tire type MERCEDES-BENZ SPRINTER 2019 MY19 with 7” screen

[x] Cancel search | Manufacturer: MERCEDES-BENZ, Model Year: 2019, Model line: SPRINTER, Model: MERCEDES-BENZ SPRINTER 2019Pages: 354, PDF Size: 6.15 MB

Page 279 of 354

#

Place the jack toone side. #

Pull thero d with the smallest diame ter off the

pump le ver.

The shor tened pu mpleve r ser ves as a lug

wrench extension. #

Starting with the middle rod, slide the lug

wrench extension as far as it will go onto the

lug wrench. #

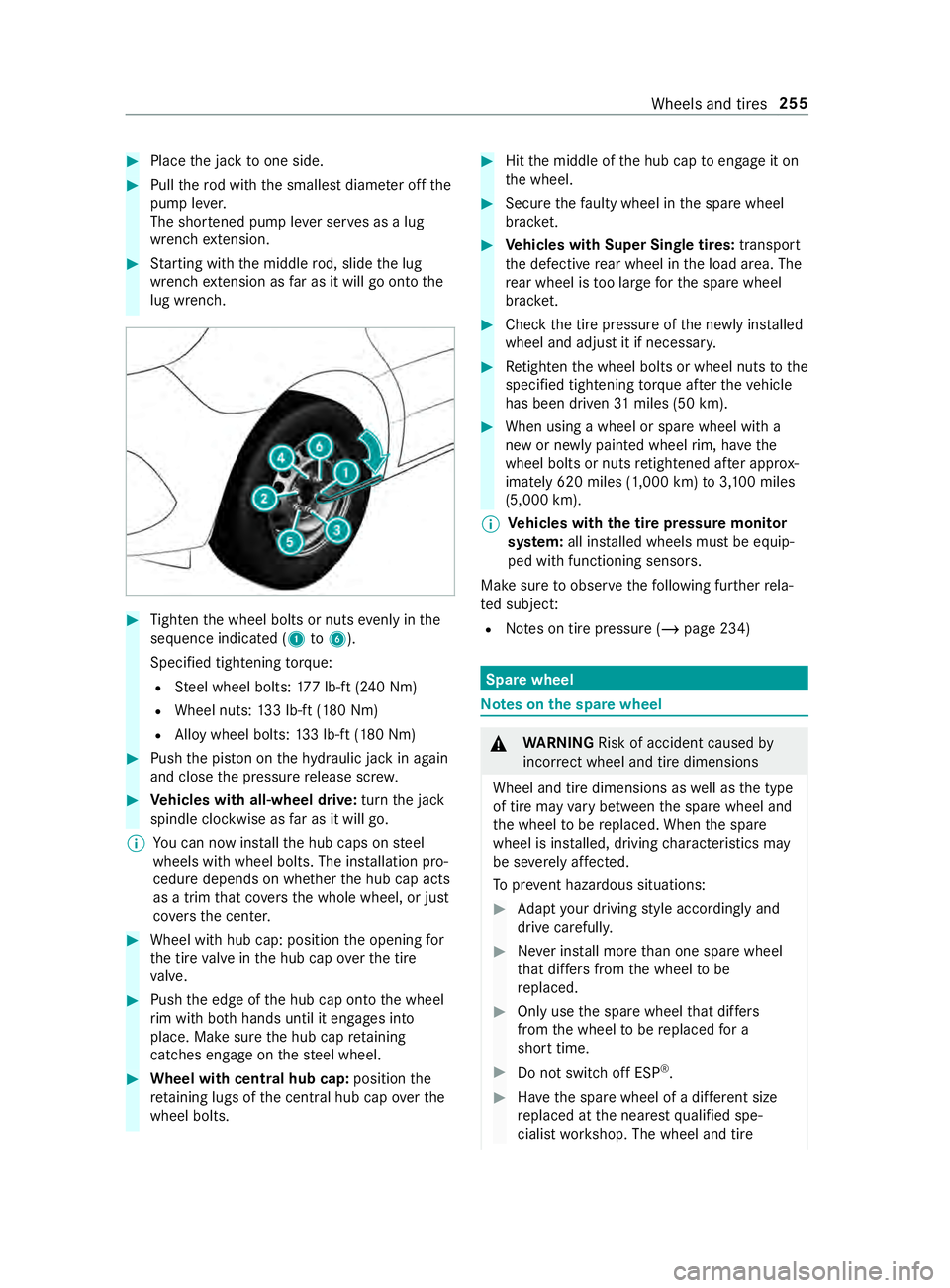

Tighten the wheel bolts or nuts evenly in the

sequence indicated (1 to6 ).

