lock Mercury Villager 2000 s Workshop Manual

[x] Cancel search | Manufacturer: MERCURY, Model Year: 2000, Model line: Villager, Model: Mercury Villager 2000Pages: 256, PDF Size: 2.21 MB

Page 190 of 256

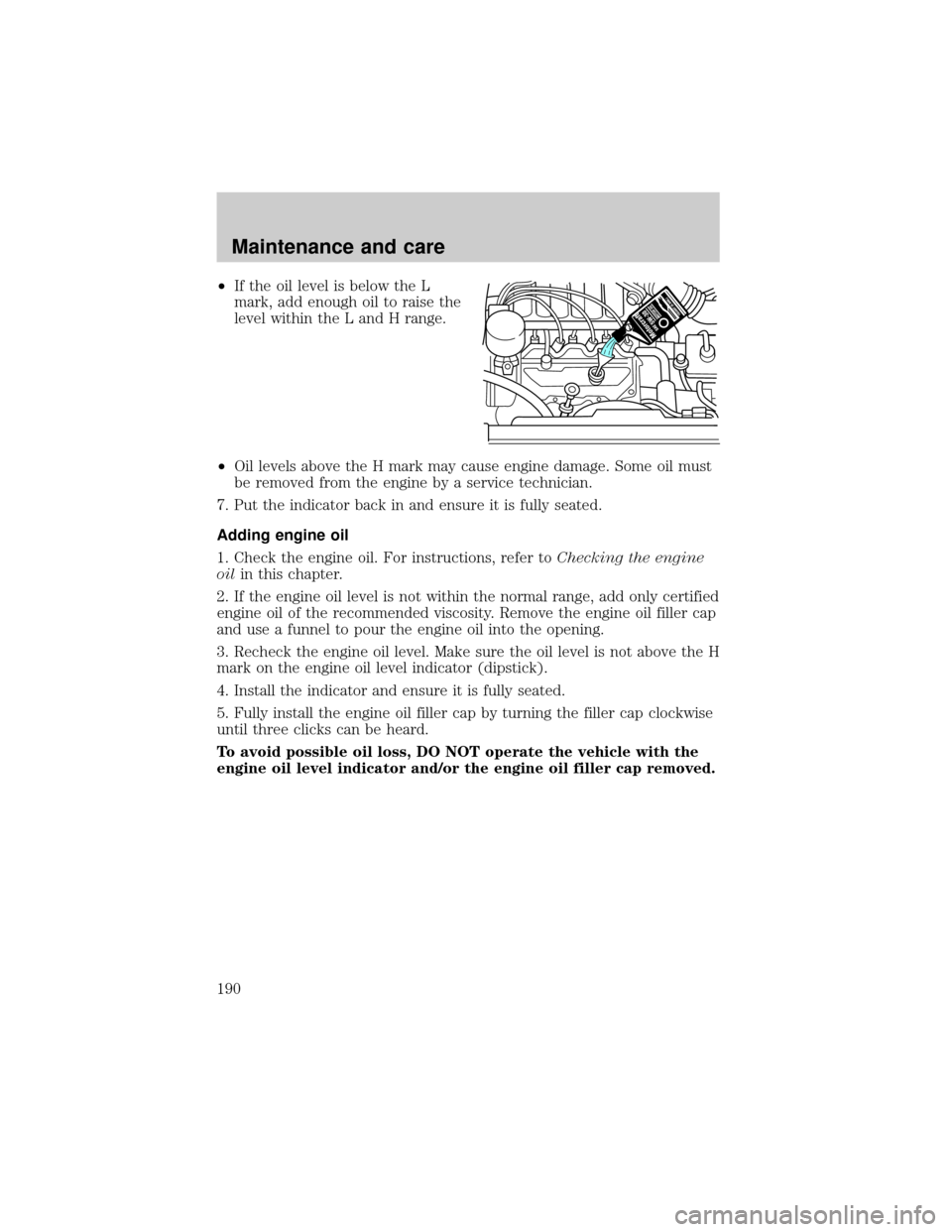

²If the oil level is below the L

mark, add enough oil to raise the

level within the L and H range.

²Oil levels above the H mark may cause engine damage. Some oil must

be removed from the engine by a service technician.

7. Put the indicator back in and ensure it is fully seated.

Adding engine oil

1. Check the engine oil. For instructions, refer toChecking the engine

oilin this chapter.

2. If the engine oil level is not within the normal range, add only certified

engine oil of the recommended viscosity. Remove the engine oil filler cap

and use a funnel to pour the engine oil into the opening.

