change time MITSUBISHI 3000GT 1991 Service Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1991, Model line: 3000GT, Model: MITSUBISHI 3000GT 1991Pages: 1146, PDF Size: 76.68 MB

Page 123 of 1146

FUEL SYSTEM - Troubleshootina13-17

PROBLEM SYMPTOMS TABLE (FOR YOUR INFORMATION)

I;

L

/

L/

Items

Won’t start(no initial combustion)-g Starting problem

2(i;il;i combustion, then

Symptom

The starter is used to crank the engine, but there is no combustion within the

cylinders, and the engine won’t start.

There is combustion within the cylinders, but then the engine soon stalls.(Starting takes a long

time.)Engine won’t start quickly.

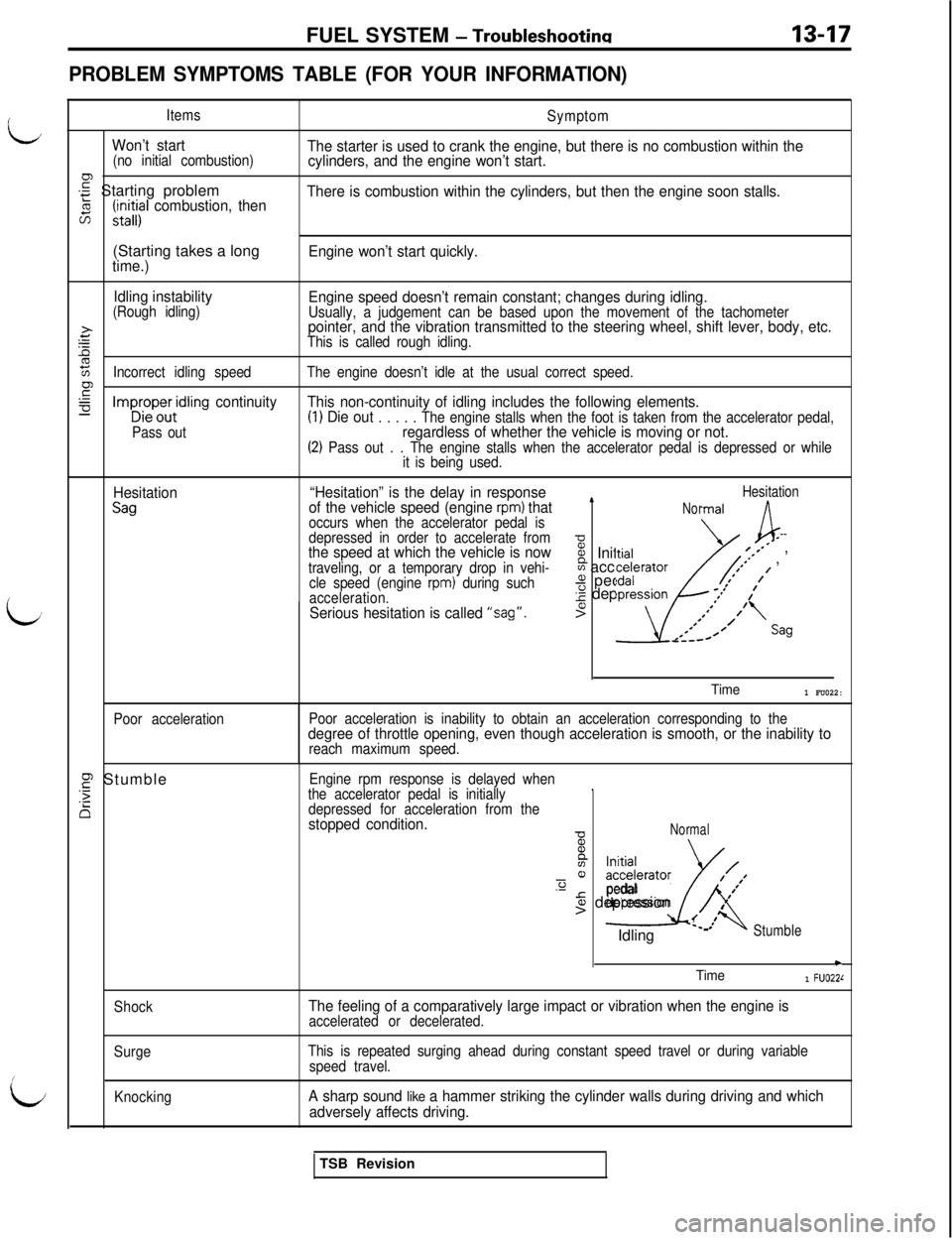

Idling instability

(Rough idling)Engine speed doesn’t remain constant; changes during idling.Usually, a judgement can be based upon the movement of the tachometer

>.rpointer, and the vibration transmitted to the steering wheel, shift lever, body, etc.

EThis is called rough idling.

s0

Incorrect idling speedThe engine doesn’t idle at the usual correct speed.

F.-=e-ImpDr;p;ertidling continuityThis non-continuity of idling includes the following elements.(1) Die outPass out. . . . . The engine stalls when the foot is taken from the accelerator pedal,regardless of whether the vehicle is moving or not.(2) Pass out . . The engine stalls when the accelerator pedal is depressed or while

it is being used.

Hesitation

Sag

“Hesitation” is the delay in responseHesitation

of the vehicle speed (engine rpm) thatLNormaloccurs when the accelerator pedal is

depressed in order to accelerate from---

the speed at which the vehicle is nowx\a,r- ,

traveling, or a temporary drop in vehi-g Initialv) accelerator**’ ,8’ /cle speed (engine rpm) during such+ pedal/,’ /

’

acceleration.2 depression

Serious hesitation is called “sag”.2

1“*’.’

/’ ,’I&L-e**’Ii Sag

Poor acceleration

Time1 FU022:

Poor acceleration is inability to obtain an acceleration corresponding to thedegree of throttle opening, even though acceleration is smooth, or the inability toreach maximum speed.

0, Stumble.F

‘iIn

Engine rpm response is delayed when

the accelerator pedal is initially.

depressed for acceleration from thestopped condition.

$Normal

x

:Initial

3acceleratorI//

c

-7

pedal2 depression,#’,

4,/Idling *--’Stumble

Shock

cTime1 FUO22L

The feeling of a comparatively large impact or vibration when the engine isaccelerated or decelerated.

SurgeThis is repeated surging ahead during constant speed travel or during variable

speed travel.

Knocking

A sharp sound like a hammer striking the cylinder walls during driving and which

adversely affects driving.TSB Revision

Page 208 of 1146

13-102FUEL SYSTEM - On-vehicle Inspection of MPI Components

TROUBLESHOOTING HINTSHint 1: If the engine is hard to start when hot, check fuel pressure and check the injector for leaks.

Hint 2:If the injector does not when the engine that is hard to start is cranked, the following as well as the

Iinjector itself may be responsible.

(1) Faulty power supply circuit to the engine control unit, faulty ground circuit

\-J

-(2) Faulty control relay

Hint 3:(3) Faulty crank angle sensor, top dead center sensor

If there is any cylinder whose idle state remains unchanged when the fuel injection of injectors is cut

one after another during idling, make following checks about such cylinder.

