ECU MERCEDES-BENZ SPRINTER 2016 MY16 Operator’s Manual

[x] Cancel search | Manufacturer: MERCEDES-BENZ, Model Year: 2016, Model line: SPRINTER, Model: MERCEDES-BENZ SPRINTER 2016Pages: 290, PDF Size: 6.44 MB

Page 235 of 290

The following points on battery care must be

observed:

XRegularly check the battery terminals and the

fastening of the negative cable to the chassis

to ensure that they are firmly seated.

XAlways keep the battery terminals and battery

surfaces clean and dry.

XLightly grease the undersides of the battery

terminals with acid-resistant grease.

XOnly clean the battery casing with a commer- cially available cleaning product.

Care

Notes on care

GWARNING

If you use openings in the bodywork or

detachable parts as steps, you could:

Rslip and/or fall

Rdamage the vehicle and cause yourself to

fall.

There is a risk of injury.

Always use secure climbing aids, e.g. a suita-

ble ladder.

!For cleaning your vehicle, do not use any of

the following:

Rdry, rough or hard cloths

Rabrasive cleaning agents

Rsolvents

Rcleaning agents containing solvents

Do not scrub.

Do not touch the surfaces or protective films

with hard objects, e.g. a ring or ice scraper.

You could otherwise scratch or damage the

surfaces and protective film.

!Do not park the vehicle for an extended

period straight after cleaning it, particularly

after having cleaned the wheels with wheel

cleaner. Wheel cleaners could cause

increased corrosion of the brake discs and

brake pads/linings. For this reason, you

should drive for a few minutes after cleaning.

Braking heats the brake discs and the brake

pads/linings, thus drying them. The vehicle

can then be parked.

HEnvironmental note

Only clean your vehicle at specially designed

wash bays. Dispose of empty containers and

used cleaning products in an environmentally responsible manner.

HEnvironmental note

Dispose of empty packaging and cleaning

cloths in an environmentally responsible man- ner.

Regular care of your vehicle is a condition for

retaining the quality in the long term.

Use care products and cleaning agents recom-

mended and approved by Mercedes-Benz.

Use care products and cleaning agents recom-

mended and approved for Sprinter vehicles.

Washing the vehicle and cleaning the

paintwork

Automatic car wash

GWARNING

Braking efficiency is reduced after washing

the vehicle. There is a risk of an accident.

After the vehicle has been washed, brake

carefully while paying attention to the traffic

conditions until full braking power is restored.

!Never clean your vehicle in a Touchless

Automatic Car Wash as these use special

cleaning agents. These cleaning agents can

damage the paintwork or plastic parts.

!Make sure that the automatic car wash is

suitable for the size of the vehicle.

Before washing the vehicle in an automatic

car wash, fold in the exterior mirrors and

remove any additional antennas. Otherwise,

the exterior mirror, antenna or the vehicle

itself could be damaged.

Make sure that the exterior mirrors are fully

folded out again and that any additional

antennas are re-installed when you leave the

automatic car wash.

Care233

Maintenance and care

Z

Page 237 of 290

Cleaning the paintwork

!Do not affix:

Rstickers

Rfilms

Rmagnetic plates or similar items

to painted surfaces. You could otherwise

damage the paintwork.

Scratches, corrosive deposits, areas affected by

corrosion and damage caused by inadequate

care cannot always be completely repaired. In

such cases, visit a qualified specialist workshop.

XRemove impurities immediately, where pos-

sible, whilst avoiding rubbing too hard.

XSoak insect remains with insect remover and

rinse off the treated areas afterwards.

XSoak bird droppings with water and rinse off

the treated areas afterwards.

XRemove coolant, brake fluid, tree resin, oils,

fuels and greases by rubbing gently with a

cloth soaked in petroleum ether or lighter

fluid.

XUse tar remover to remove tar stains.

XUse silicone remover to remove wax.

Cleaning the windows

GWARNING

You could become trapped by the windshield wipers if they start moving while cleaning the

windshield or wiper blades. There is a risk of

injury.

Always switch off the windshield wipers and

the ignition before cleaning the windshield or

wiper blades.

!Do not fold the windshield wipers away from

the windshield unless the hood is closed. Oth-

erwise, you could damage the hood.

!Hold the wiper arm securely when folding

back. The windshield could be damaged if the

wiper arm smacks against it suddenly.

!Do not use dry cloths, abrasive products,

solvents or cleaning agents containing sol-

vents to clean the inside of the windows. Do

not touch the insides of the windows with

hard objects, e.g. an ice scraper or ring. There

is otherwise a risk of damaging the windows. Before cleaning the windshield

XTurn the key to position

0in the ignition lock

or remove it.

XFold the windshield wiper arms away from the

windshield until you feel them engage.

Before switching the ignition on again, fold

the windshield wipers back into position.

Cleaning the windows

XClean the inside and outside of the windows

with a damp cloth and a cleaning agent that is

recommended and approved for Sprinter

vehicles.

Exterior

Cleaning the wheels

!Do not use any acidic or alkaline cleaning

agents. They can cause corrosion on the

wheel bolts (wheel nuts) or the retainer

springs for the wheel-balancing weights.

