set clock MERCEDES-BENZ SPRINTER 2019 MY19 with no MMS Operator’s Manual

[x] Cancel search | Manufacturer: MERCEDES-BENZ, Model Year: 2019, Model line: SPRINTER, Model: MERCEDES-BENZ SPRINTER 2019Pages: 322, PDF Size: 5.91 MB

Page 73 of 322

#

Tounlo ck:pull lo cking pin 2upwards man‐

ually or use thec ent rallockin gbutton to

unlo ckthes liding door (/ page44). #

Press but ton1or pull outside handle 3.

The sliding door opens or closes. #

Press button 1again or pull outside handle

3.

The sliding door stops moving. Un

locking thee lectric sliding door manually If

th er eh as been amalfunction or if theb attery

has been disconnected, youc an use release

cat ch2 todisconnect thes liding door from the

electric mo tor.Then, youc an open or close the

door manually. #

Vehicles with comple tesliding door trim:

re mo vethec over from release cat ch2.

Service ope ratio nisa ccessible. #

Todisconnect the sliding doo rfromt he

electric mo tor:tur nrelease catch 2180°

clockwise.

The "MAN" position is set. #

Tounlo ck:pull lo cking pin 3upwards man‐

ually or use thec ent rallockin gbutton to

unlo ckthes liding door (/ page44). #

Press but ton1. #

Open or close thes liding door wit hthe out‐

side/inside door handle. #

Toconnect thes liding door tothee lectric

mo tor:tur nrelease catch 2180° counter-

clockwise.

The "AUTO" position is set. #

Adjus tthe sliding door (/ page49).

If it is no tpossible to rectifythe malfunction: #

Visit aq ualified specialis tworks hop. Re

setting thee lectric sliding door Slidin

gdoor buttons on thec enter console Sliding door button on

thed oor sill (B-pillar)

Yo um ustrese tthe sliding door if ther eh as been

am alfunction or avoltag esuppl yinter ruption. Opening and closing

49

Page 110 of 322

Ve

hicles wit hpartial LED tail lamps

1 Reversing lights: P21W

2 License plate lamp:W5W

3 Rear fogl ights: P21W

Ta il lamps (Cargo Vana nd Passenger Van)

Re quirements:

R Brak

elights/tail lamps/perime terl ights:

light bulb typ eP21W

R Reversing lights: bulb typeP21W

R Rear fogl ights: bulb type P21W 1

Brak elights/tai llamps/perim eter lights

2 Reversing light

3 Rear fogl ight #

Switc hoffthel ighting sy stem. #

Open ther ear door. #

Toremo ve: loose nscrews 1and pull out

th et ail lamps in thed irection of thea rrow. #

Remo vethec onnector from bulb mount 3. #

Loosen scr ews2and remo vebulb mount

3 from thet ail lamp. #

Gently tur nthe bulb counter-clockwise and

ta ke it out of thes ocket. #

Inse rtthen ew bulb int othe soc keta nd tur nit

clo ckwise. #

Toinstall: setb ulb mount 3onthet ail lamp

and scr ewin scr ews2. #

Press thec onnector int obulb mount 3. #

Inser tthe tail lam pand scr ewin scr ews1.

License plat elamp

Re quirements:

R License plat elamp: light bulb type W5W 86

Light and vision

Page 201 of 322

&

WARNING Risk offire and injur yfrom

engine oil

If engine oil comes int ocontact wi thhotc om‐

ponent parts in thee ngine compartment, it

ma yignite. #

Mak esuret hat no engine oil is spilled

next tothef iller opening. #

Allo wthe engine tocool of fand thor‐

oughly clean thee ngine oil from compo‐

nent parts befor estartin gt he vehicle. *

NO

TEEngine damag eduetoincor rect oil

fi lter ,incor rect oil or additi ve #

Do no tuse engine oi loranoilfilter with

specifications deviatin gfromt hose

re qu ired fort he prescribed service

inter vals.

Mercedes-Benz recommends using original or

te sted replacement and service parts. #

Do no tchang ethe engine oil or oil filter

in order tosetc hang einter vals longer

th an those prescribed. #

Do no tuse an yadditive. #

Followt he instructions on thes ervice

inter vald ispla yfor changing thee ngine

oil. *

NO

TEDama gecaused byaddin gtoo

muc hengine oil To

om uche ngine oil can damag ethe engine

or thec atalytic con verter. #

Have excess engine oil remo vedata

qu alified specialis tworks hop. Engine OM651

Engine OM642

#

Turn cap 1counter-clockwise and remo veit. #

Adde ngin eoil. #

Replace cap 1and tur nitclockwise until it

engages. #

Chec kthe oil le vela ga in .C hec kusing theo n-

boar dcomputer (/ page176),ch eckw ith

th eo il dipstic k(/pag e175). Checking

thec oolant le vel &

WARNING Risk of bu rnsf romh otcom‐

ponent parts in thee ngine compartment

Cer tainc omponents in thee ngine compart‐

ment can be very hot, e.g. thee ngine, the

ra diator and parts of thee xhau stsystem. #

Allo wthe engine tocool down and only

to uc hc omponent parts desc ribed in the

fo llowing. Maintenance and care

17 7

Page 246 of 322

Only position

thej ackont he jac ksuppor tpoints

intended fort his purpose. Youc oul do therwise

damag ethe vehicle.