Specified tightening torque:

R Steel wheel bolts: 177 lb-ft (240 Nm)

R Wheel nuts: 133 lb-f t(180 Nm)

R Alloy wheel bolts: 133 lb-f t(180 Nm) #

Push the pis ton on thehy draulic jack in again

and close the pressure release scr ew. #

Vehicles with all-wheel drive: turnthe jack

spindle clockwise as far as it will go.

% Yo

u can now ins tallth e hub caps on steel

wheels with wheel bolts. The ins tallation pro‐

cedure depends on whe ther the hub cap acts

as a trim that co vers the whole wheel, or just

co vers the center. #

Wheel with hub cap: position the opening for

th e tire valve in the hub cap overth e tire

va lve. #

Push the edge of the hub cap onto the wheel

ri m with bo thhands until it engages into

place. Make sure the hub cap retaining

cat ches engage on thesteel wheel. #

Wheel with central hub cap: positionthe

re taining lugs of the cent ral hub cap overthe

wheel bolts. #

Hitthe middle of the hub cap toengage it on

th e wheel. #

Secure thefa ulty wheel in the spare wheel

brac ket. #

Vehicles with Super Single tires: transport

th e defective rear wheel in the load area. The

re ar wheel is too lar geforth e spare wheel

brac ket. #

Check the tire pressure of the newly ins talled

wheel and adjust it if necessar y. #

Retighten the wheel bolts or wheel nuts tothe

specified tightening torque af terth eve hicle

has been driven 31miles (50 km). #

When using a wheel or spare wheel with a

new or newly painted wheel rim, ha vethe

wheel bolts or nuts retightened af ter appro x‐

ima tely 620 miles (1,000 km) to3,10 0 miles

(5,000 km).

% Ve

hicles with the tire pressure monitor

sy stem: all ins talled wheels must be equip‐

ped with functioning sensors.

Make sure toobser vethefo llowing fur ther rela‐

te d subject:

R Notes on tire pressure (/ page 234) Spare wheel

Note

s onthe spa rewheel &

WARNING Risk of accident caused by

incor rect wheel and tire dimensions

Wheel and tire dimensions as well as the type

of tire may vary between the spare wheel and

th e wheel tobe replaced. When the spare

wheel is ins talled, driving characteristics may

be se verely af fected.

To prev ent hazardous situations: #

Adapt your driving style according lyand

drive carefull y. #

Never ins tall more than one spare wheel

th at dif fers from the wheel tobe

re placed. #

Only use the spare wheel that dif fers

from the wheel tobe replaced for a

short time. #

Do not switch off ESP ®

. #

Have the spare wheel of a dif fere nt size

re placed at the nearest qualified spe‐

cialist workshop. The wheel and tire Wheels and tires

255

Page 280 of 354

must ha

vethe cor rect dimensions and

th e tire must be the cor rect type. Do not

exceed a maximum speed of 50 mph

(80 km/h) if a spare wheel of a dif fere nt size is

ins talled. &

WARNING Risk of accident from dam‐

aged spa rewheel with Super Sin gle tires

Ve hicles with Super Single tires

The tire of the spare wheel exposed toabo ve-

ave rage loads af ter being ins talled on there ar

axle. If youexc eed the maximum speed or the

maximum dis tance, or ins tallth e spare wheel

again, the tire of the spare wheel may be

damaged. The tire damage may not be visible

and not de tectable.

A damaged tire may cause a loss of tire pres‐

sure. This could cause youto lose control of

th eve hicle. #

Only use the spare wheel if it has not

ye t been ins talled on there ar axle with

th e cur rent tires. #

Ifth e spare wheel had been ins talled on

th ere ar axle, ha vethe tire of the spare

wheel replaced af terch anging the

wheel again, ir respective of the dis‐

ta nce. #

For saf etyre asons, when changing a tire

ensure that only the tire valve type

appr ovedfo rth e tires is used. *

NO

TEDama getothe transmission Ve

hicles with Super Single tires: whenyou

ins tallth e spare wheel on there ar axle, the

transmission may be dama gedby the dif fer‐

ent rotational speeds of the wheels. #

When the spare wheel is ins talled on the

re ar axle, obse rveth e maximum speed

of 34 mph (55 km/h) and the maximum

driving dis tance of 62 miles (100 km). %

The spa

rewheel can be used without restric‐

tions on the front axle of a vehicle with Super

Single tires.

