battery Mercury Sable 2002 s User Guide

[x] Cancel search | Manufacturer: MERCURY, Model Year: 2002, Model line: Sable, Model: Mercury Sable 2002Pages: 240, PDF Size: 3.53 MB

Page 167 of 240

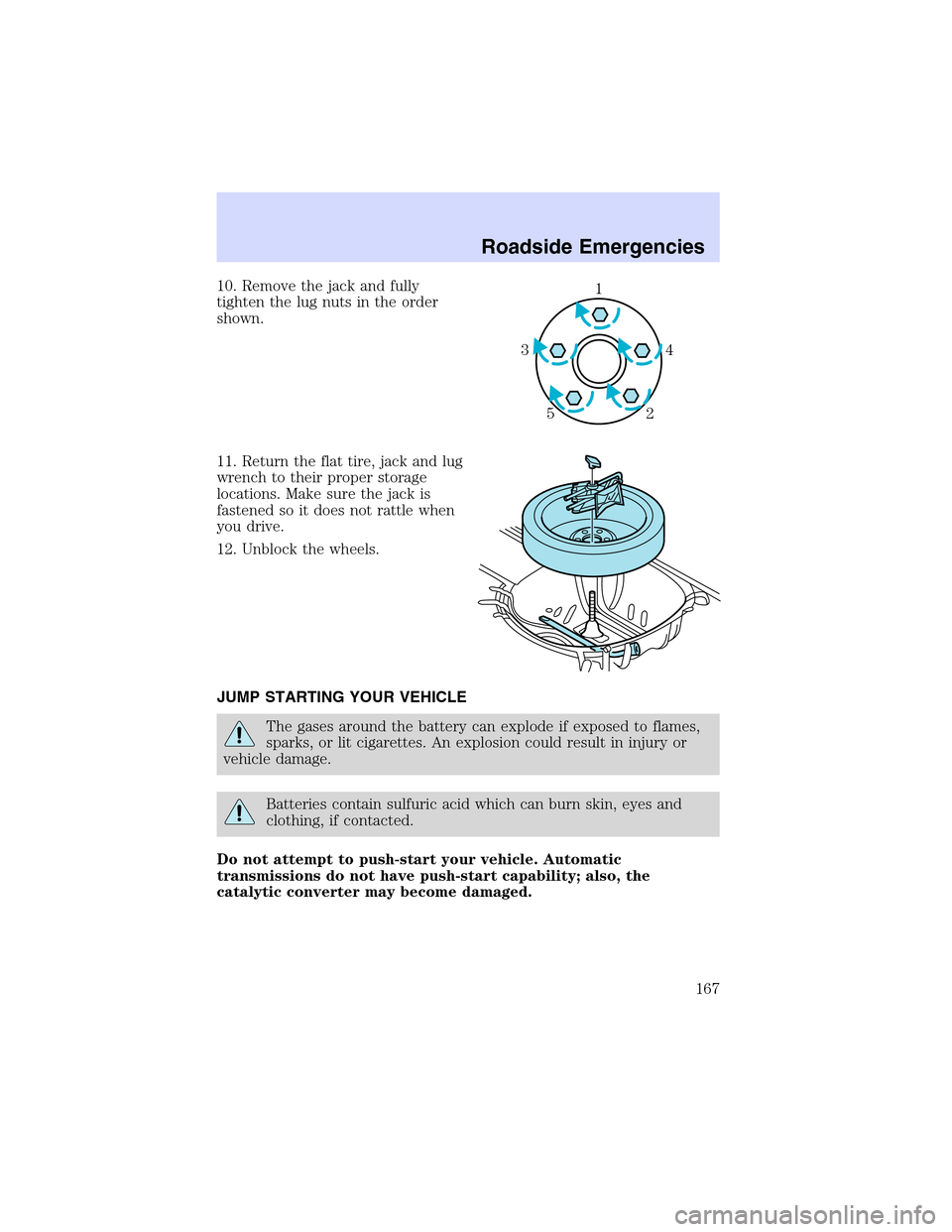

10. Remove the jack and fully

tighten the lug nuts in the order

shown.

11. Return the flat tire, jack and lug

wrench to their proper storage

locations. Make sure the jack is

fastened so it does not rattle when

you drive.

12. Unblock the wheels.

JUMP STARTING YOUR VEHICLE

The gases around the battery can explode if exposed to flames,

sparks, or lit cigarettes. An explosion could result in injury or

vehicle damage.

Batteries contain sulfuric acid which can burn skin, eyes and

clothing, if contacted.

