engine MINI Hardtop 2 Door 2004 Owner's Guide

[x] Cancel search | Manufacturer: MINI, Model Year: 2004, Model line: Hardtop 2 Door, Model: MINI Hardtop 2 Door 2004Pages: 152, PDF Size: 1.41 MB

Page 62 of 152

60

DYNAMIC STABILITY CONTROL (DSC)

*

The concept

This system optimizes driving stability and

traction, especially when just starting off,

when accelerating or when cornering. It

also maintains driving stability even in criti-

cal driving situations.

DSC recognizes unstable vehicle conditions,

such as understeering or oversteering, and,

as far as is possible within the laws of phys-

ics, helps keep the vehicle on a steady

course by reducing the rpms and by brake

applications to the individual wheels.

The DSC is operational every time you start

the engine. It contains the following func-

tions:

>All Season traction Control (ASC)

>Antilock Brake System (ABS)

>Cornering Brake Control (CBC)

>Electronic Brake Force Distribution (EBD).

The laws of physics cannot be

repealed, even with DSC. An appropri-

ate driving style always remains the respon-

sibility of the driver. Avoid using the addi-

tional safety margin provided by the system

as an excuse for taking unnecessary risks.

Do not make any modifications to the DSC

system. Allow only authorized technicians to

perform service procedures on the DSC.<

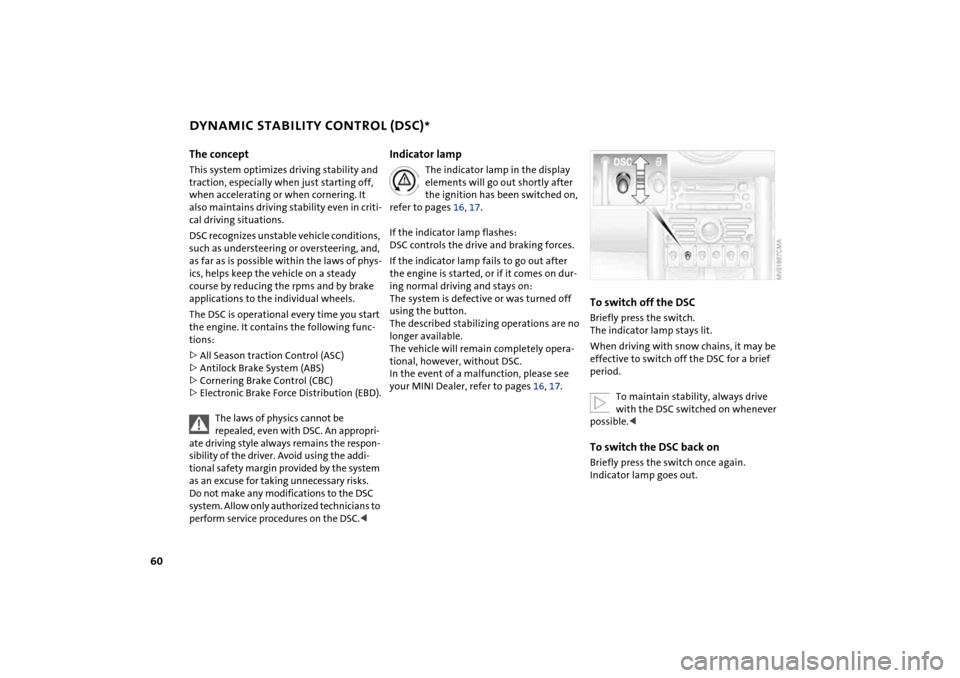

Indicator lamp

The indicator lamp in the display

elements will go out shortly after

the ignition has been switched on,

refer to pages 16, 17.

If the indicator lamp flashes:

DSC controls the drive and braking forces.

If the indicator lamp fails to go out after

the engine is started, or if it comes on dur-

ing normal driving and stays on:

The system is defective or was turned off

using the button.

The described stabilizing operations are no

longer available.

The vehicle will remain completely opera-

tional, however, without DSC.

In the event of a malfunction, please see

your MINI Dealer, refer to pages 16, 17.

To switch off the DSCBriefly press the switch.

The indicator lamp stays lit.

When driving with snow chains, it may be

effective to switch off the DSC for a brief

period.

To maintain stability, always drive

with the DSC switched on whenever

possible.