3. Recheck the engine oil level. Make sure the oil level is not above the H

mark on the engine oil level indicator (dipstick).

4. Install the indicator and ensure it is fully seated.

5. Fully install the engine oil filler cap by turning the filler cap clockwise

until three clicks can be heard.

To avoid possible oil loss, DO NOT operate the vehicle with the

engine oil level indicator and/or the engine oil filler cap removed.

Maintenance and care

190

Page 196 of 256

When the engine is cool, add a50/50 mixtureof engine coolant and

distilled water to the engine coolant reservoir, until the coolant is at the

ªcold fill levelº or within the ª cold fill rangeº as listed in the engine

coolant reservoir (depending upon application).

²NEVER increase the coolant concentration above 60%.

²NEVER decrease the coolant concentration below 40%.

²Engine coolant concentrations above 60% or below 40% will

decrease the freeze protection characteristics of the engine

coolant and may cause engine damage.

Plain water may be added in an emergency, but youmustreplace it with

a 50/50 mixture of engine coolant and distilled water as soon as possible.

Check the coolant level in the reservoir before you drive your vehicle the

next few times (with the engine cool). If necessary, add a50/50

mixtureof engine coolant and distilled water to the engine coolant

reservoir until the coolant level is at the ªcold fill levelº or within the

ªcold fill rangeº as listed on the reservoir (depending upon application).

Have your dealer check the engine cooling system for leaks if you have

to add more than 1.0 liter (1.0 quart) of engine coolant per month.

To avoid scalding hot steam or coolant from being released from

the engine cooling system, never remove the radiator cap while

the engine is running or hot. Failure to follow this warning may result

in damage to the engine's cooling system and possible severe personal

injury.

If you must remove the radiator cap, follow these steps to avoid personal

injury:

1. Before you remove the cap, turn the engine off and let it cool.

2. When the engine is cool, wrap a thick cloth around the cap. Slowly

turn cap counterclockwise until pressure begins to release.

3. Step back while the pressure releases.

4. When you are sure that all the pressure has been released, use the

cloth to turn it counterclockwise and remove the cap.

Recycled engine coolant

Ford Motor Company recommends the use of a recycled engine coolant

produced by Ford-approved processes.

Maintenance and care

196

Page 203 of 256

Battery posts, terminals and related accessories contain lead and

lead compunds. Wash hands after handling.

Your automatic transaxle electronically controls the shift feel by using an

adaptive learning strategy. During the first few hundred kilometers

(miles) of operation, it is normal for your transaxle to have abrupt shifts.

The adaptive learning strategy is maintained by power from the battery.

When the battery is disconnected or a new battery is installed, the

transaxle must relearn its adaptive strategy. Optimal shifting will resume

within a few hundred kilometers (miles) of operation.

If the battery has been disconnected or a new battery has been installed,

the clock and the preset radio stations must be reset once the battery is

reconnected.

²Always dispose of automotive

batteries in a responsible manner.

Follow your local authorized

standards for disposal. Call your

local authorized recycling center

to find out more about recycling

automotive batteries.

