engine MITSUBISHI 3000GT 1991 Service Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1991, Model line: 3000GT, Model: MITSUBISHI 3000GT 1991Pages: 1146, PDF Size: 76.68 MB

Page 196 of 1146

13-90FUEL SYSTEM - On-vehicle Inspection of MPI Components

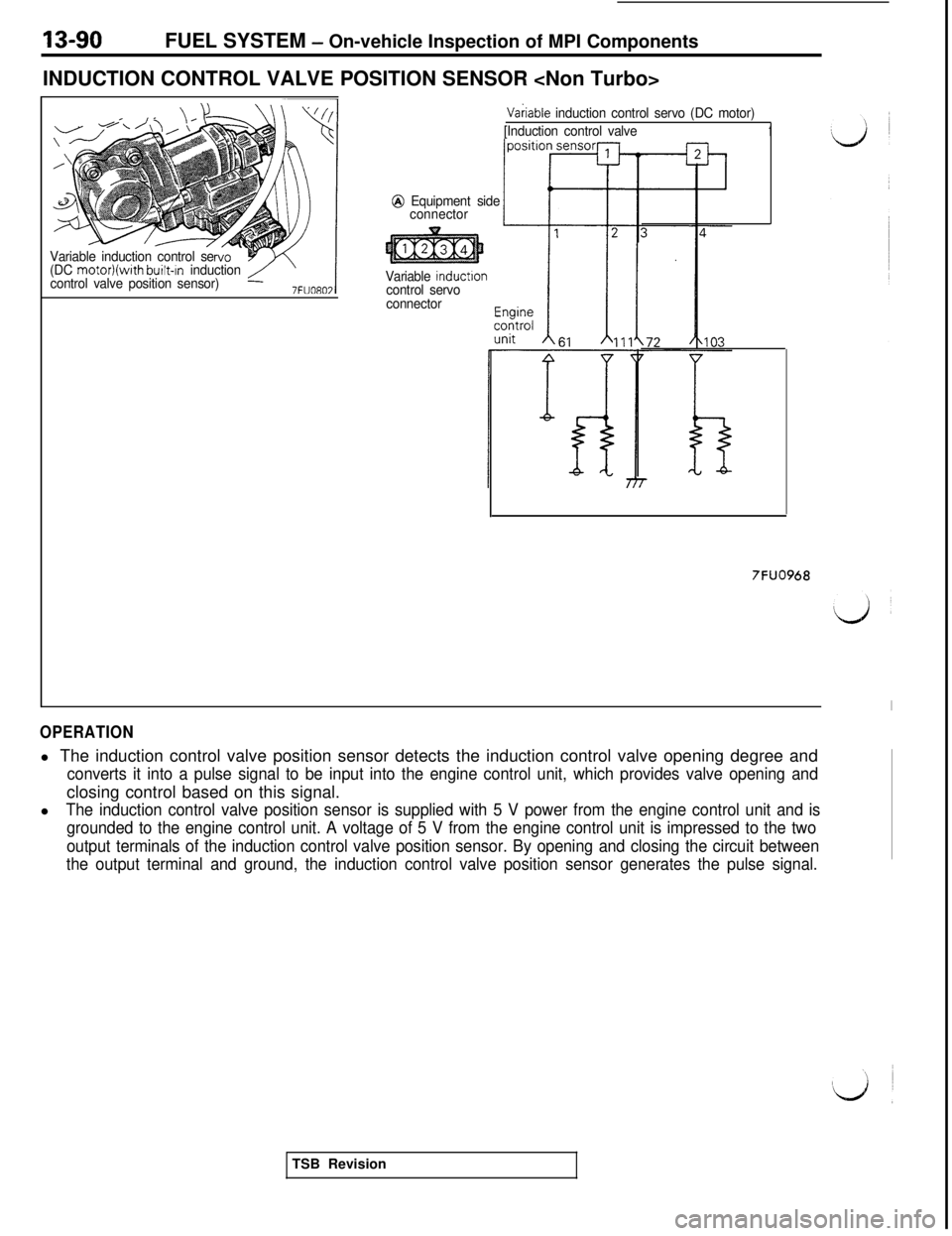

INDUCTION CONTROL VALVE POSITION SENSOR

Variable induction control se

(DC motor)(with built-In induction

control valve position sensor)

Vakiable induction control servo (DC motor)

[Induction control valve

1

@ Equipment side

connector

Variable

inductloncontrol servo

connector

7FUO968

OPERATIONl The induction control valve position sensor detects the induction control valve opening degree and

converts it into a pulse signal to be input into the engine control unit, which provides valve opening andclosing control based on this signal.

l

The induction control valve position sensor is supplied with 5 V power from the engine control unit and is

grounded to the engine control unit. A voltage of 5 V from the engine control unit is impressed to the two

output terminals of the induction control valve position sensor. By opening and closing the circuit between

the output terminal and ground, the induction control valve position sensor generates the pulse signal.TSB Revision

