clock MITSUBISHI 3000GT 1991 Workshop Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1991, Model line: 3000GT, Model: MITSUBISHI 3000GT 1991Pages: 1146, PDF Size: 76.68 MB

Page 1039 of 1146

LSUPPLEMENTAL RESTRAINT SYSTEM (SRS)

- Troub!eshooting 529-29

/ CONTINUED FROM PREVIOUS PAGE/*

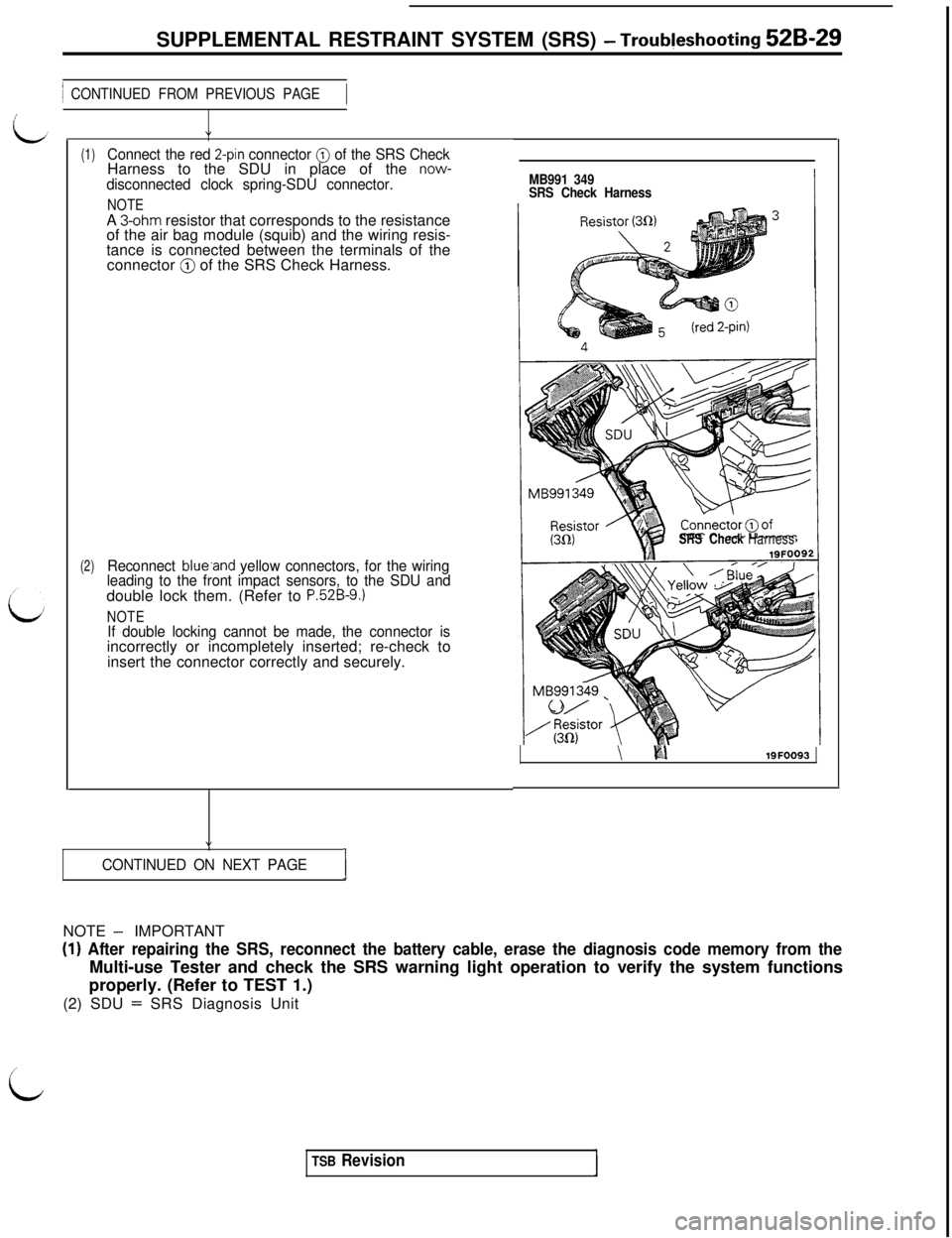

(1)Connect the red 2-pin connector @ of the SRS CheckHarness to the SDU in place of the now-disconnected clock spring-SDU connector.

NOTEA 3-ohm resistor that corresponds to the resistance

of the air bag module (squib) and the wiring resis-

tance is connected between the terminals of the

connector

@ of the SRS Check Harness.

(2)Reconnect blue.and yellow connectors, for the wiring

leading to the front impact sensors, to the SDU anddouble lock them. (Refer to

P.52B-9.)

NOTEIf double locking cannot be made, the connector isincorrectly or incompletely inserted; re-check to

insert the connector correctly and securely.

”

CONTINUED ON NEXT PAGEIMB991 349

SRS Check Harness

SRS CheckHarness

\ ii%\19FOO93NOTE

- IMPORTANT

(I) After repairing the SRS, reconnect the battery cable, erase the diagnosis code memory from theMulti-use Tester and check the SRS warning light operation to verify the system functions

properly. (Refer to TEST 1.)

(2) SDU

= SRS Diagnosis Unit

i

TSB Revision

Page 1041 of 1146

:

id

cSUPPLEMENTAL RESTRAINT SYSTEM (SRS)

