MINI COOPER 2003 Owners Manual

Manufacturer: MINI, Model Year: 2003, Model line: COOPER, Model: MINI COOPER 2003Pages: 148, PDF Size: 3.17 MB

Page 121 of 148

119

OVERVIEW REPAIRSOPERATION CONTROLS DATA INDEX

FLAT TIRE – MINI MOBILITY SYSTEM

*

Preparing for tire repair

Before using the MINI Mobility Sys-

tem read the warning and danger

precautions on the equipment.<

If possible, leave objects in which have

been forced into the tire.

Take off the tag regarding speed limits and

stick it onto the steering wheel.

Please remember that the liquid can-

ister must be replaced every four

years by your MINI Dealer if the equipment

has not been used.<

The instructions for using the MINI

Mobility System are also given on the

equipment.<

Pumping in liquid sealant1. Shake the filling canister

2. Screw the filling hose onto the filling

canister

3. Unscrew the dust protection cap from

the valve of the defective tire

4. Screw out the valve core with the valve

remover. The valve remover is located in

a package with the filling hose

Place the valve core and valve

remover only on clean surfaces.<

5. Remove the cap from the filling hose

6. Push the filling hose onto the tire valve

7. Hold the filling canister with the cap

down and squeeze.

Squeeze the entire contents of the canis-

ter into the tire

8. Remove filling hose

9. Screw valve core into the tire valve with

the valve remover.

In the event of a dirty valve core or of

losing it you will find another valve

core in a package with the filling hose.<

ba.book Seite 119 Montag, 5. August 2002 8:09 20

ProCarManuals.com

Page 122 of 148

120

FLAT TIRE – MINI MOBILITY SYSTEM

*

Reinflating the tire

1. Screw hose 1 with manometer onto the

tire valve

2. Connect plug 3 to the cigarette lighter

socket in the vehicle interior, see

page 73

3. Ignition key in position 1:

Turn on compressor 2

4. Pump up the tires to at least 26.1 psi /

180 kPa, but not to more than 36.2 psi /

250 kPa.

To check the current air pressure, shut

off the device for a short time

Do not run the compressor for

longer than 6 minutes, otherwise

the device will overheat and possibly be

damaged.<

If an air pressure of 26.1 psi /

180 kPa cannot be reached, drive

back and forth about 35 ft / 10 m so that

the liquid sealant is distributed in the

tire. Afterwards repeat the procedure.

If an air pressure of 26.1 psi / 180 kPa is

still not reached, the tire is too badly

damaged. Please contact the nearest

MINI Dealer.<

5. Turn off compressor 2

6. Unscrew hose 1 from the tire valve

7. Store the MINI Mobility System back in

the vehicle.

Distributing liquid sealantImmediately drive for 10 minutes, so that

the liquid sealant is uniformly distributed.

Do not exceed a speed of 40 mph /

60 km/h).

If possible do not drive at a speed lower

than 10 mph / 20 km/h. Stop at a suitable

location.<

ba.book Seite 120 Montag, 5. August 2002 8:09 20

ProCarManuals.com

Page 123 of 148

121

OVERVIEW REPAIRSOPERATION CONTROLS DATA INDEX

FLAT TIRE – MINI MOBILITY SYSTEM

*

Checking tire inflation pressure

1. After driving for 10 minutes:

Screw hose with manometer back onto

the tire valve

2. Check tire pressure

The tire inflation pressure must be

at least 18.8 psi / 130 kPa.

If it is not, do not continue driving.<

If 18.8 psi / 130 kPa are displayed:

3. Ignition key position 1:

Turn on compressor 2. Correct tire infla-

tion pressure to the prescribed value, see

tire inflation pressure table, page 86

4. Replace the tire as soon as possible.

The use of the MINI Mobility System

may be ineffective with tire damage

larger than approx.