LEAD

RETURN

RECYCLE

Maintenance and care

203

Page 205 of 256

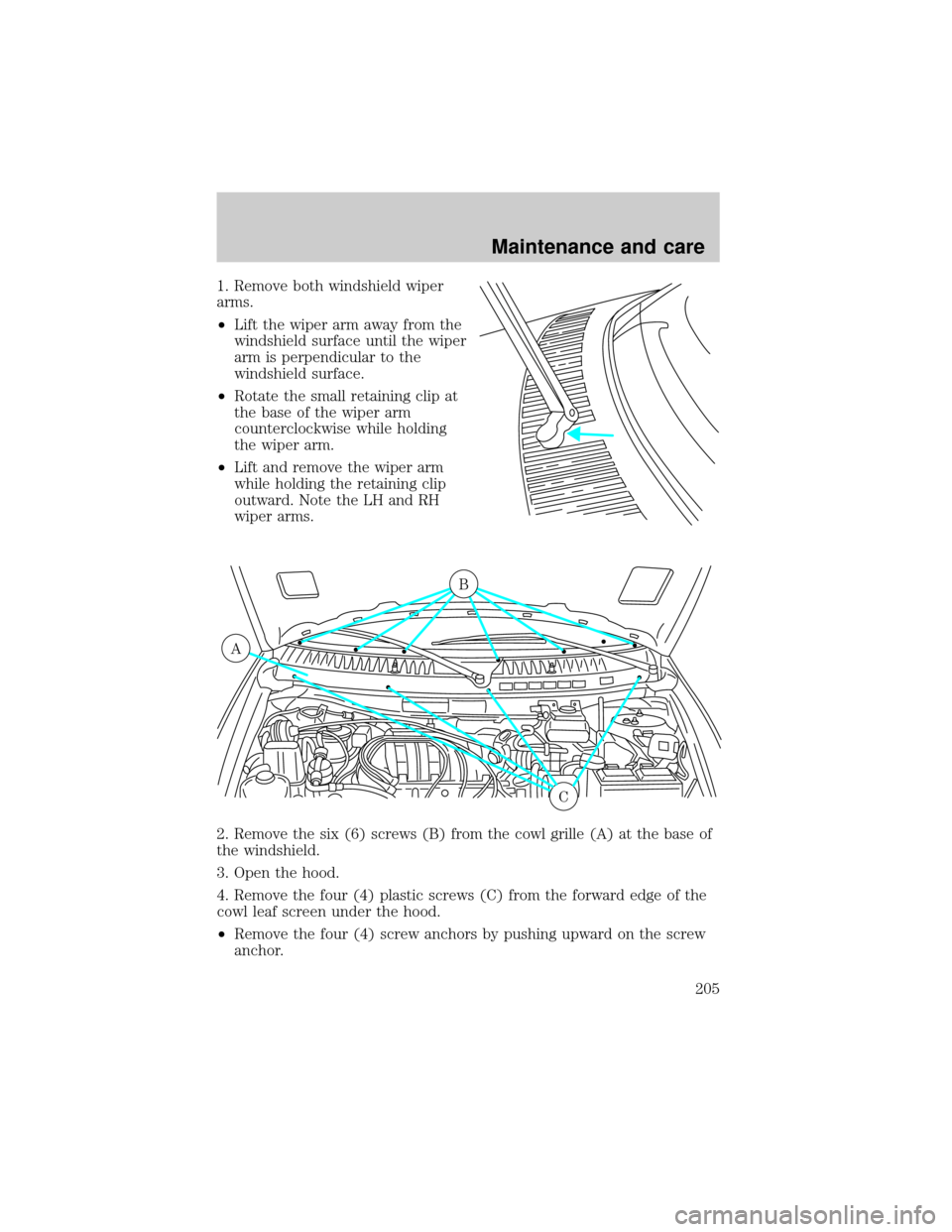

1. Remove both windshield wiper

arms.

²Lift the wiper arm away from the

windshield surface until the wiper

arm is perpendicular to the

windshield surface.

²Rotate the small retaining clip at

the base of the wiper arm

counterclockwise while holding

the wiper arm.

²Lift and remove the wiper arm

while holding the retaining clip

outward. Note the LH and RH

wiper arms.

2. Remove the six (6) screws (B) from the cowl grille (A) at the base of

the windshield.

3. Open the hood.

4. Remove the four (4) plastic screws (C) from the forward edge of the

cowl leaf screen under the hood.

²Remove the four (4) screw anchors by pushing upward on the screw

anchor.