(1) Injector and harness check

(2) Ignition plug and high tension cable check

(3) Compression pressure check

Hint 4: If the injector harness and individual part checks have resulted normal but the injector drive time is

out of specification, the following troubles are suspected.

(1)Poor combustion in the cylinder (faulty ignition plug, ignition coil, compression pressure, etc.)

(2) Loose EGR valve seating

(3) High engine resistance

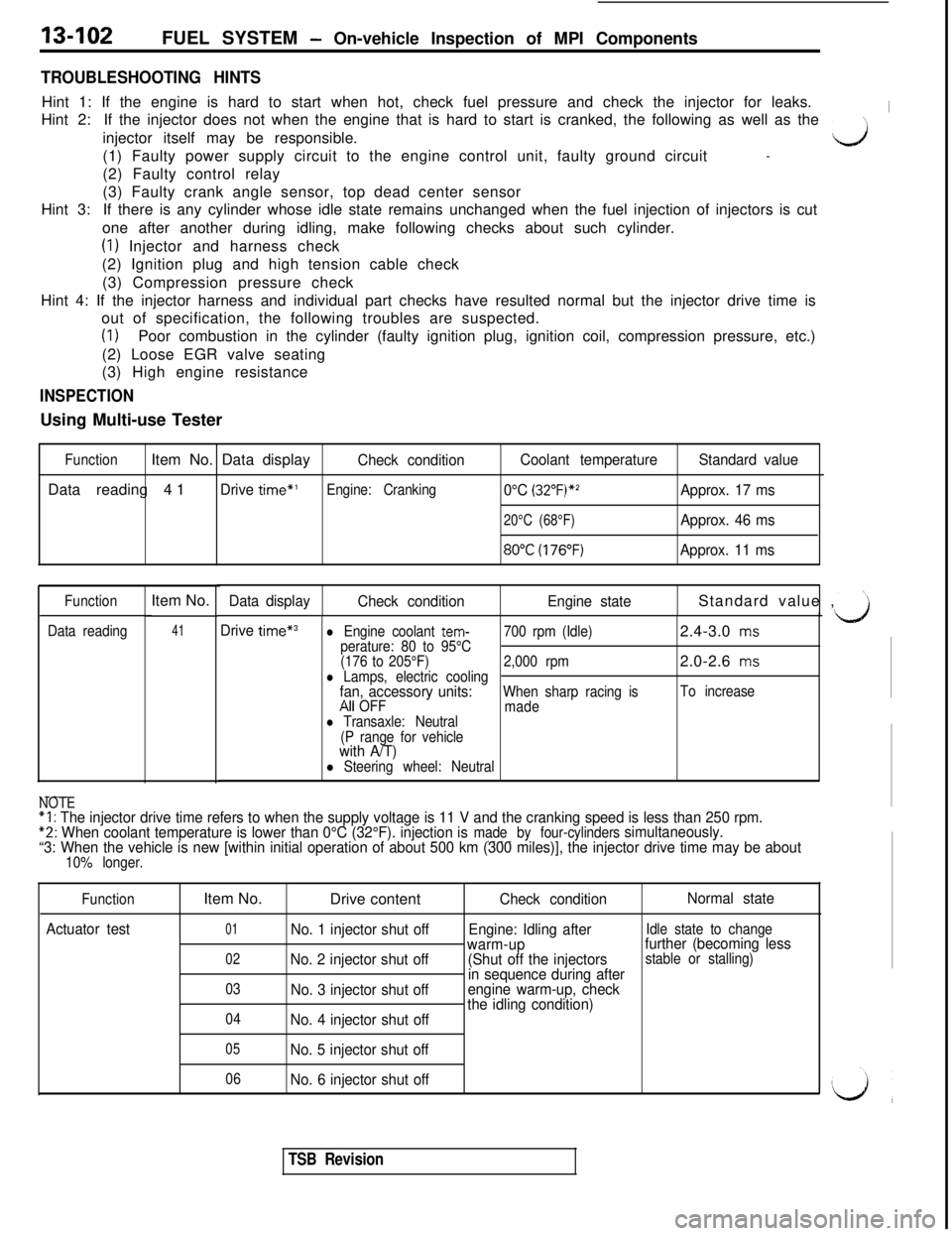

INSPECTIONUsing Multi-use Tester

FunctionItem No. Data displayCheck conditionCoolant temperatureStandard valueData reading 41

Drive time”’Engine: Cranking0°C (32”F)*zApprox. 17 ms

20°C (68°F)Approx. 46 ms

8O"C(176"F)Approx. 11 ms

Function

Data readingItem No.Data display

41Drive time*3l Engine coolant tem-perature: 80 to 95°C700 rpm (Idle)2.4-3.0 ms

(176 to 205°F)2,000 rpm2.0-2.6

msl Lamps, electric coolingfan, accessory units:When sharp racing isTo increaseAll OFF

madel Transaxle: Neutral

(P range for vehicle

with A/T)l Steering wheel: Neutral

Check conditionEngine stateStandard value ,

.---NOTE“I : The injector drive time refers to when the supply voltage is 11 V and the cranking speed is less than 250 rpm.*2: When coolant temperature is lower than 0°C (32°F). injection ismade by four-cylinders.---simultaneously.

“3: When the vehicle is new [within initial operation of about 500 km (300 miles)], the injector drive time may be about

10% longer.

Function

Actuator testItem No.

Drive content

Check conditionNormal state

01No. 1 injector shut offEngine: Idling afterIdle state to change

02No. 2 injector shut offwarm-up

(Shut off the injectorsfurther (becoming less

in sequence during afterstable or stalling)

03

No. 3 injector shut offengine warm-up, check

04No. 4 injector shut offthe idling condition)

