maintenance MERCEDES-BENZ SPRINTER 2015 MY15 Operator’s Manual

[x] Cancel search | Manufacturer: MERCEDES-BENZ, Model Year: 2015, Model line: SPRINTER, Model: MERCEDES-BENZ SPRINTER 2015Pages: 334, PDF Size: 5.94 MB

Page 272 of 334

X

Clean access step in the bumper 0043with a

power washer.

Cleaning the trailer tow hitch !

Do not clean the ball coupling with a

power washer. Do not use solvents.

! Observe the notes on care in the Opera-

tor's Manual for the trailer tow hitch and

the ball coupling manufacturer.

You can also have the maintenance work on

the ball coupling and the trailer tow hitch car-

ried out by a qualified specialist workshop. Interior

Cleaning with power washers !

When using liquids to clean the vehicle

interior, observe the following points:

R Under no circumstances use power

washers.

R Make sure that no fluids enter or remain

in gaps and cavities.

R Ensure sufficient ventilation when clean-

ing.

R Make sure that the vehicle interior is

completely dry after cleaning.

Cleaning the display !

For cleaning, do not use any of the fol-

lowing:

R alcohol-based thinner or gasoline

R abrasive cleaning agents

R commercially-available household clean-

ing agents

These may damage the display surface. Do not put pressure on the display surface

when cleaning. This could lead to irrepara-

ble damage to the display. X

Switch off the audio equipment and let the

display cool down.

X Clean the display surface with a commer-

cially available microfiber cloth and cleaner

for TFT/LCD displays.

X Dry the display surface using a dry micro-

fiber cloth.

Cleaning the plastic trim G

WARNING

Care products and cleaning agents containing solvents cause surfaces in the cockpit to

become porous. As a result, plastic parts may

come loose in the event of air bag deploy-

ment. There is a risk of injury.

Do not use any care products and cleaning

agents to clean the cockpit.

! Do not affix the following to plastic surfa-

ces:

R stickers

R films

R scented oil bottles or similar items

You can otherwise damage the plastic.

! Do not allow cosmetics, insect repellent

or sunscreen to come into contact with the

plastic trim. This maintains the high-quality look of the surfaces.

X Wipe the plastic trim and the cockpit with a

damp, lint-free cloth, e.g. a microfiber

cloth.

X Heavy soiling: use a mild detergent or care

products and cleaning agents recommen-

ded and approved by Mercedes-Benz.

Cleaning the steering wheel and selec-

tor lever X

Thoroughly wipe with a damp cloth.

Cleaning the trim elements !

Do not use solvent-based cleaning agents

such as tar remover, wheel cleaners, pol- 270

CareMaintenance and care

Page 273 of 334

ishes or waxes. There is otherwise a risk of

damaging the surface.

X Wipe the trim elements with a damp, lint-

free cloth, e.g. a microfiber cloth.

X Heavy soiling: use care products and

cleaning agents recommended and

approved for Sprinter vehicles.

Cleaning the seat covers !

Do not use microfiber cloths to clean arti-

ficial leather covers. If used often, a micro- fiber cloth can damage the cover.

! Clean:

R artificial leather covers with a cloth mois-

tened with a solution containing 1%

detergent, e.g. dish washing liquid.

R cloth covers with a microfiber cloth mois-

tened with a solution containing 1%

detergent, e.g. dish washing liquid. Wipeentire seat sections carefully to avoid

leaving visible lines. Leave the seat to dry

afterwards. Cleaning results depend on

the type of dirt and how long it has been

there.

Cleaning the seat belts G

WARNING

Seat belts can become severely weakened if

bleached or dyed. This could cause the seat

belts to tear or fail, for instance, in the event of an accident. This poses an increased risk of

injury or fatal injury.

Never bleach or dye the seat belts.

! Do not clean the seat belts using chemical

cleaning agents. Do not dry the seat belts

by heating at temperatures above 176 ‡

(80 †) or in direct sunlight.

Remove any stains or dirt immediately. This

will avoid residue or damage.

X Use clean, lukewarm water and soap solu-

tion. Cleaning the headliner X

Use a soft brush or dry shampoo to remove

heavy soiling.

Cleaning the curtains !