Page 198 of 1146

FUEL SYSTEM - On-vehicle Inspection of MPI Components

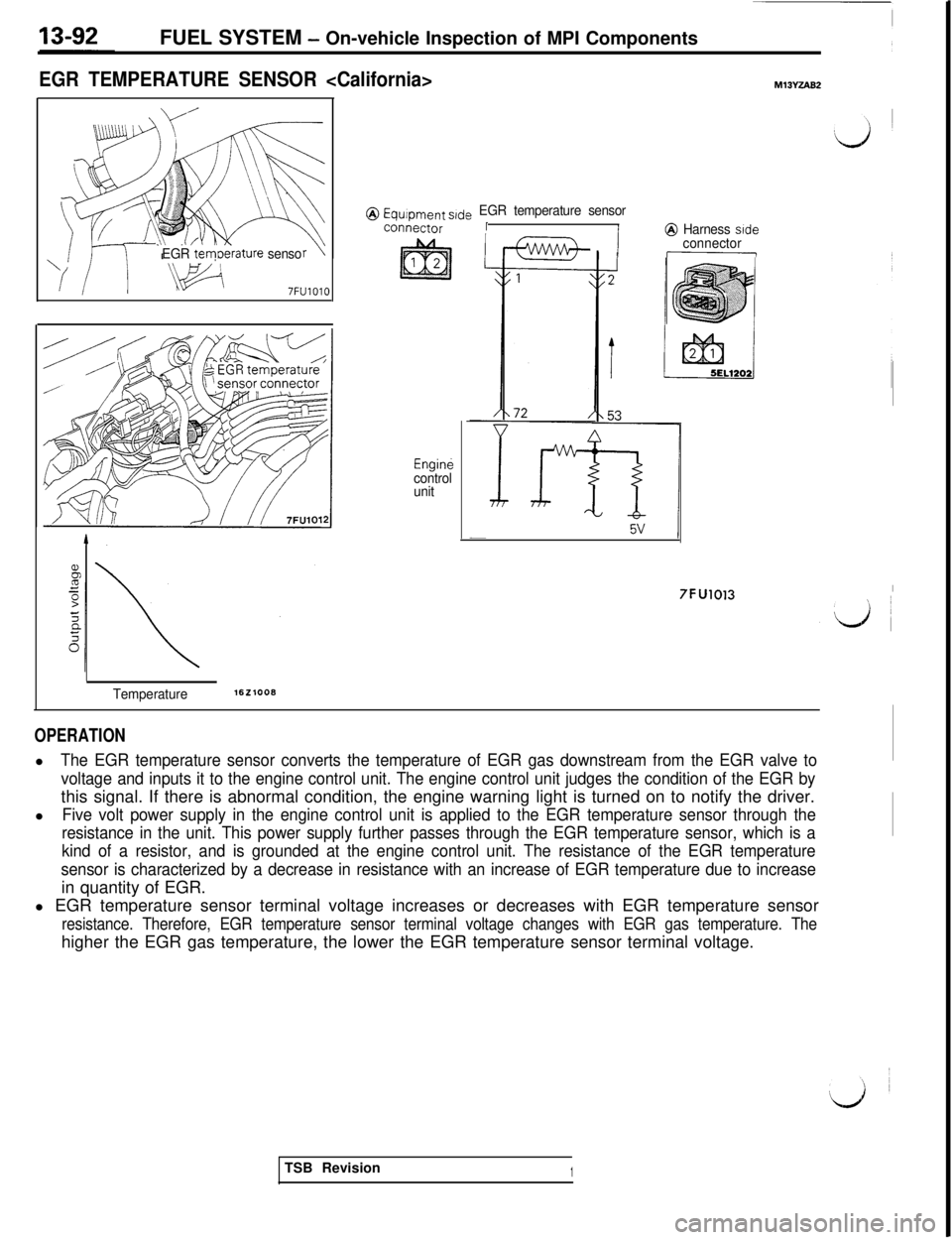

EGR TEMPERATURE SENSOR

EGR tem0erature senso

7FUlOlO

@ Equipment s,de EGR temperature sensor

connectorII@ Harness side

Enginecontrol

unit

I Iconnector

7FU1013I

Temperature1621008

OPERATIONl

The EGR temperature sensor converts the temperature of EGR gas downstream from the EGR valve to

voltage and inputs it to the engine control unit. The engine control unit judges the condition of the EGR bythis signal. If there is abnormal condition, the engine warning light is turned on to notify the driver.

l

Five volt power supply in the engine control unit is applied to the EGR temperature sensor through the

resistance in the unit. This power supply further passes through the EGR temperature sensor, which is a

kind of a resistor, and is grounded at the engine control unit. The resistance of the EGR temperature

sensor is characterized by a decrease in resistance with an increase of EGR temperature due to increasein quantity of EGR.

l EGR temperature sensor terminal voltage increases or decreases with EGR temperature sensor

resistance. Therefore, EGR temperature sensor terminal voltage changes with EGR gas temperature. Thehigher the EGR gas temperature, the lower the EGR temperature sensor terminal voltage.