Page 64 of 152

62

FLAT TIRE MONITOR The conceptAs you drive, the Flat Tire Monitor keeps

track of the tire inflation pressure in all four

tires. The system alerts you when there is a

substantial pressure loss in one of the tires

relative to another.

The tire inflation pressures are monitored

based on the speeds of the four wheels in

relation to one another. A flat tire is

detected as the result of differences in cer-

tain speed ratios, and a warning is gener-

ated.System requirementsSo that the system can 'familiarize' itself

with the correct inflation pressure, please

do the following:

1. Check the tire inflation pressure in all

tires

2. Compare them with the inflation pres-

sure table, refer to page 88, and adjust

the pressures if necessary

3. Initializing the system.

System limitations

The Flat Tire Monitor cannot alert you

to severe and sudden tire damage

caused by external factors, nor does it

detect the gradual and minor loss of pres-

sure in all four tires.<

On the other hand, the following situations

could lead to a delayed detection of pres-

sure loss or to the system not functioning:

>Driving on snow-covered or slippery

roads

>Performance-oriented driving: slip at the

drive wheels, high rates of lateral accel-

eration

>When driving with snow chains, false

warnings and undetected pressure loss

may occur

>When driving with a space-saver spare

tire, the Flat Tire Monitor cannot func-

tion.

Initializing the system

The system must be re-initialized

immediately after changing a tire

and wheel, or after correcting the pressure

in any tire. This requires a bit of driving.<

1. Before a journey, start the engine, but do

not start driving

2. Press the button long enough for the

indicator lamp in the display elements to

light up for a few seconds

3. Drive off.

It takes a few minutes before the Flat Tire

Monitor can detect a flat tire and issue an

alert.

Do not initialize the system if you are

driving with snow chains or a space-

saver spare tire.<

Page 84 of 152

82

BREAK-IN PROCEDURES To ensure that your vehicle provides maxi-

mum economy throughout a long service

life, we request that you comply with the

following information: EngineUp to 1,250 miles / 2,000 km:

>Drive at various vehicle and engine

speeds

>Do not exceed an engine speed of

4,500 rpm or a vehicle speed of 95 mph /

150 km/h.

>Absolutely avoid using the full-throttle

or kickdown position for the accelerator.

Up to 1,250 miles / 2,000 km:

Engine and road speeds can be gradually

increased.

You should also comply with these break-in

procedures if the engine has to be replaced

at a later point.

TiresDue to technical factors associated with

their manufacture, tires do not achieve

their full traction potential until after an

initial break-in period. Therefore drive care-

fully during the first 200 miles / 300 km.Brake systemApprox. 300 miles / 500 km must be driven

before the brake pads and rotors achieve

the optimum pad-surface and wear pat-

terns required for trouble-free operation

and an extended service life.ClutchRoughly 300 miles / 500 km must be driven

before the clutch starts to operate at opti-

mum efficiency. Remember to engage the

clutch carefully during this initial period.

Page 85 of 152

83

OVERVIEW REPAIRSOPERATIONCONTROLS DATA INDEX

GENERAL DRIVING NOTESParking the vehicle Condensation forms in the air conditioner

system during operation, and then exits

under the vehicle. Traces of condensed

water on the ground are therefore normal.Brakes

Do not rest your foot on the brake

pedal while driving. Even light but

consistent pedal pressure can lead to high

temperatures, brake wear and possibly

even brake failure.<

Hydroplaning

When driving on wet or slushy roads,

reduce road speed. If you do not, a

wedge of water can form between tires and

road surface. This phenomenon is charac-

terized by a partial or complete loss of con-

tact between the tires and the road surface.

The ultimate results are loss of steering and

braking control.<

Driving through water

Do not drive through water on the

road if it is deeper than 1 ft / 30 cm,

and then only at walking speed at the

most. Otherwise, the vehicle's engine, the

electrical systems and the transmission

may be damaged.<

Clothes hooks

When suspending clothing from the

hooks, ensure that they will not

obstruct the driver's vision. Do not hang

heavy objects on the hooks. If you do so,

they could cause personal injury during

braking or evasive maneuvers.<

High temperatures

High temperatures occur in any vehi-

cle equipped with a catalytic con-

verter. Do not remove the heat protection

plates fitted in the area of the exhaust sys-

tem and do not apply body-cavity pro-

tectant to this area. When driving, standing

at idle, and parking the vehicle, take care to

avoid contact between the hot exhaust sys-

tem and flammable materials, e.g. hay,

grass, leaves, etc. Such contact could lead

to a fire resulting in serious personal injury

and property damage.<

Page 86 of 152

84

REFUELING

Always switch off the engine before

refueling. If you do not, fuel cannot

be filled into the tank and the SERVICE

ENGINE SOON lamp may come on.<

1. Open the fuel filler door

2. Turn the gas cap counterclockwise

3. Put the gas cap in the bracket attached

to the fuel filler door.