The curtains must not be washed. Wash-

ing could cause the curtains to shrink and

lose their fire-retardant properties. Always

have the curtains dry-cleaned. Care

271Maintenance and care Z

Page 293 of 334

X

If the tire pressure is too high, release air by

pressing down the metal pin in the valve.

Use the tip of a pen, for example. Then,

check the tire pressure again using the tire

pressure gauge.

X Screw the valve cap onto the valve.

X Repeat the steps for the other tires. Tire pressure monitor

Important safety notes G

WARNING

Each tire, including the spare (if provided),

should be checked at least once a month

when cold and inflated to the pressure rec-

ommended by the vehicle manufacturer on

the Tire and Loading Information placard on

the driver's door B-pillar or the tire pressure

label on the inside of the fuel filler flap. If your vehicle has tires of a different size than the

size indicated on the Tire and Loading Infor-

mation placard or the tire pressure label, you should determine the proper tire pressure for

those tires.

As an added safety feature, your vehicle has

been equipped with a tire pressure monitoring system (TPMS) that illuminates a low tire pres-

sure telltale when one or more of your tires

are significantly underinflated. Accordingly,

when the low tire pressure telltale illuminates,

you should stop and check your tires as soon

as possible, and inflate them to the proper

pressure. Driving on a significantly underin-

flated tire causes the tire to overheat and can lead to tire failure. Underinflation also

reduces fuel efficiency and tire tread life, and may affect the vehicle's handling and stop-

ping ability.

Please note that the TPMS is not a substitute

for proper tire maintenance, and it is the driv-

er's responsibility to maintain correct tire

pressure, even if underinflation has not

reached the level to trigger illumination of the

TPMS low tire pressure telltale.

USA only: Your vehicle has also been equipped with a

TPMS malfunction indicator to indicate if the

system is not operating properly. The TPMS

malfunction indicator is combined with the

low tire pressure telltale. When the system

detects a malfunction, the warning lamp will

flash for approximately a minute and then

remain continuously illuminated. This

sequence will be repeated every time the vehi-

cle is started as long as the malfunction

exists.

When the malfunction indicator is illuminated,

the system may not be able to detect or signal low tire pressure as intended. TPMS malfunc-tions may occur for a variety of reasons,

including the mounting of incompatible

replacement or alternate tires or wheels on

the vehicle that prevent the TPMS from func-

tioning properly. Always check the TPMS mal-

function telltale after replacing one or more

tires or wheels on your vehicle to ensure that the replacement or alternate tires and wheels

allow the TPMS to continue to function prop-

erly.

Vehicles with a tire pressure monitor are

equipped with sensors in the wheels that

monitor the tire pressure of all four tires. The tire pressure monitor monitors the pressure

in all four tires; you set this pressure when you

activate the tire pressure monitor. The tire

pressure monitor warns you when the pres-

sure drops in one or more of the tires. The tire

pressure monitor only functions if the corre-

sponding sensors are installed on all wheels.

You should always adjust the tire pressure

according to the vehicle load. Restart the tire

pressure monitor if you change the tire pres-

sure.

The tire pressure monitor does not warn you if a tire pressure is incorrect. Observe the notes

on the recommended tire pressure

(Y page 288).

