wheel MINI COUPE ROADSTER CONVERTIBLE 2012 Workshop Manual

[x] Cancel search | Manufacturer: MINI, Model Year: 2012, Model line: COUPE ROADSTER CONVERTIBLE, Model: MINI COUPE ROADSTER CONVERTIBLE 2012Pages: 283, PDF Size: 9.38 MB

Page 232 of 283

Replacing componentsMOBILITY

231

Replacing components

Vehicle equipment

In this chapter, all production, country, and

optional equipment that is offered in the model

range is described. Equipment is also described

that is not available because of, for example,

selected options or count ry version. This also

applies to safety related functions and systems.

Toolkit

Your vehicle comes with a toolkit that varies

with the equipment version; it is stored under-

neath the flat load floor.

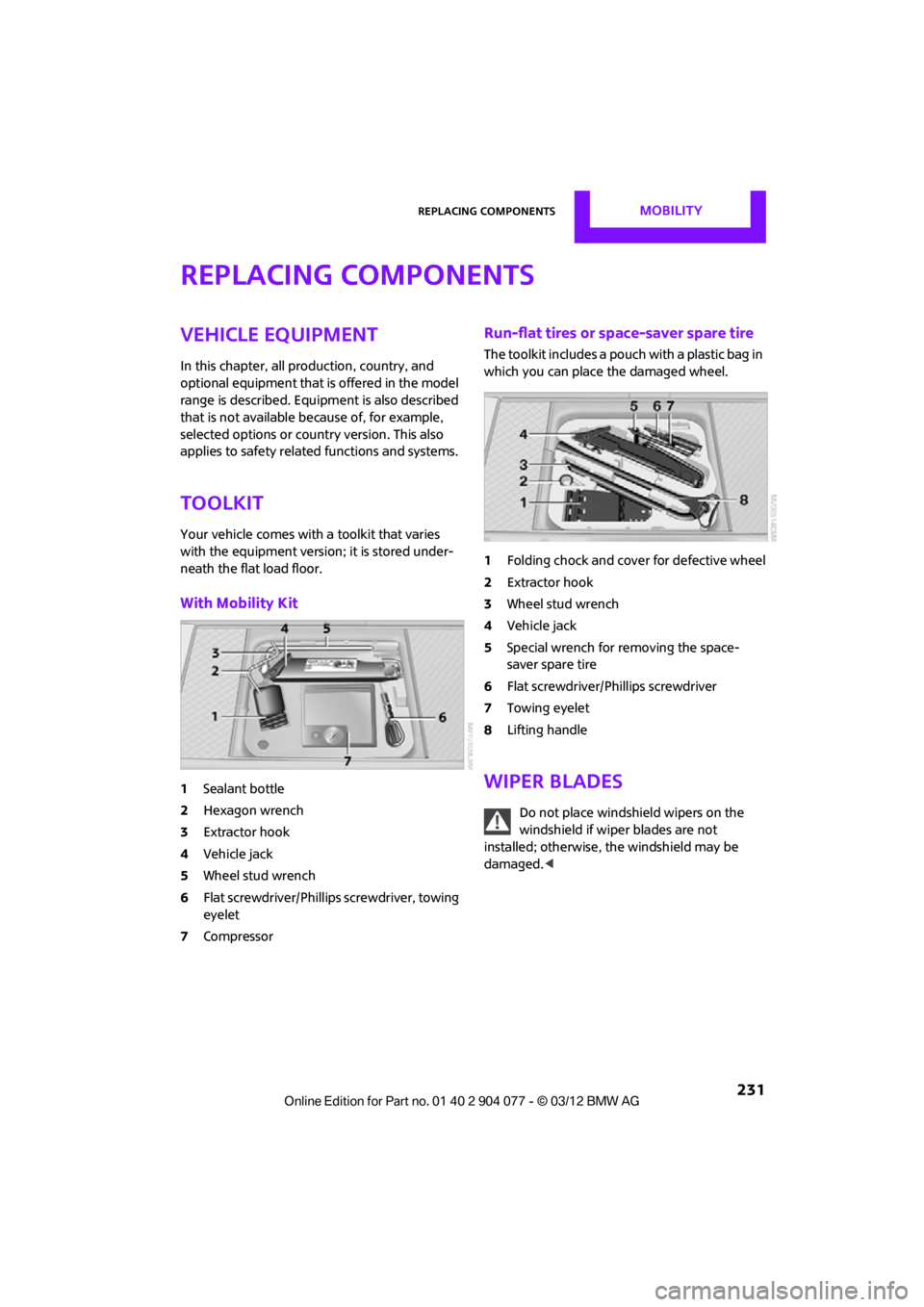

With Mobility Kit

1 Sealant bottle

2 Hexagon wrench

3 Extractor hook

4 Vehicle jack

5 Wheel stud wrench

6 Flat screwdriver/Phillips screwdriver, towing

eyelet

7 Compressor

Run-flat tires or space-saver spare tire

The toolkit includes a pouch with a plastic bag in

which you can place the damaged wheel.

1Folding chock and cove r for defective wheel

2 Extractor hook

3 Wheel stud wrench

4 Vehicle jack

5 Special wrench for removing the space-

saver spare tire

6 Flat screwdriver/Phillips screwdriver

7 Towing eyelet

8 Lifting handle

Wiper blades

Do not place windshield wipers on the

windshield if wiper blades are not

installed; otherwise, the windshield may be

damaged. <

00320051004F004C00510048000300280047004C0057004C005200510003

Page 235 of 283

MOBILITYReplacing components

234

2.Push on the catch, arrow 1, and disconnect

the connector, arrow 2.

3. To insert the new bulb and replace the

cover, proceed in reverse order.