A

B

C

Maintenance and care

205

Page 207 of 256

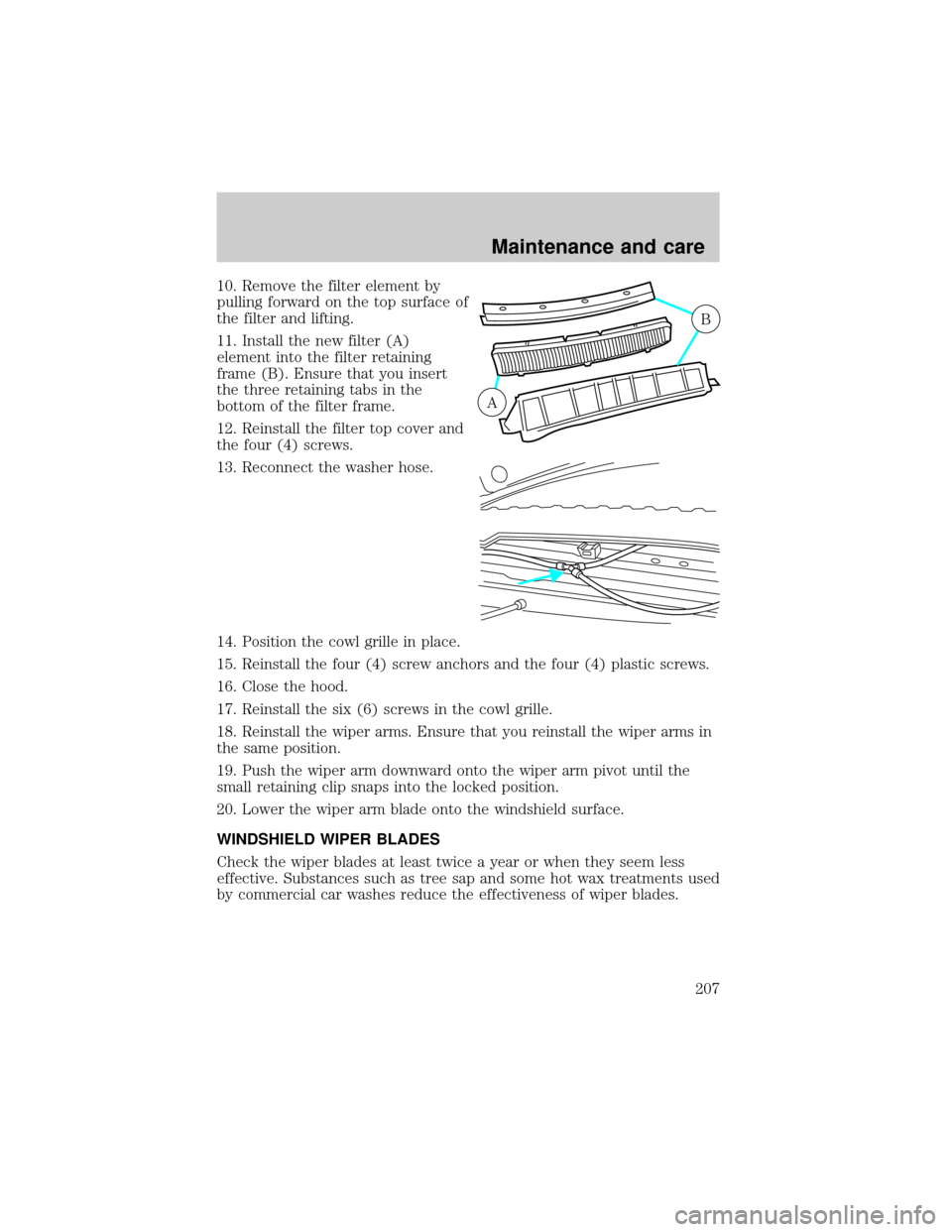

10. Remove the filter element by

pulling forward on the top surface of

the filter and lifting.

11. Install the new filter (A)

element into the filter retaining

frame (B). Ensure that you insert

the three retaining tabs in the

bottom of the filter frame.

12. Reinstall the filter top cover and

the four (4) screws.

13. Reconnect the washer hose.

14. Position the cowl grille in place.

15. Reinstall the four (4) screw anchors and the four (4) plastic screws.

16. Close the hood.

17. Reinstall the six (6) screws in the cowl grille.

18. Reinstall the wiper arms. Ensure that you reinstall the wiper arms in

the same position.

19. Push the wiper arm downward onto the wiper arm pivot until the

small retaining clip snaps into the locked position.

20. Lower the wiper arm blade onto the windshield surface.

WINDSHIELD WIPER BLADES

Check the wiper blades at least twice a year or when they seem less

effective. Substances such as tree sap and some hot wax treatments used

by commercial car washes reduce the effectiveness of wiper blades.

A

B

Maintenance and care

207

Page 208 of 256

Checking the wiper blades

If the wiper blades do not wipe properly, clean both the windshield and

wiper blades using undiluted windshield wiper solution or a mild

detergent. Rinse thoroughly with clean water. To avoid damaging the

blades, do not use fuel, kerosene, paint thinner or other solvents.

Changing the wiper blades

To replace the wiper blades:

1. Pull the wiper arm away from the

windshield and lock into the service

position.

2. Turn the blade at an angle from

the wiper arm. Push the lock pin

manually to release the blade and

pull the wiper blade down toward

the windshield to remove it from the

arm.

3. Attach the new wiper to the

wiper arm and press it into place

until a click is heard.

REAR WINDOW WIPER BLADES

Refer toWindshield Wiper Bladesin this section for more information

on rear wiper blades.

INFORMATION ABOUT UNIFORM TIRE QUALITY GRADING

New vehicles are fitted with tires

that have a rating on them called

Tire Quality Grades. The Quality

grades can be found where

applicable on the tire sidewall

between tread shoulder and

maximum section width. For

example:

²Treadwear 200 Traction AA Temperature A

Maintenance and care

208

Page 215 of 256

When the fuel filler door is open, the left hand sliding door will

not open.

When fueling your vehicle:

1. Turn the engine off.

2. Carefully turn the filler cap counterclockwise 1/4 of a turn until it

stops.