!Do not park the vehicle for an extended

period straight after cleaning it, particularly

after having cleaned the wheels with wheel

cleaner. Wheel cleaners could cause

increased corrosion of the brake discs and

brake pads/linings. For this reason, you

should drive for a few minutes after cleaning.

Braking heats the brake discs and the brake

pads/linings, thus drying them. The vehicle

can then be parked.

If you clean the wheels with a power washer,

observe the safety notes for the power washer

(

Ypage 234). You could otherwise damage the

tires.

Cleaning the wiper blades

GWARNING

You could become trapped by the windshield wipers if they start moving while cleaning the

windshield or wiper blades. There is a risk of

injury.

Always switch off the windshield wipers and

the ignition before cleaning the windshield or

wiper blades.

Care235

Maintenance and care

Z

Page 238 of 290

!Do not fold the windshield wipers away from

the windshield unless the hood is closed. Oth-

erwise, you could damage the hood.

!Do not pull the wiper blade. Otherwise, the

wiper blade could be damaged.

!Do not clean wiper blades too often and do

not rub them too hard. Otherwise, the graph-

ite coating could be damaged. This could

cause wiper noise.

!Hold the wiper arm securely when folding

back. The windshield could be damaged if the

wiper arm smacks against it suddenly.

XTurn the key to position 0in the ignition lock

or remove it.

XFold the windshield wiper arms away from the

windshield until you feel them engage.

XCarefully clean the wiper blades with a damp

cloth.

XFold back the wiper arms before switching on

the ignition.

Cleaning the exterior lighting

!Only use cleaning agents or cleaning cloths

which are suitable for plastic light lenses.

Unsuitable cleaning agents or cleaning cloths

could scratch or damage the plastic light len- ses.

XClean the plastic covers of the exterior light-

ing with a damp sponge and a mild cleaning

agent, e.g. car shampoo for Sprinter vehicles,

or with cleaning cloths.

Cleaning the mirror turn signal

!Only use cleaning agents or cleaning cloths

that are suitable for plastic lenses. Unsuitable

cleaning agents or cleaning cloths could

scratch or damage the plastic lenses of the

mirror turn signals.

XClean the plastic lenses of the mirror turn sig-

nals in the exterior mirror housing using a wet

sponge and mild cleaning agent, e.g. car

shampoo or cleaning cloths.

