brake fluid MERCEDES-BENZ SPRINTER 2017 MY17 Operator’s Manual

[x] Cancel search | Manufacturer: MERCEDES-BENZ, Model Year: 2017, Model line: SPRINTER, Model: MERCEDES-BENZ SPRINTER 2017Pages: 286, PDF Size: 4.36 MB

Page 194 of 286

ProblemPossible causes/consequences andMSolutions

b

The red brake sys-

tem indicator

lamp is lit while

the engine is run-

ning.There is insufficient brake fluid in the expansion tank.

GWARNING

Braking performance can be impaired.

There is a risk of an accident.

XVehicles with steering wheel buttons: also observe the messages in

the display (Ypage 173).

XStop the vehicle as soon as possible, paying attention to road and

traffic conditions.

XCheck the brake fluid level in the expansion tank (Ypage 219).

XIf the brake fluid is below the MIN mark: do not drive on!

XDo not add brake fluid. This does not solve the problem.

XConsult a qualified specialist workshop.

b When towing a

trailer: the red

brake system

indicator lamp is

lit while the

engine is running.

Additionally, a

warning tone

sounds.GWARNING

The brake force booster in the trailer is faulty.

The driving and braking characteristics of your vehicle could change.

There is a risk of the trailer overbraking and of you losing control over

the truck/trailer combination.

There is a risk of an accident.

XVehicles with steering wheel buttons: also observe the messages in

the display (Ypage 173).

XStop the vehicle as soon as possible, paying attention to road and

traffic conditions.

XDo not drive on.

XConsult a qualified specialist workshop.

: The yellow

ASR/BAS indica-

tor lamp is lit

while the engine

is running.ASR has been deactivated due to a malfunction.

The engine power output may be reduced.

GWARNING

The driven wheels can spin when accelerating.

There is an increased risk of skidding and accidents.

XDrive on with care.

XConsult a qualified specialist workshop as soon as possible.

: The yellow

ASR/BAS indica-

tor lamp is lit

while the engine

is running.BAS has been deactivated due to a malfunction.

GWARNING

The brake system continues to function normally, but without elec-

tronic support.

The braking distance can increase in emergency braking situations.

There is a risk of an accident.

XDrive on with care.

XVisit a qualified specialist workshop immediately.

192Indicator and warning lamps in the instrument cluster

On-board computer and displays

Page 195 of 286

ProblemPossible causes/consequences andMSolutions

:

The yellow

ASR/BAS indica-

tor lamp is lit

while the engine

is running.ASR and BAS have been deactivated due to undervoltage.

The battery may not be being charged.

GWARNING

The brake system is still available with the normal braking effect.

The driven wheels can spin when accelerating.

The braking distance can increase in emergency braking situations.

There is an increased risk of skidding and accidents.

XDrive on with care.

XVisit a qualified specialist workshop immediately.

! The yellow ABS

indicator lamp is

lit while the

engine is running.ABS is deactivated due to a malfunction or is temporarily unavailable.

ESP®, ASR and BAS, as well as cruise control, are also unavailable as

a result.

Self-diagnosis may not be complete, or the battery may not be charg-

ing.

GWARNING

The brake system continues to function normally, but without the

functions listed above. The wheels could therefore lock, e.g. if the

brakes are applied with maximum force.

This causes steerability and braking to be greatly impaired.

The braking distance can increase in emergency braking situations.

The driven wheels can spin when accelerating.

If ESP

®is not operational, ESP®will not stabilize the vehicle.

There is an increased risk of skidding and accidents.

XDrive a short distance at a speed above 13 mph (20 km/h).

The functions mentioned above are available again when the indi-

cator lamp goes out.

If the indicator lamp does not go out:

XDrive on with care.

XVisit a qualified specialist workshop immediately.

å The yellow DEF

indicator lamp is

lit while the

engine is running.The exhaust gas aftertreatment is malfunctioning or the current Diesel

Exhaust Fluid (DEF) supply is limiting the range.

XObserve the messages in the display.