Always observe all applicable precau-

tions and regulations when handling

fuels. Never carry spare fuel containers in

your vehicle. Whether empty or full, these

containers can leak, cause an explosion,

and lead to fire in the event of a collision.<

Unlocking manually In the event of an electrical malfunction,

the gas cap can be unlocked manually.

1. Remove the side trim panel on the left-

hand side of the cargo area.

Remove the first aid pouch

2. Pull the white lever toward the rear.

The central locking system releases the

gas cap

3. Open the fuel filler door.

Simple and environmentally friendly

Always observe all safety precautions

posted at the service station when

handling fuel.<

When refueling, insert the filler nozzle

completely into the filler pipe. Pulling the

nozzle out of the pipe during refueling:

>Results in premature pump shutoff

>Will reduce the effect of the fuel vapor

recovery system on the pump.

As long as the filler nozzle is used properly,

the fuel tank is full whenever the nozzle

shuts off the first time.

Page 87 of 152

85

OVERVIEW REPAIRSOPERATIONCONTROLS DATA INDEX

REFUELING FUEL SPECIFICATIONS Close the tank1. Put on gas cap

2. Turn gas cap clockwise until it clicks

3. Close fuel filler door.

Fuel tank capacity:

Approx. 13.2 gallons / 50 liters, of which

approx. 2.1 gallons / 8 liters are reserve

capacity.

Close the gas cap carefully after refu-

elling until a click is heard.

While closing, be sure not to squeeze the

strap which is fastened to the cap.

US models only:

A loose or missing cap will activate the

message CHECK GAS CAP in the Check Con-

trol

* or the Check Gas Cap lamp

*.<

Do not drive until the fuel tank is

totally empty. Otherwise engine

operations are not guaranteed and damage

could occur.<

The engine uses lead-free gasoline only.

Required fuel:

>Premium Unleaded Gasoline,

min. 91 AKI.

AKI = Anti Knock Index.

Do not use leaded fuels. The use of

leaded fuels will cause permanent

damage to the emissions-control system's

oxygen sensor and the catalytic con-

verter.<

Page 88 of 152

86

BRAKE SYSTEMBrake fluid levelIf the brake fluid level is too low and brake

pedal travel has become longer, there may

be a defect in one of the brake system's

hydraulic circuits.

Proceed to the nearest MINI Dealer.

Higher brake application pressure

may be necessary under these conditions,

there may be a slight pull to one side, and

brake pedal travel may be longer. Please

remember to adapt your driving style

accordingly.

vehicle is not used at all, and in operating

conditions where brake applications are

less frequent, there is an increased ten-

dency for corrosion of the brake rotors and

accumulation of contamination on the

brake pads. This occurs because the mini-

mal pressure that must be exerted by the

pads to clean the rotors by brake applica-

tions is not reached.

Corrosion on brake rotors is signaled by a

running or pulsation during braking; even

extended subsequent braking will not cure

this phenomenon.

It is a good idea to periodically dry the

brakes with a gentle application when driv-

ing in rain and on wet roads. Monitor traffic

conditions to ensure that this maneuver

does not endanger other road users. The

resulting heat dries the brake rotor and the

brake pads. Then if braking effect is

needed, it is immediately available.

Extended or steep mountain descents

should be driven in the gear or in the driv-

ing position in which only minimal periodic

brake application is required. This helps

avoid placing excessive loads on the brake

system. Stay within the allowable speed

range, refer to page 54.

Do not coast with the clutch pressed

or with the transmission or selector

lever in Neutral. Do not coast with the

engine switched off. The engine provides

no braking effect when the transmission is

in Neutral, and there is no power-assist for

braking when the engine is switched off.<

Brake padsBrake pad sensors in the left brake pads of

the front axle and in the right brake pads of

the rear axle monitor the brake pad condi-

tion. When the brake pads reach the wear

limit, the brake wear warning lights up,

refer to page 16.

