change wheel MERCEDES-BENZ SPRINTER 2012 MY12 Operator’s Manual

[x] Cancel search | Manufacturer: MERCEDES-BENZ, Model Year: 2012, Model line: SPRINTER, Model: MERCEDES-BENZ SPRINTER 2012Pages: 292, PDF Size: 6.75 MB

Page 218 of 292

Problem Possible causes/consequences and

0050 SolutionsThe PARKTRONIC

warning displays

implausible distances.

For example, all the

segments may be lit

even though there

is no

obstacle present. The license plate or other parts attached near the sensors may

not be secured correctly.

X

Check the license plate and attachment parts near the sensors

for correct seating. The speed cannot be

set when cruise

control

is activated 9

. The display is showing a message of high priority and cannot

therefore show a change in speed.

X

Proceed as instructed by the message in the display.

X Deactivate cruise control White stripes appear on

the rear view camera's

monitor display or the

picture flickers. The rear view camera is exposed to very bright white light or

fluorescent light.

X

Check whether the rear view camera works at another location. The rear view camera is

functioning incorrectly

or not at all. R

The surrounding area is very dark.

R The outside temperature has changed rapidly or is very high.

R The camera lens is dirty or obstructed.

X Check the rear view camera and clean the camera lens if

necessary ( Y page 163).Auxiliary heating

G

Warning

The operating safety of the vehicle can be compromised if maintenance work is carried out

incorrectly. In particular, work that is carried out incorrectly on the heater jeopardizes its

operating safety. This

could cause you to lose control of the vehicle and cause an accident. The

safety systems may also not be able to protect you or others as they are designed to do.

Always have maintenance work carried out at a qualified specialist workshop. The qualified

specialist workshop must have the necessary specialist knowledge and tools to carry out the

work required. We recommend that you use an authorized Sprinter Dealer for this purpose. In

particular, work relevant to safety or on safety-related systems must be carried out at a qualified

specialist workshop.

9 Only on vehicles with steering wheel buttons.216

Troubleshooting

Practical advice

Page 223 of 292

Engine

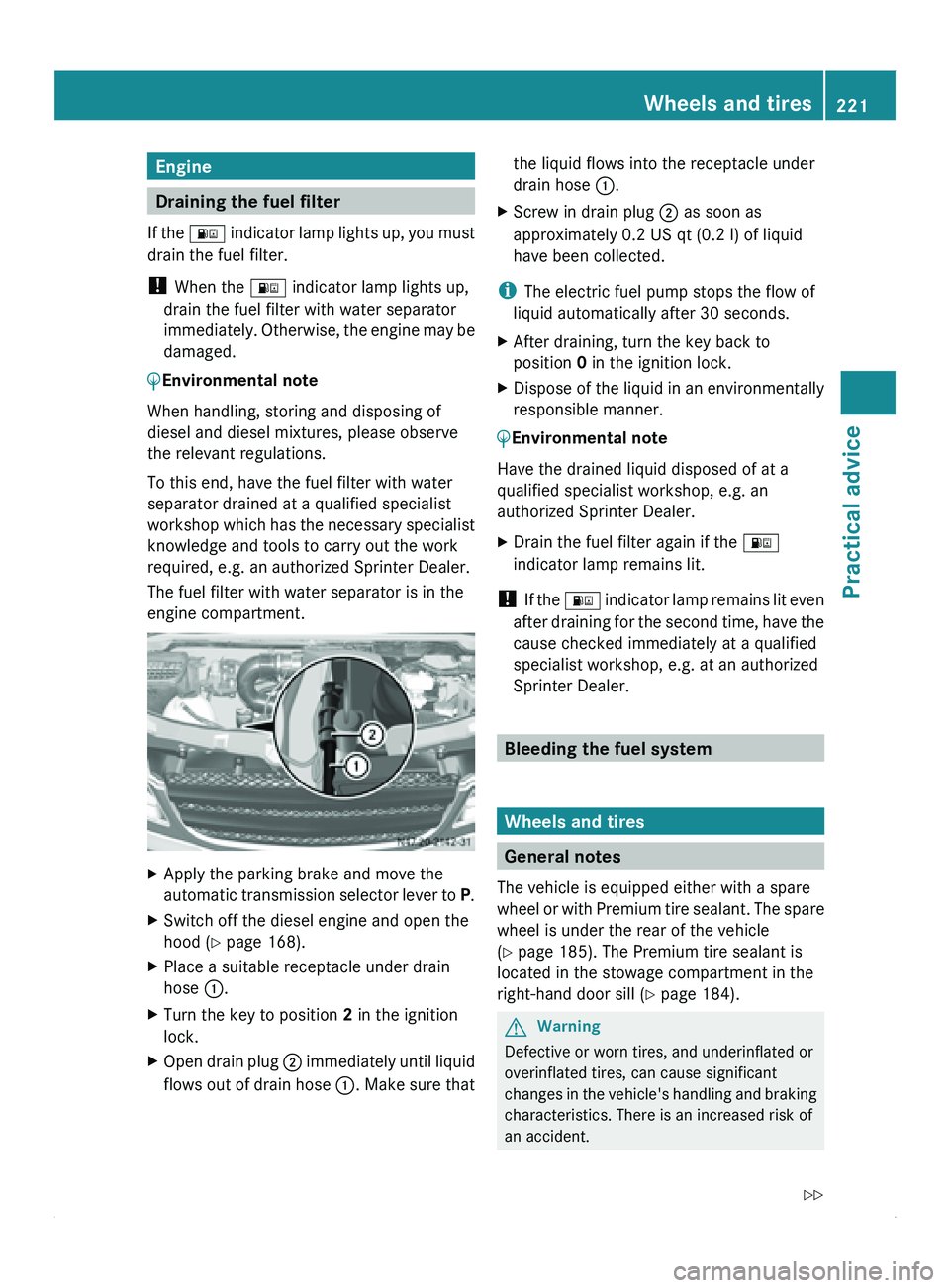

Draining the fuel filter

If the 00BA

indicator lamp lights up, you must

drain the fuel filter.

! When the 00BA indicator lamp lights up,

drain the fuel filter with water separator

immediately. Otherwise, the engine may be

damaged.

0040Environmental note

When handling, storing and disposing of

diesel and diesel mixtures, please observe

the relevant regulations.

To this end, have the fuel filter with water

separator drained at a qualified specialist

workshop which

has

the necessary specialist

knowledge and tools to carry out the work

required, e.g. an authorized Sprinter Dealer.

The fuel filter with water separator is in the

engine compartment. X

Apply the parking brake and move the

automatic

transmission selector

lever to P.

X Switch off the diesel engine and open the

hood ( Y page 168).

