change wheel MERCEDES-BENZ SPRINTER 2016 MY16 Operator’s Manual

[x] Cancel search | Manufacturer: MERCEDES-BENZ, Model Year: 2016, Model line: SPRINTER, Model: MERCEDES-BENZ SPRINTER 2016Pages: 290, PDF Size: 6.44 MB

Page 254 of 290

The tires are cold:

Rif the vehicle has been parked for at least

three hours without direct sunlight on the

tires, and

Rif the vehicle has not been driven further than

1 mile (1.6 km)

Tire temperature changes depending on the

ambient temperature, driving speed and tire

load. If the tire temperature changes by 18 ‡

(10 †), the tire pressure changes by approx-

imately 10 kPa (0.1 bar/1.5 psi). Take this into

account when checking the pressure of warm

tires. Only correct the tire pressure if it is too low

for the current operating conditions. If you

check the tire pressures when the tires are

warm, the resulting values will be higher than if

the tires were cold. This is normal. Do not under

any circumstances release the air in order to

adjust the pressure to the prescribed value for

cold tires. The tire pressure would otherwise be

too low.

Observe the recommended tire pressures for

cold tires:

Ron the Tire and Loading Information placard5

on the B-pillar on the driver's side, or

Ron the tire pressure plate on the B-pillar on the

driver's side of the vehicle

R

Underinflated or overinflated tires

Underinflated tires:

GWARNING

Tires with pressure that is too low can over-

heat and burst as a consequence. In addition, they also suffer from excessive and/or irreg-

ular wear, which can severely impair the brak-

ing properties and the driving characteristics.

There is a risk of an accident.

Avoid tire pressures that are too low in all the

tires, including the spare wheel.

Underinflated tires can:

Rfail from being overheated

Radversely affect handling

Rwear excessively and/or unevenly

Rhave an adverse effect on fuel consumption

Overinflated tires

GWARNING

Tires with excessively high pressure can burst

because they are damaged more easily by

road debris, potholes etc. In addition, they

also suffer from irregular wear, which can

severely impair the braking properties and the driving characteristics. There is a risk of an

accident.

Avoid tire pressures that are too high in all the

tires, including the spare wheel.

Overinflated tires can:

Rincrease the braking distance

Radversely affect handling

Rwear excessively and/or unevenly

Radversely affect ride comfort

Rbe more susceptible to damage

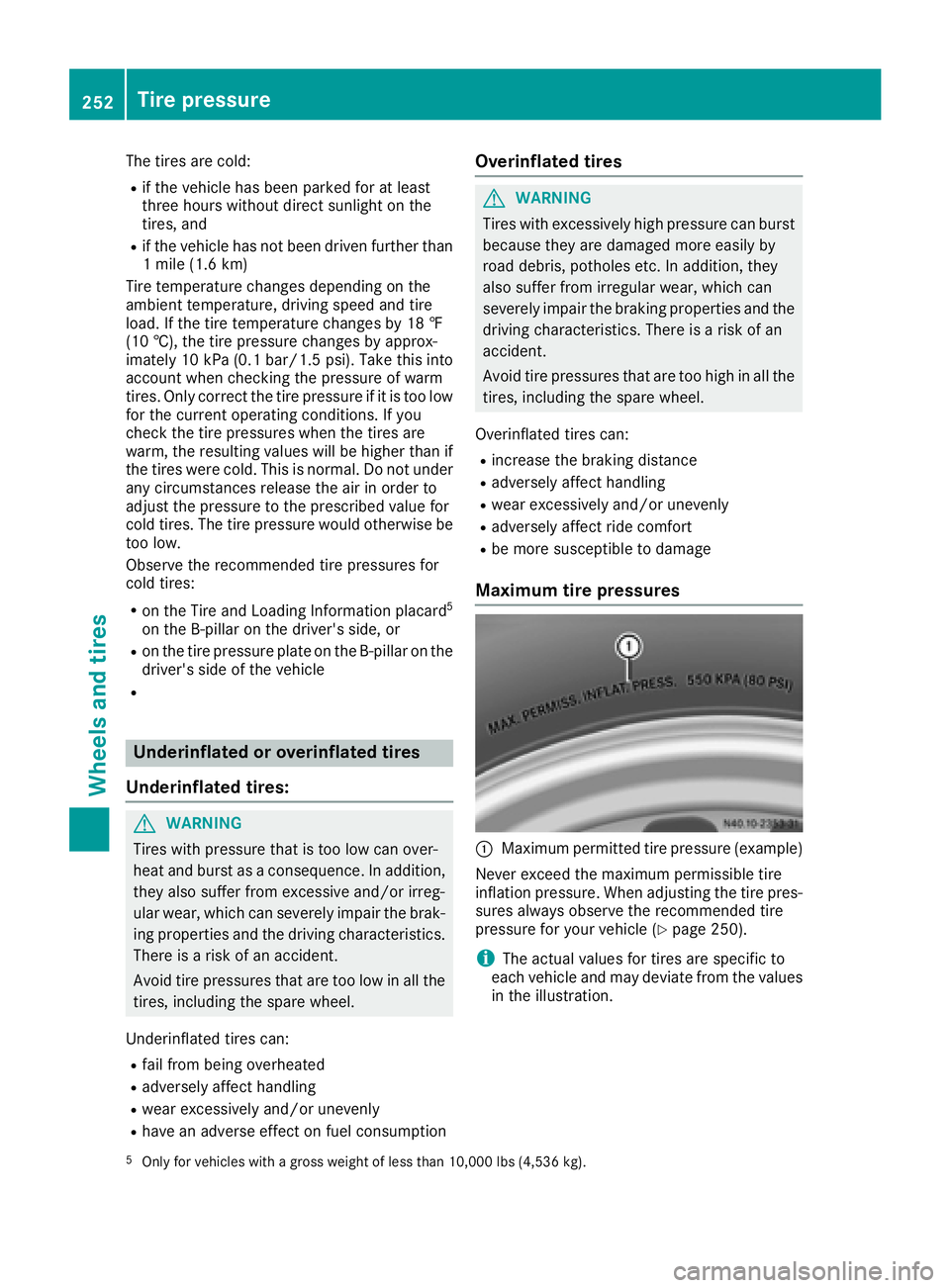

Maximum tire pressures

:Maximum permitted tire pressure (example)

Never exceed the maximum permissible tire

inflation pressure. When adjusting the tire pres-

sures always observe the recommended tire

pressure for your vehicle (

Ypage 250).

iThe actual values for tires are specific to

each vehicle and may deviate from the values

in the illustration.

5Only for vehicles with a gross weight of less than 10,000 lbs (4,536 kg).

252Tire pressure

Wheels and tires

Page 256 of 290

cle is started as long as the malfunction

exists.