- Troubleshooting 52B-31

1 CONTINUED FROM PREVIOUS PAGE(

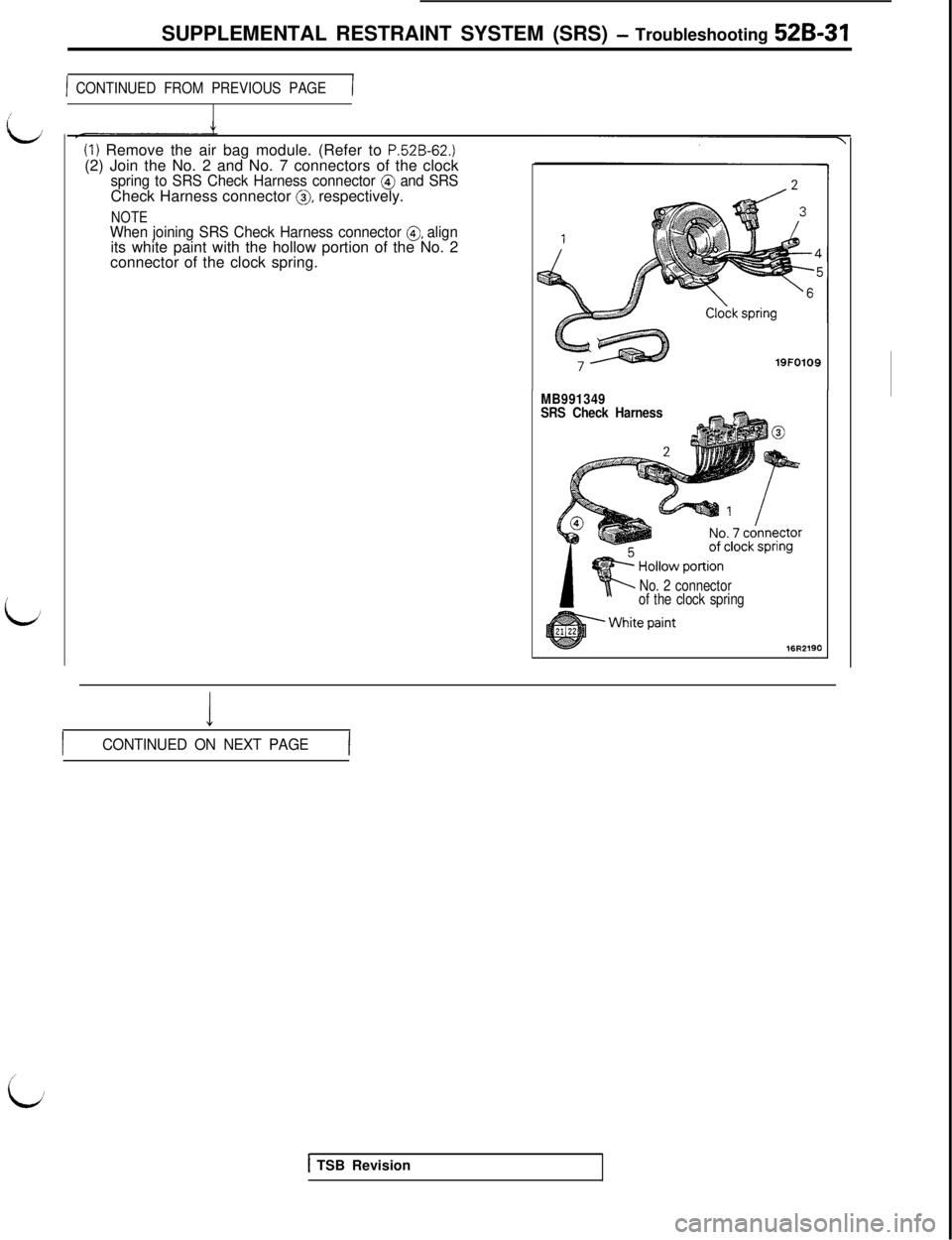

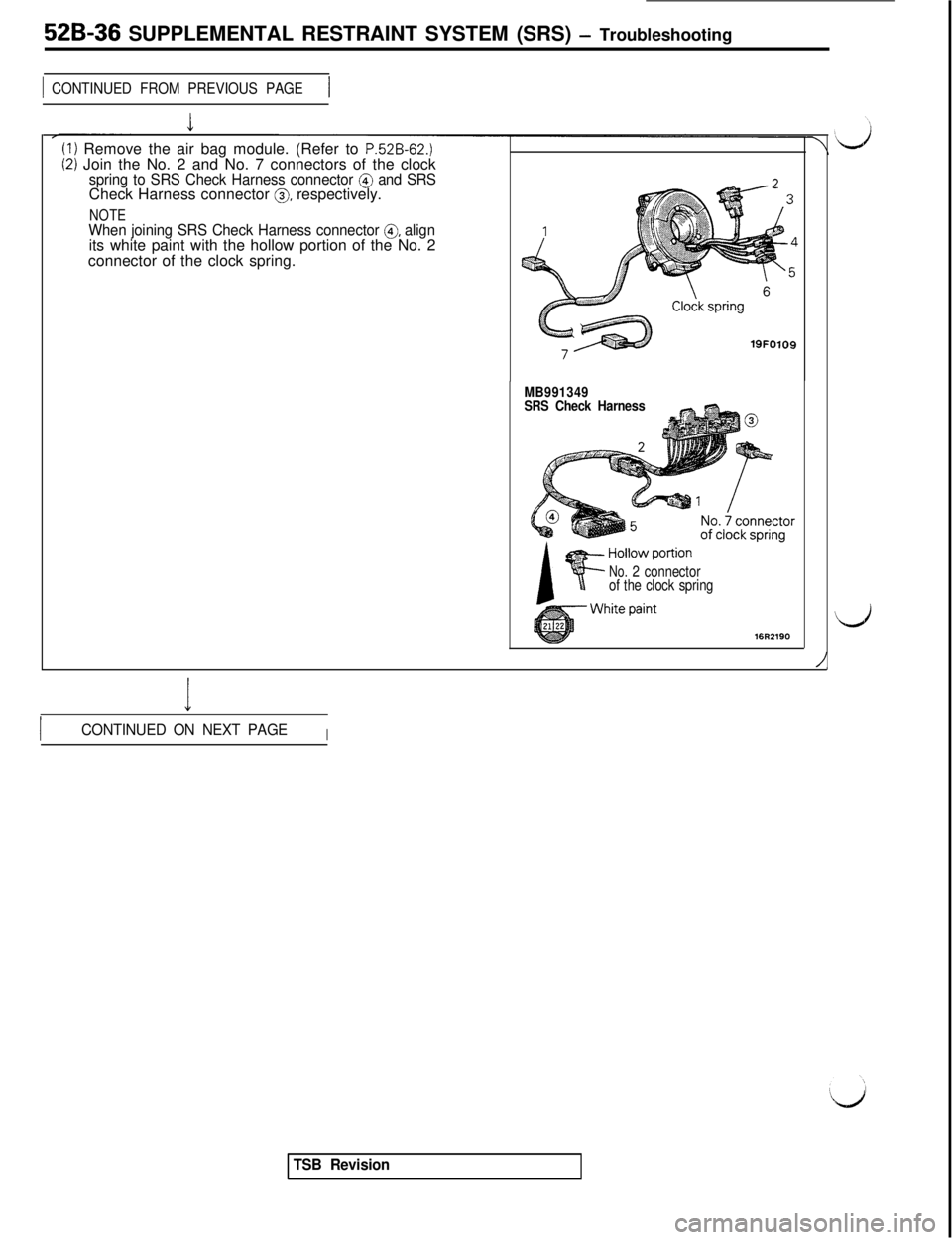

(1) Remove the air bag module. (Refer to P.52B-62.)(2) Join the No. 2 and No. 7 connectors of the clock

spring to SRS Check Harness connector @ and SRSCheck Harness connector 0, respectively.