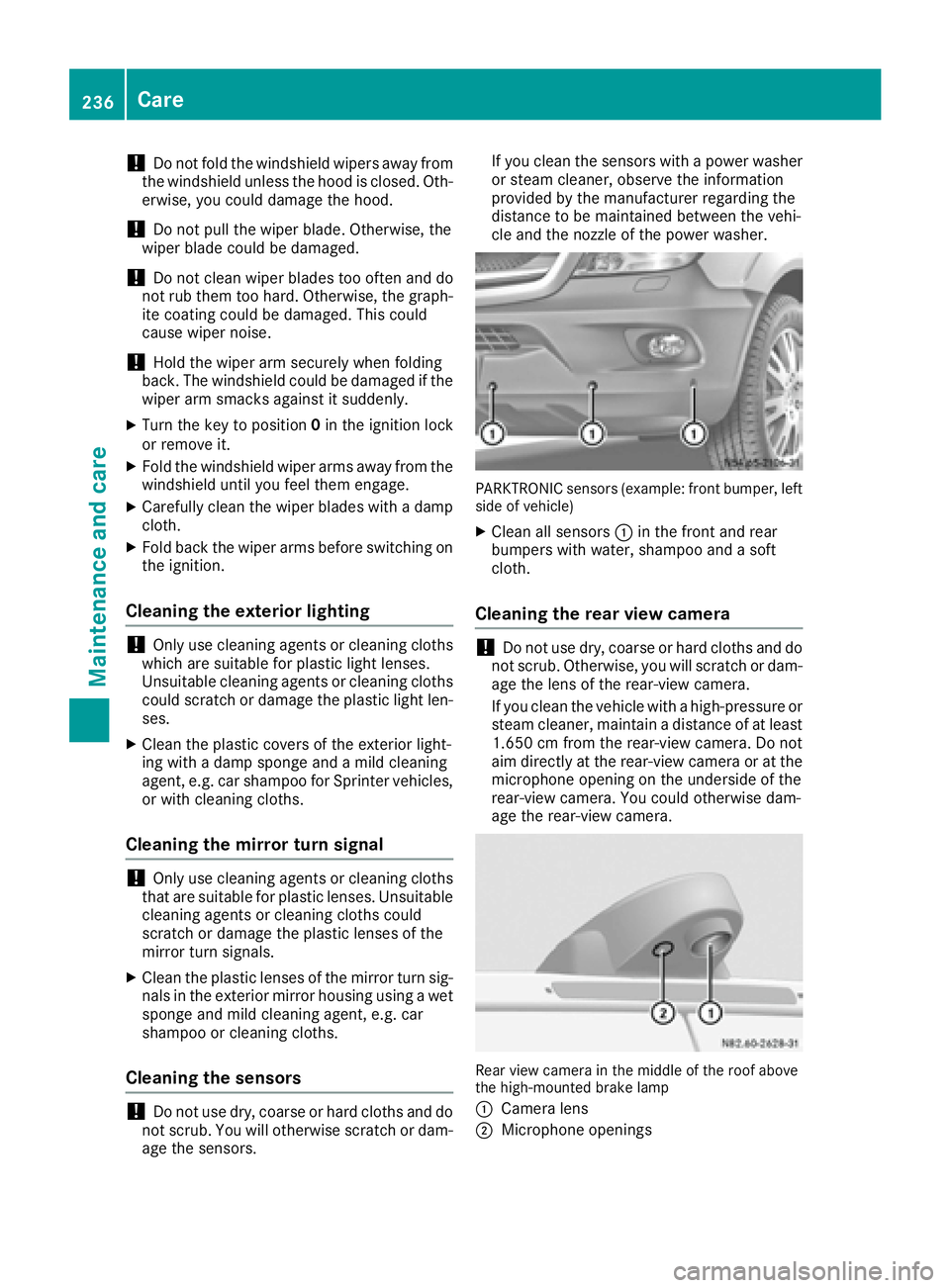

Cleaning the sensors

!Do not use dry, coarse or hard cloths and do

not scrub. You will otherwise scratch or dam-

age the sensors. If you clean the sensors with a power washer

or steam cleaner, observe the information

provided by the manufacturer regarding the

distance to be maintained between the vehi-

cle and the nozzle of the power washer.

PARKTRONIC sensors (example: front bumper, left

side of vehicle)

XClean all sensors :in the front and rear

bumpers with water, shampoo and a soft

cloth.

Cleaning the rear view camera

!Do not use dry, coarse or hard cloths and do

not scrub. Otherwise, you will scratch or dam-

age the lens of the rear-view camera.

If you clean the vehicle with a high-pressure or

steam cleaner, maintain a distance of at least

1.650 cm from the rear-view camera. Do not

aim directly at the rear-view camera or at the

microphone opening on the underside of the

rear-view camera. You could otherwise dam-

age the rear-view camera.

Rear view camera in the middle of the roof above

the high-mounted brake lamp

:

Camera lens

;Microphone openings

236Care

Maintenance and care

Page 245 of 290

Before connecting the jumper cables

On vehicles with a battery main switch, check

whether the battery main switch is switched on

(

Ypage 118).

XApply the parking brake.

XMove the selector lever of the automatic

transmission to positionP.

XSwitch off all electrical consumers, e.g. audio

equipment, blower.

XTurn the key to position0in the ignition lock

and remove it (Ypage 119).

XOpen the hood (Ypage 218).

Tow-starting and towing away

Important safety notes

GWARNING

Functions relevant to safety are restricted or

no longer available if:

Rthe engine is not running.

Rthe brake system or the power steering is

malfunctioning.

Rthere is a malfunction in the voltage supply or the vehicle's electrical system.

If your vehicle is being towed, much more

force may be necessary to steer or brake.

There is a risk of an accident.

In such cases, use a tow bar. Before towing,

make sure that the steering moves freely.

GWARNING

You can no longer steer the vehicle if the

steering wheel lock has been engaged. There

is a risk of an accident.

Always switch off the ignition when towing the

vehicle with a tow cable or a tow bar.

GWARNING

When towing or tow-starting another vehicle

and its weight is greater than the permissible

gross weight of your vehicle, the:

Rthe towing eye could detach itself

Rthe vehicle/trailer combination could roll-

over.

There is a risk of an accident.

When towing or tow-starting another vehicle,

its weight should not be greater than the per- missible gross weight of your vehicle.

Information on the gross vehicle weight can be

found on the vehicle identification plate

(

Ypage 276).

!Only secure the tow rope or tow bar at the

towing eyes. Otherwise, the vehicle could be

damaged.

!Observe the following points when towing

with a tow rope:

RSecure the tow rope on the same side on

both vehicles.

REnsure that the tow cable is not longer than

legally permitted. Mark the tow cable in the

middle, e.g. with a white cloth (30 x 30 cm).

This will make other road users aware that

the vehicle is being towed.

ROnly secure the tow cable to the towing

eye.

RObserve the brake lamps of the towing

vehicle while driving. Always maintain a dis-

tance so that the tow rope does not sag.

RDo not use steel cables or chains to tow

your vehicle. You could otherwise damage

the vehicle.

!Do not use the towing eye for recovery, this

could damage the vehicle. If in doubt, recover

the vehicl

e with a crane.

!When towing, pull away slowly and

smoothly. If the tractive power is too high, the

vehicles could be damaged.

When towing away, you must observe the legal

requirements for the country in which you are

currently driving.

It is preferable to have the vehicle transported

on a transporter or trailer instead of towing it.

Tow-starting and towing away243

Roadside Assistance

Z

Page 248 of 290

If the drive wheels get trapped on loose or

muddy ground, recover the vehicle with the

utmost care. This is especially the case if the

vehicle is laden.

Never attempt to recover a vehicle with a trailer

attached.

Pull out the vehicle backwards, if possible, using

the tracks it made when it became stuck.

Transporting the vehicle

!

You may only secure the vehicle by the

wheels, not by parts of the vehicle such as

axle or steering components. Otherwise, the

vehicle could be damaged.

Tow-starting (emergency engine

starting)

Vehicles with automatic transmission

!Vehicles with automatic transmission must

not be tow-started. You could otherwise dam-

age the automatic transmission.

You can find information on jump-starting under

"Jump-starting“ (

Ypage 242).