05No. 5 injector shut off

06No. 6 injector shut off

TSB Revision

Page 212 of 1146

13-106FUEL SYSTEM - On-vehicle Inspection of MPI Components

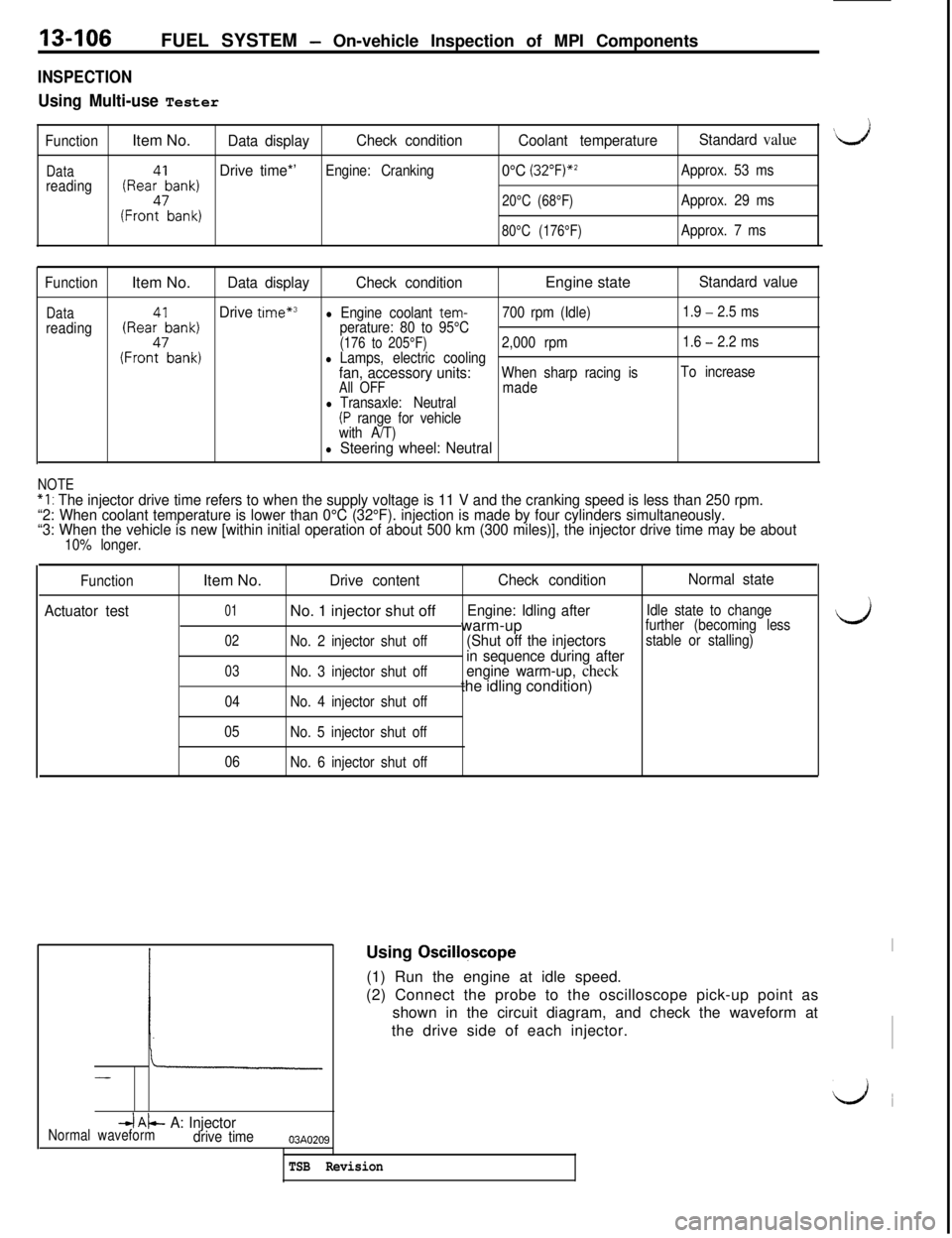

INSPECTION

Using Multi-use Tester

FunctionItem No.Data displayCheck conditionCoolant temperatureStandard value‘L,,,J

DataDrive time*’0°C (32’F)*’readingiRea:bankiEngine: CrankingApprox. 53 ms

(FronT7bank)20°C (68°F)

Approx. 29 ms

80°C (176°F)Approx. 7 ms

FunctionItem No.

Data displayCheck conditionEngine stateStandard value

Datareading(Reaebank)Drive time*3l Engine coolant tem-700 rpm (Idle)1.9 - 2.5 ms

perature: 80 to 95°C

(Front7banki(176 to 205°F)2,000 rpm1.6 - 2.2 ms

l Lamps, electric coolingfan, accessory units:To increase

All OFFWhen sharp racing is

made

l Transaxle: Neutral(P range for vehicle

with A/T)

l Steering wheel: Neutral

NOTE“I : The injector drive time refers to when the supply voltage is 11 V and the cranking speed is less than 250 rpm.

“2: When coolant temperature is lower than 0°C (32°F). injection is made by four cylinders simultaneously.

“3: When the vehicle is new [within initial operation of about 500 km (300 miles)], the injector drive time may be about

10% longer.

Function

Actuator testItem No.

Drive contentCheck conditionNormal state

01No. 1 injector shut offEngine: Idling afterIdle state to changewarm-upfurther (becoming less

02No. 2 injector shut off(Shut off the injectorsstable or stalling)

03in sequence during afterNo. 3 injector shut offengine warm-up, checkthe idling condition)

04No. 4 injector shut off

05

No. 5 injector shut off

06

No. 6 injector shut off

\,iUsing

OscillqscopeI(1) Run the engine at idle speed.

(2) Connect the probe to the oscilloscope pick-up point as

shown in the circuit diagram, and check the waveform at

the drive side of each injector.~

-

LJ

4 AL A: InjectorNormal waveformdrive time03A0209

TSB Revision

Page 245 of 1146

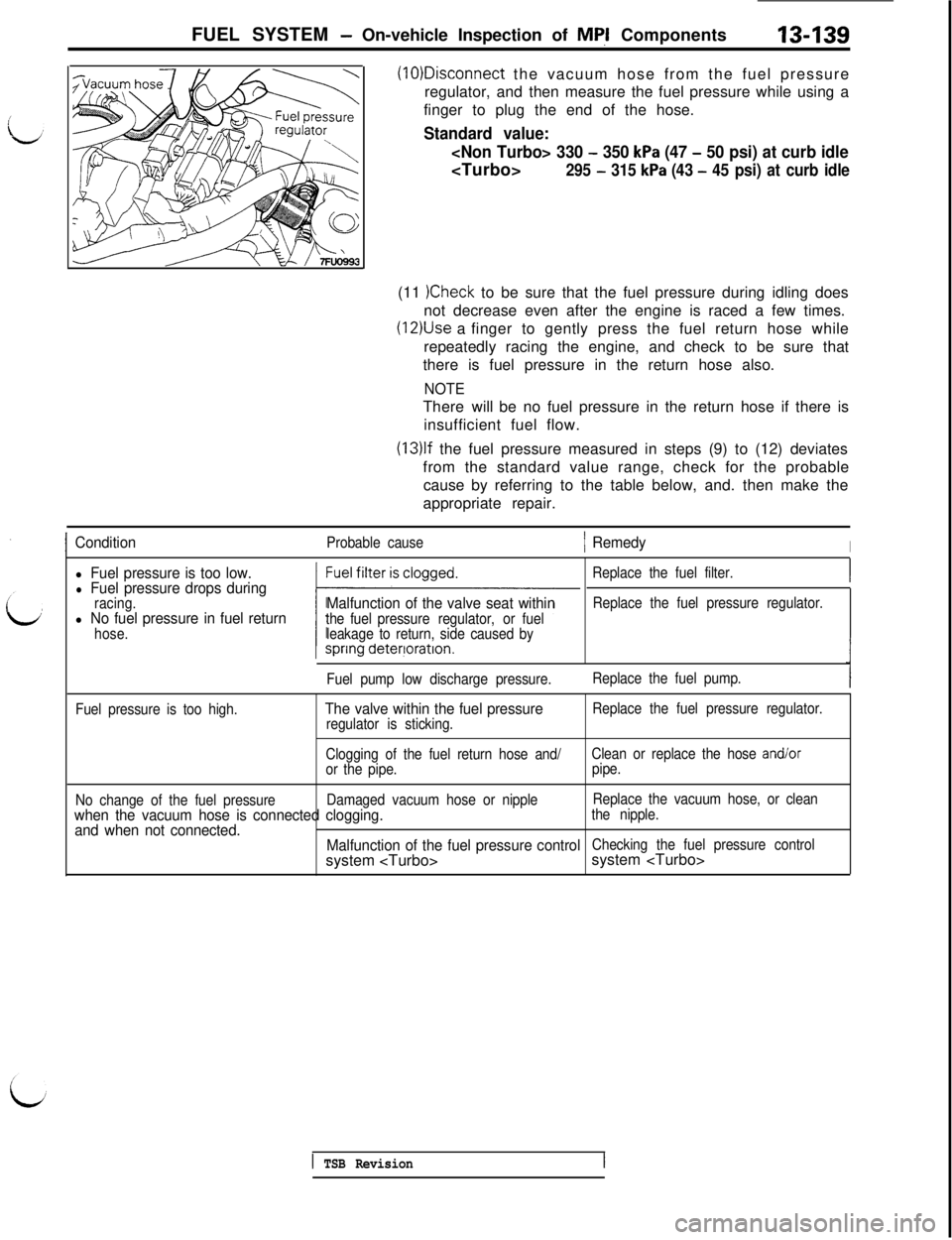

FUEL SYSTEM - On-vehicle Inspection of Mql Components13439(10)Disconnect the vacuum hose from the fuel pressure

regulator, and then measure the fuel pressure while using a

finger to plug the end of the hose.