3/16 in / 4 mm. Please

contact the nearest MINI Dealer if the tire

cannot be made drivable with the MINI

Mobility System.<

Driving on

Do not exceed the permitted maxi-

mum speed of 50 mph / 80 km/h,

otherwise an accident could happen.<

Replace the defective tire as soon as

possible and have the new wheel/tire

assembly balanced.

Have the MINI Mobility System refilled.

Please contact your MINI Dealer. They pro-

vide advice if you wish to replace the tires

on your MINI or re-equip from summer to

winter tires or vice versa.<

Tire change setYour MINI is additionally equipped with a

tire change set. This is located in the MINI

COOPER in the cargo area under the floor

mat.

When changing a tire, always observe the

safety measures on page 112, and follow

the procedure described on page 114 ff.

In case of a flat tire the tire change

set is not necessary due to the avail-

ability of the MINI Mobility System.<

ba.book Seite 121 Montag, 5. August 2002 8:09 20

ProCarManuals.com

Page 124 of 148

122

BATTERYLocation in the MINI COOPERThe battery is located in the engine com-

partment.

Exact location, see page 92.Location in the MINI COOPER SThe battery is located in the cargo area

under the floor mat.

Battery careThe battery is absolutely maintenance-free,

that is, the original electrolyte will normally

last for the service life of the battery under

moderate climatic conditions.

For all questions regarding the bat-

tery, please consult your MINI

Dealer.<

Charging the battery Only charge the battery in the vehicle via

the terminals in the engine compartment

with the engine switched off, see "Jump-

starting" on page 124.

Whenever working on the electrical

system, disconnect the cable from

the negative terminal of the battery. Fail-

ure to do this could result in fire hazards or

injury due to short circuits.

point or your MINI Dealer. Maintain

the battery in an upright position for trans-

port and storage. Secure the battery to pre-

vent it from tilting during transport.<

ba.book Seite 122 Montag, 5. August 2002 8:09 20

ProCarManuals.com

Page 125 of 148

123

OVERVIEW REPAIRSOPERATION CONTROLS DATA INDEX

FUSESIf an electrical device fails, switch it off and

check the fuse.

Plastic tweezers that you can use to pull

fuses out of their sockets can be found in

the fuse box in the vehicle interior, see next

column.In the engine compartmentIn the MINI COOPER on the right next to the

battery.

In the MINI COOPER S on the right next to

the air filter box.

Open the cover panel of the fuse box. To do

so, press the clip fastener.

In the vehicle interiorOn the left side of the footwell in the side

trim panel.

Open the cover panel of the fuse box. To do

so, press the fastener.

Do not attempt to repair a blown fuse

or replace it with a fuse of a different

color or Ampere rating. To do this could

cause a fire in the vehicle resulting from a

circuit overload.<

If a fuse blows a second time, have

the cause of the damage rectified by

your MINI Dealer.<

ba.book Seite 123 Montag, 5. August 2002 8:09 20

ProCarManuals.com

Page 126 of 148

124

WARNING TRIANGLE

*

FIRST-AID KIT

*

JUMP-STARTING

The warning triangle is located beneath the

luggage compartment cover.

Comply with legal requirements

requiring you to carry a hazard warn-

ing triangle in the vehicle.<

The first-aid kit is located on the left in the

luggage compartment, behind the side

trim panel.

Some articles in the first-aid kit are

perishable. For this reason, check the

expiration dates of each of the items regu-

larly, and replace any whose expiration

dates have passed. Source: any pharmacy.

Comply with legislation requiring you to

carry a first-aid kit in the vehicle.<

Do not use spray starter fluids to start

the engine.<

When your battery is discharged, you can

use two jumper cables to start your vehicle

with power from the battery in a second

vehicle. Correspondingly you can help start

another vehicle. Only use jumper cables

with fully insulated handles on the termi-

nal clamps.