TSB Revision

1

Page 199 of 1146

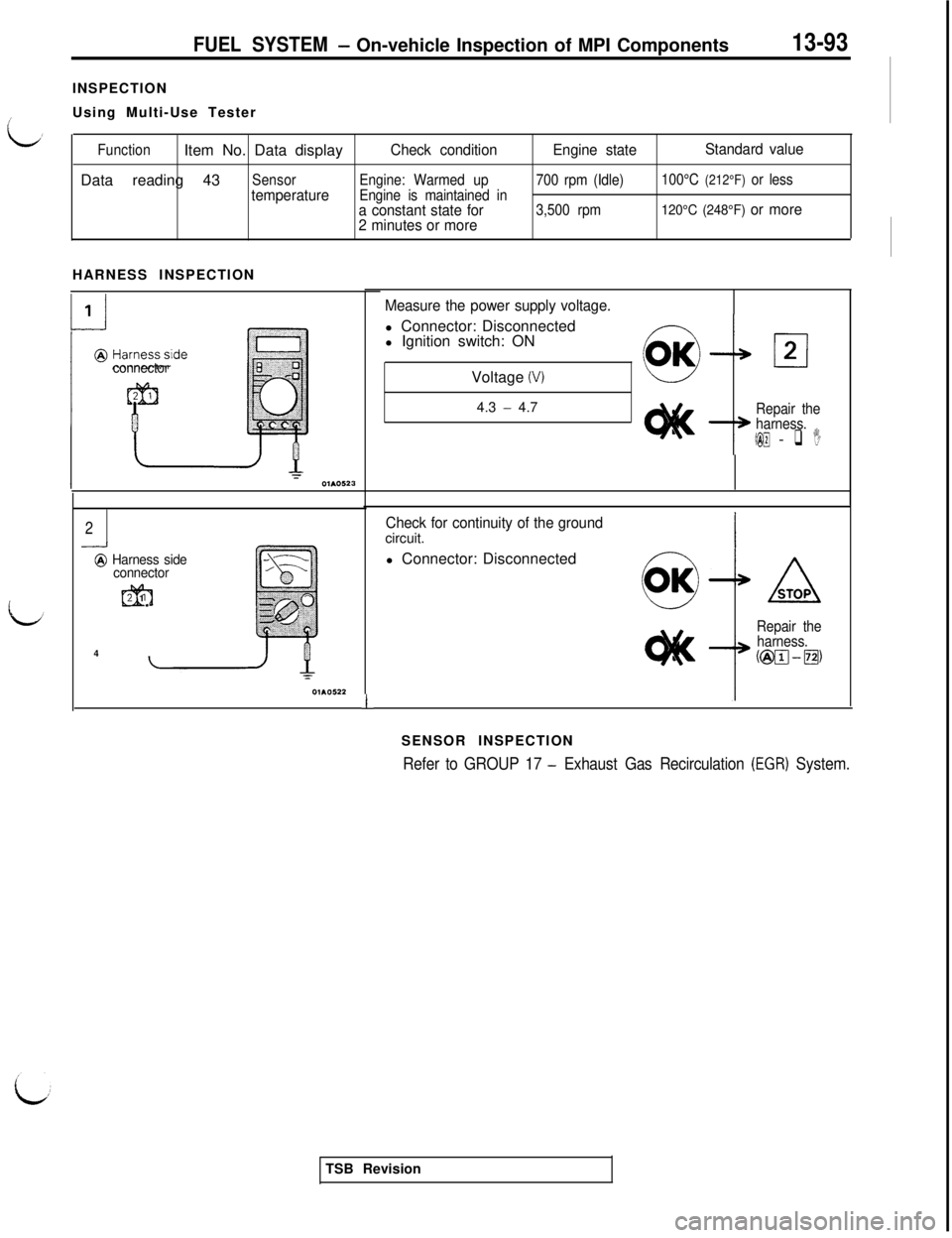

FUEL SYSTEM- On-vehicle Inspection of MPI Components13-93INSPECTION

Using Multi-Use Tester

FunctionItem No. Data displayCheck conditionEngine stateStandard valueData reading 43

SensorEngine: Warmed up700 rpm (Idle)100°C (212°F) or less

temperatureEngine is maintained in-

a constant state for3,500 rpm120°C (248°F) or more

2 minutes or moreHARNESS INSPECTION

connector

2-..-I

@ Harness side

connector

m2 1

4

1

Measure the power supply voltage.l Connector: Disconnected

l Ignition switch: ON

Voltage

(V)4.3

- 4.7Repair the

harness.

(@I@ - q I

Check for continuity of the groundcircuit.

l Connector: Disconnected

I

Repair the

harness.@@J-m,

SENSOR INSPECTION

Refer to GROUP 17 - Exhaust Gas Recirculation (EGR) System.TSB Revision

Page 200 of 1146

FUEL SYSTEM - On-vehicle Inspection of MPI Components

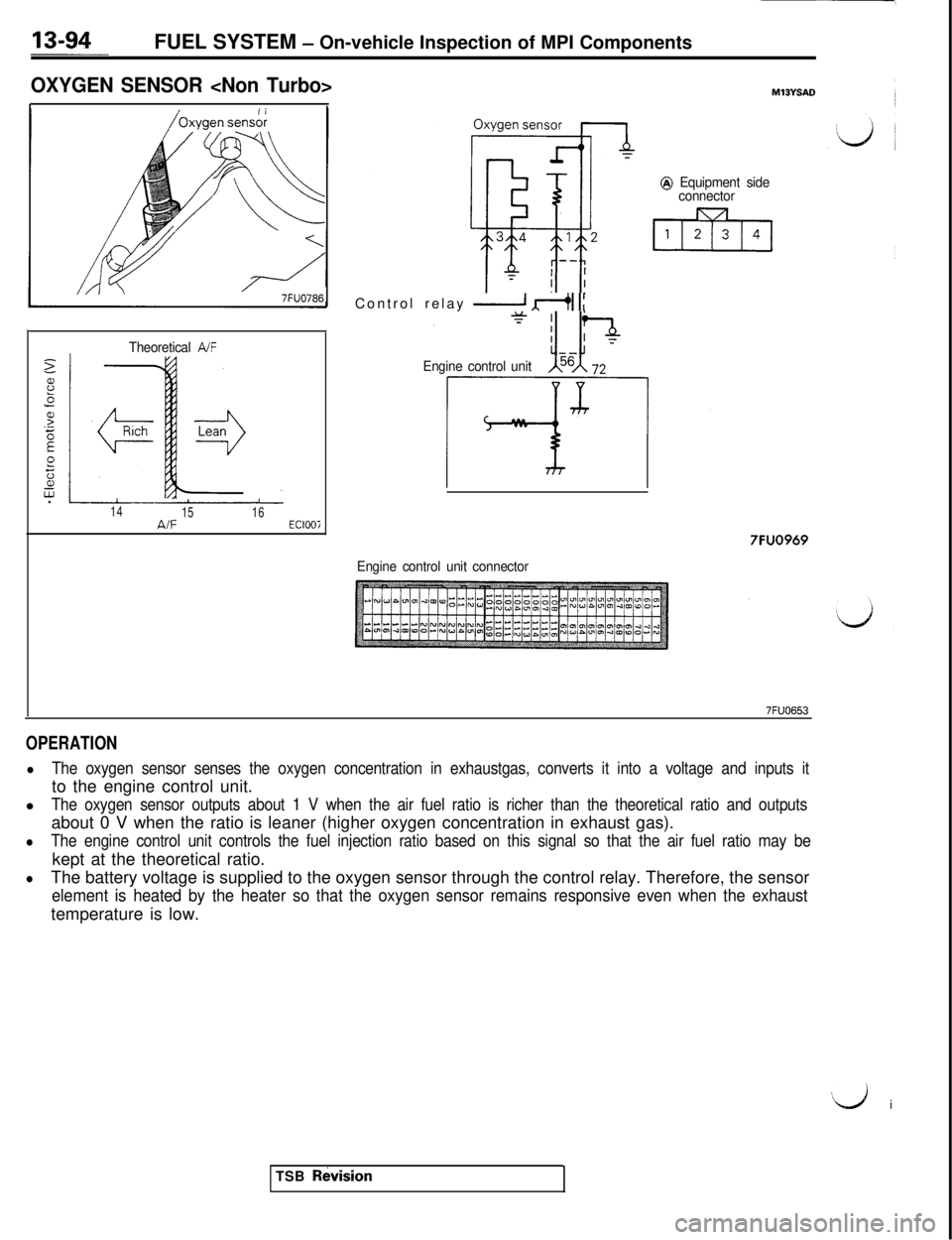

OXYGEN SENSOR

7FUO786

Theoretical A/F

14

1516A/FEClOOiControl relay

2 dI 1:

Engine control unit

@ Equipment side

connector

7FUO969

Engine control unit connector

7FUO653

OPERATION

lThe oxygen sensor senses the oxygen concentration in exhaustgas, converts it into a voltage and inputs itto the engine control unit.

l

The oxygen sensor outputs about 1 V when the air fuel ratio is richer than the theoretical ratio and outputsabout 0 V when the ratio is leaner (higher oxygen concentration in exhaust gas).

lThe engine control unit controls the fuel injection ratio based on this signal so that the air fuel ratio may bekept at the theoretical ratio.

lThe battery voltage is supplied to the oxygen sensor through the control relay. Therefore, the sensor

element is heated by the heater so that the oxygen sensor remains responsive even when the exhausttemperature is low.

‘d i

TSB

RtkisionI

Page 201 of 1146

FUEL SYSTEM - 0

n-vehicle Inspection of MPI Components13-95

TROUBLESHOOTING HINTSHint 1: Poor cleaning of exhaust gas will result if the oxygen sensor fails.

Hint 2:If the oxygen sensor check has resulted normal but the sensor output voltage is out of specification,

troubles of parts related to air fuel ratio control system are suspected.

[Examples]

(1) Faulty injector

(2) Air leaking into the intake manifold through gasket gap, etc.

(3) Faulty air flow sensor, intake air temperature sensor, barometric pressure sensor,’ engine

Data readingcoolant temperature sensor

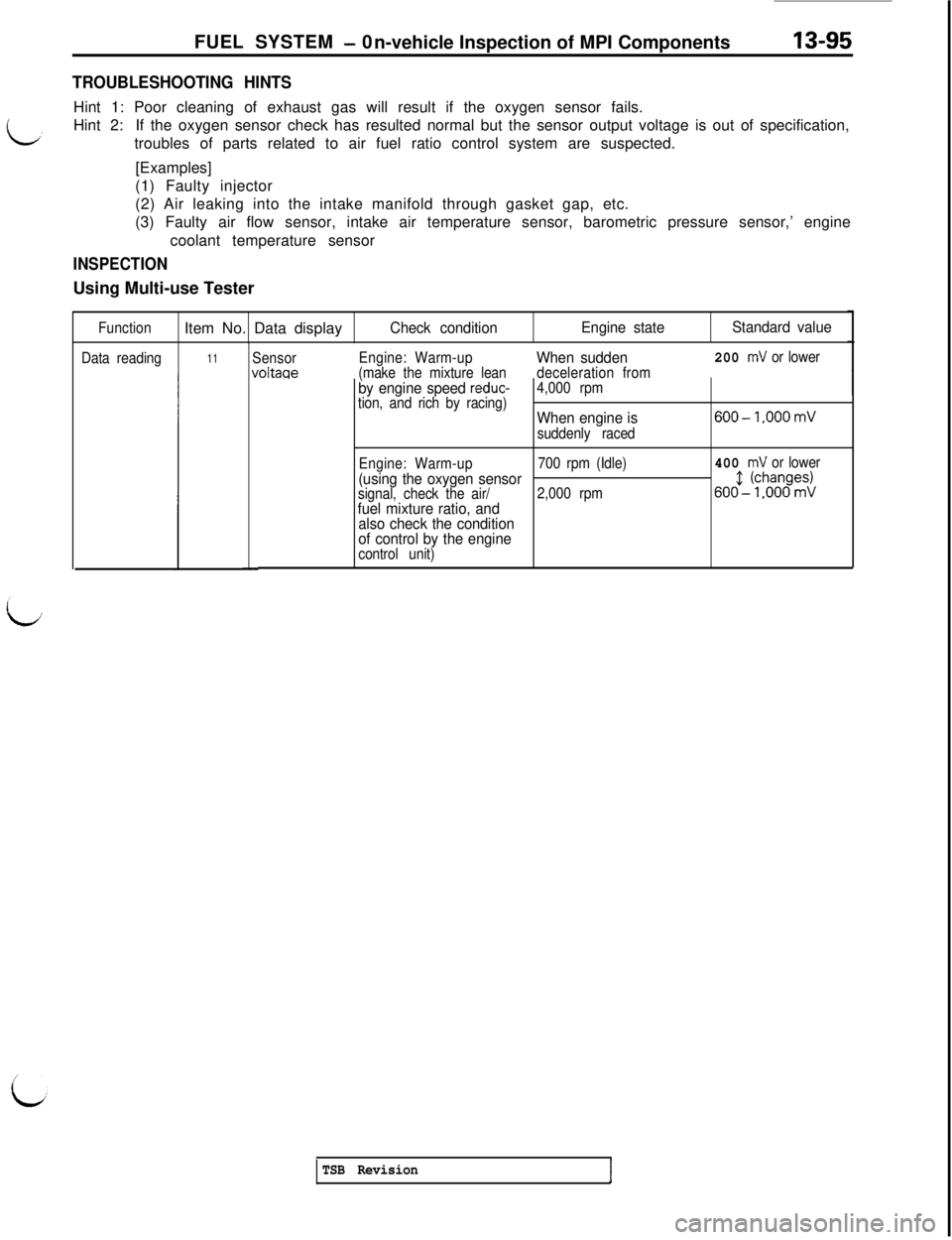

INSPECTIONUsing Multi-use Tester

FunctionItem No. Data displayCheck conditionEngine stateStandard value

11SensorvoltaceEngine: Warm-upWhen sudden200 mV or lower

(make the mixture leandeceleration from

L

by engine speed reduc-4,000 rpm

tion, and rich by racing)

When engine is600-1,000 mV

suddenly raced

Engine: Warm-up700 rpm (Idle)

400 mV or lower

(using the oxygen sensorsignal, check the air/2,000 rpm,,,5-‘$-$-;3

fuel mixture ratio, and

also check the condition

of control by the engine

control unit)