Standard value:

- 350 kPa (47 - 50 psi) at curb idle

295 - 315 kPa (43 - 45 psi) at curb idle(11

)Check to be sure that the fuel pressure during idling does

not decrease even after the engine is raced a few times.

(12)Use a finger to gently press the fuel return hose while

repeatedly racing the engine, and check to be sure that

there is fuel pressure in the return hose also.

NOTEThere will be no fuel pressure in the return hose if there is

insufficient fuel flow.

(13)lf the fuel pressure measured in steps (9) to (12) deviates

from the standard value range, check for the probable

cause by referring to the table below, and. then make the

appropriate repair.

IConditionProbable cause1 RemedyI

l Fuel pressure is too low.l Fuel pressure drops duringracing.l No fuel pressure in fuel returnhose.

Malfunction of the valve seat withinthe fuel pressure regulator, or fuel

leakage to return, side caused byReplace the fuel filter.

Replace the fuel pressure regulator.

Fuel pump low discharge pressure.Replace the fuel pump.

Fuel pressure is too high.

The valve within the fuel pressureregulator is sticking.Replace the fuel pressure regulator.

Clogging of the fuel return hose and/Clean or replace the hose

and/oror the pipe.pipe.

No change of the fuel pressureDamaged vacuum hose or nippleReplace the vacuum hose, or clean

when the vacuum hose is connected clogging.the nipple.

and when not connected.

Malfunction of the fuel pressure controlChecking the fuel pressure controlsystem

1 TSB Revision

Page 364 of 1146

21-6CLUTCH - Service Adjustment Procedures

08YO4Z

Distance between the clutch pedaland the firewall when the clutchis disengaged

08NOOl C

Good

c1‘14UOO61

When engine is

stoppedNo good

\)‘14UOO6:

When engine isstarted

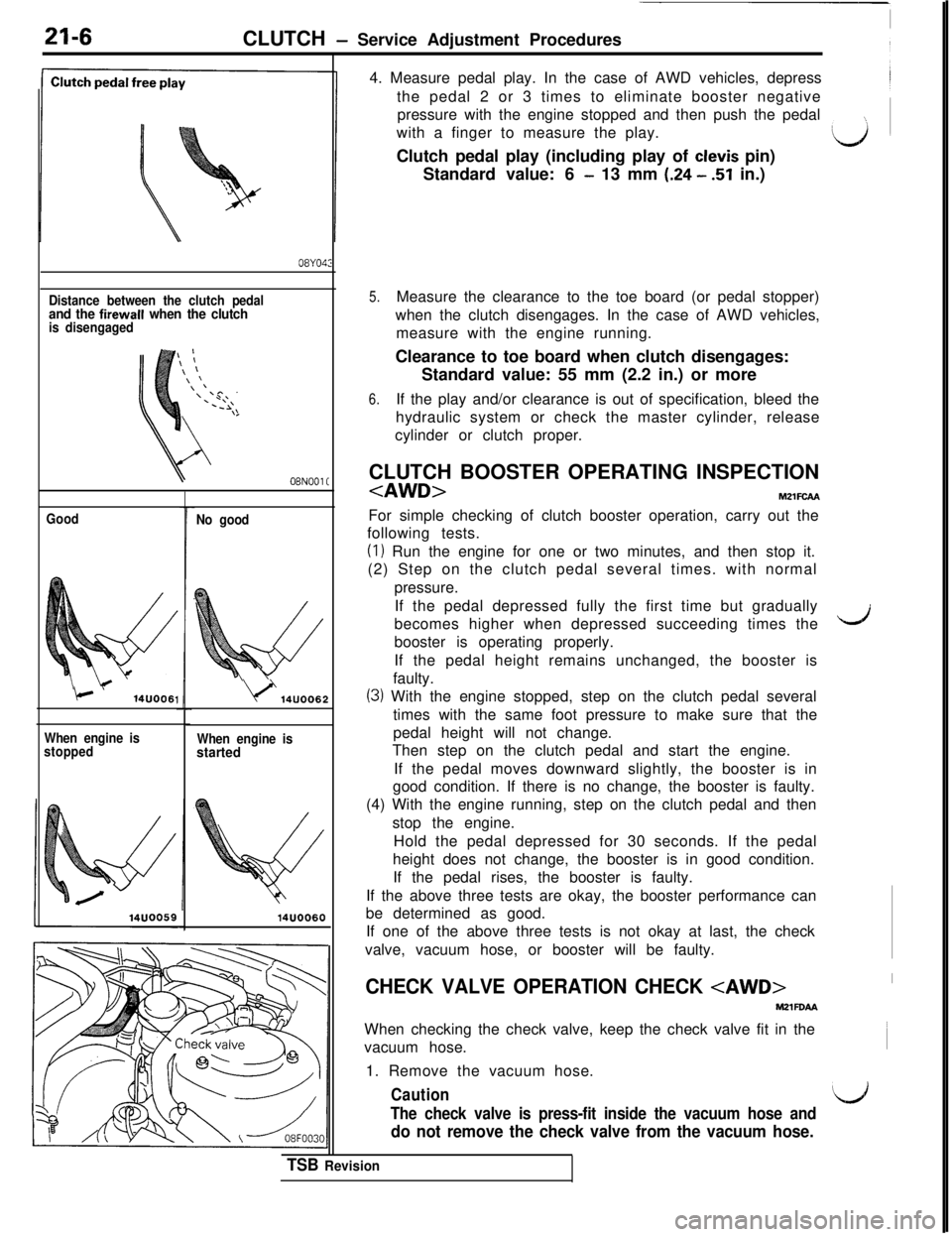

14UOO604. Measure pedal play. In the case of AWD vehicles, depress~

the pedal 2 or 3 times to eliminate booster negative

pressure with the engine stopped and then push the pedal

with a finger to measure the play.

LJClutch pedal play (including play of clevis pin)

Standard value: 6

- 13 mm (.24 - 51 in.)

2

CHECK VALVE OPERATION CHECK

MZlFOAAWhen checking the check valve, keep the check valve fit in the

vacuum hose.

1. Remove the vacuum hose.

CautionL’The check valve is press-fit inside the vacuum hose and

do not remove the check valve from the vacuum hose.