NOTEWhen joining SRS Check Harness connector 0, alignits white paint with the hollow portion of the No. 2

connector of the clock spring.

19FO109

MB991349

SRS Check Harness

No. 2 connector

of the clock spring

16R2190

I

ICONTINUED ON NEXT PAGEI

i

1 TSB Revision

Page 1042 of 1146

52B-32 SUPPLEMENTAL RESTRAINT SYSTEM (SRS) - Troubleshooting

CONTINUED FROM PREVIOUS PAGE

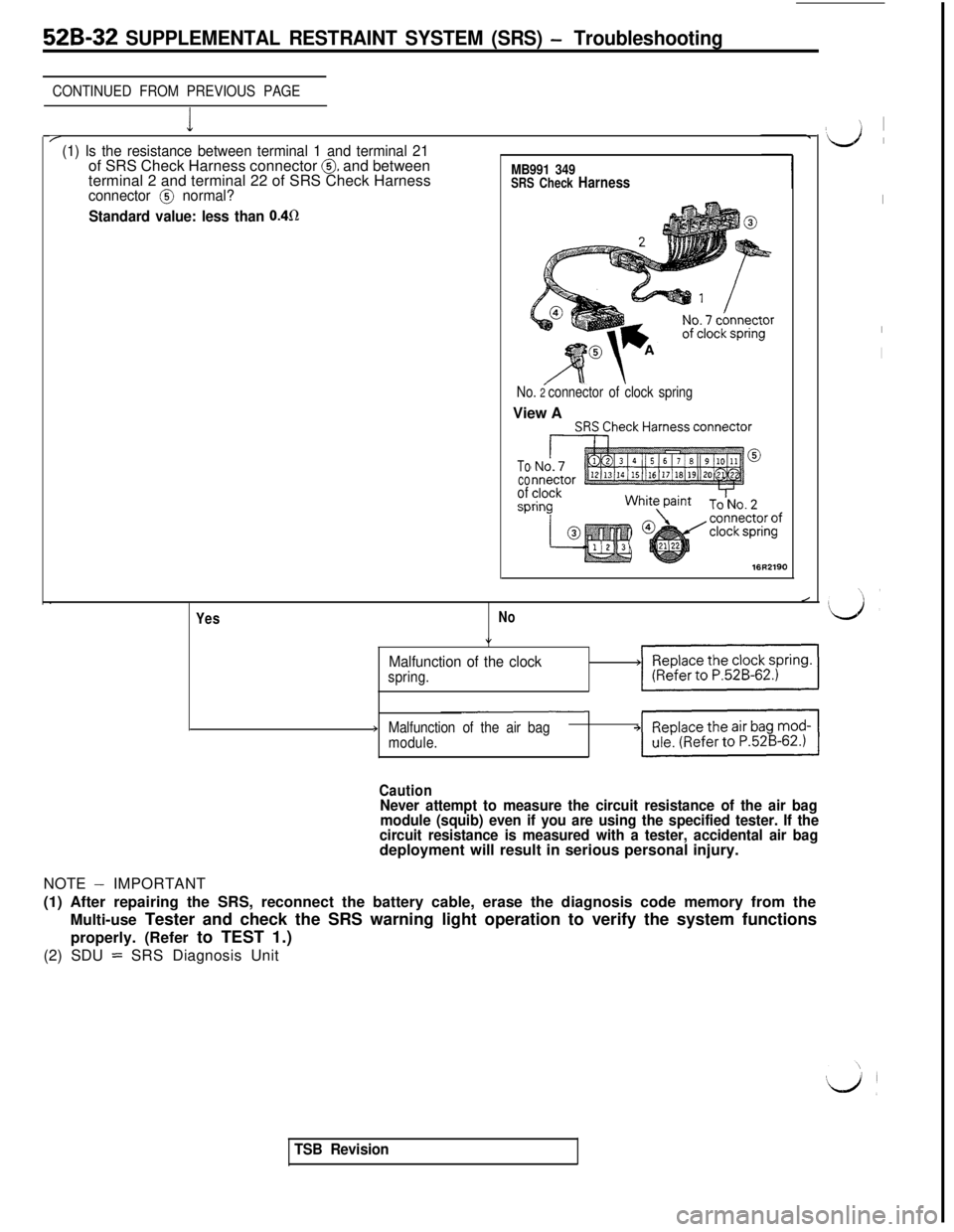

I/(1) Is the resistance between terminal 1 and terminal 21of SRS Check Harness connector @ and between

terminal 2 and terminal 22 of SRS Check HarnessMB991 349SRS Check Harnessconnector @ normal?

Standard value: less than 0.4R

No. 2 connector of clock springView A

To

co

of

SP

16R2190.

Yes

/

No

*

Malfunction of the clockspring.>V/

>Malfunction of the air bag

module.

CautionNever attempt to measure the circuit resistance of the air bag

module (squib) even if you are using the specified tester. If the

circuit resistance is measured with a tester, accidental air bagdeployment will result in serious personal injury.

NOTE

- IMPORTANT

(1) After repairing the SRS, reconnect the battery cable, erase the diagnosis code memory from the

Multi-use Tester and check the SRS warning light operation to verify the system functions

properly. (Refer to TEST 1.)

