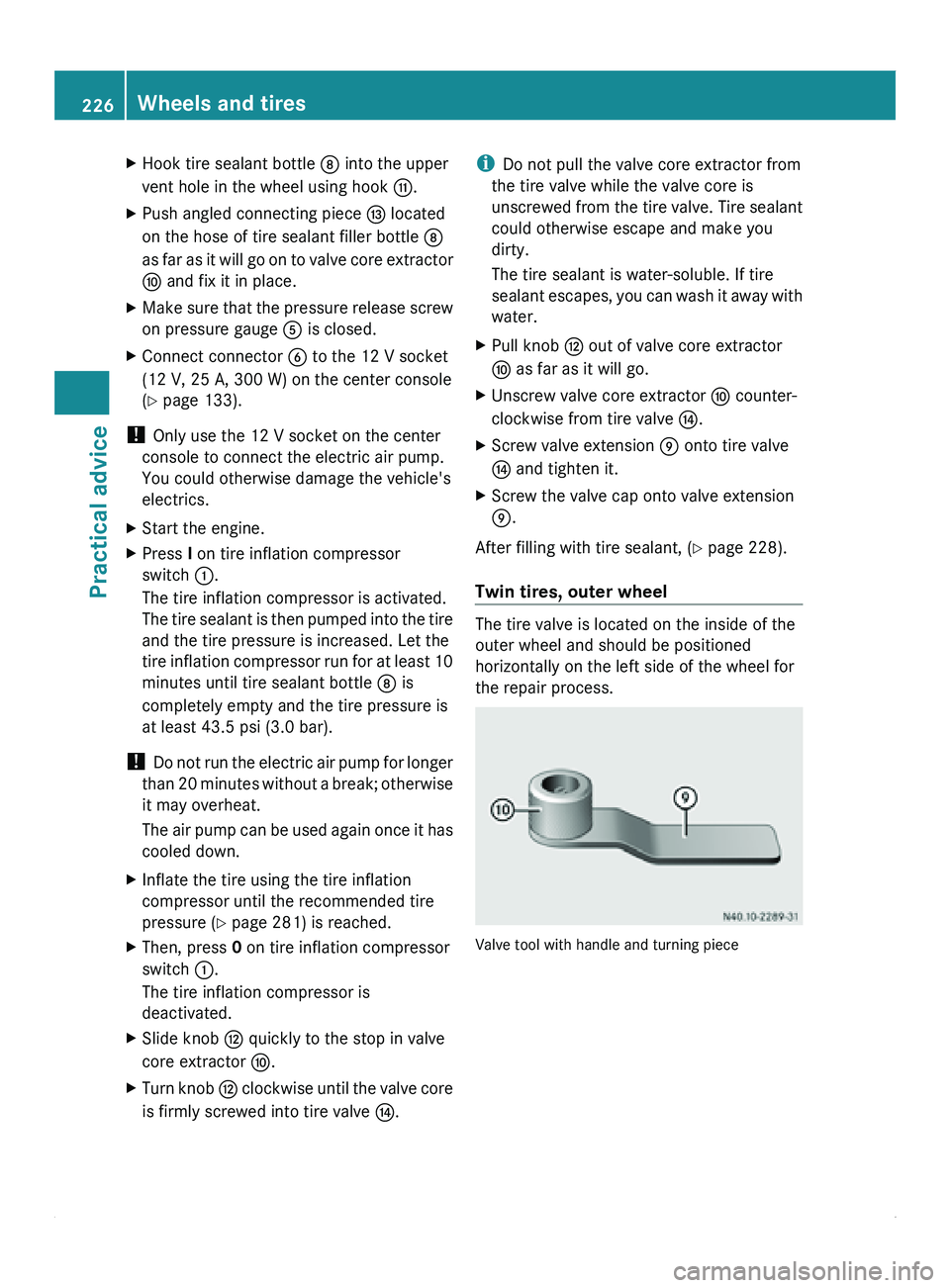

Twin tires, outer wheel The tire valve is located on the inside of the

outer wheel and should be positioned

horizontally on the left side of the wheel for

the repair process.

Valve tool with handle and turning piece226

Wheels and tires

Practical advice