X Place a suitable receptacle under drain

hose 0046.

X Turn the key to position 2 in the ignition

lock.

X Open drain plug 0047

immediately until

liquid

flows out of drain hose 0046. Make sure that the liquid flows into the receptacle under

drain hose

0046.

X Screw in drain plug 0047 as soon as

approximately 0.2 US qt (0.2 l) of liquid have been collected.

i The electric fuel pump stops the flow of

liquid automatically after 30 seconds.

X After draining, turn the key back to

position

0 in the ignition lock.

X Dispose of the liquid in an environmentally

responsible manner.

0040Environmental note

Have the drained liquid disposed of at a

qualified specialist workshop, e.g. an

authorized Sprinter Dealer.

X Drain the fuel filter again if the 00BA

indicator lamp remains lit.

! If the

00BA

indicator lamp remains lit even

after draining for the second time, have the

cause checked immediately at a qualified

specialist workshop, e.g. at an authorized

Sprinter Dealer. Bleeding the fuel system

Wheels and tires

General notes

The vehicle is equipped either with a spare

wheel or with

Premium tire sealant. The spare

wheel is under the rear of the vehicle

(Y page 185). The Premium tire sealant is

located in the stowage compartment in the

right-hand door sill ( Y page 184). G

Warning

Defective or worn tires, and underinflated or

overinflated tires, can cause significant

changes in the

vehicle's handling and braking

characteristics. There is an increased risk of

an accident. Wheels and tires

221

Practical advice

Z

Page 225 of 292

compartment in the right-hand doorway

(Y page 184).

X Affix the sticker within the driver's field of

vision. G

Warning

It is essential to comply with the

manufacturer's safety notice

on the sticker on

the electric air pump and the tire sealant

bottle. You could otherwise fail to recognize

dangers and injure yourself and others. G

Warning

Tire sealant must not come into contact with

your skin, eyes or clothing. Do not inhale the

fumes.

R If tire sealant

comes into contact with your

eyes or skin, immediately rinse thoroughly

with clean water.

R Immediately change out of clothing that

has been in contact with tire sealant.

R If an allergic reaction occurs, consult a

doctor immediately.

Keep tire sealant away from children.

R If tire sealant is swallowed, immediately

rinse your mouth out thoroughly and drink

plenty of water.

R Do not induce vomiting. Consult a doctor

immediately.

i The tire sealant is water-soluble. If tire

sealant escapes, you can wash it away with

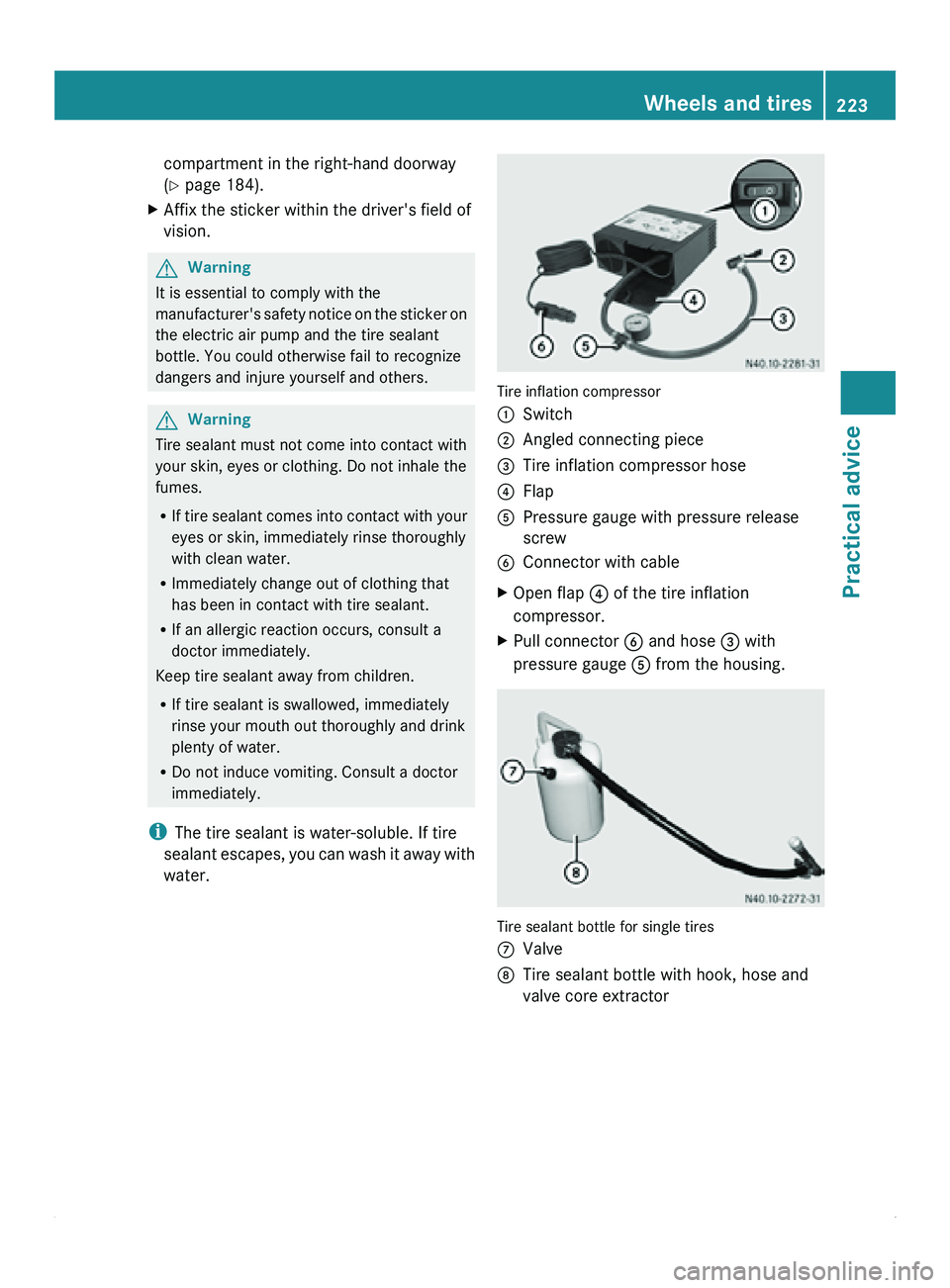

water. Tire inflation compressor

0046

Switch

0047 Angled connecting piece

008A Tire inflation compressor hose

0088 Flap

0086 Pressure gauge with pressure release

screw

0087 Connector with cable

X Open flap 0088 of the tire inflation

compressor.