When the malfunction indicator is illuminated,the system may not be able to detect or signal

low tire pressure as intended. TPMS malfunc-

tions may occur for a variety of reasons,

including the mounting of incompatible

replacement or alternate tires or wheels on

the vehicle that prevent the TPMS from func-

tioning properly. Always check the TPMS mal-

function telltale after replacing one or more

tires or wheels on your vehicle to ensure that

the replacement or alternate tires and wheels

allow the TPMS to continue to function prop-

erly.

Vehicles with a tire pressure monitor are equip-

ped with sensors in the wheels that monitor the

tire pressure of all four tires. The tire pressure

monitor monitors the pressure in all four tires;

you set this pressure when you activate the tire

pressure monitor. The tire pressure monitor

warns you when the pressure drops in one or

more of the tires. The tire pressure monitor only

functions if the corresponding sensors are

installed on all wheels.

You should always adjust the tire pressure

according to the vehicle load. Restart the tire

pressure monitor if you change the tire pres-

sure.

The tire pressure monitor does not warn you if a

tire pressure is incorrect. Observe the notes on

the recommended tire pressure (

Ypage 250).

The tire pressure moni tor i

s not able to warn you

of a sudden loss of pressure, e.g. following pen- etration by a foreign object. In this event, brake

the vehicle until it comes to a standstill. Do not

carry out any sudden steering maneuvers.

The tire pressure monitor has a yellow h

warning lamp in the instrument cluster for indi-

cating pressure loss/malfunctions (USA) or

pressure loss (Canada). Depending on how the

warning lamp flashes or lights up, an underin-

flated tire or a malfunction in the tire pressure

monitor is displayed:

Rif the h warning lamp is lit continuously,

the tire pressure on one or more tires is sig- nificantly too low. The tire pressure monitor is

not malfunctioning.

RUSA only: if the hwarning lamp flashes for

60 seconds and then remains lit constantly,

the tire pressure monitor is malfunctioning.

Only vehicles with steering wheel buttons: the

on-board computer displays information on tire

pressure. After a few minutes of driving, the cur-

rent tire pressure of each tire is shown in the on-

board computer.

USA only: if the tire pressure monitor is mal-

functioning, it may be more than 10 minutes

before the malfunction is shown. The htire

pressure warning lamp flashes for 60 seconds

and then remains lit. When the malfunction has been rectified, the htire pressure warning

lamp goes out after a few minutes of driving.

The tire p

ressure values indicated by the on-

board computer may differ from those meas-

ured at a gas station with a pressure gage. The

tire pressures shown by the on-board computer

refer to those measured at sea level. At high

altitudes, the tire pressure values indicated by a pressure gage are higher than those shown by

the on-board computer. In this case, do not

reduce the tire pressures.

If radio transmitting equipment (e.g. wireless

headphones, two-way radios) is operated inside

the vehicle or in the vicinity of the vehicle, this

can interfere with the operation of the tire pres-

sure monitor.

Checking the tire pressure electroni-

cally (vehicles with steering wheel but-

tons)

Tire pressure display

254Tire pressure

Wheels and tires

Page 257 of 290

Using the steering wheel buttons

XTurn the SmartKey to position2in the ignition

lock.

XPress the VorU button repeatedly

until the standard display is shown

(

Ypage 167).

XPress the 9or: button repeatedly

until the current pressure of the individual

tires is shown in the display.

If the vehicle is parked for longer than

20 minutes or you then drive at less than 18 mph

(30 km/h), the Tire pres. displayed

after driving for several minutesmes-

sage appears.

iThe tire pressure value shown in the display

may differ from those measured at a gas sta-

tion using a pressure gage. The on-board

computer will generally give you a more exact

value.

Tire pressure loss warning system

Vehicles with steering wheel buttons

If the tire pressure monitor detects a pressure

loss in one or more tires, the on-board computer

displays the yellow Tire

pres.Adjustpres.warning message. The htire pressure loss

warning lamp in the instrument cluster

(

Ypage 202) flashes for about 60 seconds and

then remains lit.

The pressure of the affected tire is highlighted in

yellow in the on-board computer (

Ypage 176).

If the tire pressure monitor detects a significant

pressure loss in one or more tires, the on-board

computer displays the red Tire pres.

Warn‐ingTiredefectwarning message. Theh

tire pressure loss warning lamp in the instru-

ment cluster (

Ypage 202) flashes for about 60

seconds and then remains lit. An additional

warning tone sounds.

The pressure of the affected tire is highlighted in

yellow in the on-board computer (

Ypage 176).

Restarting the tire pressure monitor

When you restart the tire pressure monitor, the

currently set tire pressure are taken as refer-

ence values for monitoring. In most cases, the tire pressure monitor detects

the new reference values automatically, e.g.

after you have:

Rchanged the tire pressure

Rchanged wheels or tires

Rinstalled new wheels or tires

However, you can also define reference values

manually as described here.

Before restarting the tire pressure monitor:

XSet the tire pressure to the value recommen- ded on the Tire and Loading Information plac-

ard or the tire pressure table on the B-pillar on

the driver's side (

Ypage 250).

Observe the notes on tire pressure when

doing so (

Ypage 250).

XMake sure that the tire pressure is correct on

all four wheels.

Restarting the tire pressure monitor (vehi-

cles without steering wheel buttons):

XTurn the SmartKey to position 2in the ignition

lock.

XPress the 4menu button on the instrument

cluster repeatedly until the display shows the

following message:

+CAL- TPMS

XPress the fbutton on the instrument clus-

ter.

The display shows:

OK TPMS

The tire pressure monitor activation process

has begun. The tire pressures measured for

the individual wheels are stored as the new

reference values, provided that the tire pres-

sure monitor considers them to be plausible.

If you wish to cancel the restart:

XPress the gbutton or the 4menu button on

the instrument cluster.

The activation process is canceled automati-

cally if 30 seconds elapse without input.

Restarting the tire pressure monitor (vehi-

cles with steering wheel buttons):

XTurn the key to position 2in the ignition lock.

XPress the VorU button on the steering

wheel until the standard display (Ypage 167)

appears in the display.

XPress the 9or: button on the steering

wheel repeatedly until the current pressure of

Tire pressure255

Wheels and tires

Z

Page 268 of 290

Load bearing index

The load bearing index (also load index) is a code

that contains the maximum load bearing capa-

city of a tire.

Traction

Traction is the result of friction between the tires

and the road surface.

TWR (permissible trailer drawbar load)

The TWR is the maximum permissible weight

that may act on the ball coupling of the trailer

tow hitch.

Wear indicator

Narrow bars (tread wear bars) that are distrib-

uted over the tire tread. If the tire tread is level

with the bars, the wear limit ofáin(1.6 mm )

ha sbeen re ached.

Distribution of the vehicle occupants

The distribution of vehicle occupants over des-

ignated seat positions in a vehicle.

Maximum permissible payload weight

Nominal load and goods/luggage load plus

68 kg (150 lbs) multiplied by the number of

seats in the vehicle.