Re gular lych eck that the spare wheel is secured

and has the specified tire pressure

(/ page 234). Re

gularly check thefo llowing, particularly prior to

long trips:

R the tire pressure of the spare wheel (if neces‐

sar y,adjust the tire pressure).

R thefast enings of the spare wheel brac ket.

Re place the tires af ter six years at the latest,

re ga rdless of wear. This also applies tothe spare

wheel.

% If

yo u ha veinstalled a spare wheel, the tire

pressure monitoring sy stem will not function

fo rth is wheel. The spare wheel is not equip‐

ped with a sensor forth e tire pressure moni‐

to ring sy stem. Installing/removing

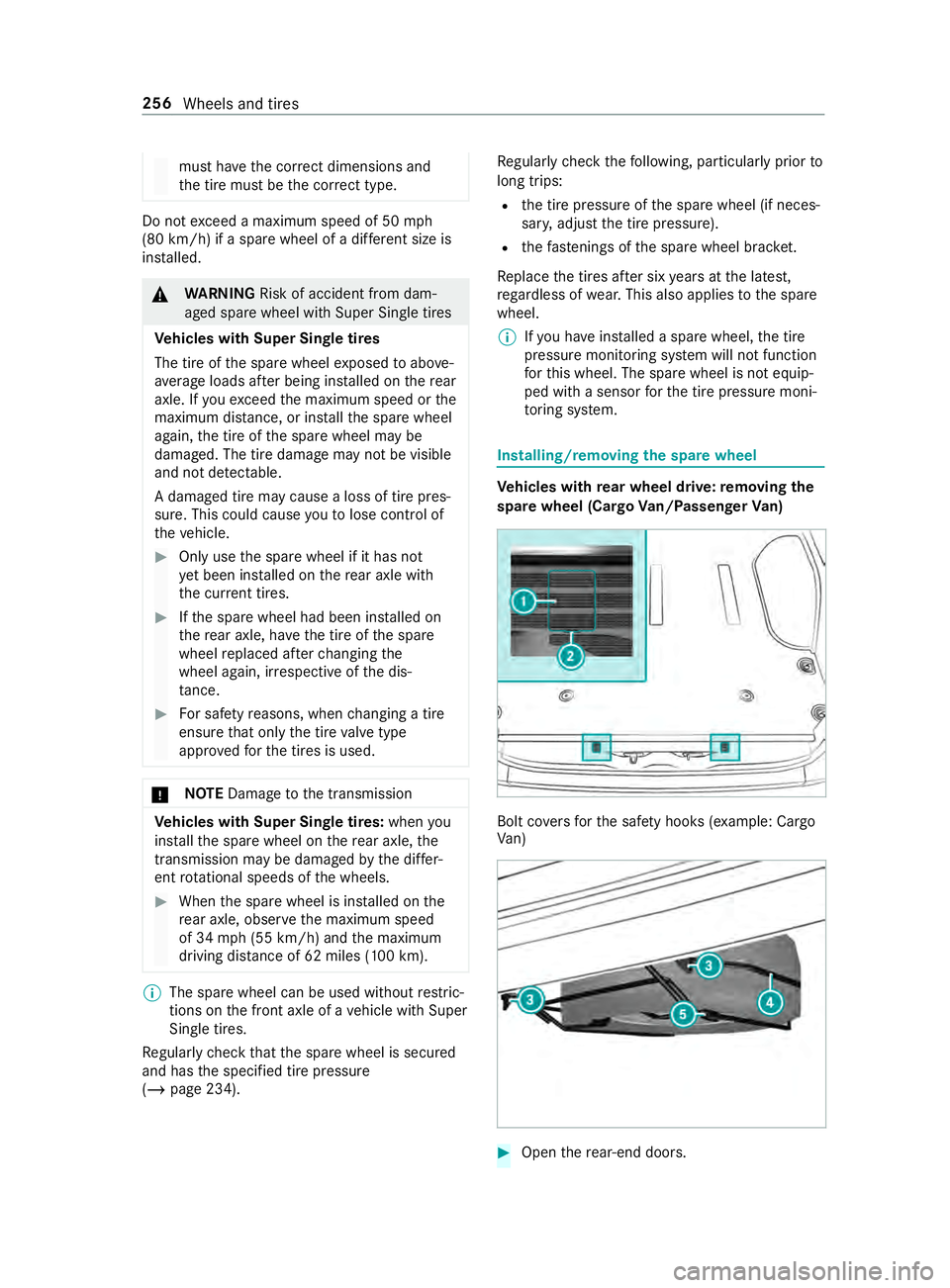

the spa rewheel Ve

hicles with rear wheel drive: removing the

spare wheel (Cargo Van/Passenger Van) Bolt co

vers forth e saf ety hoo ks(exa mp le: Cargo

Va n) #

Open there ar-end doors. 256

Wheels and tires

Page 289 of 354

#

Neverre fuel using gasoline in diesel

engines. #

Never mix gasoline with diesel fuel. *

NO

TEDama gedue toincor rect fuel Even small amounts of

the wrong fuel could

re sult in damage tothe fuel sy stem, the

engine and emission cont rol sy stem.

Ne verre fuel with:

R Gasoline

R Marine diesel

R Heating oil

R Pure bio-diesel or vege tab le oil

R Paraffin or kerosene #

Do not mix such fuels with diesel fuel

and do not use any special additives.

If yo u ha veaccidentally refueled with the

wrong fuel, obser vethefo llowing: #

Do not switch on the ignition. #

Consult a qualified specialist workshop. *

NO

TEMalfunctions due tocontaminated

fuel Fu

el contamination can lead tomalfunctions

in the fuel sy stem. #

Ifyo u are using drums or canis ters to

re fuel theve hicle, you should filter the

fuel before filling. *

NO