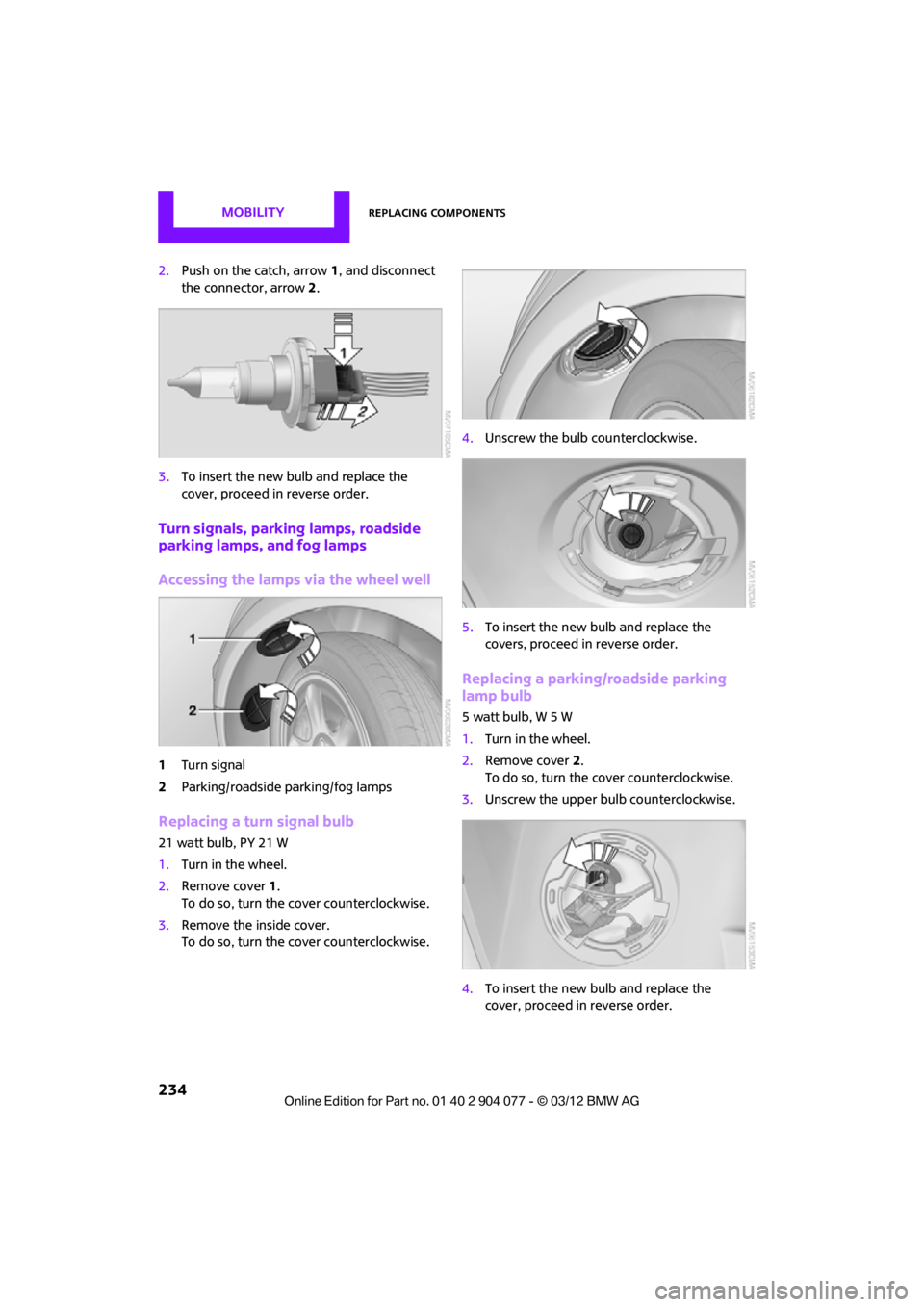

Turn signals, parking lamps, roadside

parking lamps, and fog lamps

Accessing the lamps via the wheel well

1Turn signal

2 Parking/roadside parking/fog lamps

Replacing a turn signal bulb

21 watt bulb, PY 21 W

1.Turn in the wheel.

2. Remove cover 1.

To do so, turn the cover counterclockwise.

3. Remove the inside cover.

To do so, turn the cover counterclockwise. 4.

Unscrew the bulb counterclockwise.

5. To insert the new bulb and replace the

covers, proceed in reverse order.

Replacing a parking/roadside parking

lamp bulb

5 watt bulb, W 5 W

1.Turn in the wheel.

2. Remove cover 2.

To do so, turn the cover counterclockwise.

3. Unscrew the upper bulb counterclockwise.

4. To insert the new bulb and replace the

cover, proceed in reverse order.

00320051004F004C00510048000300280047004C0057004C005200510003

Page 236 of 283

Replacing componentsMOBILITY

235

Replacing a fog lamp bulb

H8 bulb, 35 watts

1.Turn in the wheel.

2. Remove cover 2.

To do so, turn the cover counterclockwise.

3. Pull the cable connector.

4. Unscrew the lower bulb counterclockwise.

5. To insert the new bulb and replace the

cover, proceed in reverse order.

Side turn signals

5watt bulb, W5W

1.Push the lamp with the ventilation grate

forward and remove.

2. Unscrew the bulb holder counterclockwise.

3. Pull out and replace the bulb.

4. To insert the new bulb and replace the

cover, proceed in reverse order.