For your own safety: use brake pads

which the manufacturer of your MINI

has approved for your particular vehicle

model. The manufacturer of your MINI can-

not evaluate non-approved brake pads to

determine if they are suitable for use, and

therefore cannot ensure the operating

safety of the vehicle in the event of their

use.<

Page 97 of 152

95

OVERVIEW REPAIRSOPERATIONCONTROLS DATA INDEX

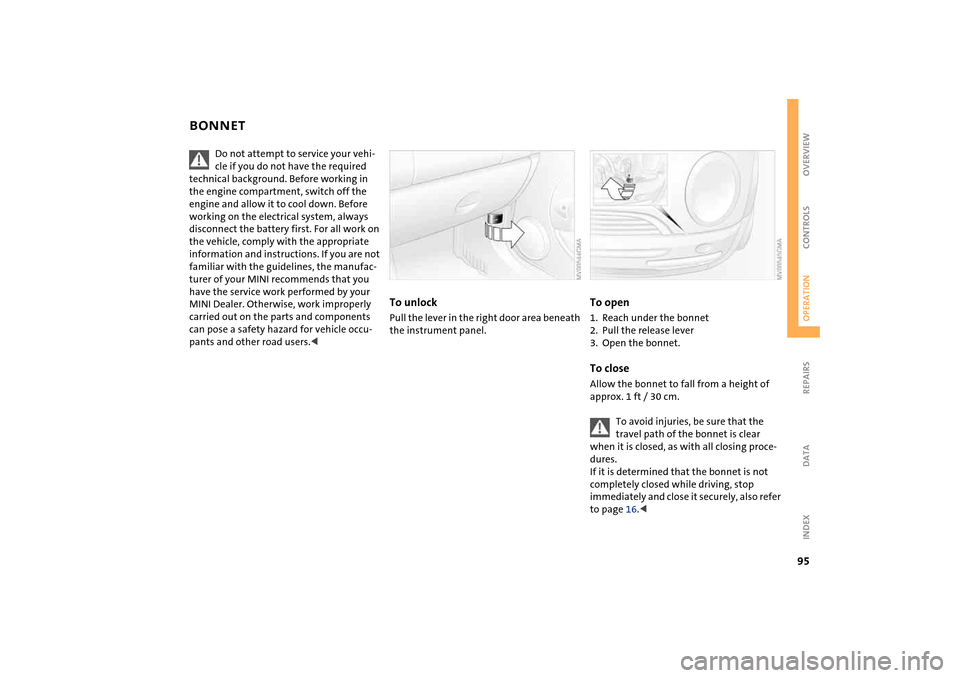

BONNET

Do not attempt to service your vehi-

cle if you do not have the required

technical background. Before working in

the engine compartment, switch off the

engine and allow it to cool down. Before

working on the electrical system, always

disconnect the battery first. For all work on

the vehicle, comply with the appropriate

information and instructions. If you are not

familiar with the guidelines, the manufac-

turer of your MINI recommends that you

have the service work performed by your

MINI Dealer. Otherwise, work improperly

carried out on the parts and components

can pose a safety hazard for vehicle occu-

pants and other road users.<

To unlockPull the lever in the right door area beneath

the instrument panel.

To open1. Reach under the bonnet

2. Pull the release lever

3. Open the bonnet.To closeAllow the bonnet to fall from a height of

approx. 1 ft / 30 cm.

To avoid injuries, be sure that the

travel path of the bonnet is clear

when it is closed, as with all closing proce-

dures.