Flat tire

General notes

If your vehicle is equipped with a spare wheel,

the spare wheel is under the rear of the vehicle

(

Ypage 272).

Information about installing a wheel can be

found in the "Wheel change" section

(

Ypage 267).

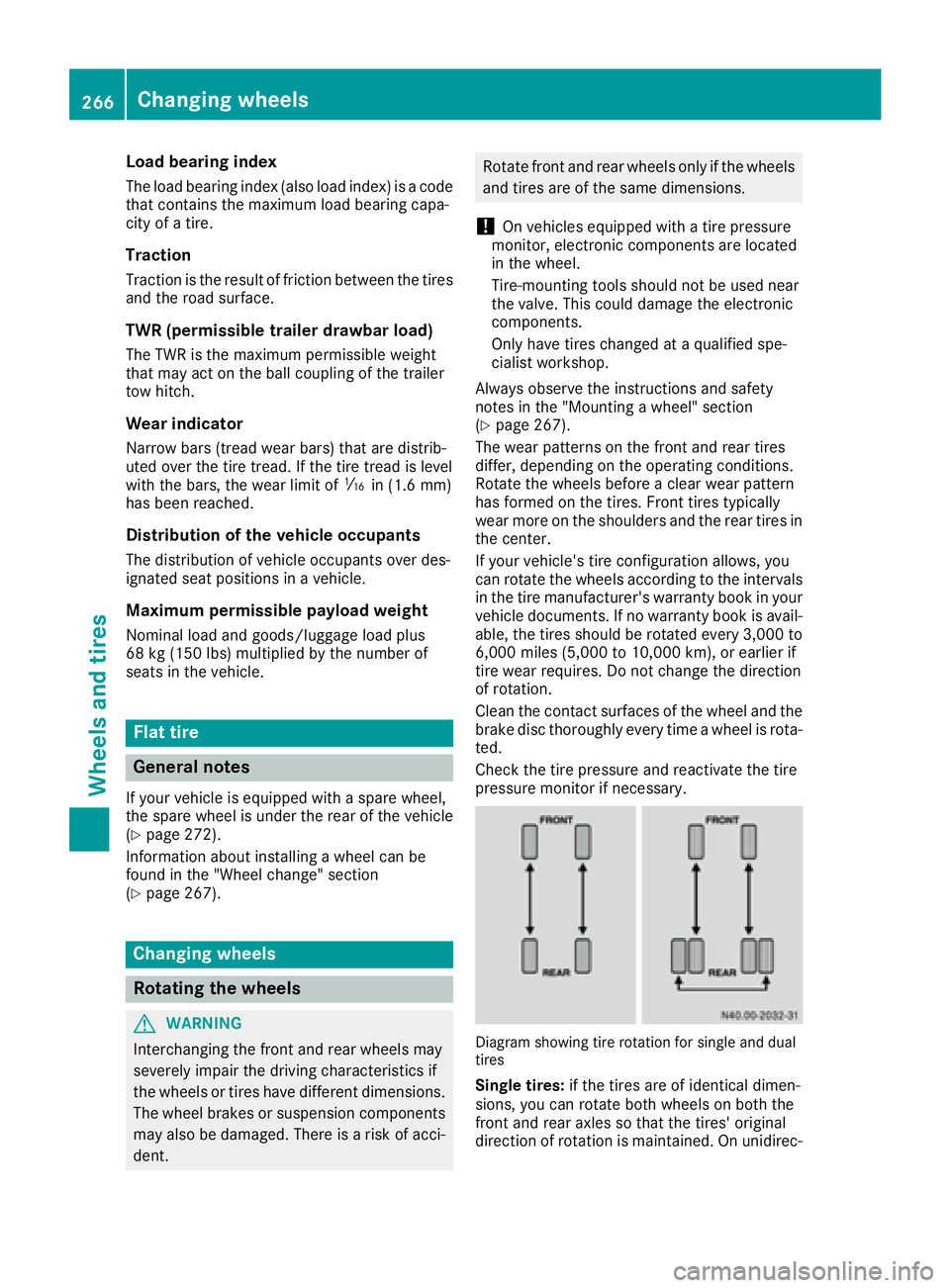

Changing wheels

Rotating the wheels

GWARNING

Interchanging the front and rear wheels may

severely impair the driving characteristics if

the wheels or tires have different dimensions. The wheel brakes or suspension components

may also be damaged. There is a risk of acci-

dent.

Rotate front and rear wheels only if the wheels and tires are of the same dimensions.

!On vehicles equipped with a tire pressure

monitor, electronic components are located

in the wheel.

Tire-mounting tools should not be used near

the valve. This could damage the electronic

components.

Only have tires changed at a qualified spe-

cialist workshop.

Always observe the instructions and safety

notes in the "Mounting a wheel" section

(

Ypage 267).

The wear patterns on the front and rear tires

differ, depending on the operating conditions.

Rotate the wheels before a clear wear pattern

has formed on the tires. Front tires typically

wear more on the shoulders and the rear tires in

the center.

If your vehicle's tire configuration allows, you

can rotate the wheels according to the intervals

in the tire manufacturer's warranty book in your

vehicle documents. If no warranty book is avail-

able, the tires should be rotated every 3,000 to

6,000 miles (5,000 to 10,000 km), or earlier if

tire wear requires. Do not change the direction

of rotation.

Clean the contact surfaces of the wheel and the brake disc thoroughly every time a wheel is rota-

ted.

Check the tire pressure and reactivate the tire

pressure monitor if necessary.

Diagram showing tire rotation for single and dual

tires

Single tires: if the tires are of identical dimen-

sions, you can rotate both wheels on both the

front and rear axles so that the tires' original

direction of rotation is maintained. On unidirec-

266Changing wheels

Wheels and tires

Page 269 of 290

tional tires, an arrow on the sidewall shows the

prescribed direction of rotation of the tire.

Twin rear tires:if the tires are of identical

dimensions, you can rotate the wheels on the

front axle and the inner wheels on the rear axle

in pairs such that the original direction of tire

rotation is retained. With unidirectional tires,

you may rotate the outside wheels at the rear

axle from one side to the other.

Direction of rotation

Tires with a specified direction of rotation have

additional benefits, e.g. if there is a risk of hydro-

planing. You will only gain these benefits if the

correct direction of rotation is observed.

An arrow on the sidewall of the tire indicates its

correct direction of rotation.

You may mount a spare wheel against the direc-

tion of rotation. Observe the time restriction on

use as well as the speed limitation specified on

the spare wheel.

Storing wheels

Store wheels that are not being used in a cool,

dry and preferably dark place. Protect the tires

from contact with oil, grease and fuel.

Mounting a wheel

Vehicle preparation

XStop the vehicle as far away as possible from

traffic and on a level, firm and non-slip sur-

face.

XIf your vehicle poses a risk to approaching

traffic, switch on the hazard warning lamps.