TSB Revision

Page 203 of 1146

FUEL SYSTEM - On-vehicle Inspection of MPI ComDonents13-97

,

7FU1014

7FUlOl5

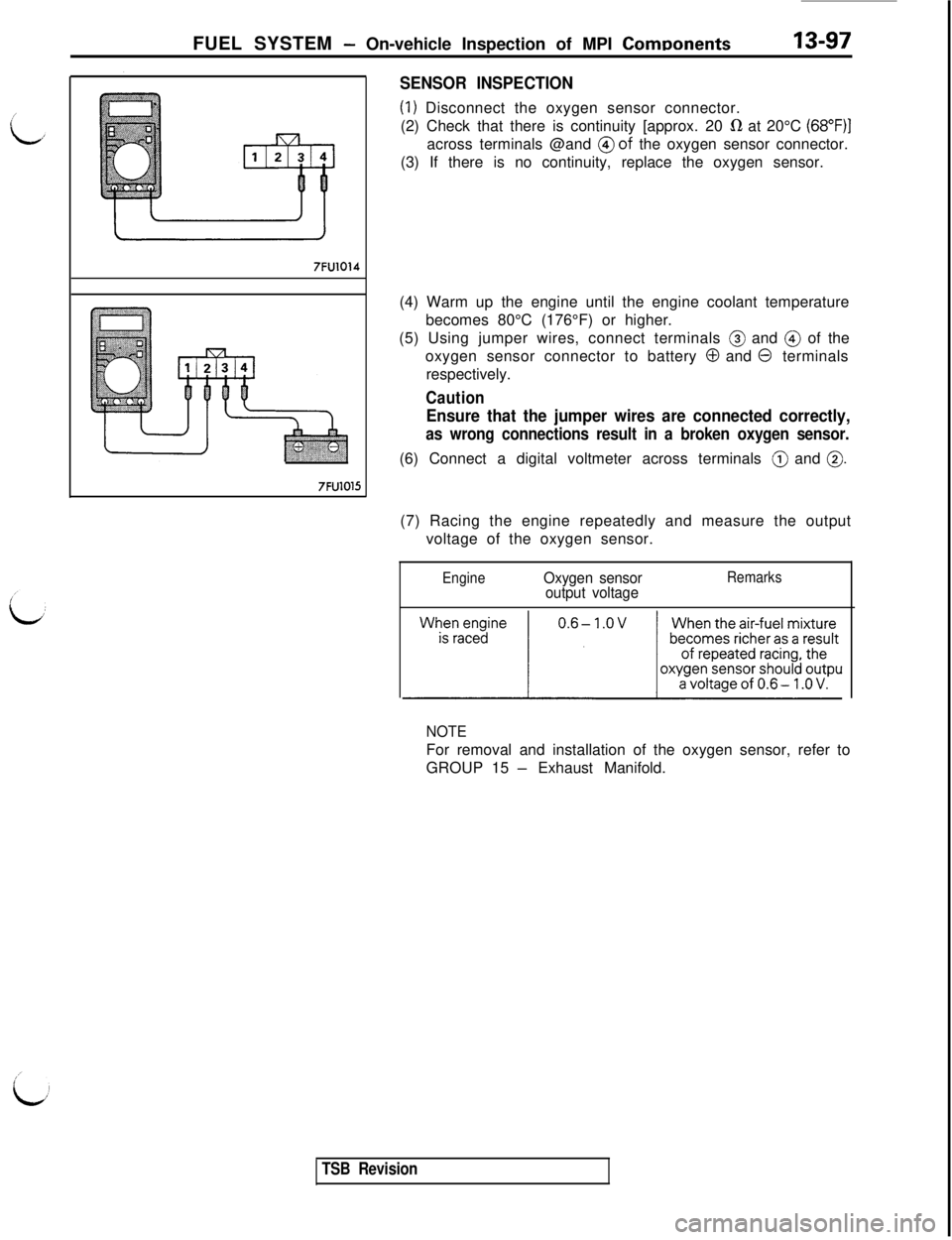

SENSOR INSPECTION

(1) Disconnect the oxygen sensor connector.

(2) Check that there is continuity [approx. 20

IR at 20°C (68”F)jacross terminals @and

@of the oxygen sensor connector.

(3) If there is no continuity, replace the oxygen sensor.

(4) Warm up the engine until the engine coolant temperature

becomes 80°C (176°F) or higher.

(5) Using jumper wires, connect terminals @ and @ of the

oxygen sensor connector to battery

0 and 0 terminals

respectively.

Caution

Ensure that the jumper wires are connected correctly,

as wrong connections result in a broken oxygen sensor.(6) Connect a digital voltmeter across terminals @ and

0.(7) Racing the engine repeatedly and measure the output

voltage of the oxygen sensor.

EngineOxygen sensor

output voltageRemarks

NOTEFor removal and installation of the oxygen sensor, refer to

GROUP 15

- Exhaust Manifold.