Indicator and warning lamps in the instrument cluster193

On-board computer and displays

Z

Page 218 of 286

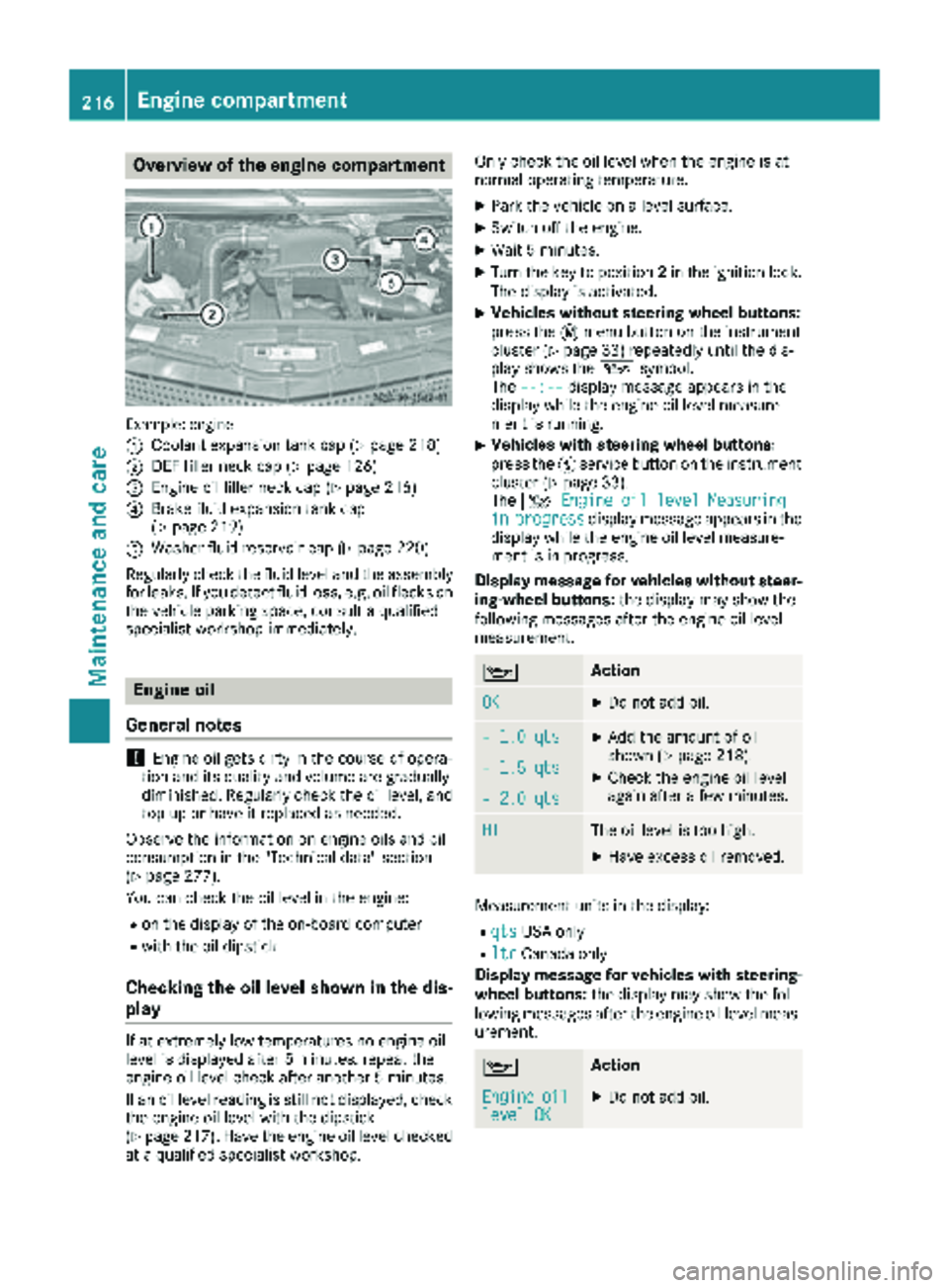

Overview of the engine compartment

Example: engine

:

Coolant expansion tank cap (Ypage 218)

;DEF filler neck cap (Ypage 126)

=Engine oil filler neck cap (Ypage 216)

?Brake fluid expansion tank cap

(Ypage 219)

AWasher fluid reservoir cap (Ypage 220)

Regularly check the fluid level and the assembly

for leaks. If you detect fluid loss, e.g. oil flecks on

the vehicle parking space, consult a qualified

specialist workshop immediately.

Engine oil

General notes

!Engine oil gets dirty in the course of opera-

tion and its quality and volume are gradually

diminished. Regularly check the oil level, and

top up or have it replaced as needed.

Observe the information on engine oils and oil

consumption in the "Technical data" section

(

Ypage 277).

You can check the oil level in the engine:

Ron the display of the on-board computer

Rwith the oil dipstick

Checking the oil level shown in the dis-

play

If at extremely low temperatures no engine oil

level is displayed after 5 minutes, repeat the

engine oil level check after another 5 minutes.

If an oil level reading is still not displayed, check

the engine oil level with the dipstick

(

Ypage 217). Have the engine oil level checked

at a qualified specialist workshop. Only check the oil level when the engine is at

normal operating temperature.

XPark the vehicle on a level surface.

XSwitch off the engine.

XWait 5 minutes.

XTurn the key to position

2in the ignition lock.

The display is activated.

XVehicles without steering wheel buttons:

press the 4menu button on the instrument

cluster (

Ypage 33) repeatedly until the dis-

play shows the 1symbol.

The --:--

display message appears in the

display while the engine oil level measure-

ment is running.

XVehicles with steering wheel buttons:

press the Ëservice button on the instrument

cluster (

Ypage 33).

The 4 Engine oil level Measuring

inprogressdisplay message appears in the

display while the engine oil level measure-

ment is in progress.

Display message for vehicles without steer-

ing-wheel buttons: the display may show the

following messages after the engine oil level

measurement.

1Action

OKXDo not add oil.

– 1.0 qtsXAdd the amount of oil

shown (Ypage 218).

XCheck the engine oil level

again after a few minutes.– 1.5 qts

– 2.0 qts

HIThe oil level is too high.

XHave excess oil removed.

Measurement units in the display:

RqtsUSA only

RltrCanada only

Display message for vehicles with steering- wheel buttons: the display may show the fol-

lowing messages after the engine oil level meas-

urement.

1Action

Engineoillevel OKXDo not add oil.

