ESP MERCEDES-BENZ SPRINTER 2012 MY12 Operator’s Manual

[x] Cancel search | Manufacturer: MERCEDES-BENZ, Model Year: 2012, Model line: SPRINTER, Model: MERCEDES-BENZ SPRINTER 2012Pages: 292, PDF Size: 6.75 MB

Page 235 of 292

X

Push the edge of the hub cap with both

hands against the wheel until it clicks into

place.

! With a hub

cap for the middle of the wheel,

make sure that the clamping lugs of the

cover are positioned over the wheel bolts.

X Hit the middle of the hub cap to engage it

on the wheel.

X Push the piston on the hydraulic jack in

again and close the pressure release

screw.

X Secure the faulty wheel in the spare wheel

bracket (Y page 185).

X Stow the jack and the vehicle tool kit.

X Check the tire pressure and correct if

necessary ( Y page 280).

X Retighten the wheel bolts or wheel nuts to

the specified tightening torque after the

vehicle has been driven for 30 miles

(50 km). Retightening wheel nuts/wheel bolts

G

Warning

After changing a wheel, for safety reasons you

must:

R have the tightening torque checked. For

wheel bolts, the tightening torque is

177 lb-ft (240 Nm) (steel wheel)/ 133 lb-ft

(180

Nm) (alloy wheel). For wheel nuts, the

tightening torque is 133 lb-ft (180 Nm). The

wheels could otherwise work loose.

R check the tire pressure and correct it if

necessary.

R have the wheel bolts/wheel nuts

retightened after driving a distance of 30

miles (50 km). The tightening torque for

wheel bolts is 177 lb-ft (240 Nm)(steel

wheel)/133 lb-ft (180 Nm) (alloy wheel).

The tightening torque for wheel nuts is

133 lb-ft (180 Nm).

R if using new or painted rims, have the wheel

bolts and wheel nuts retightened at the specified tightening torque after the vehicle

has been driven for approximately 600 to

3000 miles (1000 to

5000 km)

.

R have the direction of rotation corrected, if

reversed, as soon as possible at a qualified

specialist workshop, e.g. an authorized

Sprinter Dealer. The vehicle handling

characteristics could otherwise be

affected.

Otherwise, the operating reliability and road

safety of the vehicle could be jeopardized.

This could cause you to lose control of your

vehicle, resulting in an accident and injuring

yourself or others. Electrical system

Notes on changing bulbs

The bulbs and lamps are an essential

component of vehicle

safety. Therefore, make

sure that each bulb is always working. G

Warning

Bulbs and lamps can become very hot. For

this reason, allow them to cool down before

changing them. Otherwise, you could burn

yourself when you touch them.

Keep bulbs out of the reach of children.

Otherwise, they could, for example, damage

the bulbs and injure themselves.

Never use a bulb which has been dropped.

Such a bulb may explode and injure you.

Halogen bulbs are pressurized and could

explode when you change them, especially if

they are very hot. You should therefore wear

eye protection and gloves when you are

changing them. G

Warning

Xenon bulbs are under high voltage. You could

get an electric

shock and be seriously or even

fatally injured if you touch the electric

contacts on Xenon bulbs. Therefore, do not

remove the cover on Xenon bulbs. Electrical system

233

Practical advice

Z

Page 241 of 292

X

Insert new bulb 0047.

X Align and engage lamp housing 0046 on the

right-hand side.

! Have the bulbs for the overhead control

panel interior lights changed at a qualified

specialist workshop which has the

necessary specialist knowledge and tools

to carry out the work required. We

recommend an authorized Sprinter Dealer

for this purpose.

You could

otherwise

damage the overhead

control panel.