X Pull connector 0087 and hose 008A with

pressure gauge 0086 from the housing. Tire sealant bottle for single tires

006E

Valve

006F Tire sealant bottle with hook, hose and

valve core extractor Wheels and tires

223

Practical advice Z

Page 231 of 292

G

Warning

If the minimum tire pressure of 43.5 psi

(3 bar) still cannot

be achieved, the tire is too

badly damaged.

Do not drive any further. Consult a qualified

specialist workshop which has the necessary

specialist knowledge and tools to carry out

the work required.

For this reason, we recommend an authorized

Sprinter Dealer. In particular, work relevant to

safety or on safety-related systems must be

carried out at a qualified specialist workshop.

0040Environmental note

Have the used tire sealant disposed of at a

qualified specialist workshop, e.g. an

authorized Sprinter Dealer.

! Have the tire sealant bottle replaced

every eight years at a qualified specialist

workshop, e.g. an authorized Sprinter

Dealer. Changing a

wheel in the event of a flat

tire G

Warning

To avoid the risk of serious or even fatal injury

and to avoid damage to the vehicle, observe

the following:

R the vehicle's jack is intended only to raise

the vehicle for

a short time when changing

a wheel.

R position the jack on the appropriate jacking

point only. Make sure that the jack is

correctly positioned under the jacking point

before raising the vehicle.

R the jack must be placed on a firm, flat

surface.

R before raising the vehicle, you should also

secure it against rolling away, e.g. by

placing chocks under the wheels. Never

release the parking brake while the vehicle

is raised. R

make sure that the distance between the

underside

of the

tires and the ground does

not exceed 1.2 in (3 cm). The vehicle could

otherwise slip off the jack or tip over.

R never place your hands or feet under the

raised vehicle.

R never start the engine, and prevent other

jolts or vibrations while the vehicle is

raised. The vehicle could otherwise slip off

the jack.

Preparing to change a wheel X

Prepare the vehicle as described

(Y

page 222).

X Secure the vehicle against rolling away

using chocks or similar items.

Use the chock ( Y

page 183) to do so. G

Warning

The vehicle

could slip off the jack on uphill and

downhill gradients.

To avoid the risk of causing serious or even

fatal injury or damage to the vehicle, do not

change wheels on uphill and downhill

gradients.

On a level road:

X Place chocks in front of and behind the

wheel which is diagonally opposite the

wheel you wish to change.

X Take the vehicle tool kit and the jack from

the footwell on the co-driver's side

(Y page 182).

X Remove the spare wheel from the spare

wheel bracket ( Y page 185).

X On wheels with wheel bolts, remove the

hub cap.

X Assemble the lug wrench extension using

the middle rod

and the rod with the largest

diameter from the three-piece jack pump

lever.

X Starting with the middle rod, slide the lug

wrench extension as far as it will go onto

the lug wrench. Wheels and tires

229

Practical advice Z

Page 232 of 292

!

Only use the jack pump lever middle rod

and the rod with the largest diameter as a

lug wrench extension.

Only slide the middle

rod as far as it will go onto the lug wrench.

The rods may otherwise bend and be

distorted to such an extent that they can

no longer be used as a pump lever for the

jack. X

Loosen the wheel nuts or wheel bolts on

the wheel to

be changed by about one turn

using extended lug wrench 0046. Do not

unscrew the wheel bolts or wheel nuts

completely.

Hydraulic jack X

Insert the third rod of the jack pump lever

into the lug wrench extension.

The jack pump lever is assembled. X

Close pressure release screw 0047.

X To do this, use the flattened section on

pump lever 0046 to turn pressure release

screw 0047 clockwise to the stop. i

Never turn pressure release screw 0047

more than 1 or 2 full turns. Hydraulic fluid

could otherwise escape.

X Insert pump lever 0046 into the

recess on the

jack and secure by turning it clockwise.

X Make sure that the jack is positioned

directly under the

jacking points described

below.

X Raise the vehicle by pumping the lever until

the wheel is raised clear of the ground.

Make sure that the distance between the

underside of the

tires and the ground does

not exceed 1.2 in (3 cm).