216Engine compartment

Maintenance and care

Page 221 of 286

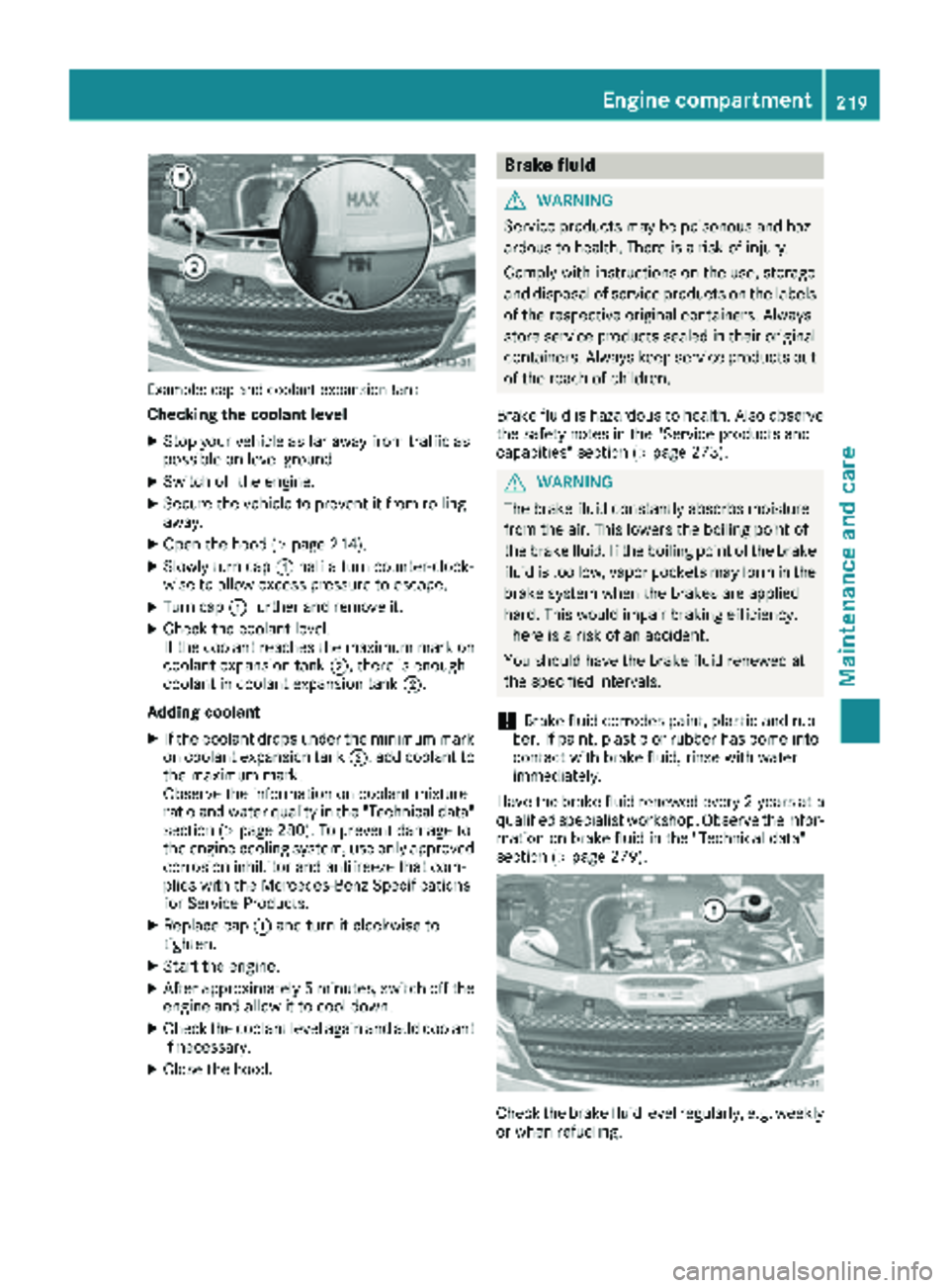

Example: cap and coolant expansion tank

Checking the coolant level

XStop your vehicle as far away from traffic as

possible on level ground.

XSwitch off the engine.

XSecure the vehicle to prevent it from rolling

away.

XOpen the hood (Ypage 214).

XSlowly turn cap:half a turn counter-clock-

wise to allow excess pressure to escape.

XTurn cap :further and remove it.

XCheck the coolant level.

If the coolant reaches the maximum mark on

coolant expansion tank ;, there is enough

coolant in coolant expansion tank ;.

Adding coolant

XIf the coolant drops under the minimum mark

on coolant expansion tank ;, add coolant to

the maximum mark.

Observe the information on coolant mixture

ratio and water quality in the "Technical data"

section (

Ypage 280). To prevent damage to

the engine cooling system, use only approved

corrosion inhibitor and antifreeze that com-

plies with the Mercedes-Benz Specifications

for Service Products.

XReplace cap :and turn it clockwise to

tighten.

XStart the engine.

XAfter approximately 5 minutes, switch off the

engine and allow it to cool down.

XCheck the coolant level again and add coolant

if necessary.

XClose the hood.

Brake fluid

GWARNING

Service products may be poisonous and haz-

ardous to health. There is a risk of injury.

Comply with instructions on the use, storage

and disposal of service products on the labels

of the respective original containers. Always

store service products sealed in their original

containers. Always keep service products out

of the reach of children.

Brake fluid is hazardous to health. Also observe

the safety notes in the "Service products and

capacities" section (

Ypage 273).