(2) SDU

= SRS Diagnosis Unit

TSB Revision

’ I

‘d ’

I

I

I

Page 1044 of 1146

526-34 SUPPLEMENTAL RESTRAINT SYSTEM (SRS) - Troubleshooting

CONTINUED FROM PREVIOUS PAGE

c

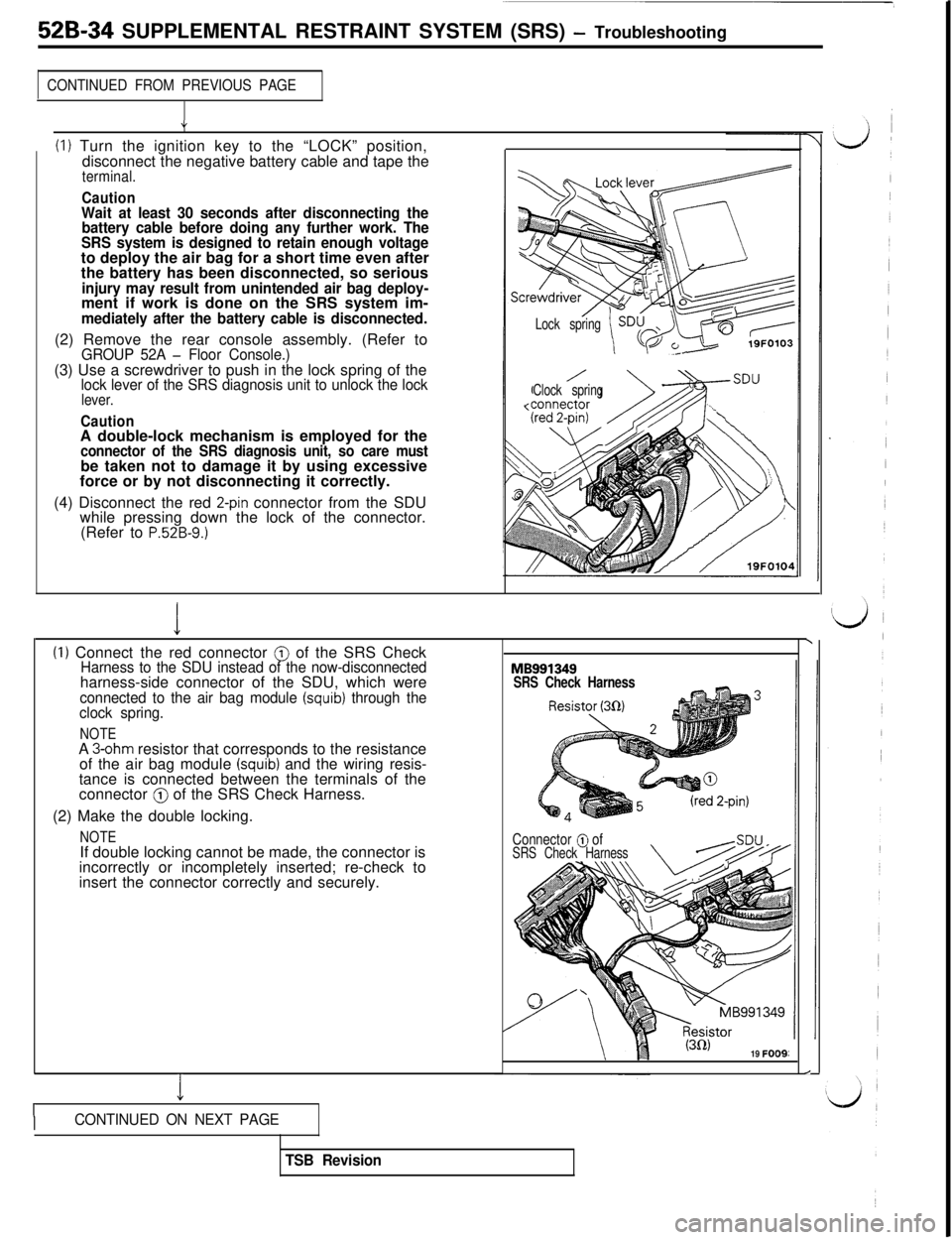

(1) Turn the ignition key to the “LOCK” position,

disconnect the negative battery cable and tape the

terminal.

CautionWait at least 30 seconds after disconnecting the

battery cable before doing any further work. The

SRS system is designed to retain enough voltageto deploy the air bag for a short time even after

the battery has been disconnected, so serious

injury may result from unintended air bag deploy-ment if work is done on the SRS system im-

mediately after the battery cable is disconnected.(2) Remove the rear console assembly. (Refer to

GROUP 52A - Floor Console.)(3) Use a screwdriver to push in the lock spring of the

lock lever of the SRS diagnosis unit to unlock the locklever.

CautionA double-lock mechanism is employed for the

connector of the SRS diagnosis unit, so care mustbe taken not to damage it by using excessive

force or by not disconnecting it correctly.

(4) Disconnect the red

2-pin connector from the SDU

while pressing down the lock of the connector.

(Refer to

P.52B-9.)

/Lock spring

/Clock spring

I\(I) Connect the red connector @ of the SRS CheckHarness to the SDU instead of the now-disconnectedharness-side connector of the SDU, which were

connected to the air bag module (squib) through the

clock spring.

NOTE

SRS Check HarnessA

3-ohm resistor that corresponds to the resistance

of the air bag module (squib) and the wiring resis-

tance is connected between the terminals of the

connector

@ of the SRS Check Harness.

(2) Make the double locking.

NOTEIf double locking cannot be made, the connector is

incorrectly or incompletely inserted; re-check to

insert the connector correctly and securely.Connector @ ofSRS Check Harness

(3R)19 FOO9:

1

/

ICONTINUED ON NEXT PAGE

TSB Revision

Page 1046 of 1146

52B-36 SUPPLEMENTAL RESTRAINT SYSTEM (SRS) - Troubleshooting

1 CONTINUED FROM PREVIOUS PAGE1(I) Remove the air bag module. (Refer to

P.52B-62.)(2) Join the No. 2 and No. 7 connectors of the clockspring to SRS Check Harness connector @ and SRSCheck Harness connector 0, respectively.

NOTEWhen joining SRS Check Harness connector 0, alignits white paint with the hollow portion of the No. 2

connector of the clock spring.