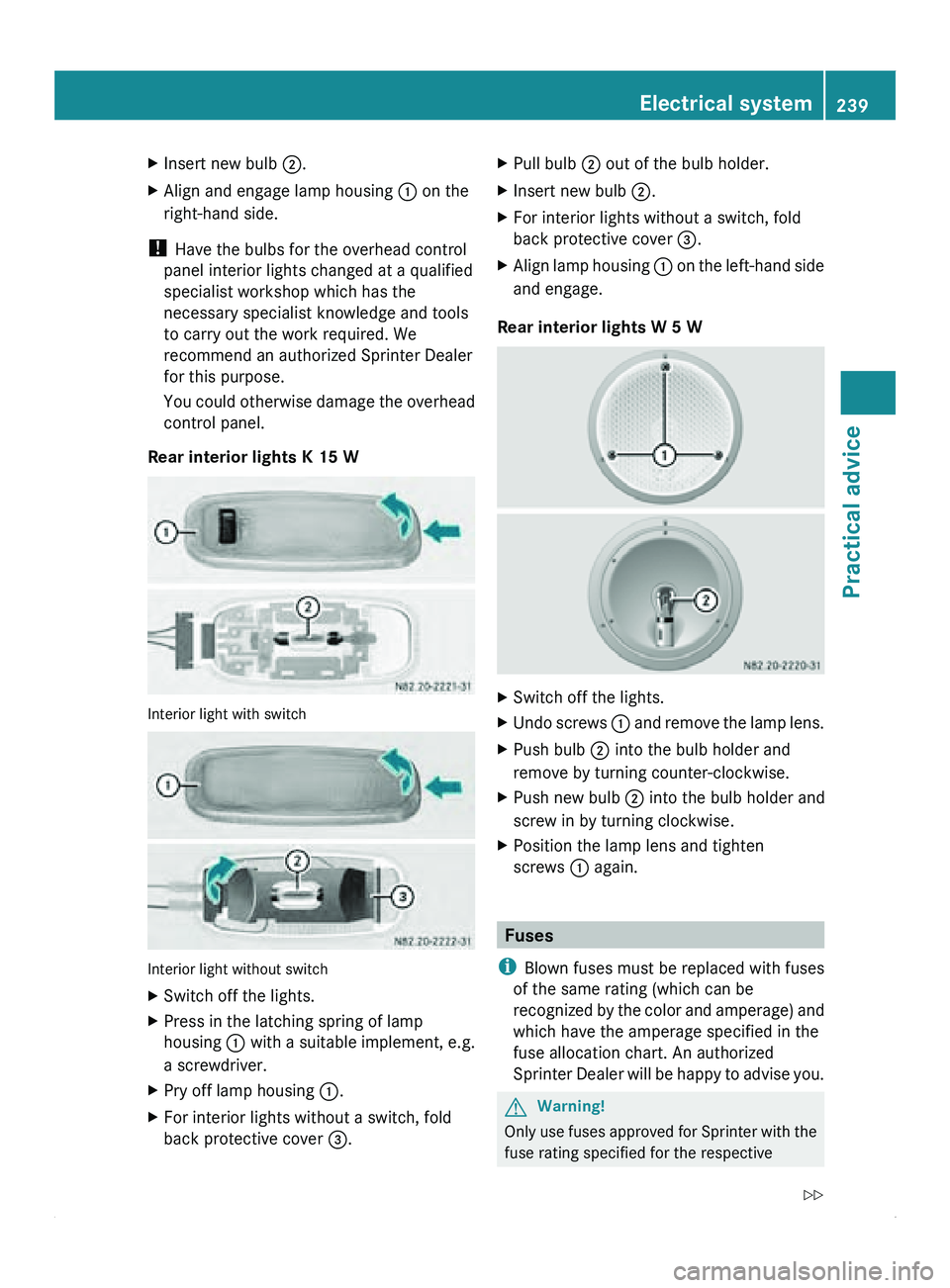

Rear interior lights K 15 W Interior light with switch

Interior light without switch

X

Switch off the lights.

X Press in the latching spring of lamp

housing 0046 with a

suitable implement, e.g.

a screwdriver.

X Pry off lamp housing 0046.

X For interior lights without a switch, fold

back protective cover 008A. X

Pull bulb 0047 out of the bulb holder.

X Insert new bulb 0047.

X For interior lights without a switch, fold

back protective cover 008A.

X Align lamp housing 0046 on the

left-hand side

and engage.

Rear interior lights W 5 W X

Switch off the lights.

X Undo screws 0046

and remove

the lamp lens.

X Push bulb 0047 into the bulb holder and

remove by turning counter-clockwise.

X Push new bulb 0047 into the bulb holder and

screw in by turning clockwise.

X Position the lamp lens and tighten

screws 0046 again. Fuses

i Blown fuses must be replaced with fuses

of the same rating (which can be

recognized by the

color and amperage) and

which have the amperage specified in the

fuse allocation chart. An authorized

Sprinter Dealer will be happy to advise you. G

Warning!

Only use fuses approved for Sprinter with the

fuse rating specified for the respective Electrical system

239

Practical advice

Z

Page 248 of 292

recycled in an environmentally

responsible manner.

Dispose of old batteries in an

environmentally responsible

manner. Take discharged batteries

to a qualified specialist workshop,

e.g. an authorized Sprinter Dealer,

or to a special collection point for

old batteries.