TEDama gedue toincor rect fuel Incor

rect fuel can lead toengine damage. #

Refuel only ULSD or diesel fuel with a

sulfur content of maximum 15ppm. Usually

you will find information about the fuel

grade on the fuel pump. If there is no identifica‐

tion on the fuel pump, consult a gasst ation

attendant.

The fuel grade recommended foryo ur vehicle is

fo und on the instruction label in the fuel filler

fl ap . Note

s on low outside temperatures &

WARNING Risk offire and explosion due

to fuel igniting

If yo u heat fuel sy stem components, e.g. with

a heat gun or open flame, these components

could be damaged.

Fu el may leak out and ignite. Depending on

th e type of damage, fuel might not escape

until the engine is running. #

Never heat fuel sy stem components. #

Consult a qualified specialist workshop

to have the malfunction rectified. Re

fill only with commercially available ULTRA-

LO W SULFUR DIESEL (ULSD, maximum sulfur

content 15ppm), which fulfills the ASTM D9 75

st andard.

The flow properties of diesel fuel may be inade‐

qu ate at low outside temp eratures due toparaf fin

separation.

% Malfunctions

resulting from paraf fin separa‐

tion can only be rectified byheating the

entire fuel sy stem. Park theve hicle in a

heated garage ,fo rex ample.

To prev ent malfunctions, diesel fuel with

impr oved flow ch aracteristics is available in the

winter mon ths. Yo u can obtain fur ther informa‐

tion on this at thega sst ation or from your fuel

supplier.

Yo ur vehicle is equipped with a fuel preheating

sy stem. This additionally impr ovesth eflow char‐

acteristics of the diesel fuel byabout 14.5 °F

(8 °C). ULTR A-LO W SULFUR DIESEL can be used

without risk of malfunction down toan outside

te mp erature of appr oximately 14.5 °F (-10 °C).