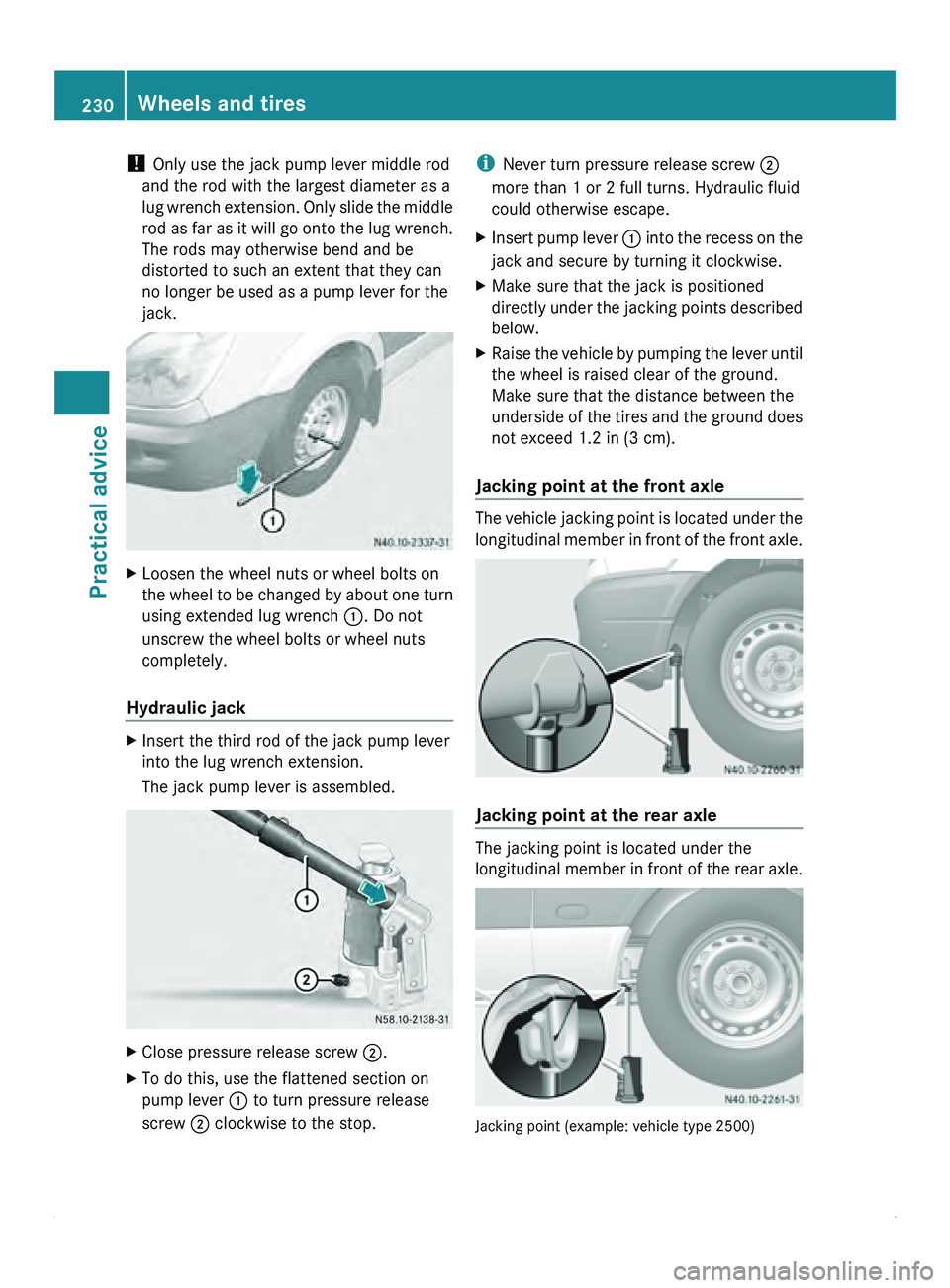

Jacking point at the front axle The vehicle jacking point is located under the

longitudinal member

in

front of the front axle. Jacking point at the rear axle

The jacking point is located under the

longitudinal member

in

front of the rear axle. Jacking point (example: vehicle type 2500)230

Wheels and tires

Practical advice

Page 233 of 292

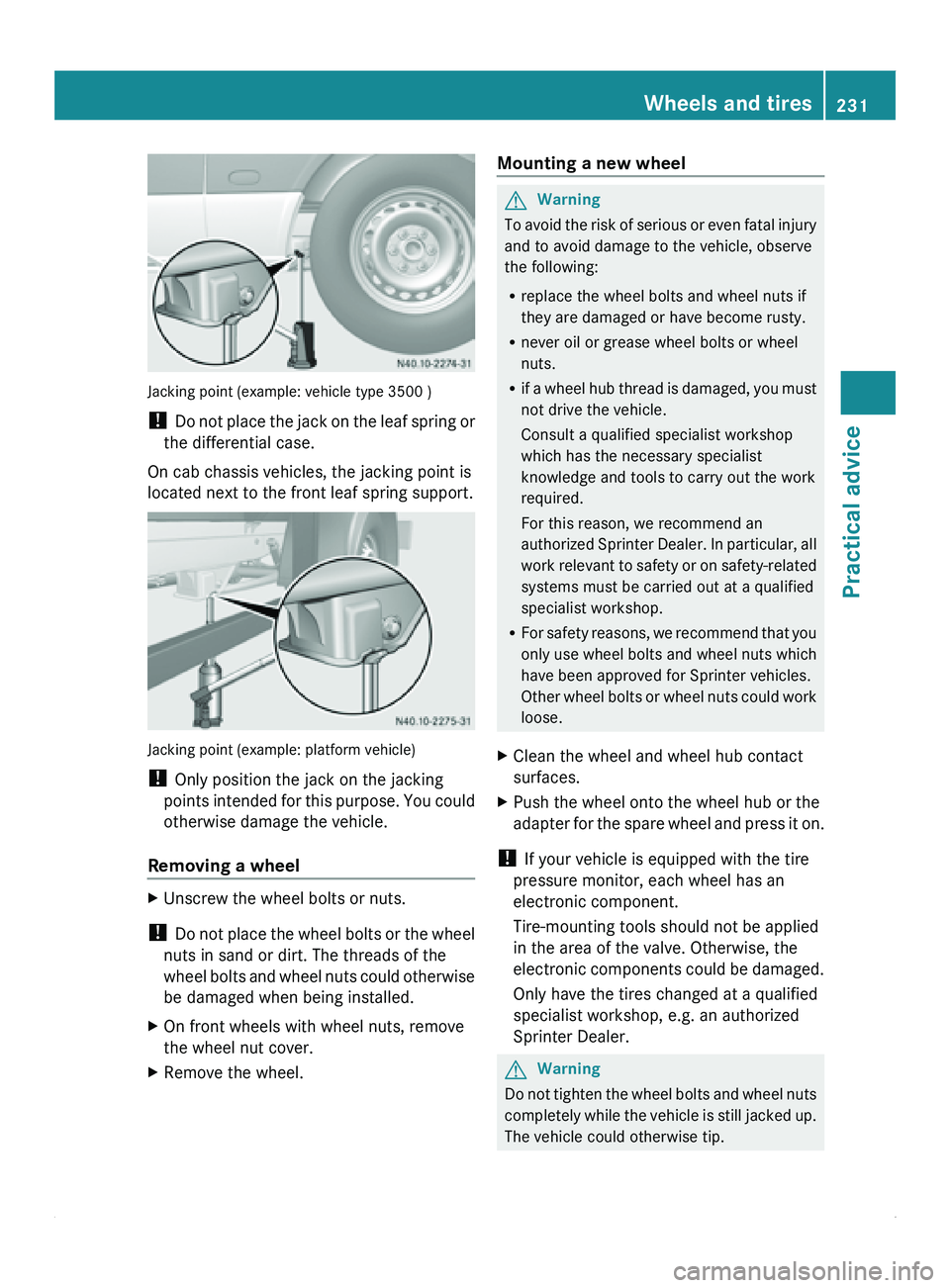

Jacking point (example: vehicle type 3500 )

!

Do not place

the jack on the leaf spring or

the differential case.

On cab chassis vehicles, the jacking point is

located next to the front leaf spring support. Jacking point (example: platform vehicle)

!

Only position the jack on the jacking

points intended for

this purpose. You could

otherwise damage the vehicle.

Removing a wheel X

Unscrew the wheel bolts or nuts.

! Do not place

the wheel bolts or the wheel

nuts in sand or dirt. The threads of the

wheel bolts and wheel nuts could otherwise

be damaged when being installed.

X On front wheels with wheel nuts, remove

the wheel nut cover.

X Remove the wheel. Mounting a new wheel G

Warning

To avoid the risk of serious or even fatal injury

and to avoid damage to the vehicle, observe

the following:

R replace the wheel bolts and wheel nuts if

they are damaged or have become rusty.

R never oil or grease wheel bolts or wheel

nuts.

R if a wheel

hub thread is damaged, you must

not drive the vehicle.

Consult a qualified specialist workshop

which has the necessary specialist

knowledge and tools to carry out the work

required.