Electrical fuses

The fuse allocation chart and further information

on the electric fuses and relays can be found in the "Fuse allocation chart" supplement.

246Electrical fuses

Roadside Assistance

Page 255 of 290

Tire valve

GWARNING

Tire valve that are not approved for your vehi-

cle by the distributor named on the inside

cover page may result in a loss of tire pres-

sure. This may affect road safety. There is a

risk of an accident.

Only use tire valve that are approved for your

vehicle by the distributor named on the inside

cover page. Always make sure you have the

correct tire valve type for the tires on your

vehicle.

!Do not screw additional weights (check

valves, etc.) onto the tire valves. The elec-

tronic components could thus be damaged.

Only for vehicles without a tire pressure moni-

tor:

For safety reasons, Mercedes-Benz recom-

mends that you only use tire valves that have

been tested for use on your vehicle.

Checking the tire pressure manually

In order to determine and adjust the tire pres-

sures, proceed as follows:

XRemove the valve cap of the tire you wish to

check.

XPress the tire pressure gauge securely onto

the valve.

XRead the tire pressure and compare it with the

recommended value on the loading informa-

tion table or the tire pressure table

(

Ypage 250).

XIf the tire pressure is too low, increase it to the

recommended value.

XIf the tire pressure is too high, release air by

pressing down the metal pin in the valve. Use

the tip of a pen, for example. Then, check the

tire pressure again using the tire pressure

gauge.

XScrew the valve cap onto the valve.

XRepeat the steps for the other tires.

Tire pressure monitor

Important safety notes

GWARNING

Each tire, including the spare (if provided),

should be checked at least once a month

when cold and inflated to the pressure rec-

ommended by the vehicle manufacturer on

the Tire and Loading Information placard on

the driver's door B-pillar or the tire pressure

label on the inside of the fuel filler flap. If your

vehicle has tires of a different size than the

size indicated on the Tire and Loading Infor-

mation placard or the tire pressure label, you

should determine the proper tire pressure for

those tires.

As an added safety feature, your vehicle has

been equipped with a tire pressure monitoring

system (TPMS) that illuminates a low tire pres-

sure telltale when one or more of your tires

are significantly underinflated. Accordingly,

when the low tire pressure telltale illuminates,

you should stop and check your tires as soon

as possible, and inflate them to the proper

pressure. Driving on a significantly underin-

flated tire causes the tire to overheat and can lead to tire failure. Underinflation also

reduces fuel efficiency and tire tread life, and

may affect the vehicle's handling and stop-

ping ability.

Please note that the TPMS is not a subs titute

fo

r proper tire maintenance, and it is the driv-

er's responsibility to maintain correct tire

pressure, even if underinflation has not

reached the level to trigger illumination of the

TPMS low tire pressure telltale.

USA only:

Your vehicle has also been equipped with a

TPMS malfunction indicator to indicate if the

system is not operating properly. The TPMS

malfunction indicator is combined with the

low tire pressure telltale. When the system

detects a malfunction, the warning lamp will

flash for approximately a minute and then

remain continuously illuminated. This

sequence will be repeated every time the vehi-

Tire pressure253

Wheels and tires

Z

Page 267 of 290

cle weight rating (GVWR) specified on the vehi-

cle identification plate at the base of the driver's

seat (

Ypage 276).

GVWR (Gross Vehicle Weight Rating)

The GVWR is the maximum permitted gross

weight of the fully laden vehicle (weight of the

vehicle including all accessories, occupants,

fuel, luggage and the drawbar noseweight if

applicable). The Gross Vehicle Weight Rating is

specified on the vehicle identification plate on

the driver seat frame (

Ypage 276).

Maximum weight of the laden vehicle

The maximum weight is the sum of:

Rthe curb weight of the vehicle

Rthe weight of the accessories

Rthe load limit

Rthe weight of the factory installed optional

equipment

Kilopascal (kPa)

Metric unit for tire pressure. 6.9 kPa are the

equivalent of 1 psi. Another tire pressure unit is

bar. 100 kilopascals(kPa) are the equivalent of

1 bar.

Load index

In addition to the load bearing index, a load

index can be stamped onto the sidewall of the

tire. It specifies the load-bearing capacity of the

tire more precisely.

Curb weight

The weight of a vehicle with standard equipment

including the maximum filling capacity of fuel,

oil, and coolant. It also includes the air-condi-

tioning system and optional equipme nt i

f these

are installed on the vehicle, but does not include

passengers or luggage.

Maximum tire load

The maximum tire load in kilograms or pounds is

the maximum weight for which a tire is

approved.

Maximum permissible tire pressure

Maximum permissible tire pressure for one tire.

Maximum load on one tire

Maximum load on one tire. This is calculated by

dividing the maximum axle load of one axle by

two.

PSI (Pounds per square inch)

Standard unit of measurement for tire pressure.

Aspect ratio

Relationship between tire height and width in

percent.

tire pressure

Pressure inside the tire applying an outward

force to every square inch of the tire's surface.

Tire pressure is specified in pounds per square

inch (psi), in kilopascal (kPa) or in bar. Tire pres-

sure should only be corrected when the tires are

cold.

Cold tire pressure

The tires are cold:

Rif the vehicle has been parked for at least

three hours without direct sunlight on the

tires, and

Rif the vehicle has not been driven further than

1 mile (1.6 km)

Tire tread

The part of the tire that comes into contact with the road.