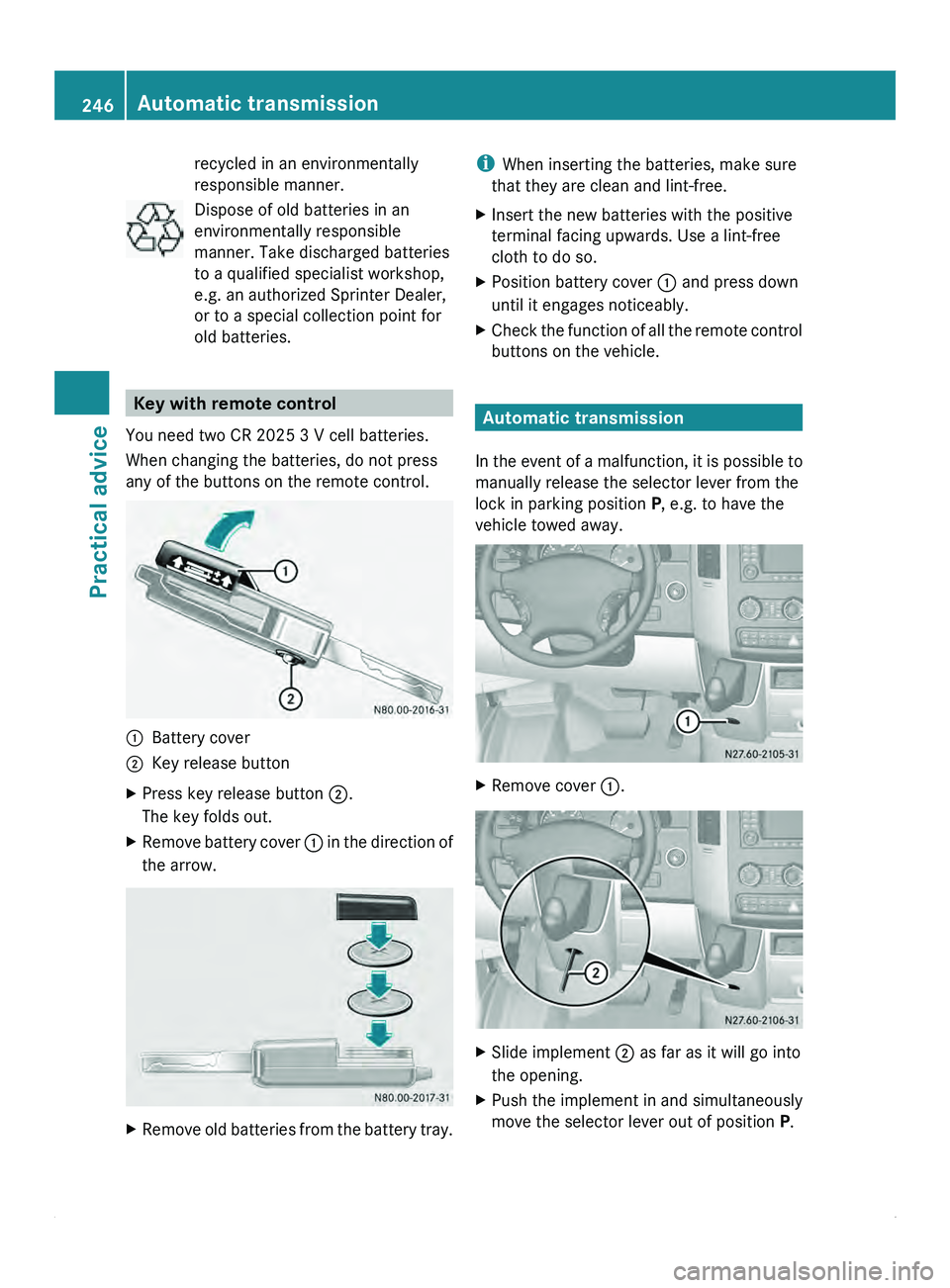

Key with remote control

You need two CR 2025 3 V cell batteries.

When changing the batteries, do not press

any of the buttons on the remote control. 0046

Battery cover

0047 Key release button

X Press key release button 0047.

The key folds out.

X Remove battery cover 0046 in

the direction of

the arrow. X

Remove old batteries from the battery tray. i

When inserting the batteries, make sure

that they are clean and lint-free.

X Insert the new batteries with the positive

terminal facing upwards. Use a lint-free

cloth to do so.

X Position battery cover 0046 and press down

until it engages noticeably.

X Check the function of all the remote control

buttons on the vehicle. Automatic transmission

In the event

of a malfunction, it is possible to

manually release the selector lever from the

lock in parking position P, e.g. to have the

vehicle towed away. X

Remove cover 0046. X

Slide implement 0047 as far as it will go into

the opening.

X Push the implement in and simultaneously

move the selector lever out of position P.246

Automatic transmission

Practical advice

Page 252 of 292

down, e.g. with the aid of another person or

by tying the propeller shaft up.

X Always remove the propeller shafts leading

to the driven axles.

! Always use new bolts when installing the

propeller shafts.

With front axle damage

X Turn the key to position 1 in the ignition

lock.

X Raise the front axle. G

Warning

A propeller shaft could fall off as it is being

removed and injure

you. Secure the propeller

shaft before removal to prevent it from falling

down, e.g. with the aid of another person or

by tying the propeller shaft up.

! The ignition must be switched off if the

vehicle is being towed with the front or rear

axle raised. Otherwise, ESP ®

may intervene

and damage the brake system.

With rear axle damage

X Turn the key to position 1 in the ignition

lock.

X Raise the rear axle.

Malfunction in the electrical system

If the battery is defective, the automatic

transmission will be locked in position P. To

shift the automatic transmission to

position N, you must provide power to the

vehicle's electrical system in the same way

as jump-starting ( Y page 247).

Have the vehicle

transported on a transporter

or trailer.

Transporting the vehicle The towing

eye can be used to pull the vehicle

onto a special transporter or trailer for

transportation.

! Only lash the

vehicle down by the wheels

or rims, not by vehicle parts such as axle or steering components. There is otherwise a

risk of damage to the vehicle.