19FO109

MB991349

SRS Check Harness

No.2 connector

of the clock spring

I

ICONTINUED ON NEXT PAGEI

\

/

TSB Revision

Page 1047 of 1146

LSUPPLEMENTAL RESTRAINT SYSTEM (SRS)

- Troubleshooting 52B-37

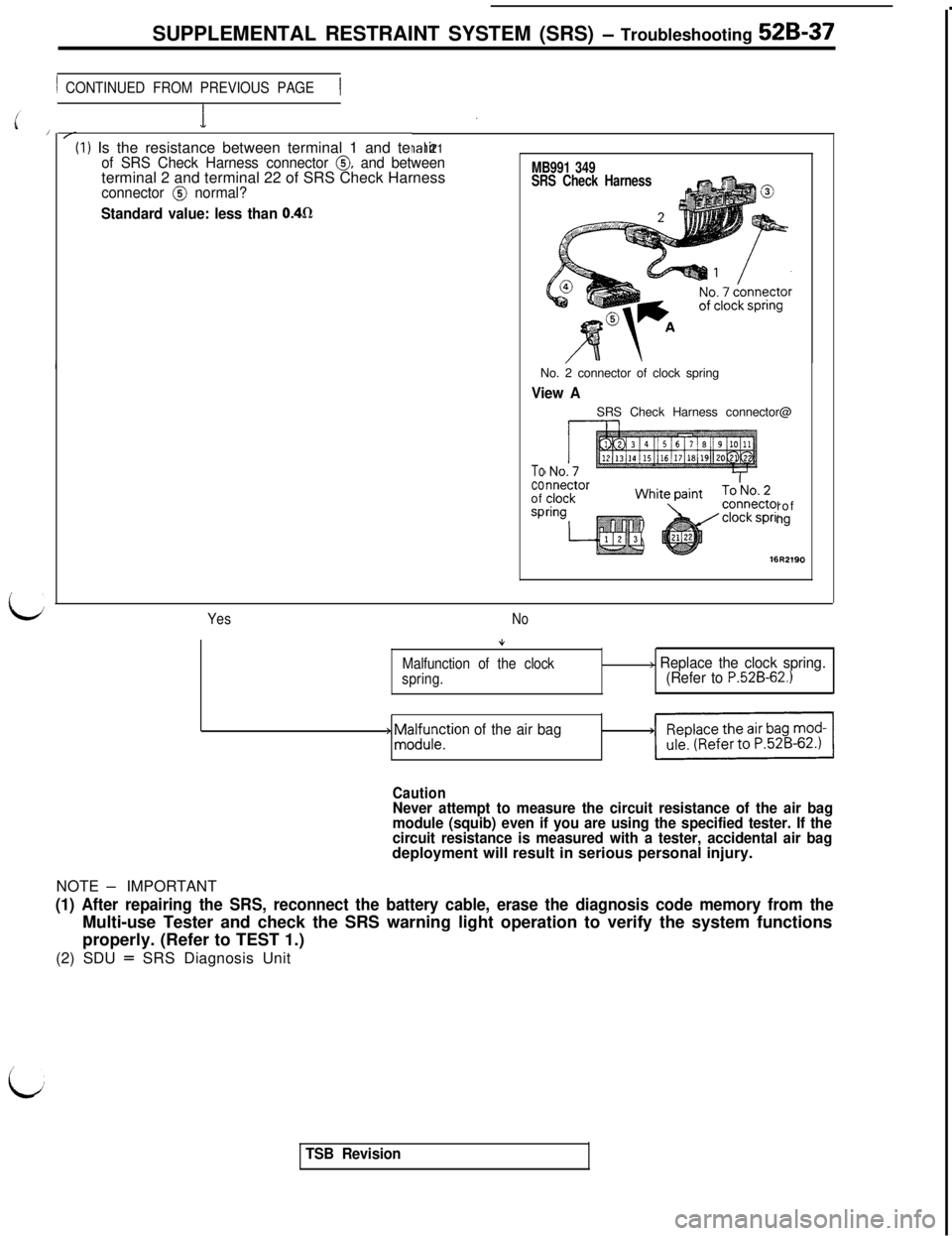

1 CONTINUED FROM PREVIOUS PAGE1(I) Is the resistance between terminal 1 and termir

ial 21of SRS Check Harness connector 0, and betweenterminal 2 and terminal 22 of SRS Check Harness

connector @ normal?

Standard value: less than 0.4fl

MB991 349

SRS Check HarnessNo. 2 connector of clock spring

View ASRS Check Harness connector@

Tocoof

sProfng

YesNo

Malfunction of the clock

spring.

+ ;z;;;tion of the air bag

> Replace the clock spring.

(Refer to P.52B-62.)

CautionNever attempt to measure the circuit resistance of the air bag

module (squib) even if you are using the specified tester. If the

circuit resistance is measured with a tester, accidental air bagdeployment will result in serious personal injury.

NOTE

- IMPORTANT

(1) After repairing the SRS, reconnect the battery cable, erase the diagnosis code memory from theMulti-use Tester and check the SRS warning light operation to verify the system functions

properly. (Refer to TEST 1.)