The tire pressure monitor is not able to warn

you of a sudden loss of pressure, e.g. follow-

ing penetration by a foreign object. In this

event, brake the vehicle until it comes to a Tire pressure

291Wheels and tires Z

Page 309 of 334

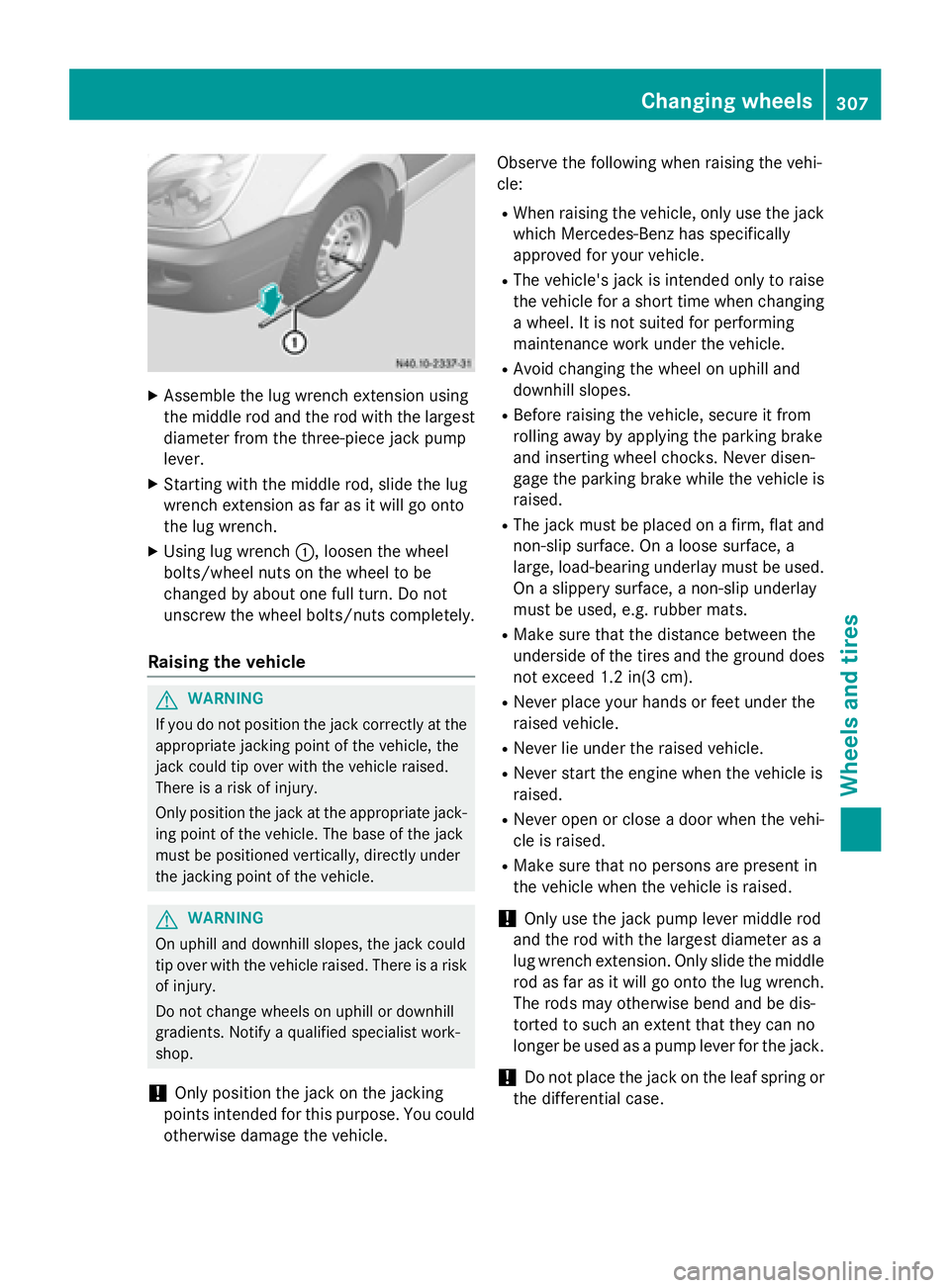

X

Assemble the lug wrench extension using

the middle rod and the rod with the largest diameter from the three-piece jack pump

lever.

X Starting with the middle rod, slide the lug

wrench extension as far as it will go onto

the lug wrench.

X Using lug wrench 0043, loosen the wheel

bolts/wheel nuts on the wheel to be

changed by about one full turn. Do not

unscrew the wheel bolts/nuts completely.

Raising the vehicle G

WARNING

If you do not position the jack correctly at the appropriate jacking point of the vehicle, the

jack could tip over with the vehicle raised.

There is a risk of injury.

Only position the jack at the appropriate jack-

ing point of the vehicle. The base of the jack

must be positioned vertically, directly under

the jacking point of the vehicle. G

WARNING

On uphill and downhill slopes, the jack could

tip over with the vehicle raised. There is a risk of injury.

Do not change wheels on uphill or downhill

gradients. Notify a qualified specialist work-

shop.

! Only position the jack on the jacking

points intended for this purpose. You could

otherwise damage the vehicle. Observe the following when raising the vehi-

cle:

R When raising the vehicle, only use the jack

which Mercedes-Benz has specifically

approved for your vehicle.