X Move the selector lever of the automatic

transmission to position N.250

Jump starting, tow-starting and towing away

Practical advice

Page 256 of 292

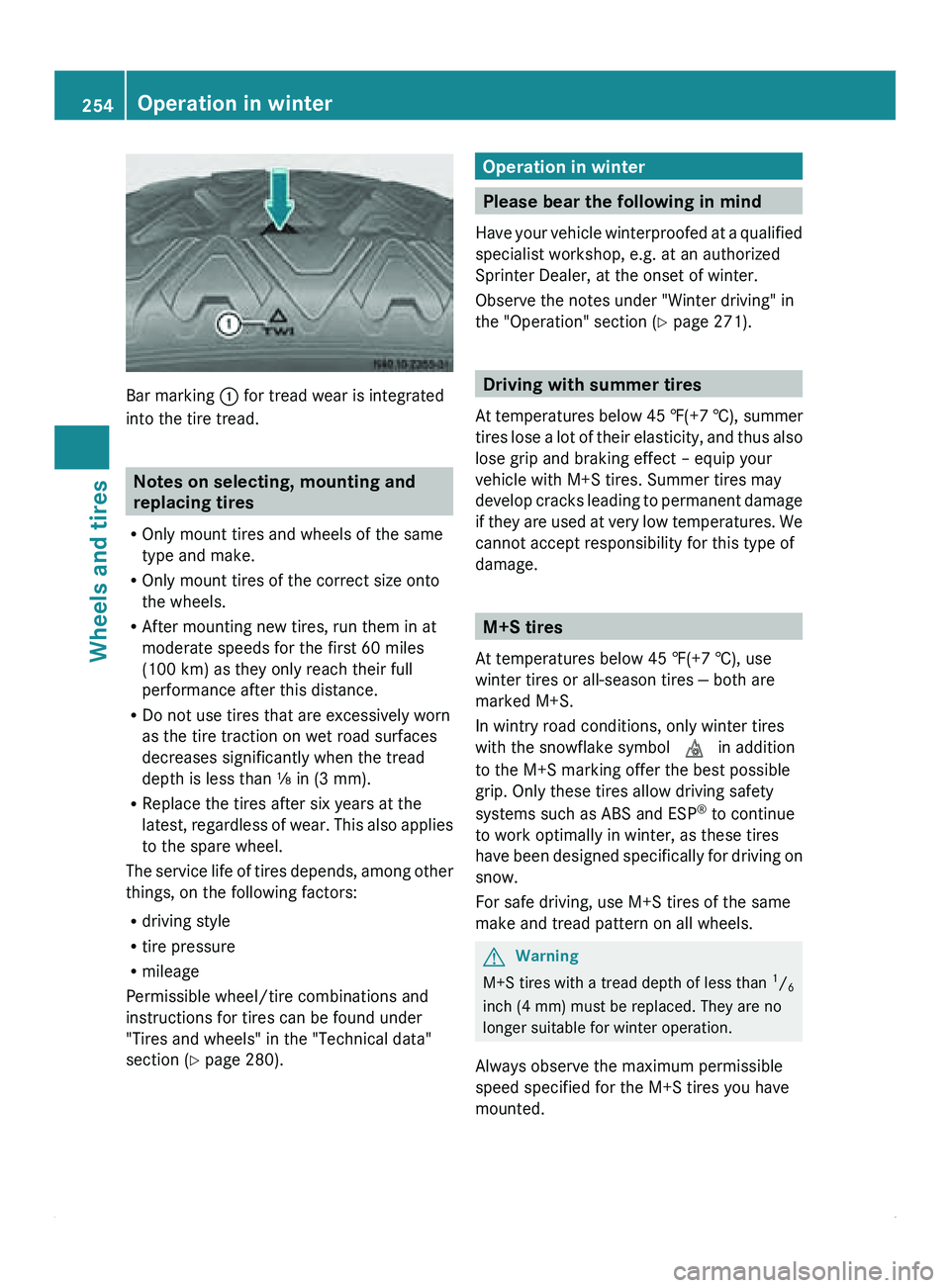

Bar marking 0046 for tread wear is integrated

into the tire tread.

Notes on selecting, mounting and

replacing tires

R Only mount tires and wheels of the same

type and make.

R Only mount tires of the correct size onto

the wheels.

R After mounting new tires, run them in at

moderate speeds for the first 60 miles

(100 km) as they only reach their full

performance after this distance.

R Do not use tires that are excessively worn

as the tire traction on wet road surfaces

decreases significantly when the tread

depth is less than ⅛ in (3 mm).

R Replace the tires after six years at the

latest, regardless of

wear. This also applies

to the spare wheel.

The service life of tires depends, among other

things, on the following factors:

R driving style

R tire pressure

R mileage

Permissible wheel/tire combinations and

instructions for tires can be found under

"Tires and wheels" in the "Technical data"

section ( Y page 280). Operation in winter

Please bear the following in mind

Have your vehicle

winterproofed at a qualified

specialist workshop, e.g. at an authorized

Sprinter Dealer, at the onset of winter.

Observe the notes under "Winter driving" in

the "Operation" section (Y page 271). Driving with summer tires

At temperatures below

45 ‡(+7 †), summer

tires lose a lot of their elasticity, and thus also

lose grip and braking effect – equip your

vehicle with M+S tires. Summer tires may

develop cracks leading to permanent damage

if they are used at very low temperatures. We

cannot accept responsibility for this type of

damage. M+S tires

At temperatures below 45 ‡(+7 †), use

winter tires or all-season tires — both are

marked M+S.

In wintry road conditions, only winter tires

with the snowflake symbol 004D in addition

to the M+S marking offer the best possible

grip. Only these tires allow driving safety

systems such as ABS and ESP ®

to continue

to work optimally in winter, as these tires

have been

designed specifically for driving on

snow.

For safe driving, use M+S tires of the same

make and tread pattern on all wheels. G

Warning

M+S tires with a tread depth of less than 1

/ 6

inch (4 mm) must be replaced. They are no

longer suitable for winter operation.

Always observe the maximum permissible

speed specified for the M+S tires you have

mounted. 254

Operation in winter

Wheels and tires

Page 261 of 292

Underinflation also reduces fuel efficiency

and tire

tread

life, and may affect the vehicle's

handling and stopping ability. Please note that

the TPMS is not a substitute for proper tire

maintenance, and it is the driver's

responsibility to maintain correct tire

pressure, even if underinflation has not

reached the level to trigger illumination of the

TPMS low tire pressure telltale.