(2) SDU

= SRS Diagnosis Unit

i

TSB Revision

Page 1048 of 1146

52B-38 SUPPLEMENTAL RESTRAINT SYSTEM (SRS) - Troubleshooting

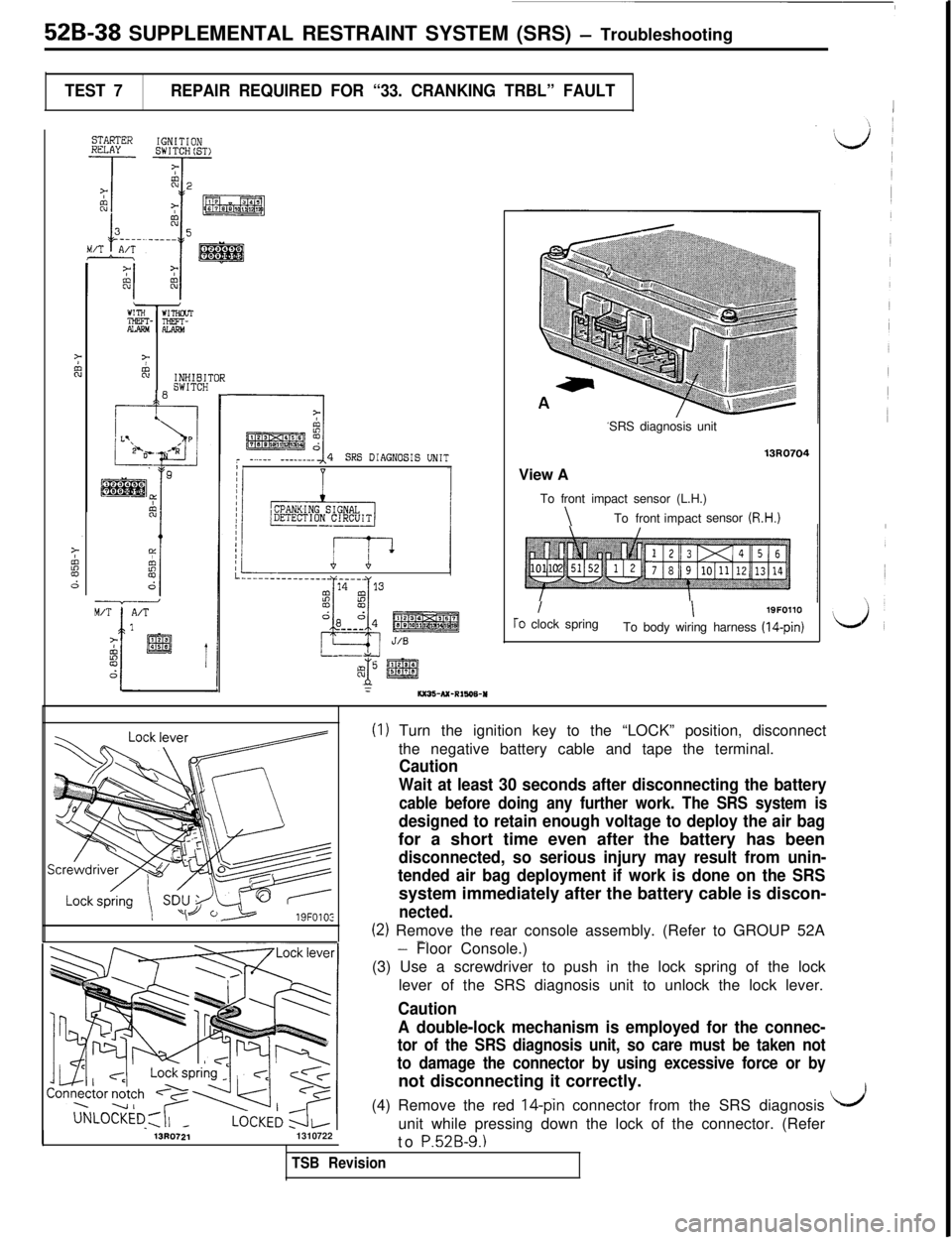

TEST 7REPAIR REQUIRED FOR “33. CRANKING TRBL” FAULT1

STARTERHULAYIGNITIONSWITCH(ST>

7%INHIBITOR

10SWITCH

FI

pkEE&r -...__ -_-_-___I4SRS DIAGNOSIS UNITI

I---..-___________ - ____

2

14 13

!z

CLYL

da d4--__J/S

-A) @g

:6x36-NC-R1606-USRS diagnosis unit

13R0704View A

To front impact sensor (L.H.)

\To frontimpactsensor (R.H.)

II19FOllOTo clock spring

To body wiring harness (14-pin)

(I) Turn the ignition key to the “LOCK” position, disconnect

the negative battery cable and tape the terminal.

Caution

Wait at least 30 seconds after disconnecting the battery

cable before doing any further work. The SRS system is

designed to retain enough voltage to deploy the air bagfor a short time even after the battery has been

disconnected, so serious injury may result from unin-

tended air bag deployment if work is done on the SRSsystem immediately after the battery cable is discon-

nected.

(2) Remove the rear console assembly. (Refer to GROUP 52A-.

13R07211310722

- Floor Console.)

(3) Use a screwdriver to push in the lock spring of the lock

lever of the SRS diagnosis unit to unlock the lock lever.

Caution

A double-lock mechanism is employed for the connec-

tor of the SRS diagnosis unit, so care must be taken not

to damage the connector by using excessive force or bynot disconnecting it correctly.

(4) Remove the red

14-pin connector from the SRS diagnosis

unit while pressing down the lock of the connector. (Refer

to

P52B-9.1

I/’