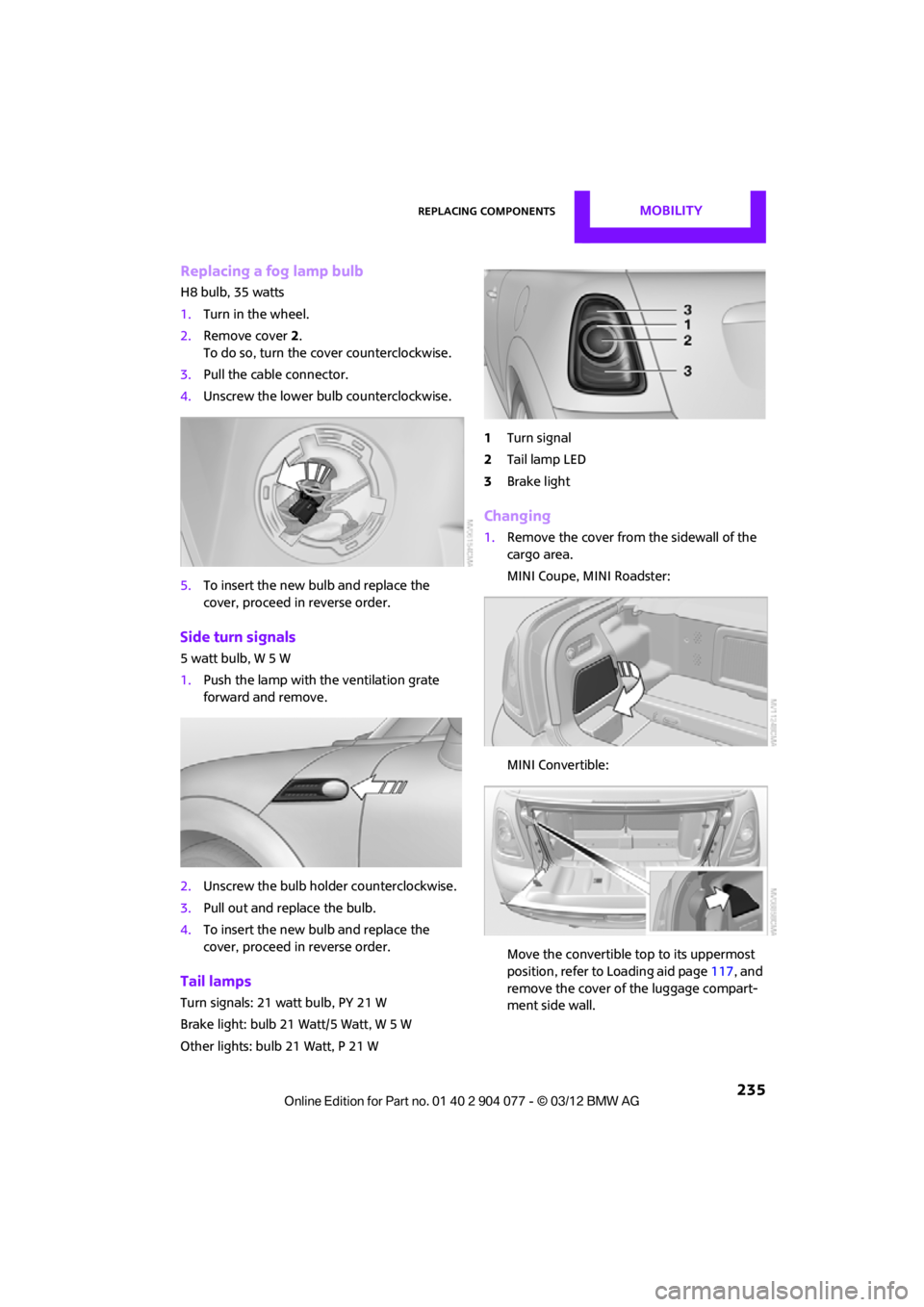

Tail lamps

Turn signals: 21 watt bulb, PY 21 W

Brake light: bulb 21 Watt/5 Watt, W 5 W

Other lights: bulb 21 Watt, P 21 W 1

Turn signal

2 Tail lamp LED

3 Brake light

Changing

1.Remove the cover from the sidewall of the

cargo area.

MINI Coupe, MINI Roadster:

MINI Convertible:

Move the convertible top to its uppermost

position, refer to Loading aid page 117, and

remove the cover of the luggage compart-

ment side wall.

00320051004F004C00510048000300280047004C0057004C005200510003

Page 238 of 283

Replacing componentsMOBILITY

237

Repairing a flat tire

Safety measures in the event of a

breakdown:

Park the vehicle as far as possible from moving

traffic and switch on the hazard warning

flashers.

Turn the steering wheel until the front wheels

are in the straight-ahead position and engage

the steering wheel lock. Engage the parking

brake and shift into 1st or reverse gear or place

the selector lever in position P.

All passengers should be outside the vehicle and

in a safe place, e.g. behind a guardrail.

Erect a warning triangle or warning flasher at the

appropriate distance if necessary. Comply with

all safety guidelines and regulations. <

In the event of a flat tire, different procedures

should be followed depending on the equip-

ment included in your vehicle:

> MINI Mobility Kit, refer to the following

section

> Run-flat tires, page 239

> Tire change with space-saver spare tire,

page 239

MINI Mobility Kit

Preparations

Use of the MINI Mobility Kit may be ineffective if

the tire puncture meas ures approx. 1/8 in/4 mm

or more. Contact the nearest MINI dealer if

the tire cannot be made drivable with the

Mobility Kit.

Do not remove foreign bodies which have

penetrated the tire if possible.

Follow the instructions on using the

Mobility Kit found on the compressor and

the sealant bottle. <

Remove the adhesive label for the speed limit

from the sealant bottle and affix it to the steer-

ing wheel.

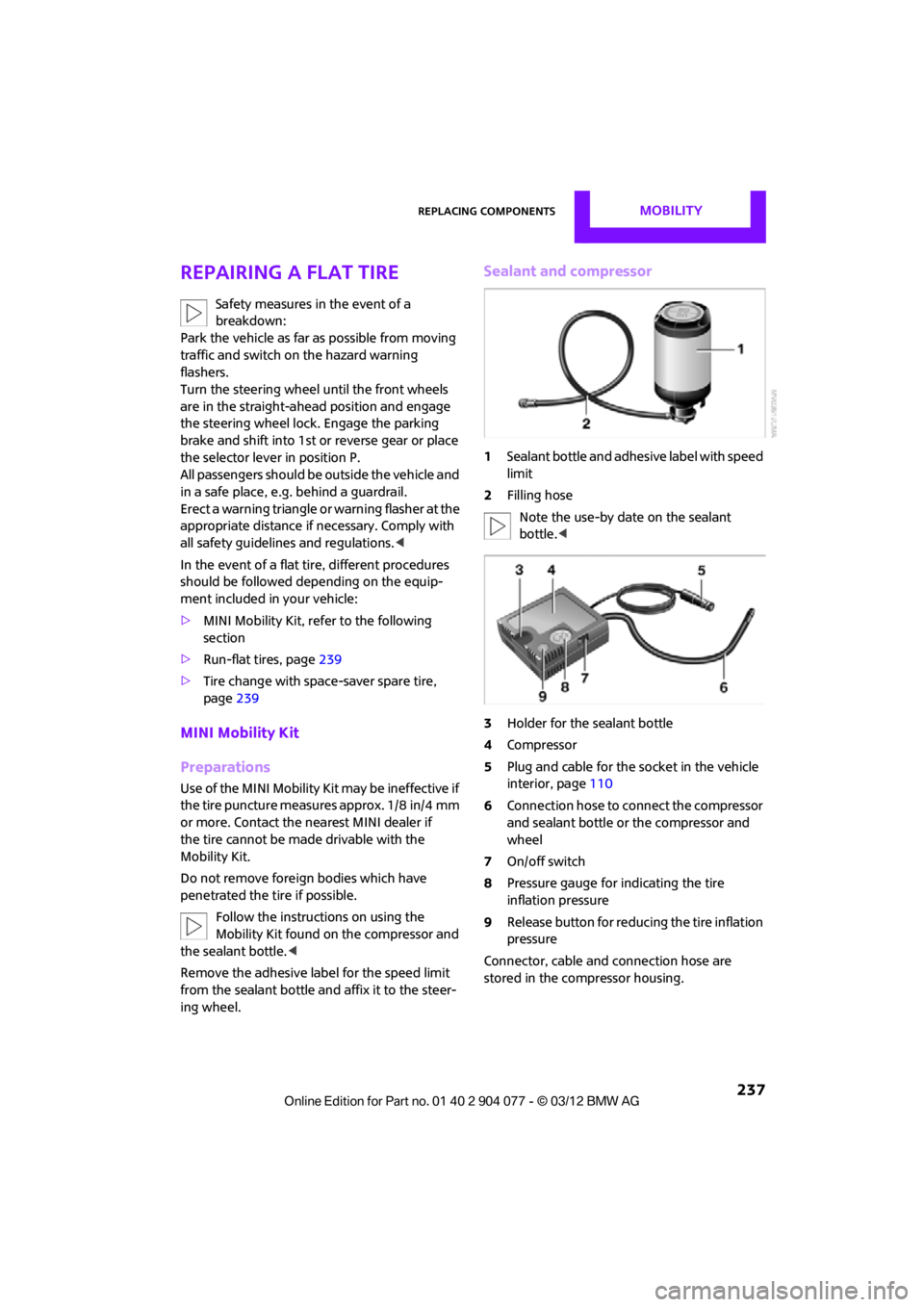

Sealant and compressor

1 Sealant bottle and adhesi ve label with speed

limit

2 Filling hose

Note the use-by date on the sealant

bottle. <

3 Holder for the sealant bottle

4 Compressor

5 Plug and cable for the socket in the vehicle

interior, page 110

6 Connection hose to connect the compressor

and sealant bottle or the compressor and

wheel

7 On/off switch

8 Pressure gauge for indicating the tire

inflation pressure

9 Release button for reduci ng the tire inflation

pressure

Connector, cable and connection hose are

stored in the compressor housing.