If it is determined that the bonnet is not

completely closed while driving, stop

immediately and close it securely, also refer

to page 16.<

Page 98 of 152

96

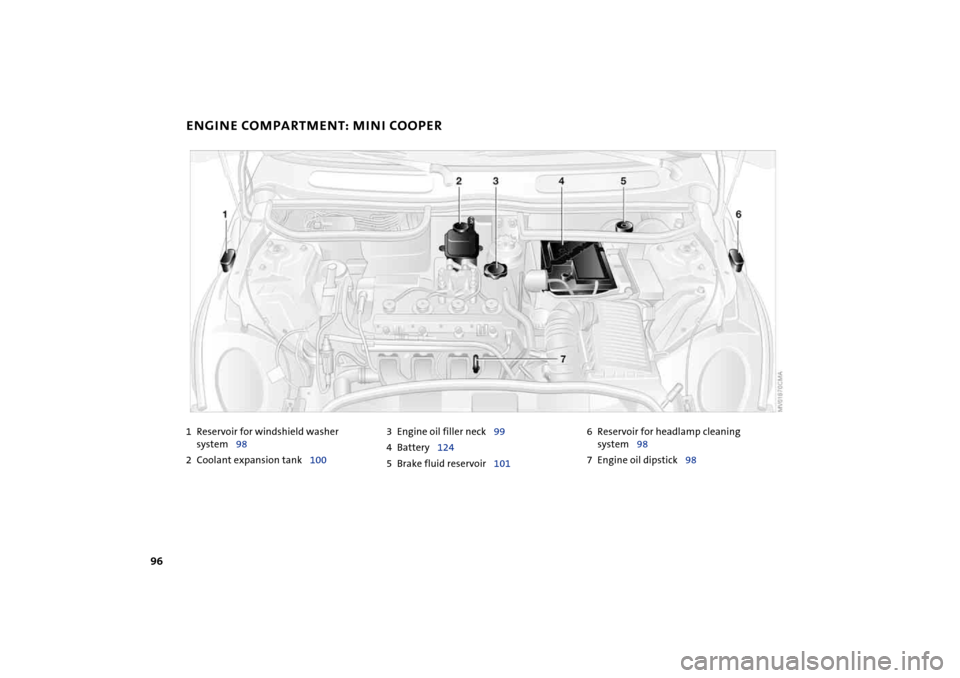

ENGINE COMPARTMENT: MINI COOPER1Reservoir for windshield washer

system98

2Coolant expansion tank1003Engine oil filler neck99

4Battery124

5Brake fluid reservoir1016Reservoir for headlamp cleaning

system98

7Engine oil dipstick98

Page 99 of 152

97

OVERVIEW REPAIRSOPERATIONCONTROLS DATA INDEX

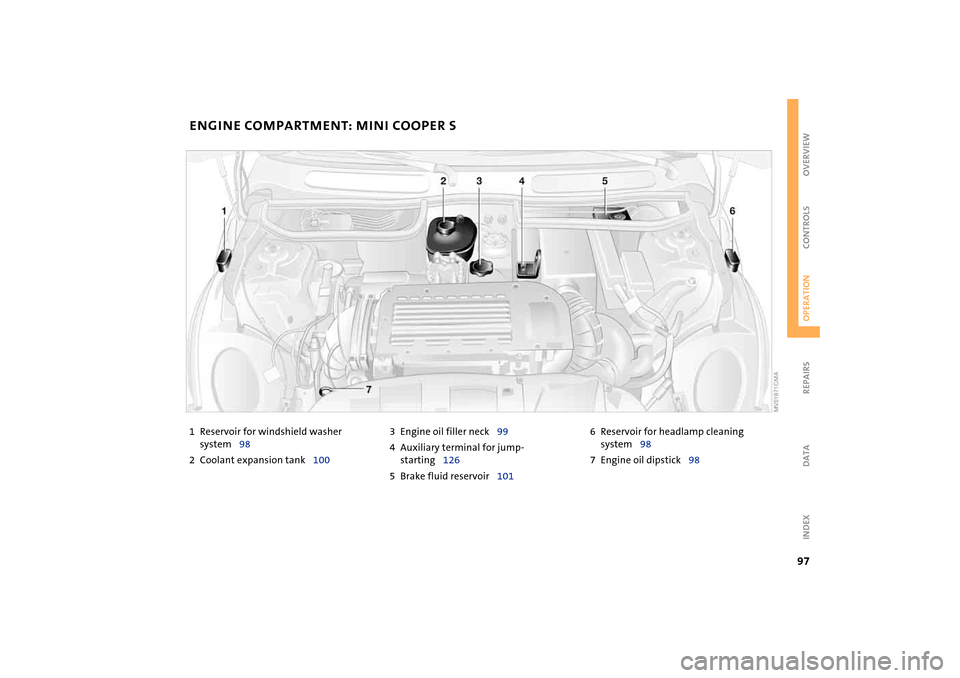

ENGINE COMPARTMENT: MINI COOPER S1Reservoir for windshield washer

system98

2Coolant expansion tank1003Engine oil filler neck99

4Auxiliary terminal for jump-

starting126

5Brake fluid reservoir1016Reservoir for headlamp cleaning

system98

7Engine oil dipstick98