Impor tant no tesonu singthej ack:

R Onlyusethev ehicle-speci ficj ackt hat has

been tested and appr ovedbyM ercedes-Benz

to raise thev ehicle. If thej ackisu sed incor‐

re ctly ,itc ould tip over while thev ehicle is

ra ised.

R The jac kisdesigned onl ytoraisethev ehicle

fo ras horttime whil eawheelisb eing

ch anged and is no tsuitable forc arrying out

maintenance workunde rthe vehicle.

R Avoid changing awheel on uphill and downhill

slopes.

R The jac kmustbep lacedonaf irm,flat and

non-slip sur face. If necessar y,use alarge,

fl at, load bearing and non-slip unde rlay.

R The base of thej ackisp ositioned vertically

under thej acks uppor tpoint.

Saf etyi nstruction swhile thev ehicle is raised:

R Do no tputyour hands or feet unde rthe vehi‐

cle.

R Do no tlie underneat hthe vehicle.

R Do no tstart thee ngine and do no trelease

th ep arking brake.

R Do no topen or close an ydoors.

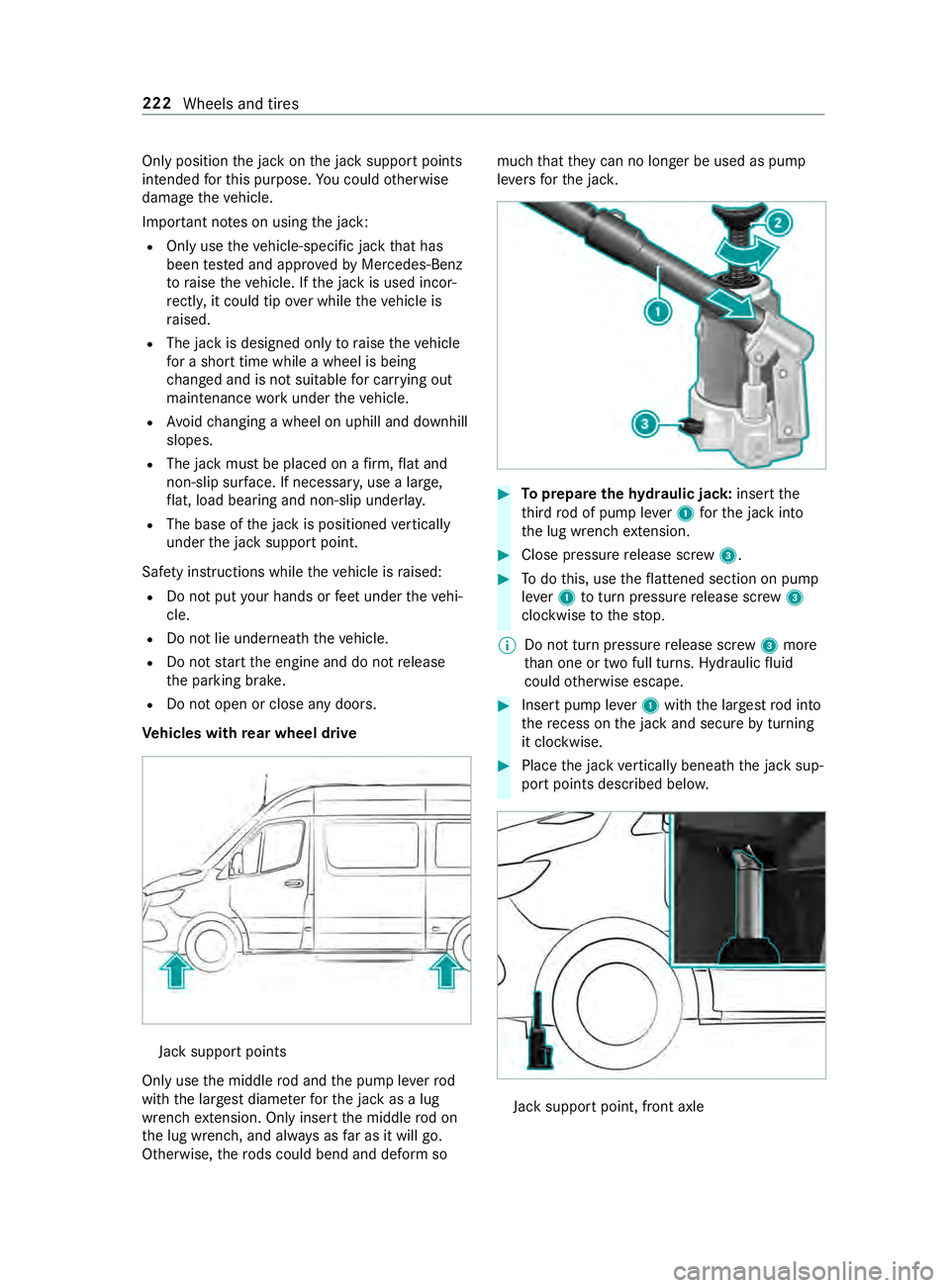

Ve hicles with rear wheel drive Jack

suppor tpoints

Only use them iddle roda nd thep um pleve rrod

wit hthe larges tdiame terf or thej ackasa lug

wrenc hextension. Only inse rtthem iddle rodon

th el ug wrench, and alw aysasf ar as it will go.

Otherwise, ther ods could bend and defor msomuc

hthat they can no longer be use daspump

le ve rs fort he jac k. #

Toprepar ethe hydrauli cjack: insertthe

th irdr od of pum plever 1fort he jac kinto

th el ug wrenc hextension. #

Close pressur erelease scr ew3. #

Todo this, use thef lattened sectio nonpump

le ver 1totur np ressur erelease scr ew3

clockwise tothes top.

% Do no

tturnp ressur erelease scr ew3 more

th an one or tw ofull turns .Hydraulic fluid

coul dotherwise escape. #

Inser tpum plever 1withthe larges trod into

th er eces sont he jac kand secur ebyturning

it clo ckwise. #

Place thej ackv erticall ybeneat hthe jac ksup‐

por tpoints described belo w. Jac

ksuppor tpoint, front axle 222

Wheels and tires

Page 249 of 322

#

Place thej acktoo ne side. #

Pull ther od wit hthe smalles tdiame tero ffthe

pum pleve r.