00320051004F004C00510048000300280047004C0057004C005200510003

Page 239 of 283

MOBILITYReplacing components

238

Using the Mobility Kit

To repair a tire puncture with the Mobility Kit,

proceed as follows:

>Fill the tire with sealant.

> Distribute the sealant.

> Correct the tire inflation pressure.

Filling the tire with sealant

Proceed in the specified order; otherwise,

sealant may emerge under high

pressure. <

1. Shake the sealant bottle.

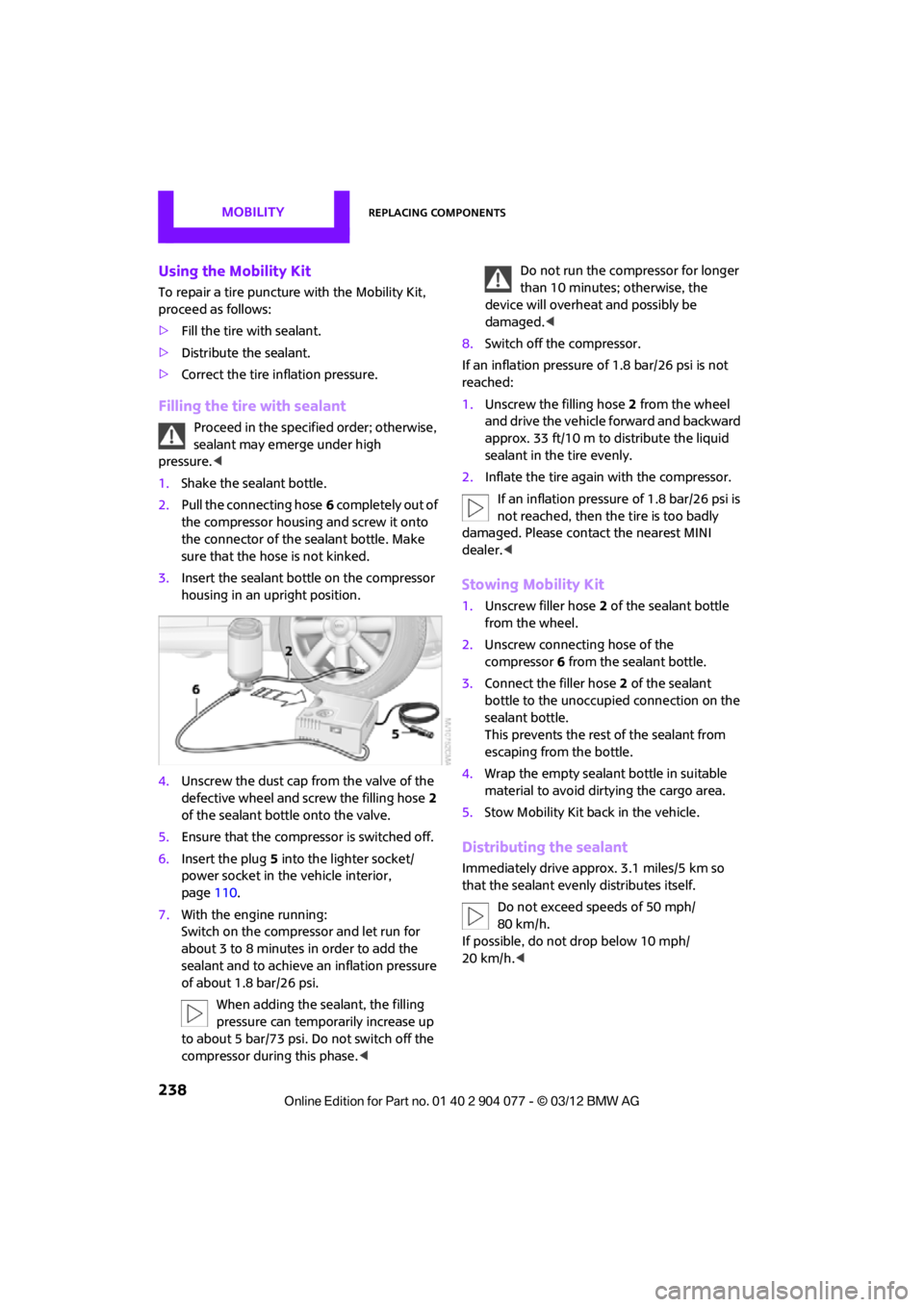

2. Pull the connecting hose 6 completely out of

the compressor housing and screw it onto

the connector of the sealant bottle. Make

sure that the hose is not kinked.

3. Insert the sealant bo ttle on the compressor

housing in an upright position.

4. Unscrew the dust cap from the valve of the

defective wheel and screw the filling hose 2

of the sealant bottle onto the valve.

5. Ensure that the compressor is switched off.

6. Insert the plug 5 into the lighter socket/

power socket in the vehicle interior,

page 110.

7. With the engine running:

Switch on the compressor and let run for

about 3 to 8 minutes in order to add the

sealant and to achieve an inflation pressure

of about 1.8 bar/26 psi.

When adding the sealant, the filling

pressure can temporarily increase up

to about 5 bar/73 psi. Do not switch off the

compressor during this phase.

device will overheat and possibly be

damaged. <

8. Switch off the compressor.

If an inflation pressure of 1.8 bar/26 psi is not

reached:

1. Unscrew the filling hose 2 from the wheel

and drive the vehicle forward and backward

approx. 33 ft/10 m to distribute the liquid

sealant in the tire evenly.

2. Inflate the tire again with the compressor.

If an inflation pressure of 1.8 bar/26 psi is

not reached, then the tire is too badly

damaged. Please contact the nearest MINI

dealer. <

Stowing Mobility Kit

1.Unscrew filler hose 2 of the sealant bottle

from the wheel.

2. Unscrew connecting hose of the

compressor 6 from the sealant bottle.

3. Connect the filler hose 2 of the sealant

bottle to the unoccupied connection on the

sealant bottle.

This prevents the rest of the sealant from

escaping from the bottle.

4. Wrap the empty sealant bottle in suitable

material to avoid dirtying the cargo area.

5. Stow Mobility Kit back in the vehicle.

Distributing the sealant

Immediately drive appr ox. 3.1 miles/5 km so

that the sealant evenly distributes itself.

Do not exceed speeds of 50 mph/

80 km/h.

If possible, do not drop below 10 mph/

20 km/h. <

00320051004F004C00510048000300280047004C0057004C005200510003

Page 240 of 283

Replacing componentsMOBILITY

239

Adjusting the tire pressure

1.After driving approx. 3.1 miles/5 km or

10 minutes, stop at a suitable location.

2. Screw the connection hose 6 of the

compressor directly onto the tire valve.

3. Insert the plug 5 into the power socket in

the vehicle interior.