Tire bead

The tire bead ensures that the tire sits securely

on the wheel. There are several stee l wires in the

bead to prevent the tire from coming loose from

the wheel rim.

Sidewall

The part of the tire between the tread and the

tire bead.

Weight of optional extras

The combined weight of those optional extras

that weigh more than the replaced standard

parts and more than 2.3 kg (5 lbs). These

optional extras, such as high-performance

brakes, a roof rack or a high-performance bat-

tery, are not included in the curb weight and the

weight of the accessories.

TIN (Tire Identification Number)

A unique identification number which can be

used by a tire manufacturer to identify tires, for

example for a product recall, and thus identify

the purchasers. The TIN is composed of the

manufacturer identification code, tire size, tire

model code and manufacturing date.

What you should know about wheels and tires265

Wheels and tires

Z

Page 269 of 290

tional tires, an arrow on the sidewall shows the

prescribed direction of rotation of the tire.

Twin rear tires:if the tires are of identical

dimensions, you can rotate the wheels on the

front axle and the inner wheels on the rear axle

in pairs such that the original direction of tire

rotation is retained. With unidirectional tires,

you may rotate the outside wheels at the rear

axle from one side to the other.

Direction of rotation

Tires with a specified direction of rotation have

additional benefits, e.g. if there is a risk of hydro-

planing. You will only gain these benefits if the

correct direction of rotation is observed.

An arrow on the sidewall of the tire indicates its

correct direction of rotation.

You may mount a spare wheel against the direc-

tion of rotation. Observe the time restriction on

use as well as the speed limitation specified on

the spare wheel.

Storing wheels

Store wheels that are not being used in a cool,

dry and preferably dark place. Protect the tires

from contact with oil, grease and fuel.

Mounting a wheel

Vehicle preparation

XStop the vehicle as far away as possible from

traffic and on a level, firm and non-slip sur-

face.

XIf your vehicle poses a risk to approaching

traffic, switch on the hazard warning lamps.

XApply the parking brake.

XTurn the front wheels to the straight-ahead

position.

XMove the selector lever of the automatic

transmission to position P.

XSwitch off the engine.

XPassengers should leave the vehicle. Make

sure that the passengers are not endangered

as they do so.

XMake sure that no one is near the danger area

while the wheel is being changed. Anyone

who is not directly assisting in the wheel change should, for example, stand behind the

barrier.

XPlace the warning triangle or warning lamp at

a suitable distance.

Observe legal requirements.

XSecure the vehicle to prevent it from rolling

away.

iObserve the safety notes on parking in the

section on "Driving and parking"

(

Ypage 130).

XOn level terrain: place chocks or other suit-

able objects under the front and rear of the

wheel that is diagonally opposite the wheel to

be changed.

XOn slight inclines: place chocks or other

suitabl e objects under the wheels on the front

and rear axles opposite the wheel to be

changed.

XTake the vehicle tool kit and the jack from the

footwell on the front-passenger side

(

Ypage 240).

XRemove the spare wheel from the spare wheel

bracket (Ypage 273). Observe the safety

notes in the "Spare wheel" section

(

Ypage 272).