Do not touch live wiring and cables

on a running engine. There is a risk of

fatal injury if you do this. Carefully observe

the following instructions to avoid personal

injury and/or damage to either vehicle or

both vehicles.<

ba.book Seite 124 Montag, 5. August 2002 8:09 20

ProCarManuals.com

Page 127 of 148

125

OVERVIEW REPAIRSOPERATION CONTROLS DATA INDEX

JUMP-STARTINGPreparing for jump-starting1. Check whether the battery of the sup-

port vehicle has 12 Volts and approxi-

mately the same capacity – measured in

Ah, printed on the battery

2. Switch off the engine of the support

vehicle

3. Switch off any electrical systems and

components in both vehicles – except

for the hazard warning flashers of the

support vehicle.

>Do not disconnect the discharged bat-

tery from the vehicle electrical system

>Make certain that there is no contact

between the bodywork of the two

vehicles – short circuit hazard!

4. With the battery of the MINI COOPER,

remove the cover panel. To do so, press

both clips at the same time

or

with the MINI COOPER S, open the cover

of the positive terminal connection for

jump-starting

*, see arrow 1.

Connect the jumper cables

Adhere to the sequence also when

providing support for other vehicles;

failure to observe this procedure can lead

to sparks at the terminals and pose an

injury hazard.<

1. On the MINI COOPER S, the positive ter-

minal connection for jump-starting, see

arrow 1, functions as the positive bat-

tery terminal.

Make a connection with the "+" jumper

cable between the positive terminal of

the discharged battery and the positive

terminal of the support battery

2. Use the second, "–" jumper cable to set

up the connection between the negative

terminals of both vehicles.

To do so:

>Connect one terminal clamp to the

negative terminal and/or to an engine

or body ground of the support vehicle

>Connect the second terminal clamp to

the negative terminal of the battery

and/or to an engine or body ground of

the vehicle to be started. For the MINI,

see arrow 2.

Performing the jump-start1. Start the engine of the vehicle providing

the current and allow to run at a fast idle

speed for several minutes

2. Start the engine on the vehicle with the

discharged battery in the usual manner.

>If the first start attempt is not suc-

cessful, wait a few minutes before

another attempt in order to allow the

discharged battery to recharge

On the MINI:

Before disconnecting the jumper

cables, switch on the lighting, rear window

defroster and the highest blower speed as

well as the engine for at least approx.

10 seconds to prevent a voltage surge from

the regulator to the electrical systems and

components.<

3. Then disconnect the jumper cables in

the reverse order.

If necessary have the battery checked and

completely charged at a MINI Dealer.

ba.book Seite 125 Montag, 5. August 2002 8:09 20

ProCarManuals.com

Page 128 of 148

126

TOWINGFor towing, use either a tow bar or a nylon

rope or nylon belts that prevent sudden

jerking movements.Tow fittingThe screw-in tow fitting is stored in the

onboard tool kit; be sure that it remains in

the vehicle at all times. This fitting is

designed for installation in the tow sockets

located at the front and rear of the vehicle.

It is intended for towing on paved road sur-

faces only.

Access to tow socketsUse a suitable object – e.g. credit card,

screwdriver – to press out the covers from

the recess.

Firmly screw in the towing eyelet

until it stops. If this is not done, the

threads could be damaged.

Never attach tie-down hooks, chains,

straps, or tow hooks to tie rods, control

arms, or any other part of the vehicle sus-

pension, as severe damage to these compo-

nents will occur, possibly leading to acci-

dents.<

Avoid staggered towing and be care-

ful that the towing rope is in tight

tension before starting to drive the vehicle

that is towing.<

Tow barsIf the tow fittings of the two vehicles are

not directly opposite one another, please

note:

>Clearance and maneuvering capability

will be strictly limited in corners

>The inclination of the tow bar generates

lateral force – critical above all if the road

surface is slippery.

