oil Mercury Sable 2002 s User Guide

[x] Cancel search | Manufacturer: MERCURY, Model Year: 2002, Model line: Sable, Model: Mercury Sable 2002Pages: 240, PDF Size: 3.53 MB

Page 187 of 240

WINDOWS AND WIPER BLADES

The windshield, rear window and wiper blades should be cleaned

regularly. If the wiper does not wipe properly, substances on the

windshield, rear window or the wiper blades may be the cause. These

may include hot wax treatments used by commercial car washes, tree

sap, or other organic contamination. To clean these items, please follow

these tips:

•The windshield or rear window may be cleaned with a non-abrasive

cleaner such as Motorcraft Ultra Clear Spray Glass Cleaner (ZC-23),

available from your dealer.

•Do not use abrasives, as they may cause scratches.

•Do not use fuel, kerosene, or paint thinner to clean any parts.

•Wiper blades can be cleaned with isopropyl (rubbing) alcohol or

windshield washer solution. Be sure to replace wiper blades when they

appear worn or do not function properly.

INSTRUMENT PANEL AND CLUSTER LENS

Clean the instrument panel with a damp cloth, then dry with a dry cloth.

•Avoid cleaners or polish that increase the gloss of the upper portion of

the instrument panel. The dull finish in this area helps protect the

driver from undesirable windshield reflection.

Do not use chemical solvents or strong detergents when cleaning

the steering wheel or instrument panel to avoid contamination of

the air bag system.

•Be certain to wash or wipe your hands clean if you have been in

contact with certain products such as insect repellent and suntan

lotion in order to avoid possible damage to the painted surfaces.

CLEANING SEATS EQUIPPED WITH SIDE AIR BAGS

Remove dust and loose dirt with a vacuum cleaner. In order to remove

stains and soil, clean with Extra Strength Upholstery Cleaner

(E8AZ-19523–AA).

Never saturate the seat covers with any cleaning solution.

Do not use chemical solvents or strong detergents when cleaning

the seat where the side air bag is mounted. Such products could

contaminate the side air bag system and affect performance of the side

air bag in a collision. The air bag may not function correctly and not

provide injury reduction benefits.

Cleaning

187

Page 188 of 240

INTERIOR

For fabric, carpets, cloth seats, safety belts and seats equipped with side

air bags:

•Remove dust and loose dirt with a vacuum cleaner.

•Remove light stains and soil with Ford Extra Strength Upholstery

Cleaner (E8AZ-19523–AA).

•If grease or tar is present on the material, spot-clean the area first

with Motorcraft Spot and Stain Remover (ZC-14).

•Never saturate the seat covers with cleaning solution.

•Do not use household cleaning products or glass cleaners, which can

stain and discolor the fabric and affect the flame retardant abilities of

the seat materials.

Do not use cleaning solvents, bleach or dye on the vehicle’s

safety belts, as these actions may weaken the belt webbing.

LEATHER SEATS (IF EQUIPPED)

Your leather seating surfaces have a clear, protective coating over the

leather.

•To clean, use a soft cloth with Motorcraft Deluxe Leather and Vinyl

Cleaner (ZC-11–A). Dry the area with a soft cloth.

•To help maintain its resiliency and color, use the Motorcraft Deluxe

Leather Care Kit (ZC-11–D), available from your authorized dealer.

•Do not use household cleaning products, alcohol solutions, solvents or

cleaners intended for rubber, vinyl and plastics, or oil/petroleum-based

leather conditioners. These products may cause premature wearing of

the clear, protective coating.

UNDERBODY

Flush the complete underside of your vehicle frequently. Keep body and

door drain holes free from packed dirt.

INTERIOR TRIM

•Clean the interior trim areas with a damp cloth, then dry by wiping

with a dry, soft, clean cloth.

•Do not use household or glass cleaners as these may damage the

finish.