USA only:

Your vehicle has also been equipped with a

TPMS malfunction indicator to indicate when

the tire pressure monitoring system is not

operating properly. The TPMS malfunction

indicator is combined with the low tire

pressure telltale. When the system detects a

malfunction, the telltale will flash for

approximately one minute and then remain

continuously illuminated. This sequence will

continue upon subsequent vehicle start-ups

as long as the malfunction exists. When the

malfunction indicator is lit, the system may

not be able to detect or signal low tire

pressure as intended.

TPMS malfunctions may occur for a variety of

reasons, including the installation of

incompatible replacement or alternate tires

or wheels on the vehicle that prevent the

TPMS from functioning properly. Always

check the TPMS malfunction telltale after

replacing one or more tires or wheels on your

vehicle to ensure that the replacement or

alternate tires and wheels allow the TPMS to

continue to function properly.

i USA only:

If the tire pressure monitor is

malfunctioning, it may take more than

10 minutes for the 0077 tire pressure

warning lamp to inform you of the

malfunction by flashing for 60 seconds and

then remaining lit.

When the malfunction has been rectified,

the tire pressure warning lamp goes out

after driving for a few minutes. Information on tire pressures is displayed in

the on-board computer. After a few minutes

of driving, the current tire pressure of each

tire is shown in the on-board computer

i

The tire pressure values indicated by the

on-board computer may differ from those

measured at a gas station with a pressure

gauge. The tire

pressures shown by the on-

board computer refer to those measured at

sea level. At high altitudes, the tire pressure

values indicated by a pressure gauge are

higher than those shown by the on-board

computer. In this case, do not reduce the

tire pressures.

i If radio transmitting equipment (e.g.

wireless headphones, two-way radios) is

operated inside the vehicle or in the vicinity

of the vehicle, this can interfere with the

operation of the tire pressure monitor.

i USA only:

This device complies with Part 15 of the

FCC Rules. Operation is subject to the

following two conditions:

1. This device may not cause harmful

interference, and

2. This device must withstand any

interference received, including

interference that may cause undesired

operation.

Unauthorized modifications to the device

could void the user’s authority to operate

the equipment.

i Canada only:

This device complies with the RSS-210

Rules from Industry Canada. Operation is

subject to the following two conditions:

1. This device may not cause harmful

interference, and

2. This device must accept any interference

received, including interference that may

cause undesired operation.