For this reason, we recommend an

authorized Sprinter Dealer. In particular, all

work relevant to safety or on safety-related

systems must be carried out at a qualified

specialist workshop.

R For safety reasons, we recommend that you

only use wheel bolts and wheel nuts which

have been approved for Sprinter vehicles.

Other wheel bolts or wheel nuts could work

loose.

X Clean the wheel and wheel hub contact

surfaces.

X Push the wheel onto the wheel hub or the

adapter for the

spare wheel and press it on.

! If your vehicle is equipped with the tire

pressure monitor, each wheel has an

electronic component.

Tire-mounting tools should not be applied

in the area of the valve. Otherwise, the

electronic components could

be damaged.

Only have the tires changed at a qualified

specialist workshop, e.g. an authorized

Sprinter Dealer. G

Warning

Do not tighten the wheel bolts and wheel nuts

completely while the

vehicle is still jacked up.

The vehicle could otherwise tip. Wheels and tires

231

Practical advice Z

Page 235 of 292

X

Push the edge of the hub cap with both

hands against the wheel until it clicks into

place.

! With a hub

cap for the middle of the wheel,

make sure that the clamping lugs of the

cover are positioned over the wheel bolts.

X Hit the middle of the hub cap to engage it

on the wheel.

X Push the piston on the hydraulic jack in

again and close the pressure release

screw.

X Secure the faulty wheel in the spare wheel

bracket (Y page 185).

X Stow the jack and the vehicle tool kit.

X Check the tire pressure and correct if

necessary ( Y page 280).

X Retighten the wheel bolts or wheel nuts to

the specified tightening torque after the

vehicle has been driven for 30 miles

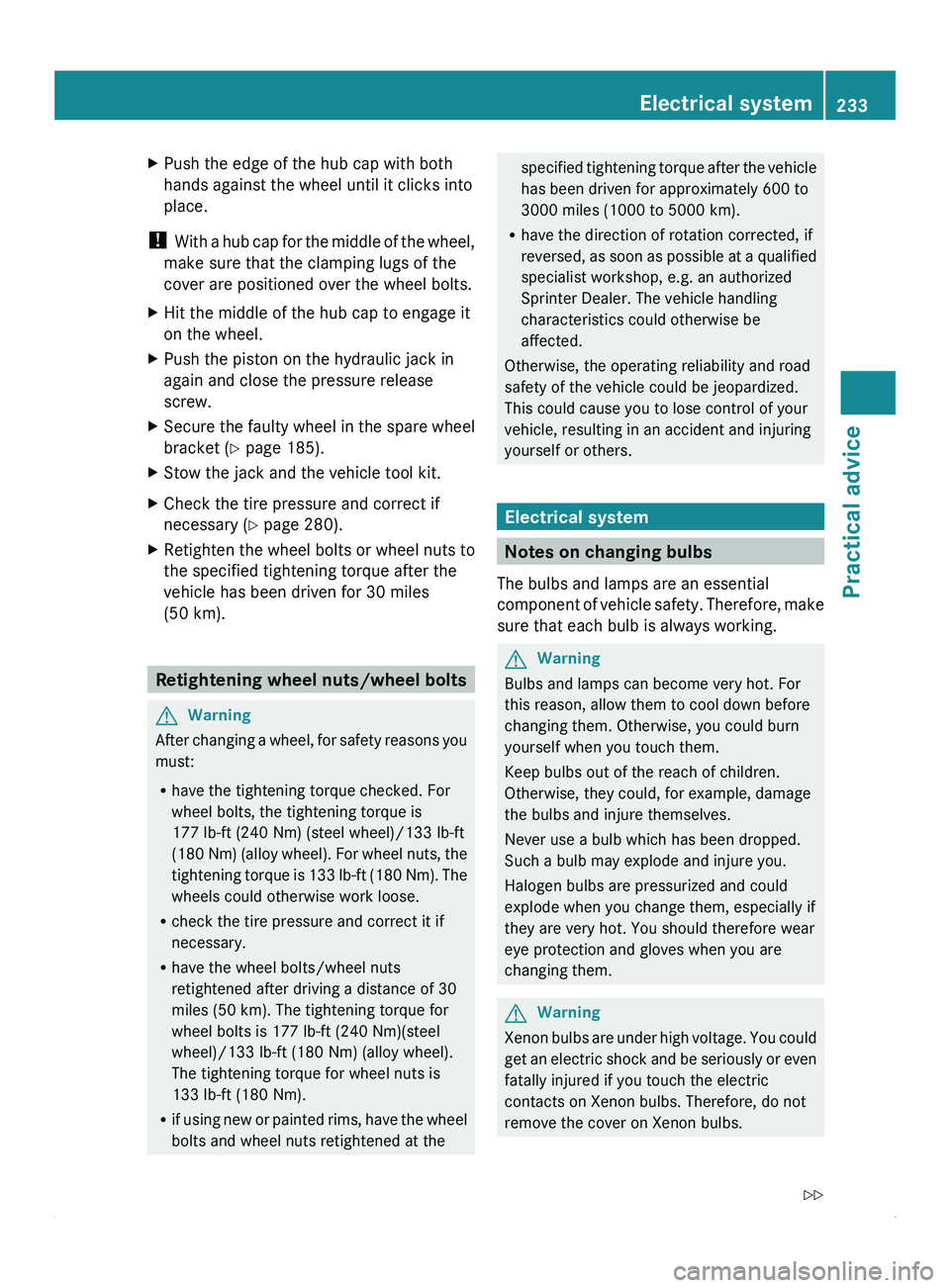

(50 km). Retightening wheel nuts/wheel bolts

G

Warning

After changing a wheel, for safety reasons you

must:

R have the tightening torque checked. For

wheel bolts, the tightening torque is

177 lb-ft (240 Nm) (steel wheel)/ 133 lb-ft

(180

Nm) (alloy wheel). For wheel nuts, the

tightening torque is 133 lb-ft (180 Nm). The

wheels could otherwise work loose.

R check the tire pressure and correct it if

necessary.

R have the wheel bolts/wheel nuts

retightened after driving a distance of 30

miles (50 km). The tightening torque for

wheel bolts is 177 lb-ft (240 Nm)(steel

wheel)/133 lb-ft (180 Nm) (alloy wheel).

The tightening torque for wheel nuts is

133 lb-ft (180 Nm).

R if using new or painted rims, have the wheel

bolts and wheel nuts retightened at the specified tightening torque after the vehicle

has been driven for approximately 600 to

3000 miles (1000 to

5000 km)

.

R have the direction of rotation corrected, if

reversed, as soon as possible at a qualified

specialist workshop, e.g. an authorized

Sprinter Dealer. The vehicle handling

characteristics could otherwise be

affected.