Cleaning

188

Page 189 of 240

FORD, LINCOLN AND MERCURY CAR CARE PRODUCTS

Your Ford, Lincoln or Mercury dealer has many quality products available

to clean your vehicle and protect its finishes. These quality products

have been specifically engineered to fulfill your automotive needs; they

are custom designed to complement the style and appearance of your

vehicle. Each product is made from high quality materials that meet or

exceed rigid specifications. For best results, use the following products

or products of equivalent quality:

Motorcraft Custom Clearcoat Polish (ZC–8–A)

Ford Custom Vinyl Protectant* (not available in Canada)

(F2AZ—19530–A)

Motorcraft Vinyl Cleaner (Canada only) (CXC-93)

Motorcraft Vinyl Conditioner (Canada only) (CXC-94)

Motorcraft Deluxe Leather and Vinyl Cleaner (not available in Canada)

(ZC-11–A)

Ford Extra Strength Tar and Road Oil Remover* (not available in

Canada) (B7A-19520–AA)

Ford Extra Strength Upholstery Cleaner (not available in Canada)

(E8AZ-19523–AA)

Motorcraft Custom Bright Metal Cleaner (ZC-15)

Motorcraft Wheel and Tire Cleaner (ZC-37–A)

Motorcraft Dash and Vinyl Cleaner (ZC-38–A)

Motorcraft Car Care Kit (ZC-26)

Ford Premium Car Wash Concentrate (F2SZ-19523–WC)

Motorcraft Carlite Glass Cleaner (Canada only) (CXC-100)

Motorcraft Spot and Stain Remover (ZC-14)

Motorcraft Detail Wash (ZC-3–A)

Motorcraft Tire Detailer (ZC-28)

Motorcraft Triple Clean (ZC-13)

Motorcraft Ultra-Clear Spray Glass Cleaner (not available in Canada)

(ZC-23)

Motorcraft Engine Shampoo and Degreaser (ZC-20)