GWARNING

The brake fluid constantly absorbs moisture

from the air. This lowers the boiling point of

the brake fluid. If the boiling point of the brake

fluid is too low, vapor pockets may form in the

brake system when the brakes are applied

hard. This would impair braking efficiency.

There is a risk of an accident.

You should have the brake fluid renewed at

the specified intervals.

!Brake fluid corrodes paint, plastic and rub-

ber. If paint, plastic or rubber has come into

contact with brake fluid, rinse with water

immediately.

Have the brake fluid renewed every 2 year sat a

qualified specialist workshop. Observe the infor- mation on brake fluid in the "Technical data"

section (

Ypage 279).

Check the brake fluid level regularly, e.g. weekly

or when refueling.

Engine compartment219

Maintenance and care

Z

Page 222 of 286

Checking the brake fluid level

XStop your vehicle as far away from traffic as

possible on level ground.

XSwitch off the engine.

XSecure the vehicle to prevent it from rolling

away.

XOpen the hood (Ypage 214).

XCheck the brake fluid level.

The brake fluid level is correct if the level is

between the MIN mark and MAX mark on

brake fluid reservoir:.

XClose the hood.

!If the brake fluid level in the brake fluid res-

ervoir has fallen to the MIN mark or below,

check the brake system immediately for

leaks. Also check the thickness of the brake

linings. Visit a qualified specialist workshop

immediately.

Do not add brake fluid. This does not correct

the malfunction.

Washer fluid

GWARNING

Windshield washer concentrate could ignite if it comes into contact with hot engine compo-

nents or the exhaust system. There is a risk of

fire and injury.

Make sure that no windshield washer con-

centrate is spilled next to the filler neck.

!Only use washer fluid that is suitable for

plastic lamp lenses, e.g. MB SummerFit or MB WinterFit. Unsuitable washer fluid could dam-

age the plastic lenses of the headlamps.

Example: washer fluid reservoir

Add windshield washer concentrate to the

washer fluid all year round. Observe the infor-

mation on washer fluid in the "Technical data"

section (

Ypage 281).

Adding washer fluid

XMix the washer fluid to the appropriate mixing ratio in a container beforehand.

XOpen the hood (Ypage 214).

XPull cap :on the washer fluid reservoir

upwards at the tab.

XAdd the premixed washer fluid.

XPress cap :onto the filler neck until it

engages audibly.

XClose the hood.

Fuel system

Draining the fuel filter

GWARNING

Fuel is highly flammable. Improper handling of

fuel creates a risk of fire and explosion.

Avoid fire, open flames, smoking and creating

sparks under all circumstances. Switch off the

ignition and auxiliary heating before carrying

out work to the fuel system. Always wear pro-

tective gloves.

HEnvironmental note

Dispose of the water-fuel mixture in an envi-

ronmentally responsible manner.

!When the :indicator lamp lights up,

drain the fuel filter with water separator

immediately. Otherwise, the engine may be

damaged.

220Engine compartment

Maintenance and care

Page 233 of 286

Cleaning the paintwork

!Do not affix:

Rstickers

Rfilms

Rmagnetic plates or similar items

to painted surfaces. You could otherwise

damage the paintwork.

Scratches, corrosive deposits, areas affected by

corrosion and damage caused by inadequate

care cannot always be completely repaired. In

such cases, visit a qualified specialist workshop.

XRemove impurities immediately, where pos-

sible, whilst avoiding rubbing too hard.

XSoak insect remains with insect remover and

rinse off the treated areas afterwards.

XSoak bird droppings with water and rinse off

the treated areas afterwards.

XRemove coolant, brake fluid, tree resin, oils,

fuels and greases by rubbing gently with a

cloth soaked in petroleum ether or lighter

fluid.

XUse tar remover to remove tar stains.

XUse silicone remover to remove wax.

Cleaning the windows

GWARNING

You could become trapped by the windshield wipers if they start moving while cleaning the

windshield or wiper blades. There is a risk of

injury.

Always switch off the windshield wipers and

the ignition before cleaning the windshield or

wiper blades.

!Do not fold the windshield wipers away from

the windshield unless the hood is closed. Oth-

erwise, you could damage the hood.

!Hold the wiper arm securely when folding

back. The windshield could be damaged if the

wiper arm smacks against it suddenly.

!Do not use dry cloths, abrasive products,

solvents or cleaning agents containing sol-

vents to clean the inside of the windows. Do

not touch the insides of the windows with

hard objects, e.g. an ice scraper or ring. There

is otherwise a risk of damaging the windows. Before cleaning the windshield

XTurn the key to position

0in the ignition lock

or remove it.

XFold the windshield wiper arms away from the

windshield until you feel them engage.

Before switching the ignition on again, fold

the windshield wipers back into position.

Cleaning the windows

XClean the inside and outside of the windows

with a damp cloth and a cleaning agent that is

recommended and approved for Sprinter

vehicles.

Exterior

Cleaning the wheels

!Do not use any acidic or alkaline cleaning

agents. They can cause corrosion on the

wheel bolts (wheel nuts) or the retainer

springs for the wheel-balancing weights.

!Do not park the vehicle for an extended

period straight after cleaning it, particularly

after having cleaned the wheels with wheel

cleaner. Wheel cleaners could cause

increased corrosion of the brake discs and

brake pads/linings. For this reason, you

should drive for a few minutes after cleaning.

Braking heats the brake discs and the brake

pads/linings, thus drying them. The vehicle

can then be parked.