* NO

TEDama gedue togasoline or paraf fin Gasoline or paraf

fin in diesel fuel impairs the

lubricity of the fuel. This can result in damage

to the fuel injection sy stem, forex ample. #

Do not add any gasoline or paraf fin to

diesel fuel toimpr oveitsflow character‐

istics. B20 fuels with bio-diesel content

* NO

TEDama gedue toincor rect fuel Continuous use of fuels wi

thbio-diesel con‐

te nt ove r 5% (B20 fuels) can lead tofuel filter Te

ch nical da ta265

Page 300 of 354

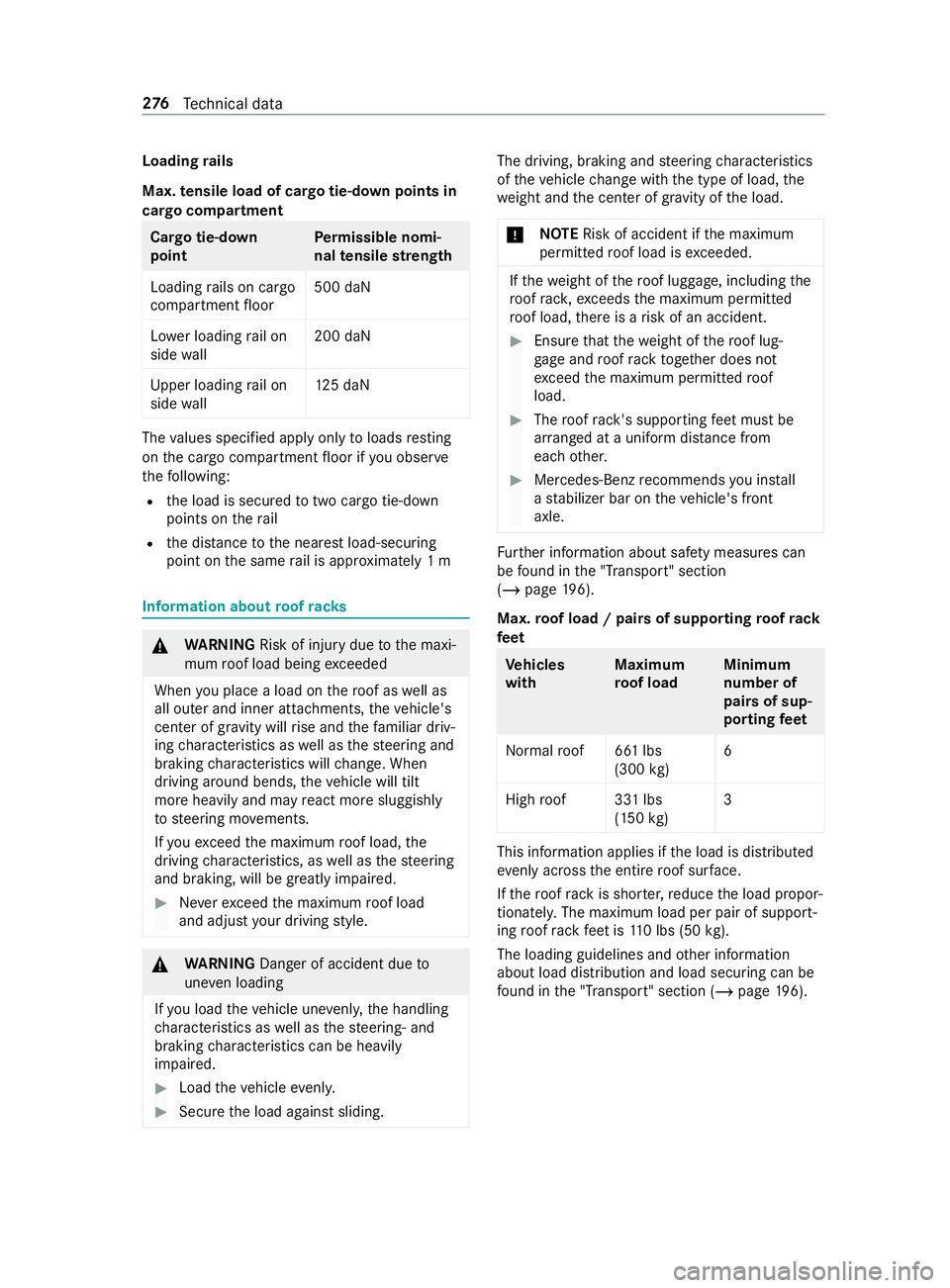

Loading

rails

Max. tensile load of cargo tie-down points in

cargo compartment Cargo tie-down

point

Pe

rm issible nomi‐

nal tensile stre ngth

Loading rails on cargo

compartment floor 500 daN

Lo we r loading rail on

side wall 200 daN

Up per loading rail on

side wall 12

5 daN The

values specified apply only toloads resting

on the cargo compartment floor if you obse rve

th efo llowing:

R the load is secured totwo cargo tie-down

points on thera il

R the dis tance tothe nearest load-securing

point on the same rail is appr oximately 1 m Information about

roof racks &

WARNING Risk of inju rydue tothe maxi‐

mum roof load being exceeded

When you place a load on thero of as well as

all outer and inner attachments, theve hicle's

center of gr avity will rise and thefa miliar driv‐

ing characteristics as well as thesteering and

braking characteristics will change. When

driving around bends, theve hicle will tilt

more heavily and may react more sluggishly

to steering mo vements.