* May be sold with the Motorcraft name

Cleaning

189

Page 192 of 240

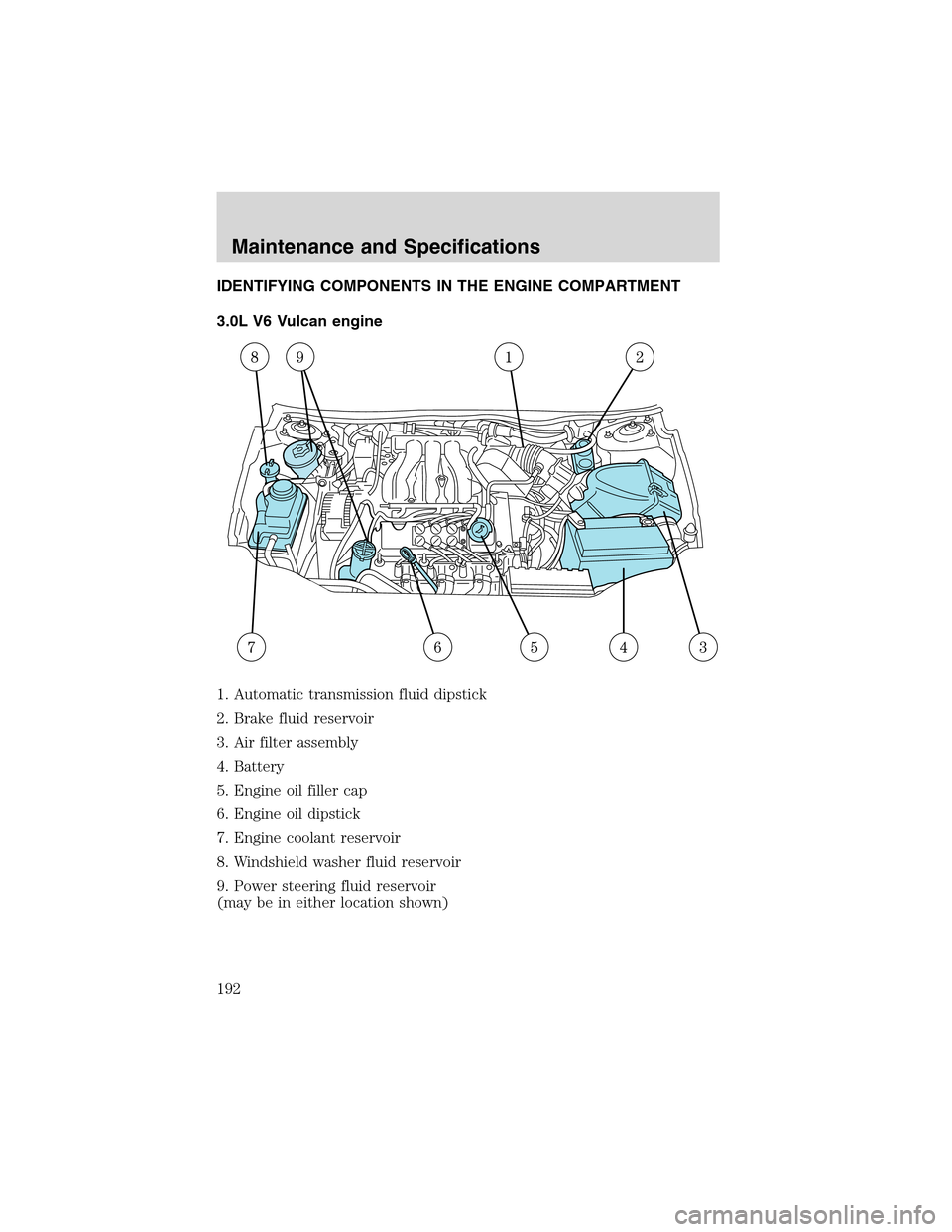

IDENTIFYING COMPONENTS IN THE ENGINE COMPARTMENT

3.0L V6 Vulcan engine

1. Automatic transmission fluid dipstick

2. Brake fluid reservoir

3. Air filter assembly

4. Battery

5. Engine oil filler cap

6. Engine oil dipstick

7. Engine coolant reservoir

8. Windshield washer fluid reservoir

9. Power steering fluid reservoir

(may be in either location shown)

