warning MERCEDES-BENZ SPRINTER 2014 MY14 Operator’s Manual

[x] Cancel search | Manufacturer: MERCEDES-BENZ, Model Year: 2014, Model line: SPRINTER, Model: MERCEDES-BENZ SPRINTER 2014Pages: 338, PDF Size: 6.78 MB

Page 297 of 338

lamp in the instrument cluster (Y

page 229)

lights up.

The tire pressure is shown in 2 red rectangles.

The pressure of the tire concerned is shown

in one of the two rectangles (Y page 199).

Additionally, a warning tone sounds.

Each tire that is affected by a significant loss

of pressure is highlighted in the pressure dis-

play.

Restarting the tire pressure monitor When you restart the tire pressure monitor,

the currently set tire pressure are taken as

reference values for monitoring.

In most cases, the tire pressure monitor

detects the new reference values automati-

cally, e.g. after you have:

R changed the tire pressure

R mounted

R mounted new wheels or tires

However, you can also define reference val-

ues manually as described here.

Before restarting the tire pressure moni-

tor:

X Set the tire pressure to the value recom-

mended on the Tire and Loading Informa-

tion placard or the tire pressure table on

the B-pillar on the driver's side

(Y page 290).

Observe the notes on tire pressure when

doing so (Y page 290).

X Make sure that the tire pressure is correct

on all four wheels. Restarting the tire pressure monitor

(vehicles without steering wheel but-

tons):

X

Turn the key to position 2in the ignition

lock.

X Press the 0079menu button on the instru-

ment cluster repeatedly until the display

shows the following message:

+CAL- TPMS

+CAL- TPMS

X Press the 0074button on the instrument clus-

ter.

The display shows:

OK TPMS OK TPMS

The tire pressure monitor activation proc-

ess has begun. The tire pressures meas-

ured for the individual wheels are stored as

the new reference values, provided that the

tire pressure monitor considers them to be

plausible.

If you wish to cancel the restart:

X Press the 0075button or the 0079menu button

on the instrument cluster.

The activation process is canceled auto-

matically if 30 seconds elapse without

input.

Restarting the tire pressure monitor

(vehicles with steering wheel buttons):

X Turn the key to position 2in the ignition

lock.

X Press the 0080or007F button on the steer-

ing wheel repeatedly until the standard dis-

play is shown ( Ypage 189).

X Press the 0041or0068 button on the steer-

ing wheel repeatedly until the current pres-

sure of the individual tires is displayed or

the display shows the following message:

Tire Tire pres.

pres. displayed

displayed after

afterdriving

driving

for several minutes

for several minutes

X Press the 0045reset button on the instru-

ment cluster.

The display shows the following message: Tire pressure

295Wheels and tires Z

Page 300 of 338

Loading the vehicle

Instruction labels for tires and loads

G

WARNING

Overloaded tires can overheat, causing a

blowout. Overloaded tires can also impair the

steering and driving characteristics and lead

to brake failure. There is a risk of accident.

Observe the load rating of the tires. The load

rating must be at least half of the GAWR of

your vehicle. Never overload the tires by

exceeding the maximum load. The Tire and Loading Information placard on the

driver’s door B-pillar

Two instruction labels on your vehicle show

the maximum possible load.

(1) Only for vehicles with a gross weight of

less than 10,000 lbs (4,536 kg):

Tire and Loading Information placard 0043

is on the B-pillar on the driver's side. Tire

and Loading Information placard 0043

shows the permissible number of occu-

pants and the maximum permissible load

of the vehicle. It also contains details of

the tire sizes and corresponding pres-

sures for tires mounted at the factory.

(2) The vehicle identification plate is located on the base of the driver's seat. The vehi-

cle identification plate informs you of the

gross vehicle weight rating. It is made up

of the vehicle weight, all vehicle occu-

pants, the fuel and the cargo. You can

also find information about the maximum Gross Axle Weight Rating on the front and

rear axle.

The maximum gross axle weight rating is

the maximum weight that can be carried

by one axle (front or rear axle). Do not

exceed the maximum gross vehicle

weight or the maximum gross axle weight

rating for the front or rear axle.