Otherwise, the operating reliability and road

safety of the vehicle could be jeopardized.

This could cause you to lose control of your

vehicle, resulting in an accident and injuring

yourself or others. Electrical system

Notes on changing bulbs

The bulbs and lamps are an essential

component of vehicle

safety. Therefore, make

sure that each bulb is always working. G

Warning

Bulbs and lamps can become very hot. For

this reason, allow them to cool down before

changing them. Otherwise, you could burn

yourself when you touch them.

Keep bulbs out of the reach of children.

Otherwise, they could, for example, damage

the bulbs and injure themselves.

Never use a bulb which has been dropped.

Such a bulb may explode and injure you.

Halogen bulbs are pressurized and could

explode when you change them, especially if

they are very hot. You should therefore wear

eye protection and gloves when you are

changing them. G

Warning

Xenon bulbs are under high voltage. You could

get an electric

shock and be seriously or even

fatally injured if you touch the electric

contacts on Xenon bulbs. Therefore, do not

remove the cover on Xenon bulbs. Electrical system

233

Practical advice

Z

Page 258 of 292

A table of recommended tire pressures can

be found on the Tire & Loading Information

placard

11

or the tire pressure plate on the

B-pillar on the driver's side of the vehicle

(Y page 256).

Use a tire pressure gauge intended for this

purpose. The outer

appearance of a tire does

not permit any reliable conclusion about the

tire pressure. On vehicles equipped with the

electronic tire pressure monitor, the tire

pressure can be checked using the on-board

computer. G

Warning!

If the tire pressure drops repeatedly:

R check the tires for foreign objects

R check whether the

wheel is losing air or the

valve is leaking

R make sure that only a valve cap approved

by the dealer listed on the inside of the

cover page is on the tire valve

Underinflated tires have a negative effect on

vehicle safety, which could lead you to cause

an accident.

Correct the tire pressure only when the tires

are cold. Tires are cold when the vehicle has

been parked for at least three hours or has

been driven less than 1 mile (1.6 km). Tire

temperature changes depending on the

ambient temperature, driving speed and tire

load. If the tire temperature changes by

18 ‡ (10 †), the tire pressure changes by

approximately 10 kPa (0.1 bar/1.5 psi). Take

this into consideration if you are checking tire

pressure when the tires are warm, and

correct the tire pressure only if it is too low

for current operating conditions. If you check

the tire pressure when the tires are warm, it

results in a higher value than when the tires

are cold. This is normal. Do not under any

circumstances release the air in order to

adjust the pressure to the prescribed value

for cold tires. Tire pressure would then be too

low. Take note of the recommended tire pressure

data for cold tires on the Tire & Loading

Information placard

11

or the tire pressure

plate on the

B-pillar on the driver's side of the

vehicle.

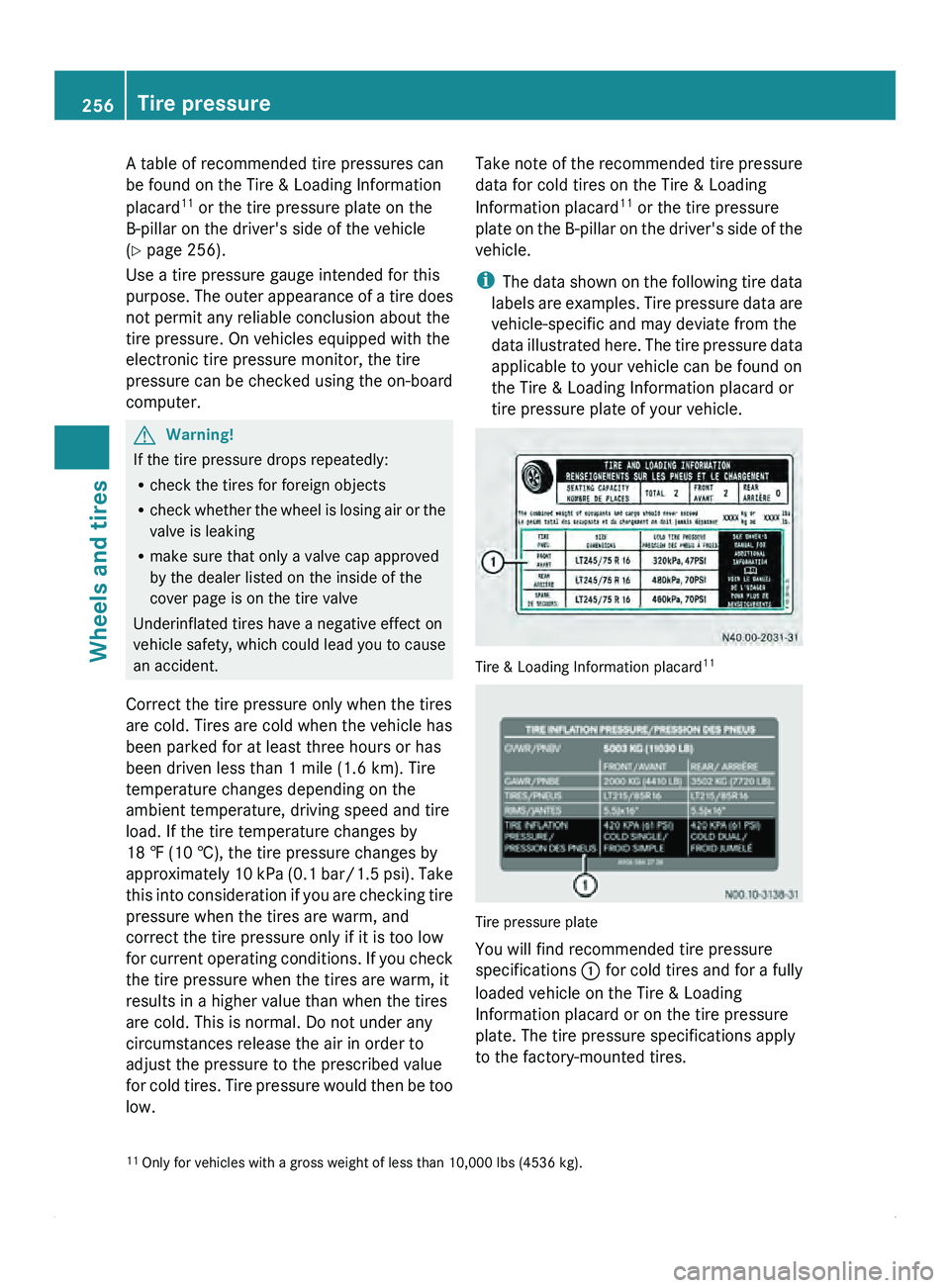

i The data shown on the following tire data

labels are examples. Tire pressure data are

vehicle-specific and may deviate from the

data illustrated here. The tire pressure data

applicable to your vehicle can be found on

the Tire & Loading Information placard or

tire pressure plate of your vehicle. Tire & Loading Information placard

11 Tire pressure plate

You will find recommended tire pressure

specifications

0046 for cold

tires and for a fully

loaded vehicle on the Tire & Loading

Information placard or on the tire pressure

plate. The tire pressure specifications apply

to the factory-mounted tires.