Maintenance and Specifications

192

Page 193 of 240

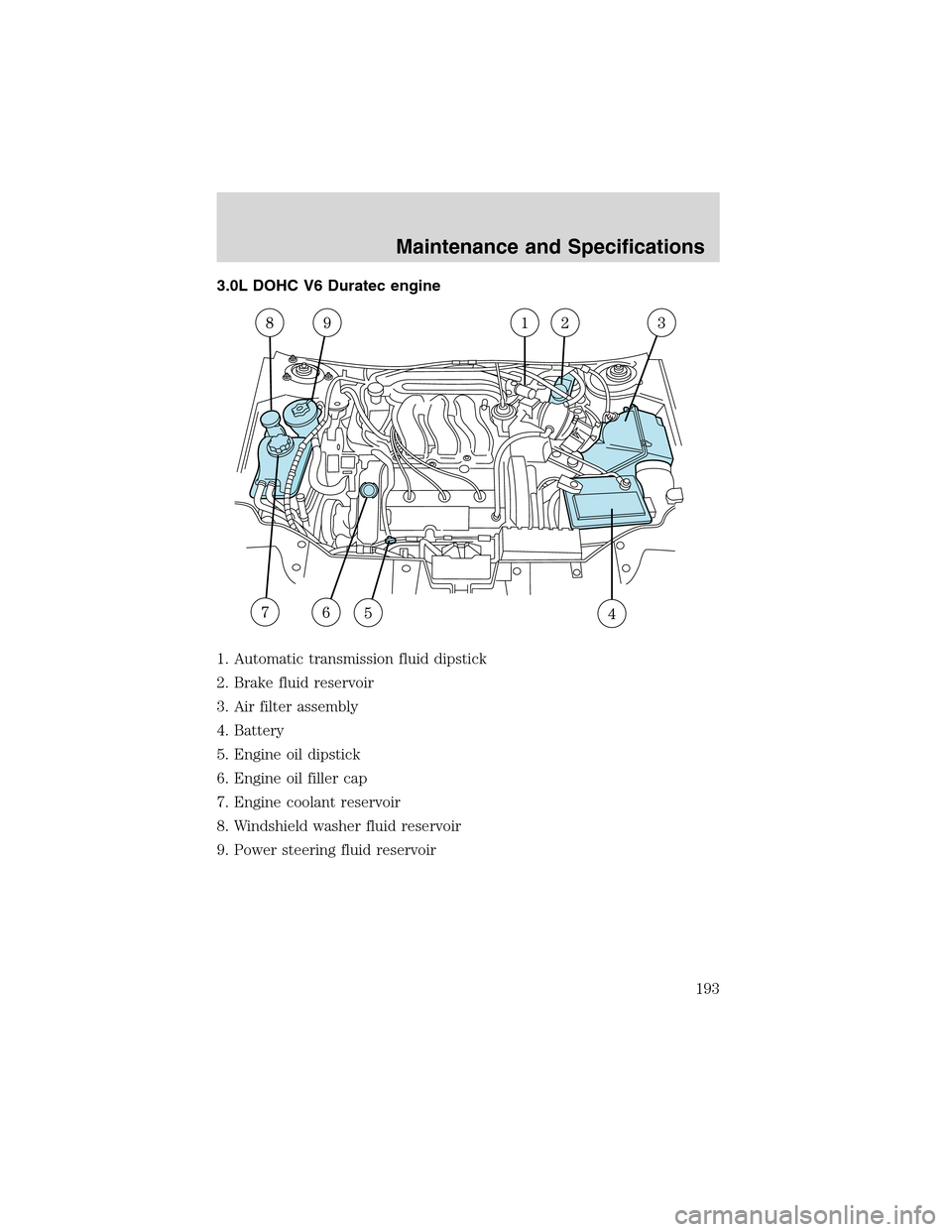

3.0L DOHC V6 Duratec engine

1. Automatic transmission fluid dipstick

2. Brake fluid reservoir

3. Air filter assembly

4. Battery

5. Engine oil dipstick

6. Engine oil filler cap

7. Engine coolant reservoir

8. Windshield washer fluid reservoir

9. Power steering fluid reservoir

Maintenance and Specifications

193

Page 195 of 240

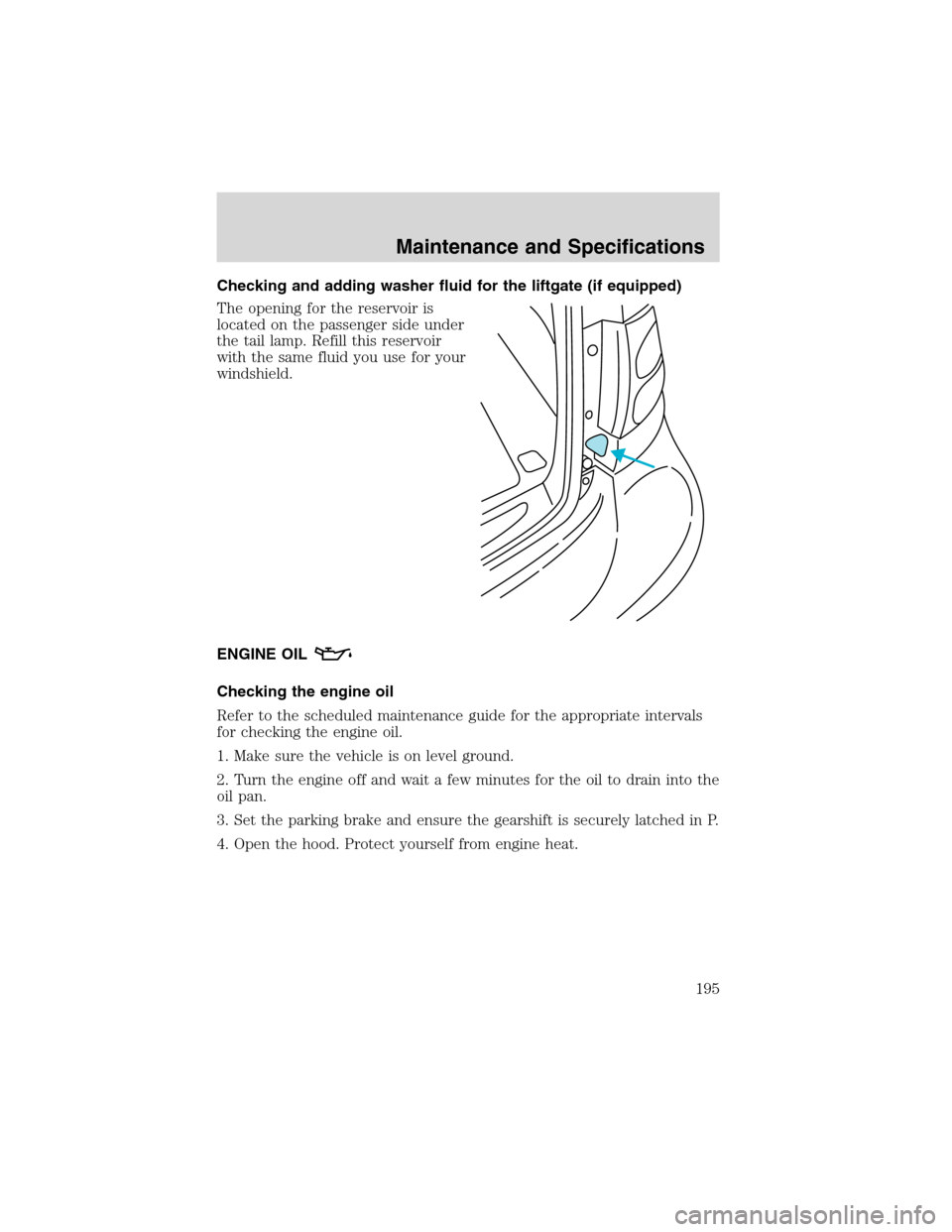

Checking and adding washer fluid for the liftgate (if equipped)

The opening for the reservoir is

located on the passenger side under

the tail lamp. Refill this reservoir

with the same fluid you use for your

windshield.

ENGINE OIL

Checking the engine oil

Refer to the scheduled maintenance guide for the appropriate intervals

for checking the engine oil.

1. Make sure the vehicle is on level ground.

2. Turn the engine off and wait a few minutes for the oil to drain into the

oil pan.