4. Adjust tire pressure to 1.8 bar/26 psi. With

the engine running:

> To increase the inflatio n pressure: switch on

the compressor. To check the current infla-

tion pressure, switch off the compressor.

Do not run the compressor for longer

than 10 minutes; otherwise, the

device will overheat and possibly be

damaged. <

> To decrease the inflation pressure: press the

release button 9.

If the tire cannot ma intain the inflation

pressure, drive the vehicle again, refer to

Distributing the sealan t. Then repeat steps

1to4.

If an inflation pressure of 1.8 bar/26 psi still

cannot be reached, then the tire is too heavily

damaged. Contact your nearest MINI dealer. <

Driving on

Do not exceed the permitted maximum

speed of 50 mph/80 km/h; doing so may

result in an accident. <

Replace the defective tire as soon as possible

and have the new wheel/tire assembly

balanced.

Have the Mobility Kit refilled.

Changing wheels

Run-flat tires

Tire change for run-flat tires:

> Prepare for tire change, page 240

> Jack up vehicle, page 241

> Tighten lug bolts, page 241

Space-saver spare tire

Tire change with space-saver spare tire:

>Remove the space-saver spare tire,

page 239

> Prepare for tire change, page 240

> Jack up vehicle, page 241

> Mount space-saver spare tire, page 241

> Tighten lug bolts, page 241

> Drive with space-saver spare tire, page 240

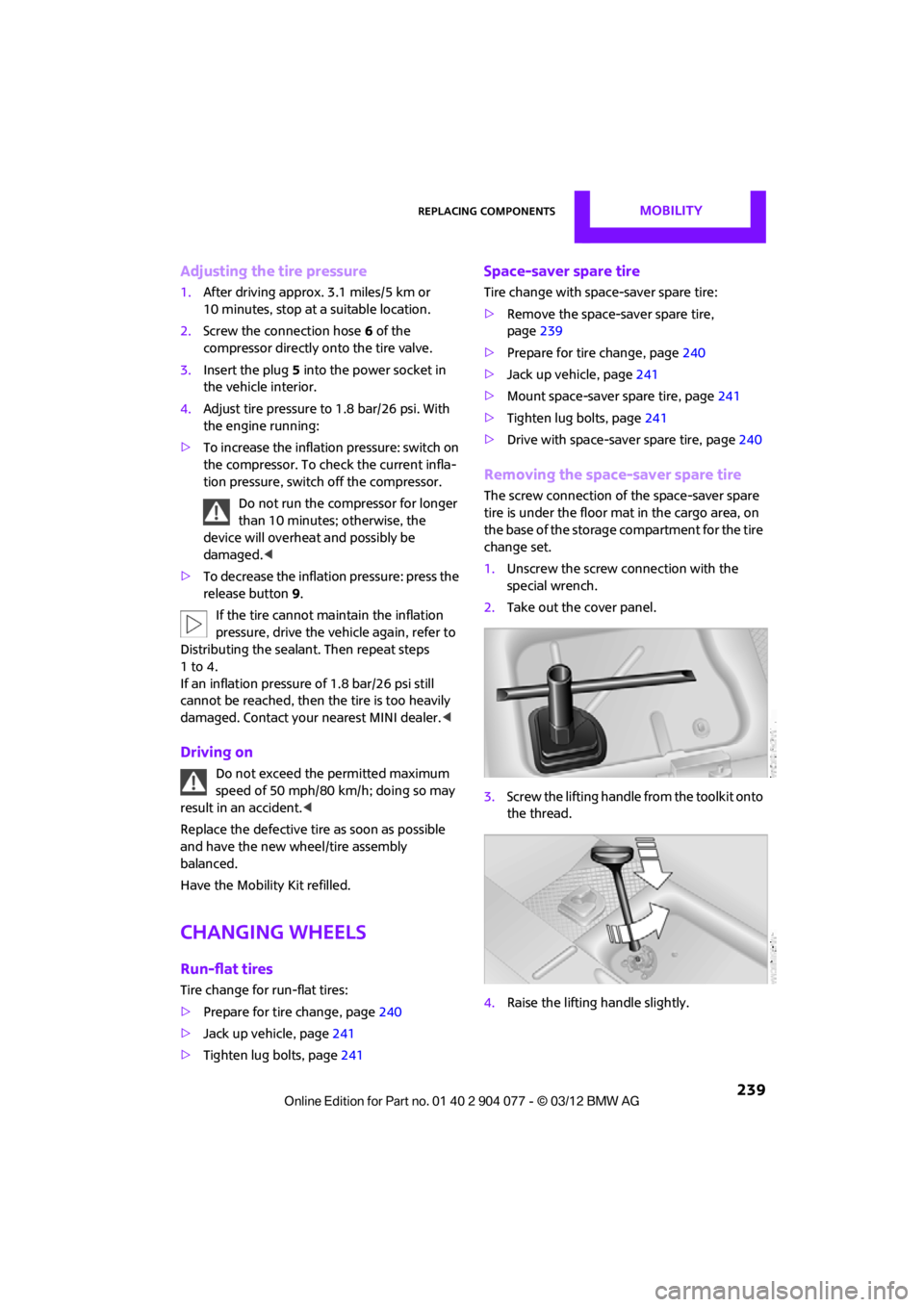

Removing the space-saver spare tire

The screw connection of the space-saver spare

tire is under the floor mat in the cargo area, on

the base of the storage compartment for the tire

change set.

1. Unscrew the screw connection with the

special wrench.

