ECU MERCEDES-BENZ SPRINTER 2016 MY16 Operator’s Manual

[x] Cancel search | Manufacturer: MERCEDES-BENZ, Model Year: 2016, Model line: SPRINTER, Model: MERCEDES-BENZ SPRINTER 2016Pages: 290, PDF Size: 6.44 MB

Page 274 of 290

Make sure the hub cap retaining catches

engage on the steel wheel.

XWheel with central hub cap: position the

retaining lugs of the central hub cap over the

wheel bolts.

XHit the middle of the hub cap to engage it on

the wheel.

XSecure the faulty wheel in the spare wheel

bracket (Ypage 273).

XVehicles with Super Single tires: transport the

defective rear wheel in the load area. The rear

wheel is too large for the spare wheel bracket.

XCheck the tire pressure of the newly mounted

wheel and adjust it if necessary.

Observe the recommended tire pressure

(

Ypage 250).

XRetighten the wheel bolts or wheel nuts to the

specified tightening torque after the vehicle

has been driven for 30 miles (50 km).

When using a wheel or spare wheel with a new or

newly painted wheel rim, have the wheel bolts or

nuts retightened again after approximately 600

to 3,000 miles (1,000 to 5,000 km). Observe the

specified tightening torque.

iVehicles with the tire pressure monitor sys-

tem: all mounted wheels must be equipped

with functioning sensors.

Wheel and tire combination

General notes

!

Retreaded tires are neither tested nor rec-

ommended for Sprinter vehicles, since previ-

ous damage cannot always be detected on

retreaded tires. We can therefore not guar-

antee driving safety. Do not mount used tires if you have no information about their previ-

ous usage.

The recommended tire pressures can be found:

Ron the Tire and Loading Information placard9

on the B-pillar on the driver's side

Ron the tire pressure table on the B-pillar on the driver's side

The recommended tire pressure can also be

found in the "Tire pressure table" section in this

Operator's Manual (

Ypage 257). The wheel/tire

combination for your vehicle can be found on the tire pressure table. Further information on

wheel/tire combination can be obtained at any

qualified specialist workshop.

Check tire pressures regularly and only when

the tires are cold. Observe the notes on the rec-

ommended tire pressure (

Ypage 250).

Follow the maintenance recommendations in

the tire manufacturer's warranty book in your

vehicle documents.

Notes on the vehicle equipment – always equip

the vehicle:

Rwith tires of the same size across an axle (left

and right)

Rwith the same type of tires on all wheels at a

given time (summer tires, winter tires)

Tires that have been specially designed and

approved for your vehicle are marked with MO

(Mercedes-Benz Original). You can find this

identification on the tires themselves and in the

following table.

iNot all wheel/tire combinations can be

installed at the factory in all countries.

Spare wheel

Important safety notes

GWARNING

Wheel and tire dimensions as well as the type of tire can vary between the spare wheel and

the wheel to be replaced. When the spare

wheel is mounted, driving characteristics may be severely affected. There is a risk of an acci-

dent.

In order to reduce risks:

Ryou should therefore adapt your driving

style and drive carefully.

Rnever mount more than one spare wheel

that differs from the wheel to be replaced.

Ronly use a spare wheel that differs from the

wheel to be replaced for a short time.

Rdo not deactivate ESP®.

Rhave a spare wheel that differs from the

wheel that has been changed replaced at

the nearest qualified specialist workshop.

9Only for vehicles with a gross weight of less than 10,000 lbs (4,536 kg).

272Spare wheel

Wheels and tires

Page 275 of 290

You must observe the correct wheel and

tire dimensions as well as the wheel type.

When using a spare wheel of a different size, do

not exceed the maximum speed of 80 km/h.

General notes

!

Check the spare wheel regularly to see that

it is secure and has the prescribed tire pres-

sure.

The procedure for mounting the spare wheel is

described in "Mounting a wheel" (

Ypage 267).

The following should be checked regularly, par-

ticularly prior to long journeys:

Rthe tire pressure of the spare wheel, which

should then be corrected if necessary

(

Ypage 250).

Rthe fastenings of the spare wheel bracket.

The spare wheel is located in a spare wheel

bracket under the rear of the vehicle.

Replace the tires after 6 years at the latest,

regardless of wear. This also applies to the spare

wheel.

iIf you have mounted a spare wheel, the tire

pressure monitor (Ypage 253) will not func-

tion for this wheel. The spare wheel is not

equipped with a sensor for monitoring tire

pressure.