3. Set the parking brake and ensure the gearshift is securely latched in P.

4. Open the hood. Protect yourself from engine heat.

Maintenance and Specifications

195

Page 196 of 240

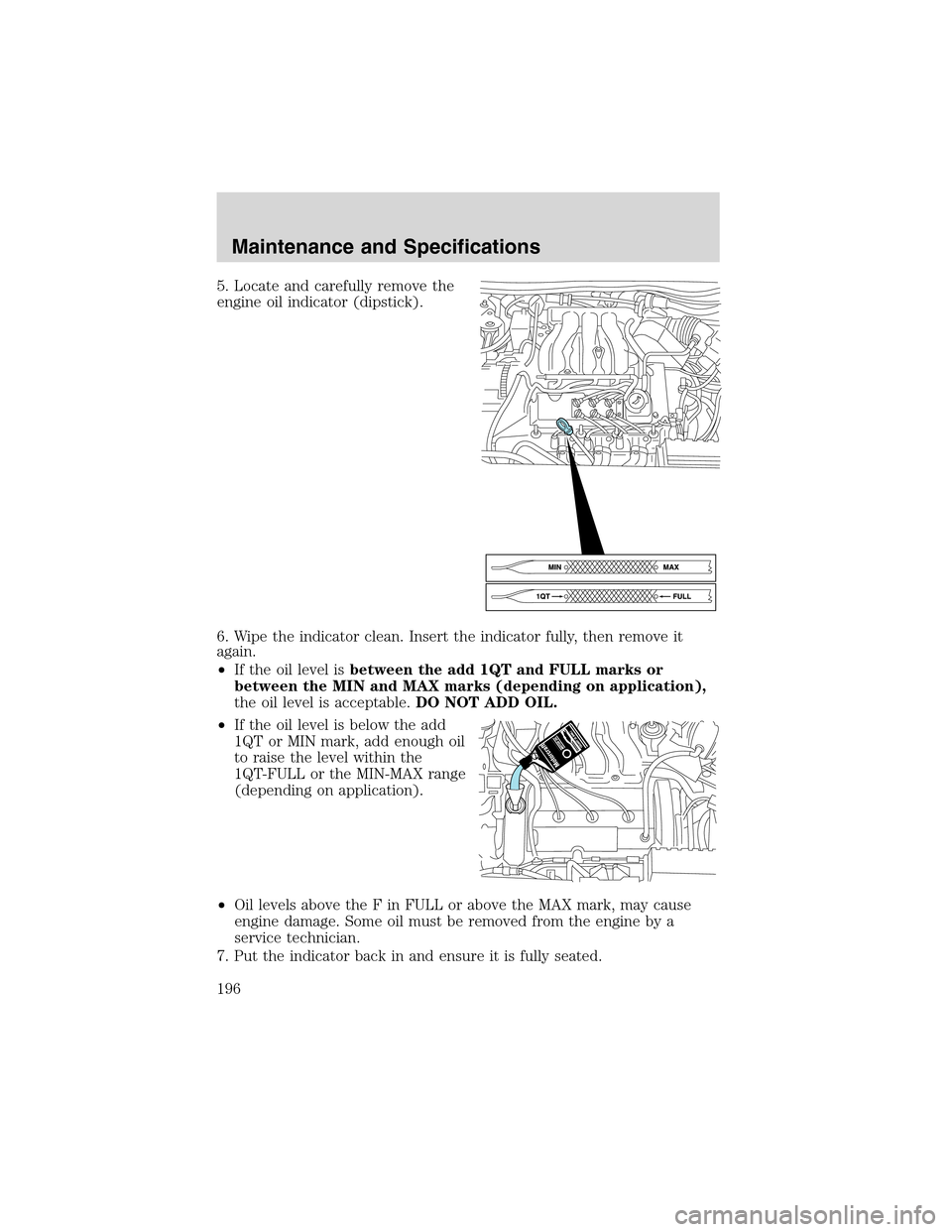

5. Locate and carefully remove the

engine oil indicator (dipstick).

6. Wipe the indicator clean. Insert the indicator fully, then remove it

again.

•If the oil level isbetween the add 1QT and FULL marks or

between the MIN and MAX marks (depending on application),

the oil level is acceptable.DO NOT ADD OIL.

•If the oil level is below the add

1QT or MIN mark, add enough oil

to raise the level within the

1QT-FULL or the MIN-MAX range

(depending on application).

•Oil levels above the F in FULL or above the MAX mark, may cause

engine damage. Some oil must be removed from the engine by a

service technician.

7. Put the indicator back in and ensure it is fully seated.

Maintenance and Specifications

196

Page 197 of 240

Adding engine oil

1. Check the engine oil. For instructions, refer toChecking the engine

oilin this chapter.

2. If the engine oil level is not within the normal range, add only certified

engine oil of the recommended viscosity. Remove the engine oil filler cap

and use a funnel to pour the engine oil into the opening.