3. Pull to remove the cap from the fuel filler pipe.

4. To install the cap, align the tabs on the cap with the notches on the

filler pipe.

5. Turn the filler cap clockwise 1/4 of a turn until it stops.

If the ªService Engine Soonº indicator comes on and stays on when you

start the engine, the fuel filler cap may not be properly installed. Turn

off the engine, remove the cap, align the cap properly and reinstall it.

If you must replace the fuel filler cap, replace it with a fuel filler

cap that is designed for your vehicle. The customer warranty may

be void for any damage to the fuel tank or fuel system if the

correct genuine Ford or Motorcraft fuel filler cap is not used.

The fuel system may be under pressure. If the fuel filler cap is

venting vapor or if you hear a hissing sound, wait until it stops

before completely removing the fuel filler cap. Otherwise, fuel may

spray out and injure you or others.

If you do not use the proper fuel filler cap, excessive pressure or

vacuum in the fuel tank may damage the fuel system or cause

the fuel system to work improperly in a collision, which may result in

possible personal injury.

Choosing the right fuel

Use only UNLEADED FUEL. The use of leaded fuel is prohibited by law

and could damage your vehicle.

Do not use fuel containing methanol. It can damage critical fuel system

components.

Your vehicle was not designed to use fuel or fuel additives with metallic

compounds, including manganese-based compounds containing MMT.

Maintenance and care

215

Page 223 of 256

²Brakelamps

²Backup lamps

²License plate lamps

Do not remove lamp bulbs unless they will be replaced immediately. If a

bulb is removed for an extended period of time, contaminants may enter

the lamp housings and affect performance.

Replacing headlamp bulbs

To remove the headlamp bulb:

1. Make sure headlamp switch is in OFF position, then open the hood.

2. Disconnect the electrical

connector from the bulb by pulling

rearward.

3. Remove the bulb retaining ring by

rotating it counterclockwise (when

viewed from the rear) to free it

from the bulb socket, and slide the

ring off the plastic base. Keep the

ring to retain the new bulb.

4. Without turning, remove the old

bulb from its socket by gently

pulling it straight back out of the

lamp assembly.

To install the new bulb:

Handle a halogen headlamp bulb carefully and keep out of

children's reach. Grasp the bulb only by its plastic base and do

not touch the glass. The oil from your hand could cause the bulb to

break the next time the headlamps are operated.

Maintenance and care

223

Page 224 of 256

1. With the flat side of the new bulb's plastic base facing upward, insert

the glass end of the bulb into the lamp assembly. Turn the bulb left or

right to align the grooves in the plastic base with the tabs in the lamp

assembly. When the grooves are aligned, push the bulb into the lamp

assembly until the plastic base contacts the rear of the lamp assembly.

2. Install the bulb retaining ring over the plastic base until it contacts the

rear of the socket by rotating clockwise until you feel a ªstop.º

3. Connect the electrical connector into the rear of the plastic base until

it snaps, locking it into position.

4. Turn the headlamps on and make sure they work properly. If the

headlamp was correctly aligned before you changed the bulb, you should

not need to align it again.

Replacing front cornering/side marker lamp bulbs

1. Remove screw from the lamp

assembly.

2. Disengage lamp assembly (it has

a snap fit).

3. Remove bulb socket by turning it

counterclockwise about

1¤4turn,

then slide it out of the lamp

assembly.

4. Carefully pull bulb straight out of

the socket and push in the new

bulb.

5. To complete installation, follow

removal procedure in the reverse

order.

Maintenance and care

224

Page 225 of 256

Replacing front turn signal lamp bulbs

1. Remove bulb socket by turning it

counterclockwise, then slide it out

of the lamp assembly.

2.

Carefully pull bulb straight out of

the socket and push in the new bulb.

3. To complete installation, follow

removal procedure in the reverse

order.

Replacing high-mount brakelamp bulbs

1. Remove the two screws and lamp

assembly from vehicle.

2. Remove the bulb by rotating

socket counterclockwise and pulling

it out of the lamp assembly.

3. Pull bulb straight out of socket

and push in the new bulb.

4. To complete installation, follow

removal procedure in the reverse

order.

Replacing tail lamp/backup/turn signal lamp bulbs

1. Open the liftgate to expose the

lamp assemblies.

2. Remove the two screws from the

lamp assembly.

3. Carefully remove the lamp

assembly by pulling it rearward.

4. Rotate bulb socket

counterclockwise and remove from

lamp assembly.

5. Carefully pull bulb straight out of

the socket and push in the new

bulb.

6. To complete installation, follow

removal procedure in the reverse order.

Maintenance and care

225