R The vehicle's jack is intended only to raise

the vehicle for a short time when changing

a wheel. It is not suited for performing

maintenance work under the vehicle.

R Avoid changing the wheel on uphill and

downhill slopes.

R Before raising the vehicle, secure it from

rolling away by applying the parking brake

and inserting wheel chocks. Never disen-

gage the parking brake while the vehicle is

raised.

R The jack must be placed on a firm, flat and

non-slip surface. On a loose surface, a

large, load-bearing underlay must be used. On a slippery surface, a non-slip underlay

must be used, e.g. rubber mats.

R Make sure that the distance between the

underside of the tires and the ground does

not exceed 1.2 in(3 cm).

R Never place your hands or feet under the

raised vehicle.

R Never lie under the raised vehicle.

R Never start the engine when the vehicle is

raised.

R Never open or close a door when the vehi-

cle is raised.

R Make sure that no persons are present in

the vehicle when the vehicle is raised.

! Only use the jack pump lever middle rod

and the rod with the largest diameter as a

lug wrench extension. Only slide the middle rod as far as it will go onto the lug wrench. The rods may otherwise bend and be dis-

torted to such an extent that they can no

longer be used as a pump lever for the jack.

! Do not place the jack on the leaf spring or

the differential case. Changing wheels

307Wheels and tires Z

Page 314 of 334

used tires if you have no information about

their previous usage.

The recommended tire pressures can be

found:

R on the Tire and Loading Information plac-

ard 10

on the B-pillar on the driver's side

R on the tire pressure table on the B-pillar on

the driver's side

The recommended tire pressure can also be

found in the "Tire pressure table" section in

this Operator's Manual (Y page 294). The

wheel/tire combination for your vehicle can

be found on the tire pressure table. Further

information on wheel/tire combination can

be obtained at any qualified specialist work-

shop.

Check tire pressures regularly and only when

the tires are cold. Observe the notes on the

recommended tire pressure (Y page 288).

Follow the maintenance recommendations in the tire manufacturer's warranty book in your

vehicle documents.

Notes on the vehicle equipment – always

equip the vehicle:

R with tires of the same size across an axle

(left/right)

R with the same type of tires on all wheels at

a given time (summer tires, winter tires)

Tires that have been specially designed and

approved for your vehicle are marked with

MO or MO1 (Mercedes-Benz Original). You

can find this identification on the tires them-

selves and in the following table.

i Not all wheel/tire combinations can be

installed at the factory in all countries. Spare wheel

Important safety notes

G

WARNING

Wheel and tire dimensions as well as the type of tire can vary between the spare wheel and the wheel to be replaced. When the spare

wheel is mounted, driving characteristics may be severely affected. There is a risk of an acci-

dent.

In order to reduce risks:

R you should therefore adapt your driving

style and drive carefully.

R never mount more than one spare wheel

that differs from the wheel to be replaced.

R only use a spare wheel that differs from the

wheel to be replaced for a short time.

R do not deactivate ESP ®

.

R have a spare wheel that differs from the

wheel that has been changed replaced at

the nearest qualified specialist workshop.

You must observe the correct wheel and

tire dimensions as well as the wheel type.

When using a spare wheel of a different size,

do not exceed the maximum speed of

80 km/h. General notes

! Check the spare wheel regularly to see

that it is secure and has the prescribed tire

pressure.

The procedure for mounting the spare wheel

is described in "Mounting a wheel"

(Y page 306).

The following should be checked regularly,

particularly prior to long journeys:

R the tire pressure of the spare wheel, which

should then be corrected if necessary

(Y page 288).

R the fastenings of the spare wheel bracket.

The spare wheel is located in a spare wheel

bracket under the rear of the vehicle.

Replace the tires after 6 years at the latest,

regardless of wear. This also applies to the

spare wheel.