3. Recheck the engine oil level. Make sure the oil level is not above the

MAX mark or the letter F in FULL on the engine oil level indicator

(dipstick).

4. Install the indicator and ensure it is fully seated.

5. Fully install the engine oil filler cap by turning the filler cap clockwise

until it stops.

To avoid possible oil loss, DO NOT operate the vehicle with the

engine oil level indicator and/or the engine oil filler cap removed.

Engine oil and filter recommendations

Look for this certification

trademark.

SAE 5W-20 engine oil is recommended.

Only use oils“Certified For Gasoline Engines”by the American

Petroleum Institute (API). Use Motorcraft or an equivalent oil meeting

Ford specification WSS-M2C153–H.SAE 5W-20 oil provides optimum

fuel economy and durability performance meeting all

requirements for your vehicle’s engine.

Do not use supplemental engine oil additives, oil treatments or engine

treatments. They are unnecessary and could, under certain conditions,

lead to engine damage which is not covered by your warranty.

Change your engine oil and filter according to the appropriate schedule

listed in the scheduled maintenance guide.

Ford production and aftermarket (Motorcraft) oil filters are designed for

added engine protection and long life. If a replacement oil filter is used

Maintenance and Specifications

197

Page 198 of 240

that does not meet Ford material and design specifications, start-up

engine noises or knock may be experienced.

It is recommended you use the appropriate Motorcraft oil filter (or

another brand meeting Ford specifications) for your engine application.