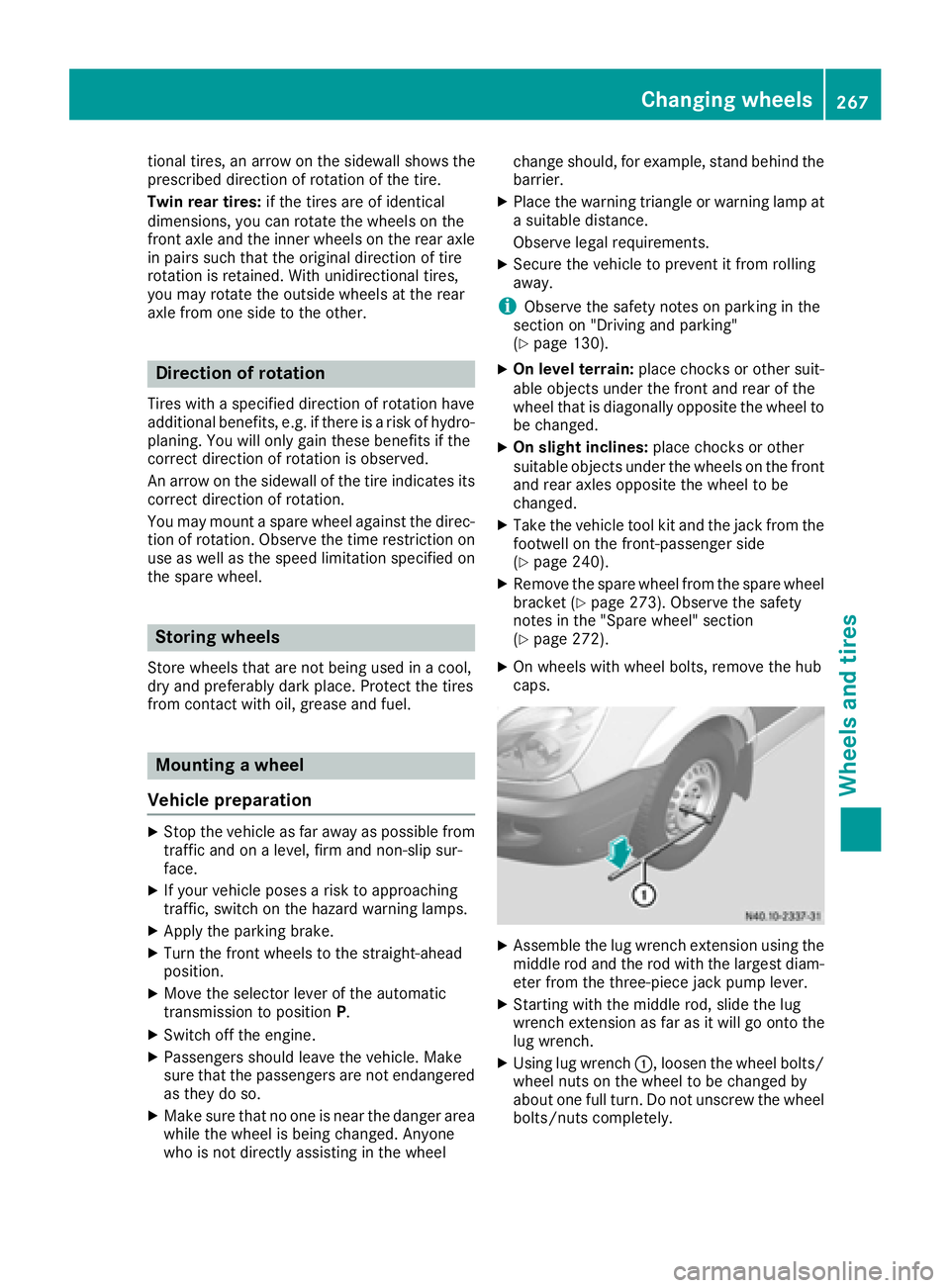

XOn wheels with wheel bolts, remove the hub

caps.

XAssemble the lug wrench extension using the

middle rod and the rod with the largest diam-

eter from the three-piece jack pump lever.

XStarting with the middle rod, slide the lug

wrench extension as far as it will go onto the

lug wrench.

XUsing lug wrench :, loosen the wheel bolts/

wheel nuts on the wheel to be changed by

about one full turn. Do not unscrew the wheel bolts/nuts completely.

Changing wheels267

Wheels an d tires

Z

Page 270 of 290

Raising the vehicle

GWARNING

If you do not position the jack correctly at the

appropriate jacking point of the vehicle, the

jack could tip over with the vehicle raised.

There is a risk of injury.

Only position the jack at the appropriate jack-

ing point of the vehicle. The base of the jack

must be positioned vertically, directly under

the jacking point of the vehicle.

GWARNING

On uphill and downhill slopes, the jack could

tip over with the vehicle raised. There is a risk

of injury.

Do not change wheels on uphill or downhill

gradients. Notify a qualified specialist work-

shop.

!Only position the jack on the jacking points

intended for this purpose. You could other-

wise damage the vehicle.

Observe the following when raising the vehicle:

RWhen raising the vehicle, only use the jack

which Mercedes-Benz has specifically

approved for your vehicle.

RThe vehicle's jack is intended only to raise the

vehicle for a short time when changing a

wheel. It is not suited for performing mainte-

nance work under the vehicle.

RAvoid changing the wheel on uphill and down- hill slopes.

RBefore raising the vehicle, secure it from roll-

ing away by applying the parking brake and

inserting wheel chocks. Never disengage the

parking brake while the vehicle is raised.

RThe jack must be placed on a firm, flat and

non-slip surface. On a loose surface, a large,

load-bearing underlay must be used. On a

slippery surface, a non-slip underlay must be

used, e.g. rubber mats.

RMake sure that the distance between the

underside of the tires and the ground does not

exceed 1.2 in(3 cm).

RNever place your hands or feet under the

ra

ised vehicle.

RNever lie under the raised vehicle.

RNever start the engine when the vehicle is

raised.

RNever open or close a door when the vehicle

is raised.

RMake sure that no persons are present in the

vehicle when the vehicle is raised.

!Only use the jack pump lever middle rod and

the rod with the largest diameter as a lug

wrench extension. Only slide the middle rod

as far as it will go onto the lug wrench. The

rods may otherwise bend and be distorted to

such an extent that they can no longer be

used as a pump lever for the jack.

!Do not place the jack on the leaf spring or

the differential case.