TSB Revision

Page 204 of 1146

FUEL SYSTEM - 0

n-vehicleInspection of MPI Components

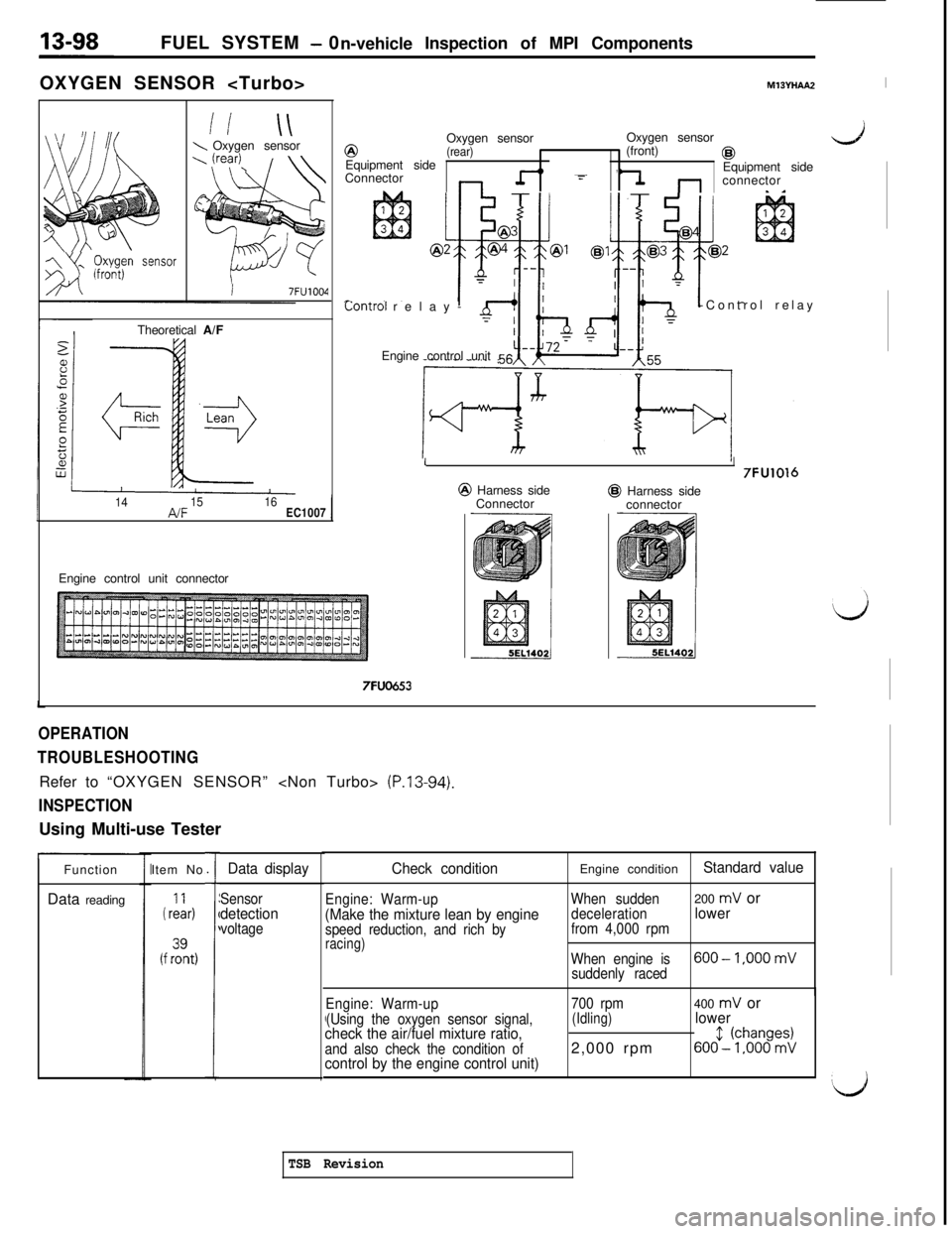

OXYGEN SENSOR

M13YHAA2I

2

2-J

_ Fr;;syn m-wr

li \\\Oxygen sensor

I7FU1004Theoretical A/F@Oxygen sensor

(rear)Oxygen sensor

Equipment side(front)@,ConnectorEquipment side:connectorf-l -1

Lonrrol relay--Control relay

Engine control unit 56

141516PJFEC1007Engine control unit connector

7FUO453

I

I7FU1016@ Harness side@ Harness side

Connector

connector

OPERATION

TROUBLESHOOTINGRefer to “OXYGEN SENSOR”

(P.13-94).

INSPECTIONUsing Multi-use Tester

Function

Data readingItem No.

i rL&

(f fzt,

,

1

Data display

Sensordetectionvoltage

Check condition

Engine: Warm-up(Make the mixture lean by enginespeed reduction, and rich byracing)Engine condition

Standard value

When sudden200 mV or

decelerationlowerfrom 4,000 rpm

When engine is

600-1.000 mV

suddenly raced

./

Engine: Warm-up

(Using the oxygen sensor signal,

check the air/fuel mixture ratio,and also check the condition ofcontrol by the engine control unit)

700 rpm(Idling)2,000 rpm400 mV orlower

6()(f--(~jbaono9~;