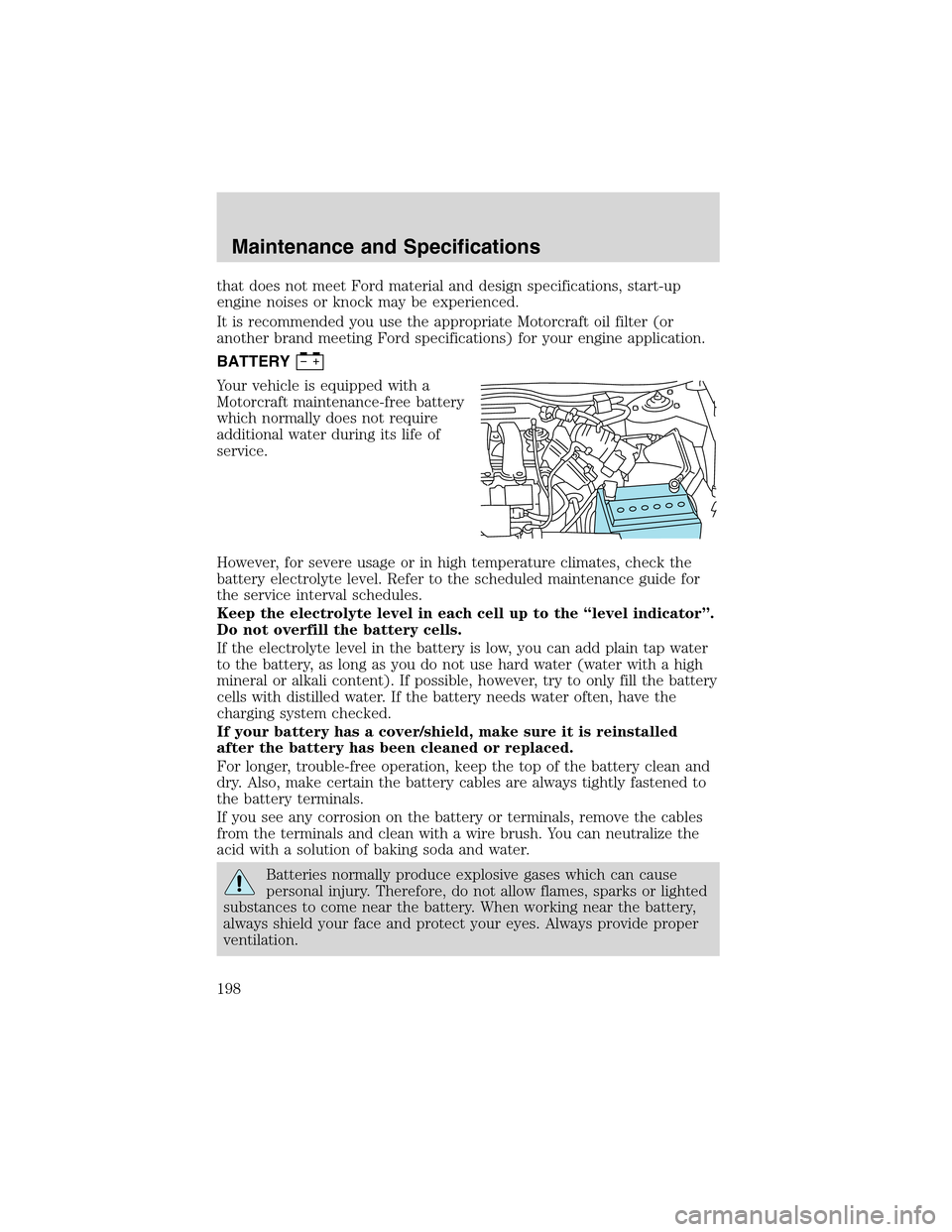

BATTERY

Your vehicle is equipped with a

Motorcraft maintenance-free battery

which normally does not require

additional water during its life of

service.

However, for severe usage or in high temperature climates, check the

battery electrolyte level. Refer to the scheduled maintenance guide for

the service interval schedules.

Keep the electrolyte level in each cell up to the“level indicator”.

Do not overfill the battery cells.

If the electrolyte level in the battery is low, you can add plain tap water

to the battery, as long as you do not use hard water (water with a high

mineral or alkali content). If possible, however, try to only fill the battery

cells with distilled water. If the battery needs water often, have the

charging system checked.

If your battery has a cover/shield, make sure it is reinstalled

after the battery has been cleaned or replaced.

For longer, trouble-free operation, keep the top of the battery clean and

dry. Also, make certain the battery cables are always tightly fastened to

the battery terminals.

If you see any corrosion on the battery or terminals, remove the cables

from the terminals and clean with a wire brush. You can neutralize the

acid with a solution of baking soda and water.

Batteries normally produce explosive gases which can cause

personal injury. Therefore, do not allow flames, sparks or lighted

substances to come near the battery. When working near the battery,

always shield your face and protect your eyes. Always provide proper

ventilation.

Maintenance and Specifications

198

Page 200 of 240

•Always dispose of automotive

batteries in a responsible manner.

Follow your local authorized

standards for disposal. Call your

local authorized recycling center

to find out more about recycling

automotive batteries.

ENGINE COOLANT

Checking engine coolant

The concentration and level of engine coolant should be checked at the

mileage intervals listed in the scheduled maintenance guide. The coolant

concentration should be maintained at 50/50 coolant and distilled water,

which equates to a freeze point of -36°C (-34°F). Coolant concentration

testing is possible with a hydrometer or antifreeze tester (such as the

Rotunda Battery and Antifreeze Tester, 014–R1060). The level of coolant

should be maintained at the“cold full”of“cold fill range”level in the

coolant reservoir. If the level falls below, add coolant per the instructions

in theAdding engine coolantsection.

Your vehicle was factory-filled with a 50/50 engine coolant and water

concentration. If the concentration of coolant falls below 40% or above

60%, the engine parts could become damaged or not work properly.A

50–50 mixture of coolant and water provides the following:

•Freeze protection down to -36°C (-34°F).

•Boiling protection up to 129°C (265°F).

•Protection against rust and other forms of corrosion.

•Enables calibrated gauges to work properly.

LEAD

RETURN

RECYCLE

Maintenance and Specifications

200