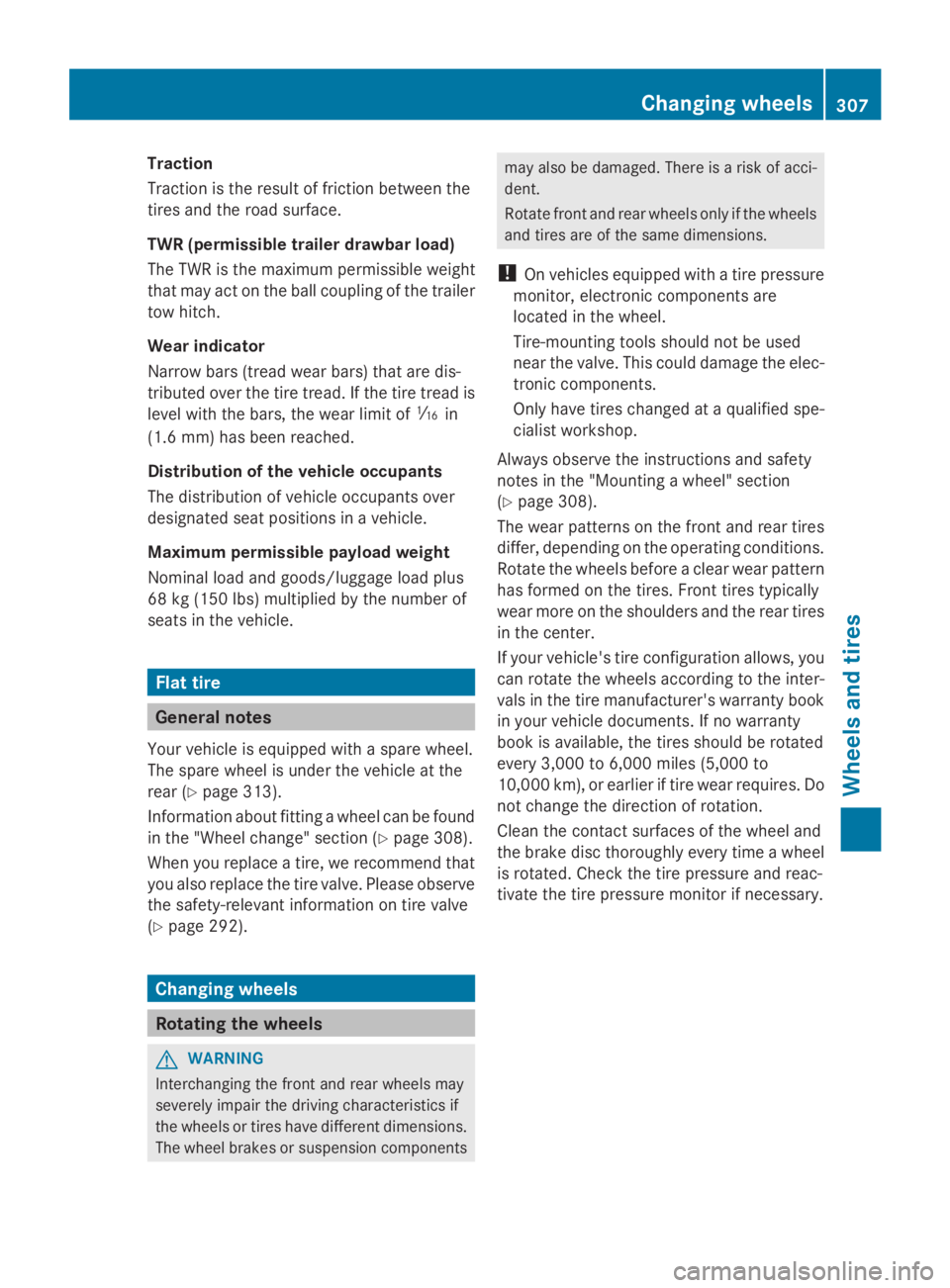

Tire and Loading Information placard

General notes Only vehicles with a gross weight of less than

10,000 lbs (4,536 kg) have a Tire and Loading

Information placard on the B-pillar on the

driver's side.

Maximum permissible gross vehicle

weight rating

0043

Maximum number of seats

0044 Maximum permissible gross vehicle

weight rating

X Specification for maximum gross vehicle

weight 0044is listed in the Tire and Loading

Information placard: "The gross weight of

occupants and luggage must not exceed

XXX kilograms or XXX lbs."

The gross weight of all vehicle occupants,

cargo, luggage and trailer load/noseweight (if

applicable) must not exceed the specified

value.

i The details on the Tire and Loading Infor-

mation placard illustration are only an 298

Loading the vehicleWheels and tires

Page 304 of 338

0087

Maximum tire pressure (Y page 292)

0085 Manufacturer

0083 Tire material (Y page 304)

0084 Tire size designation, load-bearing capa-

city and speed index (Y page 302)

006B Tire name

The markings described above are on the tire

in addition to the tire name (sales designa-

tion) and the manufacturer's name.

i Tire data is vehicle-specific and may devi-

ate from the data in the example.

Tire size designation, load bearing index

and speed index G

WARNING

Exceeding the stated tire load-bearing capa-

city and the approved maximum speed could

lead to tire damage or the tire bursting. There

is a risk of accident.

Therefore, only use tire types and sizes

approved for your vehicle model. Observe the

tire load rating and speed rating required for

your vehicle. 0043

Design standard

0044 Tire width

0087 Nominal aspect ratio in %

0085 Tire code

0083 Rim diameter

0084 Load bearing index

006B Speed index General:

depending on the manufacturer's

standards, the size imprinted in the tire wall

may not contain any letters or may contain

one letter 0043that precedes the size descrip-

tion

If "LT" precedes the size description (as

shown above): these are light truck tires

according to U.S. manufacturing standards.

If "C" precedes the size description: these are

commercial motor vehicle tires according to

European manufacturing standards.