10 Only for vehicles with a gross weight of less than 10,000 lbs (4,536 kg). 312

Spare wheelWheels and ti

res

Page 325 of 334

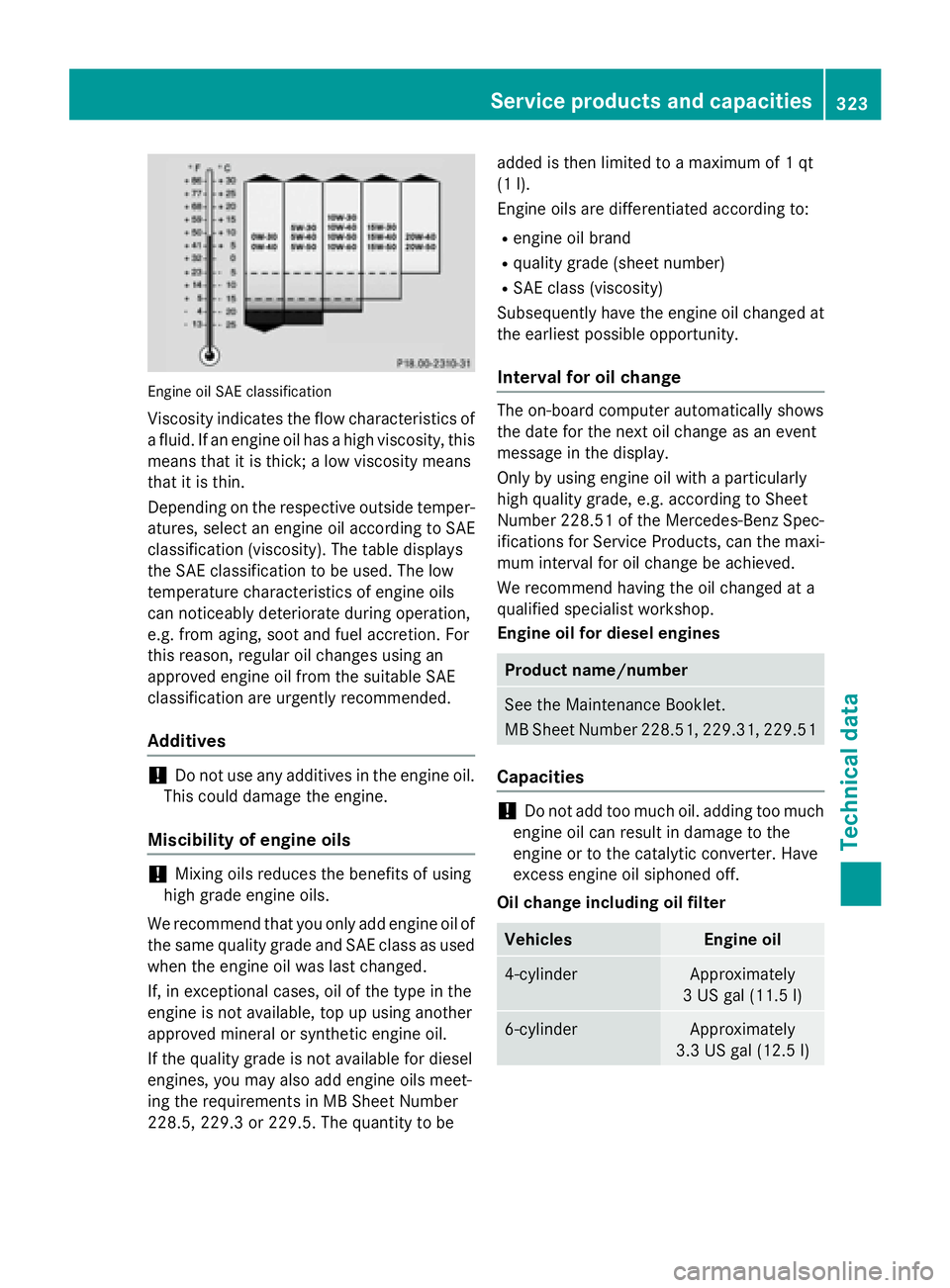

Engine oil SAE classification

Viscosity indicates the flow characteristics of a fluid. If an engine oil has a high viscosity, thismeans that it is thick; a low viscosity means

that it is thin.

Depending on the respective outside temper- atures, select an engine oil according to SAE

classification (viscosity). The table displays

the SAE classification to be used. The low

temperature characteristics of engine oils

can noticeably deteriorate during operation,

e.g. from aging, soot and fuel accretion. For

this reason, regular oil changes using an

approved engine oil from the suitable SAE

classification are urgently recommended.

Additives !

Do not use any additives in the engine oil.

This could damage the engine.