Do not attempt to push-start your vehicle. Automatic

transmissions do not have push-start capability; also, the

catalytic converter may become damaged.

1

4 3

2 5

Roadside Emergencies

167

Page 168 of 240

Preparing your vehicle

When the battery is disconnected or a new battery is installed, the

transmission must relearn its shift strategy. As a result, the transmission

may have firm and/or soft shifts. This operation is considered normal and

will not affect function or durability of the transmission. Over time, the

adaptive learning process will fully update transmission operation.

1.Use only a 12–volt supply to start your vehicle.

2. Do not disconnect the battery of the disabled vehicle as this could

damage the vehicle’s electrical system.

3. Park the booster vehicle close to the hood of the disabled vehicle

making sure the two vehiclesdo nottouch. Set the parking brake on

both vehicles and stay clear of the engine cooling fan and other moving

parts.

4. Check all battery terminals and remove any excessive corrosion before

you attach the battery cables. Ensure that vent caps are tight and level.

5. Turn the heater fan on in both vehicles to protect any electrical

surges. Turn all other accessories off.

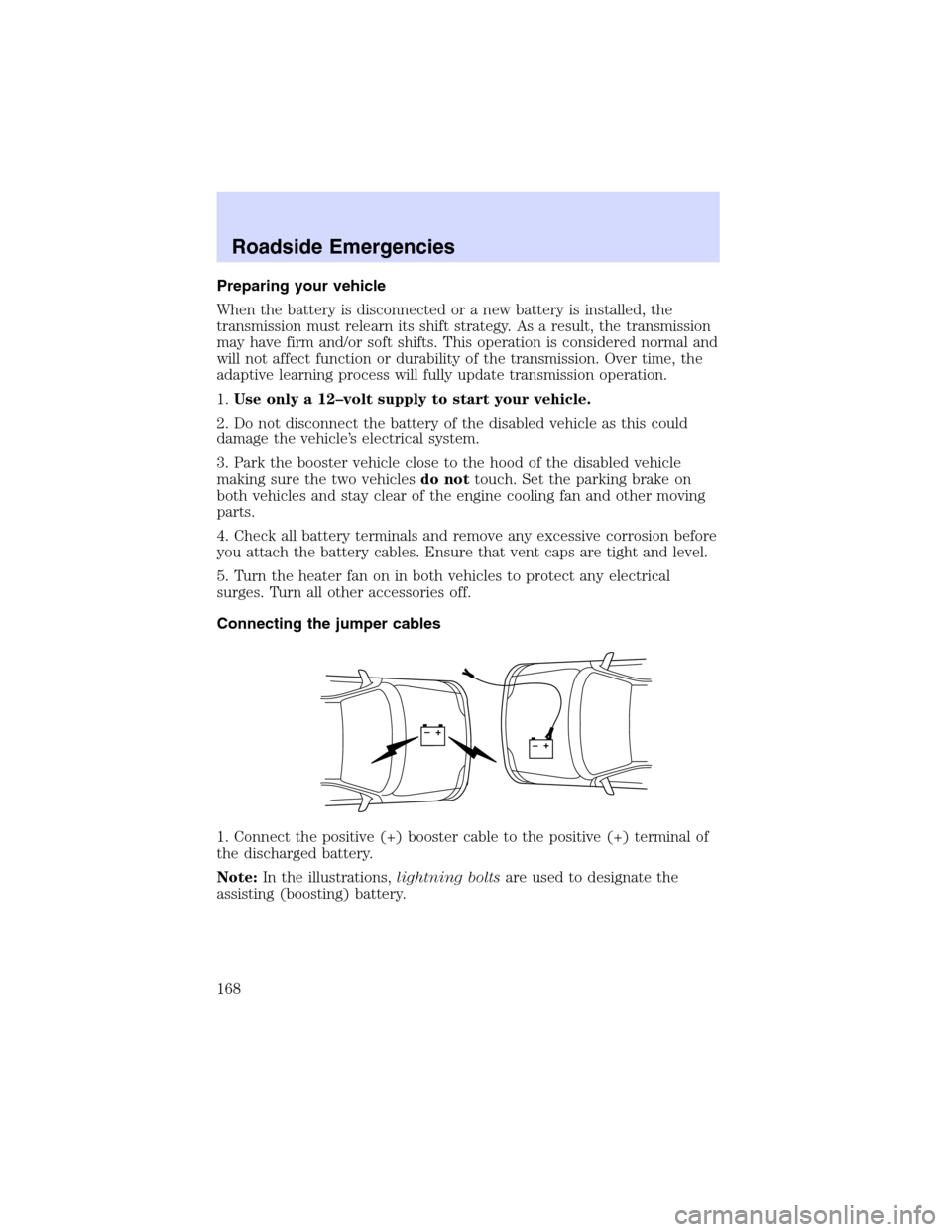

Connecting the jumper cables

1. Connect the positive (+) booster cable to the positive (+) terminal of

the discharged battery.