Tire width: tire width0044shows the nominal

tire width in millimeters.

Aspect ratio: aspect ratio0087is the size ratio

between the tire height and tire width and is

shown in percent. The aspect ratio is calcu-

lated by dividing the tire width by the tire

height.

Tire code: tire code0085specifies the tire type.

"R" represents radial tires. "D" represents

diagonal tires, "B" represents diagonal radial

tires.

Rim diameter: rim diameter0083is the diam-

eter of the bead seat, not the diameter of the

rim flange. The rim diameter is specified in

inches (in).

Load-bearing index: load-bearing index0084

is a numerical code that specifies the maxi-

mum load-bearing capacity of a tire.

Do not overload the tires by exceeding the

specified load limit. The maximum permissi-

ble load can be found on the vehicle's Tire and

Loading Information placard on the B-pillar on

the driver's side (Y page 298).

Example:

The load-bearing index 120 indicates a max-

imum load of 3,042 lb (1,380 kg) for the tire.

If two load-bearing capacity indices are speci-

fied (as shown above), the first number states

the load-bearing capacity for single tires, the

second number the load-bearing capacity for

twin tires. For further information on the max-

imum tire load in kilograms and pounds, see

(Y page 303). 302

What you should know about wheels and tiresWheels and tires

Page 309 of 338

Traction

Traction is the result of friction between the

tires and the road surface.

TWR (permissible trailer drawbar load)

The TWR is the maximum permissible weight

that may act on the ball coupling of the trailer

tow hitch.

Wear indicator

Narrow bars (tread wear bars) that are dis-

tributed over the tire tread. If the tire tread is

level with the bars, the wear limit of 00CDin

(1.6 mm) has been reached.

Distribution of the vehicle occupants

The distribution of vehicle occupants over

designated seat positions in a vehicle.

Maximum permissible payload weight

Nominal load and goods/luggage load plus

68 kg (150 lbs) multiplied by the number of

seats in the vehicle. Flat tire

General notes

Your vehicle is equipped with a spare wheel.

The spare wheel is under the vehicle at the

rear (Y page 313).

Information about fitting a wheel can be found

in the "Wheel change" section (Y page 308).

When you replace a tire, we recommend that

you also replace the tire valve. Please observe

the safety-relevant information on tire valve

(Y page 292). Changing wheels

Rotating the wheels

G

WARNING

Interchanging the front and rear wheels may

severely impair the driving characteristics if

the wheels or tires have different dimensions.

The wheel brakes or suspension components may also be damaged. There is a risk of acci-

dent.

Rotate front and rear wheels only if the wheels

and tires are of the same dimensions.

! On vehicles equipped with a tire pressure

monitor, electronic components are

located in the wheel.

Tire-mounting tools should not be used

near the valve. This could damage the elec-

tronic components.

Only have tires changed at a qualified spe-

cialist workshop.

Always observe the instructions and safety

notes in the "Mounting a wheel" section

(Y page 308).

The wear patterns on the front and rear tires

differ, depending on the operating conditions.

Rotate the wheels before a clear wear pattern

has formed on the tires. Front tires typically

wear more on the shoulders and the rear tires

in the center.

If your vehicle's tire configuration allows, you

can rotate the wheels according to the inter-

vals in the tire manufacturer's warranty book

in your vehicle documents. If no warranty

book is available, the tires should be rotated

every 3,000 to 6,000 miles (5,000 to

10,000 km), or earlier if tire wear requires. Do

not change the direction of rotation.