Unauthorized modifications to the device

could void the user’s authority to operate

the equipment. Tire pressure

259

Wheels and tires Z

Page 264 of 292

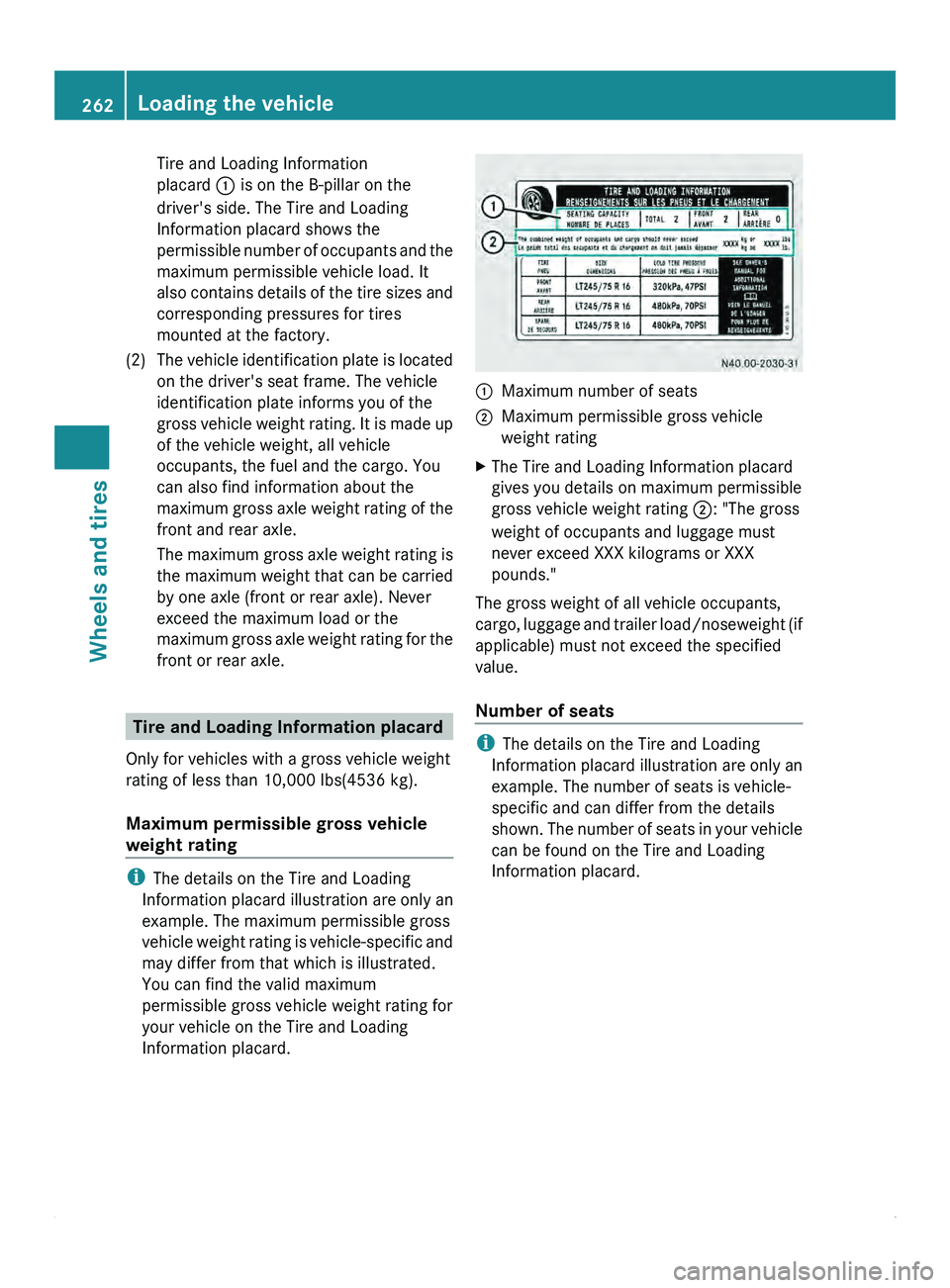

Tire and Loading Information

placard

0046 is on the B-pillar on the

driver's side. The Tire and Loading

Information placard shows the

permissible number of

occupants and the

maximum permissible vehicle load. It

also contains details of the tire sizes and

corresponding pressures for tires

mounted at the factory.

(2) The vehicle identification plate is located on the driver's seat frame. The vehicle

identification plate informs you of the

gross vehicle weight

rating. It is made up

of the vehicle weight, all vehicle

occupants, the fuel and the cargo. You

can also find information about the

maximum gross axle weight rating of the

front and rear axle.

The maximum gross axle weight rating is

the maximum weight that can be carried

by one axle (front or rear axle). Never

exceed the maximum load or the

maximum gross axle weight rating for the

front or rear axle. Tire and Loading Information placard

Only for vehicles with a gross vehicle weight

rating of less than 10,000 lbs(4536 kg).

Maximum permissible gross vehicle

weight rating i

The details on the Tire and Loading

Information placard illustration

are only an

example. The maximum permissible gross

vehicle weight rating is vehicle-specific and

may differ from that which is illustrated.

You can find the valid maximum

permissible gross vehicle weight rating for

your vehicle on the Tire and Loading

Information placard. 0046

Maximum number of seats

0047 Maximum permissible gross vehicle

weight rating

X The Tire and Loading Information placard

gives you details on maximum permissible

gross vehicle weight rating 0047: "The gross

weight of occupants and luggage must

never exceed XXX kilograms or XXX

pounds."

The gross weight of all vehicle occupants,

cargo, luggage

and

trailer load/noseweight (if

applicable) must not exceed the specified

value.

Number of seats i

The details on the Tire and Loading

Information placard illustration

are only an

example. The number of seats is vehicle-

specific and can differ from the details

shown. The number of seats in your vehicle

can be found on the Tire and Loading

Information placard. 262

Loading the vehicle

Wheels and tires

Page 269 of 292

Tire code:

tire code 0088 specifies the tire type.

"R" represents radial tires. "D" represents

diagonal tires, "B" represents diagonal radial

tires.

Rim diameter: rim diameter 0086 is the

diameter of the bead seat, not the diameter

of the rim flange. The rim diameter is

specified in inches (in).

Load bearing index: load bearing index 0087

is a numerical code which specifies the

maximum load-bearing capacity of a tire. G

Warning

The tire load rating must always be at least

half of the GAWR of your vehicle. Otherwise,

sudden tire failure may be the result which

could cause an

accident and/or serious injury

to you or others.

Always replace rims and tires with rims and

tires having the same specifications

(designation, manufacturer and type) as

shown on the original part. G

Warning

Do not overload the tires by exceeding the

specified load limit as indicated on the Tire

and Loading Information placard on the

driver's door B-pillar . Overloading the tires

can overheat them, possibly causing a

blowout. Overloading

the tires can also result

in handling or steering problems, or brake

failure.

Example:

The load bearing index 120 is equivalent to a

maximum load of 3042 lbs (1380 kg) that the

tire can carry. If two load-bearing capacity

indices are specified (as shown above), the

first number states the load-bearing capacity

for single tires, the second number the load-

bearing capacity for twin tires. For further

information on the maximum tire load in

kilograms and pounds, see ( Y page 265).