5.Measure the clearance to the toe board (or pedal stopper)

when the clutch disengages. In the case of AWD vehicles,

measure with the engine running.

Clearance to toe board when clutch disengages:

Standard value: 55 mm (2.2 in.) or more

6.If the play and/or clearance is out of specification, bleed the

hydraulic system or check the master cylinder, release

cylinder or clutch proper.

CLUTCH BOOSTER OPERATING INSPECTION

following tests.

(I) Run the engine for one or two minutes, and then stop it.

(2) Step on the clutch pedal several times. with normal

pressure.

If the pedal depressed fully the first time but gradually

becomes higher when depressed succeeding times the

dbooster is operating properly.

If the pedal height remains unchanged, the booster is

faulty.

(3) With the engine stopped, step on the clutch pedal several

times with the same foot pressure to make sure that the

pedal height will not change.

Then step on the clutch pedal and start the engine.

If the pedal moves downward slightly, the booster is in

good condition. If there is no change, the booster is faulty.

(4) With the engine running, step on the clutch pedal and then

stop the engine.

Hold the pedal depressed for 30 seconds. If the pedal

height does not change, the booster is in good condition.

If the pedal rises, the booster is faulty.

If the above three tests are okay, the booster performance can

be determined as good.

If one of the above three tests is not okay at last, the check

valve, vacuum hose, or booster will be faulty.

TSB Revision

Page 674 of 1146

33B-12ELECTRONIC CONTROL SUSPENSION (EC9 - i?:~~u:‘?s*men*

12FOOOESERVICE ADJUSTMENT PROCEDURES

I

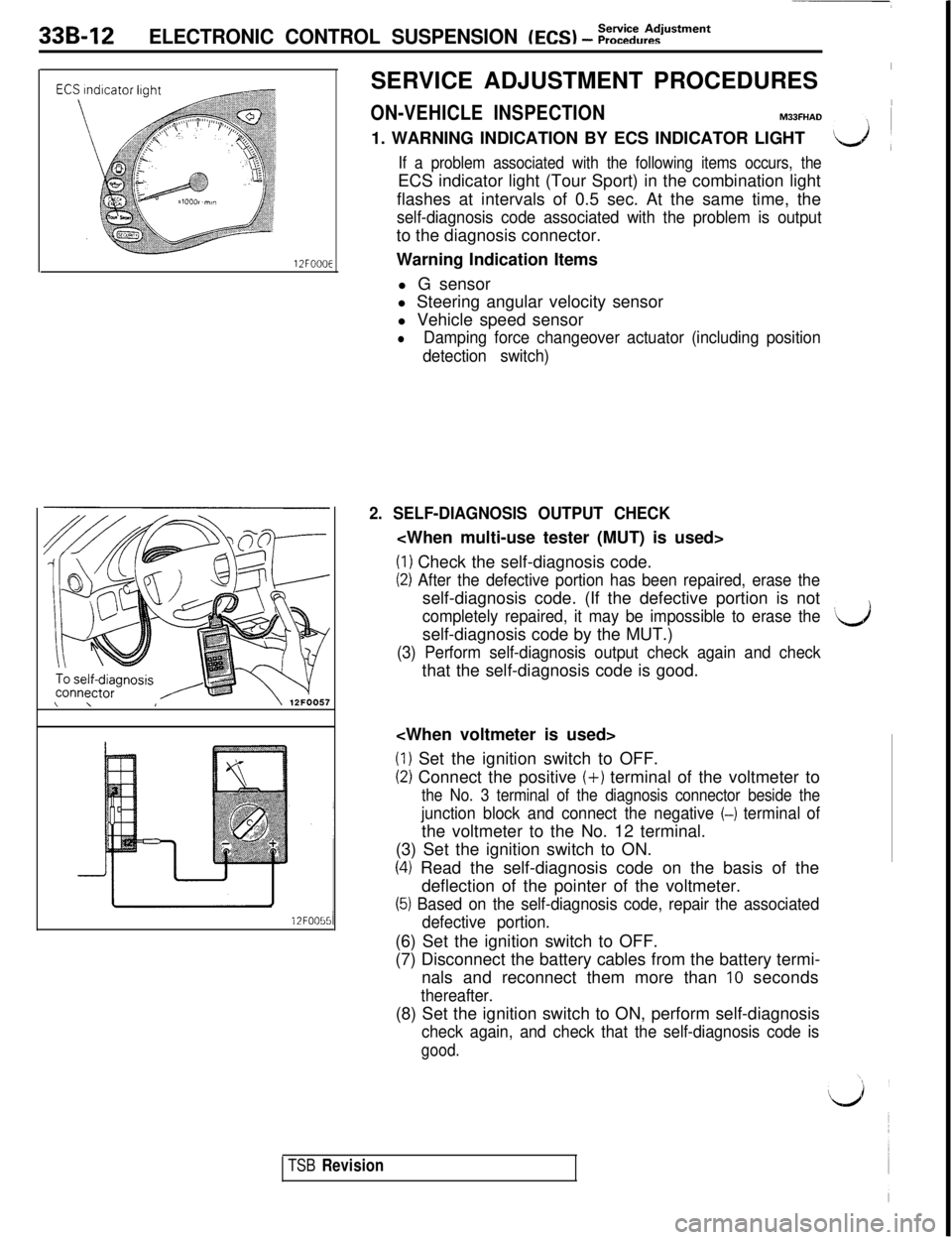

ON-VEHICLE INSPECTIONIM33FHAD1. WARNING INDICATION BY ECS INDICATOR LIGHT

If a problem associated with the following items occurs, theECS indicator light (Tour Sport) in the combination light

flashes at intervals of 0.5 sec. At the same time, the

self-diagnosis code associated with the problem is outputto the diagnosis connector.

Warning Indication Items

l G sensor

l Steering angular velocity sensor

l Vehicle speed sensor

lDamping force changeover actuator (including position

detection switch)

2. SELF-DIAGNOSIS OUTPUT CHECK

(I) Check the self-diagnosis code.

(2) After the defective portion has been repaired, erase theself-diagnosis code. (If the defective portion is not

completely repaired, it may be impossible to erase the’self-diagnosis code by the MUT.)d

(3) Perform self-diagnosis output check again and checkthat the self-diagnosis code is good.

(1) Set the ignition switch to OFF.

(2) Connect the positive (+) terminal of the voltmeter to

the No. 3 terminal of the diagnosis connector beside the

junction block and connect the negative (--) terminal ofthe voltmeter to the No. 12 terminal.

(3) Set the ignition switch to ON.

(4) Read the self-diagnosis code on the basis of the

deflection of the pointer of the voltmeter.

(5) Based on the self-diagnosis code, repair the associated

defective portion.(6) Set the ignition switch to OFF.

(7) Disconnect the battery cables from the battery termi-

nals and reconnect them more than

10 seconds

thereafter.(8) Set the ignition switch to ON, perform self-diagnosis

check again, and check that the self-diagnosis code is

good.