XApply the parking brake.

XTurn the front wheels to the straight-ahead

position.

XMove the selector lever of the automatic

transmission to position P.

XSwitch off the engine.

XPassengers should leave the vehicle. Make

sure that the passengers are not endangered

as they do so.

XMake sure that no one is near the danger area

while the wheel is being changed. Anyone

who is not directly assisting in the wheel change should, for example, stand behind the

barrier.

XPlace the warning triangle or warning lamp at

a suitable distance.

Observe legal requirements.

XSecure the vehicle to prevent it from rolling

away.

iObserve the safety notes on parking in the

section on "Driving and parking"

(

Ypage 130).

XOn level terrain: place chocks or other suit-

able objects under the front and rear of the

wheel that is diagonally opposite the wheel to

be changed.

XOn slight inclines: place chocks or other

suitabl e objects under the wheels on the front

and rear axles opposite the wheel to be

changed.

XTake the vehicle tool kit and the jack from the

footwell on the front-passenger side

(

Ypage 240).

XRemove the spare wheel from the spare wheel

bracket (Ypage 273). Observe the safety

notes in the "Spare wheel" section

(

Ypage 272).

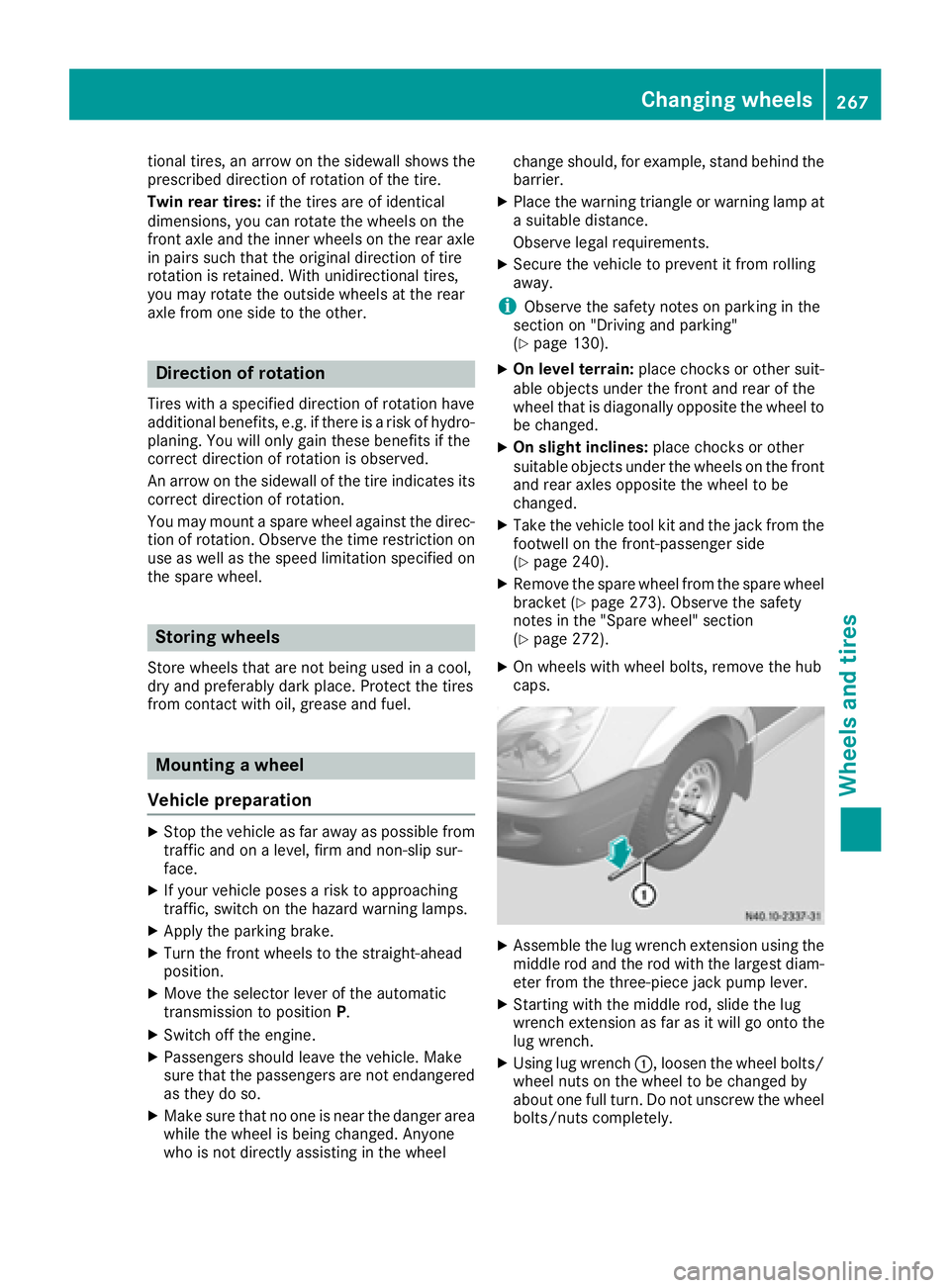

XOn wheels with wheel bolts, remove the hub

caps.

XAssemble the lug wrench extension using the

middle rod and the rod with the largest diam-

eter from the three-piece jack pump lever.

XStarting with the middle rod, slide the lug

wrench extension as far as it will go onto the

lug wrench.

XUsing lug wrench :, loosen the wheel bolts/

wheel nuts on the wheel to be changed by

about one full turn. Do not unscrew the wheel bolts/nuts completely.

Changing wheels267

Wheels an d tires

Z

Page 270 of 290

Raising the vehicle

GWARNING

If you do not position the jack correctly at the

appropriate jacking point of the vehicle, the

jack could tip over with the vehicle raised.

There is a risk of injury.

Only position the jack at the appropriate jack-

ing point of the vehicle. The base of the jack

must be positioned vertically, directly under

the jacking point of the vehicle.

GWARNING

On uphill and downhill slopes, the jack could

tip over with the vehicle raised. There is a risk

of injury.

Do not change wheels on uphill or downhill

gradients. Notify a qualified specialist work-

shop.

!Only position the jack on the jacking points

intended for this purpose. You could other-

wise damage the vehicle.

Observe the following when raising the vehicle:

RWhen raising the vehicle, only use the jack

which Mercedes-Benz has specifically

approved for your vehicle.

RThe vehicle's jack is intended only to raise the

vehicle for a short time when changing a

wheel. It is not suited for performing mainte-

nance work under the vehicle.

RAvoid changing the wheel on uphill and down- hill slopes.

RBefore raising the vehicle, secure it from roll-

ing away by applying the parking brake and

inserting wheel chocks. Never disengage the

parking brake while the vehicle is raised.

RThe jack must be placed on a firm, flat and

non-slip surface. On a loose surface, a large,

load-bearing underlay must be used. On a

slippery surface, a non-slip underlay must be

used, e.g. rubber mats.