Removing and installing the spare

wheel

Cargo Van/Passenger Van

Bolt covers for the safety catches (example: Cargo

Van)

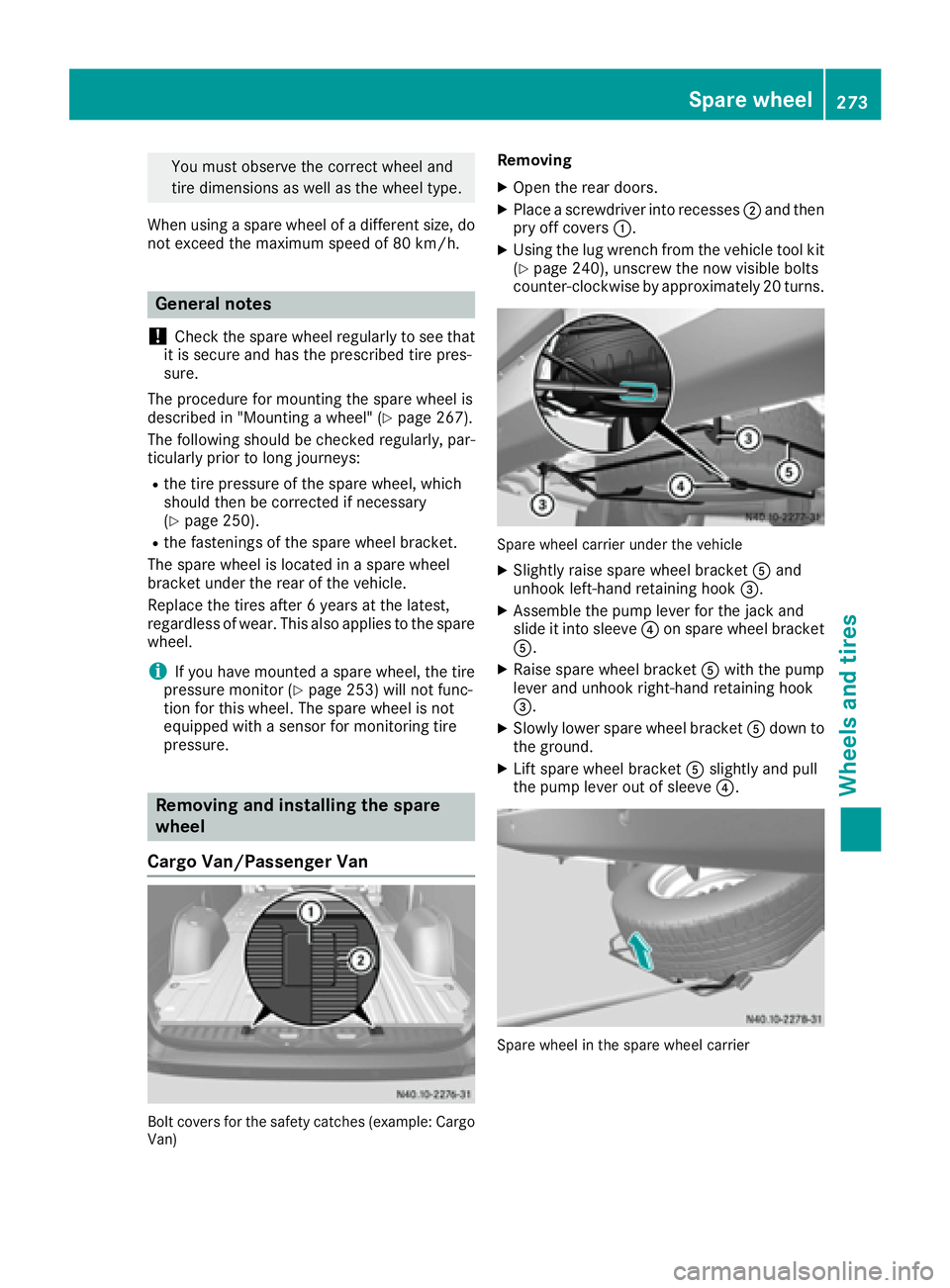

Removing

XOpen the rear doors.

XPlace a screwdriver into recesses ;and then

pry off covers :.

XUsing the lug wrench from the vehicle tool kit

(Ypage 240), unscrew the now visible bolts

counter-clockwise by approximately 20 turns.

Spare wheel carrier under the vehicle

XSlightly raise spare wheel bracket Aand

unhook left-hand retaining hook =.

XAssemble the pump lever for the jack and

slide it into sleeve?on spare wheel bracket

A.

XRaise spare wheel bracket Awith the pump

lever and unhook right-hand retaining hook

=.

XSlowly lower spare wheel bracket Adown to

the ground.

XLift spare wheel bracket Aslightly and pull

the pump lever out of sleeve ?.