TSB Revision

Page 679 of 1146

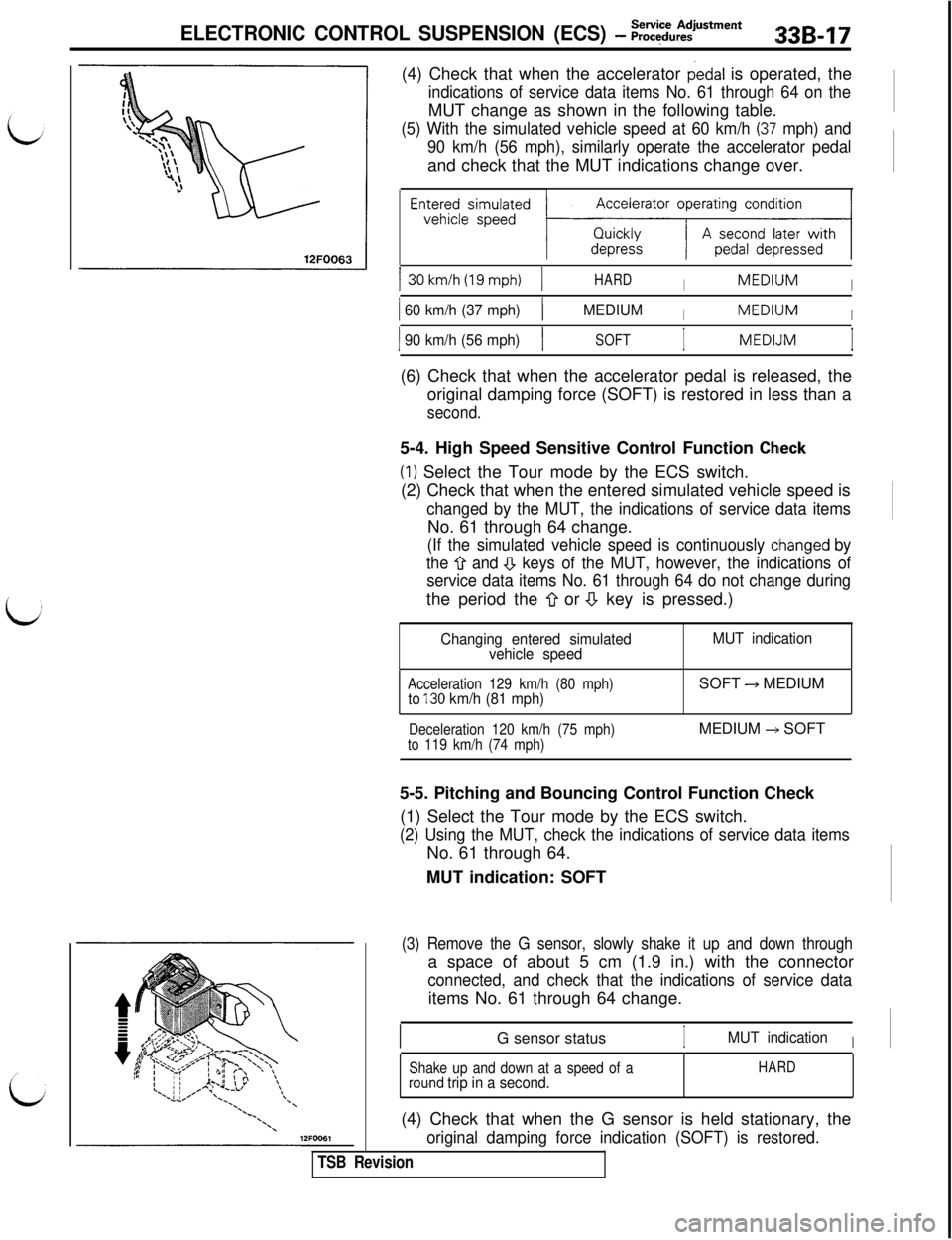

ELECTRONIC CONTROL SUSPENSION (ECS) - :;:~u:~men*33B17(4) Check that when the accelerator

dedal is operated, the

indications of service data items No. 61 through 64 on theMUT change as shown in the following table.

(5) With the simulated vehicle speed at 60 km/h (37’ mph) and

90 km/h (56 mph), similarly operate the accelerator pedaland check that the MUT indications change over.

Accelerator operating condition

EnE~~esismp~~ed ~;zz-KzxJ130km/h(19mph)

1HARDIMEDllJMI

1 60 km/h (37 mph)1MEDIUMIMEDllJMI

1 90 km/h (56 mph)1SOFTIMEDLJMI(6) Check that when the accelerator pedal is released, the

original damping force (SOFT) is restored in less than a

second.5-4. High Speed Sensitive Control Function

Chleck(I) Select the Tour mode by the ECS switch.

(2) Check that when the entered simulated vehicle speed is

changed by the MUT, the indications of service data itemsNo. 61 through 64 change.

(If the simulated vehicle speed is continuously cihanged by

the

Q and .!J keys of the MUT, however, the indications of

service data items No. 61 through 64 do not change duringthe period the

0 or a key is pressed.)

Changing entered simulated

vehicle speedMUT indication

Acceleration 129 km/h (80 mph)to 130 km/h (81 mph)SOFT + MEDIUM

Deceleration 120 km/h (75 mph)

to 119 km/h (74 mph)MEDIUM +, SOFT

5-5. Pitching and Bouncing Control Function Check

(1) Select the Tour mode by the ECS switch.

(2) Using the MUT, check the indications of service data itemsNo. 61 through 64.

MUT indication: SOFT

(3) Remove the G sensor, slowly shake it up and down througha space of about 5 cm (1.9 in.) with the connector

connected, and check that the indications of service dataitems No. 61 through 64 change.

G sensor status

IMUT indicationI

Shake up and down at a speed of arou.nd trip in a second.HARD(4) Check that when the G sensor is held stationary, the

original damping force indication (SOFT) is restored.