TSB Revision

Page 1055 of 1146

SUPPLEMENTAL RESTRAINT SYSTEM (SRS) - Troubleshooting 52B-45

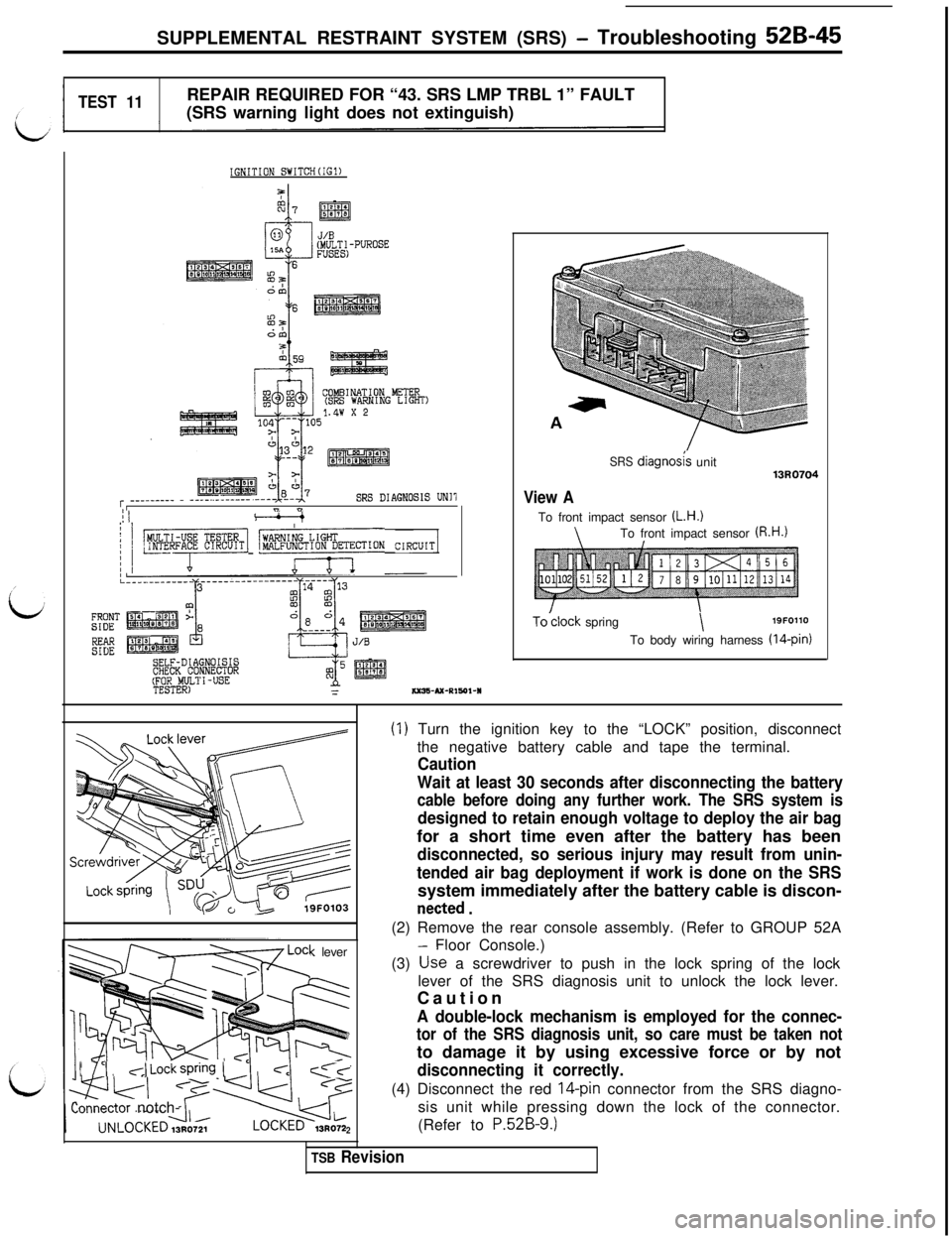

TEST 11REPAIR REQUIRED FOR “43. SRS LMP TRBL 1” FAULT

(SRS warning light does not extinguish)

IGNITION SWITCH(IG1)

COMBINATION METER(SRS WARNING LIGHT)1.4w x 2

r _________ - ____..__-----SRS DIAGNOSIS UN11I" n

/ 1 -1 "fT%~~ION CIRCUIT/

SELF-DIAGNOISISCHECK CONNECTOR(TFEOSRTOF.h~ll-USE=Kx35-Ax-RIY)I-I

SRS diagno&unit13R0704

View ATo front impact sensor (L.H.)

\To front impact sensor (R.H.1

To’clock spring\19FOllO

To body wiring harness (14-pin)

< lever

I 7’1,~,JLockspring (

2

(1) Turn the ignition key to the “LOCK” position, disconnect

the negative battery cable and tape the terminal.

Caution

Wait at least 30 seconds after disconnecting the battery

cable before doing any further work. The SRS system is

designed to retain enough voltage to deploy the air bagfor a short time even after the battery has been

disconnected, so serious injury may result from unin-

tended air bag deployment if work is done on the SRSsystem immediately after the battery cable is discon-

netted .(2) Remove the rear console assembly. (Refer to GROUP 52A

Floor Console.)

(3) Use a screwdriver to push in the lock spring of the lock

lever of the SRS diagnosis unit to unlock the lock lever.

Caution

A double-lock mechanism is employed for the connec-

tor of the SRS diagnosis unit, so care must be taken notto damage it by using excessive force or by not

disconnecting it correctly.(4) Disconnect the red

16pin connector from the SRS diagno-

sis unit while pressing down the lock of the connector.

(Refer to

P.52B-9.)

TSB Revision

Page 1061 of 1146

SRS Maintenance and

SUPPLEMENTAL RESTRAINT SYSTEM (SRS) - Post-coltision Diagnosis 52B-51

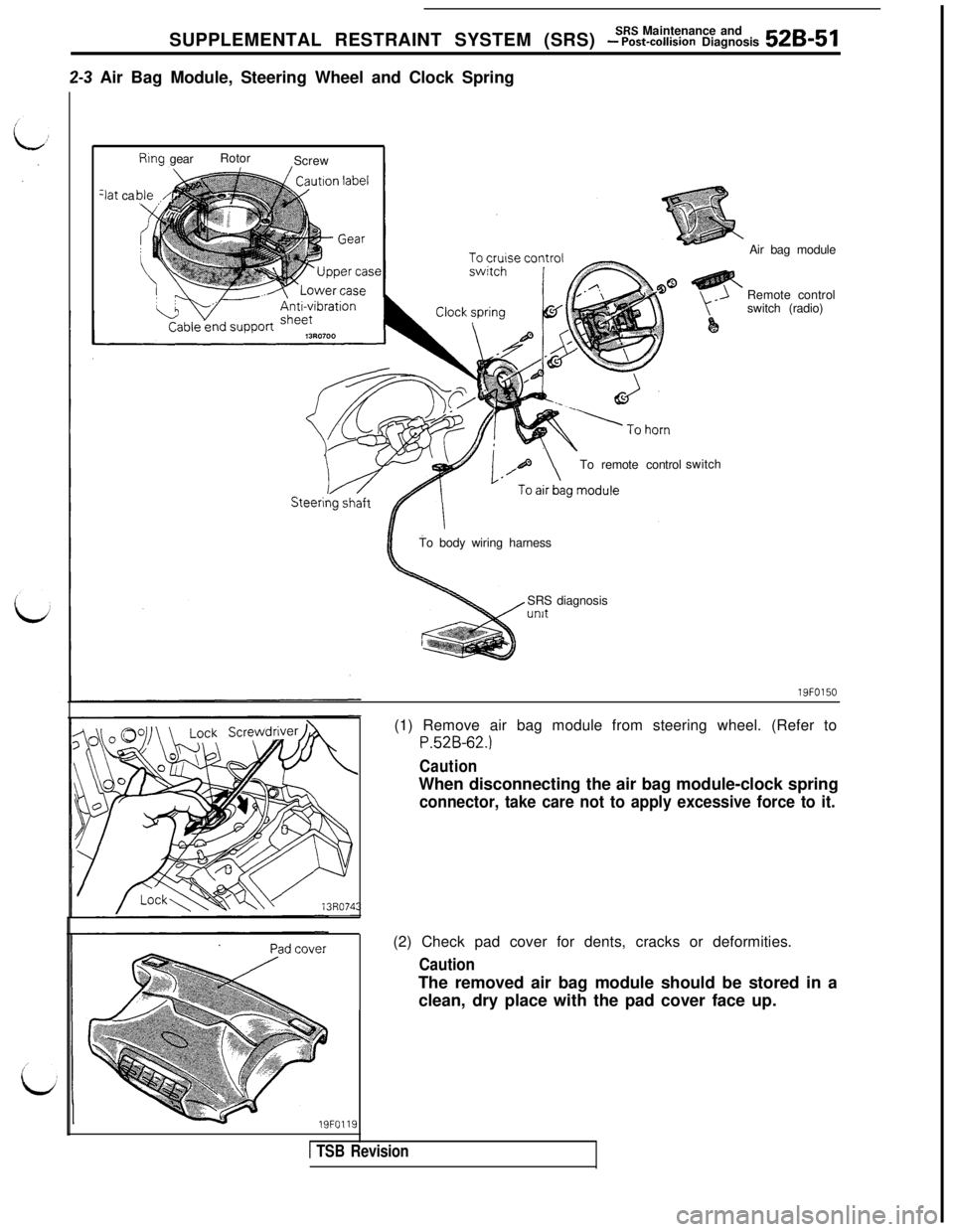

2-3 Air Bag Module, Steering Wheel and Clock Spring

Rtng gearRotor

Screw

3at ca

To remote controlswitchAir bag module

Remote control

switch (radio)

To body wiring harness

SRS diagnosisunit

19FO150

19FO119(1) Remove air bag module from steering wheel. (Refer to

P.52B-62.)