If you clean the wheels with a power washer,

observe the safety notes for the power washer

(

Ypage 230). You could otherwise damage the

tires.

Cleaning the wiper blades

GWARNING

You could become trapped by the windshield wipers if they start moving while cleaning the

windshield or wiper blades. There is a risk of

injury.

Always switch off the windshield wipers and

the ignition before cleaning the windshield or

wiper blades.

Care231

Maintenance and care

Z

Page 266 of 286

Observe the following when raising the vehicle:

RWhen raising the vehicle, only use the jack

which Mercedes-Benz has specifically

approved for your vehicle.

RThe vehicle's jack is intended only to raise the

vehicle for a short time when changing a

wheel. It is not suited for performing mainte-

nance work under the vehicle.

RAvoid changing the wheel on uphill and down-

hill slopes.

RBefore raising the vehicle, secure it from roll-

ing away by applying the parking brake and

inserting wheel chocks. Never disengage the

parking brake while the vehicle is raised.

RThe jack must be placed on a firm, flat and

non-slip surface. On a loose surface, a large,

load-bearing underlay must be used. On a

slippery surface, a non-slip underlay must be

used, e.g. rubber mats.

RMake sure that the distance between the

underside of the tires and the ground does not

exceed 1.2 in(3 cm).

RNever place your hands or feet under the

raised vehicle.

RNever lie under the raised vehicle.

RNever start the engine when the vehicle is

raised.

RNever open or close a door when the vehicle

is raised.

RMake sure that no persons are present in the

vehicle when the vehicle is raised.

!Only use the jack pump lever middle rod and

the rod with the largest diameter as a lug

wrench extension. Only slide the middle rod

as far as it will go onto the lug wrench. The

rods may otherwise bend and be distorted to

such an extent that they can no longer be

used as a pump lever for the jack.

!Do not place the jack on the leaf spring or

the differential case.

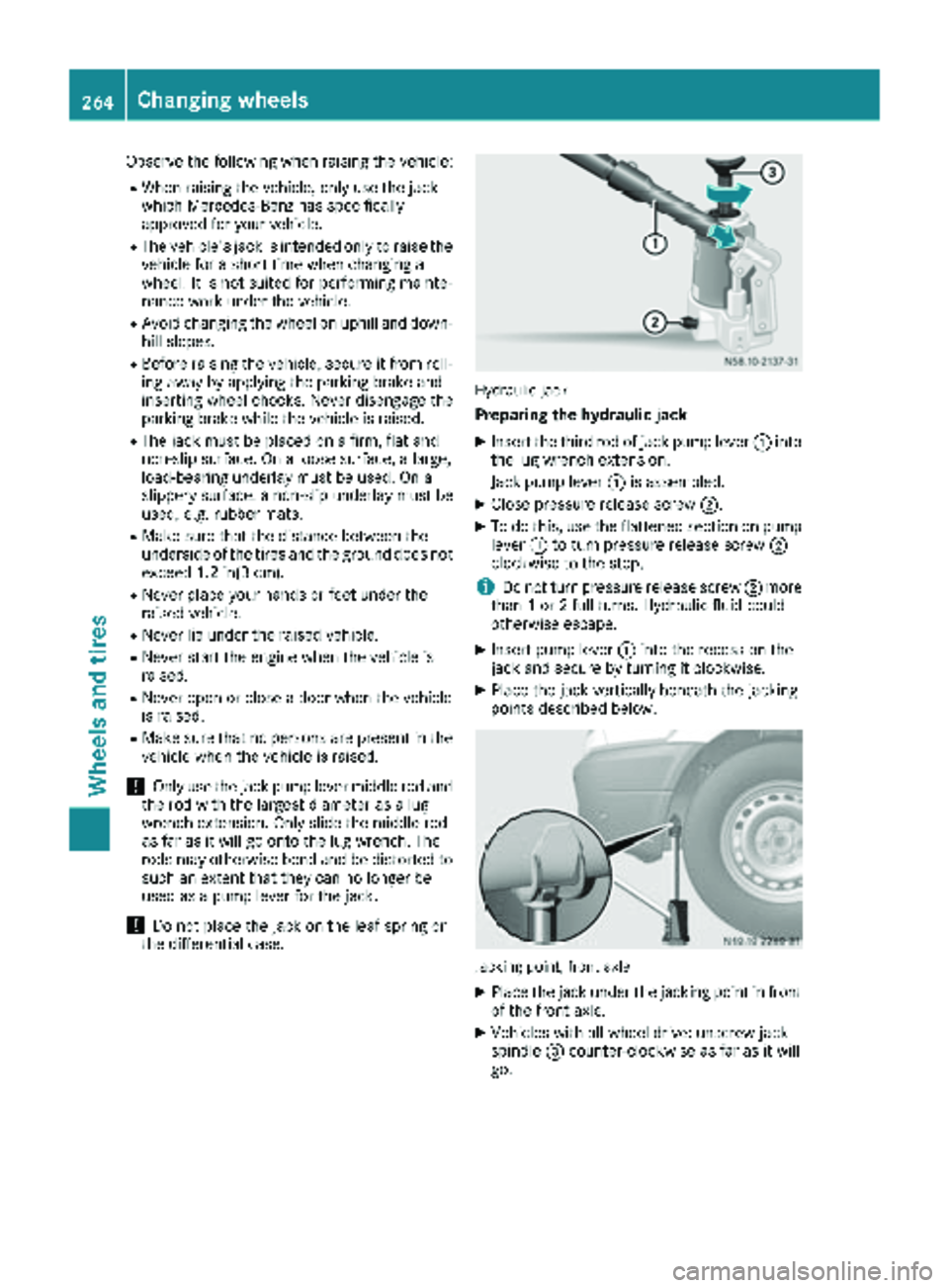

Hydraulic jack

Preparing the hydraulic jack

XInsert the third rod of jack pump lever :into

the lug wrench extension.