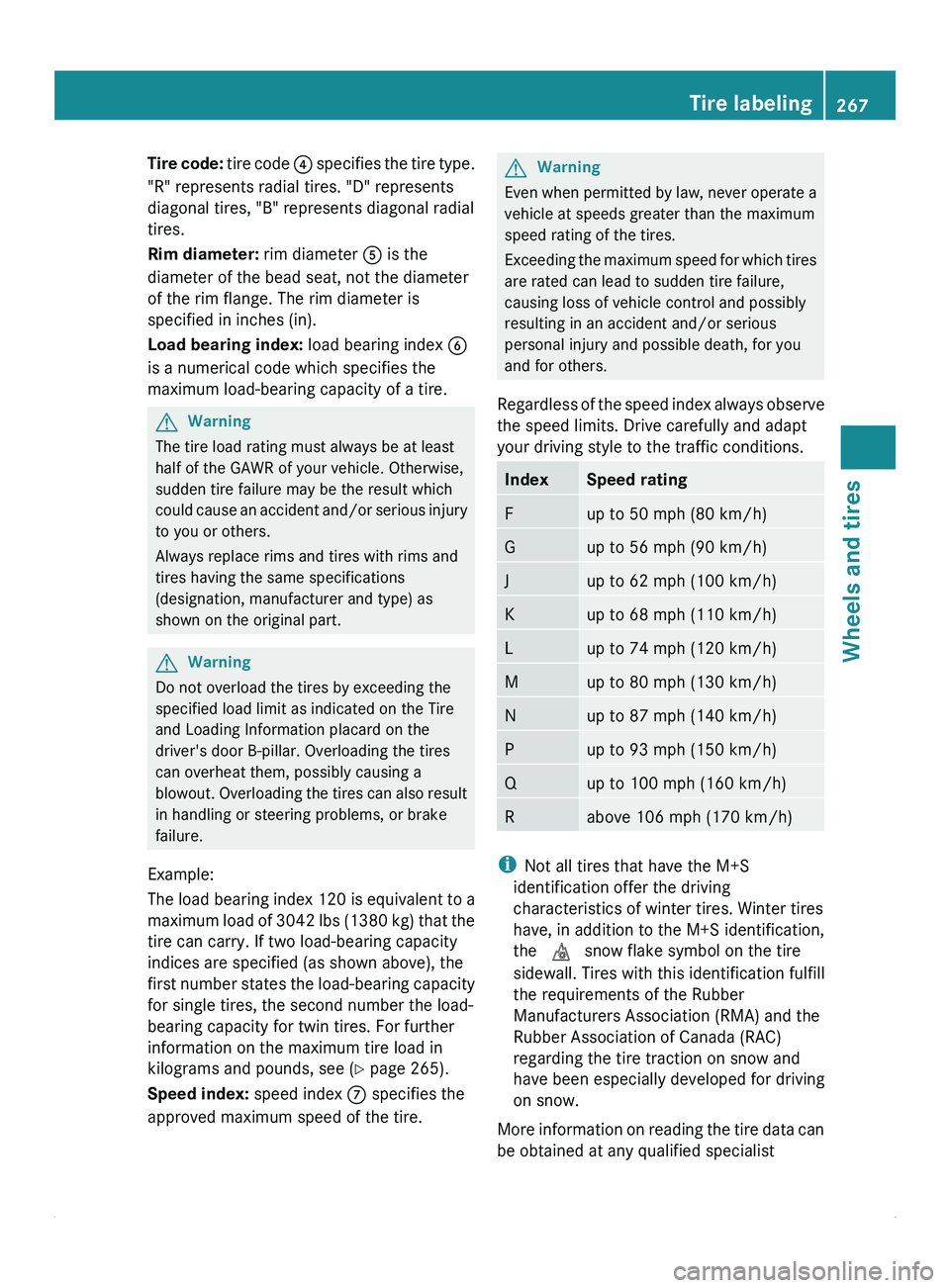

Speed index: speed index 006E specifies the

approved maximum speed of the tire. G

Warning

Even when permitted by law, never operate a

vehicle at speeds greater than the maximum

speed rating of the tires.

Exceeding the maximum

speed for which tires

are rated can lead to sudden tire failure,

causing loss of vehicle control and possibly

resulting in an accident and/or serious

personal injury and possible death, for you

and for others.

Regardless of the speed index always observe

the speed limits. Drive carefully and adapt

your driving style to the traffic conditions. Index Speed rating

F up to 50 mph (80 km/h)

G up to 56 mph (90 km/h)

J up to 62 mph (100 km/h)

K up to 68 mph (110 km/h)

L up to 74 mph (120 km/h)

M up to 80 mph (130 km/h)

N up to 87 mph (140 km/h)

P up to 93 mph (150 km/h)

Q up to 100 mph (160 km/h)

R above 106 mph (170 km/h)

i

Not all tires that have the M+S

identification offer the driving

characteristics of winter tires. Winter tires

have, in addition

to the M+S identification,

the 004D snow flake symbol on the tire

sidewall. Tires with this identification fulfill

the requirements of the Rubber

Manufacturers Association (RMA) and the

Rubber Association of Canada (RAC)

regarding the tire traction on snow and

have been especially developed for driving

on snow.

More information on reading the tire data can

be obtained at any qualified specialist Tire labeling

267

Wheels and tires Z

Page 270 of 292

workshop, e.g. at an authorized Sprinter

Dealer.