Clean the contact surfaces of the wheel and

the brake disc thoroughly every time a wheel

is rotated. Check the tire pressure and reac-

tivate the tire pressure monitor if necessary. Changing wheels

307Wheels and tires Z

Page 310 of 338

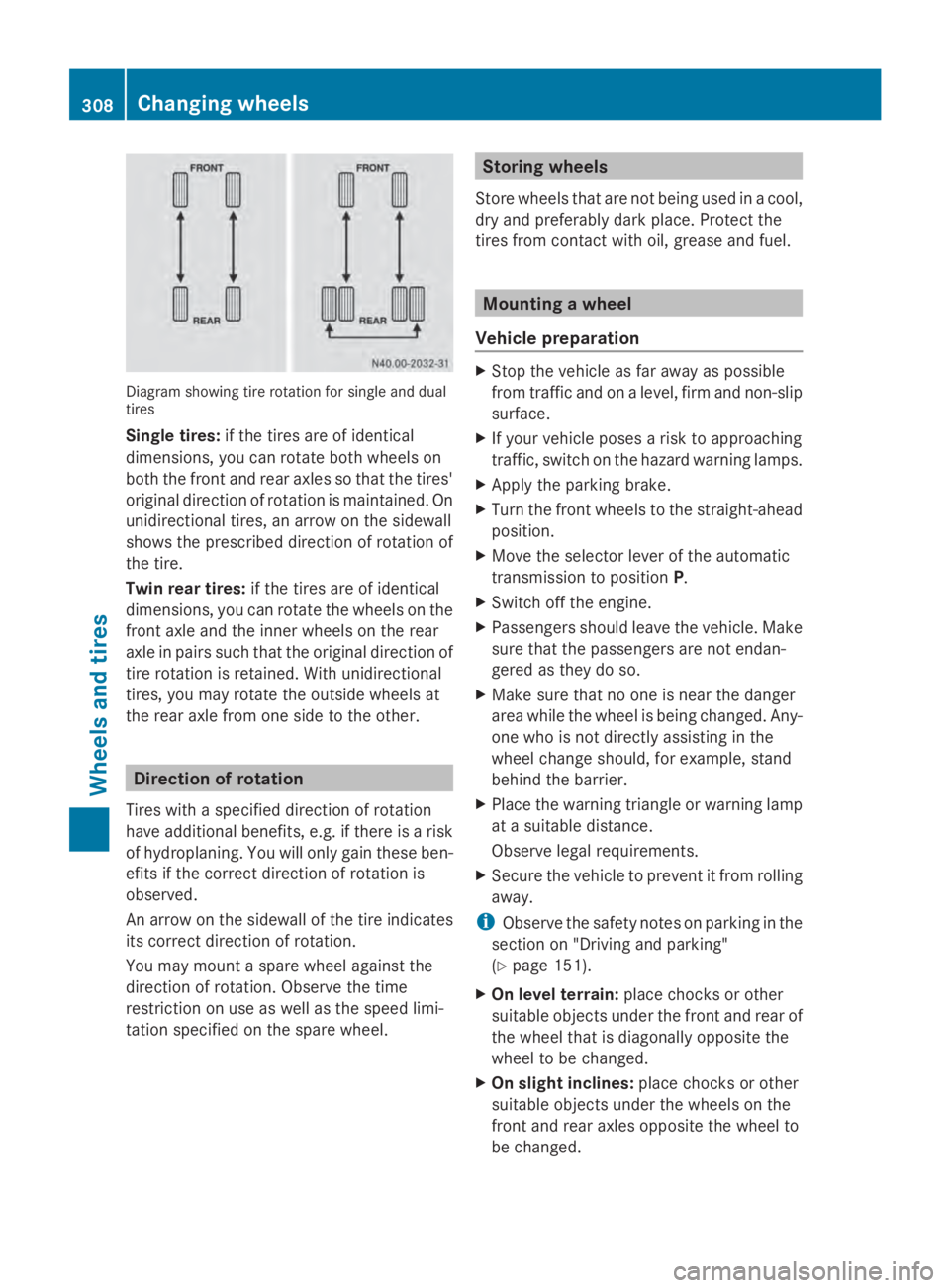

Diagram showing tire rotation for single and dual

tires

Single tires: if the tires are of identical

dimensions, you can rotate both wheels on

both the front and rear axles so that the tires'

original direction of rotation is maintained. On

unidirectional tires, an arrow on the sidewall

shows the prescribed direction of rotation of

the tire.

Twin rear tires: if the tires are of identical

dimensions, you can rotate the wheels on the

front axle and the inner wheels on the rear

axle in pairs such that the original direction of

tire rotation is retained. With unidirectional

tires, you may rotate the outside wheels at

the rear axle from one side to the other. Direction of rotation

Tires with a specified direction of rotation

have additional benefits, e.g. if there is a risk

of hydroplaning. You will only gain these ben-

efits if the correct direction of rotation is

observed.

An arrow on the sidewall of the tire indicates

its correct direction of rotation.

You may mount a spare wheel against the

direction of rotation. Observe the time

restriction on use as well as the speed limi-

tation specified on the spare wheel. Storing wheels

Store wheels that are not being used in a cool,

dry and preferably dark place. Protect the

tires from contact with oil, grease and fuel. Mounting a wheel

Vehicle preparation X

Stop the vehicle as far away as possible

from traffic and on a level, firm and non-slip

surface.

X If your vehicle poses a risk to approaching

traffic, switch on the hazard warning lamps.

X Apply the parking brake.

X Turn the front wheels to the straight-ahead

position.

X Move the selector lever of the automatic

transmission to position P.

X Switch off the engine.

X Passengers should leave the vehicle. Make

sure that the passengers are not endan-

gered as they do so.

X Make sure that no one is near the danger

area while the wheel is being changed. Any-

one who is not directly assisting in the

wheel change should, for example, stand

behind the barrier.

X Place the warning triangle or warning lamp

at a suitable distance.

Observe legal requirements.

X Secure the vehicle to prevent it from rolling

away.

i Observe the safety notes on parking in the

section on "Driving and parking"

(Y page 151).

X On level terrain: place chocks or other

suitable objects under the front and rear of

the wheel that is diagonally opposite the

wheel to be changed.

X On slight inclines: place chocks or other

suitable objects under the wheels on the

front and rear axles opposite the wheel to

be changed. 308

Changing wheelsWheels and tires

Page 311 of 338

X

Take the vehicle tool kit and the jack from

the footwell on the co-driver's side

(Y page 276).