Miscibility of engine oils !

Mixing oils reduces the benefits of using

high grade engine oils.

We recommend that you only add engine oil of

the same quality grade and SAE class as used when the engine oil was last changed.

If, in exceptional cases, oil of the type in the

engine is not available, top up using another

approved mineral or synthetic engine oil.

If the quality grade is not available for diesel

engines, you may also add engine oils meet-

ing the requirements in MB Sheet Number

228.5, 229.3 or 229.5. The quantity to be added is then limited to a maximum of 1 qt

(1 l).

Engine oils are differentiated according to:

R engine oil brand

R quality grade (sheet number)

R SAE class (viscosity)

Subsequently have the engine oil changed at

the earliest possible opportunity.

Interval for oil change The on-board computer automatically shows

the date for the next oil change as an event

message in the display.

Only by using engine oil with a particularly

high quality grade, e.g. according to Sheet

Number 228.51 of the Mercedes-Benz Spec-

ifications for Service Products, can the maxi-

mum interval for oil change be achieved.

We recommend having the oil changed at a

qualified specialist workshop.

Engine oil for diesel engines Product name/number

See the Maintenance Booklet.

MB Sheet Number 228.51, 229.31, 229.51

Capacities

!

Do not add too much oil. adding too much

engine oil can result in damage to the

engine or to the catalytic converter. Have

excess engine oil siphoned off.

Oil change including oil filter Vehicles Engine oil

4-cylinder Approximately

3 US gal (11.5 l) 6-cylinder Approximately

3.3 US gal (12.5 l) Service products and capacities

323Technical data Z

Page 326 of 334

Information about oil consumption

!

If the vehicle is predominantly used for

short-distance driving, this could lead to a

malfunction in the automatic cleaning func- tion for the diesel particle filter. As a result,

fuel may accumulate in the engine oil and

cause engine failure.

Therefore, if you mainly drive short distan-

ces, you should drive on a highway or on

rural roads for 20 minutes every 310 miles

(500 km). This ensures sufficient regener-

ation of the diesel particle filter.

Depending on the driving style, the vehicle

consumes a maximum of 1.0 US qt (1.0 l) of

engine oil over a distance of 620 miles

(1000 km).

Oil consumption may be higher if:

R the vehicle is new.

R you mainly operate the vehicle under ardu-

ous operating conditions.

R you frequently drive at high engine speeds.

Regular maintenance is one of the precondi-

tions for moderate rates of consumption.

You can only estimate the oil consumption

after you have driven a considerable distance.

Check the engine oil level on a regular basis,

e.g. weekly or each time you refuel

(Y page 250). Transmission and power steering oil

Automatic transmission Service product: automatic transmission

fluid Product name/number Maintenance

interval Shell ATF 3403/M-115

MB Sheet No. 236.10 —

Fuchs/Shell ATF 3353

MB Sheet No. 236.12 Further information can be obtained at any

qualified specialist workshop.

Rear axle Service product: transmission oil

Product name/number Maintenance

interval BP Energear Hypo DC

80W-90

MB Sheet No. 235.20 —

Mobil Delvac Synthetic

Gear Oil 75W-90

MB Sheet No. 235.8 Further information can be obtained at any

qualified specialist workshop.

Steering Service product: power steering fluid

Product name/number Maintenance

interval Mobil ATF‑

D,

Exxon Mobil Corporation

or equivalent

MB Sheet No. 236.3 —

The steering is maintenance-free. Further

information can be obtained at any qualified

specialist workshop. Brake fluid

G

WARNING

Brake fluid is hazardous to health. Do not

swallow brake fluid. See a doctor immediately if you swallow brake fluid.

Make sure that brake fluid does not come into

contact with skin, clothing or eyes. Rinse

affected areas with plenty of clean water and

consult a doctor if necessary. 324

Service products and capacitiesTechnical data

Page 327 of 334

Always wear gloves and eye protection when

topping up brake fluid.

Store brake fluid only in the original closed

container and keep it out of the reach of chil- dren. Comply with safety regulations when

handling brake fluid. G

WARNING

The brake fluid constantly absorbs moisture

from the air. This lowers the boiling point of

the brake fluid. If the boiling point of the brake fluid is too low, vapor pockets may form in the brake system when the brakes are applied

hard. This would impair braking efficiency.