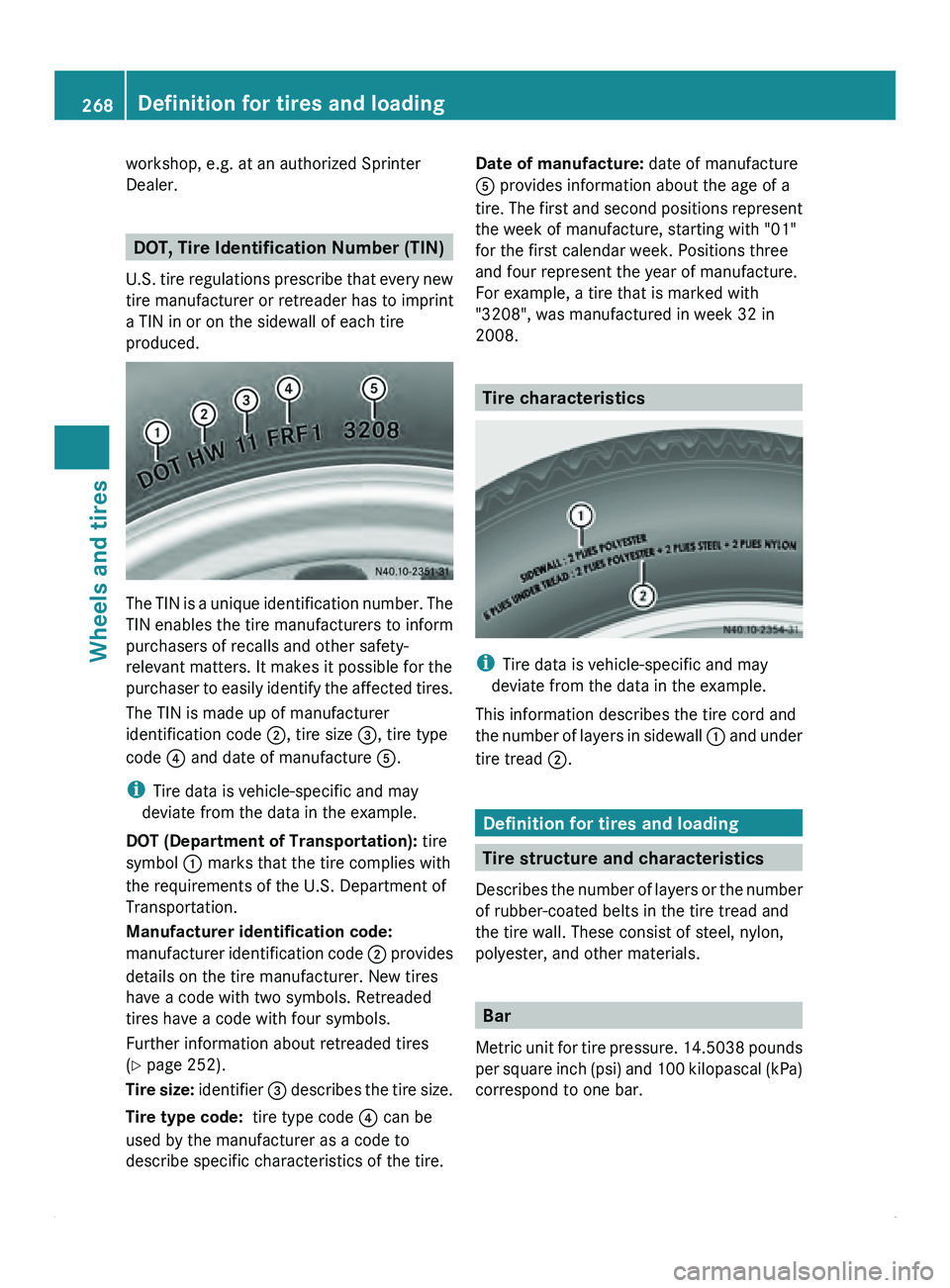

DOT, Tire Identification Number (TIN)

U.S. tire regulations

prescribe that every new

tire manufacturer or retreader has to imprint

a TIN in or on the sidewall of each tire

produced. The TIN is a unique identification number. The

TIN enables the tire manufacturers to inform

purchasers of recalls and other safety-

relevant matters. It makes it possible for the

purchaser to

easily

identify the affected tires.

The TIN is made up of manufacturer

identification code 0047, tire size 008A, tire type

code 0088 and date of manufacture 0086.

i Tire data is vehicle-specific and may

deviate from the data in the example.

DOT (Department of Transportation): tire

symbol 0046 marks that the tire complies with

the requirements of the U.S. Department of

Transportation.

Manufacturer identification code:

manufacturer identification code 0047 provides

details on the tire manufacturer. New tires

have a code with two symbols. Retreaded

tires have a code with four symbols.

Further information about retreaded tires

(Y page 252).

Tire size: identifier 008A describes the tire size.

Tire type code: tire type code 0088 can be

used by the manufacturer as a code to

describe specific characteristics of the tire. Date of manufacture:

date of manufacture

0086 provides information about the age of a

tire. The

first

and second positions represent

the week of manufacture, starting with "01"

for the first calendar week. Positions three

and four represent the year of manufacture.

For example, a tire that is marked with

"3208", was manufactured in week 32 in

2008. Tire characteristics

i

Tire data is vehicle-specific and may

deviate from the data in the example.

This information describes the tire cord and

the number of

layers in sidewall 0046 and under

tire tread 0047. Definition for tires and loading

Tire structure and characteristics

Describes the number

of layers or the number

of rubber-coated belts in the tire tread and

the tire wall. These consist of steel, nylon,

polyester, and other materials. Bar

Metric unit for

tire pressure. 14.5038 pounds

per square inch (psi) and 100 kilopascal (kPa)

correspond to one bar. 268

Definition for tires and loading

Wheels and tires

Page 275 of 292

You may mount a spare wheel against the

direction of rotation. Observe the time

restriction on use as well as the speed

limitation specified on the spare wheel.

Storing wheels

Store wheels that

are not being used in a cool,

dry and preferably dark place. Protect the

tires from contact with oil, grease and fuel. Cleaning wheels

G

Warning

Do not use power washers with circular jet

nozzles (concentrated-power jets) to clean

your vehicle, especially

for cleaning tires. You

could otherwise damage the tires and cause

an accident. Changing wheels

273

Wheels and tires Z