battery Mercury Mercury Cougar 2002 Owner's Manual

[x] Cancel search | Manufacturer: MERCURY, Model Year: 2002, Model line: Mercury Cougar, Model: Mercury Mercury Cougar 2002Pages: 216, PDF Size: 4.04 MB

Page 3 of 216

Customer Assistance 152

Reporting safety defects (U.S. only) 160

Cleaning 161

Maintenance and Specifications 167

Engine compartment 170

Engine oil 172

Battery 175

Fuel information 182

Part numbers 198

Refill capacities 199

Lubricant specifications 200

Accessories 204

Index 207

All rights reserved. Reproduction by any means, electronic or mechanical

including photocopying, recording or by any information storage and retrieval

system or translation in whole or part is not permitted without written

authorization from Ford Motor Company. Ford may change the contents without

notice and without incurring obligation.

Copyright 2002 Ford Motor Company

Table of Contents

3

Page 9 of 216

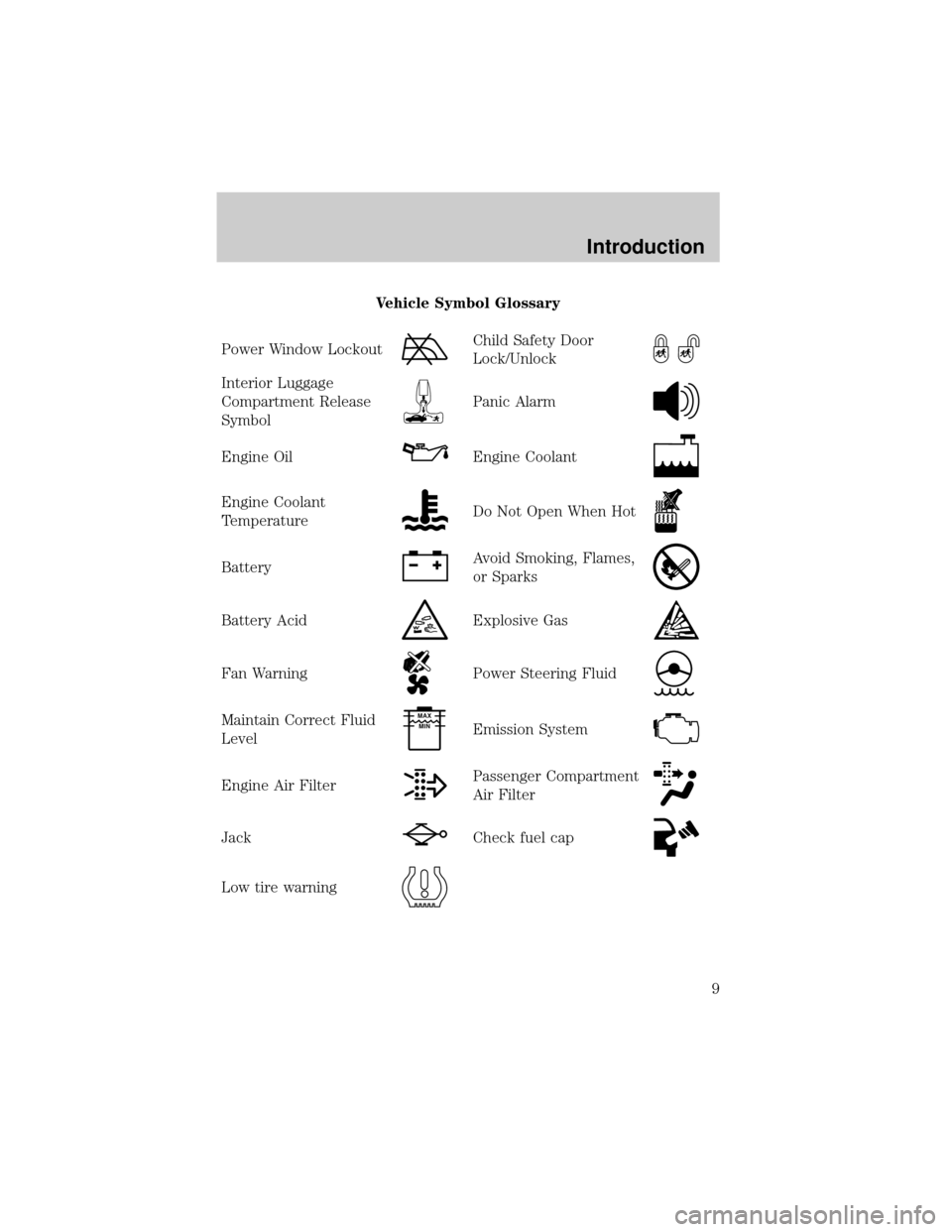

Vehicle Symbol Glossary

Power Window Lockout

Child Safety Door

Lock/Unlock

Interior Luggage

Compartment Release

Symbol

Panic Alarm

Engine OilEngine Coolant

Engine Coolant

TemperatureDo Not Open When Hot

BatteryAvoid Smoking, Flames,

or Sparks

Battery AcidExplosive Gas

Fan WarningPower Steering Fluid

Maintain Correct Fluid

LevelMAX

MIN

Emission System

Engine Air FilterPassenger Compartment

Air Filter

JackCheck fuel cap

Low tire warning

Introduction

9

Page 12 of 216

Safety belt

Illuminates to remind you to fasten

your safety belts. For more

information, refer to theSeating

and safety restraintschapter.

Air bag readiness

Illuminates to confirm that the air

bags (front and side) are

operational. If the light fails to

illuminate, continues to flash or

remains on, have the system

serviced immediately.

Charging system

Illuminates when the battery is not

charging properly.

Engine oil pressure

Illuminates when the oil pressure

falls below the normal range. Check

the oil level and add oil if needed.

Refer toEngine oilin the

Maintenance and specificationschapter.