X Remove the spare wheel from the spare

wheel bracket (Y page 314). Observe the

safety notes in the "Spare wheel" section

(Y page 313).

X On wheels with wheel bolts, remove the

hub caps. X

Assemble the lug wrench extension using

the middle rod and the rod with the largest

diameter from the three-piece jack pump

lever.

X Starting with the middle rod, slide the lug

wrench extension as far as it will go onto

the lug wrench.

X Using lug wrench 0043, loosen the wheel

bolts/wheel nuts on the wheel to be

changed by about one full turn. Do not

unscrew the wheel bolts/nuts completely.

Raising the vehicle G

WARNING

If you do not position the jack correctly at the

appropriate jacking point of the vehicle, the

jack could tip over with the vehicle raised.

There is a risk of injury.

Only position the jack at the appropriate jack-

ing point of the vehicle. The base of the jack

must be positioned vertically, directly under

the jacking point of the vehicle. G

WARNING

On uphill and downhill slopes, the jack could

tip over with the vehicle raised. There is a risk

of injury.

Do not change wheels on uphill or downhill

gradients. Notify a qualified specialist work-

shop.

! Only position the jack on the jacking

points intended for this purpose. You could

otherwise damage the vehicle.

Observe the following when raising the vehi-

cle:

R When raising the vehicle, only use the jack

which Mercedes-Benz has specifically

approved for your vehicle.

R The vehicle's jack is intended only to raise

the vehicle for a short time when changing

a wheel. It is not suited for performing

maintenance work under the vehicle.

R Avoid changing the wheel on uphill and

downhill slopes.

R Before raising the vehicle, secure it from

rolling away by applying the parking brake

and inserting wheel chocks. Never disen-

gage the parking brake while the vehicle is

raised.

R The jack must be placed on a firm, flat and

non-slip surface. On a loose surface, a

large, load-bearing underlay must be used.

On a slippery surface, a non-slip underlay

must be used, e.g. rubber mats.

R Make sure that the distance between the

underside of the tires and the ground does

not exceed 1,2 in(3 cm).

R Never place your hands or feet under the

raised vehicle.

R Never lie under the raised vehicle.

R Never start the engine when the vehicle is

raised.

R Never open or close a door when the vehi-

cle is raised.