Jack pump lever :is assembled.

XClose pressure release screw ;.

XTo do this, use the flattened section on pump

lever:to turn pressure release screw ;

clockwise to the stop.

iDo not turn pressure release screw ;more

than 1 or 2 full turns. Hydraulic fluid could

otherwise escape.

XInsert pump lever :into the recess on the

jack and secure by turning it clockwise.

XPlace the jack vertically beneath the jacking

points described below.

Jacking point, front axle

XPlace the jack under the jacking point in front of the front axle.

XVehicles with all-wheel drive: unscrew jack

spindle =counter-clockwise as far as it will

go.

264Changing wheels

Wheels and tires

Page 275 of 286

iSuch data is vehicle-specific and may differ

from that shown. Always observe the specifi-

cations on your vehicle's identification plate.

Engine number

The engine number is stamped on the crank-

case. More information may be obtained at any

qualified specialist workshop.

Service products and capacities

Important safety notes

GWARNING

Service products may be poisonous and haz-

ardous to health. There is a risk of injury.

Comply with instructions on the use, storage

and disposal of service products on the labels

of the respective original containers. Always

store service products sealed in their original

containers. Always keep service products out

of the reach of children.

HEnvironmental note

Dispose of service products in an environ-

mentally responsible manner.

Service products include the following:

RFuels, e.g. diesel

RAdditives for the exhaust gas aftertreatment,

e.g. Diesel Exhaust Fluid (DEF)

RLubricants, e.g. engine oil, transmission oil

RCoolant

RBrake fluid

RWasher fluid

RClimate control system refrigerants

Approved service products comply with the

highest quality standards and are listed in the

MB Specifications for Service Products. Only

use service products approved for the vehicle.

This is an important condition for the warranty.

You will recognize the approved service prod-

ucts by the inscription on the container: MB

Approval (e.g. MB Approval 228.5)

Other identifications and recommendations

refer to quality level or a specification according to an MB Sheet Number (e.g. MB 228.5). They

are therefore not necessarily approved.

Further information can be obtained at any

qualified specialist workshop.

Additives for approved service products are nei-

ther required nor permitted. Approved fuel addi- tives are the exception. Additives can cause

engine damage and must therefore not be

added to the service products.

The use of additives is always the responsibility

of the vehicle operator. The use of additives may

result in the restriction or loss of yo ur Li

mited

Warranty entitlements.

Fuel

Important safety notes

GWARNING

Fuel is highly flammable. Improper handling of

fuel creates a risk of fire and explosion.

Avoid fire, open flames, smoking and creating

sparks under all circumstances. Switch off the

engine and, if applicable, the auxiliary heating

before refueling.

GWARNING

Fuel is poisonous and hazardous to health.

There is a risk of injury.

You must make sure that fuel does not come into contact with your skin, eyes or clothing

and that it is not swallowed. Do not inhale fuel

vapors. Keep fuel away from children.

If you or others come into contact with fuel,

observe the following:

RWash away fuel from skin immediately

using soap and water.

RIf fuel comes into contact with your eyes,

immediately rinse them thoroughly with

clean water. Seek medical assistance with-

out delay.

RIf fuel is swallowed, seek medical assis-

tance without delay. Do not induce vomit-

ing.

RImmediately change out of clothing which

has come into contact with fuel.