Check coolant (if equipped)

Illuminates when the coolant level in

the coolant reservoir is low and

more needs to be added. For more

information on adding engine

coolant, refer toEngine coolantin

theMaintenance and specificationschapter.

Check transaxle

Illuminates when a transaxle

problem has been detected and

shifting may be restricted. If this

lamp remains on, have your vehicle

serviced immediately.

Instrument Cluster

12

Page 139 of 216

Fuse/Relay

LocationFuse Amp

RatingPassenger Compartment Fuse

Panel Description

30 7.5A Engine management, Locking

system, Instrument cluster

31 7.5A Panel dimmer, License plate

lamps, Glove box lamp, Belt

minder module

32 Ð Not used

33 7.5A Left-side lamps

34 7.5A Power mirrors, Clock, Interior

lamps

35 7.5A Right-side lamps

36 15A Radio

37 30A Heater blower

38 7.5A Air bags

R12 Ð Courtesy lamps

R13 Ð Rear window defrost

R14 Ð Blower motor

R15 Ð Front wiper

R16 Ð Ignition

D2 Ð Reverse voltage protection

*Have these fuses replaced by your dealer or qualified technician.

Power distribution box

The power distribution box is located in the engine compartment. The

power distribution box contains high-current fuses that protect your

vehicle's main electrical systems from overloads.

Always disconnect the battery before servicing high current

fuses.

Always replace the cover to the power distribution box before

reconnecting the battery or refilling fluid reservoirs

If the battery has been disconnected and reconnected, refer to the

Batterysection of theMaintenance and specificationschapter.

Roadside Emergencies

139

Page 145 of 216

4. Insert the tapered end of the jack

handle beneath the hub cover (if

equipped) and push in. Twist off to

remove the cover. Loosen each

wheel lug nut one-half turn

counterclockwise but do not remove

them until the wheel is raised off

the ground.

5. Place the jack under vehicle in

location indicated by arrows (closest

to the tire requiring changing), then

jack up the vehicle until the tire is

clear of the ground.