‘d

TSB Revision

Page 205 of 1146

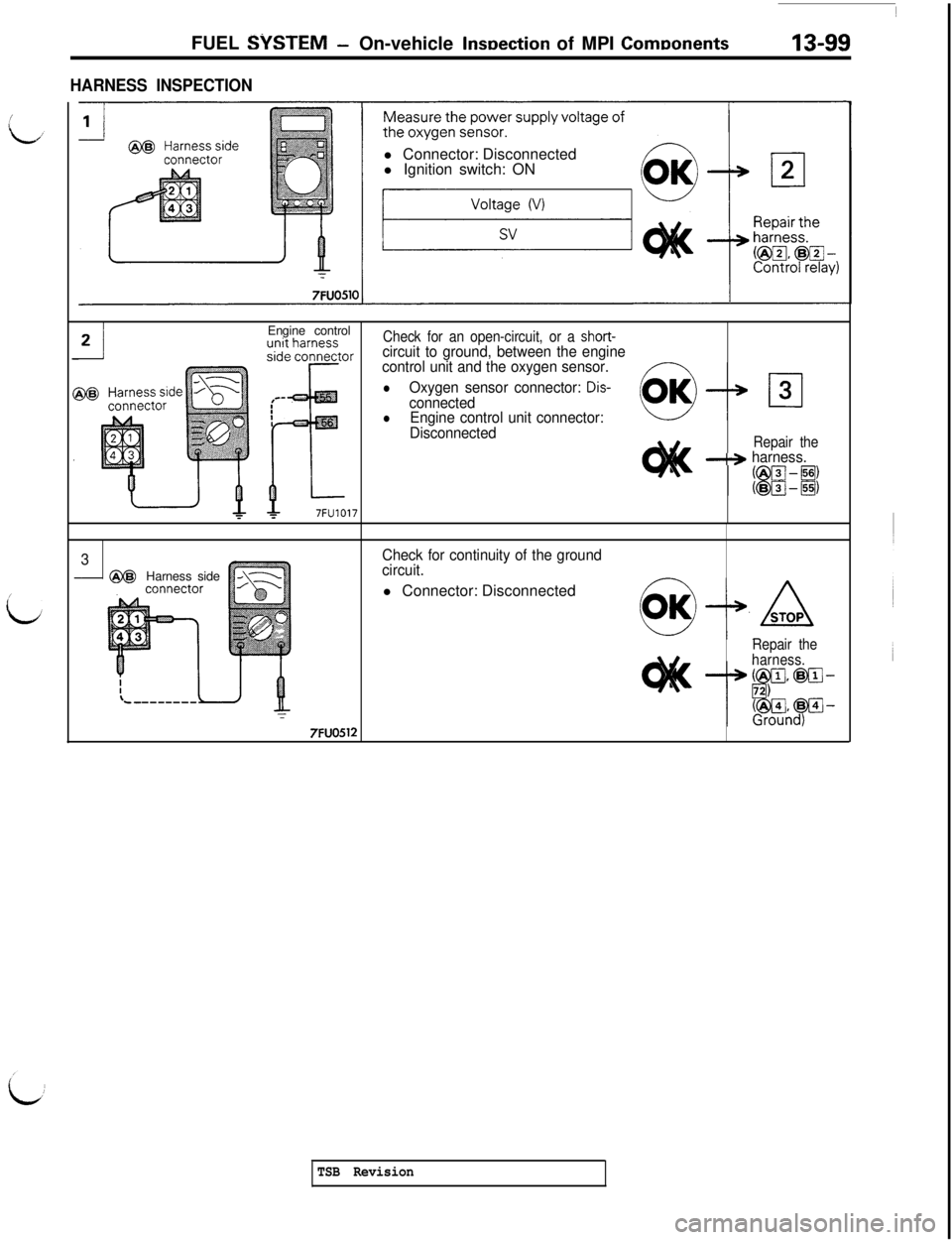

1

FUEL SYSTEM- On-vehicle InsDection of MPI ComDonents13-99

HARNESS INSPECTIONl Connector: Disconnected

l Ignition switch: ON

Engine control

Check for an open-circuit, or a short-circuit to ground, between the engine

control unit and the oxygen sensor.

lOxygen sensor connector: Dis-connectedlEngine control unit connector:

Disconnected

Repair the-+ harness.

3Check for continuity of the ground

- @@

Harness sidecircuit.l Connector: Disconnected

Repair the

harness.

7FUO512

TSB Revision

Page 206 of 1146

13-100FUEL SYSTEM - 0

n-vehicleInspection of MPI Components

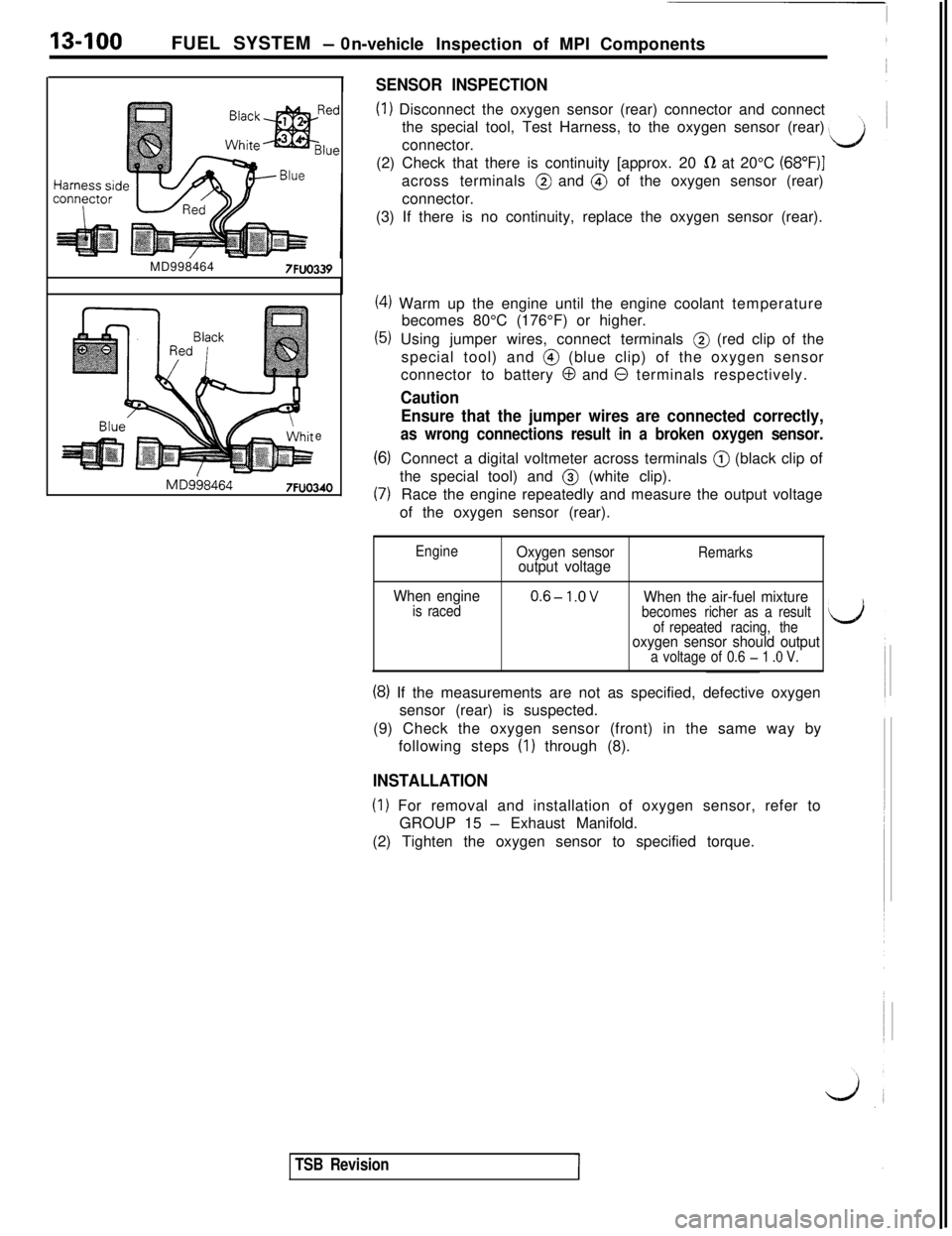

SENSOR INSPECTION

(1) Disconnect the oxygen sensor (rear) connector and connect

the special tool, Test Harness, to the oxygen sensor (rear)

connector.