TSB Revision

Page 680 of 1146

33B-18ELECTRONIC CONTROL SUSPENSION (EC9 - ~::::u:?‘s*men*

\/I

I(Front)(Rear)I

12FOOG

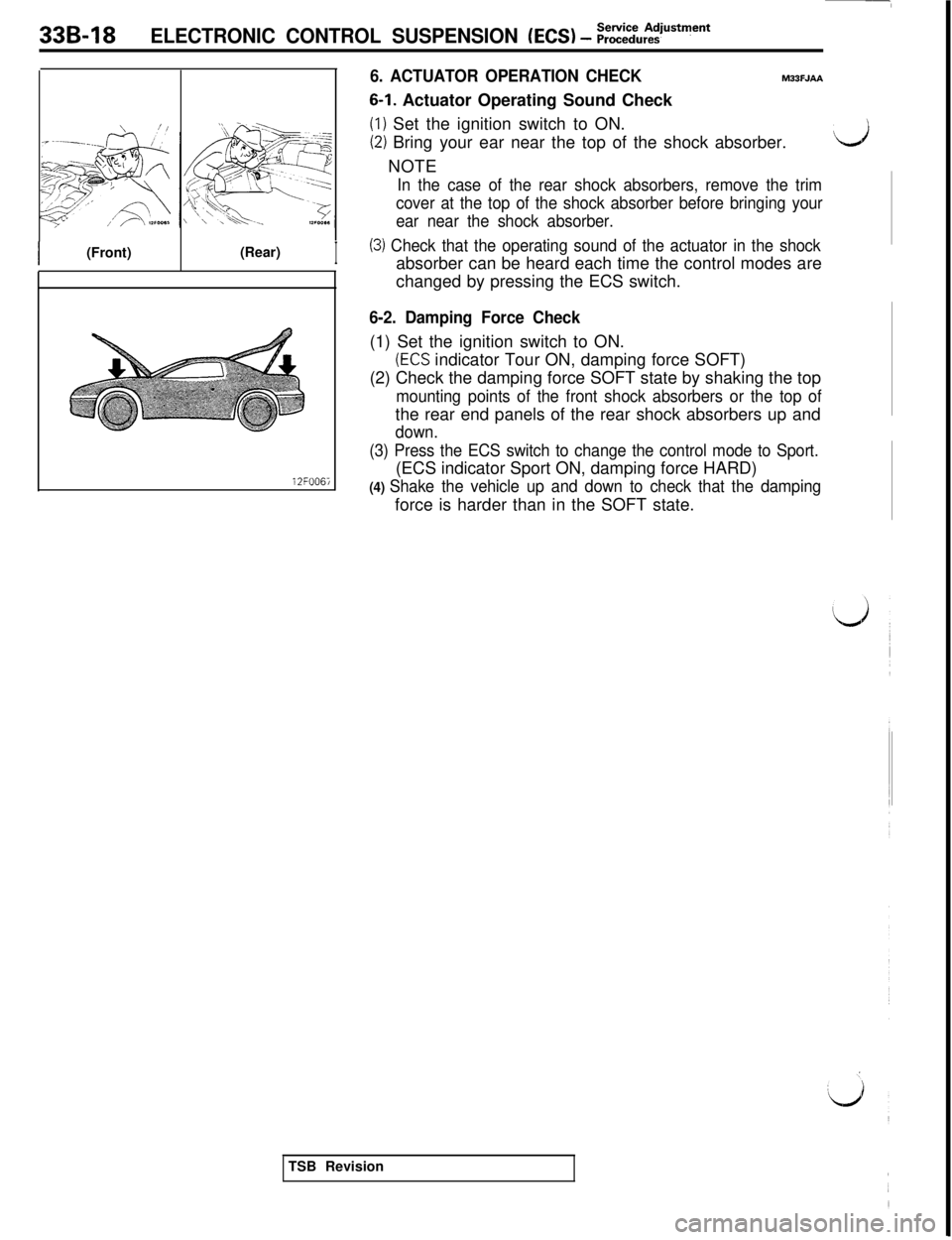

6. ACTUATOR OPERATION CHECKM33FJAA

6-1. Actuator Operating Sound Check

(I) Set the ignition switch to ON.

(2) Bring your ear near the top of the shock absorber.dNOTE

In the case of the rear shock absorbers, remove the trim

cover at the top of the shock absorber before bringing your

ear near the shock absorber.

(3) Check that the operating sound of the actuator in the shockabsorber can be heard each time the control modes are

changed by pressing the ECS switch.

6-2. Damping Force Check(1) Set the ignition switch to ON.

(ECS indicator Tour ON, damping force SOFT)

(2) Check the damping force SOFT state by shaking the top

mounting points of the front shock absorbers or the top ofthe rear end panels of the rear shock absorbers up and

down.

(3) Press the ECS switch to change the control mode to Sport.(ECS indicator Sport ON, damping force HARD)

(4) Shake the vehicle up and down to check that the dampingforce is harder than in the SOFT state.

TSB Revision

Page 768 of 1146

35-46SERVICE BRAKES - Service Adjustment Procedures

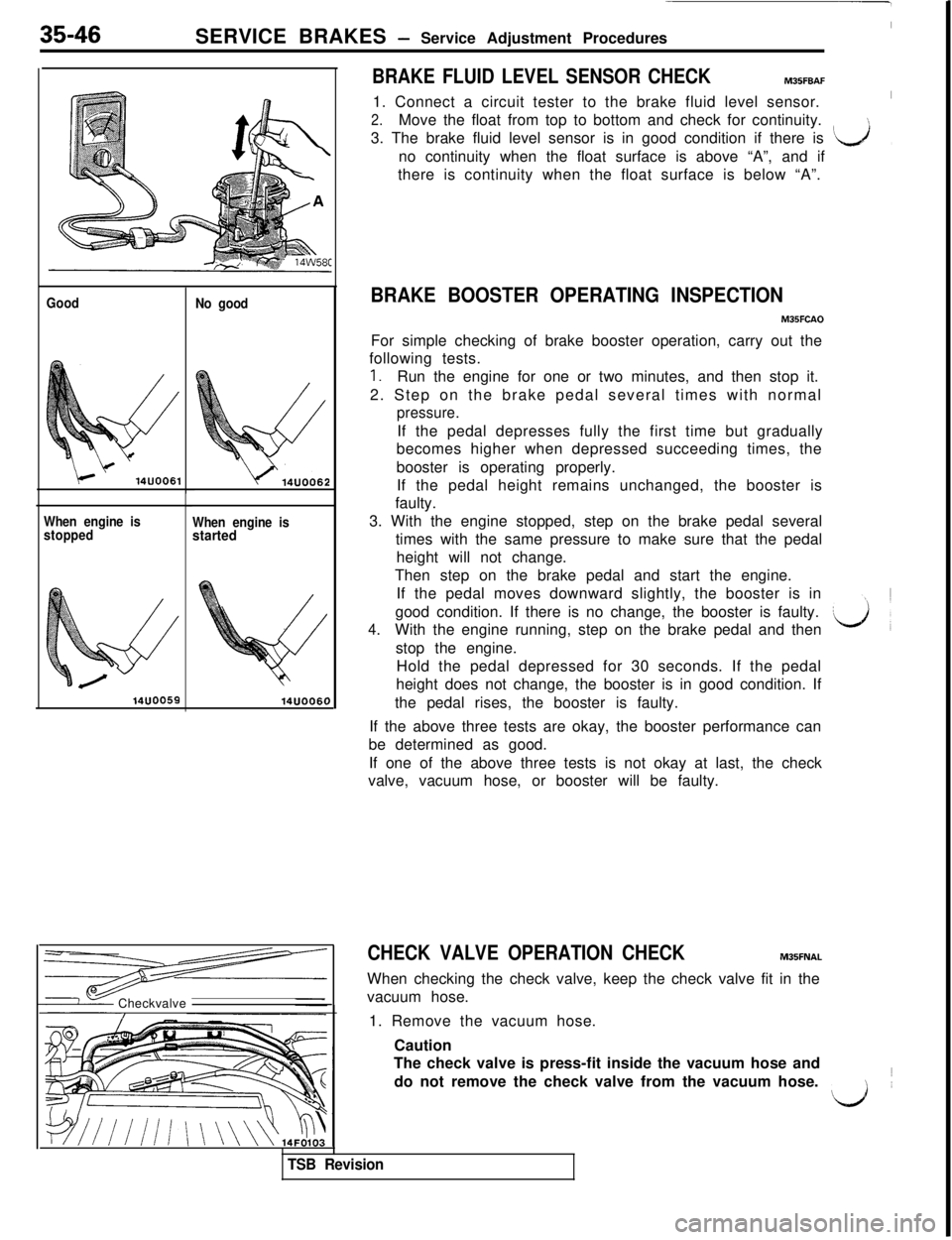

BRAKE FLUID LEVEL SENSOR CHECK

I

MBSFBAF

Good

k‘14UOO61

When engine is

stoppedNo good

When engine isstarted

14UOO6C)Checkvalve/1. Connect a circuit tester to the brake fluid level sensor.