Note:In the illustrations,lightning boltsare used to designate the

assisting (boosting) battery.

+–+–

Roadside Emergencies

168

Page 169 of 240

2. Connect the other end of the positive (+) cable to the positive (+)

terminal of the assisting battery.

3. Connect the negative (-) cable to the negative (-) terminal of the

assisting battery.

+–+–

+–+–

Roadside Emergencies

169

Page 170 of 240

4. Make the final connection of the negative (-) cable. Make the

connection to an exposed metal part of the stalled vehicle’s engine, away

from the battery and the carburetor/fuel injection system.Do notuse

fuel lines, engine rocker covers or the intake manifold asgrounding

points.

Do not connect the end of the second cable to the negative (-)

terminal of the battery to be jumped. A spark may cause an

explosion of the gases that surround the battery.

5. Ensure that the cables are clear of fan blades, belts, moving parts of

both engines, or any fuel delivery system parts.

Jump starting

1. Start the engine of the booster vehicle and run the engine at

moderately increased speed.

2. Start the engine of the disabled vehicle.

3. Once the disabled vehicle has been started, run both engines for an

additional three minutes before disconnecting the jumper cables.

+–+–

Roadside Emergencies

170

Page 171 of 240

Removing the jumper cables

Remove the jumper cables in the reverse order that they were

connected.

1. Remove the jumper cable from thegroundmetal surface.

2. Remove the jumper cable on the negative (-) connection of the

booster vehicle’s battery.

+–+–

+–+–

Roadside Emergencies

171

Page 172 of 240

3. Remove the jumper cable from the positive (+) terminal of the booster

vehicle’s battery.

4. Remove the jumper cable from the positive (+) terminal of the

disabled vehicle’s battery.

After the disabled vehicle has been started and the jumper cables

removed, allow it to idle for several minutes so the engine computer can

relearnits idle conditions.

+–+–

+–+–

Roadside Emergencies

172

Page 190 of 240

SERVICE RECOMMENDATIONS

To help you service your vehicle:

•We highlight do-it-yourself items in the engine compartment for easy

location.

•We provide a scheduled maintenance guide which makes tracking

routine service easy.

If your vehicle requires professional service, your dealership can provide

the necessary parts and service. Check yourWarranty Guide/Owner

Information Guideto find out which parts and services are covered.

Use only recommended fuels, lubricants, fluids and service parts

conforming to specifications. Motorcraft parts are designed and built to

provide the best performance in your vehicle.

PRECAUTIONS WHEN SERVICING YOUR VEHICLE

Be especially careful when inspecting or servicing your vehicle.

•Do not work on a hot engine.

•When the engine is running, keep loose clothing, jewelry or long hair

away from moving parts.

•Do not work on a vehicle with the engine running in an enclosed

space, unless you are sure you have enough ventilation.

•Keep all lit cigarettes, open flames and other lit material away from

the battery and all fuel related parts.

If you disconnect the battery, the engine must“relearn”its idle

conditions before your vehicle will drive properly, as explained in the

Batterysection in this chapter.

Working with the engine off

1. Set the parking brake, and ensure the gearshift is securely latched in

(P) park.

2. Turn off the engine and remove the key.

3. Block the wheels to prevent the vehicle from moving unexpectedly.

Working with the engine on

1. Set the parking brake and ensure the gearshift is securely latched in P

(Park).

2. Block the wheels to prevent the vehicle from moving unexpectedly.

Note:Do not start your engine with the air cleaner removed and do not

remove it while the engine is running.