2. Take out the cover panel.

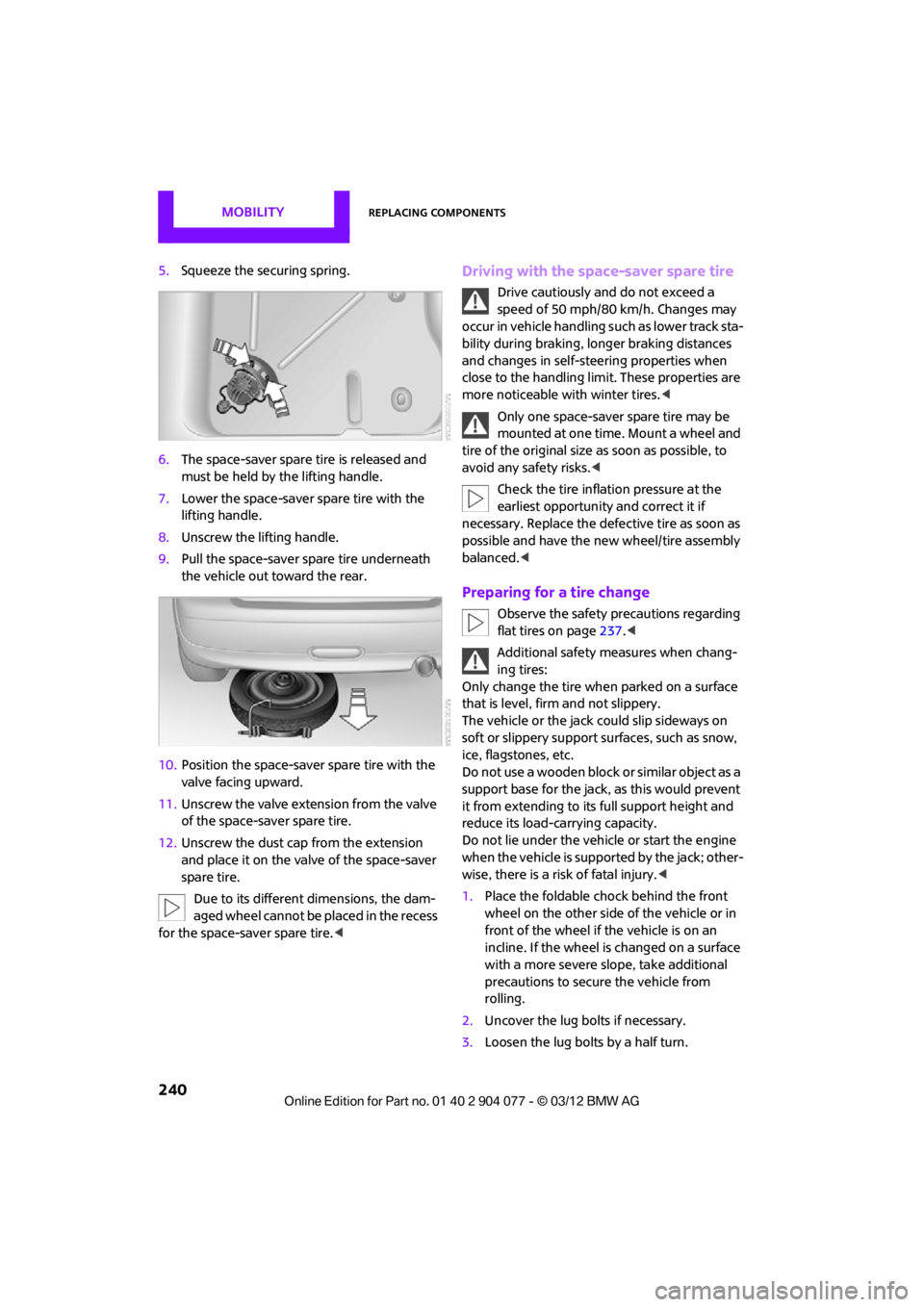

3. Screw the lifting handle from the toolkit onto

the thread.

4. Raise the lifting handle slightly.

00320051004F004C00510048000300280047004C0057004C005200510003

Page 241 of 283

MOBILITYReplacing components

240

5.Squeeze the securing spring.

6. The space-saver spare tire is released and

must be held by the lifting handle.

7. Lower the space-saver spare tire with the

lifting handle.

8. Unscrew the lifting handle.

9. Pull the space-saver spare tire underneath

the vehicle out toward the rear.

10. Position the space-save r spare tire with the

valve facing upward.

11. Unscrew the valve extension from the valve

of the space-saver spare tire.

12. Unscrew the dust cap from the extension

and place it on the valve of the space-saver

spare tire.

Due to its different dimensions, the dam-

aged wheel cannot be placed in the recess

for the space-saver spare tire.

speed of 50 mph/80 km/h. Changes may

occur in vehicle handling such as lower track sta-

bility during braking, longer braking distances

and changes in self-steering properties when

close to the handling limit. These properties are

more noticeable with winter tires. <

Only one space-saver spare tire may be

mounted at one time. Mount a wheel and

tire of the original size as soon as possible, to

avoid any safety risks. <

Check the tire inflation pressure at the

earliest opportunity and correct it if

necessary. Replace the defe ctive tire as soon as

possible and have the ne w wheel/tire assembly

balanced. <

Preparing for a tire change

Observe the safety precautions regarding

flat tires on page 237.<

Additional safety measures when chang-

ing tires:

Only change the tire wh en parked on a surface

that is level, firm and not slippery.

The vehicle or the jack could slip sideways on

soft or slippery support surfaces, such as snow,

ice, flagstones, etc.

Do not use a wooden block or similar object as a

support base for the jack, as this would prevent

it from extending to its full support height and

reduce its load-carrying capacity.

Do not lie under the vehicle or start the engine

when the vehicle is supported by the jack; other-

wise, there is a risk of fatal injury. <

1. Place the foldable chock behind the front

wheel on the other side of the vehicle or in

front of the wheel if the vehicle is on an

incline. If the wheel is changed on a surface

with a more severe sl ope, take additional

precautions to secure the vehicle from

rolling.