RMake sure that the distance between the

underside of the tires and the ground does not

exceed 1.2 in(3 cm).

RNever place your hands or feet under the

ra

ised vehicle.

RNever lie under the raised vehicle.

RNever start the engine when the vehicle is

raised.

RNever open or close a door when the vehicle

is raised.

RMake sure that no persons are present in the

vehicle when the vehicle is raised.

!Only use the jack pump lever middle rod and

the rod with the largest diameter as a lug

wrench extension. Only slide the middle rod

as far as it will go onto the lug wrench. The

rods may otherwise bend and be distorted to

such an extent that they can no longer be

used as a pump lever for the jack.

!Do not place the jack on the leaf spring or

the differential case.

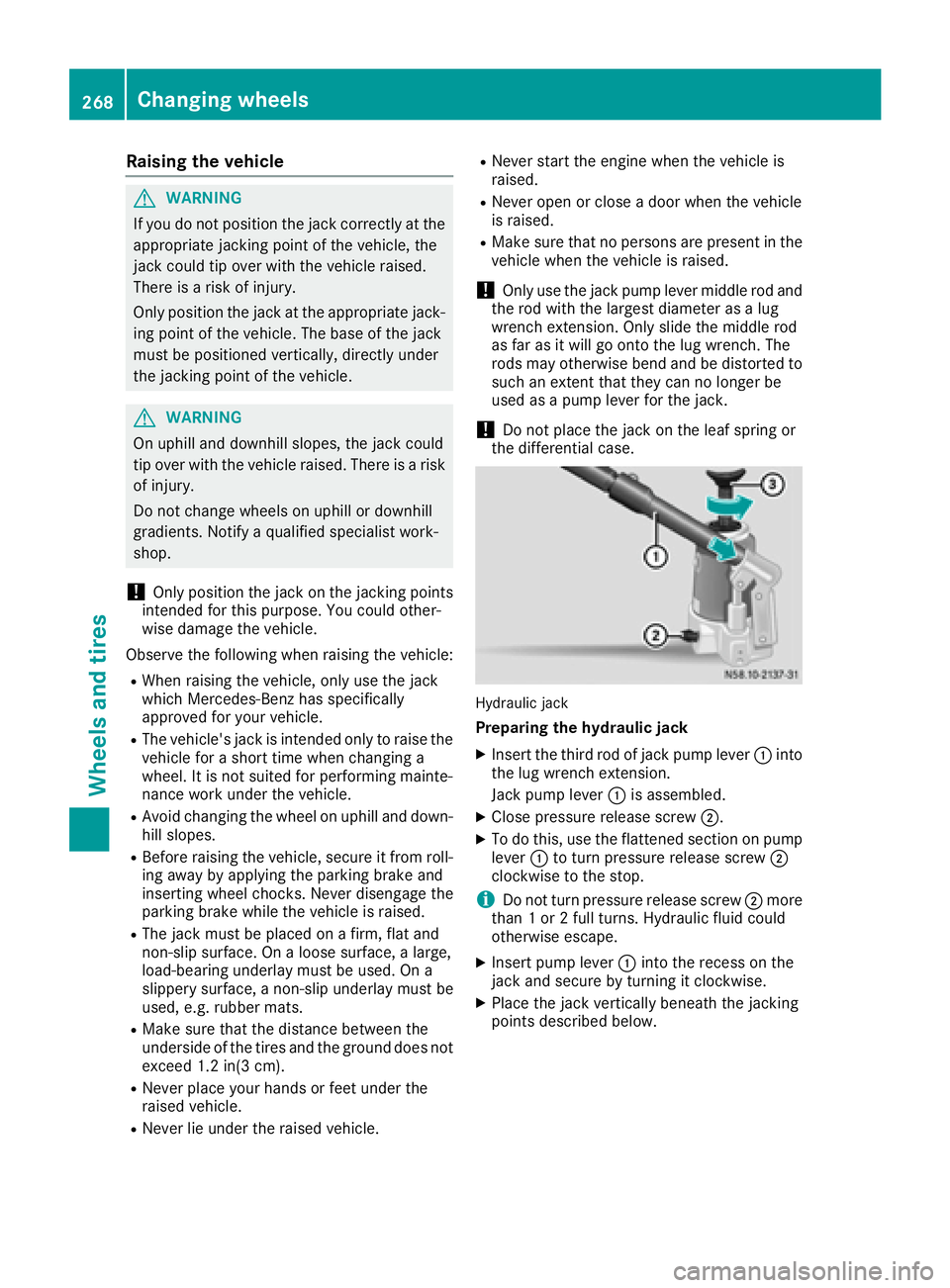

Hydraulic jack

Preparing the hydraulic jack

XInsert the third rod of jack pump lever :into

the lug wrench extension.

Jack pump lever :is assembled.

XClose pressure release screw ;.

XTo do this, use the flattened section on pump

lever:to turn pressure release screw ;

clockwise to the stop.

iDo not turn pressure release screw ;more

than 1 or 2 full turns. Hydraulic fluid could

otherwise escape.

XInsert pump lever :into the recess on the

jack and secure by turning it clockwise.

XPlace the jack vertically beneath the jacking

points described below.