11 Only for vehicles with a gross weight of less than 10,000 lbs (4536 kg).256

Tire pressure

Wheels and tires

Page 262 of 292

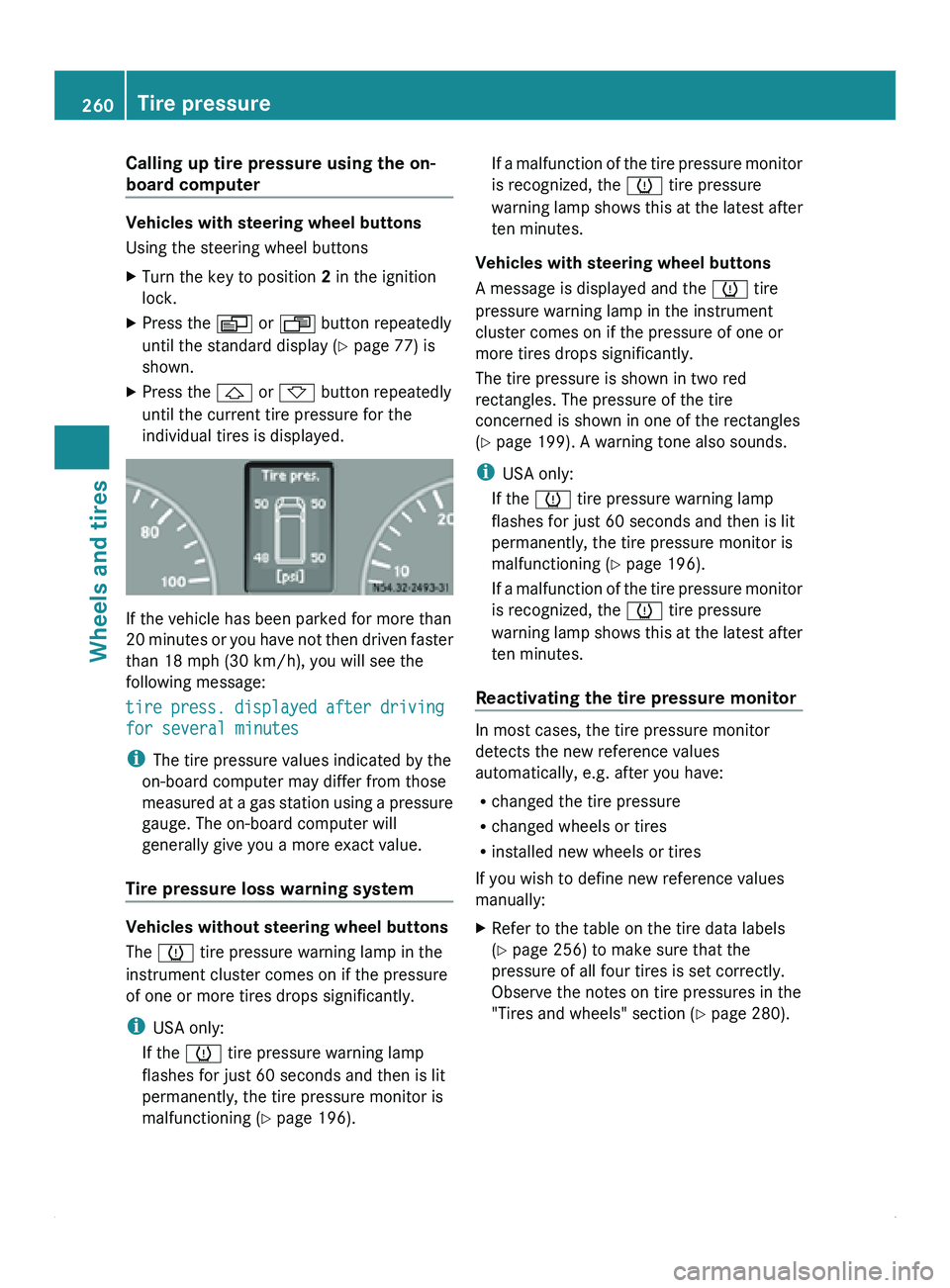

Calling up tire pressure using the on-

board computer

Vehicles with steering wheel buttons

Using the steering wheel buttons

X

Turn the key to position 2 in the ignition

lock.

X Press the 0059 or 0058 button repeatedly

until the standard display ( Y page 77) is

shown.

X Press the

0029 or 002D button repeatedly

until the current tire pressure for the

individual tires is displayed. If the vehicle has been parked for more than

20 minutes

or

you have not then driven faster

than 18 mph (30 km/h), you will see the

following message:

tire press. displayed after driving

for several minutes

i The tire pressure values indicated by the

on-board computer may differ from those

measured at a gas station using a pressure

gauge. The on-board computer will

generally give you a more exact value.

Tire pressure loss warning system Vehicles without steering wheel buttons

The 0077 tire pressure warning lamp in the

instrument cluster comes on if the pressure

of one or more tires drops significantly.

i

USA only:

If the 0077 tire pressure warning lamp

flashes for just 60 seconds and then is lit

permanently, the tire pressure monitor is

malfunctioning (Y page 196). If a malfunction of the tire pressure monitor

is recognized, the 0077 tire pressure

warning lamp

shows

this at the latest after

ten minutes.

Vehicles with steering wheel buttons

A message is displayed and the 0077 tire

pressure warning lamp in the instrument

cluster comes on if the pressure of one or

more tires drops significantly.

The tire pressure is shown in two red

rectangles. The pressure of the tire

concerned is shown in one of the rectangles

(Y page 199). A warning tone also sounds.

i USA only:

If the 0077 tire pressure warning lamp

flashes for just 60 seconds and then is lit

permanently, the tire pressure monitor is

malfunctioning (Y page 196).

If a malfunction of the tire pressure monitor

is recognized, the 0077 tire pressure

warning lamp shows this at the latest after

ten minutes.

Reactivating the tire pressure monitor In most cases, the tire pressure monitor

detects the new reference values

automatically, e.g. after you have:

R

changed the tire pressure

R changed wheels or tires

R installed new wheels or tires

If you wish to define new reference values

manually:

X Refer to the table on the tire data labels

(Y page 256) to make sure that the

pressure of all four tires is set correctly.