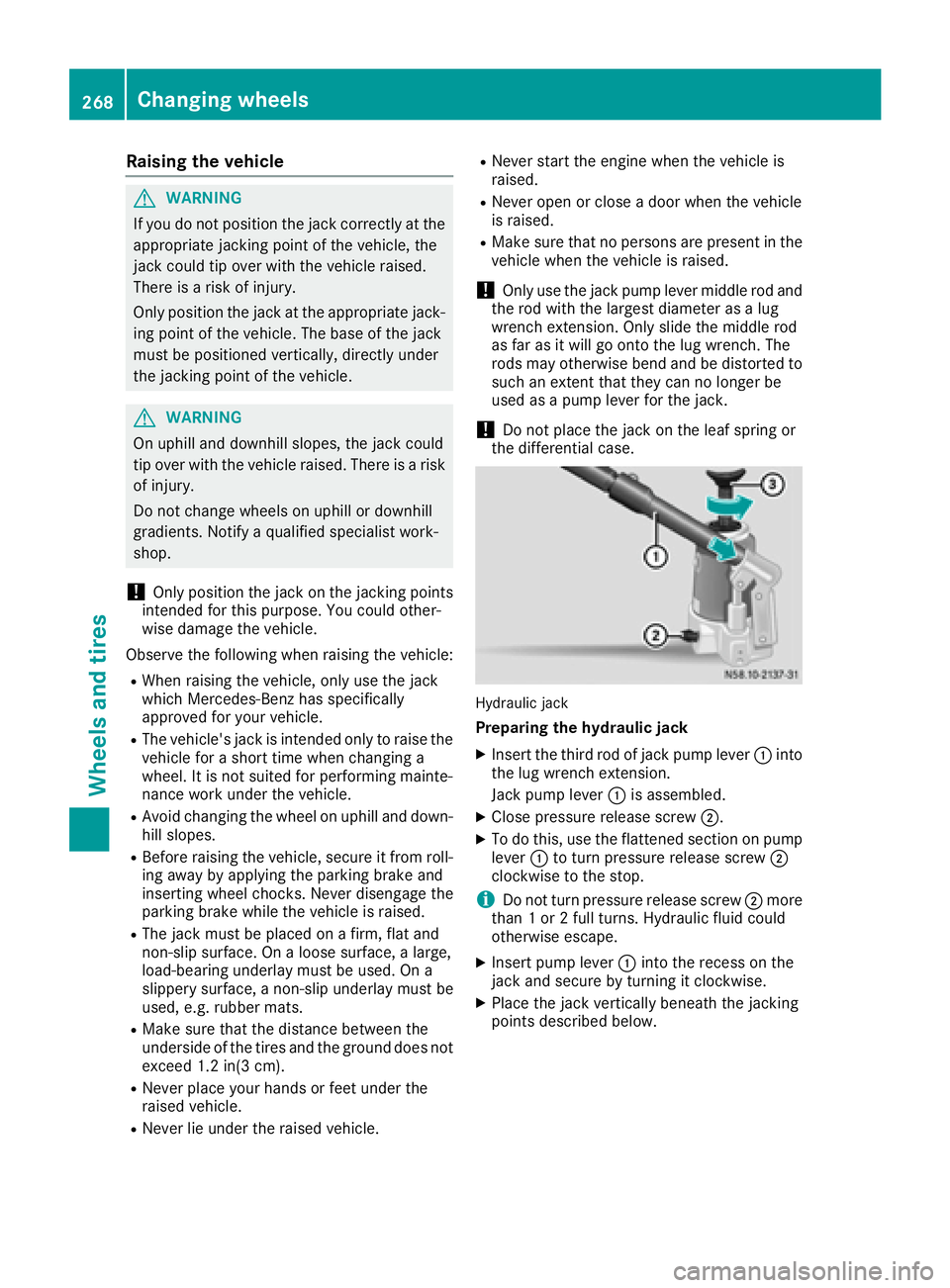

Hydraulic jack

Preparing the hydraulic jack

XInsert the third rod of jack pump lever :into

the lug wrench extension.

Jack pump lever :is assembled.

XClose pressure release screw ;.

XTo do this, use the flattened section on pump

lever:to turn pressure release screw ;

clockwise to the stop.

iDo not turn pressure release screw ;more

than 1 or 2 full turns. Hydraulic fluid could

otherwise escape.

XInsert pump lever :into the recess on the

jack and secure by turning it clockwise.

XPlace the jack vertically beneath the jacking

points described below.

268Changing wheels

Wheels and tires

Page 273 of 290

Slide the new wheel onto the wheel hub and

push it on.

Wheels with centering by wheel bolts:

XVehicles with alloy wheels: take the short

wheel bolts that secure the steel spare wheel

out of the vehicle tool kit.

XScrew in the wheel bolts and tighten them

lightly.

For wheels with wheel nuts:

XFront wheels with wheel nut covers: press the

wheel nut covers onto the wheel nuts.

XScrew in the three wheel nuts over the fixing

discs of the wheel nut cover.

XTurn the wheel so that the wheel bolts are in

the middle of the holes.

XScrew on the rest of the wheel nuts.

XSlightly tighten all the wheel nuts.

Lowering the vehicle

GWARNING

The wheels could work loose if the wheel nuts and bolts are not tightened to the specified

tightening torque. There is a risk of accident.

Have the tightening torque immediately

checked at a qualified specialist workshop

after a wheel is changed.

!Only use the jack pump lever middle rod and

the rod with the largest diameter as a lug

wrench extension. Only slide the middle rod

as far as it will go onto the lug wrench. The

rods may otherwise bend and be distorted to

such an extent that they can no longer be

used as a pump lever for the jack.

!Vehicles with Super Single tires: if you

install the spare wheel, do not exceed the

maximum speed of 40 mph (60 km/h) and do

not drive further than 65 miles(100 km).

The transmission could otherwise be dam-

aged by the difference in wheel rotation

speeds.