R Make sure that no persons are present in

the vehicle when the vehicle is raised. Changing wheels

309Wheels and tires Z

Page 313 of 338

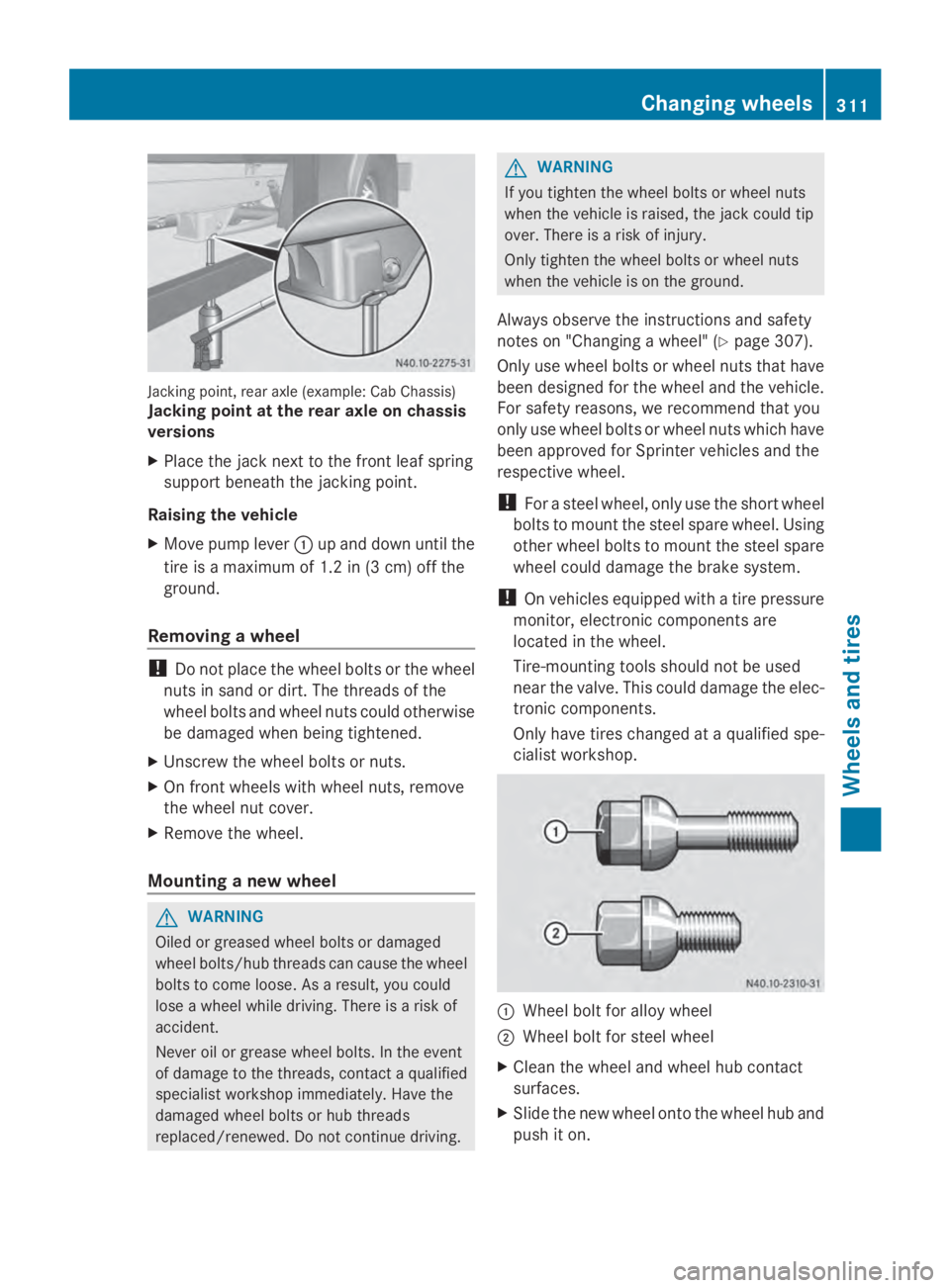

Jacking point, rear axle (example: Cab Chassis)

Jacking point at the rear axle on chassis

versions

X Place the jack next to the front leaf spring

support beneath the jacking point.

Raising the vehicle

X Move pump lever 0043up and down until the

tire is a maximum of 1.2 in (3 cm) off the

ground.

Removing a wheel !

Do not place the wheel bolts or the wheel

nuts in sand or dirt. The threads of the

wheel bolts and wheel nuts could otherwise

be damaged when being tightened.

X Unscrew the wheel bolts or nuts.

X On front wheels with wheel nuts, remove

the wheel nut cover.

X Remove the wheel.

Mounting a new wheel G

WARNING

Oiled or greased wheel bolts or damaged

wheel bolts/hub threads can cause the wheel

bolts to come loose. As a result, you could

lose a wheel while driving. There is a risk of

accident.

Never oil or grease wheel bolts. In the event

of damage to the threads, contact a qualified

specialist workshop immediately. Have the

damaged wheel bolts or hub threads

replaced/renewed. Do not continue driving. G

WARNING

If you tighten the wheel bolts or wheel nuts

when the vehicle is raised, the jack could tip

over. There is a risk of injury.

Only tighten the wheel bolts or wheel nuts

when the vehicle is on the ground.

Always observe the instructions and safety

notes on "Changing a wheel" ( Ypage 307).

Only use wheel bolts or wheel nuts that have

been designed for the wheel and the vehicle.

For safety reasons, we recommend that you

only use wheel bolts or wheel nuts which have

been approved for Sprinter vehicles and the

respective wheel.

! For a steel wheel, only use the short wheel

bolts to mount the steel spare wheel. Using

other wheel bolts to mount the steel spare

wheel could damage the brake system.

! On vehicles equipped with a tire pressure

monitor, electronic components are

located in the wheel.

Tire-mounting tools should not be used

near the valve. This could damage the elec-

tronic components.

Only have tires changed at a qualified spe-

cialist workshop. 0043

Wheel bolt for alloy wheel

0044 Wheel bolt for steel wheel

X Clean the wheel and wheel hub contact

surfaces.

X Slide the new wheel onto the wheel hub and

push it on. Changing wheels

311Wheels and tires Z

Page 314 of 338

Wheels with centering by wheel bolts:

X

Vehicles with alloy wheels: take the short

wheel bolts that fit the steel spare wheel

out of the vehicle tool kit.

X Screw in the wheel bolts and tighten them

lightly.

For wheels with wheel nuts:

X Front wheels with wheel nut covers: press

the wheel nut covers onto the wheel nuts.

X Screw in the three wheel nuts over the fix-

ing discs of the wheel nut cover.

X Turn the wheel so that the wheel bolts are

in the middle of the holes.

X Screw on the rest of the wheel nuts.

X Slightly tighten all the wheel nuts.

Lowering the vehicle G

WARNING

The wheels could work loose if the wheel nuts

and bolts are not tightened to the specified

tightening torque. There is a risk of accident.

Have the tightening torque immediately

checked at a qualified specialist workshop

after a wheel is changed.

! Only use the jack pump lever middle rod

and the rod with the largest diameter as a

lug wrench extension. Only slide the middle

rod as far as it will go onto the lug wrench.