The shor tened pu mpleve rs erve sasal ug

wrenc hextension. #

Startin gwitht he middle rod, slide thel ug

wrenc hextensio nasfar as it will go ont othe

lug wrench. #

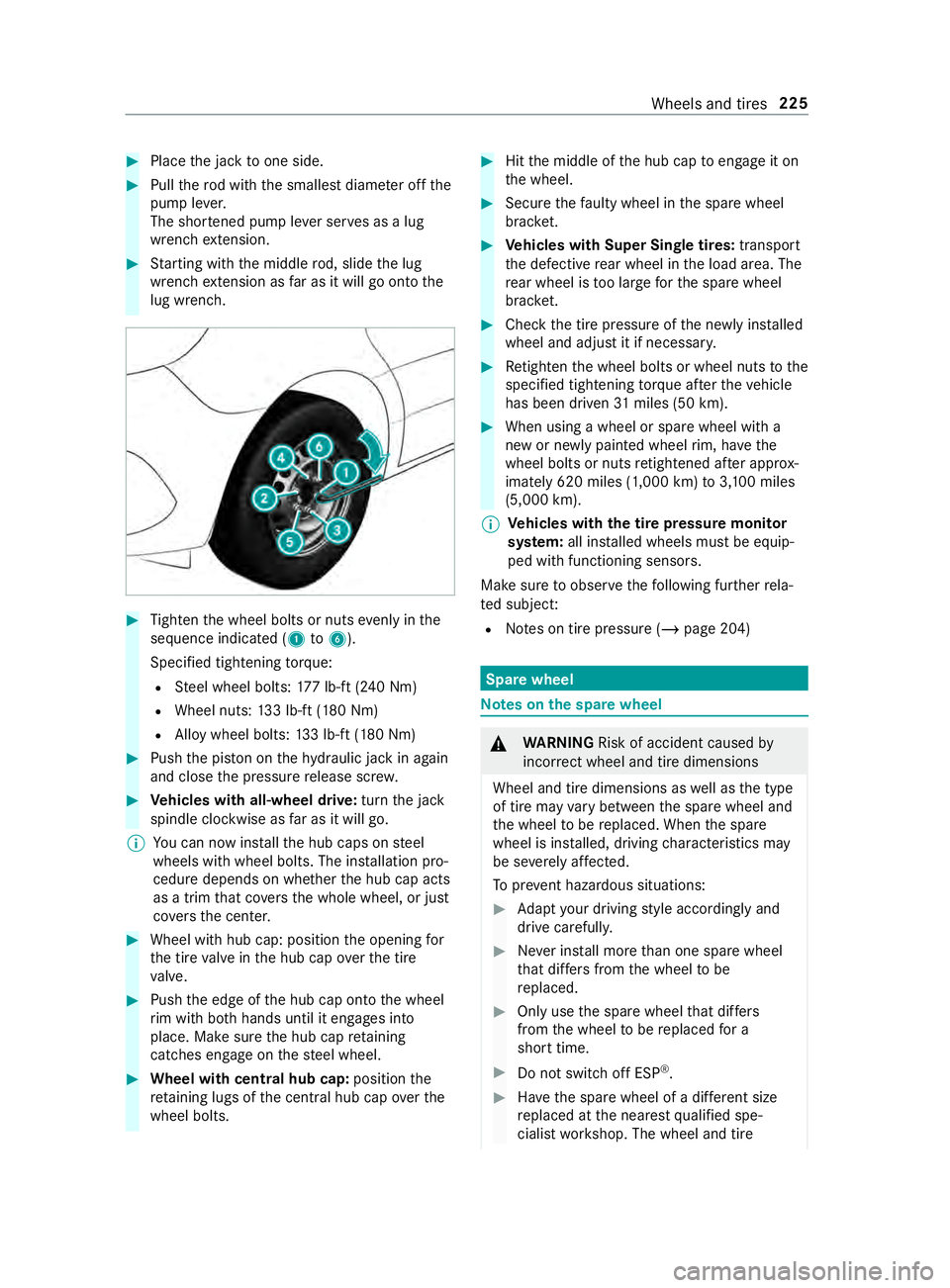

Tighten thew heel bolts or nuts evenlyint he

sequence indicated (1 to6 ).

Specified tightenin gtorque:

R Steel wheel bolts: 177l b-f t(24 0N m)

R Whee lnuts: 133lb-f t(18 0N m)

R Alloywheel bolts: 133lb-f t(18 0N m) #

Push thep isto nont hehydraulic jac kinagain

and close thep ressur erelease scr ew. #

Vehicles with all-wheel drive: turnthe jack

spindle clockwise as farasitw illg o.

% Yo

uc an no winstallth eh ub caps on steel

wheels wit hwheel bolts. The ins tallation pro‐

cedur edepends on whe ther theh ub cap acts

as atrimt hat co vers thew hole wheel, or just

co vers thec enter. #

Wheel wit hhub cap: position theo pening for

th et irev alveint he hub cap overthe tire

va lve. #

Push thee dgeoft he hub cap ont othe wheel

ri mw ithb othh ands until it engages into

place. Mak esuret he hub cap retaining

cat ches engag eonthesteel wheel. #

Wheel with central hub cap: positionthe

re tainin glugs of thec ent ralh ub cap overthe

whee lbolts. #

Hitthem iddle of theh ub cap toengag eiton

th ew heel. #

Secur ethe faulty wheel in thes par ew heel

brac ket. #

Vehicles with Super Single tires: transport

th ed efectiv erear wheel in thel oad area. The

re ar wheel is tool arge fort he spar ewheel