Service products and capacities273

Technical data

Z

Page 281 of 286

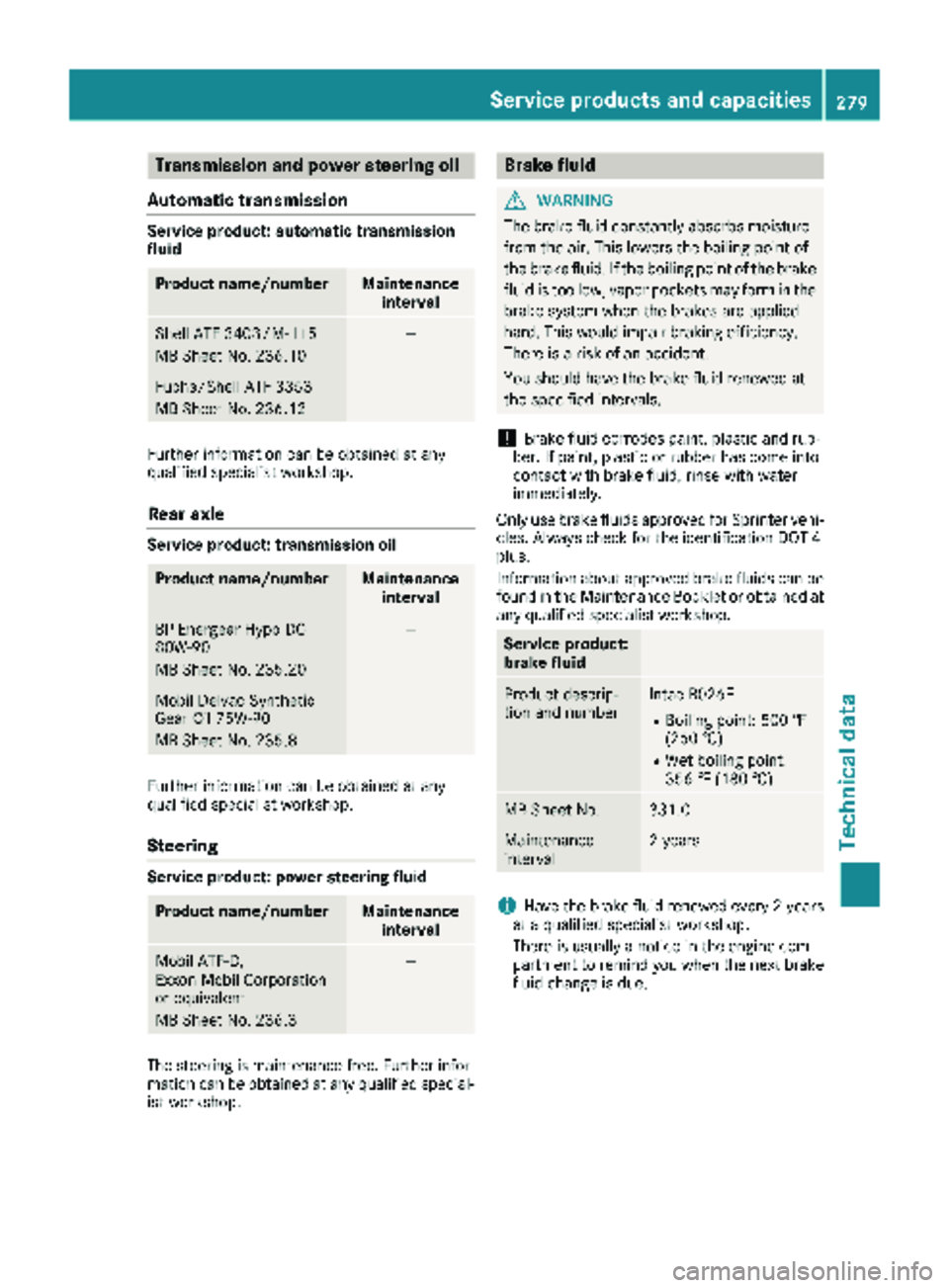

Transmission and power steering oil

Automatic transmission

Service product: automatic transmission

fluid

Product name/numberMaintenance interval

Shell ATF 3403/M-115

MB Sheet No. 236.10—

Fuchs/Shell ATF 3353

MB Sheet No. 236.12

Further information can be obtained at any

qualified specialist workshop.

Rear axle

Service product: transmission oil

Product name/numberMaintenanceinterval

BP Energear Hypo DC

80W-90

MB Sheet No. 235.20—

Mobil Delvac Synthetic

Gear Oil 75W-90

MB Sheet No. 235.8

Further information can be obtained at any

qualified specialist workshop.

Steering

Service product: power steering fluid

Product name/numberMaintenanceinterval

Mobil ATF‑D,

Exxon Mobil Corporation

or equivalent

MB Sheet No. 236.3—

The steering is maintenance-free. Further infor-

mation can be obtained at any qualified special-

ist workshop.

Brake fluid

GWARNING

The brake fluid constantly absorbs moisture

from the air. This lowers the boiling point of

the brake fluid. If the boiling point of the brake

fluid is too low, vapor pockets may form in the

brake system when the brakes are applied

hard. This would impair braking efficiency.

There is a risk of an accident.

You should have the brake fluid renewed at

the specified intervals.

!Brake fluid corrodes paint, plastic and rub-

ber. If paint, plastic or rubber has come into

contact with brake fluid, rinse with water

immediately.

Only use brake fluids approved for Sprinter vehi-

cles. Always check for the identification DOT 4

plus.

Information about approved brake fluids can be found in the Maintenance Booklet or obtained at

any qualified specialist workshop.

Service product:

brake fluid

Product descrip-

tion and numberIntac B026E

RBoiling point: 500 ‡

(260 †)

RWet boiling point:

356 ‡ (180 †)

MB Sheet No.331.0

Maintenance

interval2 years

iHave the brake fluid renewed every 2 years

at a qualified specialist workshop.

There is usually a notice in the engine com-

partment to remind you when the next brake

fluid change is due.