6. Remove the lug nuts with the lug wrench.

7. Replace the flat tire with the spare tire, making sure the valve stem is

facing outward. Reinstall the lug nuts until the wheel is snug against the

hub. Do not fully tighten the lug nuts until the wheel has been lowered.

8. Lower the wheel by turning the jack handle counterclockwise.

9. Remove the jack and fully tighten the lug nuts in the order shown.

10. Put flat tire, jack and lug wrench away. Make sure the jack is

fastened so it does not rattle when you drive. Unblock the wheels.

JUMP STARTING YOUR VEHICLE

The gases around the battery can explode if exposed to flames,

sparks, or lit cigarettes. An explosion could result in injury or

vehicle damage.

Batteries contain sulfuric acid which can burn skin, eyes and

clothing, if contacted.

Do not attempt to push-start your vehicle. Automatic

transmissions do not have push-start capability; also, the

catalytic converter may become damaged.

Roadside Emergencies

145

Page 146 of 216

Preparing your vehicle

When the battery is disconnected or a new battery is installed, the

transmission must relearn its shift strategy. As a result, the transmission

may have firm and/or soft shifts. This operation is considered normal and

will not affect function or durability of the transmission. Over time, the

adaptive learning process will fully update transmission operation.

1.Use only a 12±volt supply to start your vehicle.

2. Do not disconnect the battery of the disabled vehicle as this could

damage the vehicle's electrical system.

3. Park the booster vehicle close to the hood of the disabled vehicle

making sure the two vehiclesdo nottouch. Set the parking brake on

both vehicles and stay clear of the engine cooling fan and other moving

parts.

4. Check all battery terminals and remove any excessive corrosion before

you attach the battery cables. Ensure that vent caps are tight and level.

5. Turn the heater fan on in both vehicles to protect any electrical

surges. Turn all other accessories off.

Connecting the jumper cables

1. Connect the positive (+) booster cable to the positive (+) terminal of

the discharged battery.

Note:In the illustrations,lightning boltsare used to designate the

assisting (boosting) battery.

+–+–

Roadside Emergencies

146

Page 147 of 216

2. Connect the other end of the positive (+) cable to the positive (+)

terminal of the assisting battery.

3. Connect the negative (-) cable to the negative (-) terminal of the

assisting battery.

+–+–

+–+–

Roadside Emergencies

147

Page 148 of 216

4. Make the final connection of the negative (-) cable to an exposed

metal part of the stalled vehicle's engine, away from the battery and the

carburetor/fuel injection system.Do notuse fuel lines, engine rocker

covers or the intake manifold asgroundingpoints.

Do not connect the end of the second cable to the negative (-)

terminal of the battery to be jumped. A spark may cause an

explosion of the gases that surround the battery.

5. Ensure that the cables are clear of fan blades, belts, moving parts of

both engines, or any fuel delivery system parts.

Jump starting

1. Start the engine of the booster vehicle and run the engine at

moderately increased speed.

2. Start the engine of the disabled vehicle.

3. Once the disabled vehicle has been started, run both engines for an

additional three minutes before disconnecting the jumper cables.

+–+–

Roadside Emergencies

148

Page 149 of 216

Removing the jumper cables

Remove the jumper cables in the reverse order that they were

connected.

1. Remove the jumper cable from thegroundmetal surface.

Note:In the illustrations,lightning boltsare used to designate the

assisting (boosting) battery.

2. Remove the jumper cable on the negative (-) connection of the

booster vehicle's battery.

+–+–

+–+–

Roadside Emergencies

149

Page 150 of 216

3. Remove the jumper cable from the positive (+) terminal of the booster

vehicle's battery.

4. Remove the jumper cable from the positive (+) terminal of the

disabled vehicle's battery.

After the disabled vehicle has been started and the jumper cables

removed, allow it to idle for several minutes so the engine computer can

relearnits idle conditions.

+–+–

+–+–

Roadside Emergencies

150