There is a risk of an accident.

You should have the brake fluid renewed at

the specified intervals.

! Brake fluid corrodes paint, plastic and

rubber. If paint, plastic or rubber has come

into contact with brake fluid, rinse with

water immediately.

Only use brake fluids approved for Sprinter

vehicles. Always check for the identification

DOT 4 plus.

Information about approved brake fluids can

be found in the Maintenance Booklet or

obtained at any qualified specialist workshop. Service product:

brake fluid Product name/

number Intac B026E

R Boiling point: 500 ‡

(260 †)

R Wet boiling point:

356 ‡ (180 †) MB Sheet No. 331.0

Maintenance

interval 2 years

i

Have the brake fluid renewed every 2

years at a qualified specialist workshop. There is usually a notice in the engine com-

partment to remind you when the next

brake fluid change is due. Coolant

Important safety notes G

WARNING

If antifreeze comes into contact with hot com- ponents in the engine compartment, it may

ignite. There is a risk of fire and injury.

Let the engine cool down before you add anti-

freeze. Make sure that antifreeze is not spilled

next to the filler neck. Thoroughly clean the

antifreeze from components before starting

the engine.

! Take care not to spill any coolant on pain-

ted surfaces. You could otherwise damage

the paintwork.

When handling, storing and disposing of cool-

ant and antifreeze, please observe the rele-

vant regulations and the safety notes in the

"Service products and capacities" section

(Y page 318).

Coolant additive with antifreeze

requirements !

Use only approved antifreeze/corrosion

inhibitor that complies with MB Specifica-

tion for Service Products, Sheet Number

325. Using other, non-approved anti-

freeze/corrosion inhibitors may cause

damage to the coolant system and reduce

the engine's service life.

Coolant is a mixture of water and antifreeze/ corrosion inhibitor. It performs the following

tasks:

R corrosion protection

R antifreeze protection

R raises the boiling point

When the vehicle is first delivered, it is filled

with a coolant mixture that ensures adequate antifreeze and corrosion protection. Coolant Service products and capacities