The rods may otherwise bend and be dis-

torted to such an extent that they can no

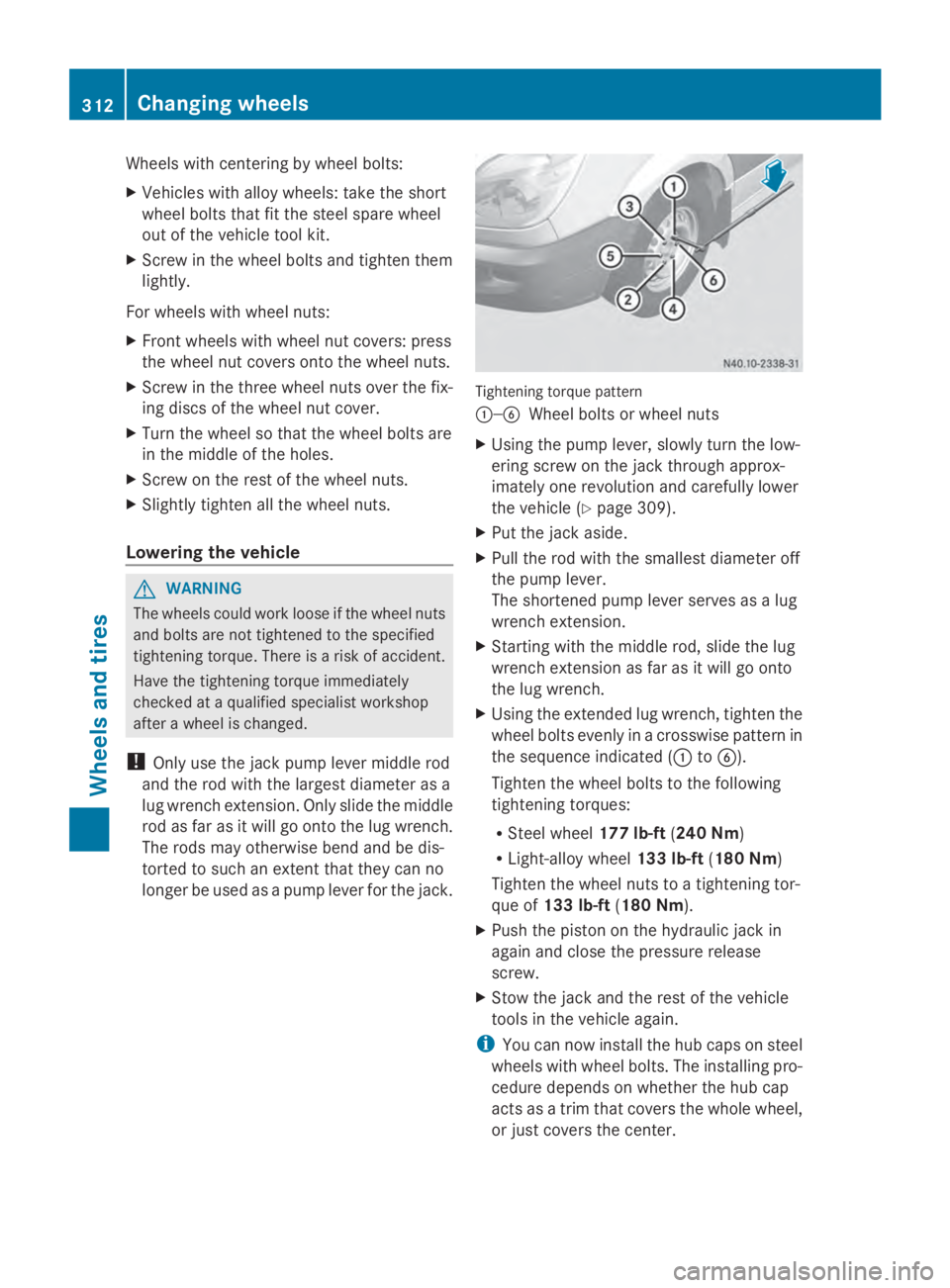

longer be used as a pump lever for the jack. Tightening torque pattern

0043—0084

Wheel bolts or wheel nuts

X Using the pump lever, slowly turn the low-

ering screw on the jack through approx-

imately one revolution and carefully lower

the vehicle (Y page 309).

X Put the jack aside.

X Pull the rod with the smallest diameter off

the pump lever.

The shortened pump lever serves as a lug

wrench extension.

X Starting with the middle rod, slide the lug

wrench extension as far as it will go onto

the lug wrench.

X Using the extended lug wrench, tighten the

wheel bolts evenly in a crosswise pattern in

the sequence indicated (0043 to0084).

Tighten the wheel bolts to the following

tightening torques:

R Steel wheel 177 lb-ft(240 Nm)

R Light-alloy wheel 133 lb-ft(180 Nm)

Tighten the wheel nuts to a tightening tor-

que of 133 lb-ft (180 Nm).

X Push the piston on the hydraulic jack in

again and close the pressure release

screw.

X Stow the jack and the rest of the vehicle

tools in the vehicle again.

i You can now install the hub caps on steel

wheels with wheel bolts. The installing pro-

cedure depends on whether the hub cap

acts as a trim that covers the whole wheel,

or just covers the center. 312

Changing wheelsWheels and tires

Page 315 of 338

X

Wheel with hub cap: position the opening

for the tire valve in the hub cap over the tire

valve.

X Push the edge of the hub cap with both

hands against the wheel until it clicks into

place. Make sure the hub cap retaining

catches engage on the steel wheel.