Observe the notes on tire pressures in the

"Tires and wheels" section ( Y page 280).260

Tire pressure

Wheels and tires

Page 274 of 292

characteristics could otherwise be

affected.

Otherwise, the operating reliability and road

safety of the vehicle could be jeopardized.

This could cause you to lose control of your

vehicle, resulting in an accident and injuring

yourself or others.

The vehicle tires

are an essential component

in the overall performance and stability of the

vehicle. The service life of tires is dependent

upon and proportional to tire type, speed

rating, environmental conditions, tire load,

tire pressure, road quality and individual

driving style.

For this reason, we recommend regularly

checking wear and correct tire pressure as

well as – according to the appropriate tire

configuration of the vehicle – regularly

rotating the tires.

The wear patterns on the front and rear tires

differ, depending on the operating conditions.

Rotate the wheels before a clear wear pattern

has formed on the tires. Front tires typically

wear more on the shoulders and the rear tires

in the center.

If your vehicle's tire configuration allows, you

can rotate the wheels according to the

intervals in the tire manufacturer's warranty

book in your vehicle documents. If no

warranty book is available, the tires should be

rotated every 3000 to 6000 miles

(5000 to 10000 km), or earlier if tire wear

requires. Do not change the direction of

rotation.

Clean the contact surfaces of the wheel and

the brake disc thoroughly every time a wheel

is rotated. Check the tire pressures.

! If your vehicle is equipped with the tire

pressure monitor, each wheel has an

electronic component.

Tire-mounting tools should not be applied

in the area of the valve. Otherwise, the

electronic components could be damaged. Only have the tires changed at a qualified

specialist workshop, e.g. an authorized

Sprinter Dealer.

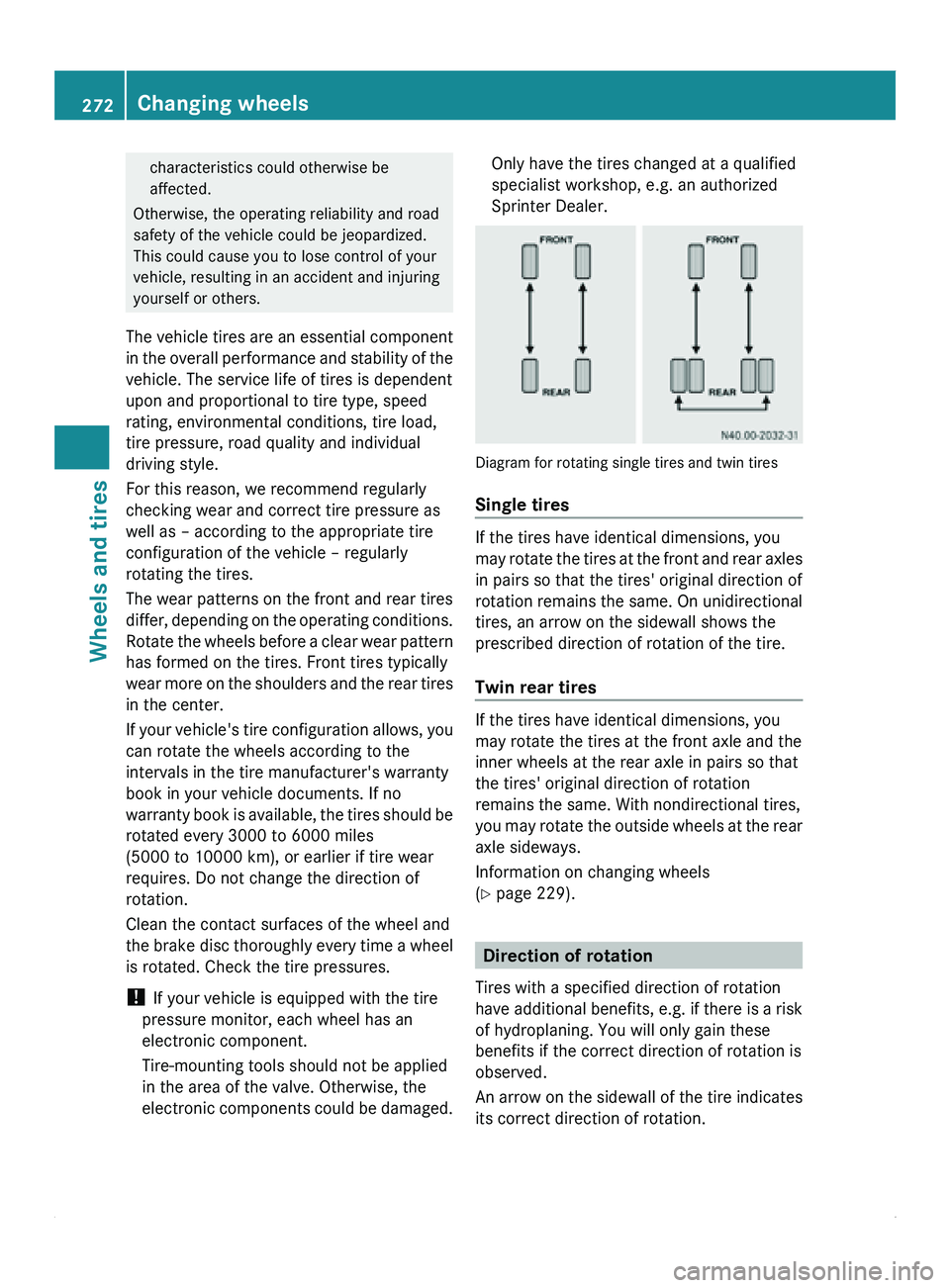

Diagram for rotating single tires and twin tires

Single tires

If the tires have identical dimensions, you

may rotate

the

tires at the front and rear axles

in pairs so that the tires' original direction of

rotation remains the same. On unidirectional

tires, an arrow on the sidewall shows the

prescribed direction of rotation of the tire.

Twin rear tires If the tires have identical dimensions, you

may rotate the tires at the front axle and the

inner wheels at the rear axle in pairs so that

the tires' original direction of rotation

remains the same. With nondirectional tires,

you may

rotate

the outside wheels at the rear

axle sideways.

Information on changing wheels

(Y page 229). Direction of rotation

Tires with a specified direction of rotation

have

additional benefits,

e.g. if there is a risk

of hydroplaning. You will only gain these

benefits if the correct direction of rotation is

observed.

An arrow on the sidewall of the tire indicates

its correct direction of rotation. 272

Changing wheels

Wheels and tires