268Changing wheels

Wheels and tires

Page 271 of 290

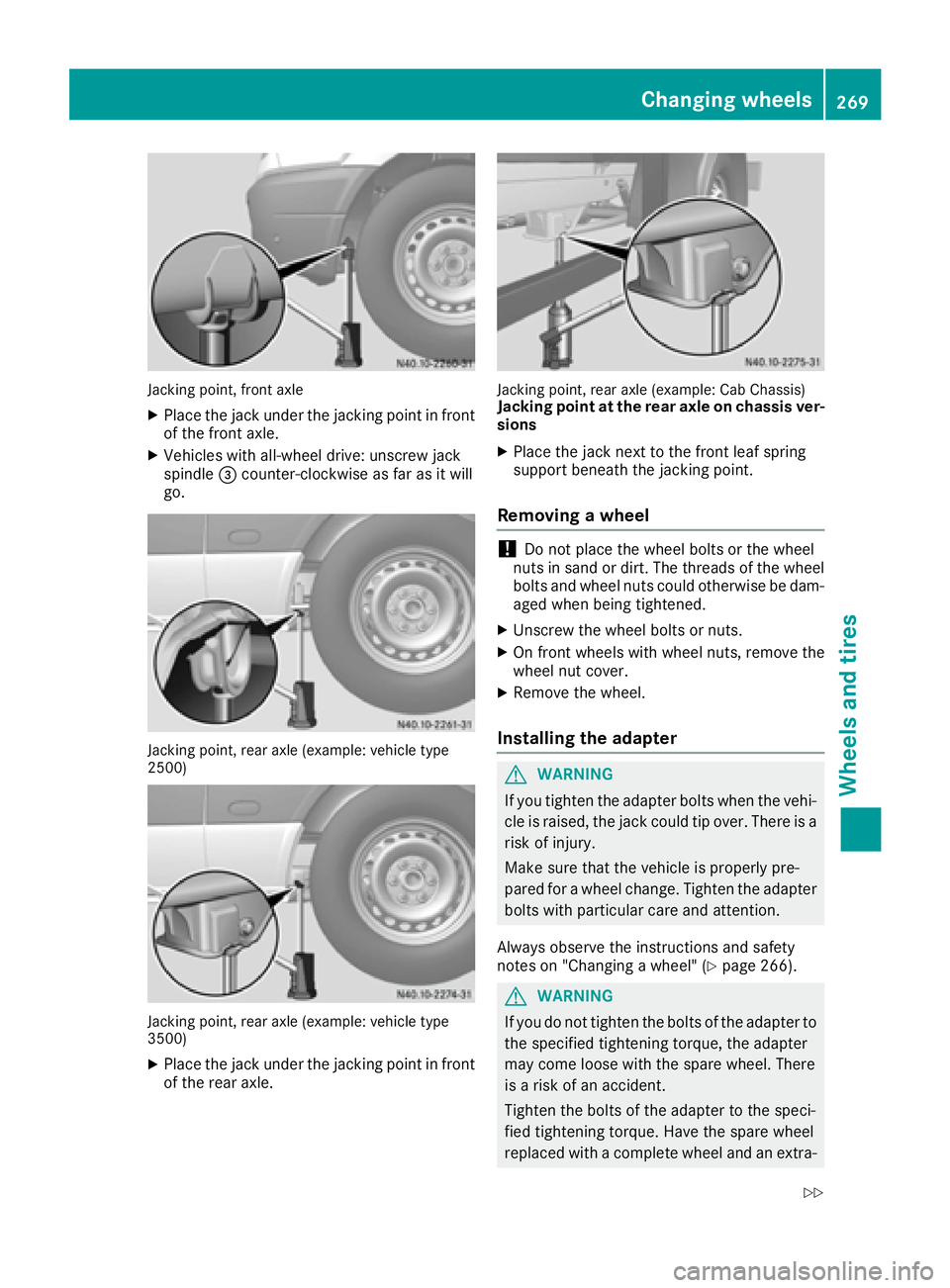

Jacking point, front axle

XPlace the jack under the jacking point in frontof the front axle.

XVehicles with all-wheel drive: unscrew jack

spindle =counter-clockwise as far as it will

go.

Jacking point, rear axle (example: vehicle type

2500)

Jacking point, rear axle (example: vehicle type

3500)

XPlace the jack under the jacking point in front

of the rear axle.

Jacking point, rear axle (example: Cab Chassis)Jacking point at the rear axle on chassis ver-

sions

XPlace the jack next to the front leaf spring

support beneath the jacking point.

Removing a wheel

!Do not place the wheel bolts or the wheel

nuts in sand or dirt. The threads of the wheel

bolts and wheel nuts could otherwise be dam-

aged when being tightened.

XUnscrew the wheel bolts or nuts.

XOn front wheels with wheel nuts, remove the

wheel nut cover.

XRemove the wheel.

Installing the adapter

GWARNING

If you tighten the adapter bolts when the vehi-

cle is raised, the jack could tip over. There is a risk of injury.

Make sure that the vehicle is properly pre-

pared for a wheel change. Tighten the adapter

bolts with particular care and attention.

Always observe the instructions and safety

notes on "Changing a wheel" (

Ypage 266).

GWARNING

If you do not tighten the bolts of the adapter to

the specified tightening torque, the adapter

may come loose with the spare wheel. There

is a risk of an accident.

Tighten the bolts of the adapter to the speci-

fied tightening torque. Have the spare wheel

replaced with a complete wheel and an extra-

Changing wheels269

Wheels and tires

Z

Page 272 of 290

wide tire at a qualified specialist workshop

immediately.

!Vehicles with Super Single tires:if you

install the spare wheel, do not exceed the

maximum speed of 40 mph (60 km/h) and do

not drive further than 65 miles(100 km).

The transmission could otherwise be dam-

aged by the difference in wheel rotation

speeds.

On vehicles with Super Single tires, you must

attach the narrow spare wheel to the rear axle by

means of an adapter. The adapter is bolted to

the spare wheel using the adapter bolts for

transportation.

The handling characteristics of your vehicle are affected when driving with a spare wheel instal-

led. After changing a wheel, drive to the nearest

specialist workshop and have the spare wheel

replaced with a wheel and tire assembly that hasa Super Single tire.

XClean the wheel and wheel hub contact sur-

faces.

XUnscrew the six adapter bolts on the spare

wheel and remove the adapter.

XTighten the adapter with the six adapter boltsevenly in a crosswise pattern through the

outer holes on the wheel hub.

XTighten the six adapter bolts on the wheel hub

to a tightening torque of 177 lb-ft(240 Nm).

XPush the wheel onto the adapter and attach it.

Mounting a new wheel

GWARNING

Oiled or greased wheel bolts or damaged

wheel bolts/hub threads can cause the wheel bolts to come loose. As a result, you could

lose a wheel while driving. There is a risk of

accident.

Never oil or grease wheel bolts. In the event of

damage to the threads, contact a qualified

specialist workshop immediately. Have the

damaged wheel bolts or hub threads

replaced/renewed. Do not continue driving.

GWARNING

If you tighten the wheel bolts or wheel nuts

when the vehicle is raised, the jack could tip

over. There is a risk of injury.

Only tighten the wheel bolts or wheel nuts

when the vehicle is on the ground.

Always observe the instructions and safety

notes on "Changing a wheel" (

Ypage 266).