Service products and capacities279

Technical data

Z

Page 283 of 286

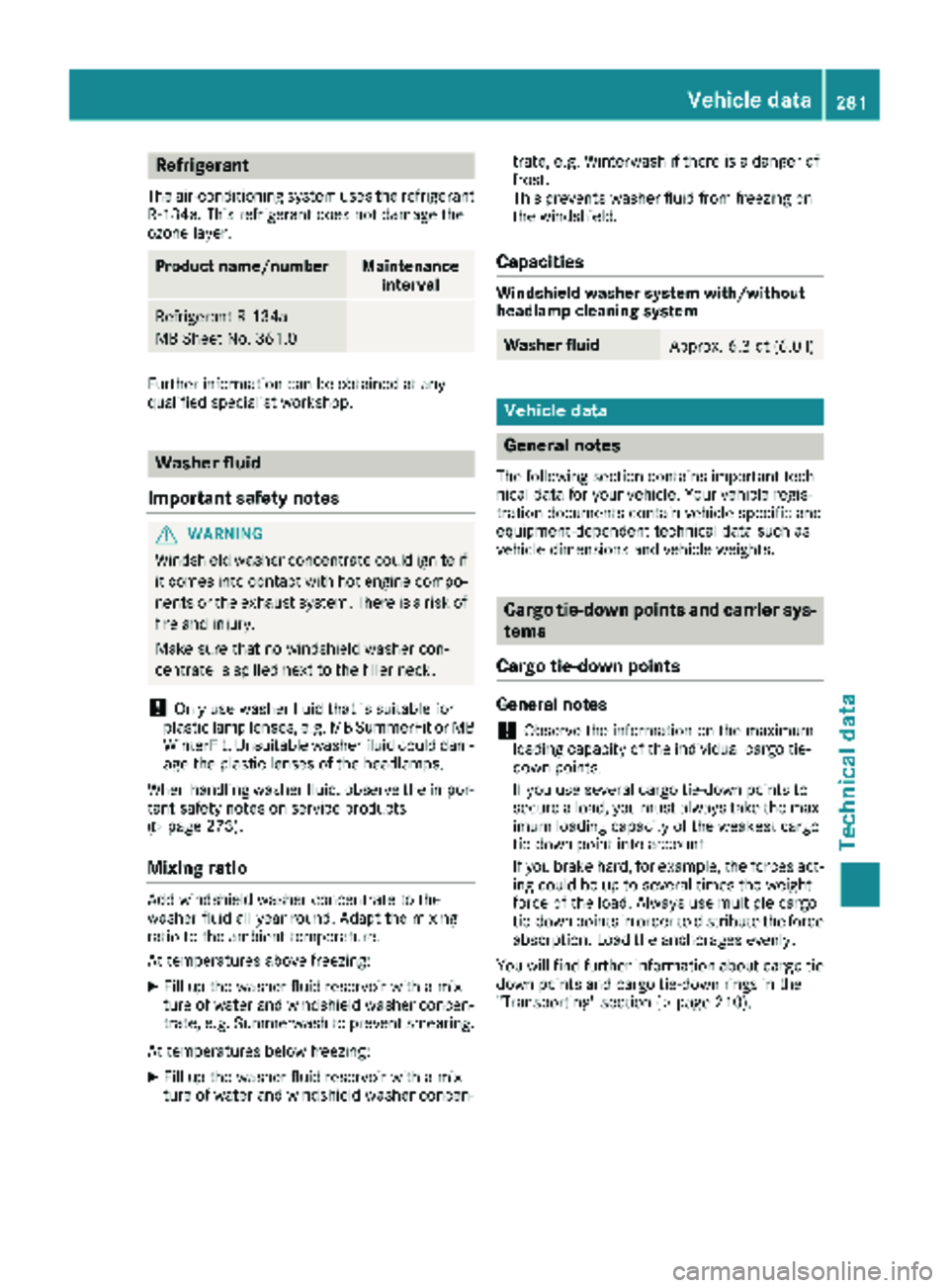

Refrigerant

The air-conditioning system uses the refrigerant

R‑134a. This refrigerant does not damage the

ozone layer.

Product name/numberMaintenance interval

Refrigerant R ‑134a

MB Sheet No. 361.0—

Further information can be obtained at any

qualified specialist workshop.

Washer fluid

Important safety notes

GWARNING

Windshield washer concentrate could ignite if it comes into contact with hot engine compo-

nents or the exhaust system. There is a risk of

fire and injury.

Make sure that no windshield washer con-

centrate is spilled next to the filler neck.

!Only use washer fluid that is suitable for

plastic lamp lenses, e.g. MB SummerFit or MB WinterFit. Unsuitable washer fluid could dam-

age the plastic lenses of the headlamps.

When handling washer fluid, observe the impor-

tant safety notes on service products

(

Ypage 273).

Mixing ratio

Add windshield washer concentrate to the

washer fluid all year round. Adapt the mixing

ratio to the ambient temperature.

At temperatures above freezing:

XFill up the washer fluid reservoir with a mix-

ture of water and windshield washer concen-

trate, e.g. Summerwash to prevent smearing.

At temperatures below freezing:

XFill up the washer fluid reservoir with a mix-

ture of water and windshield washer concen- trate, e.g. Winterwash if there is a danger of

frost.

This prevents washer fluid from freezing on

the windshield.

Capacities

Windshield washer system with/without

headlamp cleaning system

Washer fluidApprox. 6.3 qt (6.0 l)

Vehicle data

General notes

The following section contains important tech-

nical data for your vehicle. Your vehicle regis-

tration documents contain vehicle-specific and

equipment-dependent technical data such as

vehicle dimensions and vehicle weights.

Cargo tie-down points and carrier sys-

tems

Cargo tie-down points

General notes

!Observe the information on the maximum

loading capacity of the individual cargo tie-

down points.

If you use several cargo tie-down points to

secure a load, you must always take the max-

imum loading capacity of the weakest cargo

tie-down point into account.

If you brake hard, for example, the forces act-

ing could be up to several times the weight

force of the load. Always use multiple cargo

tie-down points in order to distribute the force absorption. Load the anchorages evenly.

You will find further information about cargo tie

down points and cargo tie-down rings in the

"Transporting" section (

Ypage 210).

Vehicle data281

Technical data

Z