Maintenance and Specifications

190

Page 192 of 240

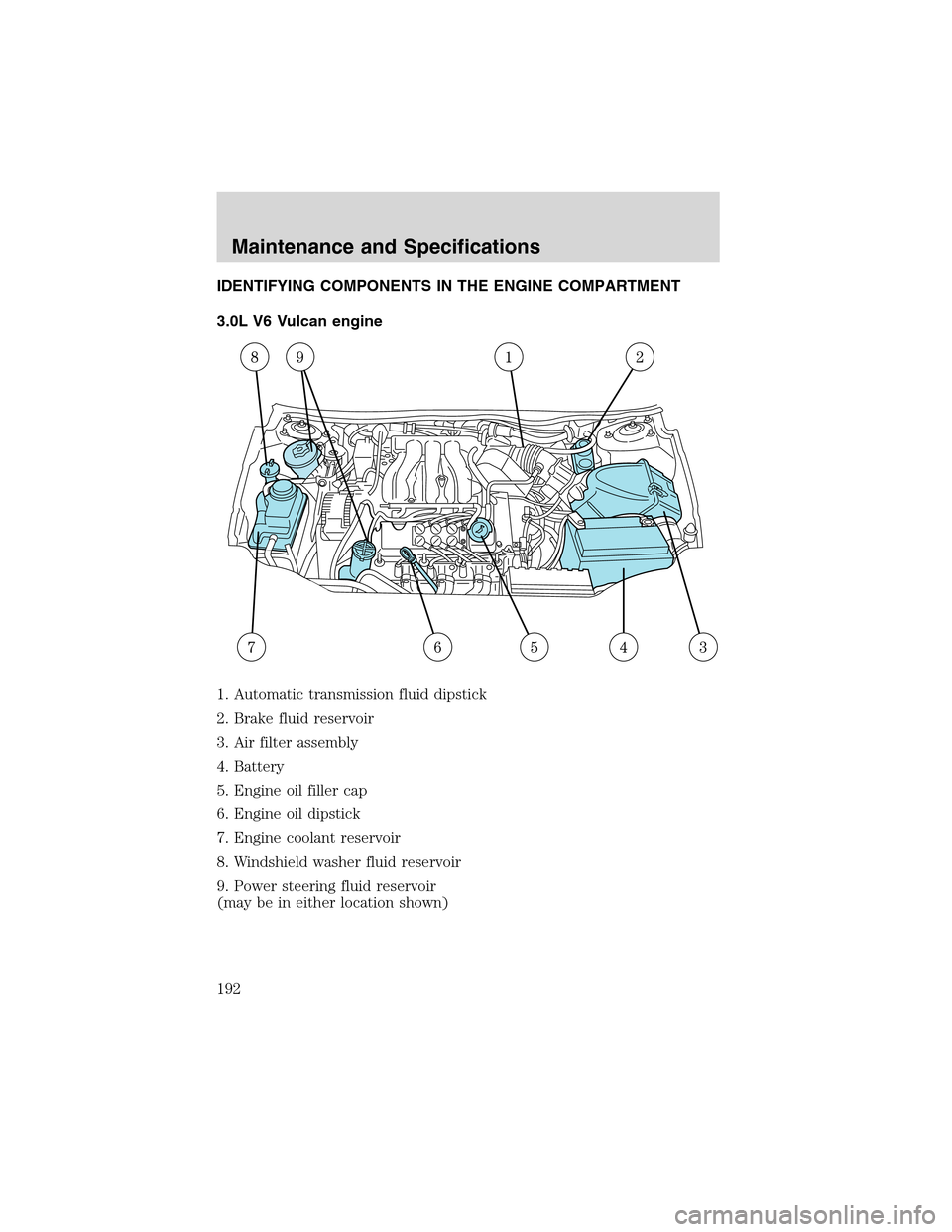

IDENTIFYING COMPONENTS IN THE ENGINE COMPARTMENT

3.0L V6 Vulcan engine

1. Automatic transmission fluid dipstick

2. Brake fluid reservoir

3. Air filter assembly

4. Battery

5. Engine oil filler cap

6. Engine oil dipstick

7. Engine coolant reservoir

8. Windshield washer fluid reservoir

9. Power steering fluid reservoir

(may be in either location shown)