X Wheel with central hub cap: position the

retaining lugs of the central hub cap over

the wheel bolts.

X Hit the middle of the hub cap to engage it

on the wheel.

X Secure the faulty wheel in the spare wheel

bracket (Y page 314).

X Check the tire pressure of the newly

mounted wheel and adjust it if necessary.

Observe the recommended tire pressure

(Y page 290).

X Retighten the wheel bolts or wheel nuts to

the specified tightening torque after the

vehicle has been driven for 30 miles

(50 km).

When using a wheel/spare wheel with a new

or newly painted wheel rim, have the wheel

bolts/nuts retightened again after approx-

imately 600 to 3,000 miles (1,000 to

5,000 km). Observe the specified tightening

torque.

i Vehicles with the tire pressure monitor

system: all mounted wheels must be equip-

ped with functioning sensors. Wheel and tire combination

General notes

! Retreaded tires are neither tested nor rec-

ommended for Sprinter vehicles, since pre-

vious damage cannot always be detected

on retreaded tires. We can therefore not

guarantee driving safety. Do not mount

used tires if you have no information about

their previous usage. The recommended tire pressures can be

found:

R

on the Tire and Loading Information plac-

ard 8

on the B-pillar on the driver's side

R on the tire pressure table on the B-pillar on

the driver's side

The recommended tire pressure can also be

found in the "Tire pressure table" section in

these Operating Instructions (Y page 297).

The wheel/tire combination for your vehicle

can be found on the tire pressure table. Fur-

ther information on wheel/tire combination

can be obtained at any qualified specialist

workshop.

Check tire pressures regularly and only when

the tires are cold. Observe the notes on the

recommended tire pressures (Y page 290).

Follow the maintenance recommendations in

the tire manufacturer's warranty book in your

vehicle documents.

Notes on the vehicle equipment – always

install the vehicle:

R with tires of the same size across an axle

(left/right)

R with the same type of tires on all wheels at

a given time (summer tires, winter tires) Spare wheel

Important safety notes

G

WARNING

Wheel and tire dimensions as well as the type

of tire can vary between the spare wheel and

the wheel to be replaced. When the spare

wheel is mounted, driving characteristics may

be severely affected. There is a risk of an acci-

dent.

In order to reduce risks:

R you should therefore adapt your driving

style and drive carefully.

R never mount more than one spare wheel

that differs from the wheel to be replaced.

8 Only for vehicles with a gross weight of less than 10,000 lbs(4,536 kg). Spare wheel

313Wheels and tires

Z

Page 320 of 338

Genuine Sprinter parts

! Air bags and Emergency Tensioning Devi-

ces, as well as control units and sensors for

these restraint systems, may be installed in

the following areas of your vehicle:

R doors

R door pillars

R door sills

R seats

R cockpit

R instrument cluster

R center console

Do not install accessories such as audio

systems in these areas. Do not carry out

repairs or welding. You could impair the

operating efficiency of the restraint sys-

tems.

Have aftermarket accessories installed at

a qualified specialist workshop. H

Environmental note

We supply reconditioned assemblies and

parts which are of the same quality as new

parts. The same New Vehicle Limited War-

ranty applies as for new parts.

We test genuine Sprinter parts, as well as

conversion parts and accessories that have

been specifically approved for the type of

vehicle, for:

R reliability

R safety

R suitability

Despite ongoing market research, we are

unable to assess other parts. If individual or

official approval is given, we assume no

responsibility for use in Sprinter vehicles.

In some countries, certain parts are only offi-

cially approved for installation or modification

if they comply with legal requirements. All

genuine Sprinter parts satisfy these require-

ments. Make sure that all parts are suitable

for your vehicle. All authorized Sprinter Dealers maintain a

supply of genuine Sprinter parts for required

service and repair work. Also, the strategi-

cally distributed parts delivery centers pro-

vide quick and reliable parts service.

Always specify the vehicle identification num-

ber (VIN) and engine number when ordering

genuine Sprinter parts (Y page 319). Vehicle electronics

Tampering with the engine electron-

ics

G

WARNING

Always have work on the engine electronics

and related components carried out at a quali-

fied specialist workshop. Otherwise, the vehi-

cle's operating safety could be affected.

! Only have engine electronics and the cor-

responding parts, such as control units,

sensors or connector leads, serviced in a

qualified specialist workshop. Otherwise,

the vehicle parts may wear more quickly.

This can lead to loss of the New Vehicle

Limited Warranty. Installing electrical or electronic

equipment

G

WARNING

You and others may damage your health due

to excessive electromagnetic radiation. By

using an external antenna, the possible health

risks of electromagnetic fields, which are

under discussion among the scientific com-

munity, should be largely prevented.

Therefore, only have the exterior antenna

installed at a qualified specialist workshop.

Electrical and electronic devices may have a

detrimental effect on both the comfort and

the operating safety of the vehicle. If equip-

ment of this kind is retrofitted, its electro- 318

Vehicle electronicsTechnical data