2. Uncover the lug bolts if necessary.

3. Loosen the lug bolts by a half turn.

00320051004F004C00510048000300280047004C0057004C005200510003

Page 242 of 283

Replacing componentsMOBILITY

241

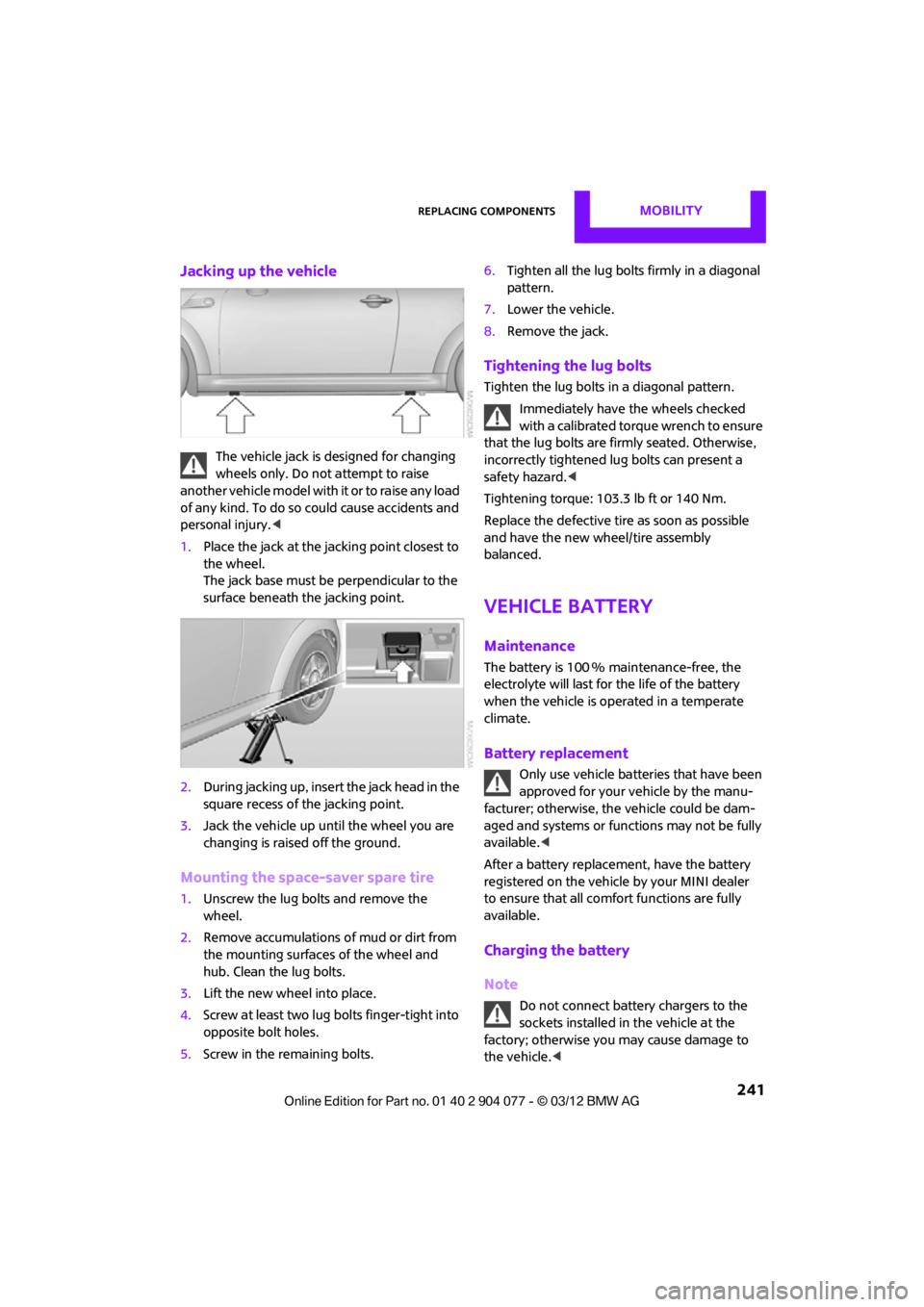

Jacking up the vehicle

The vehicle jack is designed for changing

wheels only. Do not attempt to raise

another vehicle model with it or to raise any load

of any kind. To do so could cause accidents and

personal injury. <

1. Place the jack at the jacking point closest to

the wheel.

The jack base must be perpendicular to the

surface beneath the jacking point.

2. During jacking up, insert the jack head in the

square recess of the jacking point.

3. Jack the vehicle up until the wheel you are

changing is raised off the ground.

Mounting the space-saver spare tire

1.Unscrew the lug bolts and remove the

wheel.

2. Remove accumulations of mud or dirt from

the mounting surfaces of the wheel and

hub. Clean the lug bolts.

3. Lift the new wheel into place.

4. Screw at least two lug bolts finger-tight into

opposite bolt holes.

5. Screw in the remaining bolts. 6.

Tighten all the lug bolts firmly in a diagonal

pattern.

7. Lower the vehicle.

8. Remove the jack.

Tightening the lug bolts

Tighten the lug bolts in a diagonal pattern.

Immediately have the wheels checked

with a calibrated torque wrench to ensure

that the lug bolts are firmly seated. Otherwise,

incorrectly tightened lug bolts can present a

safety hazard. <

Tightening torque: 103.3 lb ft or 140 Nm.

Replace the defective tire as soon as possible

and have the new wheel/tire assembly

balanced.

Vehicle battery

Maintenance

The battery is 100 % maintenance-free, the

electrolyte will last for the life of the battery

when the vehicle is operated in a temperate

climate.

Battery replacement

Only use vehicle batteries that have been

approved for your vehicle by the manu-

facturer; otherwise, the vehicle could be dam-

aged and systems or func tions may not be fully

available. <

After a battery replacement, have the battery

registered on the vehicle by your MINI dealer

to ensure that all comfort functions are fully

available.

Charging the battery

Note

Do not connect battery chargers to the

sockets installed in the vehicle at the

factory; otherwise you may cause damage to

the vehicle.<

00320051004F004C00510048000300280047004C0057004C005200510003

Page 246 of 283

Giving and receiving assistanceMOBILITY

245

Using a tow fitting

The screw-in tow fitting must always be carried

in the car. It can be screwed in at the front or

rear of the MINI.

It is stored in the toolkit in the cargo area

underneath the cover on the right-hand side,

page231.