I

2.Move the float from top to bottom and check for continuity.

3. The brake fluid level sensor is in good condition if there is

‘k&Jno continuity when the float surface is above “A”, and if,there is continuity when the float surface is below “A”.

BRAKE BOOSTER OPERATING INSPECTION

M35FCAOFor simple checking of brake booster operation, carry out the

following tests.

1.Run the engine for one or two minutes, and then stop it.

2. Step on the brake pedal several times with normal

pressure.If the pedal depresses fully the first time but gradually

becomes higher when depressed succeeding times, the

booster is operating properly.

If the pedal height remains unchanged, the booster is

faulty.

3. With the engine stopped, step on the brake pedal several

times with the same pressure to make sure that the pedal

height will not change.

Then step on the brake pedal and start the engine.

If the pedal moves downward slightly, the booster is in

good condition. If there is no change, the booster is faulty.

4.With the engine running, step on the brake pedal and then

stop the engine.

Hold the pedal depressed for 30 seconds. If the pedal

height does not change, the booster is in good condition. If

the pedal rises, the booster is faulty.

If the above three tests are okay, the booster performance can

be determined as good.

If one of the above three tests is not okay at last, the check

valve, vacuum hose, or booster will be faulty.

CHECK VALVE OPERATION CHECKM35FNALWhen checking the check valve, keep the check valve fit in the

vacuum hose.

1. Remove the vacuum hose.

Caution

The check valve is press-fit inside the vacuum hose and

do not remove the check valve from the vacuum hose.1

d~

TSB Revision

Page 775 of 1146

L.

SERVICE BRAKES -Service Adjustment Procedures35-53

I14A0398

14F003r

i14A04014NOO27

7

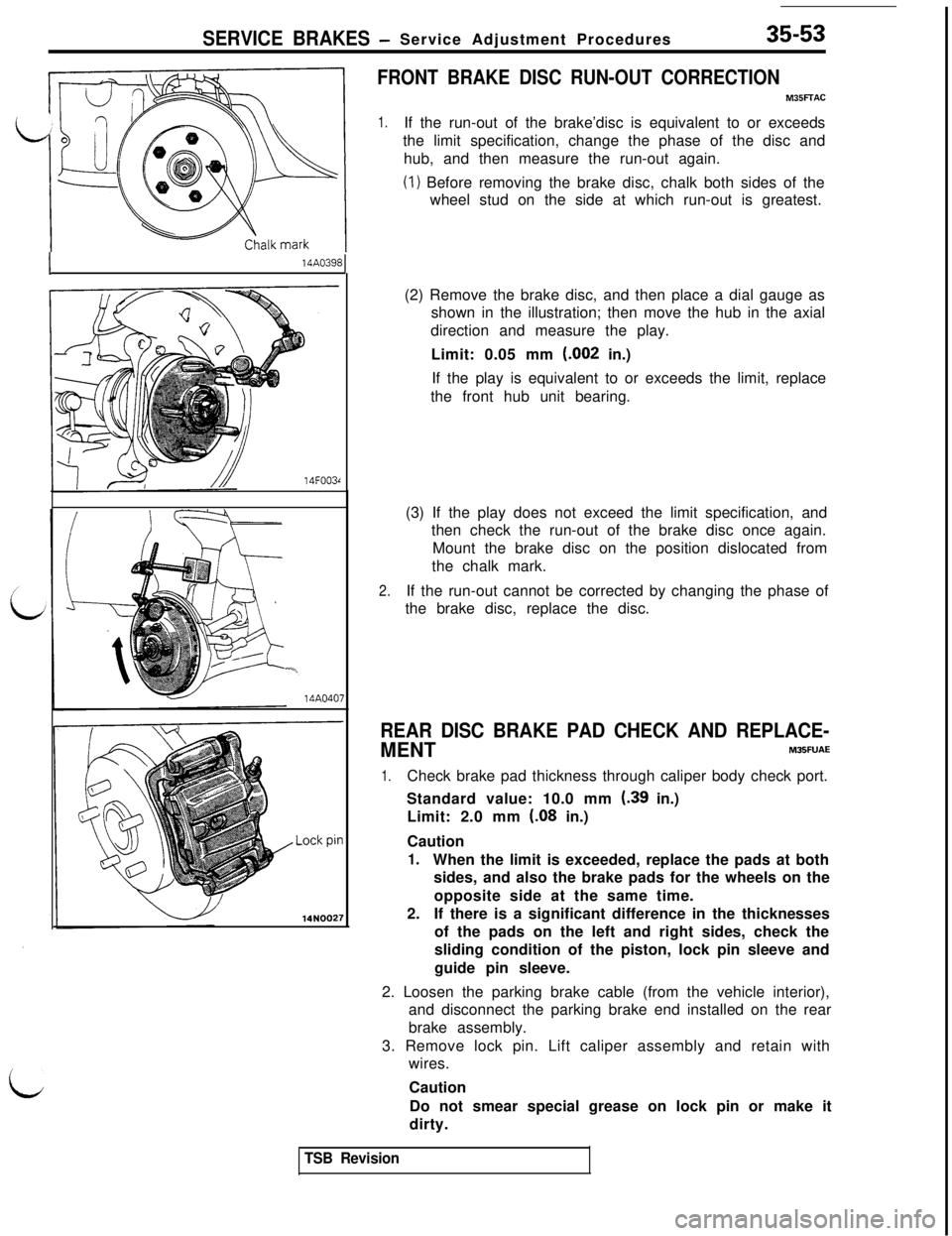

FRONT BRAKE DISC RUN-OUT CORRECTION

M35FFAC

1.If the run-out of the brake’disc is equivalent to or exceeds

the limit specification, change the phase of the disc and

hub, and then measure the run-out again.

(1) Before removing the brake disc, chalk both sides of the

wheel stud on the side at which run-out is greatest.

(2) Remove the brake disc, and then place a dial gauge as

shown in the illustration; then move the hub in the axial

direction and measure the play.

Limit: 0.05 mm (.002 in.)

If the play is equivalent to or exceeds the limit, replace

the front hub unit bearing.

(3) If the play does not exceed the limit specification, and

then check the run-out of the brake disc once again.

Mount the brake disc on the position dislocated from

the chalk mark.

2.If the run-out cannot be corrected by changing the phase of

the brake disc, replace the disc.

REAR DISC BRAKE PAD CHECK AND REPLACE-

MENTM35FUAE

1.Check brake pad thickness through caliper body check port.

Standard value: 10.0 mm

(39 in.)

Limit: 2.0 mm

(08 in.)

Caution

1.When the limit is exceeded, replace the pads at both

sides, and also the brake pads for the wheels on the

opposite side at the same time.

2.If there is a significant difference in the thicknesses

of the pads on the left and right sides, check the

sliding condition of the piston, lock pin sleeve and

guide pin sleeve.

2. Loosen the parking brake cable (from the vehicle interior),

and disconnect the parking brake end installed on the rear

brake assembly.

3. Remove lock pin. Lift caliper assembly and retain with

wires.

Caution

Do not smear special grease on lock pin or make it

dirty.

TSB Revision