Do not tow a vehicle that is heavier

than the towing vehicle, otherwise it

will no longer be possible to control the

vehicle's response.<

ba.book Seite 126 Montag, 5. August 2002 8:09 20

ProCarManuals.com

Page 129 of 148

127

OVERVIEW REPAIRSOPERATION CONTROLS DATA INDEX

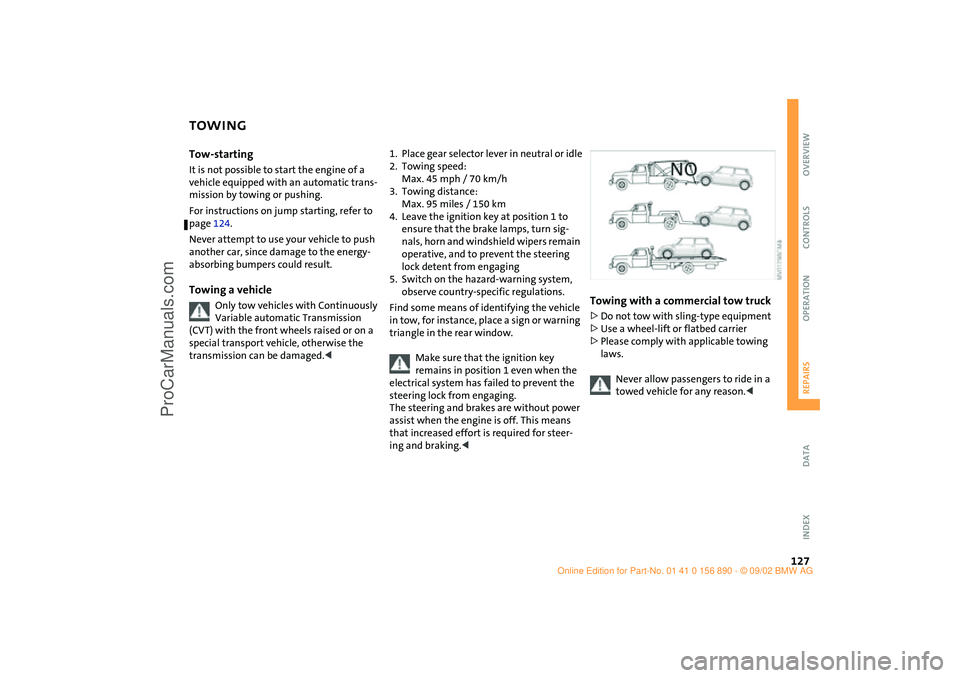

TOWINGTow-startingIt is not possible to start the engine of a

vehicle equipped with an automatic trans-

mission by towing or pushing.

For instructions on jump starting, refer to

page 124.

Never attempt to use your vehicle to push

another car, since damage to the energy-

absorbing bumpers could result.Towing a vehicle

Only tow vehicles with Continuously

Variable automatic Transmission

(CVT) with the front wheels raised or on a

special transport vehicle, otherwise the

transmission can be damaged.<

1. Place gear selector lever in neutral or idle

2. Towing speed:

Max. 45 mph / 70 km/h

3. Towing distance:

Max. 95 miles / 150 km

4. Leave the ignition key at position 1 to

ensure that the brake lamps, turn sig-

nals, horn and windshield wipers remain

operative, and to prevent the steering

lock detent from engaging

5. Switch on the hazard-warning system,

observe country-specific regulations.

Find some means of identifying the vehicle

in tow, for instance, place a sign or warning

triangle in the rear window.

Make sure that the ignition key

remains in position 1 even when the

electrical system has failed to prevent the

steering lock from engaging.

The steering and brakes are without power

assist when the engine is off. This means

that increased effort is required for steer-

ing and braking.<

Towing with a commercial tow truck >Do not tow with sling-type equipment

>Use a wheel-lift or flatbed carrier

>Please comply with applicable towing

laws.

Never allow passengers to ride in a

towed vehicle for any reason.<

ba.book Seite 127 Montag, 5. August 2002 8:09 20

ProCarManuals.com

Page 130 of 148

128

ba.book Seite 128 Montag, 5. August 2002 8:09 20

ProCarManuals.com