325Technical data Z

Page 328 of 334

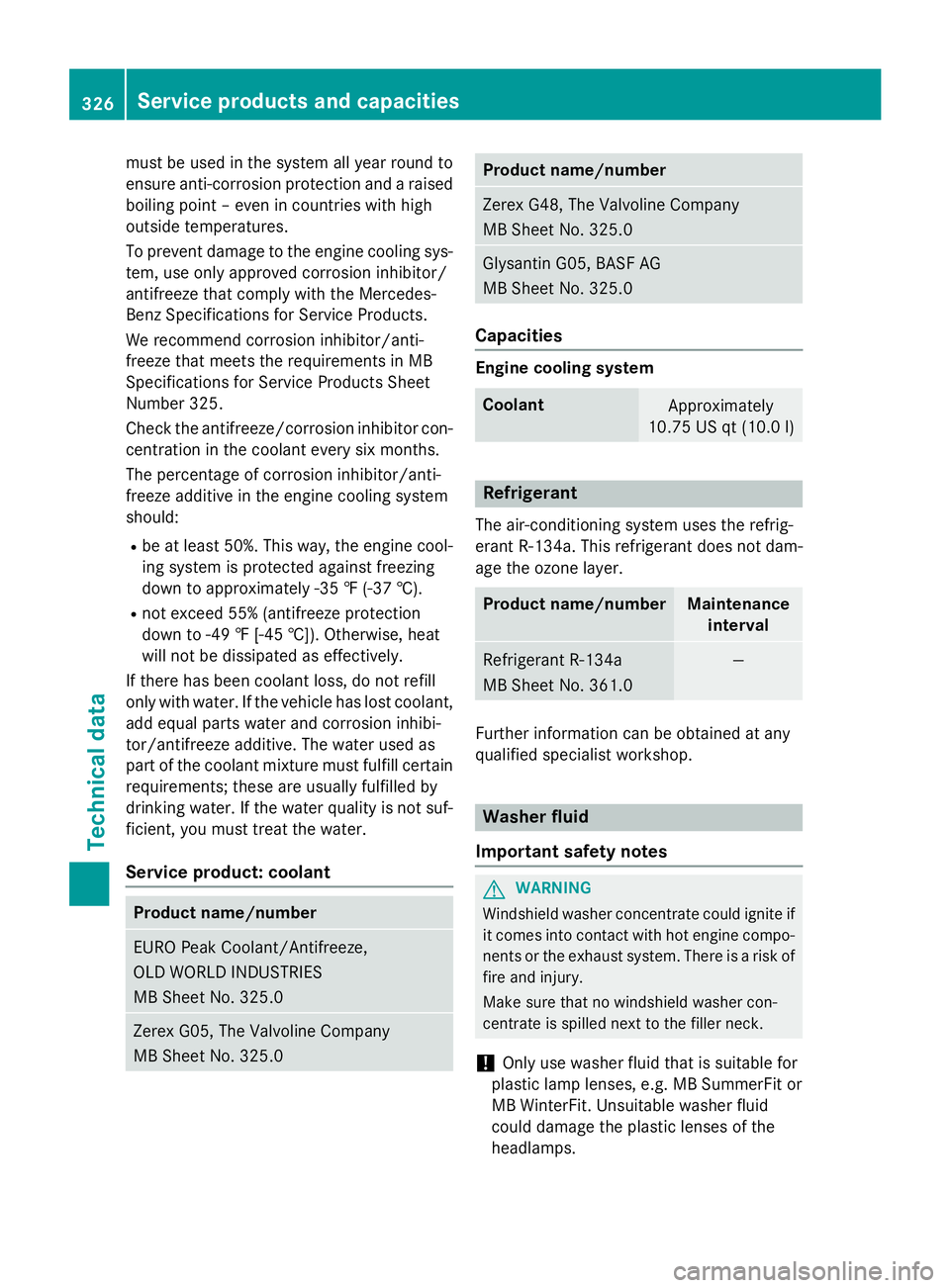

must be used in the system all year round to

ensure anti-corrosion protection and a raised

boiling point – even in countries with high

outside temperatures.

To prevent damage to the engine cooling sys- tem, use only approved corrosion inhibitor/

antifreeze that comply with the Mercedes-

Benz Specifications for Service Products.

We recommend corrosion inhibitor/anti-

freeze that meets the requirements in MB

Specifications for Service Products Sheet

Number 325.

Check the antifreeze/corrosion inhibitor con- centration in the coolant every six months.

The percentage of corrosion inhibitor/anti-

freeze additive in the engine cooling system

should:

R be at least 50%. This way, the engine cool-

ing system is protected against freezing

down to approximately -35 ‡ (-37 †).

R not exceed 55% (antifreeze protection

down to -49 ‡ [-45 †]). Otherwise, heat

will not be dissipated as effectively.

If there has been coolant loss, do not refill

only with water. If the vehicle has lost coolant,

add equal parts water and corrosion inhibi-

tor/antifreeze additive. The water used as

part of the coolant mixture must fulfill certain requirements; these are usually fulfilled by

drinking water. If the water quality is not suf-ficient, you must treat the water.

Service product: coolant Product name/number

EURO Peak Coolant/Antifreeze,

OLD WORLD INDUSTRIES

MB Sheet No. 325.0

Zerex G05, The Valvoline Company

MB Sheet No. 325.0 Product name/number

Zerex G48, The Valvoline Company

MB Sheet No. 325.0

Glysantin G05, BASF AG

MB Sheet No. 325.0

Capacities

Engine cooling system

Coolant

Approximately

10.75 US qt (10.0 l) Refrigerant

The air-conditioning system uses the refrig-

erant R‑134a. This refrigerant does not dam-

age the ozone layer. Product name/number Maintenance

interval Refrigerant R‑134a

MB Sheet No. 361.0 —

Further information can be obtained at any

qualified specialist workshop. Washer fluid

Important safety notes G

WARNING

Windshield washer concentrate could ignite if it comes into contact with hot engine compo-

nents or the exhaust system. There is a risk of

fire and injury.

Make sure that no windshield washer con-

centrate is spilled next to the filler neck.

! Only use washer fluid that is suitable for

plastic lamp lenses, e.g. MB SummerFit or

MB WinterFit. Unsuitable washer fluid

could damage the plastic lenses of the

headlamps. 326

Service products and capacitiesTechnical data