CautionWhen disconnecting the air bag module-clock spring

connector, take care not to apply excessive force to it.(2) Check pad cover for dents, cracks or deformities.

CautionThe removed air bag module should be stored in a

clean, dry place with the pad cover face up.

1 TSB Revision

Page 1062 of 1146

52B-52 SUPPLEMENTAL RESTRAINT SYSTEM fSRSI - ~Z-%~~~~aK&%kTo air bagmodule

To SRS dragnosls unit

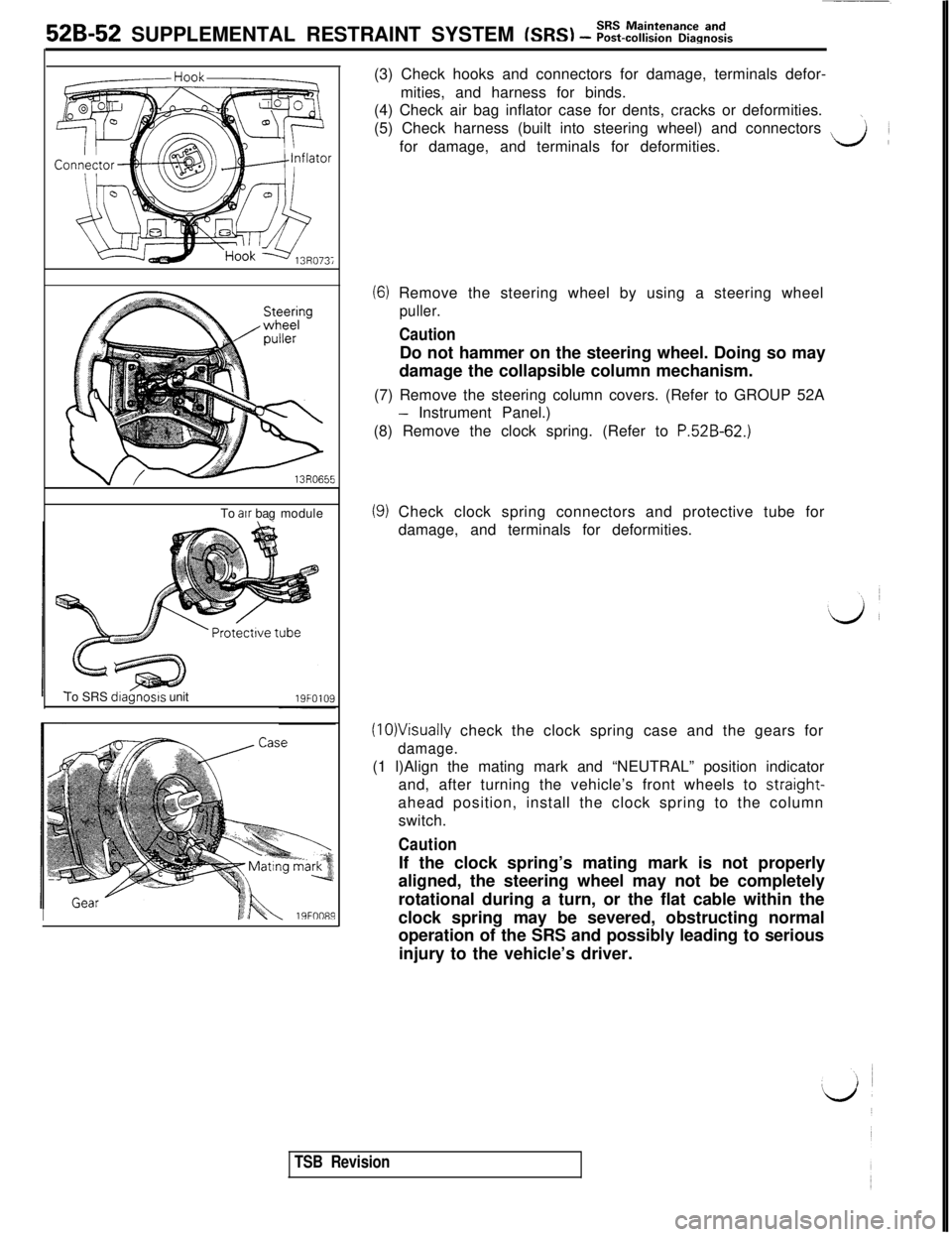

I19FOO89(3) Check hooks and connectors for damage, terminals defor-

mities, and harness for binds.

(4) Check air bag inflator case for dents, cracks or deformities.

\(5) Check harness (built into steering wheel) and connectors

~for damage, and terminals for deformities.LA

(6) Remove the steering wheel by using a steering wheel

puller.

CautionDo not hammer on the steering wheel. Doing so may

damage the collapsible column mechanism.

(7) Remove the steering column covers. (Refer to GROUP 52A

- Instrument Panel.)

(8) Remove the clock spring. (Refer to

P.52B-62.)

(9) Check clock spring connectors and protective tube for

damage, and terminals for deformities.

(10)Visually check the clock spring case and the gears for

damage.(1 l)Align the mating mark and “NEUTRAL” position indicator

and, after turning the vehicle’s front wheels to straight-

ahead position, install the clock spring to the column

switch.

CautionIf the clock spring’s mating mark is not properly

aligned, the steering wheel may not be completely

rotational during a turn, or the flat cable within the

clock spring may be severed, obstructing normal

operation of the SRS and possibly leading to serious

injury to the vehicle’s driver.

TSB Revision