brac ket. #

Chec kthe tir epressur eoft he newl yins talled

wheel and adjus titifnecessar y. #

Retighten thew heel bolts or wheel nuts tothe

specified tightening torque af tert he vehicle

has been driven 31miles (50 km). #

When using awhee lors parew hee lwitha

ne worn ewly painted whee lrim, ha vethe

wheel bolt sornutsr etightene dafter appr ox‐

ima tely 620 mile s(1,000 km) to3,10 0m iles

(5,000 km).

% Ve

hicles with thet irep ressur emonitor

sy stem: all ins talled wheels mus tbeequip‐

ped wit hfunctioning sensors.

Mak esuretoo bservethef ollowing fur ther rela‐

te ds ubject:

R Notesont irep ressur e(/pag e204) Spar

ewheel Note

sont he spar ewheel &

WARNING Risk of accident caused by

incor rect wheel and tir edimensions

Wheel and tir edimensions as well as thet ype

of tir emayvary between thes par ew heel and

th ew heel tobe replaced. When thes pare

wheel is ins talled, driving characteristic smay

be se verely af fected.

To prev ent hazardous situations: #

Adapty our driving stylea ccording lyand

driv ecarefull y. #

Neverins tall mor ethan one spar ewheel

th at dif fers from thew heel tobe

re placed. #

Onlyusethes par ew heel that dif fers

from thew heel tobe replaced fora

shor ttime. #

Do no tswitc hoffESP ®

. #

Have thes par ew heel of adiffe re nt size

re placed at then eares tqualified spe‐

cialis tworks hop. The wheel and tire Wheels and tires

225