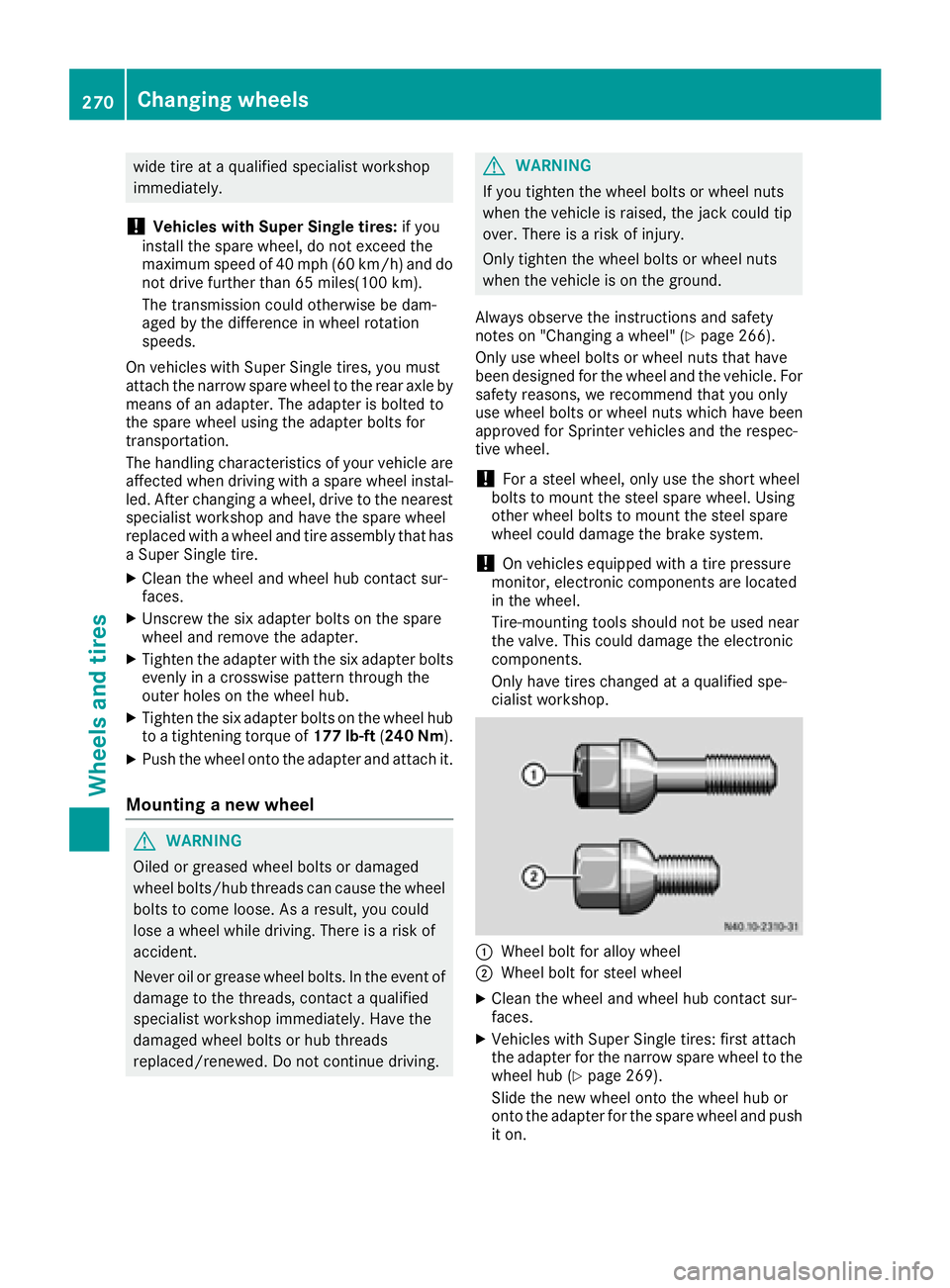

Only use wheel bolts or wheel nuts that have

been designed for the wheel and the vehicle. For safety reasons, we recommend that you only

use wheel bolts or wheel nuts which have been

approved for Sprinter vehicles and the respec-

tive wheel.

!For a steel wheel, only use the short wheel

bolts to mount the steel spare wheel. Using

other wheel bolts to mount the steel spare

wheel could damage the brake system.

!On vehicles equipped with a tire pressure

monitor, electronic components are located

in the wheel.

Tire-mounting tools should not be used near

the valve. This could damage the electronic

components.

Only have tires changed at a qualified spe-

cialist workshop.

:Wheel bolt for alloy wheel

;Wheel bolt for steel wheel

XClean the wheel and wheel hub contact sur-

faces.

XVehicles with Super Single tires: first attach

the adapter for the narrow spare wheel to the

wheel hub (

Ypage 269).

Slide the new wheel onto the wheel hub or

onto the adapter for the spare wheel and push

it on.

270Changing wheels

Wheels and tires

Page 273 of 290

Slide the new wheel onto the wheel hub and

push it on.

Wheels with centering by wheel bolts:

XVehicles with alloy wheels: take the short

wheel bolts that secure the steel spare wheel

out of the vehicle tool kit.

XScrew in the wheel bolts and tighten them

lightly.

For wheels with wheel nuts:

XFront wheels with wheel nut covers: press the

wheel nut covers onto the wheel nuts.

XScrew in the three wheel nuts over the fixing

discs of the wheel nut cover.

XTurn the wheel so that the wheel bolts are in

the middle of the holes.

XScrew on the rest of the wheel nuts.

XSlightly tighten all the wheel nuts.

Lowering the vehicle

GWARNING

The wheels could work loose if the wheel nuts and bolts are not tightened to the specified

tightening torque. There is a risk of accident.

Have the tightening torque immediately

checked at a qualified specialist workshop

after a wheel is changed.

!Only use the jack pump lever middle rod and

the rod with the largest diameter as a lug

wrench extension. Only slide the middle rod

as far as it will go onto the lug wrench. The

rods may otherwise bend and be distorted to

such an extent that they can no longer be

used as a pump lever for the jack.

!Vehicles with Super Single tires: if you

install the spare wheel, do not exceed the

maximum speed of 40 mph (60 km/h) and do

not drive further than 65 miles(100 km).

The transmission could otherwise be dam-

aged by the difference in wheel rotation

speeds.