Use only the tow fitting provided with the

vehicle and screw it all the way in. Use the

tow fitting for towing on paved roads only. Avoid

lateral loading of the tow fitting, e.g. do not lift

the vehicle by the tow fitting. Otherwise, the tow

fitting and the vehicle could be damaged. <

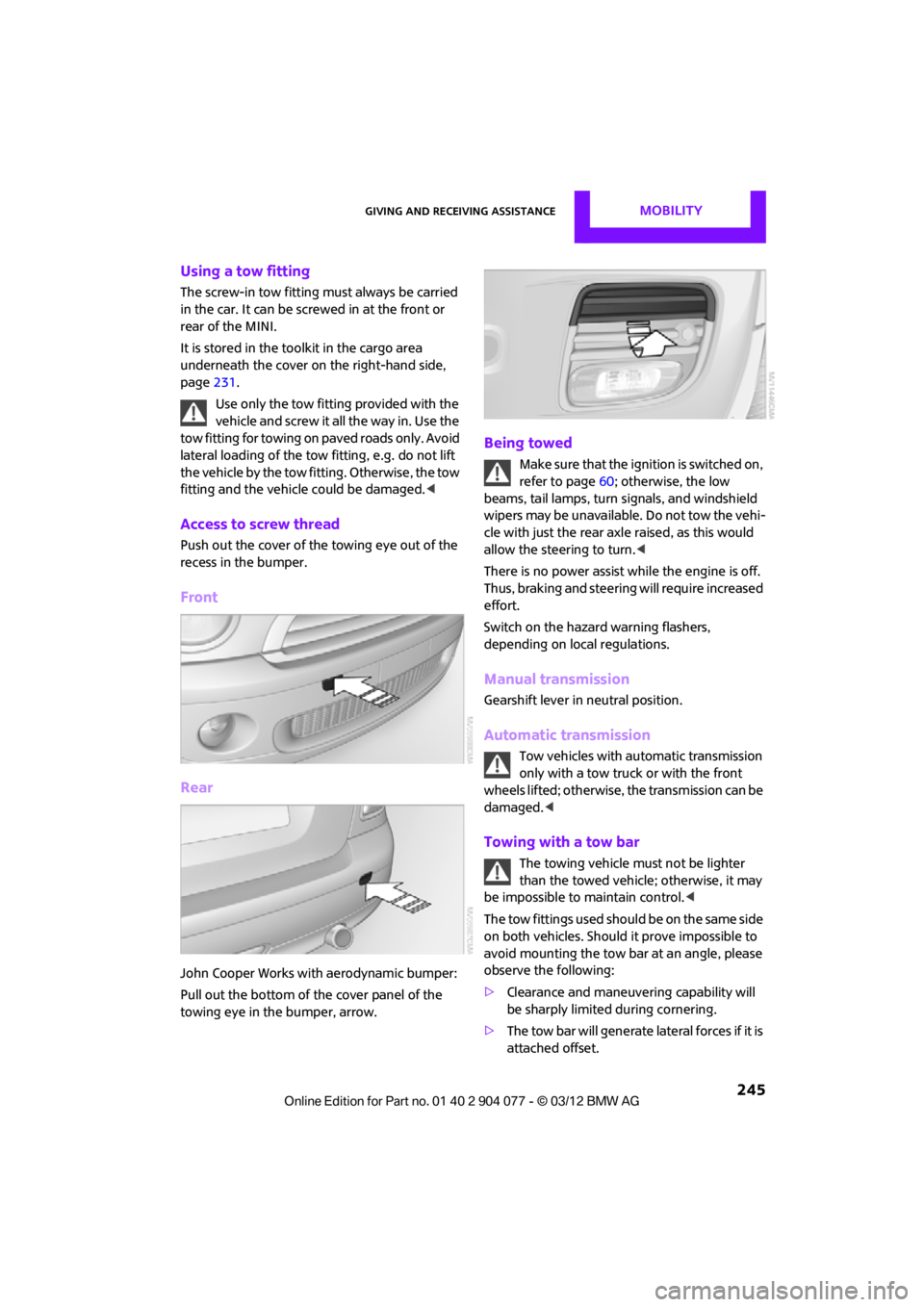

Access to screw thread

Push out the cover of the towing eye out of the

recess in the bumper.

Front

Rear

John Cooper Works with aerodynamic bumper:

Pull out the bottom of the cover panel of the

towing eye in the bumper, arrow.

Being towed

Make sure that the ignition is switched on,

refer to page60; otherwise, the low

beams, tail lamps, turn signals, and windshield

wipers may be unavailable. Do not tow the vehi-

cle with just the rear ax le raised, as this would

allow the steering to turn. <

There is no power assist while the engine is off.

Thus, braking and steering will require increased

effort.

Switch on the hazard warning flashers,

depending on local regulations.

Manual transmission

Gearshift lever in neutral position.

Automatic transmission

Tow vehicles with automatic transmission

only with a tow truck or with the front

wheels lifted; otherwise, the transmission can be

damaged. <

Towing with a tow bar

The towing vehicle must not be lighter

than the towed vehicle; otherwise, it may

be impossible to maintain control. <

The tow fittings used should be on the same side

on both vehicles. Should it prove impossible to

avoid mounting the tow bar at an angle, please

observe the following:

> Clearance and maneuvering capability will

be sharply limited during cornering.

> The tow bar will generate lateral forces if it is

attached offset.

00320051004F004C00510048000300280047004C0057004C005200510003

Page 253 of 283

REFERENCETechnical data

252

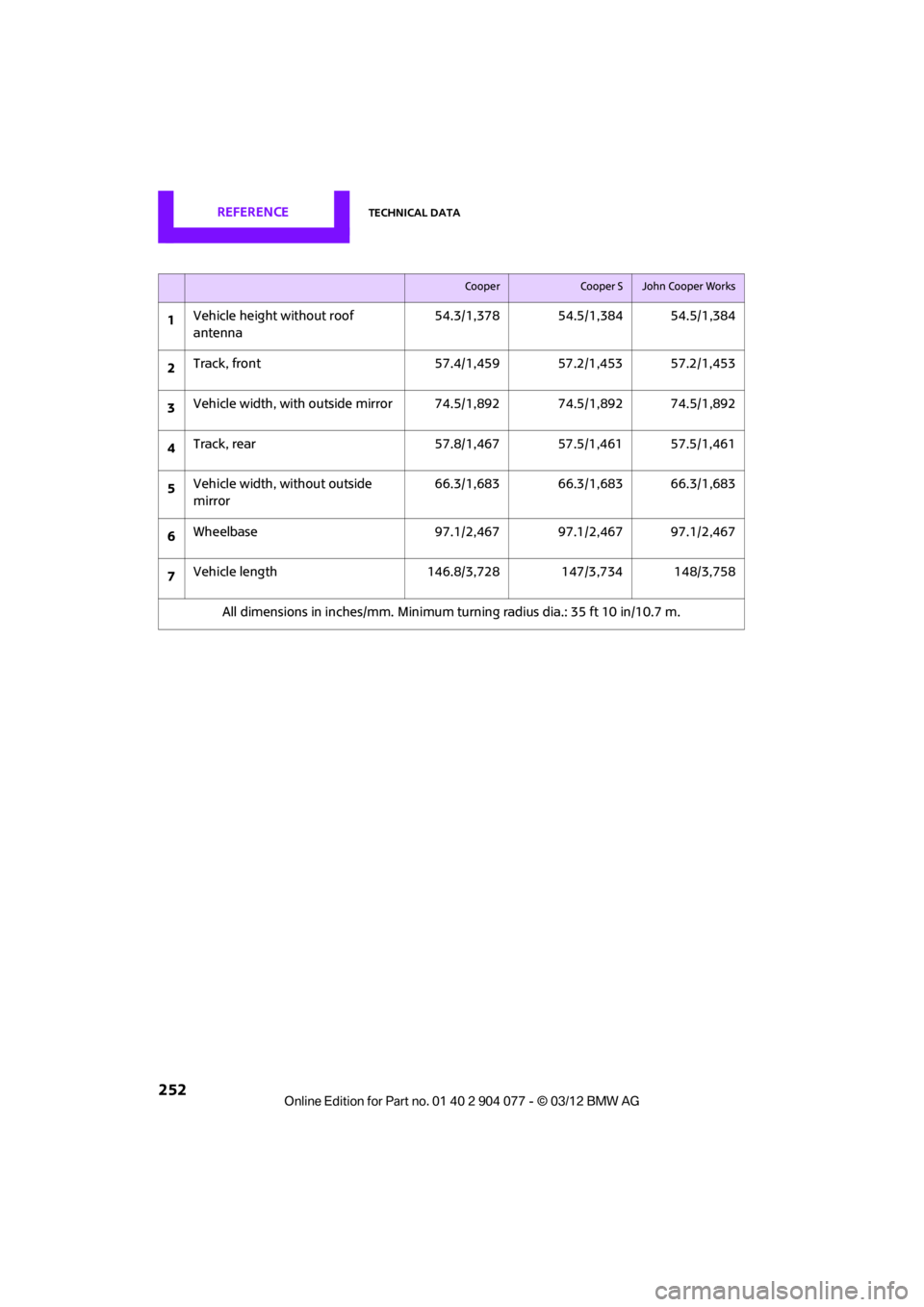

CooperCooper SJohn Cooper Works

1Vehicle height without roof

antenna 54.3/1,378 54.5/1,384 54.5/1,384

2 Track, front 57.4/1,459 57.2/1,453 57.2/1,453

3 Vehicle width, with outside

mirror 74.5/1,892 74.5/1,892 74.5/1,892

4 Track, rear

57.8/1,467 57.5/1,461 57.5/1,461

5 Vehicle width, without outside

mirror 66.3/1,683 66.3/1,683 66.3/1,683

6 Wheelbase

97.1/2,467 97.1/2,467 97.1/2,467

7 Vehicle length

146.8/3,728 147/3,734 148/3,758

All dimensions in inches/mm. Minimum turning radius dia.: 35 ft 10 in/10.7 m.

00320051004F004C00510048000300280047004C0057004C005200510003