MD998464

7FUO339

e

MD9584647FUO340(2) Check that there is continuity [approx. 20

R at 20°C (68”F)Iacross terminals @ and @ of the oxygen sensor (rear)

connector.

(3) If there is no continuity, replace the oxygen sensor (rear).

(4) Warm up the engine until the engine coolant temperature

becomes 80°C (176°F) or higher.

(5) Using jumper wires, connect terminals @ (red clip of the

special tool) and @ (blue clip) of the oxygen sensor

connector to battery

0 and 0 terminals respectively.

Caution

Ensure that the jumper wires are connected correctly,

as wrong connections result in a broken oxygen sensor.

(6)Connect a digital voltmeter across terminals @ (black clip of

(7)the special tool) and @ (white clip).

Race the engine repeatedly and measure the output voltage

of the oxygen sensor (rear).

EngineOxygen sensor

output voltageRemarks

When engineis raced0.6-l.OVWhen the air-fuel mixturebecomes richer as a result

of repeated racing, the

oxygen sensor should outputa voltage of 0.6 - 1 .O V.

(8) If the measurements are not as specified, defective oxygen

sensor (rear) is suspected.

(9) Check the oxygen sensor (front) in the same way by

following steps

(I) through (8).

INSTALLATION

(1) For removal and installation of oxygen sensor, refer to

GROUP 15

- Exhaust Manifold.

(2) Tighten the oxygen sensor to specified torque.

TSB Revision

Page 207 of 1146

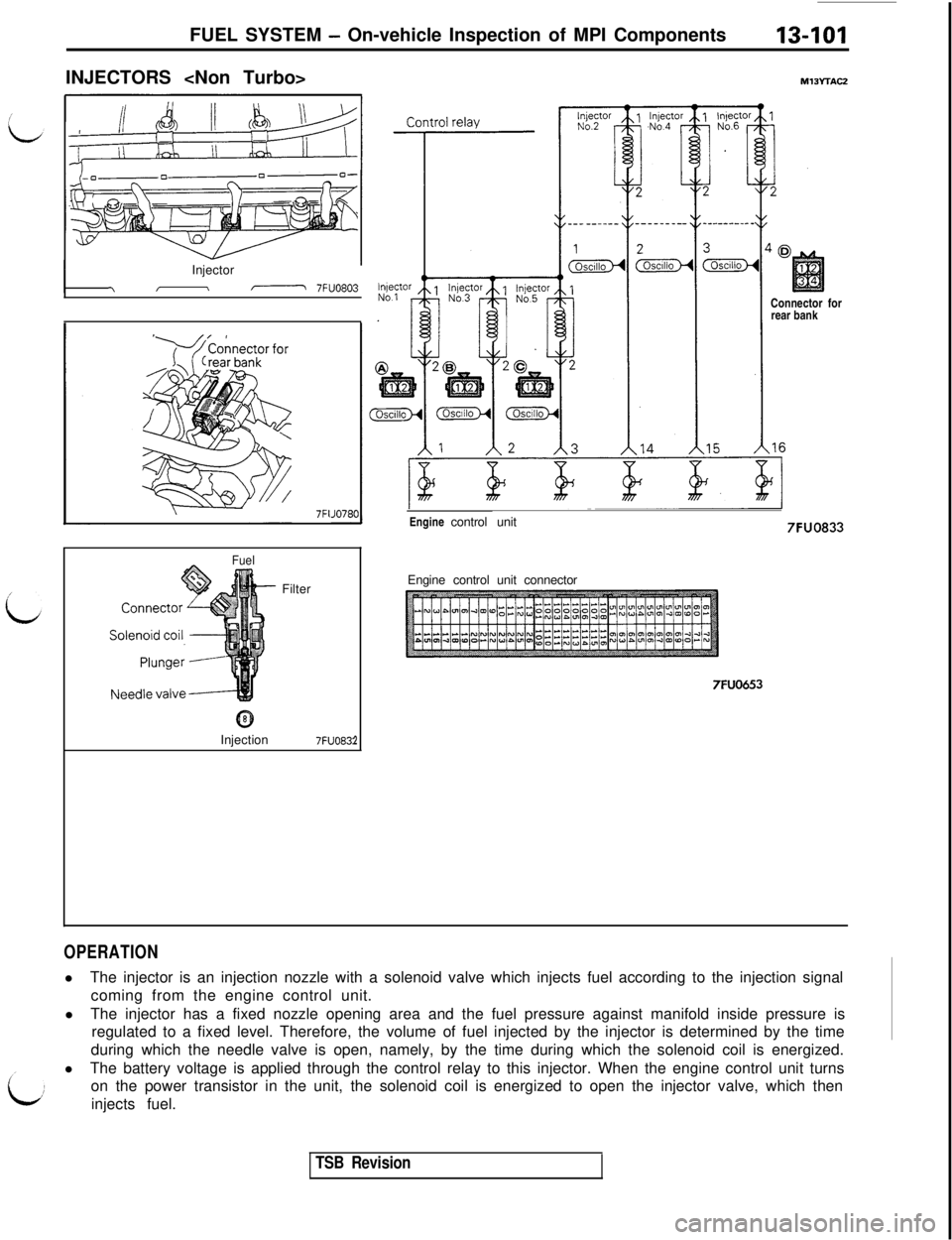

FUEL SYSTEM - On-vehicle Inspection of MPI Components13-101INJECTORS

M13YTAC2

IInjectorII\- 7FUO803

7FI

FuelFilter

@Injection

7FUO83:2Connector for

rear bank

Engine control unit7FUO833

Engine control unit connector

7FUO653

OPERATIONlThe injector is an injection nozzle with a solenoid valve which injects fuel according to the injection signal

coming from the engine control unit.

lThe injector has a fixed nozzle opening area and the fuel pressure against manifold inside pressure is

regulated to a fixed level. Therefore, the volume of fuel injected by the injector is determined by the time

during which the needle valve is open, namely, by the time during which the solenoid coil is energized.

lThe battery voltage is applied through the control relay to this injector. When the engine control unit turns

on the power transistor in the unit, the solenoid coil is energized to open the injector valve, which then

injects fuel.

TSB Revision