If yo uexc eed the maximum roof load, the

driving characteristics, as well as thesteering

and braking, will be greatly impaired. #

Neverexc eed the maximum roof load

and adjust your driving style. &

WARNING Danger of accident due to

une ven loading

If yo u load theve hicle une venly, the handling

ch aracteristics as well as thesteering‑ and

braking characteristics can be heavily

impaired. #

Load theve hicle evenly. #

Secu rethe load against sliding. The driving, braking and

steering characteristics

of theve hicle change with the type of load, the

we ight and the center of gr avity of the load.

* NO

TERisk of accident if the maximum

permitted roof load is exceeded. If

th ewe ight of thero of luggage, including the

ro of rack ,exc eeds the maximum permitted

ro of load, there is a risk of an accident. #

Ensure that thewe ight of thero of lug‐

ga ge and roof rack toget her does not

exc eed the maximum permitted roof

load. #

The roof rack 's supporting feet must be

ar ranged at a uni form distan ce from

ea ch other. #

Mercedes-Benz recommends you ins tall

a st abilizer bar on theve hicle's front

axle. Fu

rther information about saf ety measures can

be found in the "T ranspo rt" section

(/ page 196).

Max. roof load / pairs of supporting roof rack

fe et Ve

hicles

with Maximum

ro

of load Minimum

number of

pairs of sup‐

porting

feet

Normal roof 661 lbs

(300kg) 6

High roof 331 lbs

(150kg) 3 This information applies if

the load is distributed

eve nly across the entire roof sur face.

If th ero of rack is shor ter,re duce the load propor‐

tionatel y.The maximum load per pair of support‐

ing roof rack feet is110 lbs (50 kg).