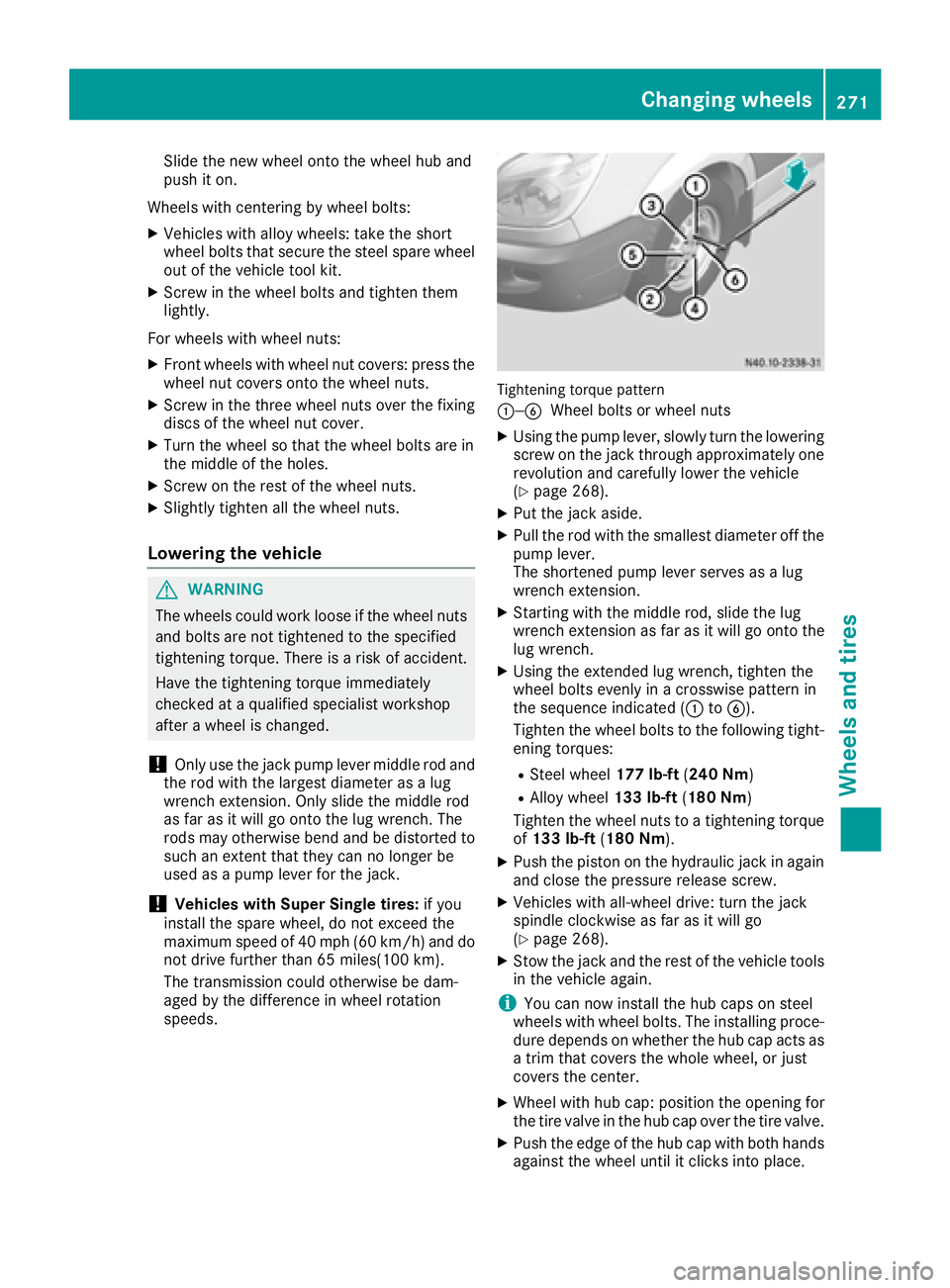

Tightening torque pattern

:—B

Wheel bolts or wheel nuts

XUsing the pump lever, slowly turn the lowering

screw on the jack through approximately one revolution and carefully lower the vehicle

(

Ypage 268).

XPut the jack aside.

XPull the rod with the smallest diameter off the

pump lever.

The shortened pump lever serves as a lug

wrench extension.

XStarting with the middle rod, slide the lug

wrench extension as far as it will go onto the

lug wrench.

XUsing the extended lug wrench, tighten the

wheel bolts evenly in a crosswise pattern in

the sequence indicated ( :toB).

Tighten the wheel bolts to the following tight-

ening torques:

RSteel wheel 177 lb-ft(240 Nm)

RAlloy wheel 133 lb-ft(180 Nm)

Tighten the wheel nuts to a tightening torque

of 133 lb-ft (180 Nm).

XPush the piston on the hydraulic jack in again

and close the pressure release screw.

XVehicles with all-wheel drive: turn the jack

spindle clockwise as far as it will go

(

Ypage 268).

XStow the jack and the rest of the vehicle tools

in the vehicle again.

iYou can now install the hub caps on steel

wheels with wheel bolts. The installing proce-

dure depends on whether the hub cap acts as

a trim that covers the whole wheel, or just

covers the center.

XWheel with hub cap: position the opening for

the tire valve in the hub cap over the tire valve.

XPush the edge of the hub cap with both hands against the wheel until it clicks into place.

Changing wheels271

Wheels and tires

Z