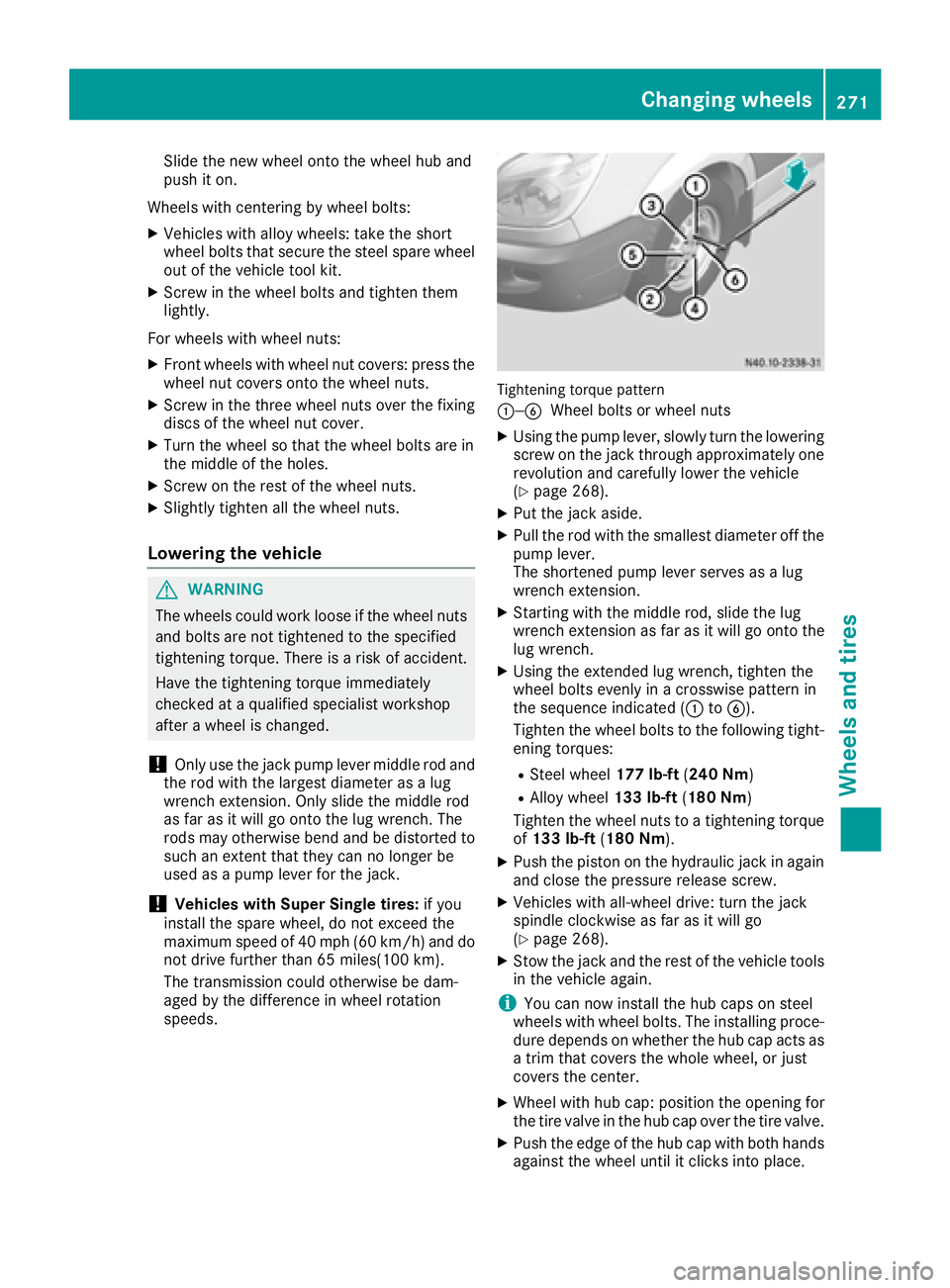

Tightening torque pattern

:—B

Wheel bolts or wheel nuts

XUsing the pump lever, slowly turn the lowering

screw on the jack through approximately one revolution and carefully lower the vehicle

(

Ypage 268).

XPut the jack aside.

XPull the rod with the smallest diameter off the

pump lever.

The shortened pump lever serves as a lug

wrench extension.

XStarting with the middle rod, slide the lug

wrench extension as far as it will go onto the

lug wrench.

XUsing the extended lug wrench, tighten the

wheel bolts evenly in a crosswise pattern in

the sequence indicated ( :toB).

Tighten the wheel bolts to the following tight-

ening torques:

RSteel wheel 177 lb-ft(240 Nm)

RAlloy wheel 133 lb-ft(180 Nm)

Tighten the wheel nuts to a tightening torque

of 133 lb-ft (180 Nm).

XPush the piston on the hydraulic jack in again

and close the pressure release screw.

XVehicles with all-wheel drive: turn the jack

spindle clockwise as far as it will go

(

Ypage 268).

XStow the jack and the rest of the vehicle tools

in the vehicle again.

iYou can now install the hub caps on steel

wheels with wheel bolts. The installing proce-

dure depends on whether the hub cap acts as

a trim that covers the whole wheel, or just

covers the center.

XWheel with hub cap: position the opening for

the tire valve in the hub cap over the tire valve.

XPush the edge of the hub cap with both hands against the wheel until it clicks into place.

Changing wheels271

Wheels and tires

Z

Page 274 of 290

Make sure the hub cap retaining catches

engage on the steel wheel.

XWheel with central hub cap: position the

retaining lugs of the central hub cap over the

wheel bolts.

XHit the middle of the hub cap to engage it on

the wheel.

XSecure the faulty wheel in the spare wheel

bracket (Ypage 273).

XVehicles with Super Single tires: transport the

defective rear wheel in the load area. The rear

wheel is too large for the spare wheel bracket.

XCheck the tire pressure of the newly mounted

wheel and adjust it if necessary.

Observe the recommended tire pressure

(

Ypage 250).

XRetighten the wheel bolts or wheel nuts to the

specified tightening torque after the vehicle

has been driven for 30 miles (50 km).

When using a wheel or spare wheel with a new or

newly painted wheel rim, have the wheel bolts or

nuts retightened again after approximately 600

to 3,000 miles (1,000 to 5,000 km). Observe the

specified tightening torque.

iVehicles with the tire pressure monitor sys-

tem: all mounted wheels must be equipped

with functioning sensors.

Wheel and tire combination

General notes

!

Retreaded tires are neither tested nor rec-

ommended for Sprinter vehicles, since previ-

ous damage cannot always be detected on

retreaded tires. We can therefore not guar-

antee driving safety. Do not mount used tires if you have no information about their previ-

ous usage.

The recommended tire pressures can be found:

Ron the Tire and Loading Information placard9

on the B-pillar on the driver's side

Ron the tire pressure table on the B-pillar on the driver's side

The recommended tire pressure can also be

found in the "Tire pressure table" section in this

Operator's Manual (

Ypage 257). The wheel/tire

combination for your vehicle can be found on the tire pressure table. Further information on

wheel/tire combination can be obtained at any

qualified specialist workshop.

Check tire pressures regularly and only when

the tires are cold. Observe the notes on the rec-

ommended tire pressure (

Ypage 250).

Follow the maintenance recommendations in

the tire manufacturer's warranty book in your

vehicle documents.

Notes on the vehicle equipment – always equip

the vehicle:

Rwith tires of the same size across an axle (left

and right)

Rwith the same type of tires on all wheels at a

given time (summer tires, winter tires)

Tires that have been specially designed and

approved for your vehicle are marked with MO

(Mercedes-Benz Original). You can find this

identification on the tires themselves and in the

following table.

iNot all wheel/tire combinations can be

installed at the factory in all countries.

Spare wheel

Important safety notes

GWARNING

Wheel and tire dimensions as well as the type of tire can vary between the spare wheel and

the wheel to be replaced. When the spare

wheel is mounted, driving characteristics may be severely affected. There is a risk of an acci-

dent.

In order to reduce risks:

Ryou should therefore adapt your driving

style and drive carefully.

Rnever mount more than one spare wheel

that differs from the wheel to be replaced.

Ronly use a spare wheel that differs from the

wheel to be replaced for a short time.

Rdo not deactivate ESP®.

Rhave a spare wheel that differs from the

wheel that has been changed replaced at

the nearest qualified specialist workshop.

9Only for vehicles with a gross weight of less than 10,000 lbs (4,536 kg).

272Spare wheel

Wheels and tires