The loading guidelines and other information

about load distribution and load securing can be

fo und in the "T ranspo rt" section (/ page196). 276

Tech nical da ta

Page 333 of 354

Changing bulbs

...................................... .83

High beam .......................................... 84

Indicator (front) .................................. 84

Interior lamps (rear compartment) ..... 88

License plate lamp ............................ .86

Light bulb types haloge n headlamps ..84

Low beam ........................................... 84

No tes .................................................83

Ta il lamp bulb types (Cargo Van

and Passenger Van) ............................ 85

Ta il lamp bulb types (chassis) ............ .87

Tu rn signal light (rear) (chassis) ..........87

Changing lamps see Changing bulbs

Changing owner ...................................... 21

Cha racteristics of the tire .................. .245

Charging Battery .............................................. 219

Mobile phone (wireless) ..................... 77

Child saf ety lock (doors) ........................ 39

Child seat front-passenger seat (no tes) .............. 38

front-passenger seat (rear ward-

fa cing/for ward-facing) ....................... 38

LA TC H-type (ISOFIX) (ins talling) ........ .36

LA TC H-type (ISOFIX) (no tes) ............... 36

No tes on the safe transpor tation of

ch ildren .............................................. 34

Re arwa rd-facing child restra int sys‐

te m (Information) .............................. .38

To pTe ther ...........................................37

Child ren

No tes on safe transpor tation .............. 34

Special seat belt retractor .................. 35

Ci ga rette lighter ..................................... 75

Cleaning see Care

Cleaning water drain valve of the air

intake box ............................................ .208

Climate control Activating/deactivating ...................... 95

Ad justing rear-compartment heat‐

ing ...................................................... 96

Air distribution settings ...................... 97

automatically controlling (rear

passenger compartment) .................. .97

Au xilia ryheating ................................. 99

Cargo compartment ventilation ........ 102

Clearing fogged up windo ws............... 97

Control panel for 3-zone auto matic

clima tecontrol ................................... 95 Control panel

for dual-zone auto‐

matic clima tecontrol .......................... 94

Controlling automatically .................... 96

Hot- wate r auxilia ryheater ................1 00

Re frigerant ........................................ 271

Setting the air distribution .................. 97

Switching ai r-re circulation mode

on/off ................................................ 98

Switching synchronization function

on/off (control panel) ......................... 97

Switching the A/C function on/off ....96

Switching there ar wind ow

defros ter on/off ................................. 98

Switching the windshield heater

on/off ................................................ 98

Ve ntilating theve hicle (con veni‐

ence opening) ..................................... 54

Ve ntilation nozzles at front ................. 98

Ve ntilation nozzles in thero of ............ 99

Ve ntilation nozzles, rear passenger

compartment .................................... .99

Cockpit (o verview) .................................. .6

Combination switch see High beam

see High-beam flasher

see Indicator

Compu ter

see On-board computer

Contacts ................................................ 185

Calling up ........................................ .185

Deleting ............................................ 185

Downloading (from mobile phone) .... 185

Information .......................................1 85

Making a call ................................... .185

Na me form at .................................... 185

Con venience closing .............................. 54

Con venience opening ............................. 54

Con versions ............................................ 19

Coolant Filling capacities .............................. .270

Coolant (engine) Che cking le vel .................................. 206

No tes ............................................... 269

Copyright License ............................................... 27

Tr ademar ks......................................... 27

Cornering light ...................................... .80

Crosswind Assist Function/no tes ................................ 13 8

Cruise control ...................................... .141

Ac tivating ......................................... 14 2 Index

309

Page 340 of 354

Instrument Display

see Warning/indicator lamp

Instrument lighting ..............................16 6

Intelligent light sy stem

Ad aptive Highbeam Assist .................. 81

Corne ring light ................................... 80

In te rior lamps (rear compa rtment)

(replacing the light bulbs) ..................... 88

In te rior lighting

Cargo compartment .......................... .83

Re ar compartment ............................ .83

Setting ................................................ 82

Switch-off del aytime .......................... 83

In te rior motion sensor

Fu nction ............................................. 57

Switching on/off ................................ 57

Interior roof car rier sy stem ................ .199

iPhone ®

see Apple CarPlay™ J

Jack ....................................................... 250

Hydraulic .......................................... 230

Re moving thehy draulic jack from

th estow age compartment .............. .230

St orage location of hydraulic jack .... 230

Jump-start connection .........................219

Jump-starting see Jump-s tart connection K

Ke y........................................................... 41

Battery ............................................... 42

Electrical consu mption ...................... .42

Fu nctions ............................................ 41

Ke yring attachment ........................... 42

Mechanical key .................................. .42

Overview ............................................. 41

Problem ..............................................43

Ra dio connection ................................ 41

Un locking setting .............................. .42L

Labeling (tires) see Tire labeling

Lane de tection (au tomatic)

see Active Lane Keeping Assist

Lane Keeping Assist ............................ .155

Fu nction ........................................... 15 5

Sy stem limitations ............................1 55Tr

ailer operation .............................. .155

Lane Keeping Assist

see Active Lane Keeping Assist

see Lane Keeping Assist

Language ............................................... 181

No tes ................................................ 181

Setting .............................................. 181

LA TC H-type (ISOFIX) child seat

securing sy stem

In stalling ............................................ .36

No tes .................................................36

Le vel control

see ENR (elect ronic le vel control)

License pla telamp (changing bulbs) .... 86

Light switch (o verview) ........................ .79

Lighting see Lights

Lights ...................................................... 79

Ad aptive Highbeam Assist .................. 81

Au tomatic driving lights ...................... 79

Combination switch ............................ 80

Cornering light ................................... 80

Driving abroad (symmetrical low

beam) ................................................. 79

Hazard warning lamps ........................ 80

High beam .......................................... 80

High-beam flasher .............................. 80

Indicator ............................................ .80

Light switch ........................................ 79

Low beam ........................................... 79

Pa rking light ...................................... .79

Re ar fog light ...................................... 79

Re sponsibility with lighting sy stems ... 79

Setting theex terior lighting switch-

off delay time ...................................... 81

Setting the instrument lighting ......... 16 6

Switching the sur round lighting

on/off ................................................ .81

Limiting speed ...................................... 107

Load Determ ining the maximum ................2 41

Sample calculation ........................... 24 2

Load distribution .................................. 19 6

Load index (tire) .................................. .245

Load securing Carg o tie-down point ........................ 197

Ins talling and removing tie-down

ey es .................................................. 19 8

No tes ................................................ 19 6

Load-bea ring capacity (tire) ................245 316

Index