Maintenance and Specifications

192

Page 193 of 240

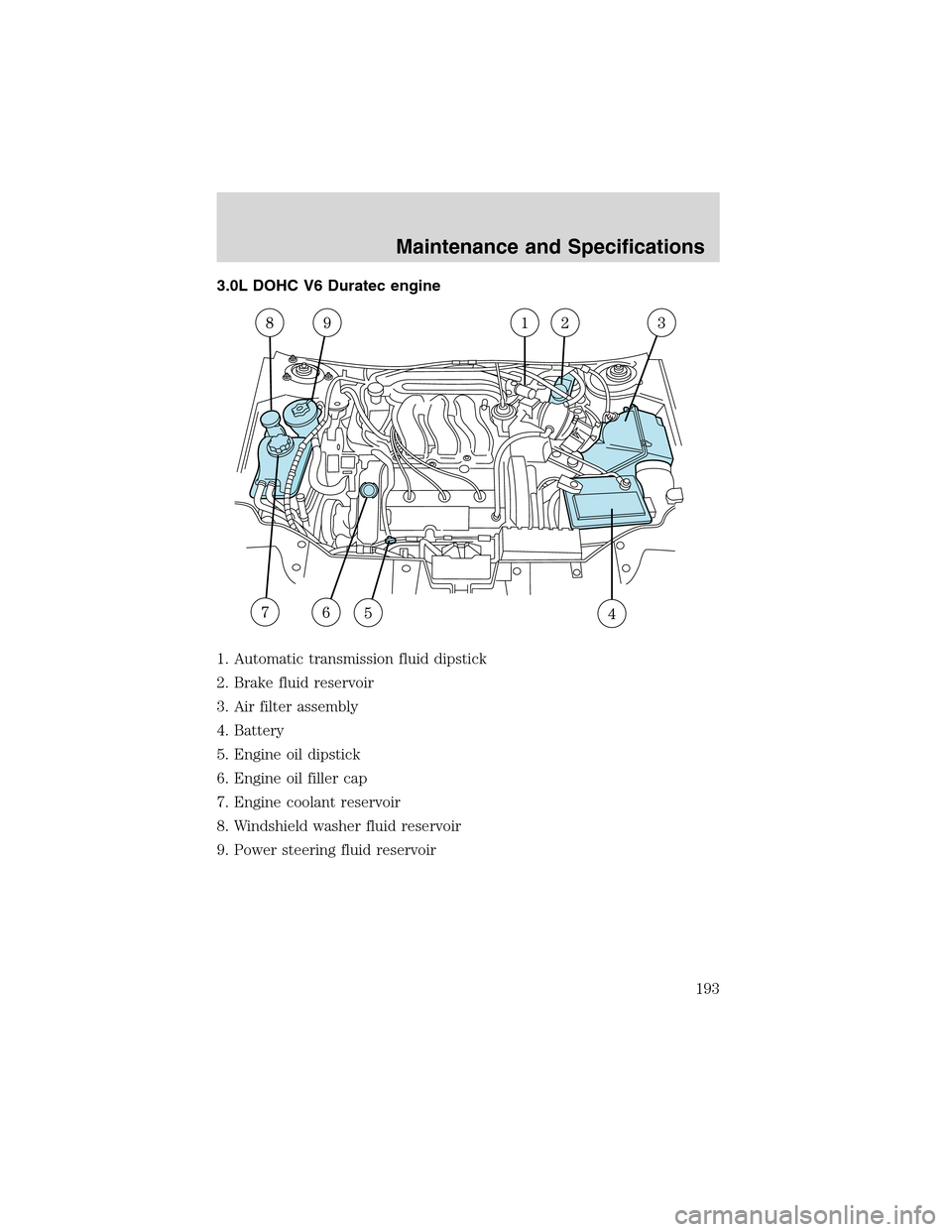

3.0L DOHC V6 Duratec engine

1. Automatic transmission fluid dipstick

2. Brake fluid reservoir

3. Air filter assembly

4. Battery

5. Engine oil dipstick

6. Engine oil filler cap

7. Engine coolant reservoir

8. Windshield washer fluid reservoir

9. Power steering fluid reservoir

Maintenance and Specifications

193

Page 198 of 240

that does not meet Ford material and design specifications, start-up

engine noises or knock may be experienced.

It is recommended you use the appropriate Motorcraft oil filter (or

another brand meeting Ford specifications) for your engine application.

BATTERY

Your vehicle is equipped with a

Motorcraft maintenance-free battery

which normally does not require

additional water during its life of

service.

However, for severe usage or in high temperature climates, check the

battery electrolyte level. Refer to the scheduled maintenance guide for

the service interval schedules.

Keep the electrolyte level in each cell up to the“level indicator”.

Do not overfill the battery cells.

If the electrolyte level in the battery is low, you can add plain tap water

to the battery, as long as you do not use hard water (water with a high

mineral or alkali content). If possible, however, try to only fill the battery

cells with distilled water. If the battery needs water often, have the

charging system checked.

If your battery has a cover/shield, make sure it is reinstalled

after the battery has been cleaned or replaced.

For longer, trouble-free operation, keep the top of the battery clean and

dry. Also, make certain the battery cables are always tightly fastened to

the battery terminals.

If you see any corrosion on the battery or terminals, remove the cables

from the terminals and clean with a wire brush. You can neutralize the

acid with a solution of baking soda and water.

Batteries normally produce explosive gases which can cause

personal injury. Therefore, do not allow flames, sparks or lighted

substances to come near the battery. When working near the battery,

always shield your face and protect your eyes. Always provide proper

ventilation.

Maintenance and Specifications

198