Spare wheel in the spare wheel carrier

Spare wheel273

Wheels and tires

Z

Page 287 of 290

!Only use washer fluid that is suitable for

plastic lamp lenses, e.g. MB SummerFit or MB

WinterFit. Unsuitable washer fluid could dam-

age the plastic lenses of the headlamps.

When handling washer fluid, observe the impor-

tant safety notes on service products

(

Ypage 277).

Mixing ratio

Add windshield washer concentrate to the

washer fluid all year round. Adapt the mixing

ratio to the ambient temperature.

At temperatures above freezing:

XFill up the washer fluid reservoir with a mix-

ture of water and windshield washer concen-

trate, e.g. Summerwash to prevent smearing.

At temperatures below freezing:

XFill up the washer fluid reservoir with a mix-

ture of water and windshield washer concen-

trate, e.g. Winterwash if there is a danger of

frost.

This prevents washer fluid from freezing on

the windshield.

Capacities

Windshield washer system with/without

headlamp cleaning system

Washer fluidApprox. 6.3 qt (6.0 l)

Vehicle data

General notes

The following section contains important tech-

nical data for your vehicle. Your vehicle regis-

tration documents contain vehicle-specific and

equipment-dependent technical data such as

vehicle dimensions and vehicle weights.

Cargo tie-down points and carrier sys-

tems

Cargo tie-down points

General notes

!Observe the information on the maximum

loading capacity of the individual cargo tie-

down points.

If you use several cargo tie-down points to

secure a load, you must always take the max-

imum loading capacity of the weakest cargo

tie-down point into account.

If you brake hard, for example, the forces act-

ing could be up to several times the weight

force of the load. Always use multiple cargo

tie-down points in order to distribute the force absorption. Load the anchorages evenly.

You will find further information about cargo tie

down points and cargo tie-down rings in the

"Transporting" section (

Ypage 214).

Cargo tie-down rings

The maximum tensile load of the cargo tie-down rings is:

Cargo tie-down

ringsPermissible nomi- nal tensile load

Passenger Vans786.5 lbf

(3500 N)

Cargo Van1124.0 lbf (5000 N)

Load rails

The maximum tensile loads of the cargo tie-

down points in the cargo compartment are:

Cargo tie-down

pointPermissible nomi- nal tensile load

Load rails on cargo

compartment floor1124.0 lbf

(5000 N)

Lower load rail on

sidewall562.0 lbf(2500 N)

Upper load rail on

sidewall337.0 lbf(1500 N)

Vehicle data285

Technical data

Z

Page 288 of 290

The values specified apply only to loads placed

on the cargo compartment floor if:

Rthe load is secured to 2 cargo tie-down points

on the rail and

Rthe distance to the nearest load-securing

point on the same rail is approximately 3 ft

(1 m).

Roof carrier

GWARNING

When you load the roof, the center of gravity

of the vehicle rises and the driving character-

istics change. If you exceed the maximum roof

load, the driving characteristics, as well as

steering and braking, will be greatly impaired.

There is a risk of an accident.

Never exceed the maximum roof load and

adjust your driving style.

GWARNING

If you distribute the load unevenly in the vehi- cle, the handling as well as the steering and

braking characteristics are severely affected.

There is a risk of an accident.

Distribute the load evenly in the vehicle.

Secure the load to prevent it from slipping.

!The weight of any load carried on the roof,

including the roof carrier, must not exceed

the maximum permissible roof load.

The roof carrier supports must be mounted at

equal distances.

We recommend that you have a stabilizer

installed on the front axle.

!For safety reasons, we recommend that you

only use roof carrier systems that have been

tested and approved for the Sprinter. This will

help to avoid damage. The data is valid for a load distributed evenly

over the entire roof area. Maximum roof load

and minimum number of pairs of roof carrier

supports on vehicles with:

Maximum

roof loadMinimum

number of

pairs of sup- ports

Standard

roof660 lbs

(300 kg)6

High roof330 lbs

(150 kg)3

Reduce the load on shorter roof carriers pro-

portionately. The maximum load per pair of roof

carrier supports is 110 lbs (50 kg).

Loading directions and other information con-

cerning load distribution and load securing can

be found in the "Transporting" section

(

Ypage 212).

Trailer tow hitch

General notes

We recommend that you have the trailer tow

hitch mounted at an authorized Sprinter Dealer. Use only a trailer tow hitch that has been tested

and approved specially for your vehicle by the

distributor named on the inside of the front

cover. Only use a ball coupling that is approved for your vehicle and Sprinter trailer tow hitch.

You can also find information on the permitted

dimensions of the ball coupling on the identifi-

cation plate of the trailer tow hitch.

You can obtain advice from a qualified specialist

workshop. Also observe the information on tow-

ing a trailer in the "Driving and parking" section

(

Ypage 155).

286Vehicle data

Technical data